Pyrohydrolysis flash separation device, pyrohydrolysis flash separation technology, pyrohydrolysis system and pyrohydrolysis technology

A separation device and thermal hydrolysis technology, which is applied in the direction of pyrolysis treatment of sludge, sludge treatment through temperature control, etc., can solve the problems of sludge discharge pump damage, limited application range, large pressure fluctuations, etc., to reduce vibration and improve The safety production factor and the effect of reducing pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

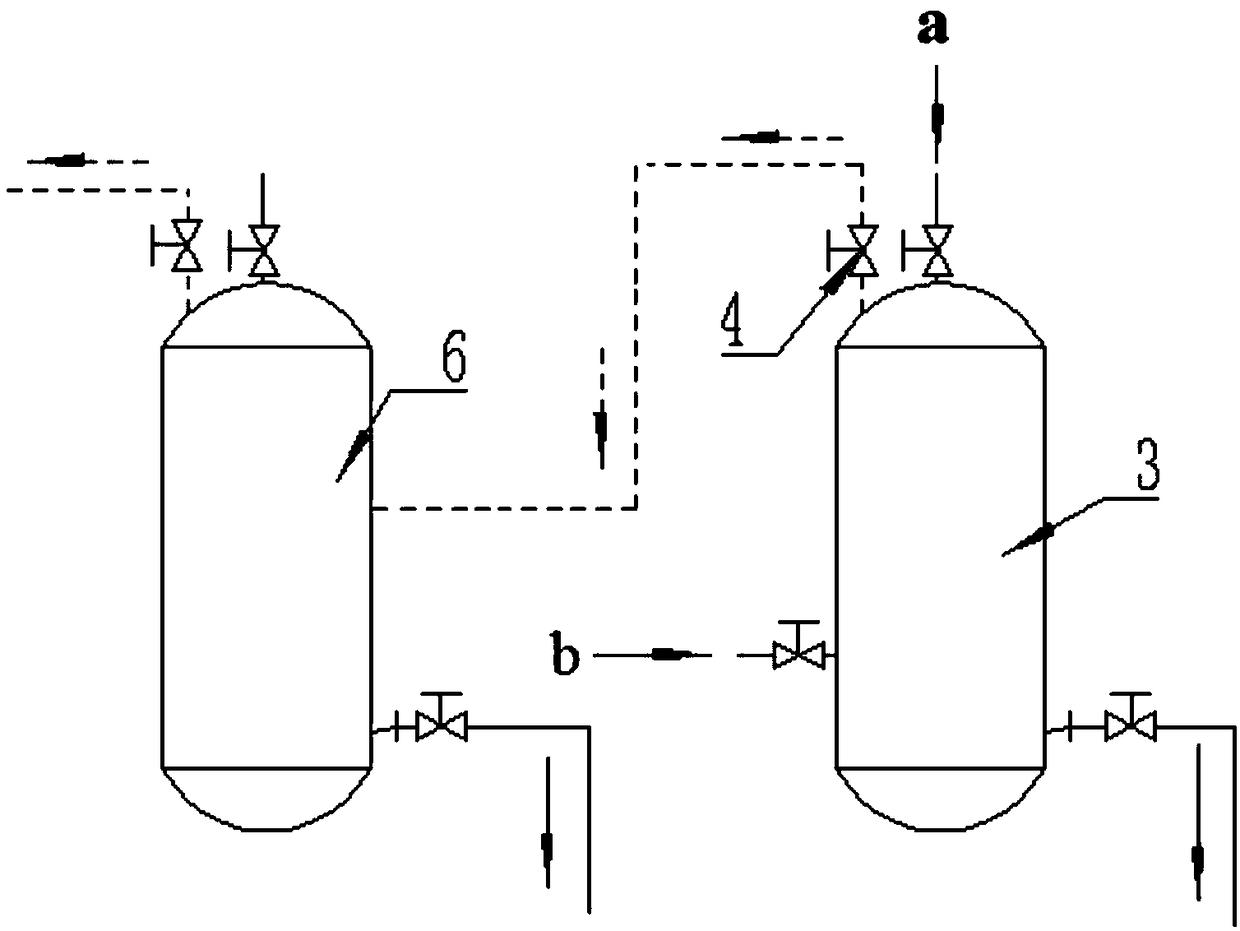

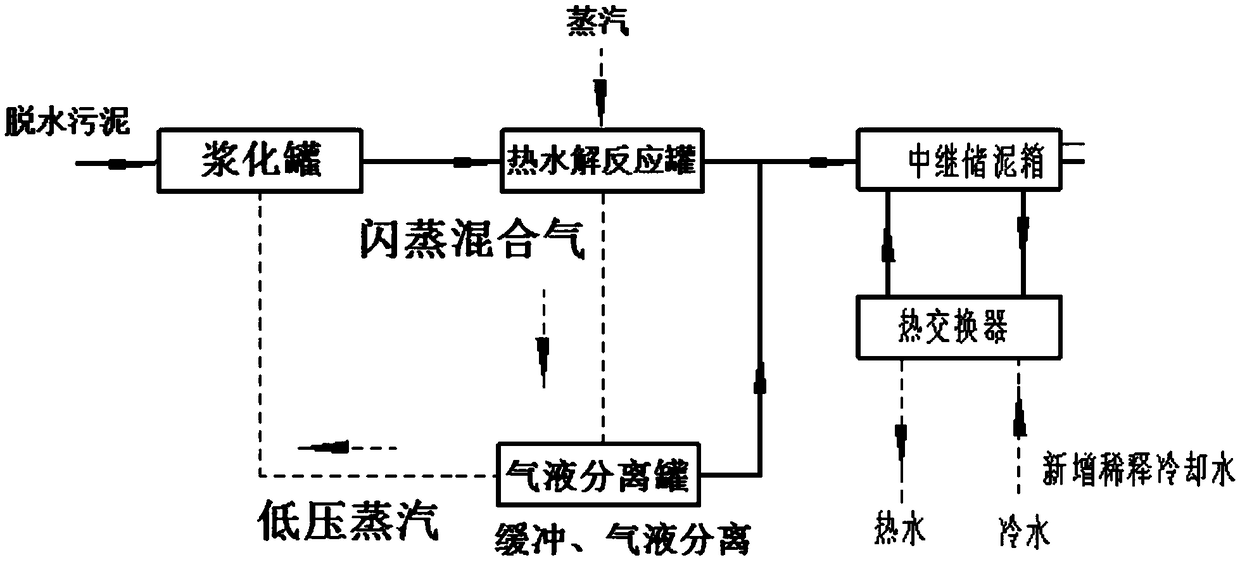

[0047] Such as figure 1 As shown, a thermal hydrolysis flash separation device includes a thermal hydrolysis reaction tank 3 and a gas-liquid separation tank 6. The thermal hydrolysis reaction tank 3 and the gas-liquid separation tank 6 are connected through pipelines, and the thermal hydrolysis reaction tank 3 The pipeline between the gas-liquid separation tank 6 is provided with a pressure relief valve 4 for regulating the pressure relief process of the thermal hydrolysis reaction tank 3, and the pressure relief valve 4 is arranged on the top of the thermal hydrolysis reaction tank 3, and the thermal hydrolysis reaction tank 3 It is equal to the volume of the gas-liquid separation tank 6.

[0048] In this embodiment, the sludge is transported to the thermal hydrolysis reaction tank 3. After reaching the design capacity standard of the thermal hydrolysis reaction tank 3, the relevant valves (including the pressure relief valve 4) are closed, and the sludge is transferred to t...

Embodiment 2

[0052] A kind of thermal hydrolysis flash separation process, adopts the thermal hydrolysis flash separation device in embodiment 1 to carry out flash separation, comprises the following steps:

[0053] (1) After the thermal hydrolysis reaction of the dewatered sludge in the thermal hydrolysis reaction tank 3 is completed, the opening and duration of the pressure relief valve 4 are controlled to regulate the pressure release process of the thermal hydrolysis reaction tank 3, which specifically includes three stages: Control the opening of pressure relief valve 4 to 30% for 180 seconds; control the opening of pressure relief valve 4 to 60% for 120 seconds; control the opening of pressure relief valve 4 to 100% for 600 seconds , thereby realizing the effective regulation and control of the pressure release process of the thermal hydrolysis reaction tank 3, and then effectively controlling the flash evaporation process of the thermal hydrolysis reaction tank 3, so that the feed li...

Embodiment 3

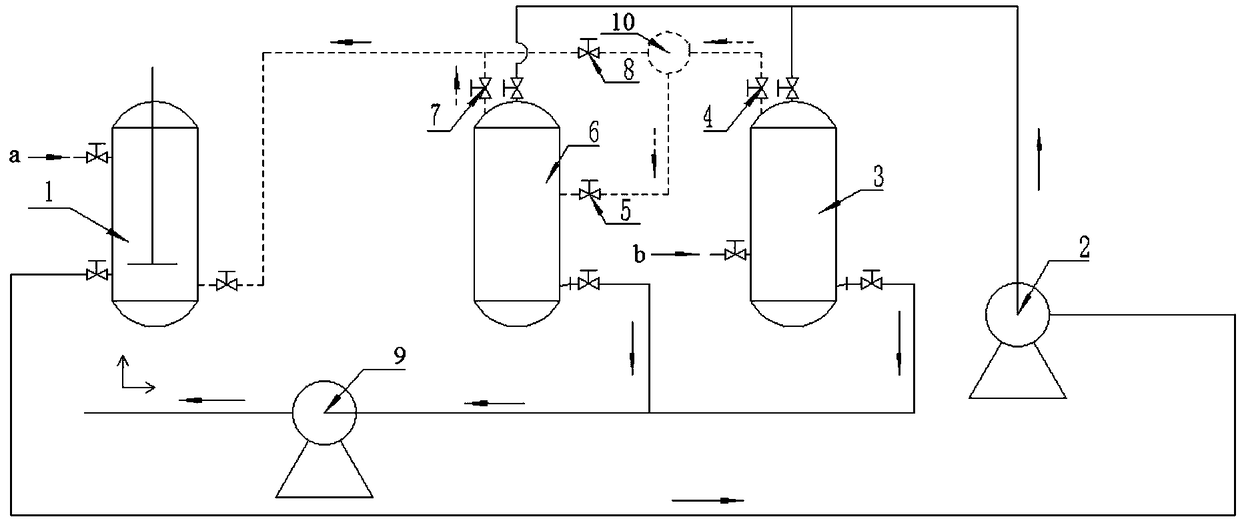

[0057] Such as figure 2As shown, a thermal hydrolysis system includes a slurry tank 1, a mud inlet pump 2, a thermal hydrolysis reaction tank 3, and a gas-liquid separation tank 6 connected end to end through pipelines, and the thermal hydrolysis reaction tank 3 and the gas-liquid separation tank The pipeline between 6 is provided with a pressure relief valve 4 for regulating the pressure release process of the thermal hydrolysis reaction tank 3, and the pressure relief valve 4 is arranged on the top of the thermal hydrolysis reaction tank 3, and the thermal hydrolysis reaction tank 3 and the gas-liquid separation tank 6 The volumes are equal, the pipeline between the pressure relief valve 4 and the gas-liquid separation tank 6 is provided with a first shut-off valve 5, and the pipeline between the gas-liquid separation tank 6 and the slurry tank 1 is provided with a second shut-off valve 7, The second shut-off valve 7 is arranged on the top of the gas-liquid separation tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com