Residual oil hydrogenation method

A technology of residual oil hydrogenation and hydrogenation catalyst, which is applied in the field of residual oil hydrogenation, can solve problems such as complex process operation, lower product quality, and poor system stability, and achieve easy process operation, good product quality, and large operating flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

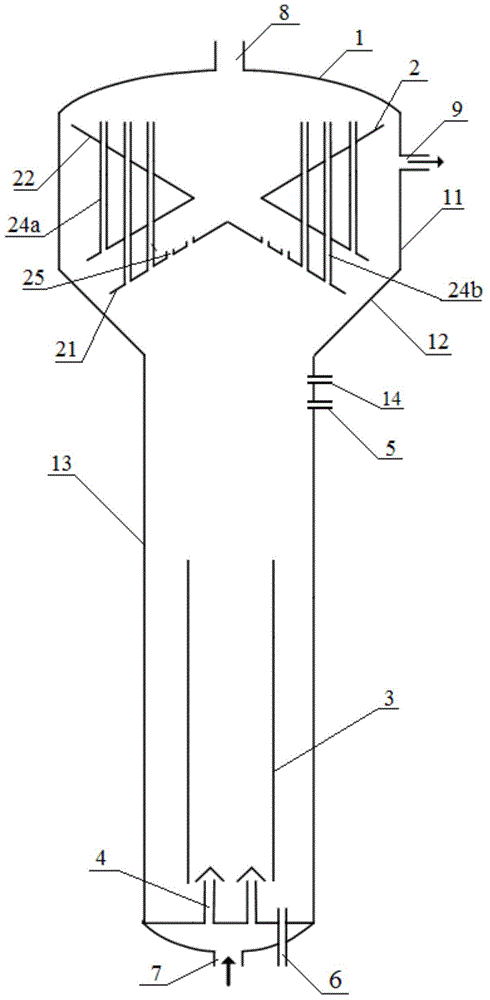

Image

Examples

Embodiment 1

[0093] The specific dimensions of the ebullated bed reactor used in this example are shown in Table 1 below.

[0094] Table 1

[0095] code name

[0096] The above-mentioned ebullating bed reactor was used to carry out the cold model experiment, wherein the solid-phase catalyst added through the catalyst inlet 5 was a spherical catalyst with a particle size of 0.2-0.3mm, and the total storage capacity of the catalyst was 60% of the effective volume of the reactor. The liquid phase uses straight-run kerosene, and the volume space velocity is 0.25-3.0h -1 . Nitrogen is used in the gas phase, and the gas-oil volume ratio is 20-150. Eight gas nozzles 10 are provided, and the gas volume injected into the gas nozzles accounts for 15% of the total gas volume. The experimental results in the changing range of conditions show that the carryover of the solid phase catalyst is extremely low, the maximum is 1.5μg / g. At the same time, it can be observed in the experiment that...

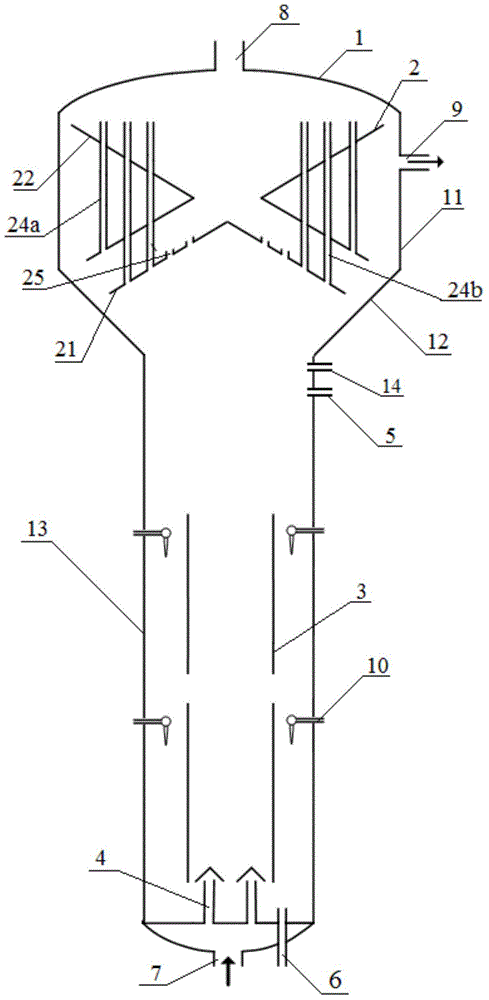

Embodiment 2

[0098] The specific dimensions of the ebullated bed reactor used in this example are shown in Table 2 below.

[0099] Table 2

[0100] code name

value

code name

value

d 1 / mm

300

h 1 / mm

5250

d 2 / mm

220

h 2 / mm

3000

d 3 / mm

400

h 3 / mm

600

[0101] d 4 / mm

360

h 4 / mm

87

d 5 / mm

300

h 5 / mm

480

d 6 / mm

480

α / °

60

d 7 / mm

340

β / °

60

d 8 / mm

540

ω / °

60

d 9 / mm

300

φ / °

60

d 10 / mm

550

θ / °

60

d 11 / mm

440

The total opening area of the first gas separation pipe 24a / mm 2

3000

d 12 / mm

500

The total opening area of the second gas separation pipe 24b / mm 2

6000

d 13 / mm

600

The total opening area of the third gas separation pipe 24c / mm 2

8000

The tot...

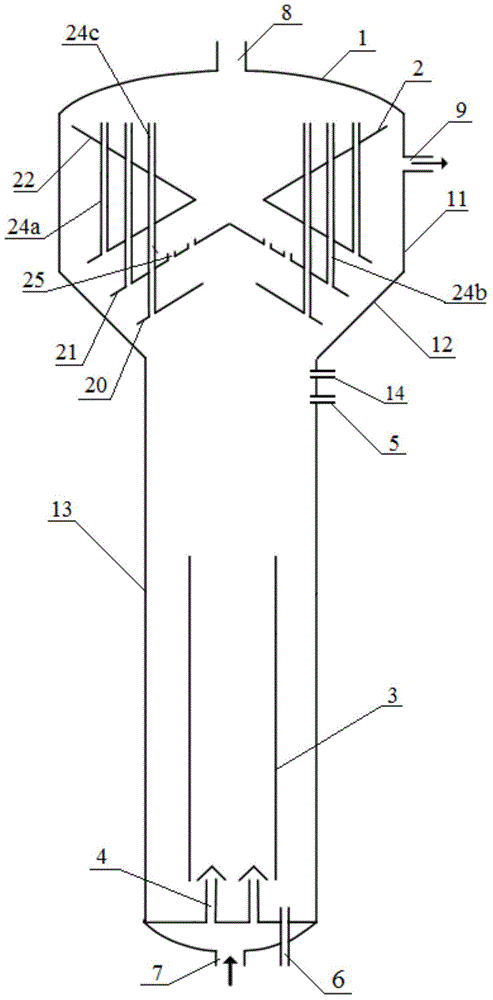

Embodiment 3-5

[0105] Embodiments 3 and 4 adopt the medium-sized thermal reactor made according to the ratio of embodiment 1, and embodiment 5 adopts the medium-sized thermal reactor made according to the ratio of embodiment 2, wherein the solid-phase catalyst added through the catalyst inlet 5 is physicochemically The properties are shown in Table 3, and the solid-phase catalyst loading is 55% of the effective volume of the reactor. The residue raw materials are shown in Table 4. Table 5 shows the distillate oil carrying the suspended bed hydrogenation catalyst injected through the catalyst inlet 14 . The amount of gas injected through the nozzle 10 accounts for 20% by volume of the total gas amount. The reaction conditions and test results in the reactor are shown in Table 6.

[0106] table 3

[0107]

[0108] Table 4

[0109] nature

value

Density(20℃) / (g / cm 3 )

1.029

Carbon residue / wt%

19.61

Sulfur content / wt%

4.53

Nitrogen con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com