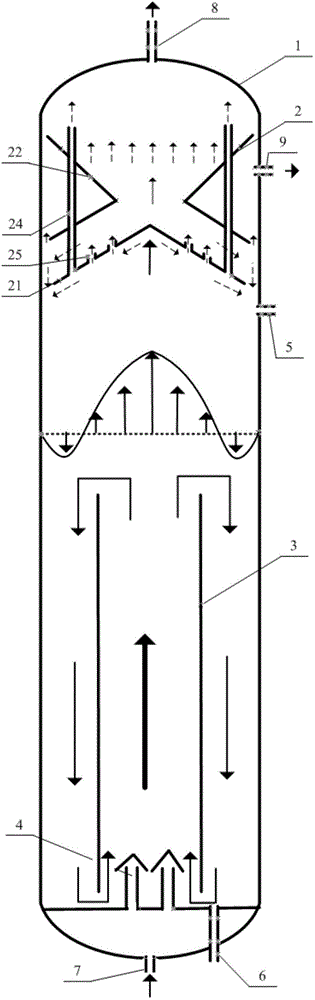

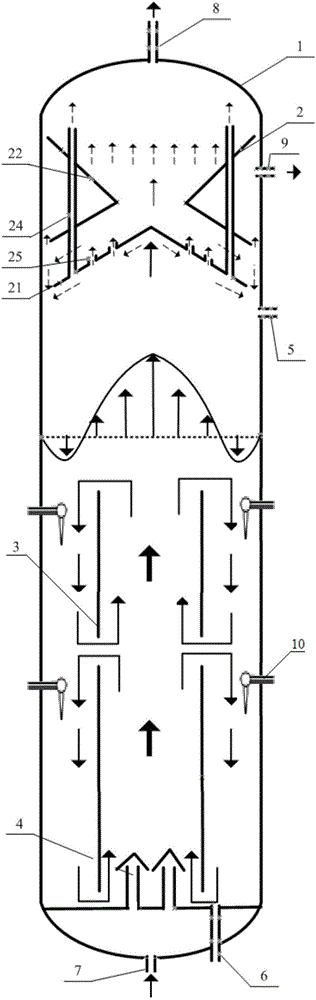

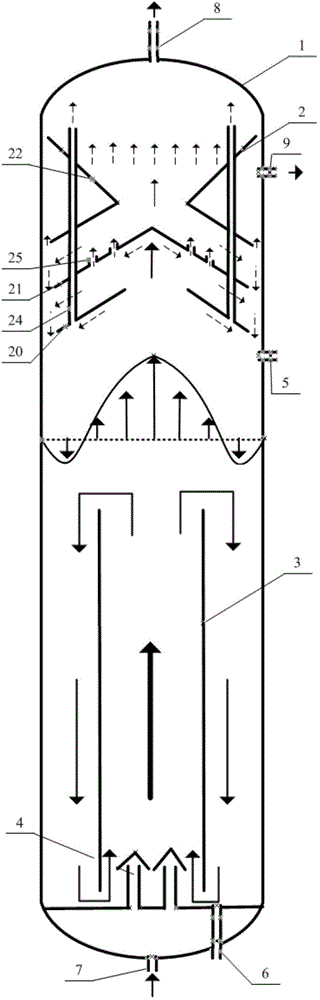

Fluidized bed reactor

A fluidized bed reactor and boiling zone technology, applied in chemical instruments and methods, treatment with moving solid particles, chemical/physical processes, etc., can solve problems such as lower product quality, high material requirements, and large energy consumption, and achieve Improved efficiency and flexibility, easy operation, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The specific dimensions of the ebullated bed reactor used in this example are shown in Table 1 below.

[0065] Table 1

[0066] code name

[0067] The above-mentioned ebullating bed reactor was used to carry out the cold model experiment, in which the solid phase catalyst was a spherical catalyst with a particle size of 0.2-0.3 mm, and the catalyst loading was 60% of the effective volume of the reactor. Straight-run kerosene is used for the liquid phase, and the volume space velocity is 0.25-3.0h-1. Nitrogen is used in the gas phase, and the gas-oil volume ratio is 20-150. The experimental results in the changing range of conditions show that the carryover of the solid phase catalyst is extremely low, the maximum is 2.0μg / g. At the same time, it can be observed in the experiment that there is sufficient circulating gas in the downcomer of the reactor, and the fluidization state of the solid-phase catalyst is good.

Embodiment 2

[0069] The specific dimensions of the ebullated bed reactor used in this example are shown in Table 2 below.

[0070] Table 2

[0071] code name

value

code name

value

d 1 / mm

300

h 1 / mm

3000

d 2 / mm

240

h 2 / mm

1500

d 3 / mm

280

h 3 / mm

900

d 4 / mm

260

α / °

60

d 5 / mm

150

β / °

60

d 6 / mm

285

ω / °

60

d 7 / mm

170

φ / °

60

[0072] d 8 / mm

285

The total opening area of the gas separation tube / mm 2

8000

d 9 / mm

160

The total opening area of the through hole / mm 2

15000

d 10 / mm

290

[0073] The above-mentioned ebullating bed reactor was used to carry out the cold model experiment, wherein the solid-phase catalyst was selected as a spherical catalyst with a particle size of 0.5-0.6mm, and the catalyst loading was 50% of the eff...

Embodiment 3-5 and comparative example 1

[0077] Embodiment 3-5 uses the medium-sized hot state reactor made in the ratio of embodiment 1, and comparative example 1 uses the ebullating bed reactor described in CN1448212A. Examples 3-5 and Comparative Example 1 used the same ebullated bed catalyst and residual oil raw material, the physicochemical properties of the catalyst are shown in Table 3, and the properties of the residual oil raw material are shown in Table 4. The process conditions and test results of Examples 3-5 and Comparative Example 1 are shown in Table 5.

[0078] Table 3: Main physicochemical properties of ebullated bed catalysts

[0079]

[0080]

[0081] Table 4: Properties of residual oil raw materials

[0082] nature

value

Density(20℃) / (g / cm 3 )

1.029

Carbon residue / wt%

19.61

Sulfur content / wt%

4.53

Nitrogen content / wt%

0.23

(Ni+V) content / (μg / g)

275.8

Asphaltenes (C 7 content) / wt%

6.5

[0083] Table 5:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com