Patents

Literature

164results about How to "Reduce carryover" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

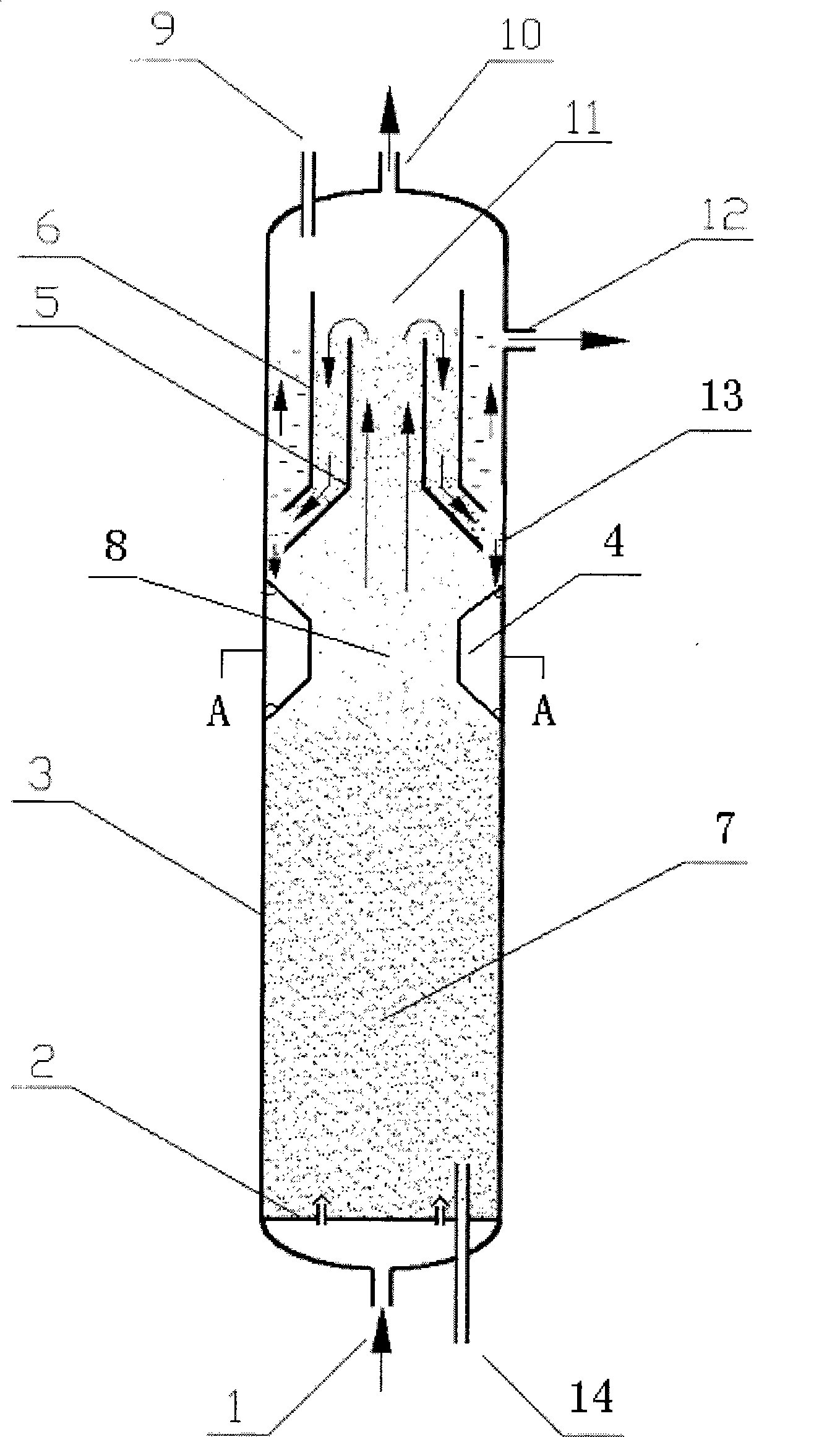

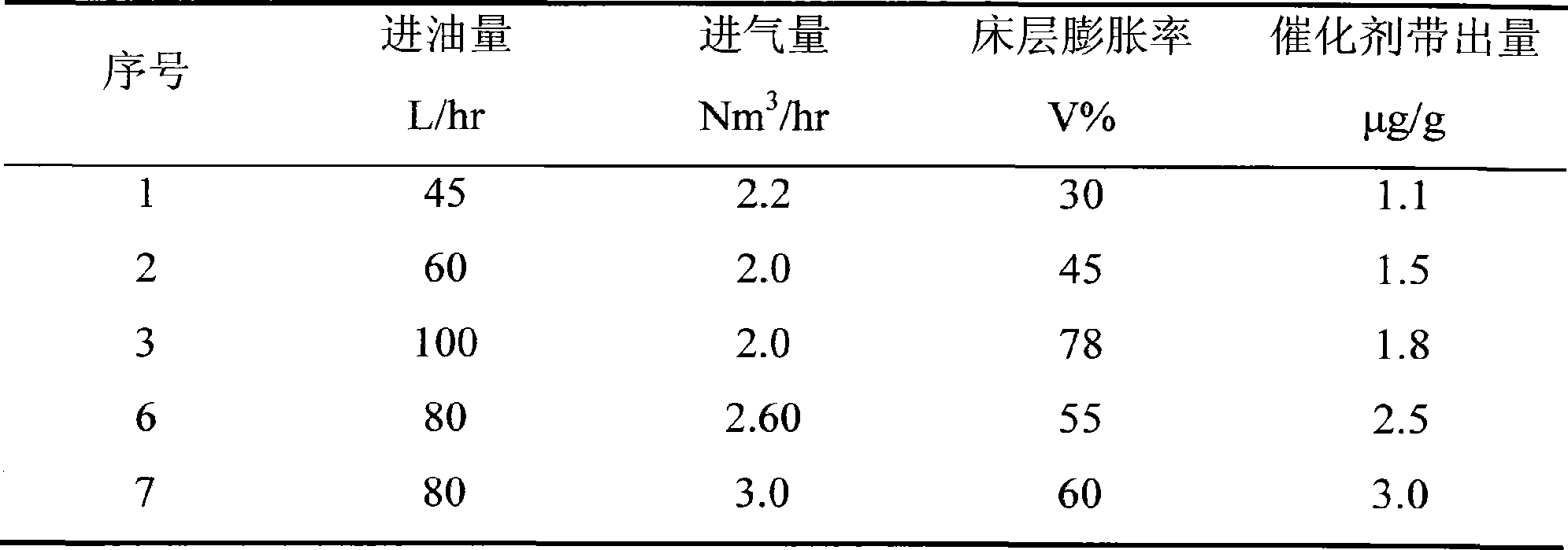

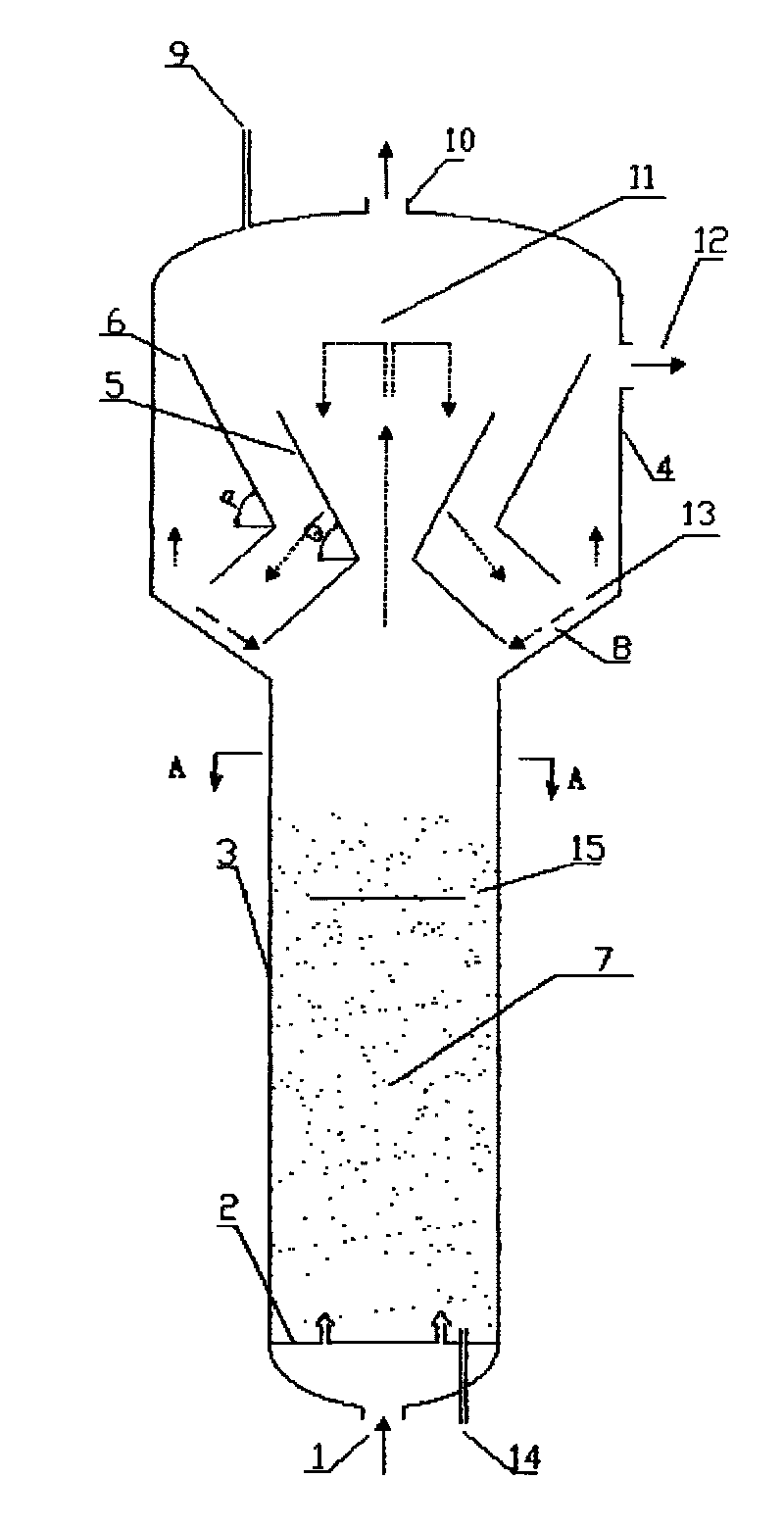

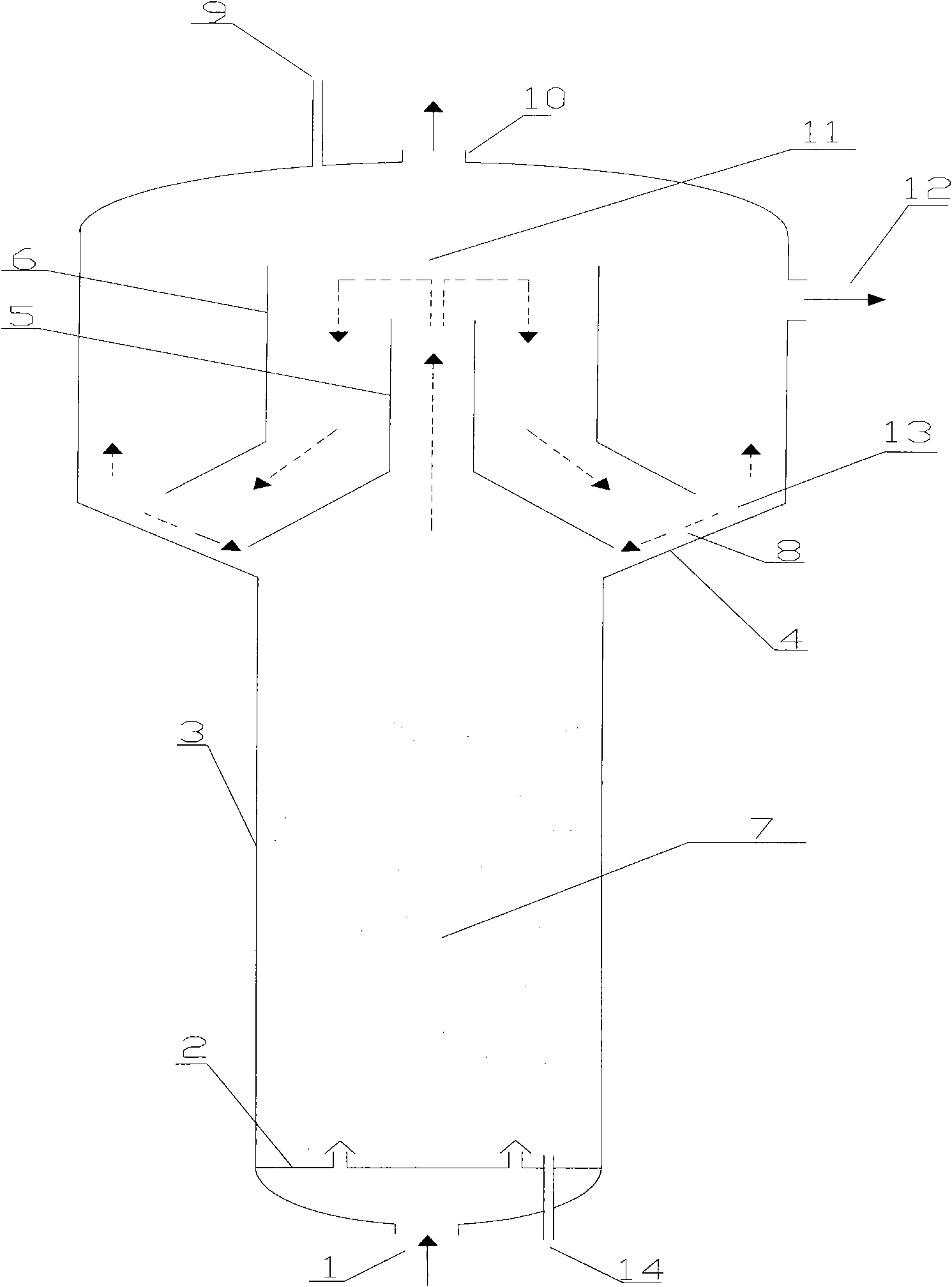

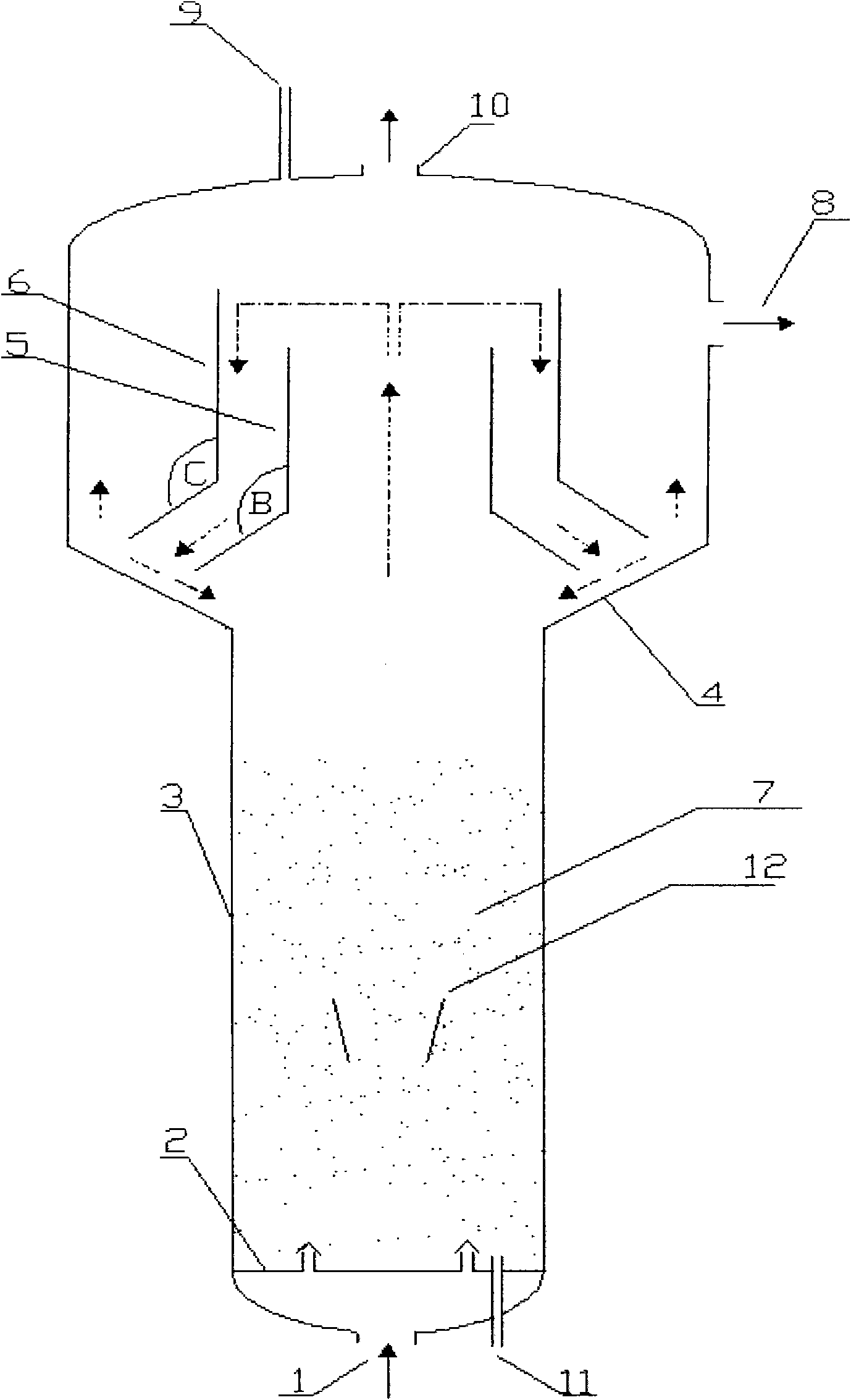

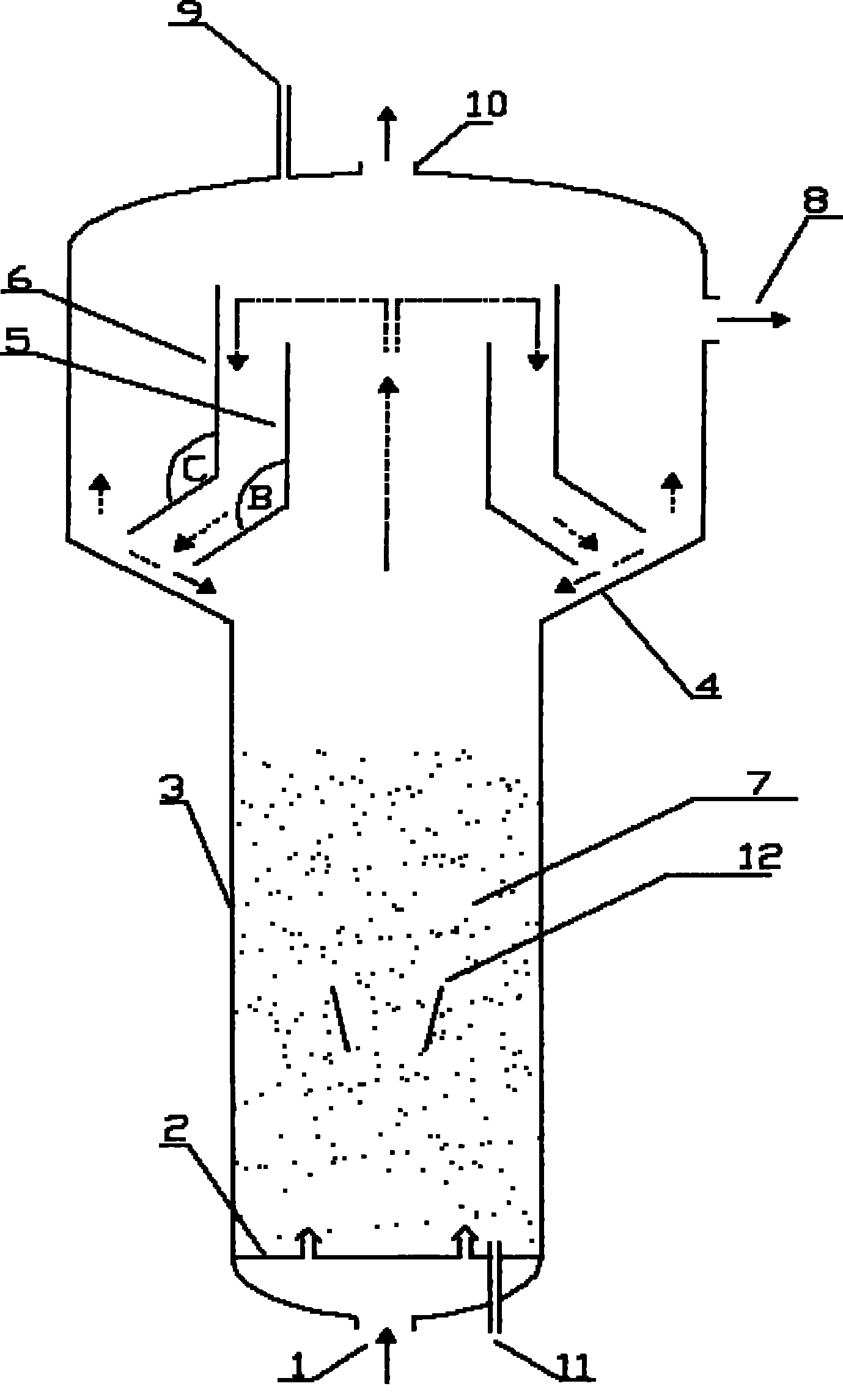

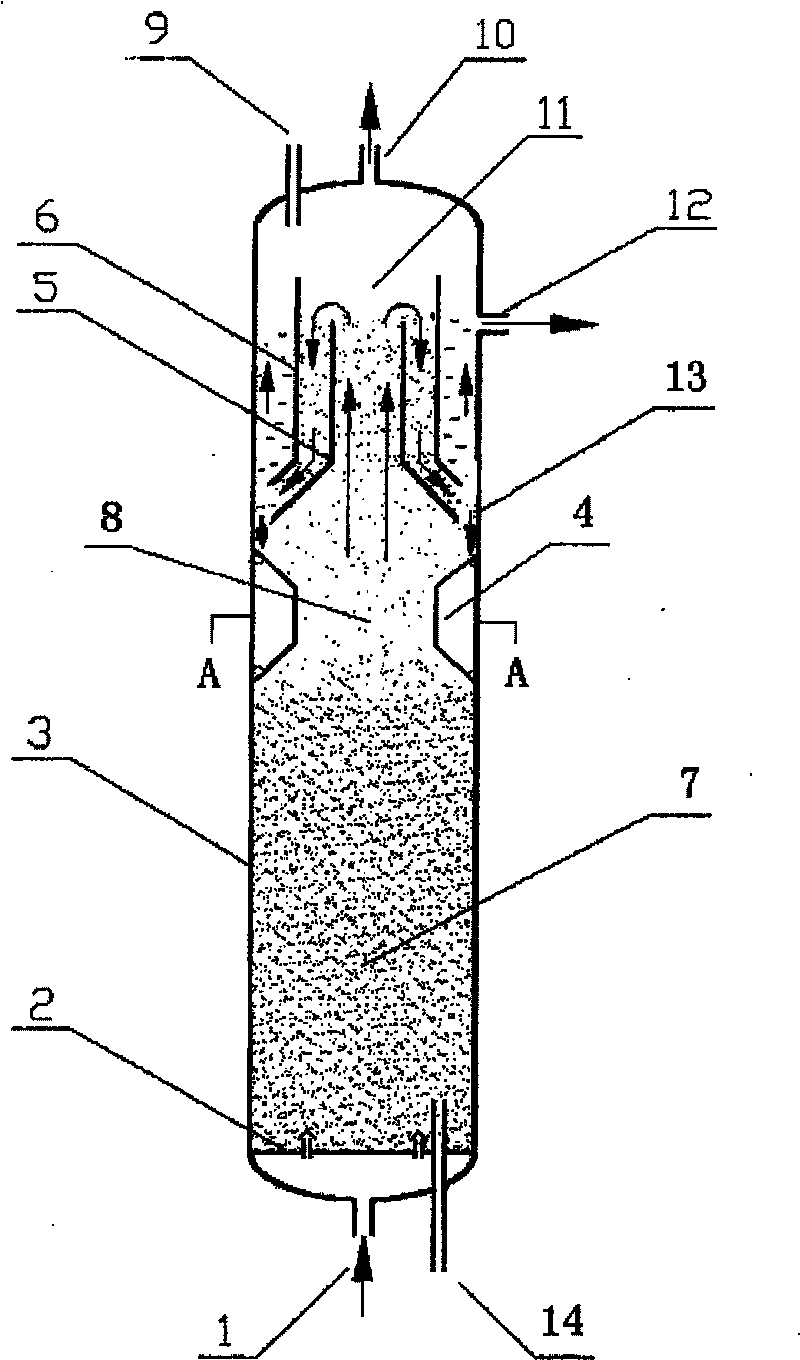

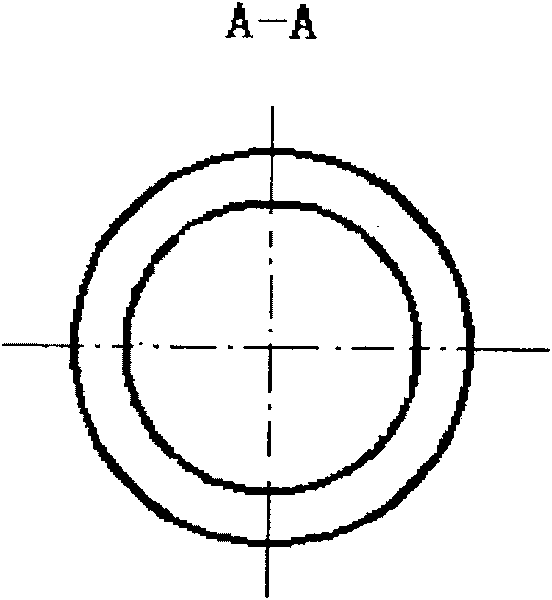

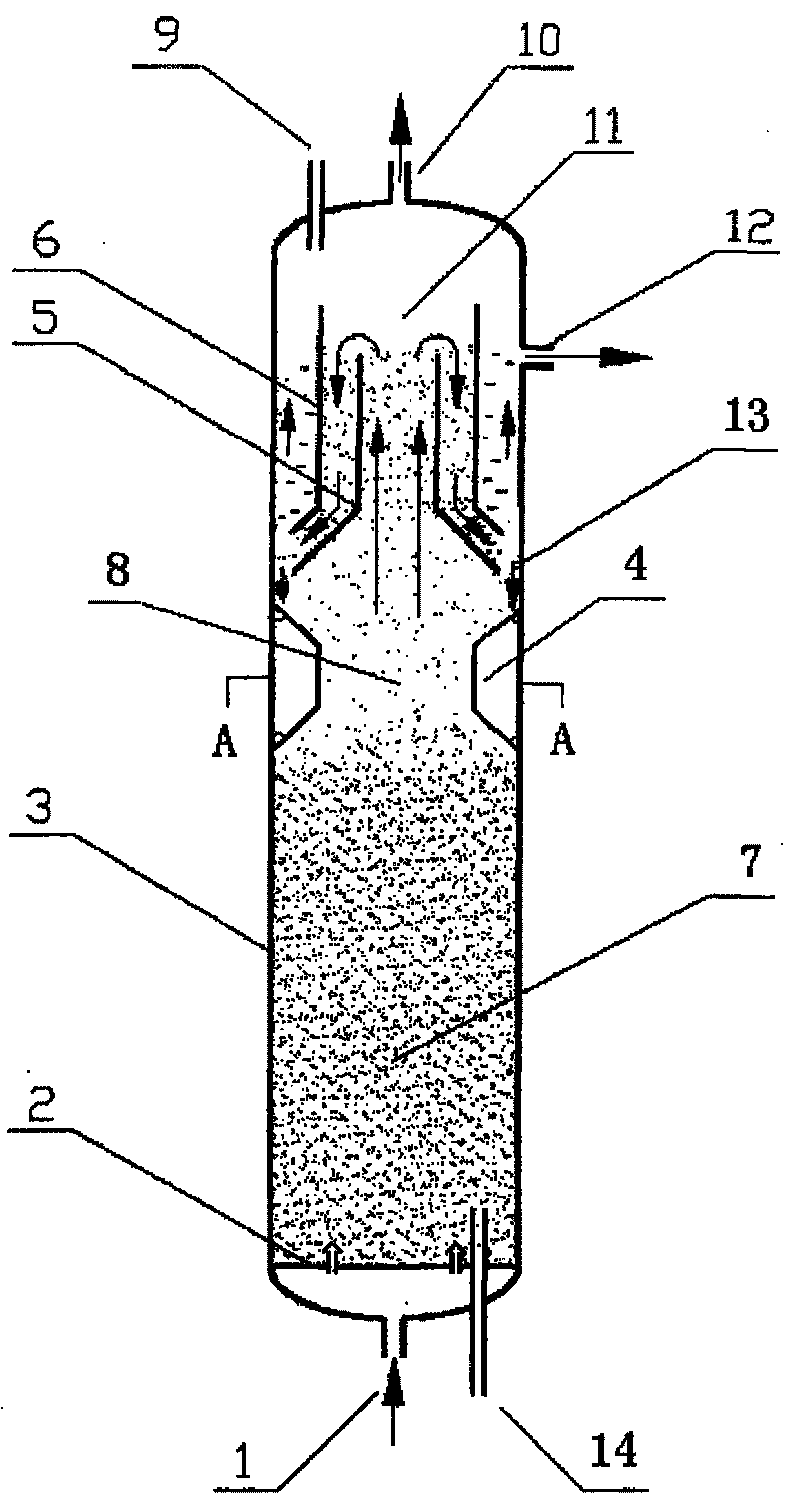

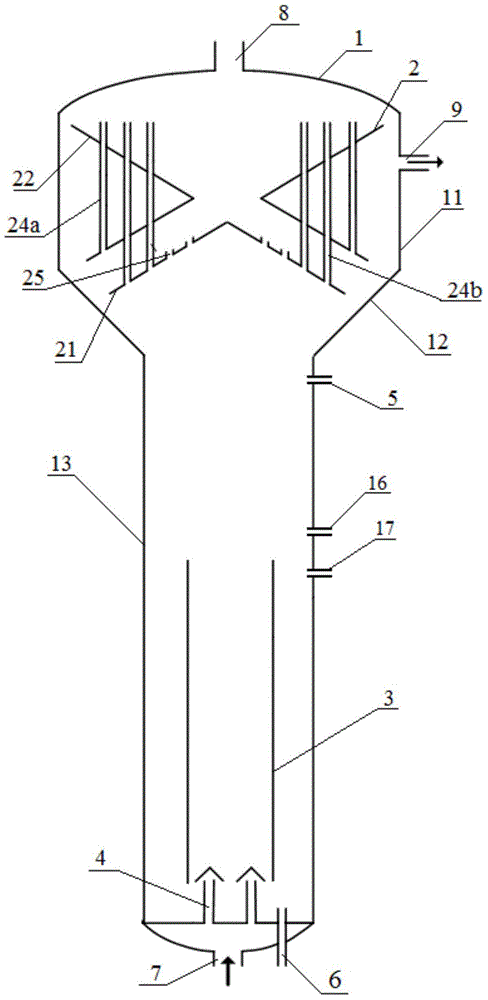

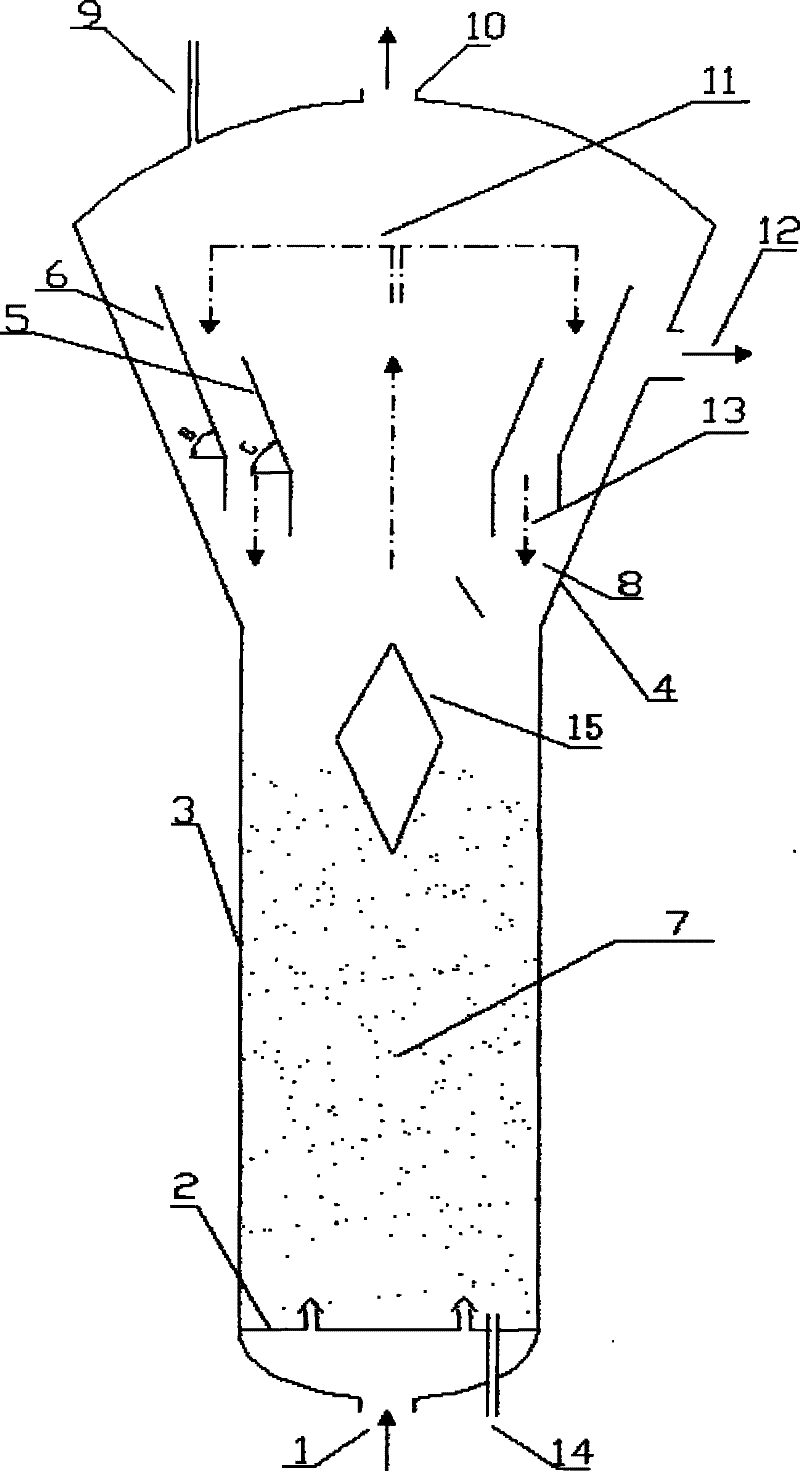

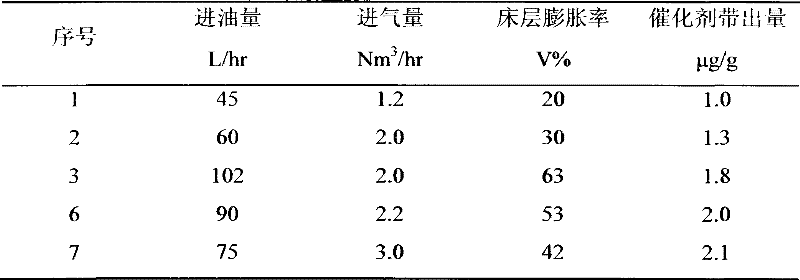

Novel bubbling bed reactor

ActiveCN101376092AGreat operating flexibilityEfficient separationHydrocarbon oils refiningChemical/physical processesConvex structureChemical reaction

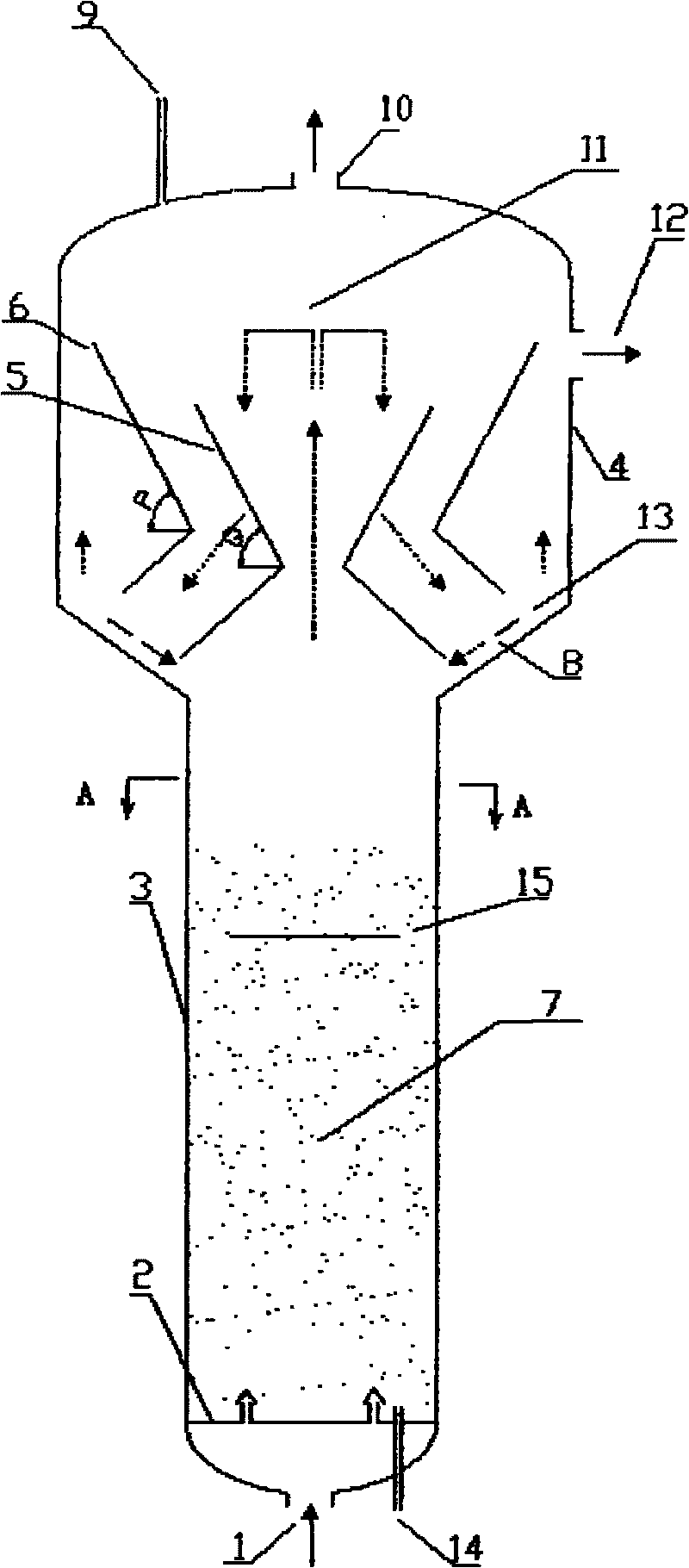

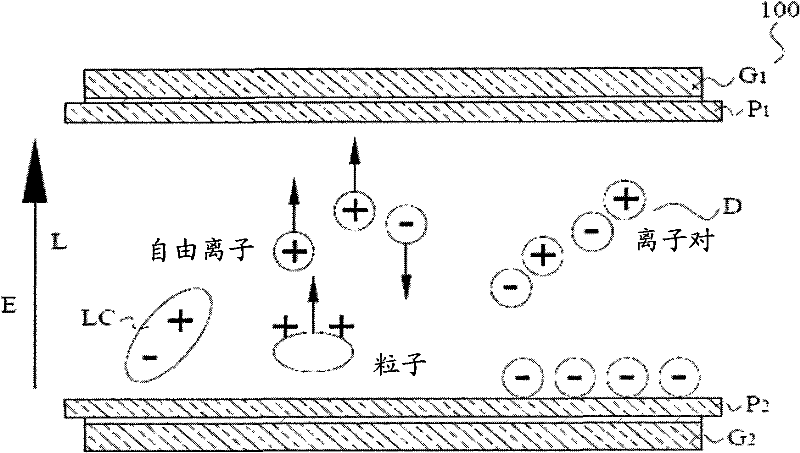

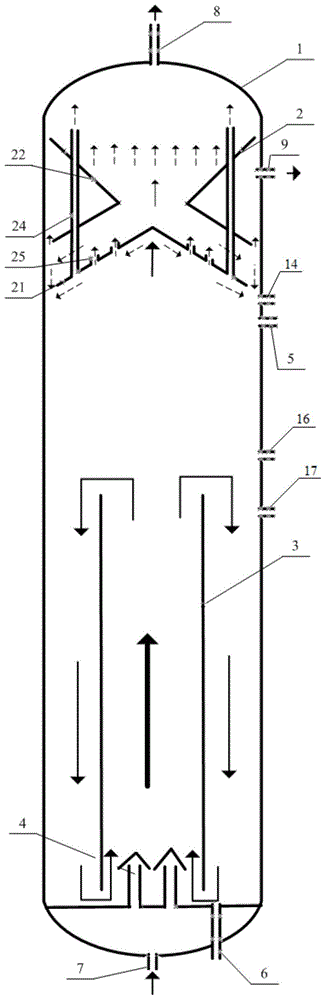

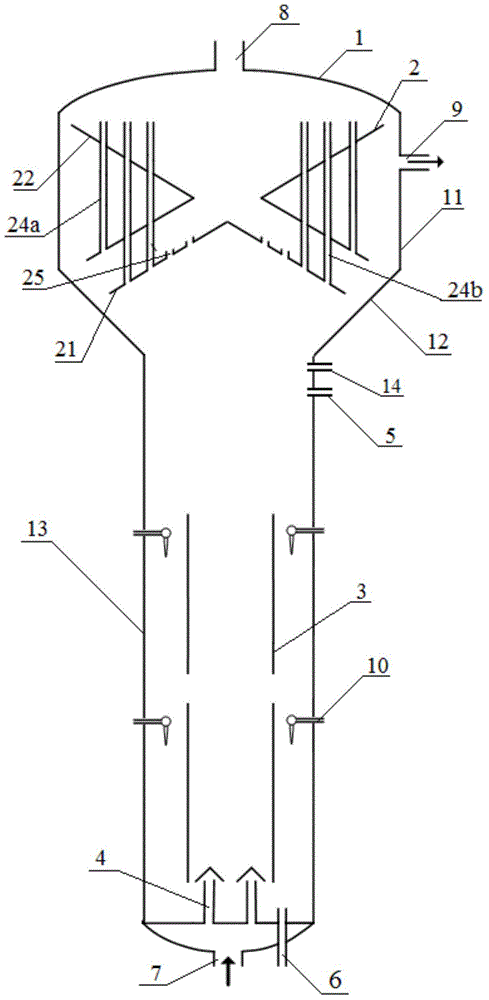

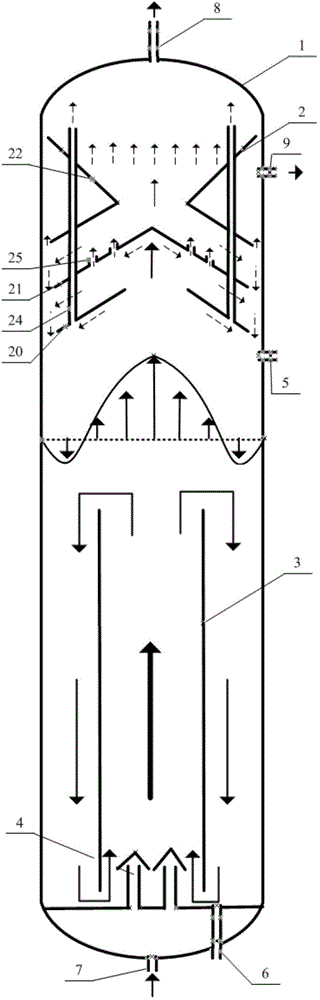

The invention discloses a new fluidized bed hydrogenation reactor. The fluidized bed hydrogenation reactor of the invention comprises a cylinder-shaped reactor shell perpendicular to the ground, a three-phase separator arranged at the upper part in the reactor shell and a guiding structure arranged at the middle upper part of the reactor. The guiding structure is an annular convex structure arranged on the inner wall of the reactor and has the lengthwise section of a trapezoid or an arc along the axle of the reactor. The combination of the guiding structure and the three-phase separator increases the operating flexibility of the three-phase separator, and ensures the high-efficiency separation on the three-phase separator, thereby greatly reducing the carrying amount of catalyst. The fluidized bed hydrogenation reactor of the invention can be applied to the chemical reactions between different liquids or gases and solid grains under the condition of contacting, and is characterized by large catalyst inventory, high reactor utility ratio, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

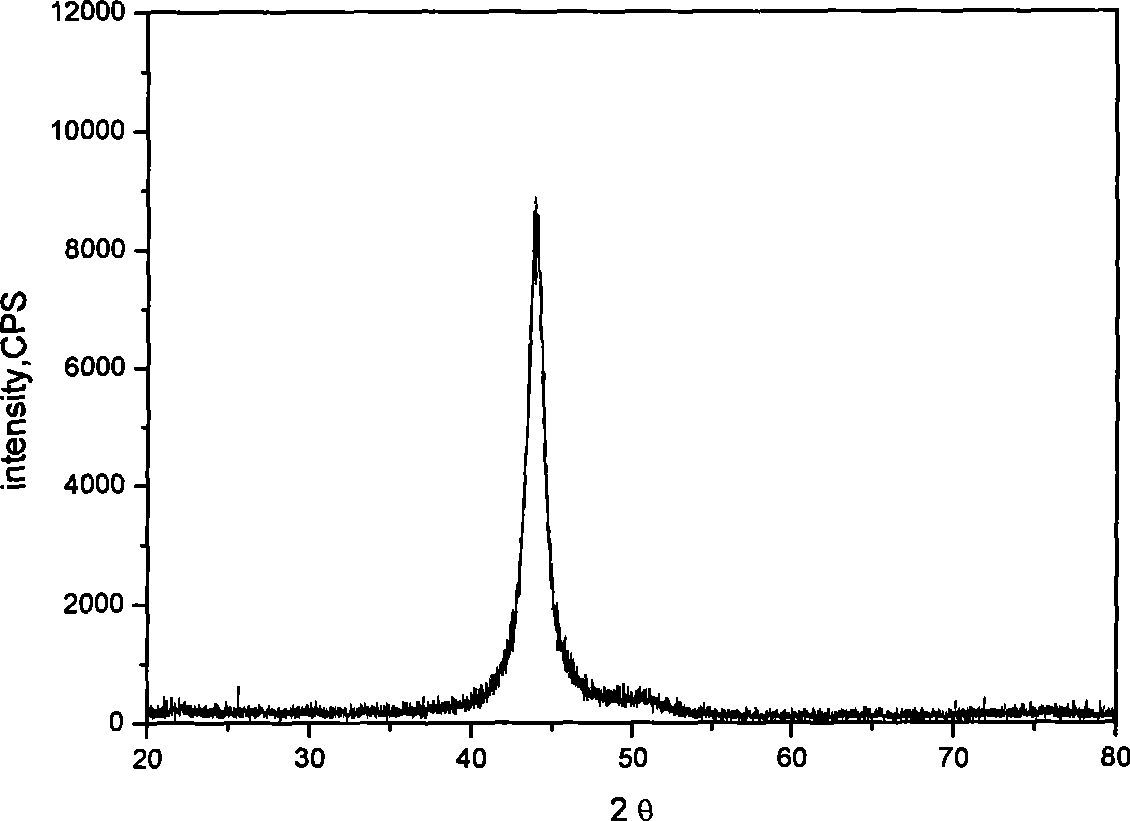

Anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplate liquid thereof

The invention relates to an anticorrosive wearable electrodeposit clad layer of Ni-W-P ternary alloy and manufacturing technique and electroplates liquid thereof, which takes the nickel sulfate, sodium tungstate, phosphate as the main material, electrically depositing the Ni-WP amorphous mixture of amorphous or nanocrystalline alloy coating. The characteristics of the electroplate technique are following: corrosive solution is very small, the entire production of the use of cleaner production, less emissions, in line with the requirements of sustainable production. W of the coating for the content of 1-45wt%, P content of 0.1-5wt%, nickel is the residue. The plating layer is bright and dense; the hardness is 400-1100Hv, which is resistant to acid, alkali, salt and hydrogen sulfide corrosion, wear resistance is better than or equivalent to chrome plating, can not only replace decorative chromium or hard chromium is widely used, and can be used for oil field exploration equipment to deal with wear-resistant anti-corrosion.

Owner:湖南纳菲尔新材料科技股份有限公司

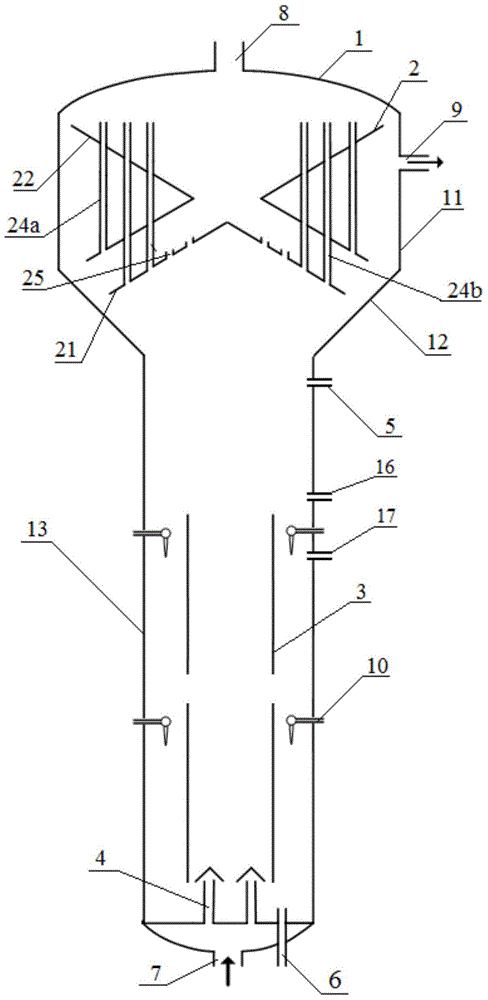

Fluidized bed reactor

ActiveCN101721960AGreat operating flexibilityEfficient separationChemical/physical processesChemical reactionFluidized bed

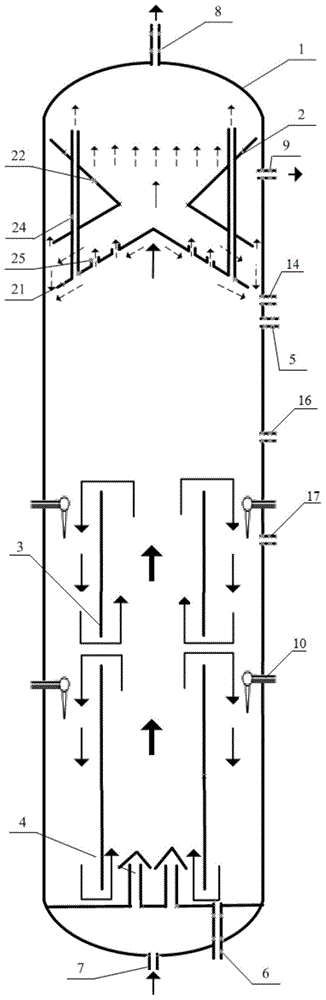

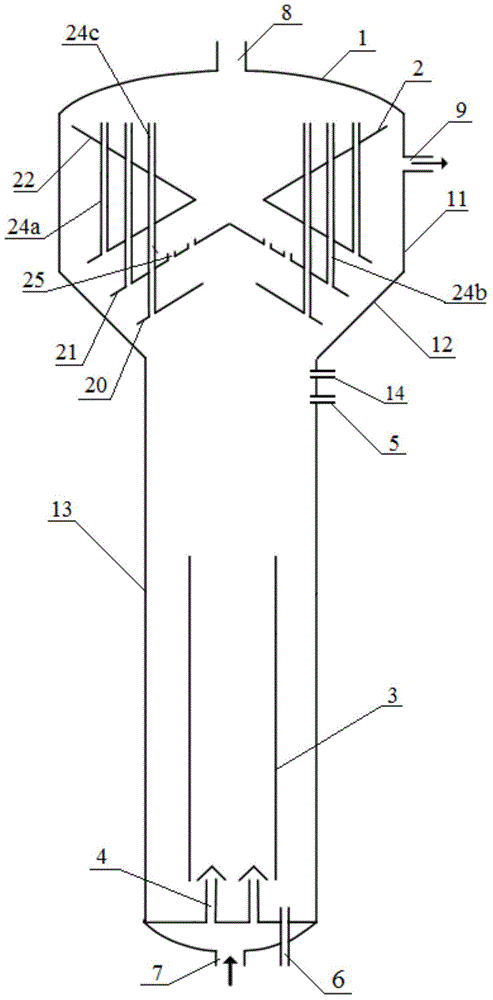

The invention discloses a fluidized bed reactor which comprises a reactor shell and a three-phase separator, the three-phase separator is arranged at the upper part inside the reactor shell and is of a sleeve structure comprising an inner sleeve and an outer sleeve, the upper ends and lower ends of the inner sleeve and the outer sleeve are both of opening structures, the inner sleeve and the outer sleeve are respectively composed of an upper section and a lower section, the upper sections of the inner sleeve and the outer sleeve are in reverse frustum structures, and the lower sections of the inner sleeve and the outer sleeve are in frustum structures. By designing a novel three-phase separating structure, the invention can further improve separating effect, reduce catalyst carrying-out amount, and enhance the operation elasticity of the three-phase separator. The reactor is mainly applicable to chemical reactions between liquid and gas substances of different types and solid particles under contact condition, and has the advantages of large catalyst inventory, high reactor use ratio, simple structure, easy operation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

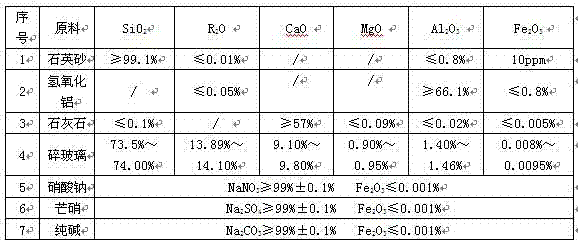

Preparation method of solar ultrawhite ultrathin glass and product thereof

InactiveCN102219376AIron sulfide reductionHigh whitenessGlass furnace apparatusGlass rolling apparatusFragilityIron sulfide

The invention relates to the field of production of ultrawhite rolled glass, in particular to a preparation method of solar ultrawhite ultrathin glass and a product thereof. The preparation method of the solar ultrawhite ultrathin glass comprises the following steps of: selecting and preparing raw materials; conveying the raw materials; melting; forming glass; annealing; detecting; and cutting and packaging. In the preparation method, iron content is controlled by taking different measures in the steps of selecting and conveying the raw materials, so that iron sulfide in the final solar glass is greatly reduced and the whiteness of the glass is improved; in the melting process, bubbles in the melted glass liquid is reduced by exhausting air and debubbling, controlling temperature and adding a glass clarifying agent, so that absorption rate is reduced and light transmittance is improved; and the annealing step of the glass finished product is a key link of the production process and plays an important role in the quality of the ultrathin glass product, so the defects that the ultrathin glass is easy to harden and easy to break during production and has high fragility are overcome by controlling rolling velocity, temperature and annealing rate in the process of glass forming and glass annealing.

Owner:ZHEJIANG JINGXING SOLAR ENERGY TECH

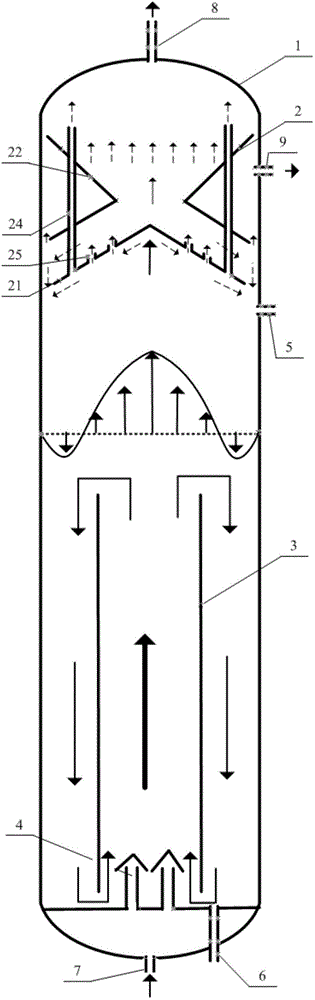

Fluidized bed reactor

ActiveCN101618305AGreat operating flexibilityEfficient separationChemical/physical processesChemical reactionFluidized bed

The invention discloses an improved fluidized bed reactor, which comprises a reactor shell and a three-phase separator, wherein the reactor shell comprises an expanding section and a straight cylinder section from up to bottom; the three-phase separator is arranged in the expanding section; the diameter of the expanding section is 1.2 to 2 times larger than that of the straight cylinder section, and the ratio of the diameter to the height of the expanding section is 0.3-2.0:1. The expanding section and the three-phase separator of the reactor are organically combined, so that the operational flexibility of the three-phase separator is improved, and the highly-efficient separation of the three-phase separator is ensured. The reactor is mainly used for the chemical reaction of various liquids and gases under a condition of contacting solid particles, and has the advantages of large catalyst reserve, high utilization rate of the reactor, simple structure, easy operation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

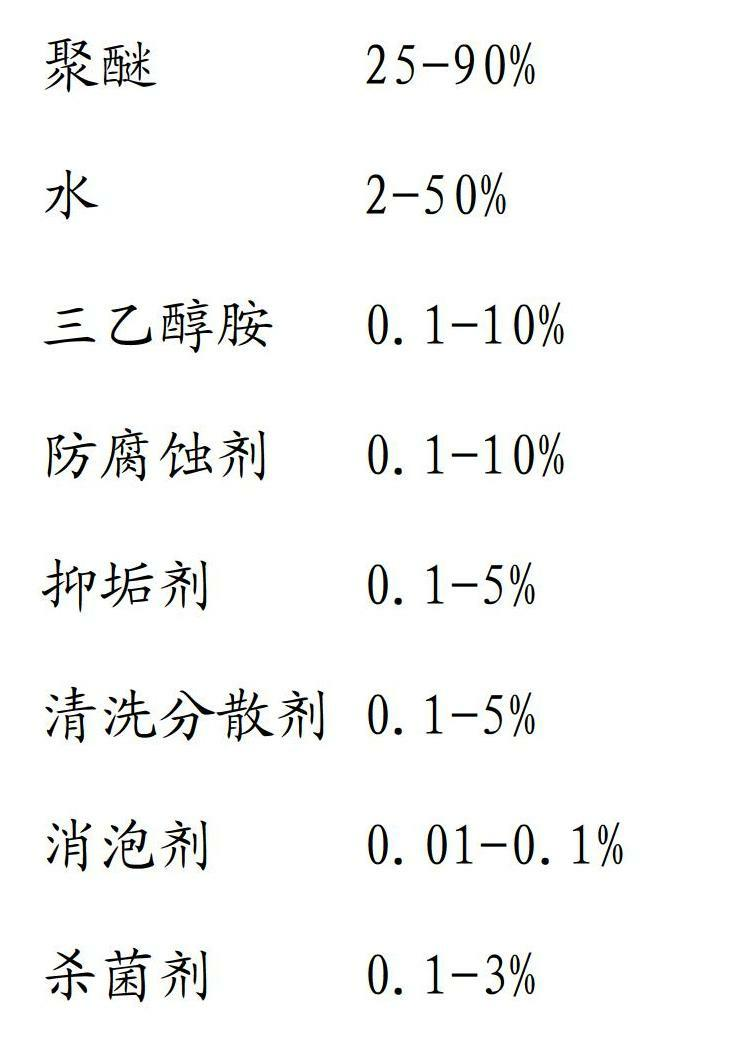

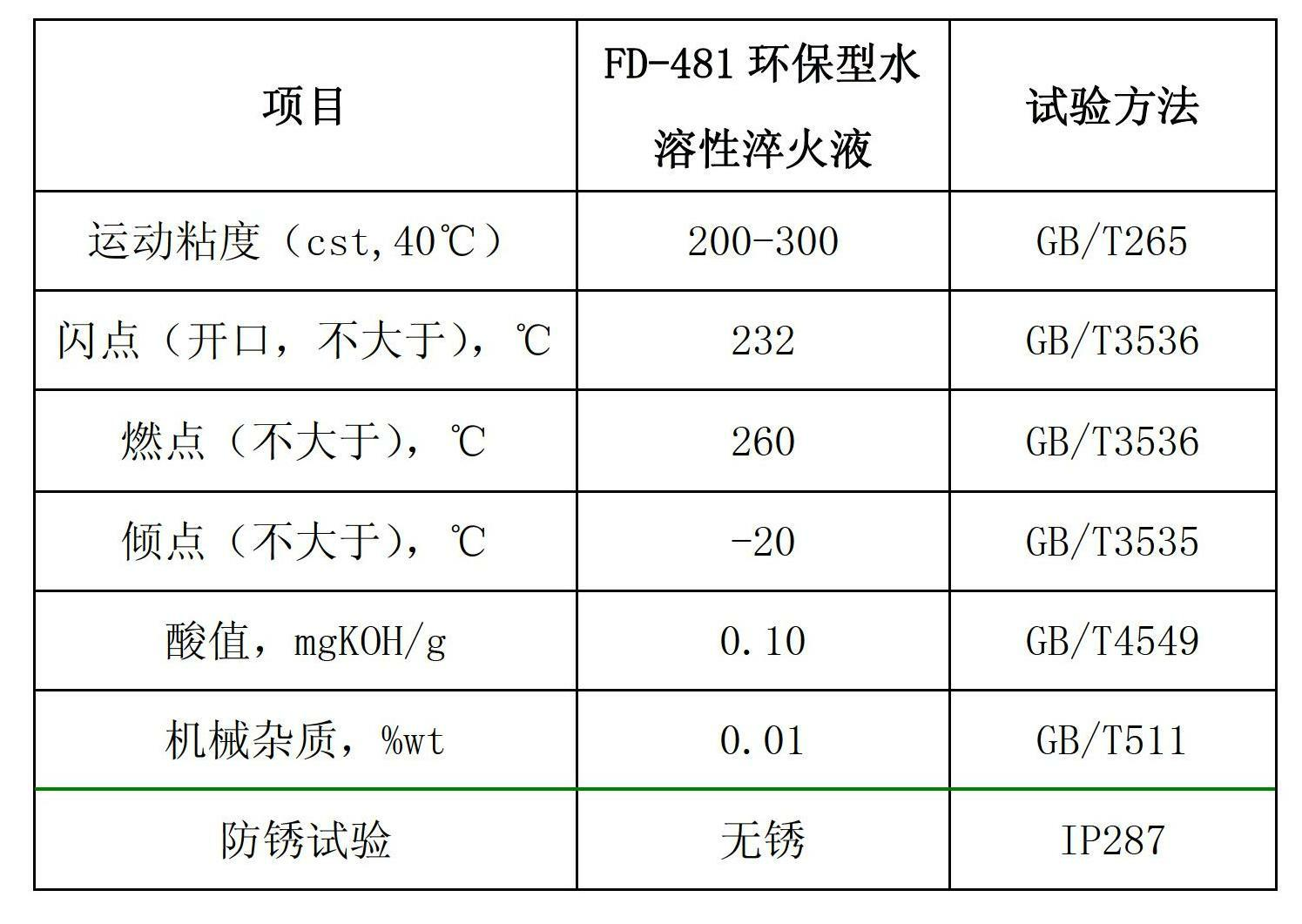

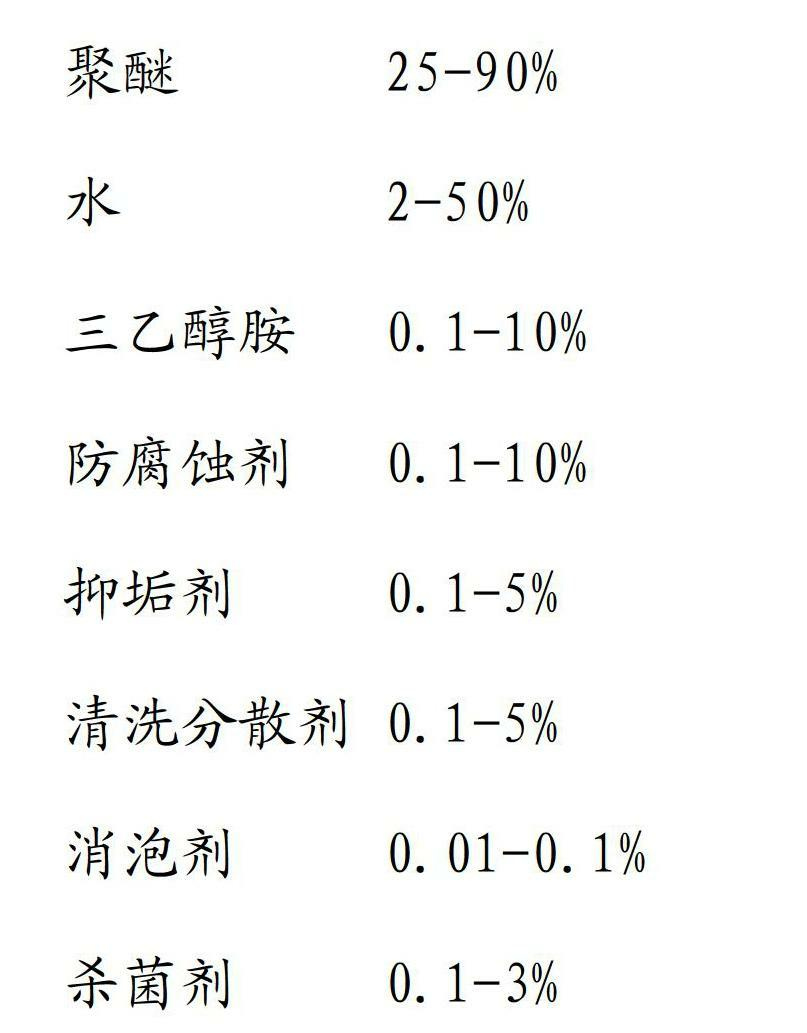

Environmental protection water-solubility quenching liquid

ActiveCN102643963AImprove final performanceImprove machining accuracyQuenching agentsSolubilitySurface cleaning

The invention discloses environmental protection water-solubility quenching liquid, which, by weight, comprises components of 25-90% of polyether, 2-50% of water, 0.1-10% of triethanolamine, 0.1-10% of anticorrosive agent, 0.1-5% of dirty restrain agent, 0.1-5% of washing dispersing agent, 0.01-0.1% of antifoaming agent and 0.1-3% of fungicide. The polyether molecular weight is 30000-50000. The water-solubility quenching liquid is compounded with balanced rust-inhibiting additive and the washing dispersing agent, has great cooling speed in a high-temperature cooling stage, can refine grains, has moderate cooling speed in a low-temperature cooling stage, effectively solves cracking and deformation problems in a workpiece cooling process, and improves surface quality of a workpiece. Excellent rust-proof performance effectively protects the quenched workpiece, and rust-proof requirements between working procedures are completely met. The environmental protection water-solubility quenching liquid has prominent surface cleaning performance, scale cinder is avoided, output quantity is small, production efficiency is improved, and production cost is saved.

Owner:上海福岛新材料科技有限公司

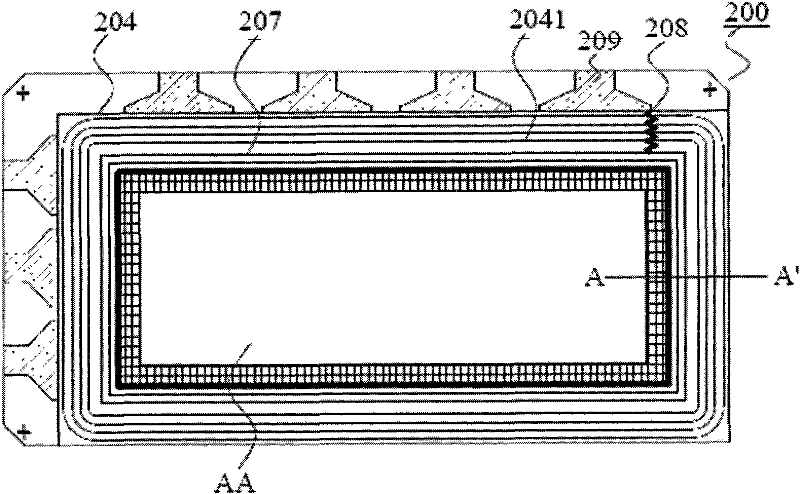

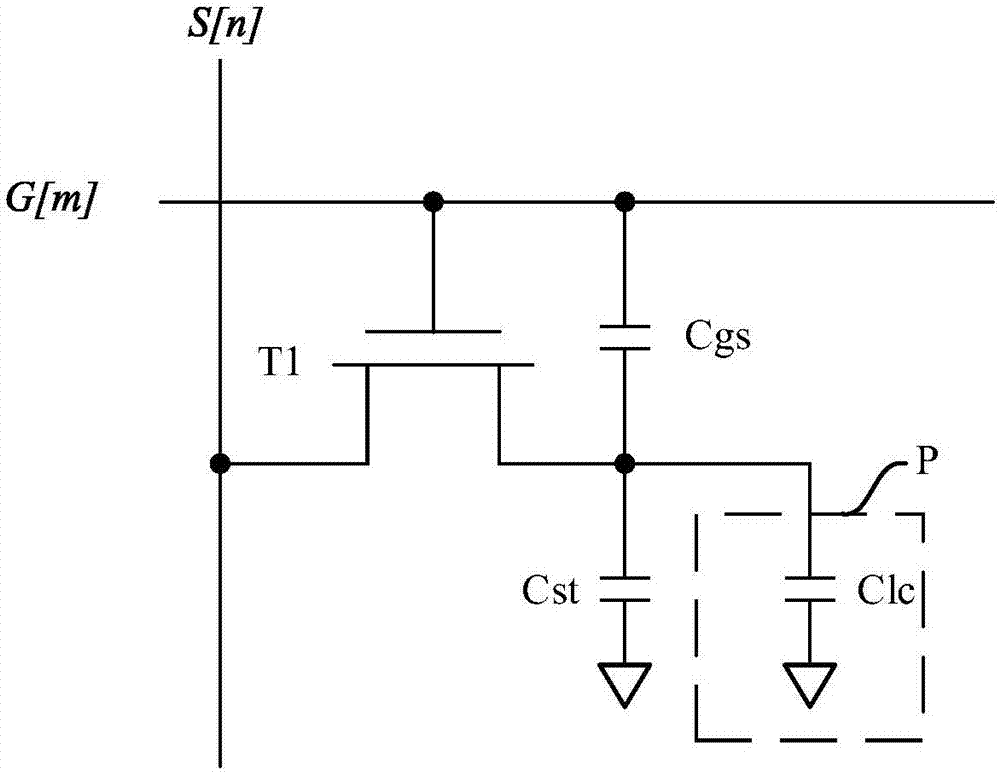

Liquid crystal display device

InactiveCN102540586AReduce carryoverImage retention does not affectStatic indicating devicesOptical filtersLiquid crystalElectric field

The invention provides a liquid crystal display device comprising a first glass substrate, a second glass substrate, a liquid crystal layer, a color optical filter, a transparent electrode, a plurality of pixel electrodes and at least one conductive pattern, wherein the liquid crystal layer is arranged between the first glass substrate and the second glass substrate; the color optical filter is arranged on the first glass substrate and comprises a black matrix region and a pixel region; the transparent electrode is arranged between the color optical filter and the liquid crystal layer; the plurality of pixel electrodes are arranged on the second glass substrate; and the at least one conductive pattern is arranged on a non-display region of the second glass substrate and forms an electric field together with the opposite transparent electrode and is used for adsorbing ions so as to reduce the image retention phenomenon in a display region.

Owner:华映视讯(吴江)有限公司 +1

Compound type binder used for pellet

The invention discloses a compound type binder used for pellet, which comprises the following raw materials in percentage by weight: 70-80% of clay powder, 10-20% of sodium humate, 3-6% of sodium carboxymethyl cellulose and 2-4% of sodium carbonate. The compound type binder used for the pellet of the invention is a pellet binder prepared by combining inorganic substance and organic substance, hasgood hydrophily and high viscosity, can be dissolved into water, replaces bentonite completely, has extremely low carry-in amount of detrimental impurity of the inorganic substance and does not influence the iron grade of the pellet; and when added into iron finemeal pellet for production, the invention does not change the original process and is an ideal and synergistic pellet binder.

Owner:王建忠

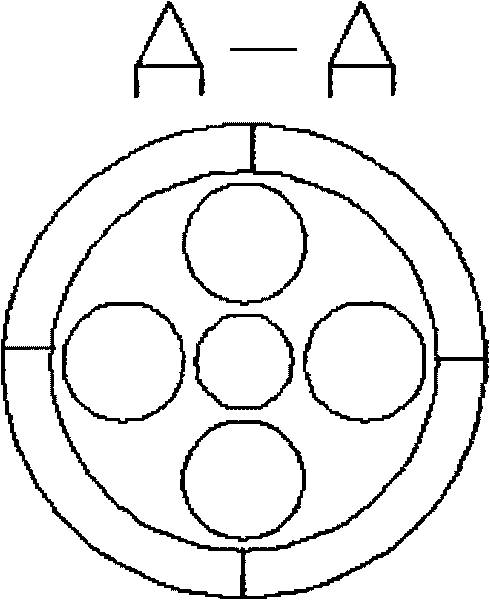

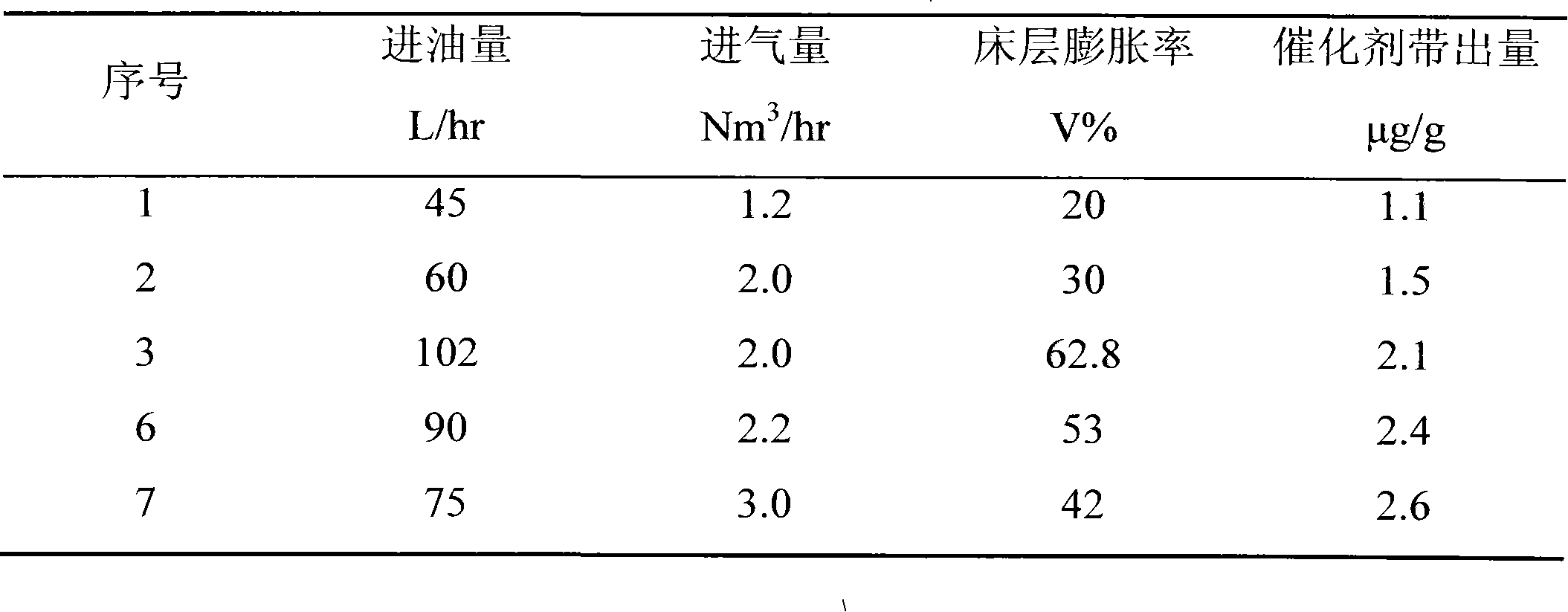

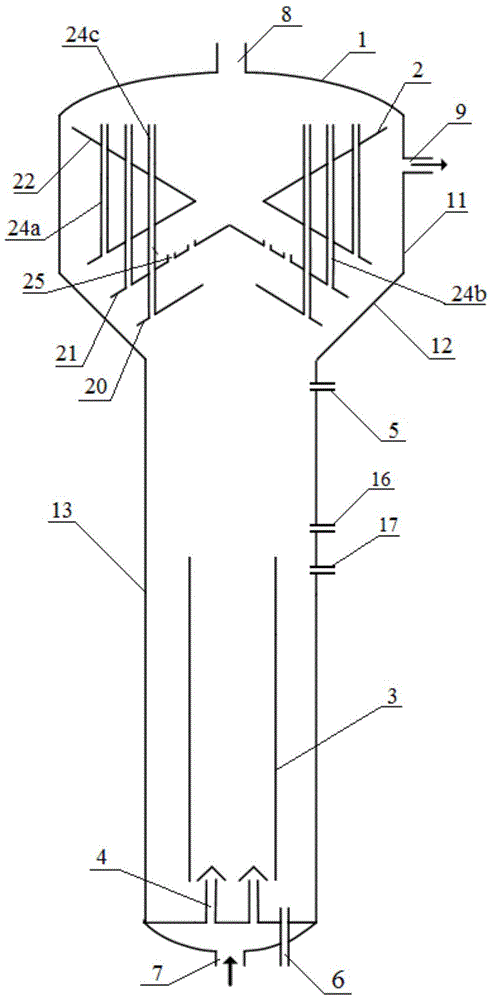

Three-phase boiling bed reactor

InactiveCN102463077AGreat operating flexibilityReduce carryoverChemical/physical processesChemical reactionStraight tube

The invention discloses a three-phase boiling bed reactor, which comprises a reactor casing and a three-phase separator, wherein the three-phase separator is positioned at the upper part in the reactor casing and comprises two homocentric round tubes with different inner diameters: an inner tube and an outer tube, the upper ends and the lower ends of the inner tube and the outer tube are all open, and the inner tube and the outer tube respectively comprise a straight tube section and a diffusion section. The three-phase boiling bed reactor is characterized in that the diameter of the straight tube section of the inner tube of the three-phase separator is 0.6 to 0.9 time of the diameter of the reactor casing. Through analyzing the speed distribution rule of liquid in the boiling bed reactor in the radial direction positions, the structure of the three-phase separator is reasonably set, so the operation elasticity of the three-phase separator is increased, and the efficient separation of the three-phase separator is ensured. The reactor is mainly applicable to the chemical reaction taken by different kinds of liquid and gas substances under the condition of being contacted with solid particles, and the reactor has the advantages that the catalyst inventory is large, the utilization rate of the reactor is high, the structure is simple, the operation is easy, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

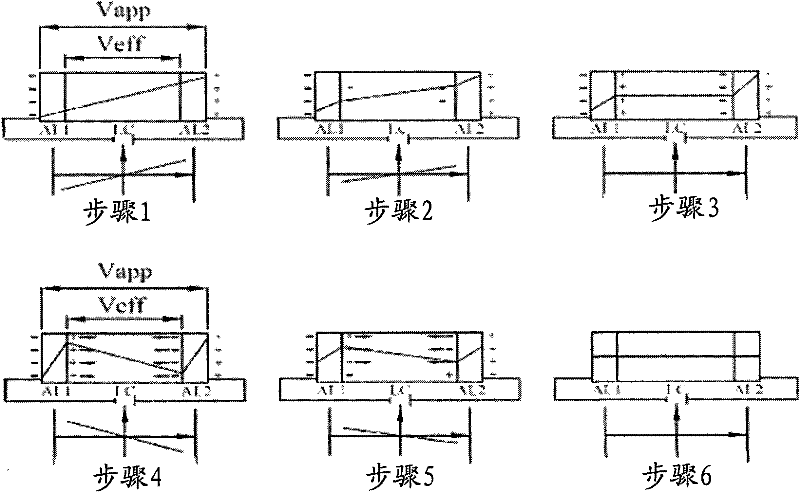

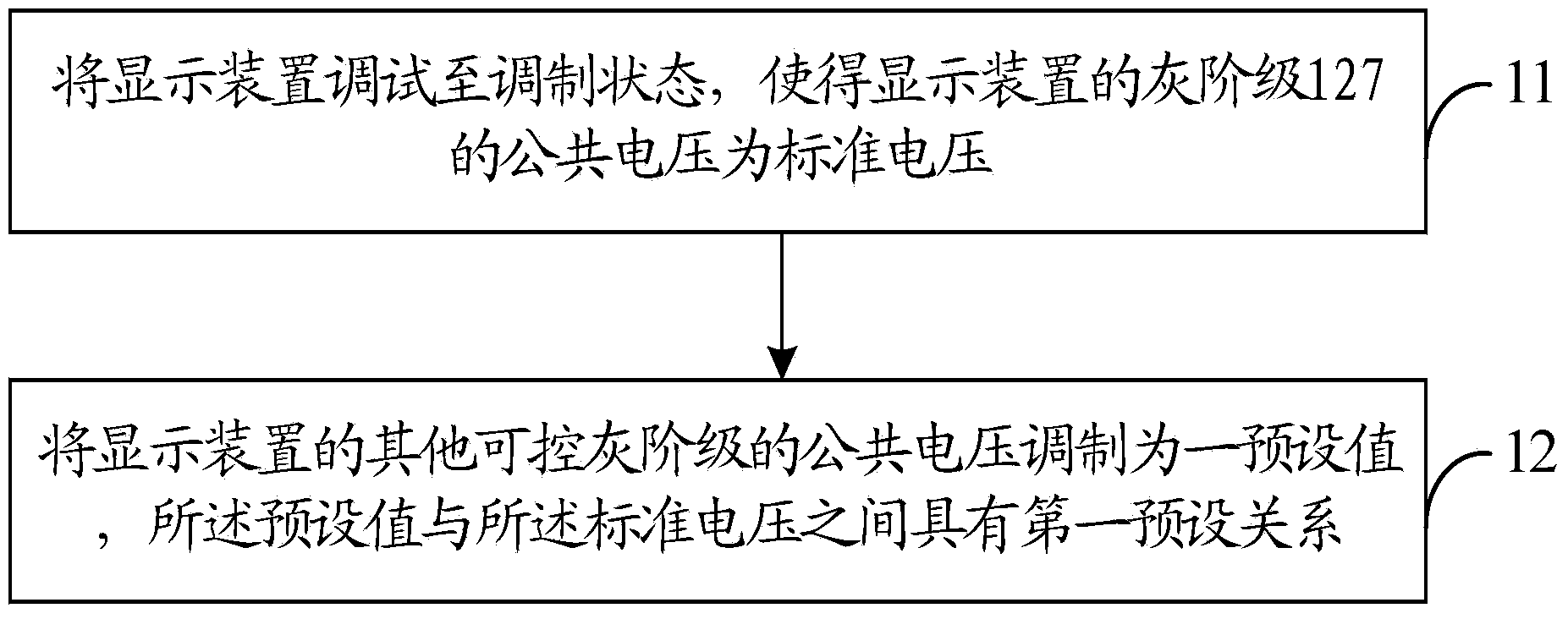

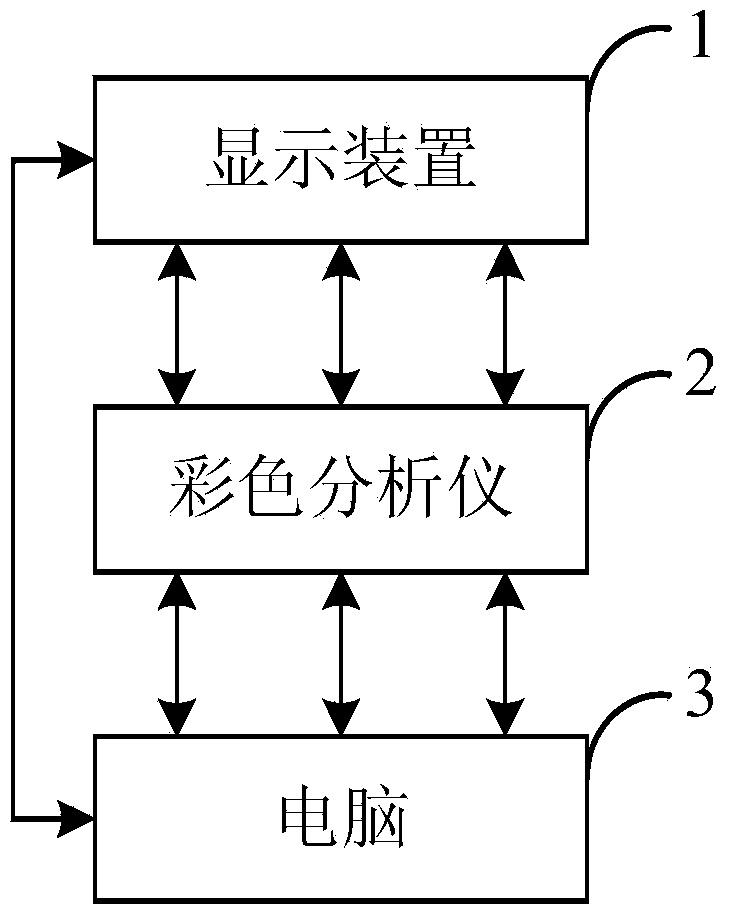

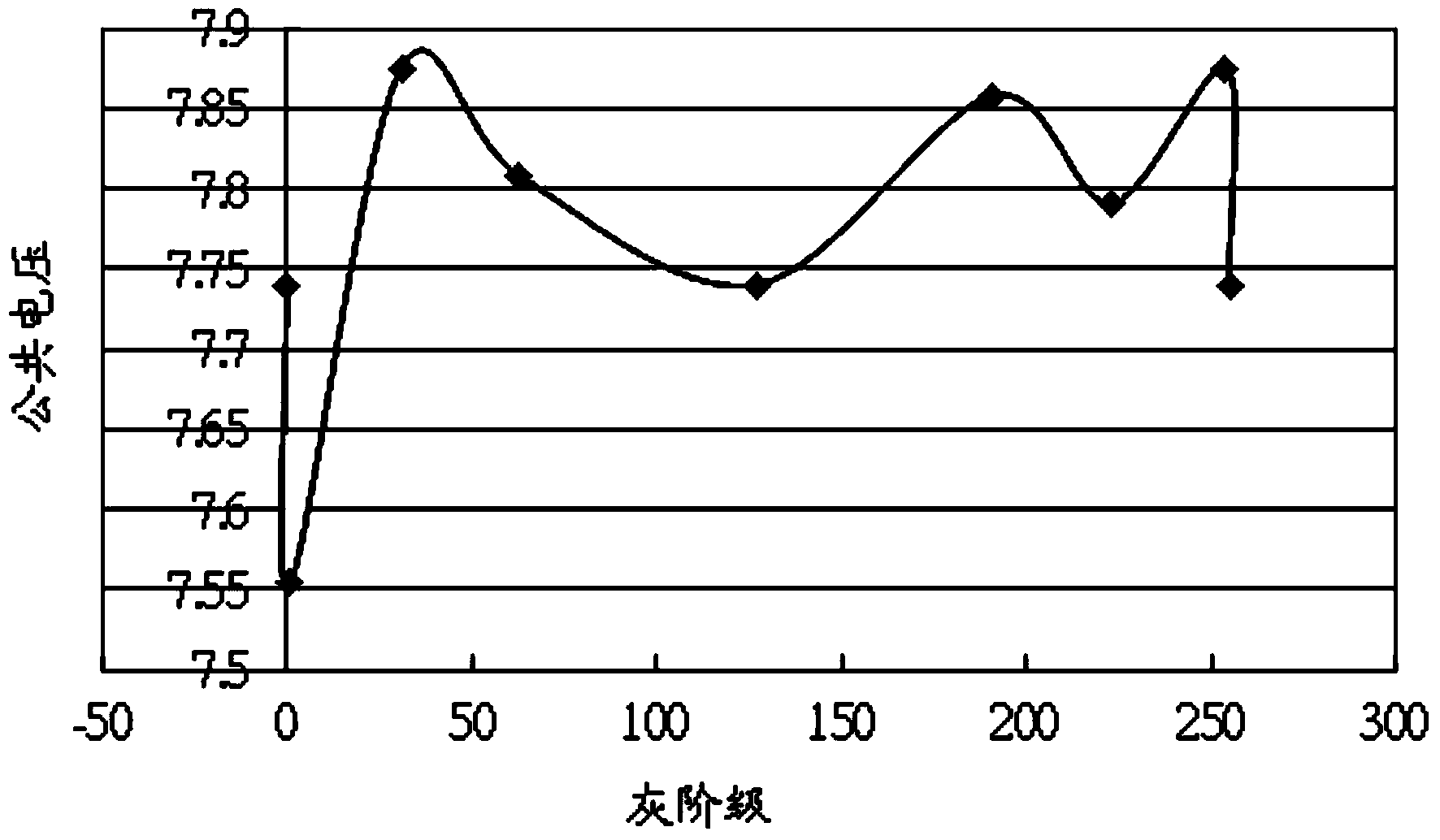

Image display quality modulating method and device for display device

InactiveCN103810963AEnsure that the screen display quality requirementsReduce carryoverCathode-ray tube indicatorsDisplay deviceLevel line

The invention provides an image display quality modulating method and an image display quality modulating device for a display device. The method comprises the steps of debugging the display device to be in a modulating state, so as to enable the common voltage of the gray scale 127 of the display to be a standard voltage; and modulating the common voltages of other controllable gray scales of the display device to be a preset value, wherein a first preset relation is arranged between the preset valve and the standard voltage. Therefore, the common voltages of the gray scales in the display device are maintained in a same horizontal line, so that the image residual phenomenon can be maximally reduced, and the screen display quality requirement of the display device can be guaranteed.

Owner:BEIJING BOE DISPLAY TECH CO LTD +1

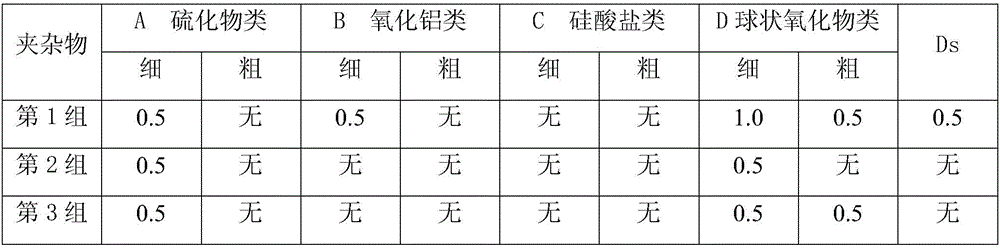

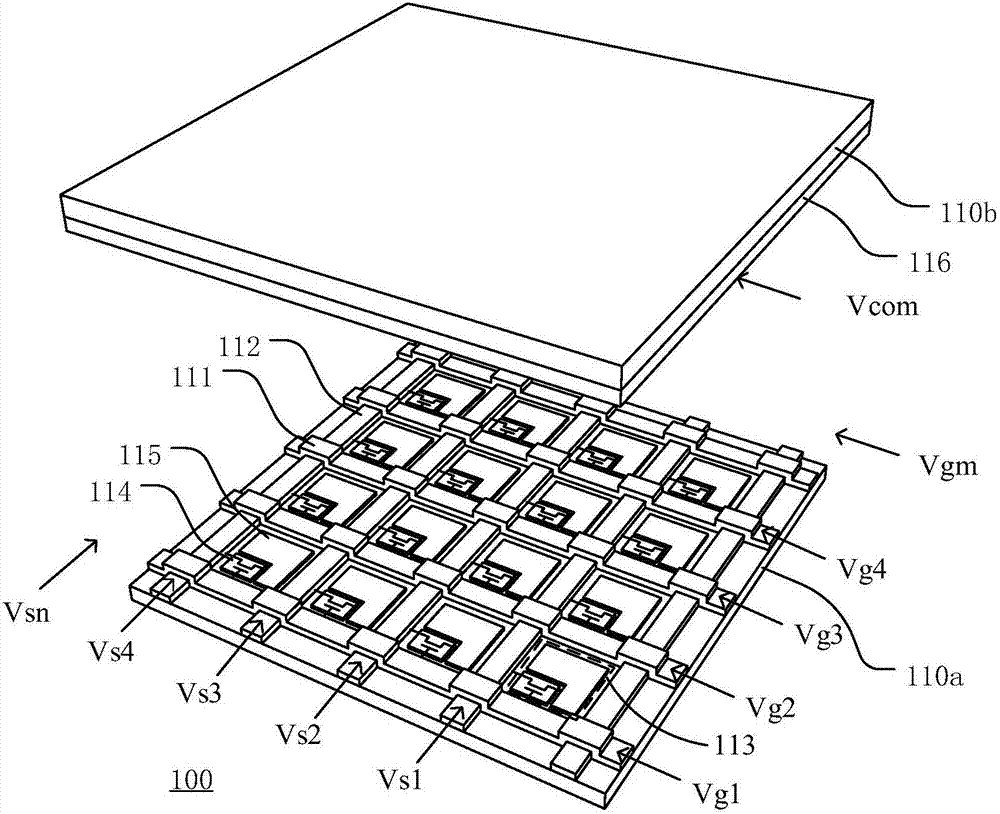

Method for electrodepositing nanocrystalline chromium-nickel alloy coating with carboxylic acid or its salt -urea impulse

A process for pulse electro-deposition nanometer Cr-Ni alloy plating of carboxylic acid or the salt-urea system of carboxylic acid is provided, which relates to the technology for surface engineering and surface treatment, comprises the pretreating and pulse electro-deposition treatment of the plating. The current efficiency of the plating solution system in the invention is up to 45.28%, about 35% higher than the 10% current efficiency in conventional trivalent Cr plating solution system; the toxicity of Cr3+ in the plating solution is only 1% of Cr6+, and the Cr content in the plating solution is only 1 / 7 of that in the plating solution of chromic acid. The invention is characterized by low toxicity and energy consumption, and greatly reduces the production cost of Cr-Ni plating and the environmental pollution during the production. The nanometer Cr-Ni plating prepared by the present invention is bright, intense, flat, and strongly bonded with the substrate, and is of excellent resistance to wear and corrosion in air. The invention is applicable for corrosion protection and decoration of metallic or metal alloy surfaces.

Owner:CENT SOUTH UNIV

Production process for high-purity bearing steel

InactiveCN106591536ALow residual elementsReduce gas contentProcess efficiency improvementLow nitrogenSlag

The invention belongs to the technical field of steel preparation, and particularly relates to a production process for high-purity bearing steel. The production process comprises the following steps: firstly, adding blast-furnace molten iron and steel scrap in an electric converter and smelting; secondly, alloying a steel ladle by virtue of an alloy, an aluminium cake and a low-nitrogen carburant; thirdly, discharging molten steel into the steel ladle subjected to the alloying treatment after the smelting is completed, slagging and enabling the slagging result to meet the requirements of while slag in the earlier stage of refining, obtaining the while slag and then carrying out aluminium line feeding operation; fourthly, hoisting molten steel qualified after the refining into a vacuum tank and carrying out vacuum treatment; and finally carrying out continuous casting. Cancel of molten steel modification treatment is realized; and moreover, the molten steel is high in castability and meets the production requirements of high-standard bearing steel.

Owner:ZENITH STEEL GROUP CORP

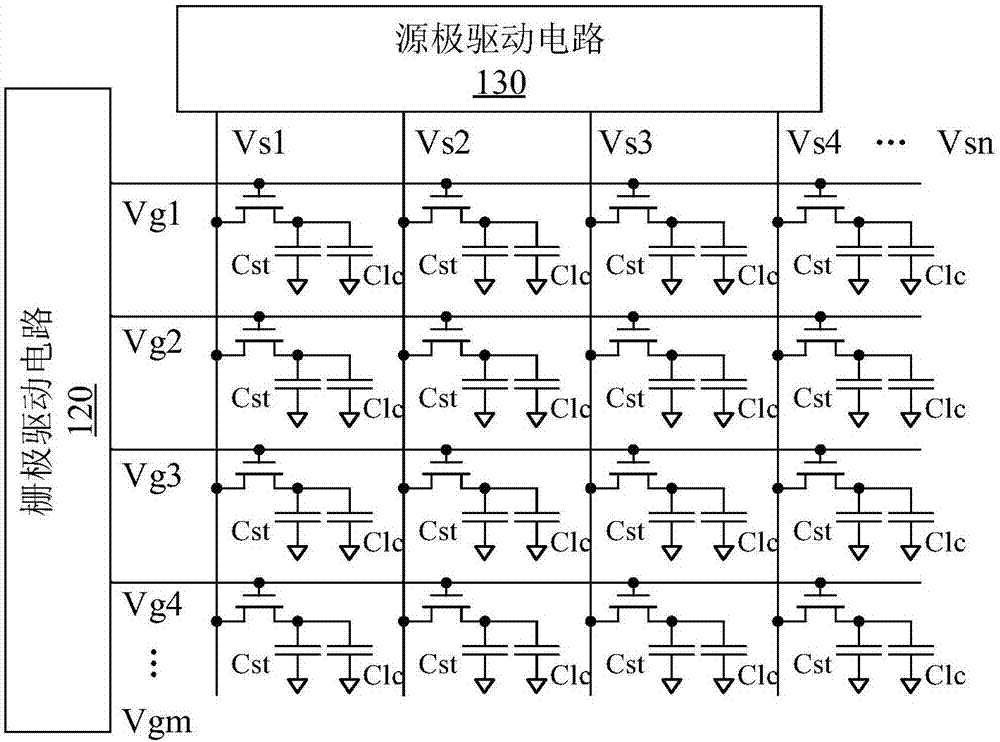

Display device

InactiveCN106971697AImprove display qualityReduce carryoverStatic indicating devicesCapacitanceDisplay device

The invention discloses a display device comprising a display panel, a grid drive circuit and a source drive circuit. The display panel comprises multiple pixel units which are arranged according to rows and columns, multiple grid scanning lines which are arranged according to the rows, multiple compensation potential lines which are arranged according to the rows and multiple source data lines which are arranged according to the columns. Each pixel unit comprises a thin film transistor, a pixel electrode and a compensation capacitor. The grid drive circuit is used for providing grid voltage to the grid electrodes of the thin film transistors of the pixels of the corresponding row. The source drive circuit is used for providing source voltage to the source electrodes of the thin film transistors of the pixels of the corresponding column so as to set display voltage between the electrode plates of a liquid crystal capacitor. The grid drive circuit comprises multiple grid drive circuits. Each grid drive unit comprises a compensation module and is used for providing compensation voltage to the compensation capacitors of the pixels of the corresponding row in multiple pixels according to a front grid drive signal and a rear grid drive signal. According to the display device, compensation of feed-through voltage can be realized through the grid drive circuit, the compensation capacitors and the compensation potential lines.

Owner:KUSN INFOVISION OPTOELECTRONICS

Method for preparing high pure ammonium paramolybdate

InactiveCN1480404AReduce the liquid-solid ratioReduce carryoverCrystallization separationMolybdeum compoundsSal ammoniacEthylenediamine

A process for preparing high-purity ammonium paramolybdate from ammonium polymolybdate as raw material includes adding purified water and ammonia water, heating while stirring, stirring under a certain steam pressure for evaporation crystallizing while boiling the solution, concentrating, solid-liquid separation, and baking. Its advantages are high purity and high crystallizing rate (94.5-96%.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Novel bubbling bed reactor

ActiveCN101376092BGreat operating flexibilityEfficient separationHydrocarbon oils refiningChemical/physical processesConvex structureChemical reaction

The invention discloses a new fluidized bed hydrogenation reactor. The fluidized bed hydrogenation reactor of the invention comprises a cylinder-shaped reactor shell perpendicular to the ground, a three-phase separator arranged at the upper part in the reactor shell and a guiding structure arranged at the middle upper part of the reactor. The guiding structure is an annular convex structure arranged on the inner wall of the reactor and has the lengthwise section of a trapezoid or an arc along the axle of the reactor. The combination of the guiding structure and the three-phase separator increases the operating flexibility of the three-phase separator, and ensures the high-efficiency separation on the three-phase separator, thereby greatly reducing the carrying amount of catalyst. The fluidized bed hydrogenation reactor of the invention can be applied to the chemical reactions between different liquids or gases and solid grains under the condition of contacting, and is characterized bylarge catalyst inventory, high reactor utility ratio, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

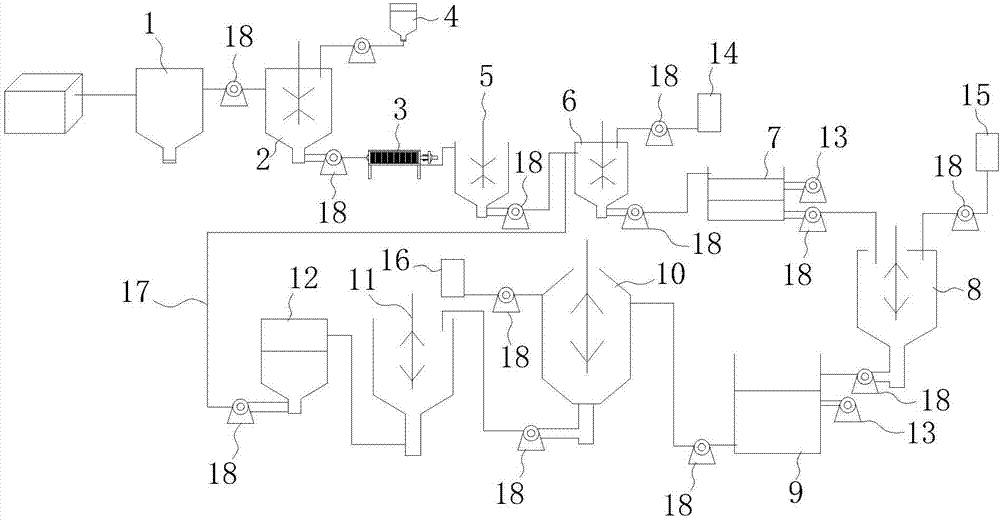

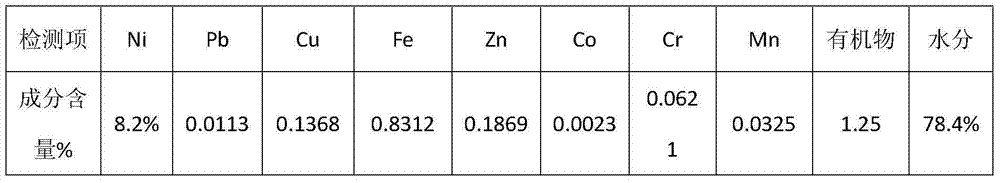

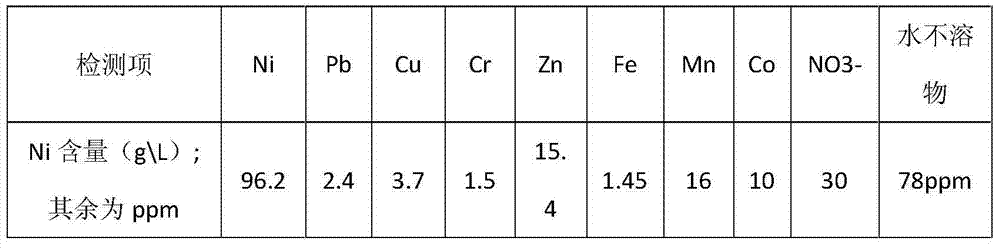

Method and equipment for preparing electroplating-grade nickel sulfate from nickel-containing wastewater produced in surface treatment process

ActiveCN104229906AReduce carryoverReduce volumeMultistage water/sewage treatmentNickel sulfatesFiltrationSulfate

The invention discloses a method and equipment for preparing electroplating-grade nickel sulfate from nickel-containing wastewater produced in a surface treatment process, and belongs to the technical field of nickel-containing wastewater treatment process. The method is characterized by comprising the following steps: (1) collecting nickel-containing wastewater; (2) performing sedimentation and press filtration on nickel in the nickel-containing wastewater, and smashing nickel mud to obtain nickel slurry; (3) dissolving the nickel slurry into acid; (4) filtering a nickel sulfate solution; (5) removing impurities from the nickel sulfate solution for purification, and performing secondary filtration; (6) performing vacuum evaporative concentration, crystallization, filtration and centrifugal drying on the nickel sulfate solution to obtain nickel sulfate crystals. The invention aims to provide the method and the equipment which can reduce the waste of nickel resources, reduce potential hazard of nickel to the natural environment and realize recycling of the nickel resources and are used for preparing the electroplating-grade nickel sulfate from the nickel-containing wastewater produced in the surface treatment process. The method and the equipment are used for treating the nickel-containing wastewater.

Owner:MEIZHOU ENVIRONMENTAL EQUIP

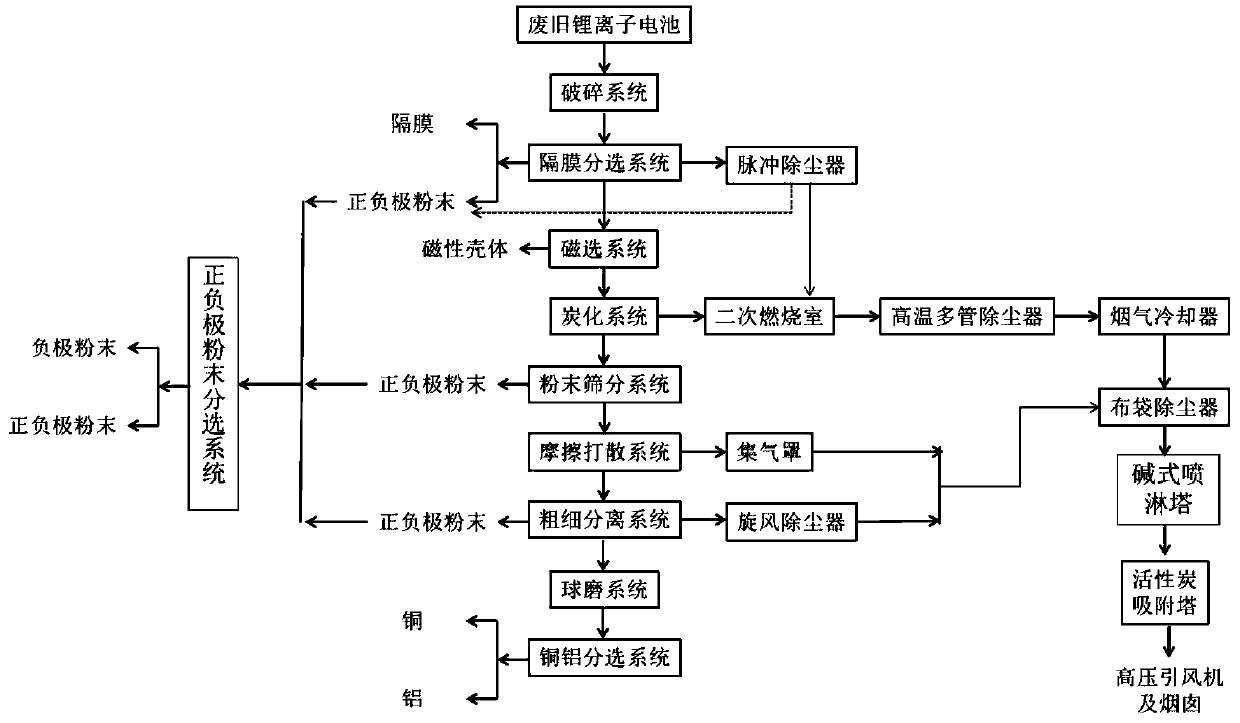

Efficient environment-friendly waste lithium ion battery recycling process

InactiveCN111282956ASolve technical problems such as pollution-free treatmentImprove sorting efficiencyTransportation and packagingSolid waste disposalPower batteryCarbonization

The invention provides an efficient environment-friendly waste lithium ion battery recycling process, and relates to the technical field of waste lithium ion power battery recycling. The efficient environment-friendly waste lithium ion battery recycling process comprises the steps of smashing treatment, primary screening, carbonization treatment, secondary screening, copper-aluminum sorting treatment, powder treatment and gas treatment. By means of the treatment steps of waste lithium ions, the sorting efficiency of diaphragms is greatly improved, and meanwhile the carry-out amount of positivepowder and negative powder screened out of the diaphragms is reduced; electrolyte, a binder and other organic matter are subjected to innocent treatment, and meanwhile environmental pollution in thetreatment process is avoided; and in the offcut conveying process, a sealing and air conveying manner is adopted, and the leakage of dust is greatly reduced.

Owner:江苏鼎健环保科技有限公司

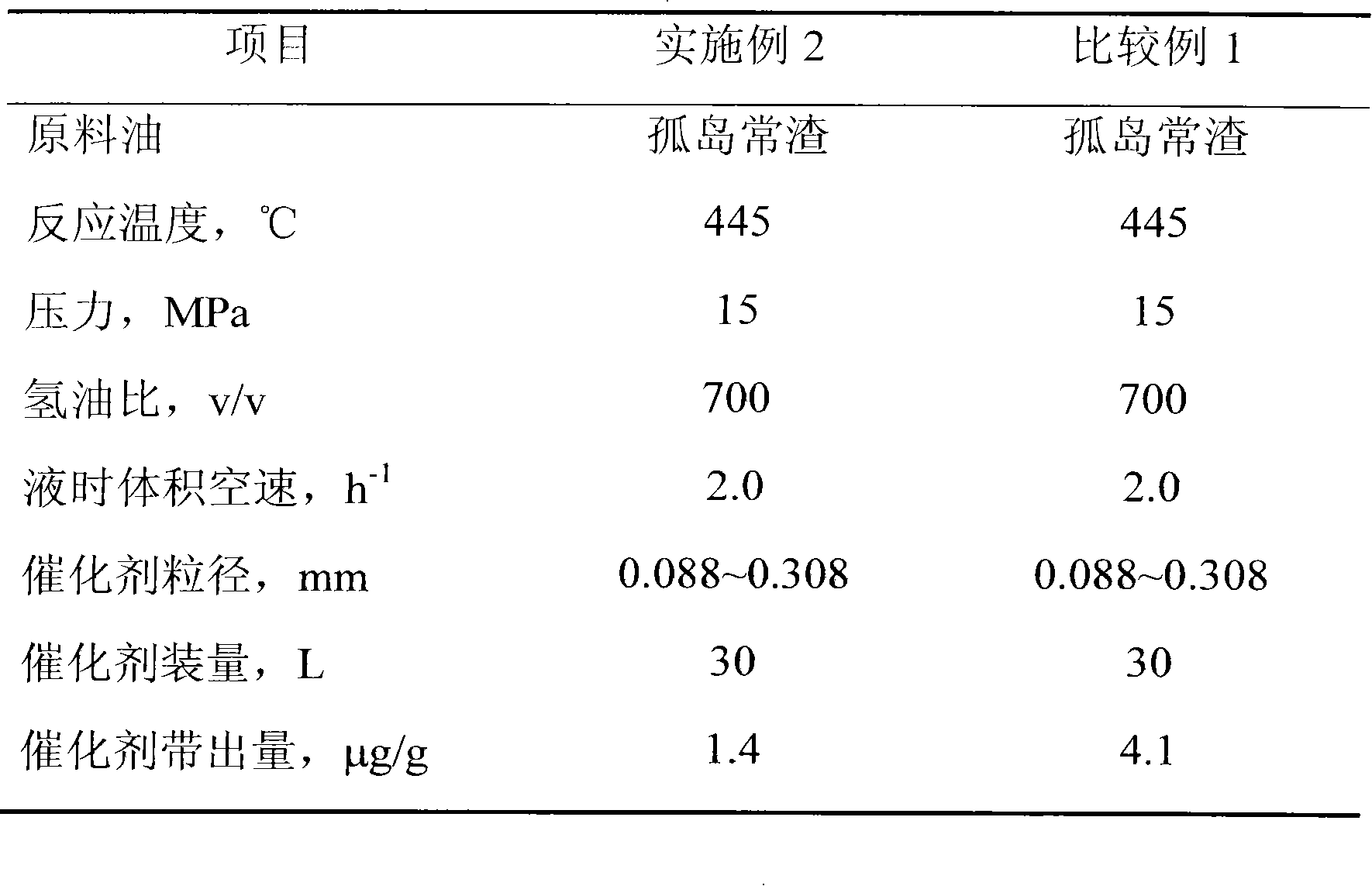

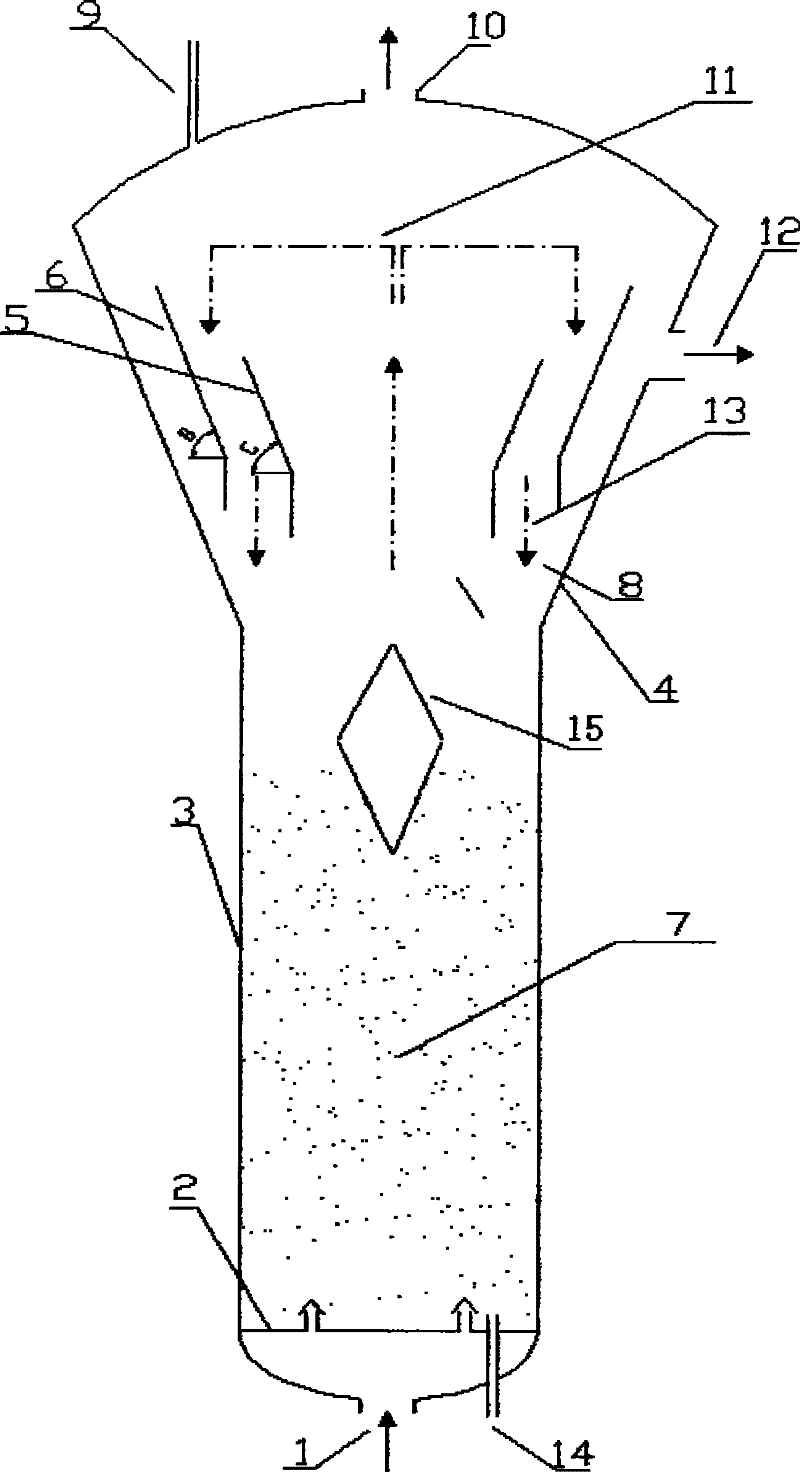

Residual oil hydrogenation method

ActiveCN104560140AEasy to operateReduce energy consumptionChemical/physical processesTreatment with moving solid particlesFluidized bedHydrogenation reaction

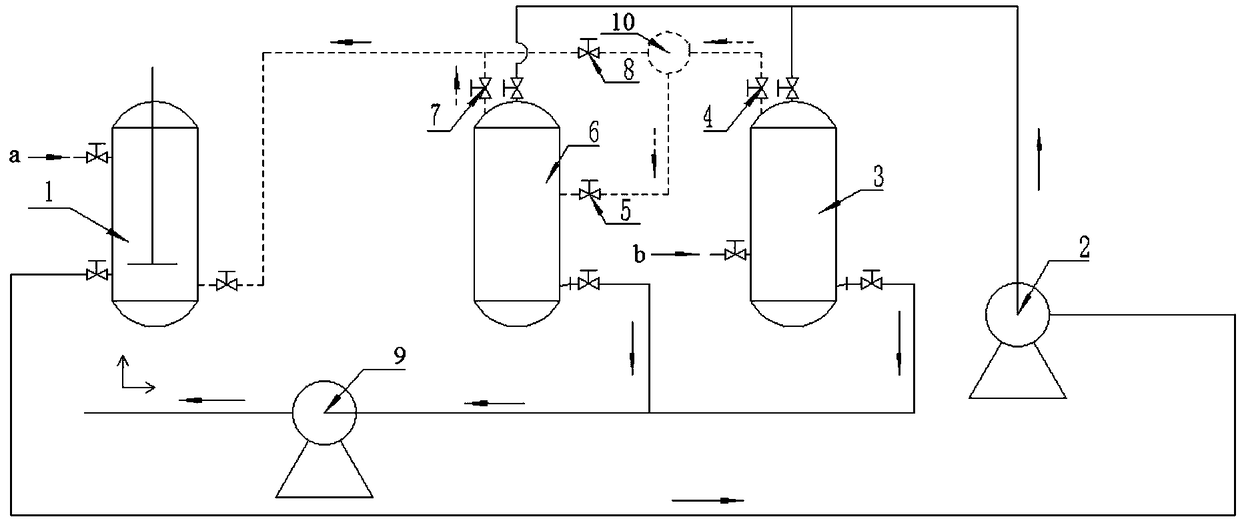

The invention relates to a residual oil hydrogenation method. The method is carried out in a fluidized bed reactor; a three-phase separation region, a fluidizing region and a circulation region are arranged in the fluidized bed reactor in sequence from top to bottom. The residual oil hydrogenation method comprises the steps: injecting a first fluidized bed hydrogenation catalyst from the upper part of the circulation region, and injecting a second fluidized bed hydrogenation catalyst and a suspended bed hydrogenation catalyst from the upper part of the fluidizing region to enable the residual oil and hydrogen to be subjected to the hydrogenation reaction in the fluidized bed reactor, wherein the particle size of the first fluidized bed hydrogenation catalyst is 0.05-0.8mm greater than that of the second fluidized bed hydrogenation catalyst; according to corresponding oxide, the content of the active metal components in the first fluidized bed hydrogenation catalyst is10-80 percent lower than that of the active metal components in the second fluidized bed hydrogenation catalyst. According to the residual oil hydrogenation method disclosed by the invention, better reaction effect can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

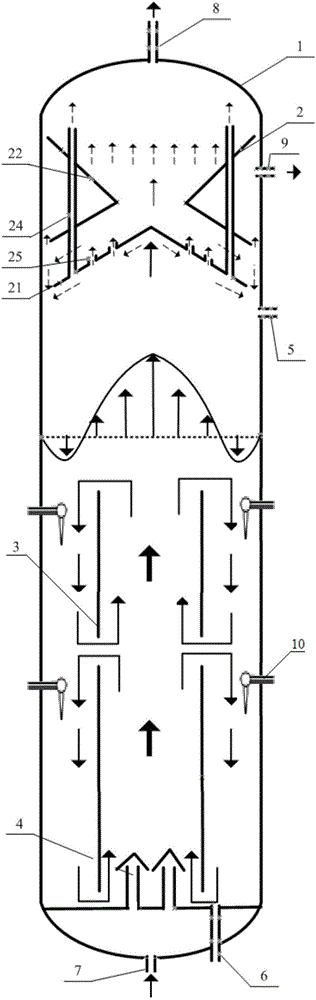

Residual oil hydrogenation method

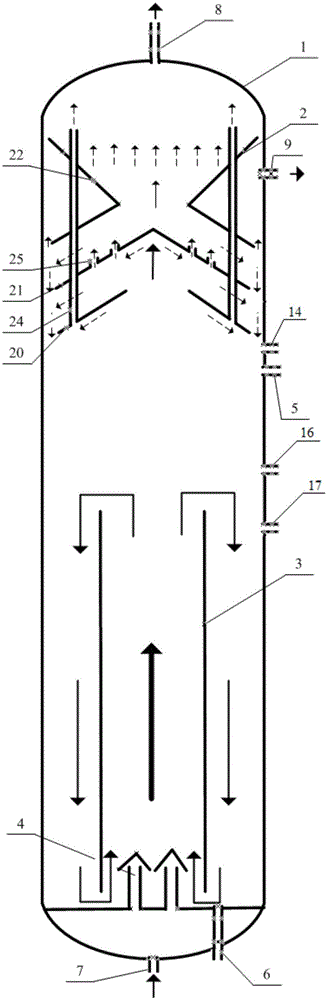

ActiveCN104560158AEasy to operateReduce energy consumptionTreatment with hydrotreatment processesHydrogenation reactionFluidized bed

The invention relates to a residual oil hydrogenation method. The method is carried out in a fluidized bed reactor; the fluidized bed reactor comprises a shell (1), a three-phase separation component (2) and an inner pipe (3), wherein the shell (1) comprises an expansion section (11), a transitional section (12) and a straight cylinder section (13) in sequence from top to bottom; the diameter of the expansion section (11) is greater than that of the straight cylinder section (13); the three-phase separation component (2) is arranged in the expansion section (11) and the transitional section (12) to form a three-phase separation region; the inner pipe (3) is arranged at the lower part in the straight cylinder section (13) to form a circulation region and a fluidizing region positioned between the circulation region and the three-phase separation region. The residual oil hydrogenation method comprises the steps: injecting a fluidized bed hydrogenation catalyst and a suspended bed hydrogenation catalyst from the upper part of the fluidizing region to enable the residual oil and hydrogen to be subjected to the hydrogenation reaction in the fluidized bed reactor. According to the residual oil hydrogenation method disclosed by the invention, better reaction effect can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

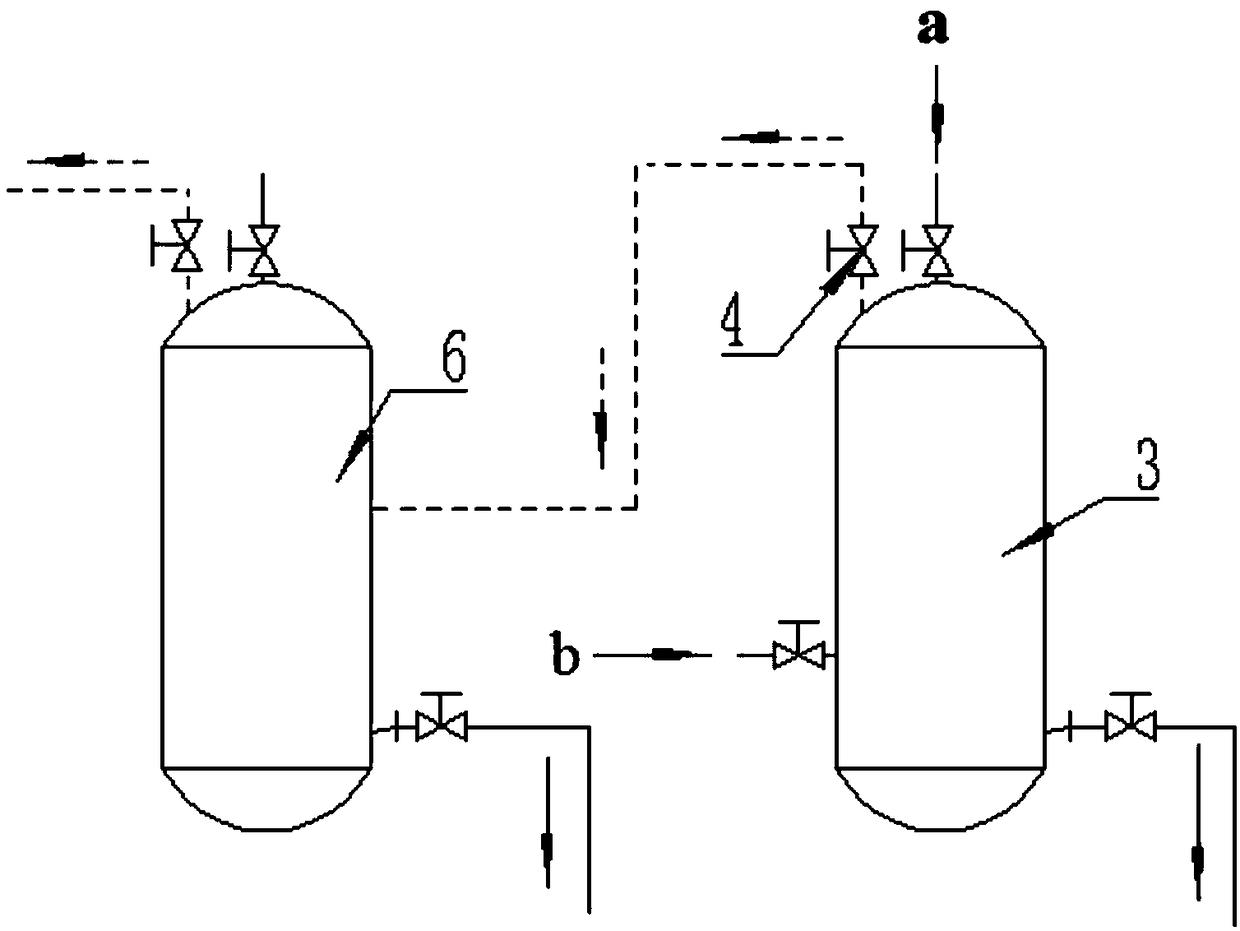

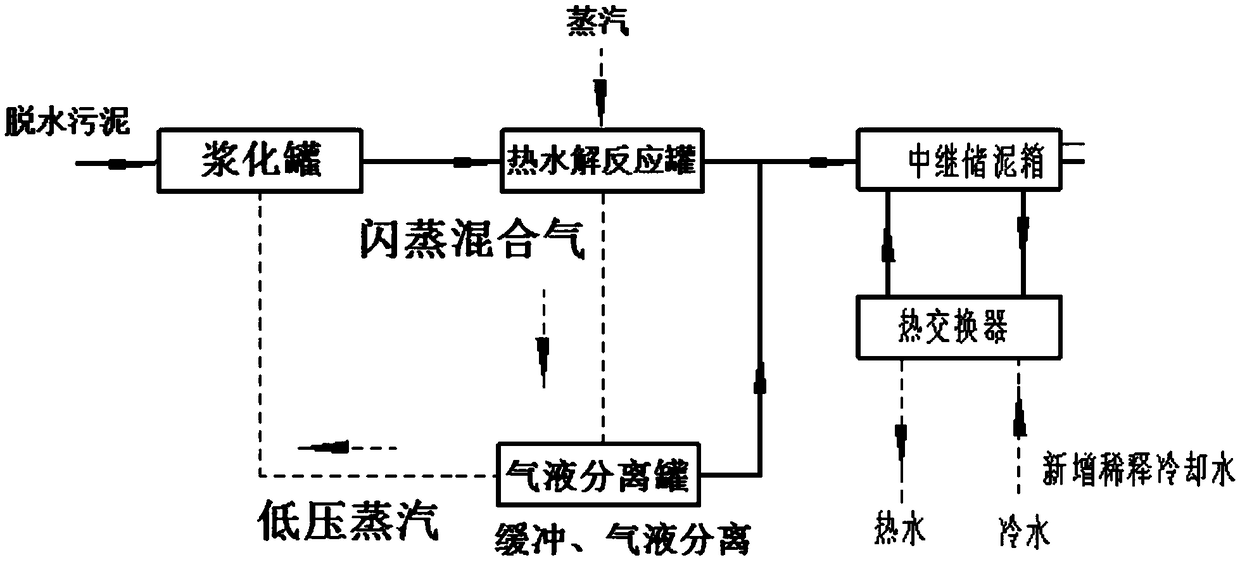

Pyrohydrolysis flash separation device, pyrohydrolysis flash separation technology, pyrohydrolysis system and pyrohydrolysis technology

PendingCN108840548ASmall pressure fluctuationsReduce vibrationSludge treatment by thermal conditioningSludge treatment by pyrolysisTreatment needRelief valve

The invention discloses a pyrohydrolysis flash separation device, a pyrohydrolysis flash separation technology, a pyrohydrolysis system and a pyrohydrolysis technology. The pyrohydrolysis flash separation device comprises a pyrohydrolysis reaction tank and a gas-liquid separation tank which are communicated through a pipe, wherein a pressure relief valve is arranged on the pipe therebetween. By the pyrohydrolysis flash separation technology, the pyrohydrolysis flash separation device is used for flash separation. The pyrohydrolysis system comprises a slurrying tank, a mud inlet pump, the pyrohydrolysis reaction tank and the gas-liquid separation tank which are sequentially communicated end to end through pipes; the pressure relief valve is arranged on the pipe between the pyrohydrolysis reaction tank and the gas-liquid separation tank. By the pyrohydrolysis technology, the pyrohydrolysis system is used for pyrohydrolysis. The pyrohydrolysis flash separation device and the pyrohydrolysis system have the advantages of small floor area, low production cost, a high safety production factor and the like, and the pyrohydrolysis flash separation technology and the pyrohydrolysis technology have the advantages of a simple process, easy operation, high treatment efficiency, a good gas-liquid separation effect and the like, so that actual treatment needs can be met and an application prospect is very good.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

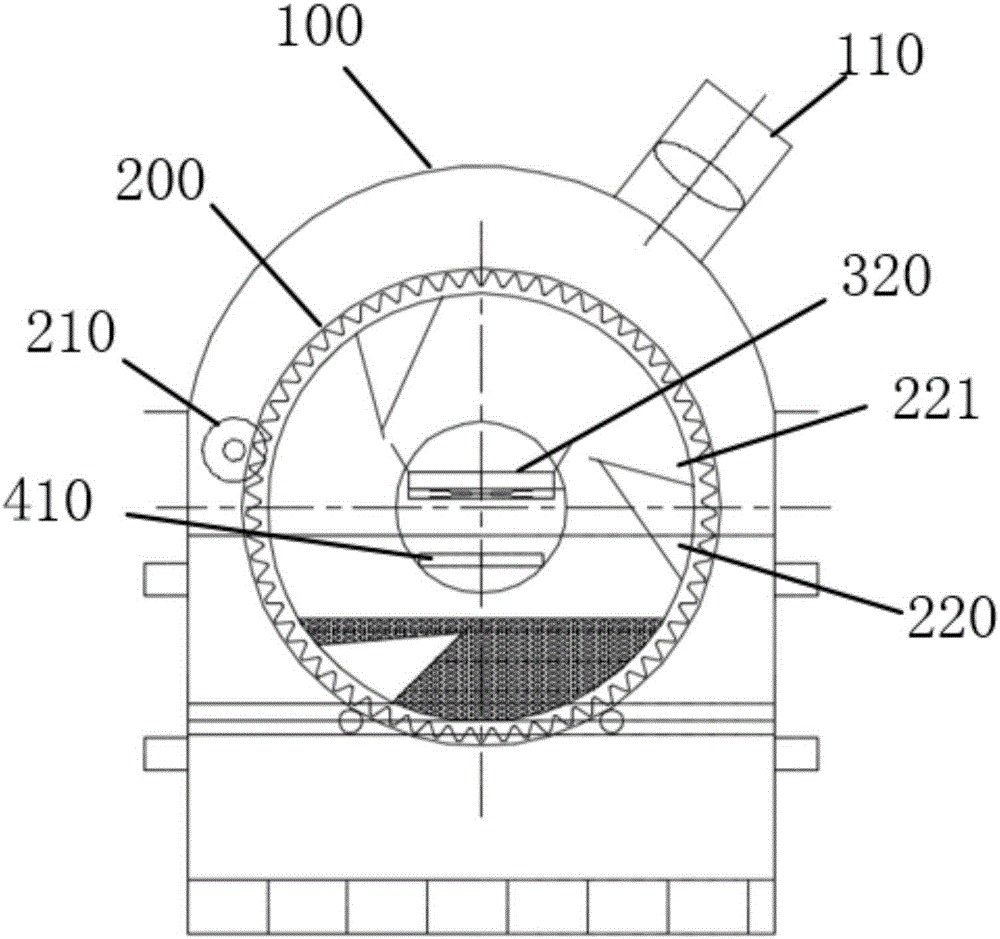

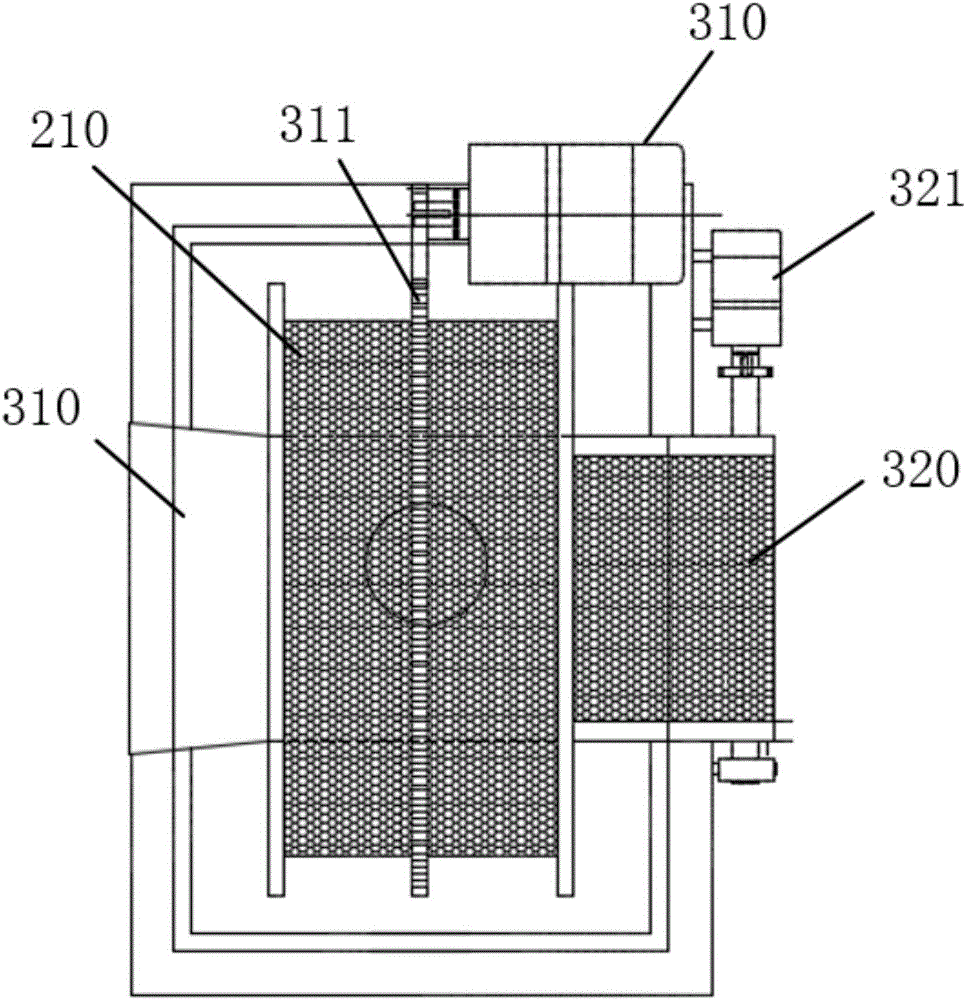

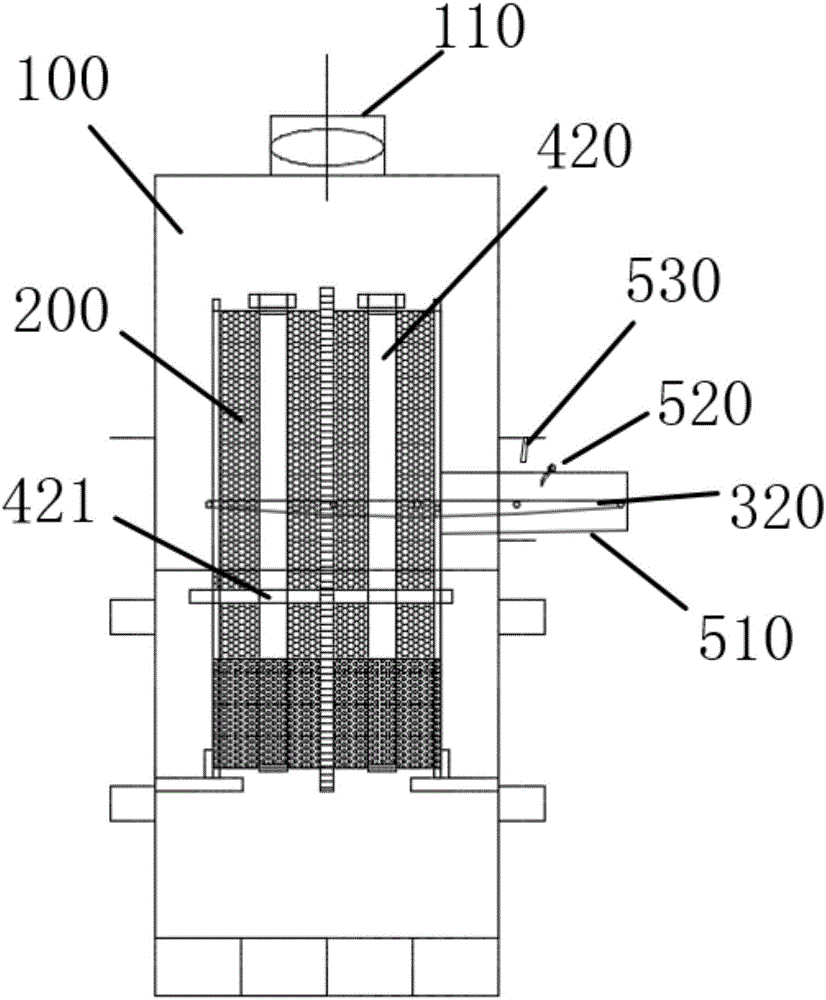

Barrel plating device and barrel plating automatic production line

The invention provides a barrel plating device and a barrel plating automatic production line. The barrel plating device comprises a shell, a roller rotationally arranged in the shell, a motor in transmission connection with the roller, a feeding belt used for receiving materials and a discharging belt used for outputting the materials. The feeding belt is arranged at the front end, in the axis direction, of the roller. The discharging belt is arranged at the rear end, in the axis direction, of the roller. According to the barrel plating device and the barrel plating automatic production line, the roller does not need to enter or get out of a trough, the discharging amount of trough liquor is small, consumption is low, and the waste water discharge amount is small.

Owner:北京汉昌绿源环保工程有限公司

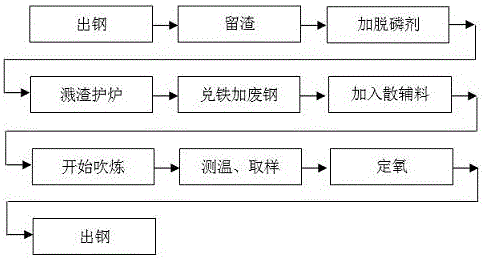

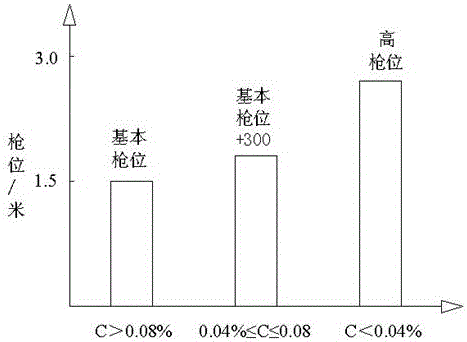

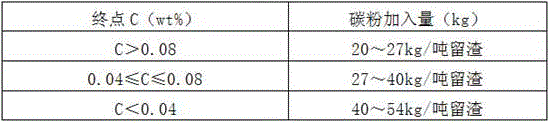

Dephosphorization method for oxygen top-blown converter slag remainder

InactiveCN106119459AReduce phosphorus contentReduce carryoverManufacturing convertersProcess efficiency improvementSmelting processHeat losses

The invention discloses a dephosphorization method for oxygen top-blown converter slag remainder. The dephosphorization method includes the steps that before slag-splashing for protection of a converter, a dephosphorization agent is added to the slag remainder in the converter after tapping, then inert gases are top-blown by an oxygen gun for the operation of slag-splashing for protection of the converter, and dephoshprized slag remainder serve as initial slag of the next melt of smelting. According to the method, the oxygen top-blown converter slag remainder operation is combined with the slag remainder dephosphorization process, the phosphorus content in the slag remainder can be lowered effectively, and the drag-in amount of phosphorus in the next melt of converter smelting process is lowered, so that the lime addition amount in the next melt of converter smelting process can be reduced, and the converter smelting cost is lowered. By the adoption of the dephosphorization method, part of the phosphorus element in the slag remainder in the converter can be removed, the slag amount is small in the smelting process, the heat loss is low, the iron loss is small, the converter slag dephosphorization effect is good, and the smelting cost is lowered remarkably.

Owner:TANGSHAN IRON & STEEL GROUP

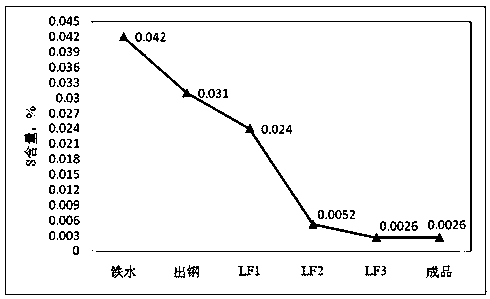

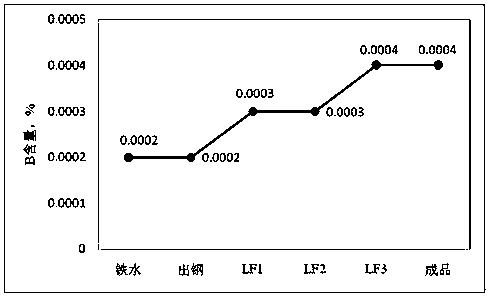

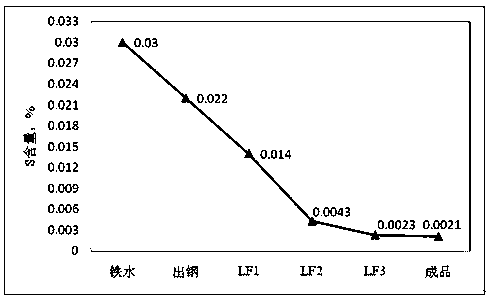

Smelting method of low-sulfur and low-boron steel

InactiveCN110423947AReduce carbon contentReduce carryoverProcess efficiency improvementSmelting processAlloy

The invention provides a smelting method of low-sulfur and low-boron steel. The steel comprises, by weight, 0.05%-0.18% of C, 0.10%-0.35% of Si, 1.10%-1.60% of Mn, no more than 0.020% of P, no more than 0.003% of S, 0.010%-0.050% of Nb, 0.008%-0.025% of Ti, no more than 0.30% of Ni, no more than 0.20% of Mo, no more than 0.25% of Cr, no more than 0.0005% of B, and 0.010%-0.050% of Als. The smelting process includes a converter, an LF furnace, an RH furnace and CC. Pretreatment for desulfuration is not needed, the carbon content of steel discharged out of the converter is slightly decreased toreduce molten steel w[B], low-B alloys such as manganese metal and mid-carbon ferromanganese are added, liquid cast waste slag is used, and the quantity of recovered liquid cast slag is controlled, sothat rapid slagging and desulfuration are guaranteed, and the quantity of B dragged into slag is reduced; the LF furnace only adopts aluminum wire deoxidation, and a large quantity of argon is blownfrom the bottom to achieve stirring, so that the probability that boric oxide in the slag is reduced and molten steel enters the slag is lowered while the sulfur content in the molten steel is decreased; and when the sulfur content in the molten steel reaches a required sulfur content, the argon blown from the bottom is regulated to be weak, stirring is conducted to reduce the quantity of added B,and an obtained finished products meets w[S]<=0.003 and w[B]<=0.0005.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

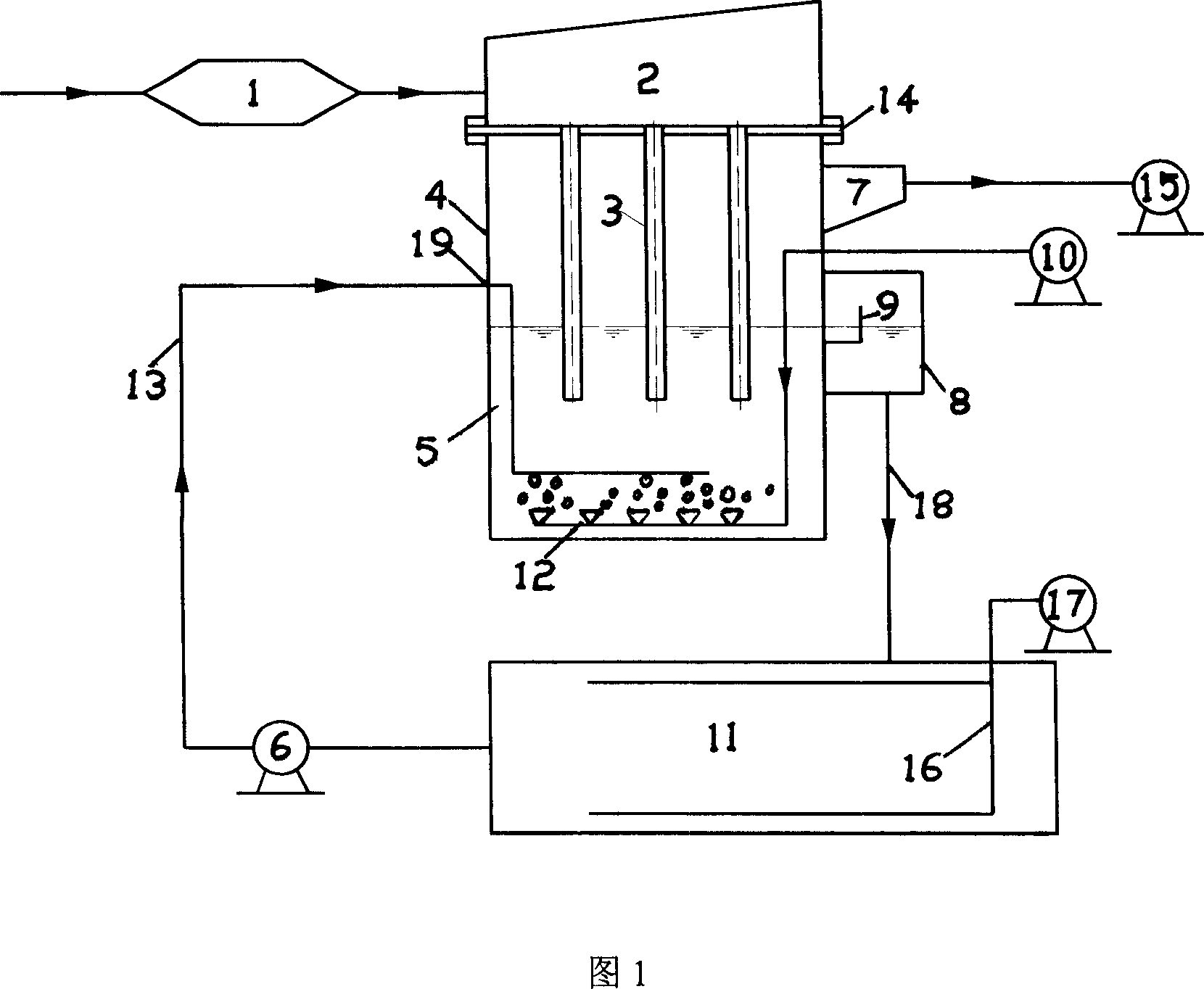

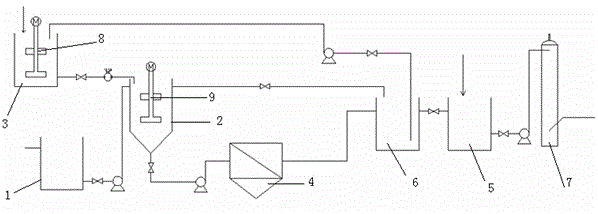

Enhanced biological spraying and bubbling gas absorbing purifier

InactiveCN1986034AReasonable designSimple designDispersed particle separationAir quality improvementLine tubingEngineering

The present invention belongs to the field of environment protection technology, and is especially one kind of enhanced biological spraying and bubbling gas absorbing purifier. The purifier consists of an atomizing cooler, a spraying and bubbling wash unit, a dewatering unit, an overflow trough, a regeneration pond, etc. The spraying and bubbling wash unit consists of an upper tank, a bubbling pipe, a lower tank and a liquid biological medium layer. Inside the lower tank, there are liquid biological medium layer, stirring pipeline in the bottom and bubbling pipe inserted into the liquid biological medium layer. The present invention has simple structure, reasonably designed pipeline, and easy maintenance.

Owner:TONGJI UNIV

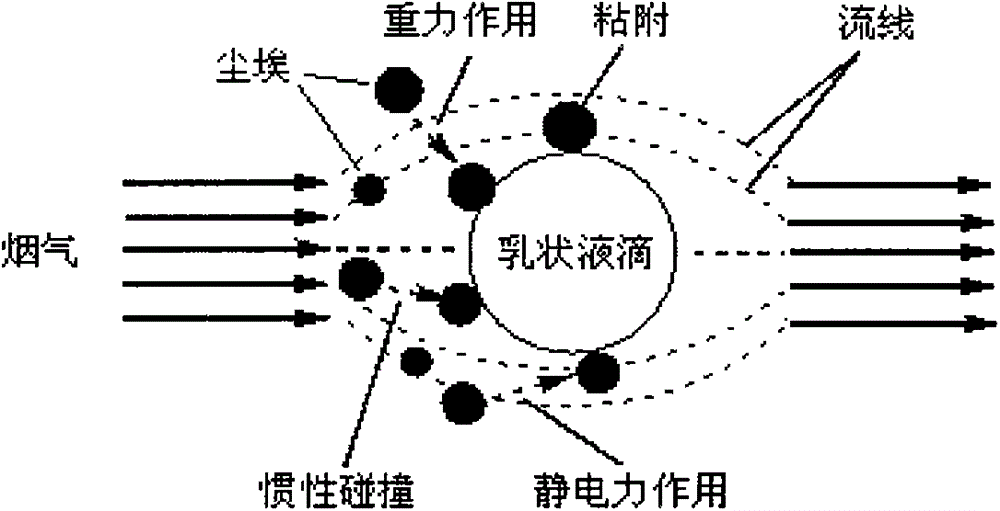

Method for removing dust out of smoke

InactiveCN104014210AFully contactedImprove dust removal effectSemi-permeable membranesLiquid separation by electricityBoiling pointSlurry

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

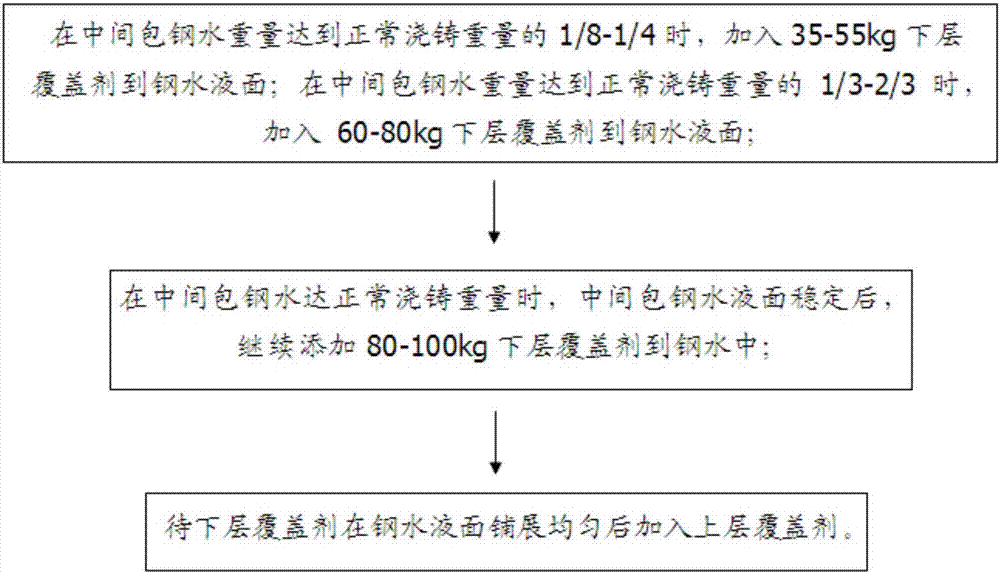

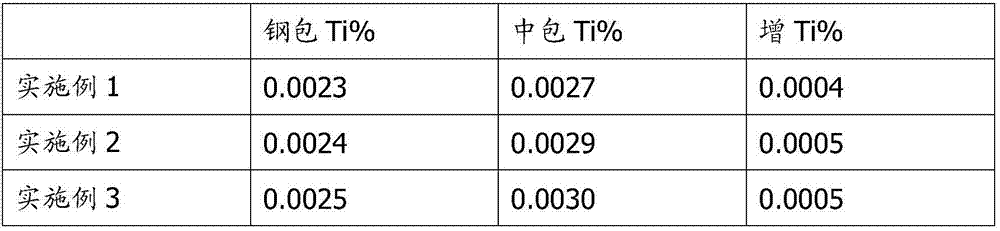

Low-titanium-content double-layer covering agent for silicon steel and use method of low-titanium-content double-layer covering agent

The invention provides a low-titanium-content double-layer covering agent for silicon steel and a use method of the low-titanium-content double-layer covering agent. The low-titanium-content double-layer covering agent comprises an upper layer covering agent part and a lower layer covering agent part; the lower layer covering agent part is contacted with molten steel; the upper layer covering agent part is located above the lower layer covering agent part; the upper layer covering agent part comprises the following raw materials, by weight percentage, 44-62% of SiO2, 2-10% of MgO, 1-10% of CaO, greater than 0 and less than or equal to 7% of Fe2O3, 20-38% of Al2O3, greater than 0 and less than or equal to 1% of C (all), greater than 0 and less than or equal to 0.5% of TiO2, and the balance ignition lost; and the lower layer covering agent part comprises the following raw materials, by weight percentage, 15-25% of SiO2, 3-8% of MgO, 48-68% of CaO, 2-10% of Fe2O3, greater than 0 and less than or equal to 1% of Al2O3, greater than 0 and less than or equal to 1% of C (all), greater than 0 and less than or equal to 0.2% of TiO2, and the balance ignition loss. With the use of the low-titanium-content double-layer covering agent, the content of titanium in molten silicon steel can be reduced effectively.

Owner:BEIJING SHOUGANG CO LTD

Treatment method and device of wastewater containing superfine silicon powder

InactiveCN104671498ALow costReduce carryoverDispersed particle separationEnergy based wastewater treatmentSilica fumeExhaust fumes

The invention discloses a treatment method and device of wastewater containing superfine silicon powder, and belongs to the field of treatment of wastewater containing silicon powder in polycrystalline silicon industry. The method comprises the following steps: with a 20%-32% NaOH solution as a precipitant, adding the wastewater containing the superfine silicon powder, flocculating the superfine silicon powder in the wastewater, and naturally participating for about an hour. By virtue of the high-concentration NaOH solution as the precipitant, the problems that silicon powder particles in the wastewater generated by the cutting process of a silicon core and the like are too small, and high in surface activity, are hydrogenated with water, suspend in water for a long period of time (over half a year) without participation, and are difficult to filter are solved; the burden of an existing filter-press process can be greatly relieved; the filtering efficiency is improved; resource utilization is realized by supernatant alkaline water and filtrate alkaline water for a chlorosilane waste gas leaching process as absorbents; meanwhile, the treatment pressure of a subsequent wastewater treatment system is relieved; and the method and the device are simple in technology in treatment of the wastewater containing the superfine silicon powder, short in flocculation and precipitation time, good in treatment effect and low in cost.

Owner:KUNMING UNIV OF SCI & TECH +1

Residual oil hydrogenation method

ActiveCN104560139AEasy to operateReduce energy consumptionHydrocarbon oil crackingTreatment with moving solid particlesHydrogenation reactionFluidized bed

The invention relates to a residual oil hydrogenation method. The method is carried out in a fluidized bed reactor; a three-phase separation region, a fluidizing region and a circulation region are arranged in the fluidized bed reactor in sequence from top to bottom. The residual oil hydrogenation method comprises the steps: injecting a first fluidized bed hydrogenation catalyst from the upper part of the circulation region, and injecting a second fluidized bed hydrogenation catalyst from the upper part of the fluidizing region to enable the residual oil and hydrogen to be subjected to the hydrogenation reaction in the fluidized bed reactor, wherein the particle size of the first fluidized bed hydrogenation catalyst is 0.05-0.8mm greater than that of the second fluidized bed hydrogenation catalyst; according to corresponding oxide, the content of the active metal components in the first fluidized bed hydrogenation catalyst is 10-80 percent lower than that of the active metal components in the second fluidized bed hydrogenation catalyst. According to the residual oil hydrogenation method disclosed by the invention, better reaction effect can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluidized bed reactor

ActiveCN101721961BGreat operating flexibilityEfficient separationChemical/physical processesChemical reactionFluidized bed

Owner:CHINA PETROLEUM & CHEM CORP +1

Fluidized bed reactor

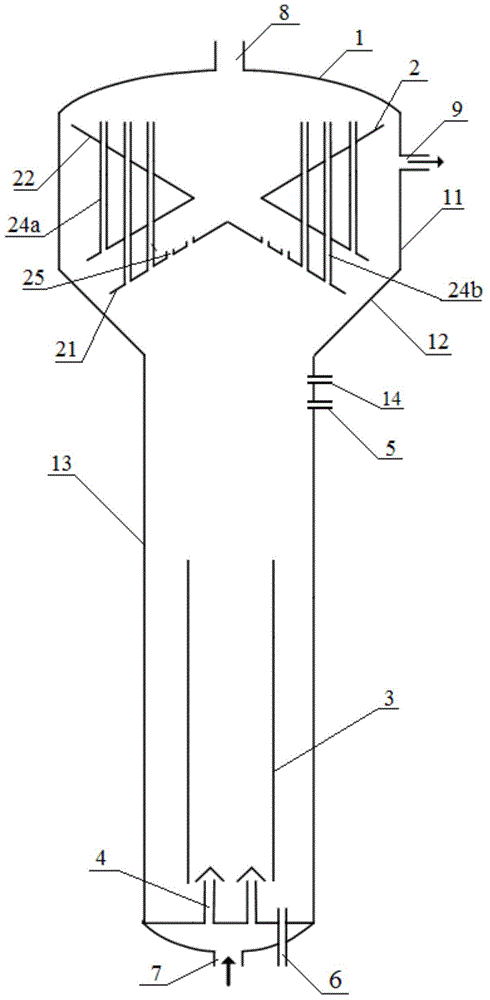

ActiveCN104549063ARaise the catalyst concentrationImprove utilization efficiencyChemical/physical processesTreatment with moving solid particlesFluidized bedEngineering

The invention relates to a fluidized bed reactor. The fluidized bed reactor comprises a casing, a three-phase separation component, an inner tube and a gas-liquid distributor, wherein a three-phase separation region, a fluidized region and a circulation region are successively formed in the casing from top to bottom, the three-phase separation component is arranged at the three-phase separation region, the inner tube is arranged at the circulation region, and the gas-liquid distributor is arranged at the bottom of the inner tube; the three-phase separation component comprises a cone-shaped baffle which is formed in the circumferential direction, and a hollow revolving body arranged above the cone-shaped baffle, a through hole is formed in the cone-shaped baffle, the minimum distance from the through hole to the longitudinal central axis of the casing is larger than the minimum distance from the inner side of the hollow revolving body to the longitudinal central axis of the casing, the upper part of the hollow revolving body is in an inverted-frustum shape, and the lower part of the hollow revolving body is in a frustum shape. The fluidized bed reactor provided by the invention can obtain better reacting effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com