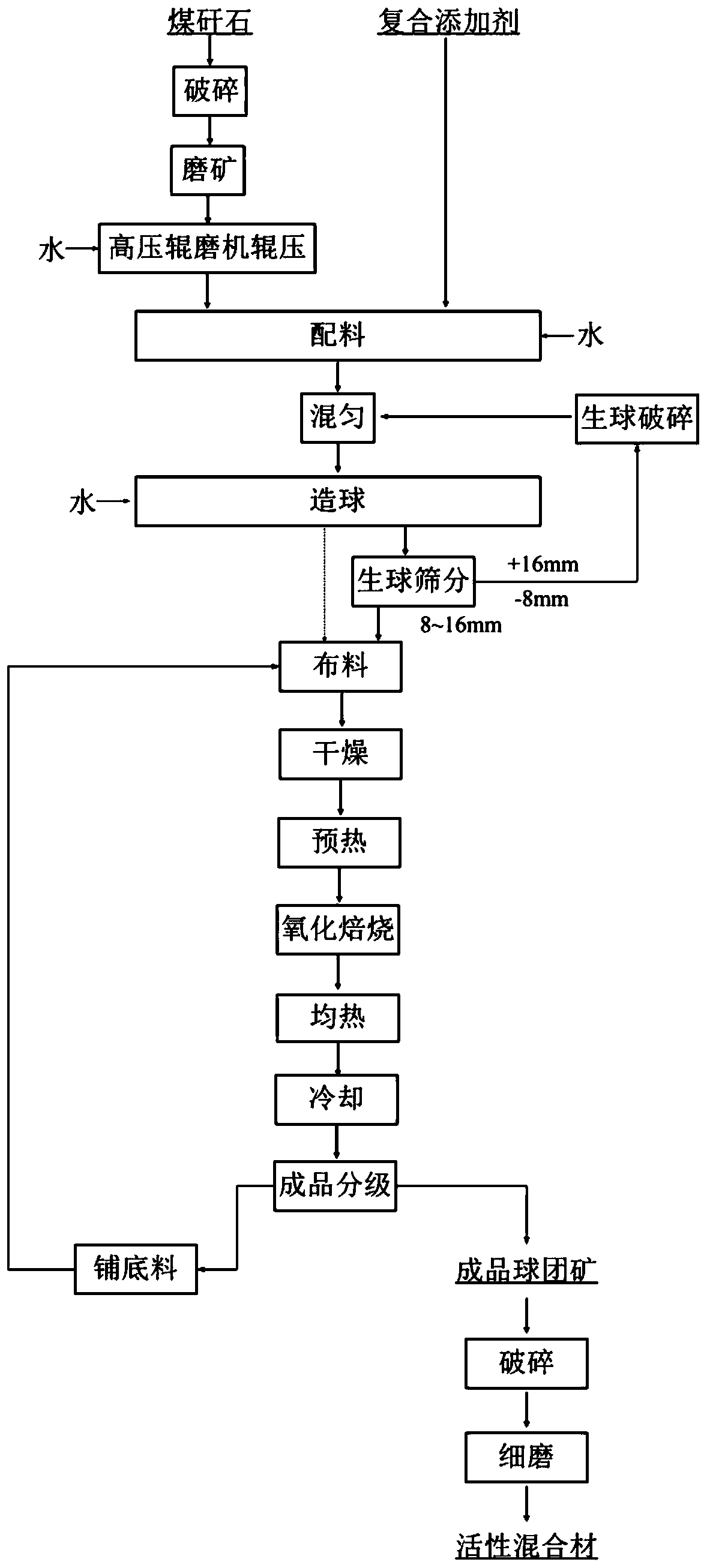

A method for preparing active mixture by belt roaster pellet method

A technology of belt-type roasting machine and active mixed materials, which is applied in the fields of application, clay products, household appliances, etc., can solve the problems of poor activity and low output of coal gangue, and achieve improved roasting decarburization, improved quality and activity, and improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] After the coal gangue is crushed to -1mm, dry grinding to -0.074mm 80%, the obtained finely ground coal gangue is rolled through high-pressure roller milling, the rolling pressure is 400KN / m, and the rolling moisture is controlled at 7.5%, improving Specific surface area up to 1650cm 2 / g, and then add compound additives (40% sodium humate, 40% quicklime, 10% magnetite, 10% hematite) with a mass ratio of 2%, and mix in an intensive mixer for 1.5min (1600~ 2000rpm), and then pelletized in a disc pelletizer to prepare green pellets with a particle size of 8-15mm and a water content of 8.5%. The drop strength of the green pellets is 5.5 times / 0.5m, and the compressive strength of the pellets is 11.4N / piece, the bursting temperature of green balls is 450°C.

[0073] The green balls are dried at 400°C for 4 minutes on a belt roaster (the height of the green ball layer is 150mm), preheated at 800°C for 12 minutes, and then oxidized and roasted at 1150°C for 20 minutes, and...

Embodiment 2

[0077] After the coal gangue is crushed to -1mm, dry grinding to -0.074mm 80%, the obtained finely ground coal gangue is rolled through high-pressure roller milling, the rolling pressure is 400KN / m, and the rolling moisture is controlled at 7.5%, improving Specific surface area up to 1650cm 2 / g, then add compound additives (40% sodium humate, 40% quicklime, 10% magnetite, 10% hematite) with a mass ratio of 4%, and mix in an intensive mixer for 1.5min (1600~ 2000rpm), and then pelletized in a disc pelletizer to prepare green pellets with a particle size of 8-15mm and a water content of 8.5%. The drop strength of the green pellets is 6.5 times / 0.5m, and the compressive strength of the pellets is 13.2N / piece, the bursting temperature of green balls is 480°C.

[0078] Green balls are dried at 400°C for 4 minutes on a belt roaster (the height of the green ball layer is 150mm), preheated at 800°C for 12 minutes, and then oxidized and roasted at 1200°C for 20 minutes, and the oxi...

Embodiment 3

[0083] After the coal gangue is crushed to -1mm, dry grinding to -0.074mm 80%, the obtained finely ground coal gangue is rolled by high-pressure roller mill, the rolling pressure is 500KN / m, and the rolling moisture is controlled at 7.5%. Specific surface area up to 1600cm 2 / g, then add compound additives with a mass ratio of 5% (30% sodium humate, 50% quicklime, 10% magnetite, 10% hematite), and mix in an intensive mixer for 1min (1600~2000rpm ), and then pelletized in a disc pelletizer to prepare green pellets with a particle size of 8-15mm and a water content of 8.5%. 1, the bursting temperature of green balls is 520°C.

[0084] The green balls are dried at 450°C for 4 minutes on a belt roaster (the height of the green ball layer is 150mm), preheated at 800°C for 12 minutes, and then oxidized and roasted at 1200°C for 20 minutes, and the oxidized roasted product is placed at 1050°C for 5 minutes, and the product is completed. During the soaking process, it is quickly tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com