A kind of converter slag pellet and its forming binder

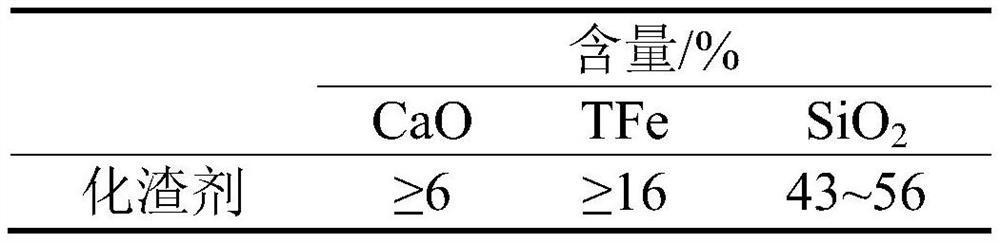

A slag-reducing agent and binder technology, applied in the metallurgical field, can solve the problems of accumulation of environmental pollution, waste of resources, etc., and achieve the effect of improving production efficiency and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

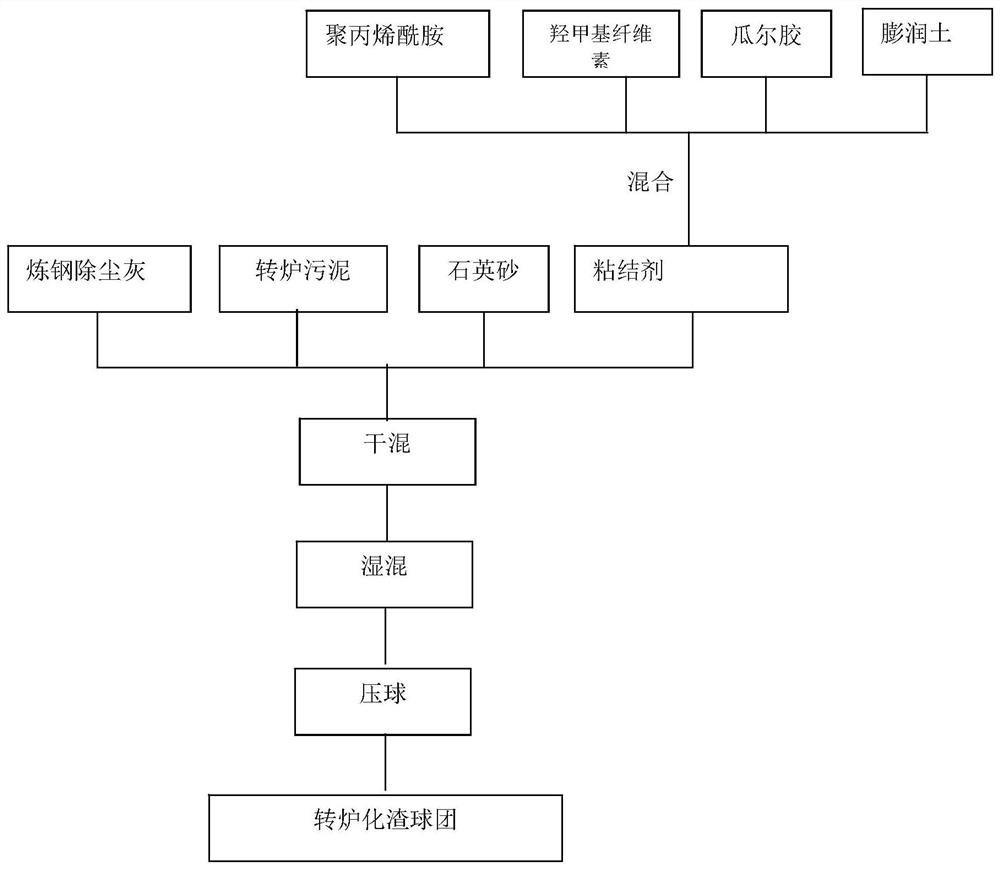

[0035] Such as figure 1 Shown, the method for preparing converter slagging agent pellets, concrete steps are as follows:

[0036] (1), preparation of binder: 12 parts by weight of anionic polyacrylamide, 7 parts by weight of carboxymethyl cellulose, 79 parts by weight of sodium bentonite and 2 parts by weight of cationic guar gum are evenly mixed to obtain a composite bond agent. The molecular weight of polyacrylamide is 22 million.

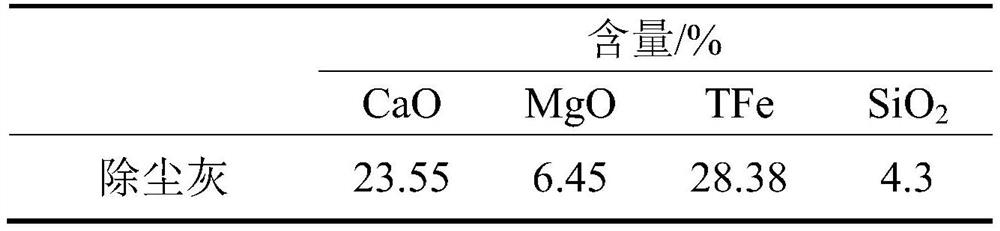

[0037] (2) Mixing of converter slagging agent materials. Add 42 parts by weight of steelmaking dust, 8 parts by weight of converter sludge, 43 parts by weight of quartz sand and 1.5 parts by weight of solid organic binder into a roller mixer for dry mixing for 4 minutes, add 9 parts by weight of water, and wet mix for 5 minutes . In order to avoid excessive smoke and dust during the mixing process of the steelmaking dedusting ash, 3 parts by weight of water can be sprayed in the dedusting ash in advance, so that the material will not raise du...

Embodiment 2

[0040] Such as figure 1 Shown, the method for preparing converter slagging agent pellets, concrete steps are as follows:

[0041] (1), preparation of binder: 12 parts by weight of anionic polyacrylamide, 6 parts by weight of carboxymethyl cellulose, 79 parts by weight of sodium bentonite and 3 parts by weight of cationic guar gum are evenly mixed to obtain a composite bond agent. The molecular weight of polyacrylamide is 22 million.

[0042] (2) Mixing of converter slagging agent materials. Add 42 parts by weight of steelmaking dust, 8 parts by weight of converter sludge, 43 parts by weight of quartz sand and 1.5 parts by weight of solid organic binder into a roller mixer for dry mixing for 5 minutes, add 10 parts by weight of water, and wet mix for 5 minutes . In order to avoid excessive smoke and dust during the mixing process of the steelmaking dedusting ash, 3 parts by weight of water can be sprayed in the dedusting ash in advance, so that the material will not raise d...

Embodiment 3

[0045] Such as figure 1 Shown, the method for preparing converter slagging agent pellets, concrete steps are as follows:

[0046] (1), preparation of binder: 12 parts by weight of anionic polyacrylamide, 10 parts by weight of carboxymethyl cellulose, 72 parts by weight of sodium bentonite and 6 parts by weight of cationic guar gum are evenly mixed to obtain a composite bond agent. The molecular weight of polyacrylamide is 22 million.

[0047] (2) Mixing of converter slagging agent materials. Add 44 parts by weight of steelmaking dust, 10 parts by weight of converter sludge, 45 parts by weight of quartz sand and 1.5 parts by weight of solid organic binder into a roller mixer for dry mixing for 6 minutes, add 12 parts by weight of water, and wet mix for 6 minutes . In order to avoid excessive smoke and dust during the mixing process of steelmaking dust removal ash, 4 parts by weight of water can be sprayed in the dust removal ash in advance, so that the material will not rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com