Patents

Literature

68results about How to "Achieve secondary separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

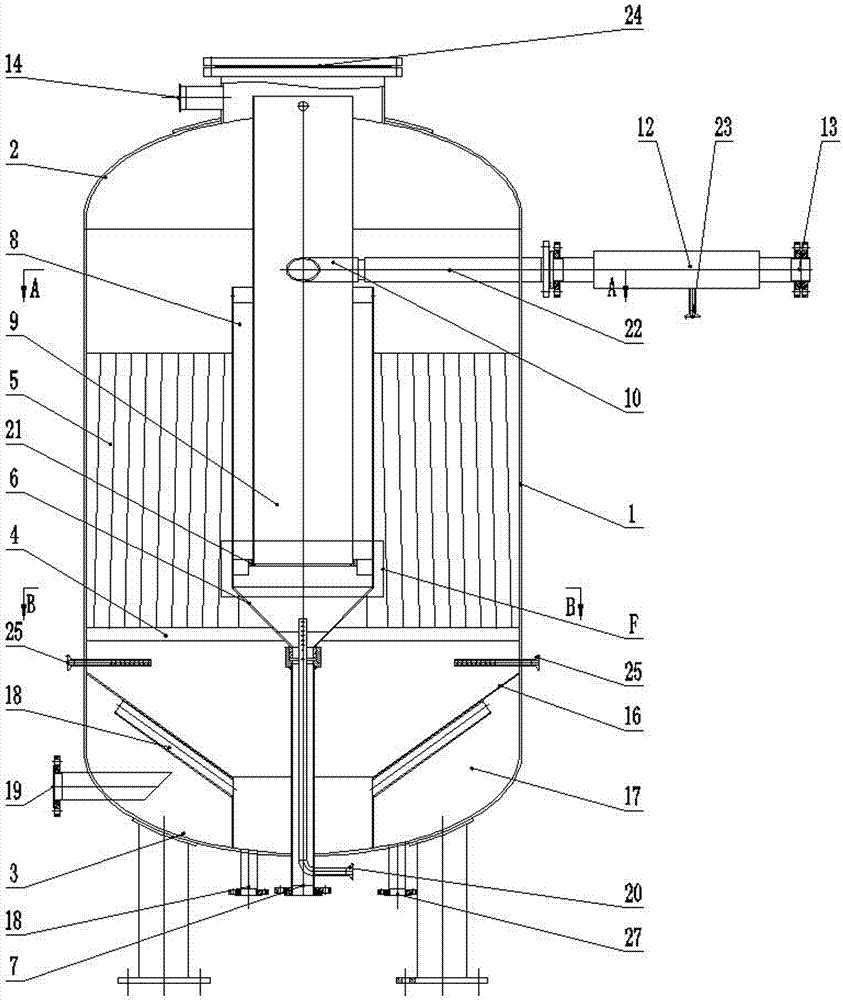

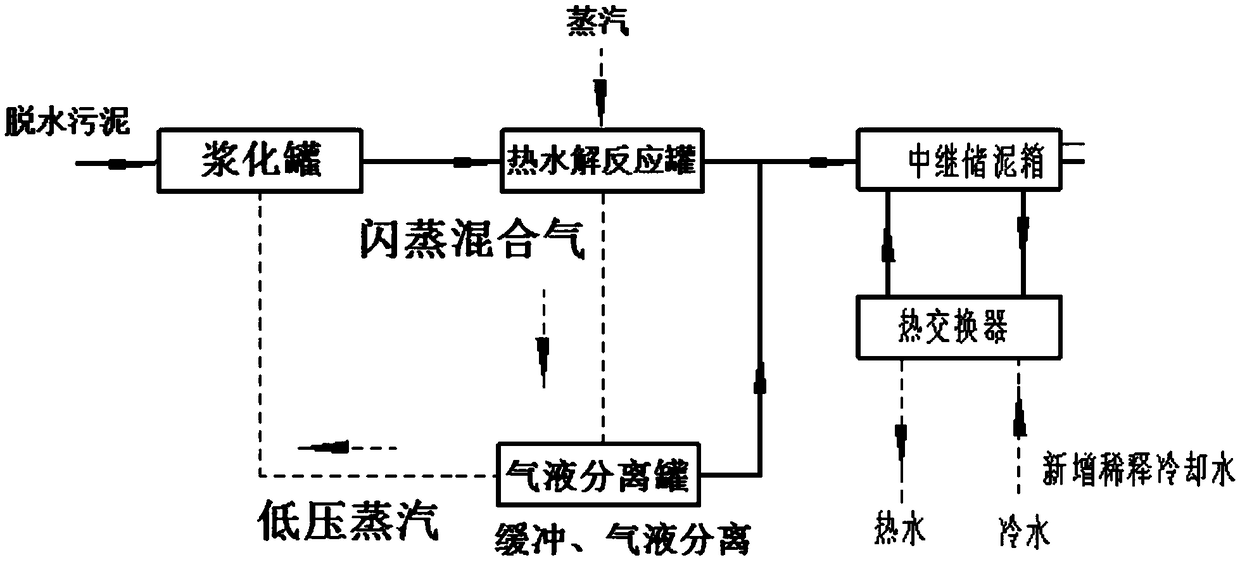

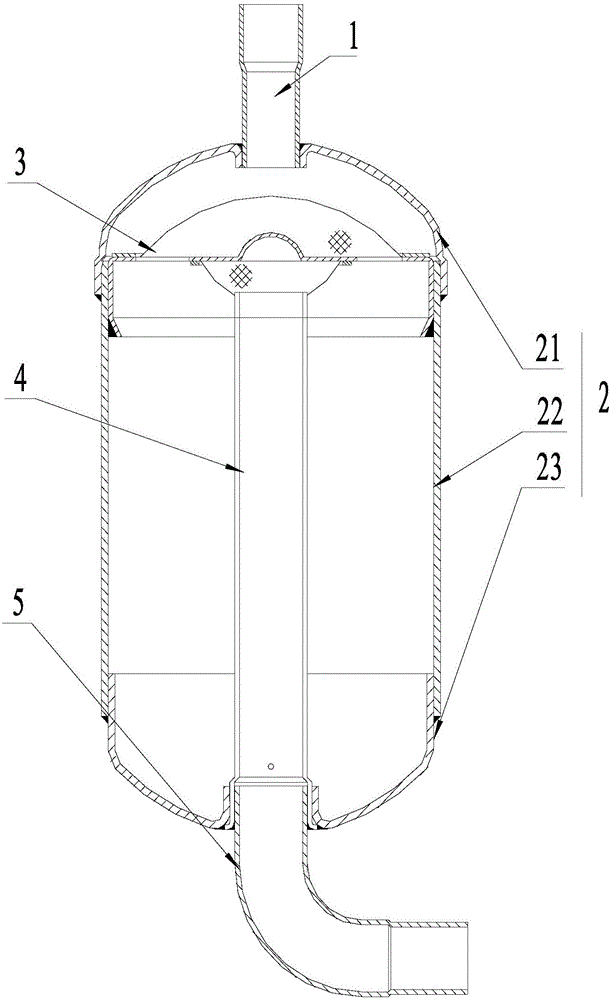

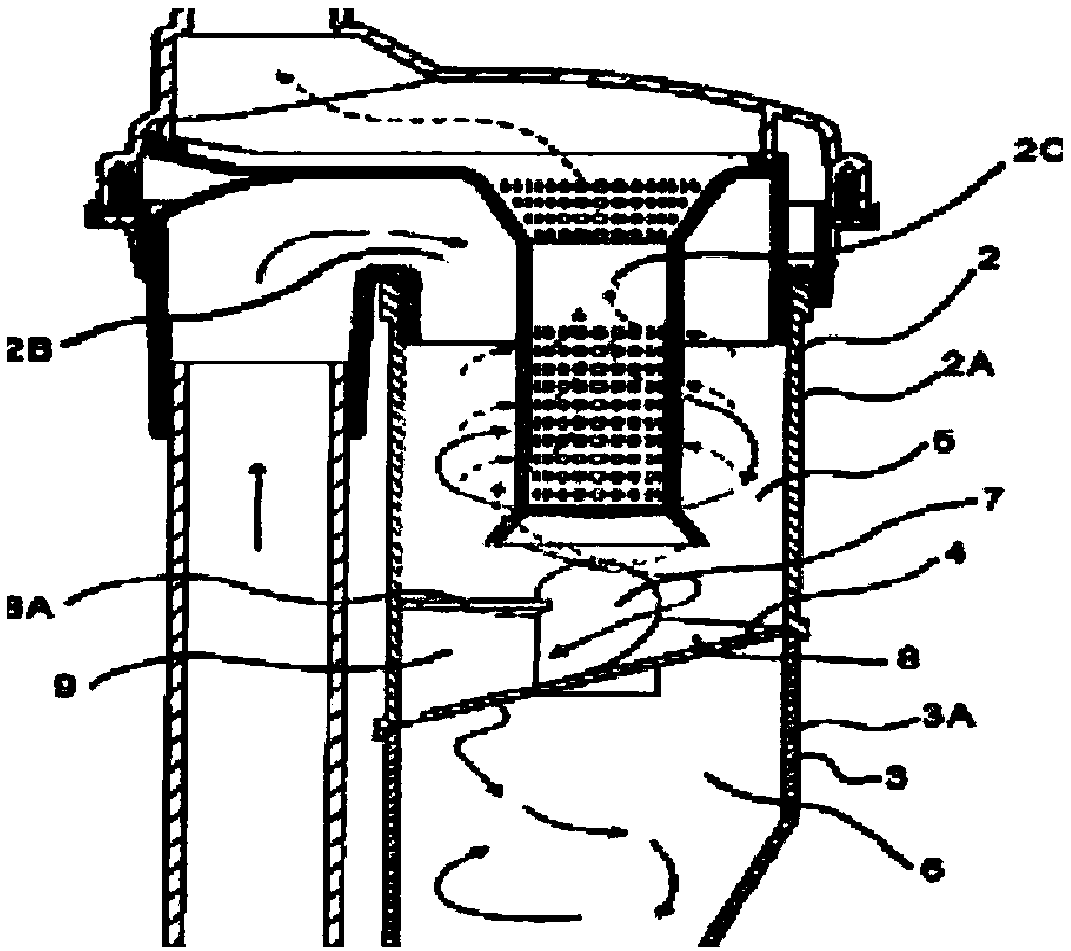

Gas-liquid separator

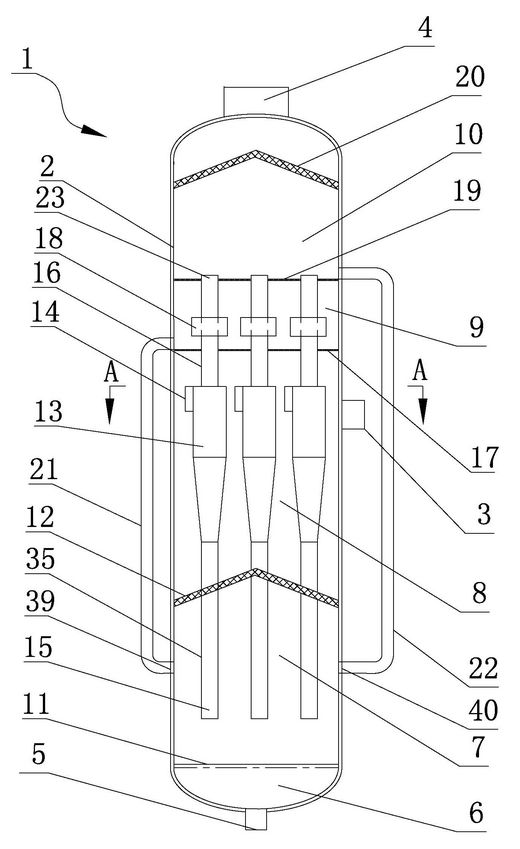

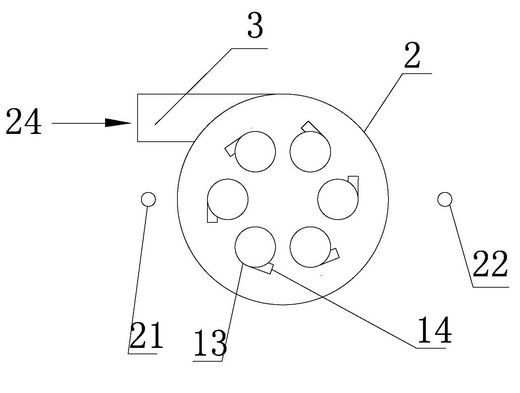

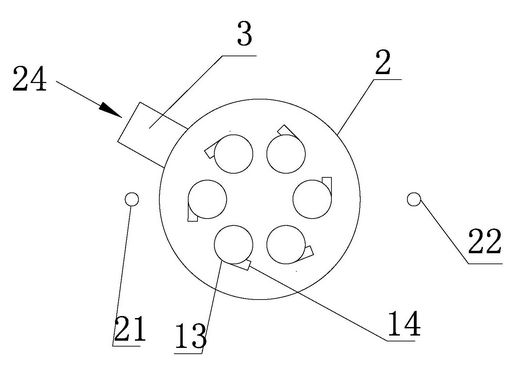

InactiveCN102489101AGood for reflux collectionGuaranteed uptimeCombination devicesVapor–liquid separatorFluid phase

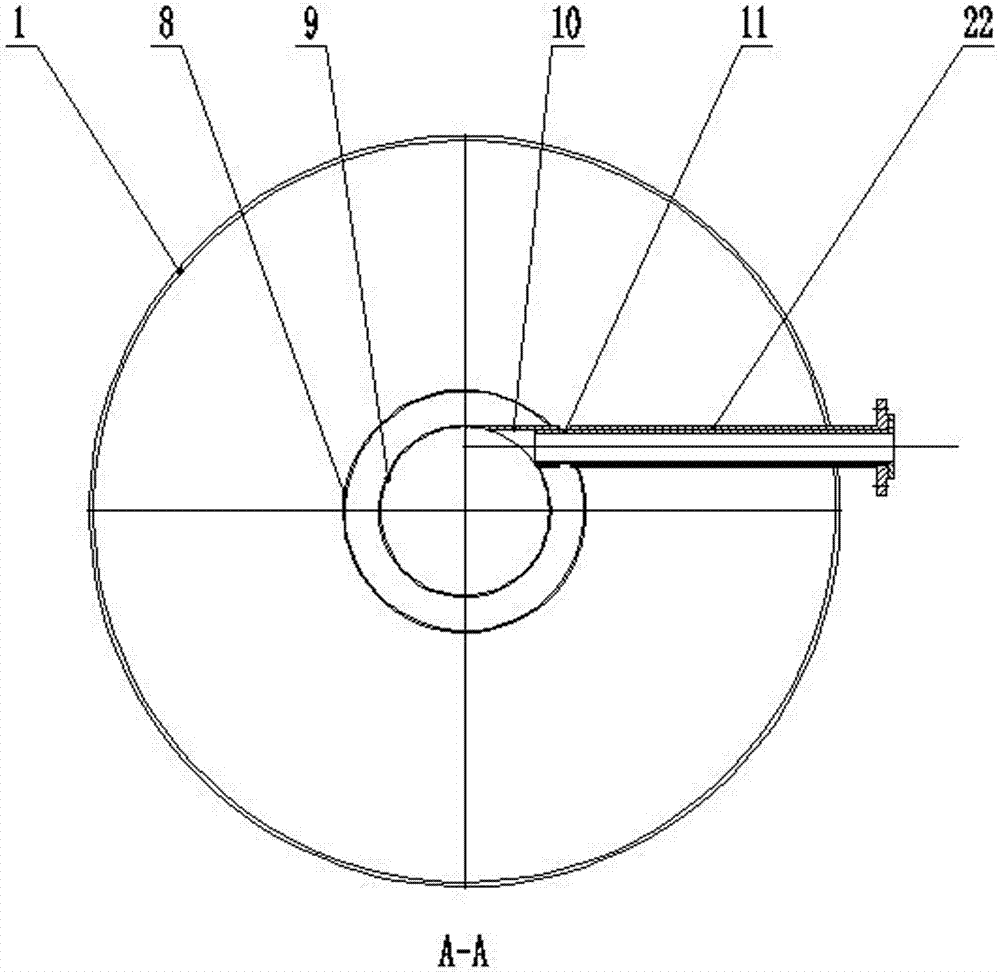

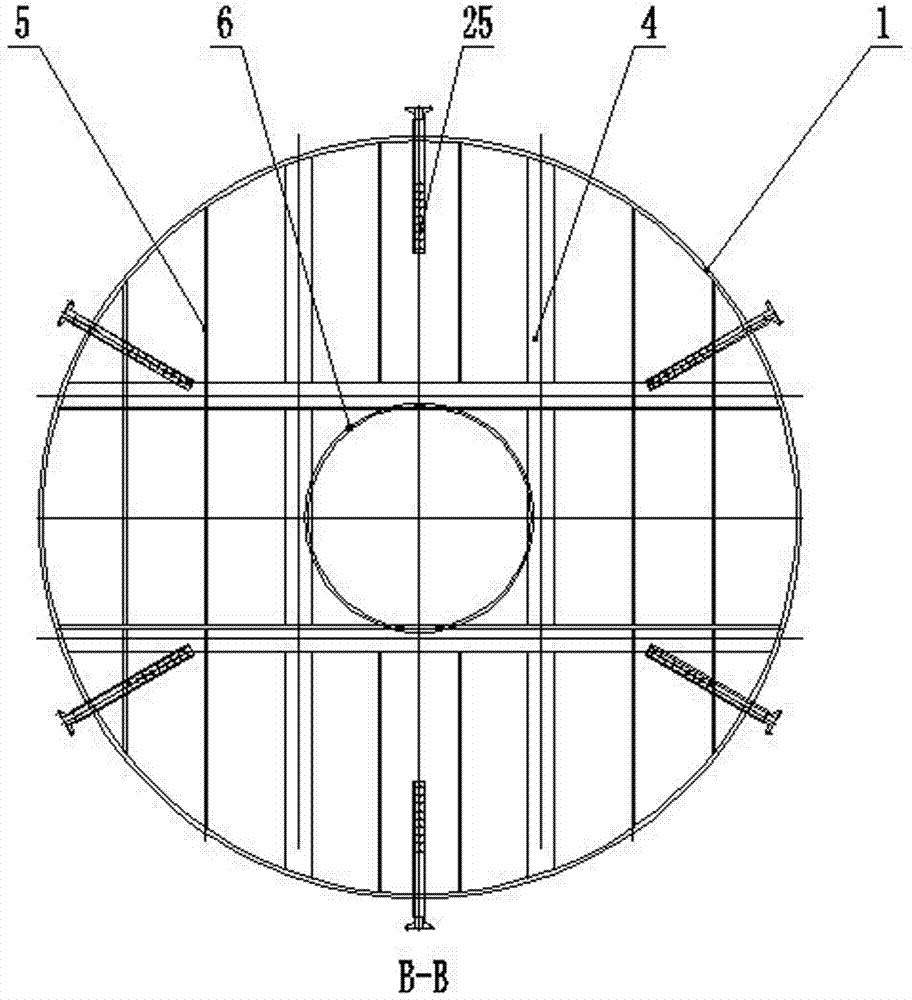

The invention relates to the technical field of petrochemical industry, especially to a gas-liquid separator for separating a gas phase flow from a liquid phase flow in a mixed gas-liquid flow. The space inside the shell of the gas-liquid separator is divided into a liquid collection zone (6), a cyclone apocenosis tail gas coalescence zone (7), a cyclone separation zone (8), an ascension pipe separation zone (9) and an ascension pipe exhaust tail liquid coalescence zone (10). A first-stage separation adopts cyclone separation; a second-stage separation adopts ascension pipe ejection separation or vortex separation; and a third-stage separation adopts a froth killer to further purify gases, so as to realize complete gas-liquid separation. The gas-liquid separator provided by the invention has a flexible structure and structure arrangement is optimized. More than two cyclone separators and the ascension pipe separator over the cyclone separators are integrated for the first-stage and second-stage separation. In the ascension pipe separation zone, exhaust momentum of the cyclone separators is utilized to strengthen the separation effect and realize the secondary separation process. The structure of the froth killer is improved so as to strengthen the separation effect as a whole.

Owner:QINGDAO JINGRUN PETROCHEM DESIGN INST CO LTD

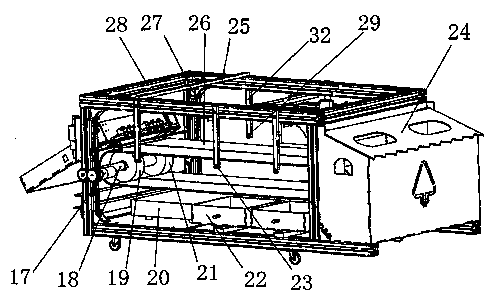

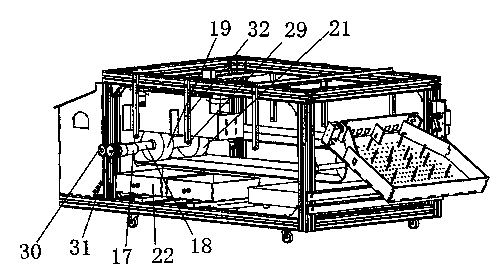

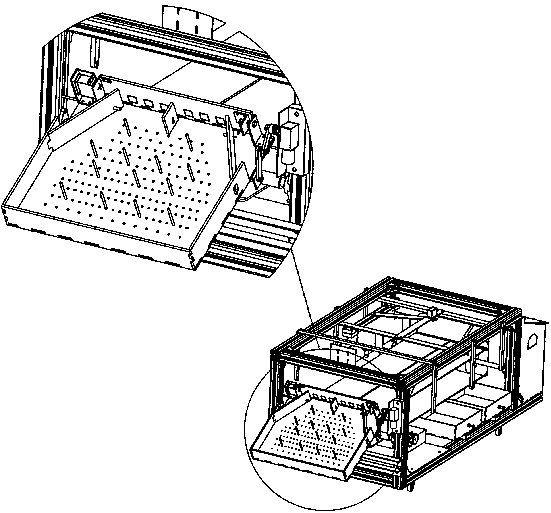

Double-layered vibrating fluidized-bed drying-classification apparatus

InactiveCN101825390AEmission reductionImprove classification efficiencyGas current separationDrying solid materials with heatFluidized bed dryingClosed chamber

The invention relates to a double-layered vibrating fluidized-bed drying-classification apparatus, in particular to a doubled-layered vibrating fluidized apparatus for the moisture control and classification of coking coal, which belongs to the technical field of drying equipment. The drying-classification apparatus comprises steel supports, a fluidized drying-classification chamber, a coal feed inlet, a large coal particle outlet and a sealed fine coal particle buffer bin, the fluidized drying-classification chamber is connected with the steel supports, the coal feed inlet, the large coal particle outlet and the sealed fine coal particle buffer bin are respectively communicated with the fluidized drying-classification chamber, the fluidized drying-classification chamber is a closed chamber which consists of an upper fluidized drying-classification chamber arranged on the upper part and a lower fluidized drying-classification chamber arranged on the lower part, and a pressure-equalized bellows is arranged on the bottom of the fluidized drying-classification chamber. The invention has the advantages of simple structure, little investment, high coal classification efficiency and smooth operation, and is particularly applicable to the particle size classification and humidity regulation of coking coal in the coking industry.

Owner:LAIWU IRON & STEEL GRP

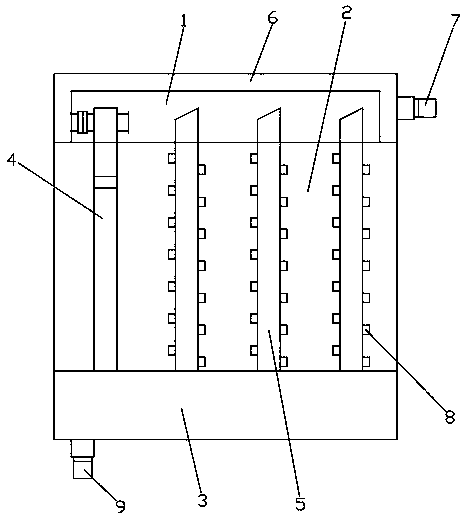

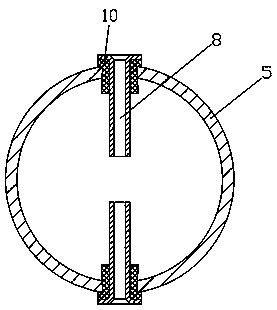

Kitchen wastewater oil-water separation device

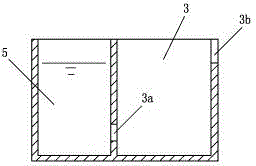

ActiveCN103754985AEasy to separateAchieve secondary separationFatty/oily/floating substances removal devicesLiquid separationWater pipeGas separation

The invention relates to a kitchen wastewater oil-water separation device. The shell is provided with a water inlet pipe; a first vertical plate (5) and a second vertical plate (6) are arranged in the shell to sequentially constitute a first oil-water separation region (7), a second oil-water separation region (8) and a water collection region (9); the upper part of the first oil-water separation region is communicated with the upper part of the second oil-water separation region; the lower part of the second oil-water separation region is communicated with the lower part of the water collection region; a stirring component (10) is arranged in the first oil-water separation region, an oil collection tank is arranged on the upper part of the second oil-water separation region, and the upper part of the water collection region is provided with a water collection tank; side plates of the water collection tank are weir plate components (11) capable of adjusting waterflow liquid level; mobile weir plates (13) in the weir plate components (11) can move horizontally along fixed weir plates (12); the mobile weir plates can be moved to adjust the waterflow liquid level; and a sloping plate component (17) is arranged in the second oil-water separation region. The kitchen wastewater oil-water separation device has primary and secondary oil-water separation, has the characteristics of simple structure and high operation stability, can lower the manufacturing cost and is convenient for maintenance and cleaning.

Owner:CHINA MACHINERY INT ENG DESIGN & RES INST

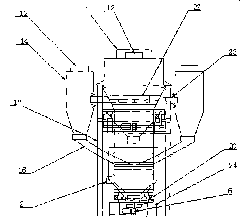

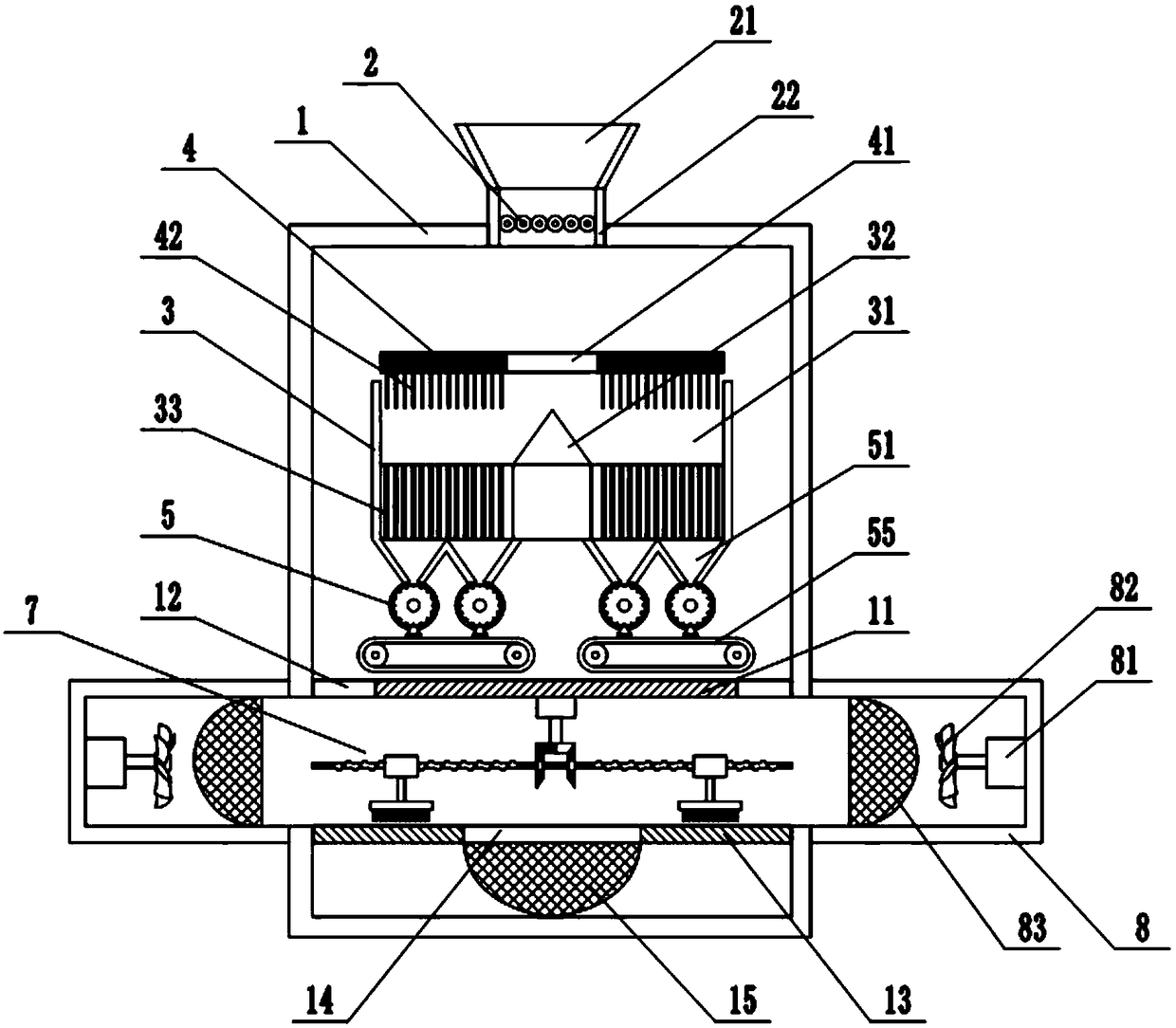

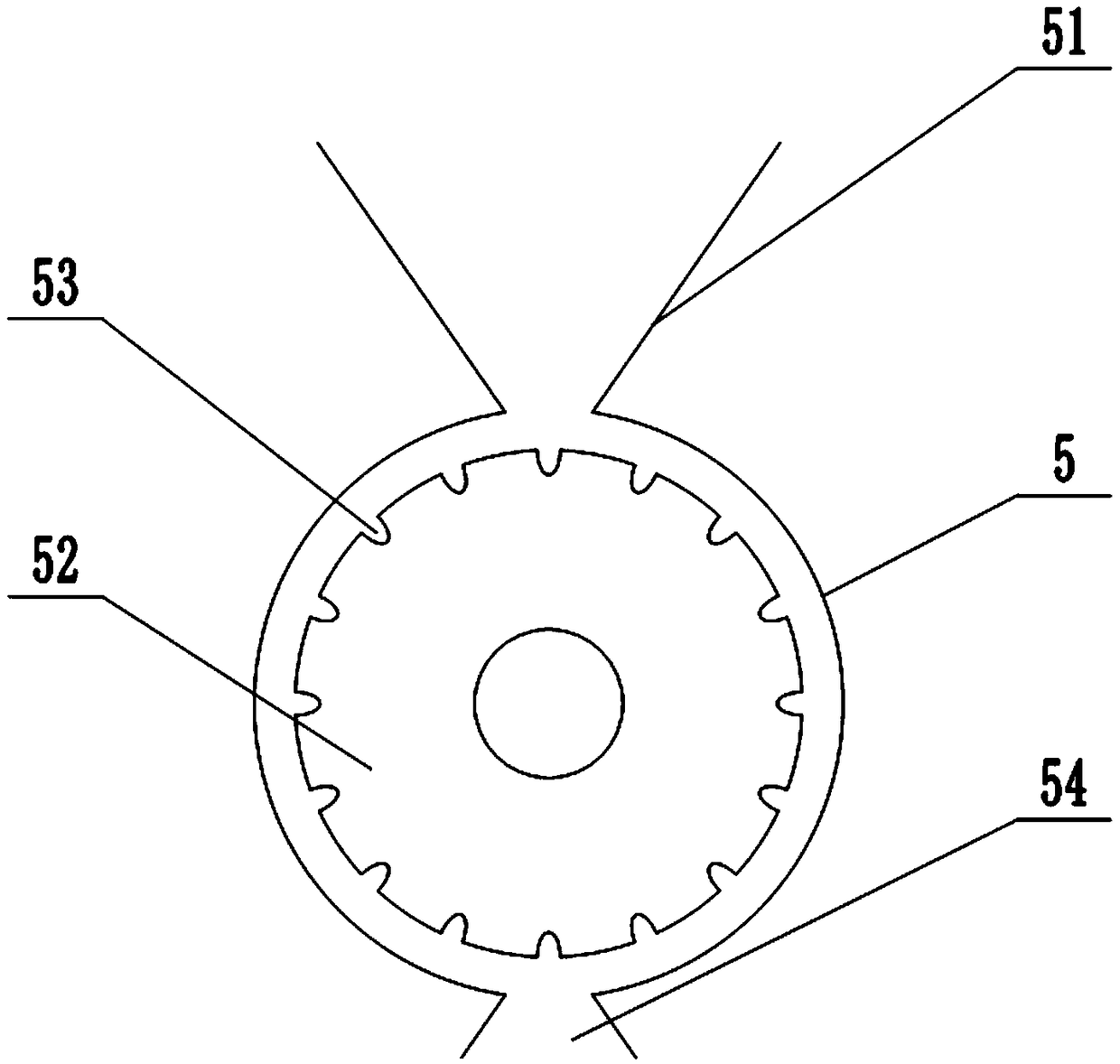

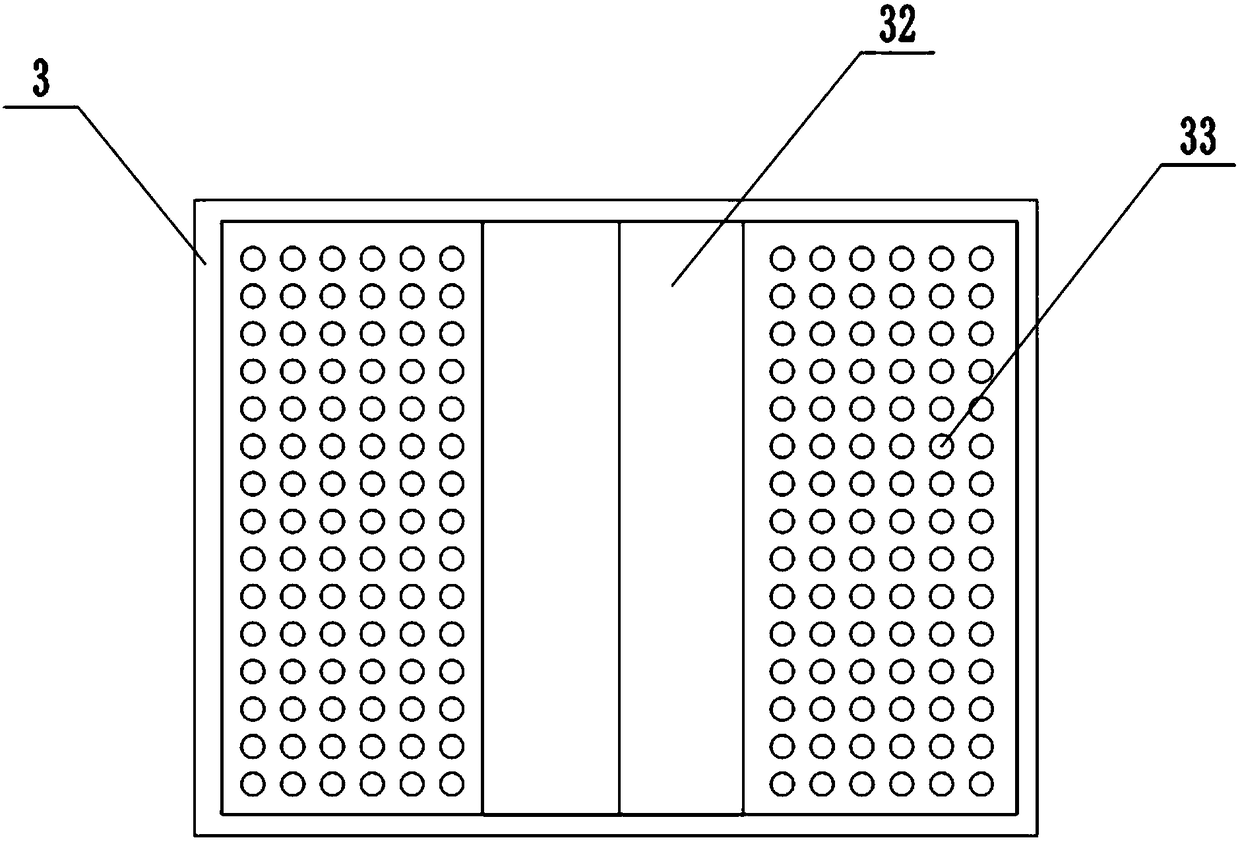

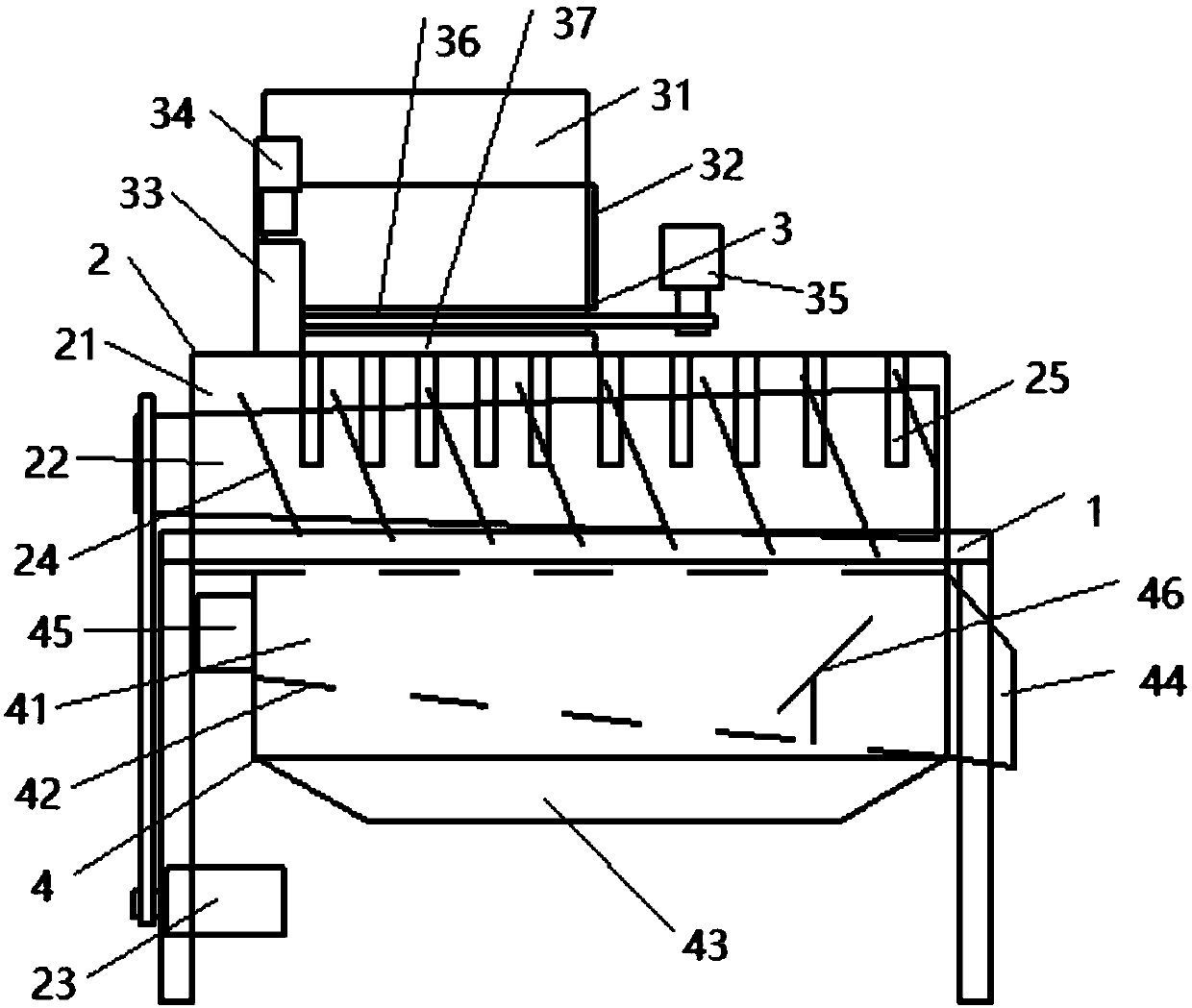

Grain processing equipment

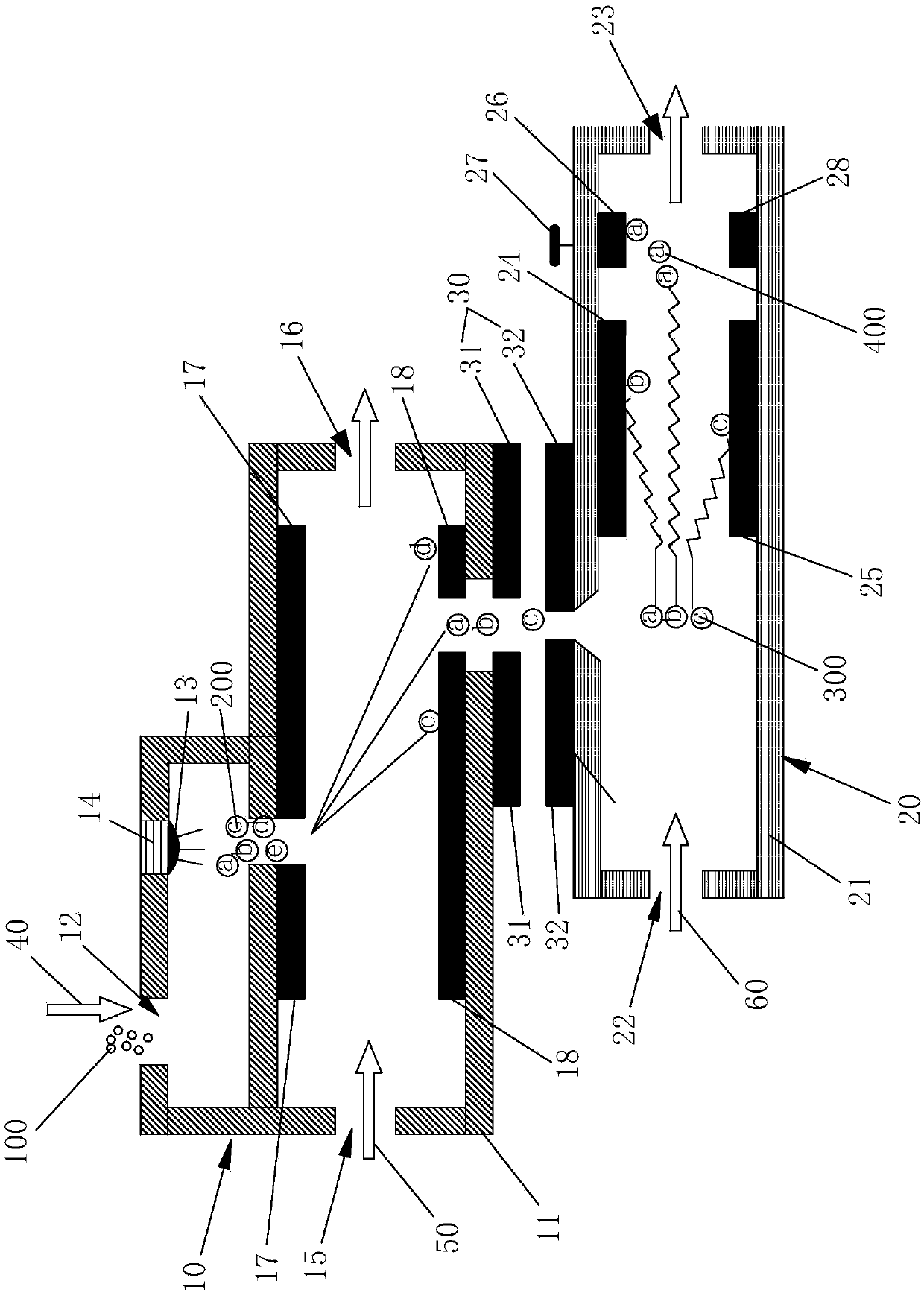

ActiveCN109317241AAchieve separationAchieve a separationGrain huskingGrain polishingString bagEngineering

The invention relates to the technical field of agricultural mechanical equipment and discloses grain processing equipment. The grain processing equipment comprises a box and a feeding mechanism. Theinterior of the box is partitioned into a processing area, a screening area and a collecting area from top to bottom in sequence. A reciprocating motion mechanism, a rectangular pressing plate and a base stand are arranged in the processing area. Plungers are densely distributed on the lower surface of the rectangular pressing plate. Through grooves used for being matched with the plungers are formed in the base stand. Receiving hoppers and shells are arranged under the base stand. The interior of each shell is rotationally connected with a rotary drum. Bar-shaped grooves are formed in the lateral side of each rotary drum correspondingly. Conveying belts are arranged below the shells correspondingly. A screening mechanism is arranged in the screening area. Air suction mechanisms are mounted on the two sides of the screening area correspondingly. A first collecting string bag is arranged in the collecting area. Through friction force generated when the plungers drive unhusked rice to move in the through grooves of the base stand and friction generated when the rotary drums drive the unhusked rice to rub against the inner walls of the shells, husks on the surfaces of the unhusked rice can be ground and separated from the surfaces of rice.

Owner:象山锦绣升平食品有限公司

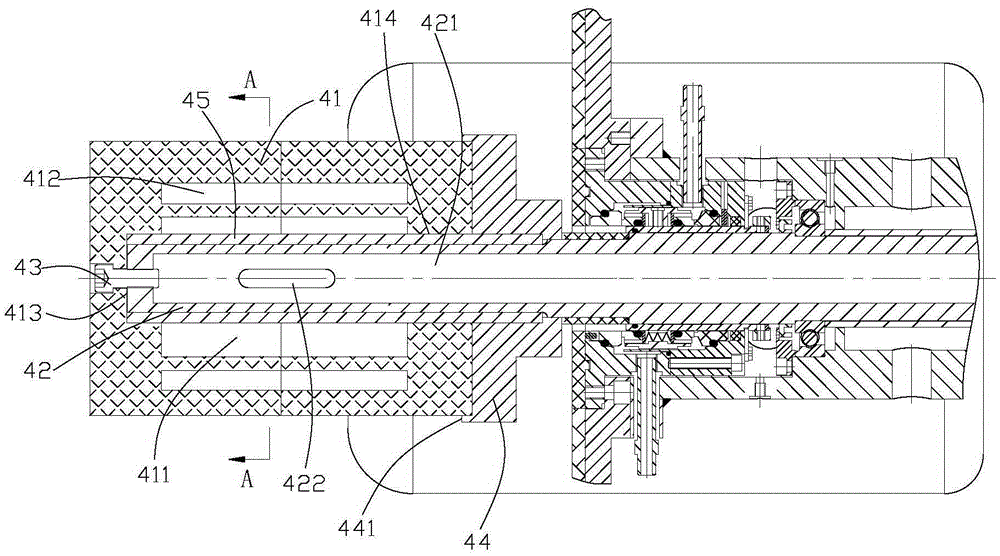

Differential ion mobility spectrometry and high field asymmetric waveform ion mobility spectrometry combination device

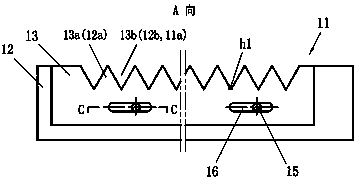

ActiveCN107818908AAchieve secondary separationRealize on-site inspectionParticle separator tubesWeak currentIon selective electrode

The invention relates to a differential ion mobility spectrometry and high field asymmetric waveform ion mobility spectrometry combination device, which comprises a differential ion mobility spectrometry, a high field asymmetric waveform ion mobility spectrometry and an interface device connecting the differential ion mobility spectrometry and the high field asymmetric waveform ion mobility spectrometry, and is characterized in that the differential ion mobility spectrometry comprises a first substrate, a first gas inlet port, an ion source, an ion source substrate, a second gas inlet port, afirst tail gas port, a first ion selective electrode and a second ion selective electrode, the high field asymmetric waveform ion mobility spectrometry comprises a second substrate, a third gas inletport, a second tail gas port, a first ion separation electrode, a second ion separation electrode, a weak current detection electrode, a weak current detector and a bias electrode, and the interface device is composed of a first traction electrode and a second traction electrode. According to the technical scheme, the device realizes twice separation for differences in spatial position and migration speed of ions of a substance under test, and can realize field detection of the ion mobility spectrometry for pollutants in a complex environment.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Air conditioner oil returning system

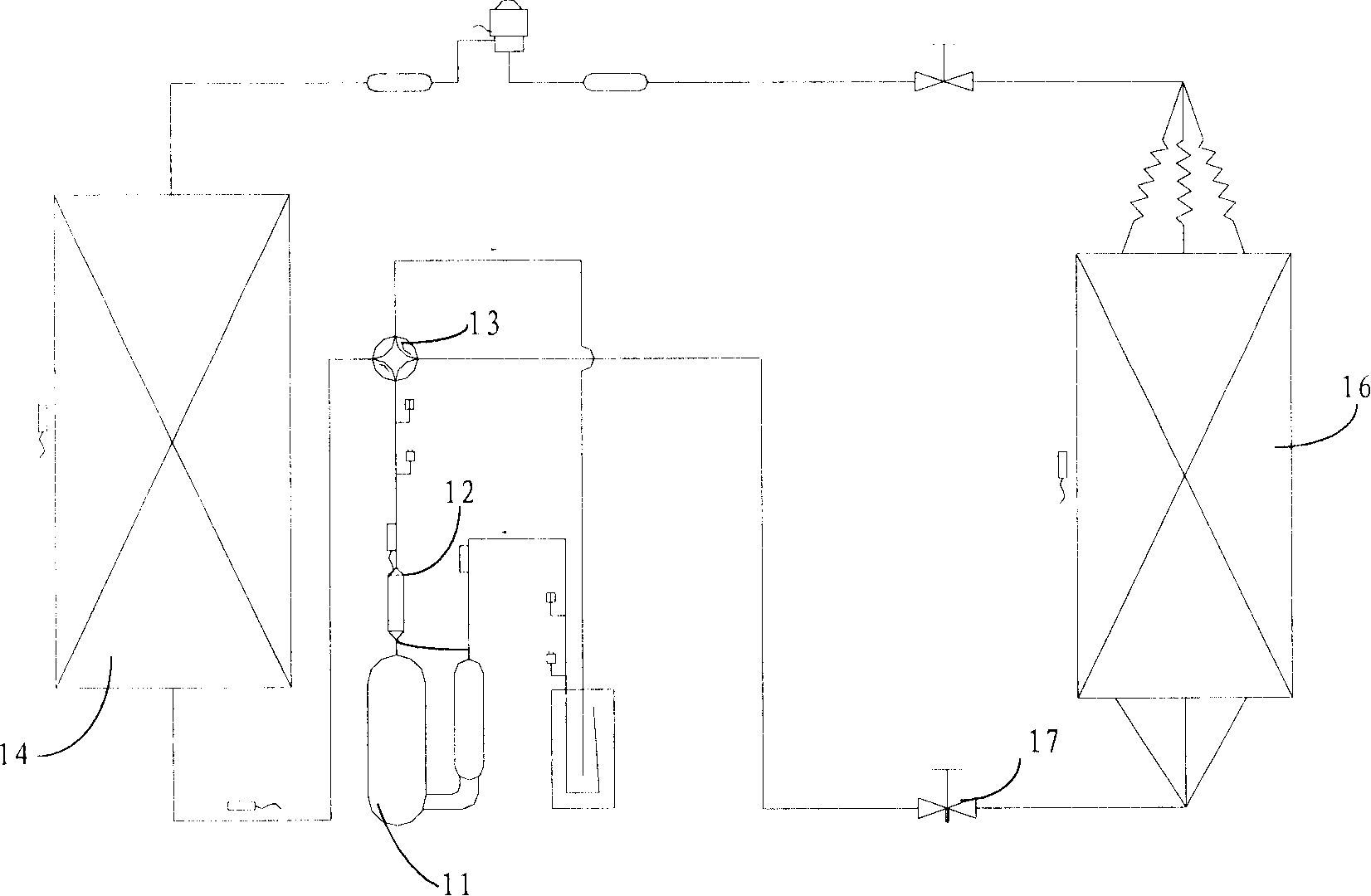

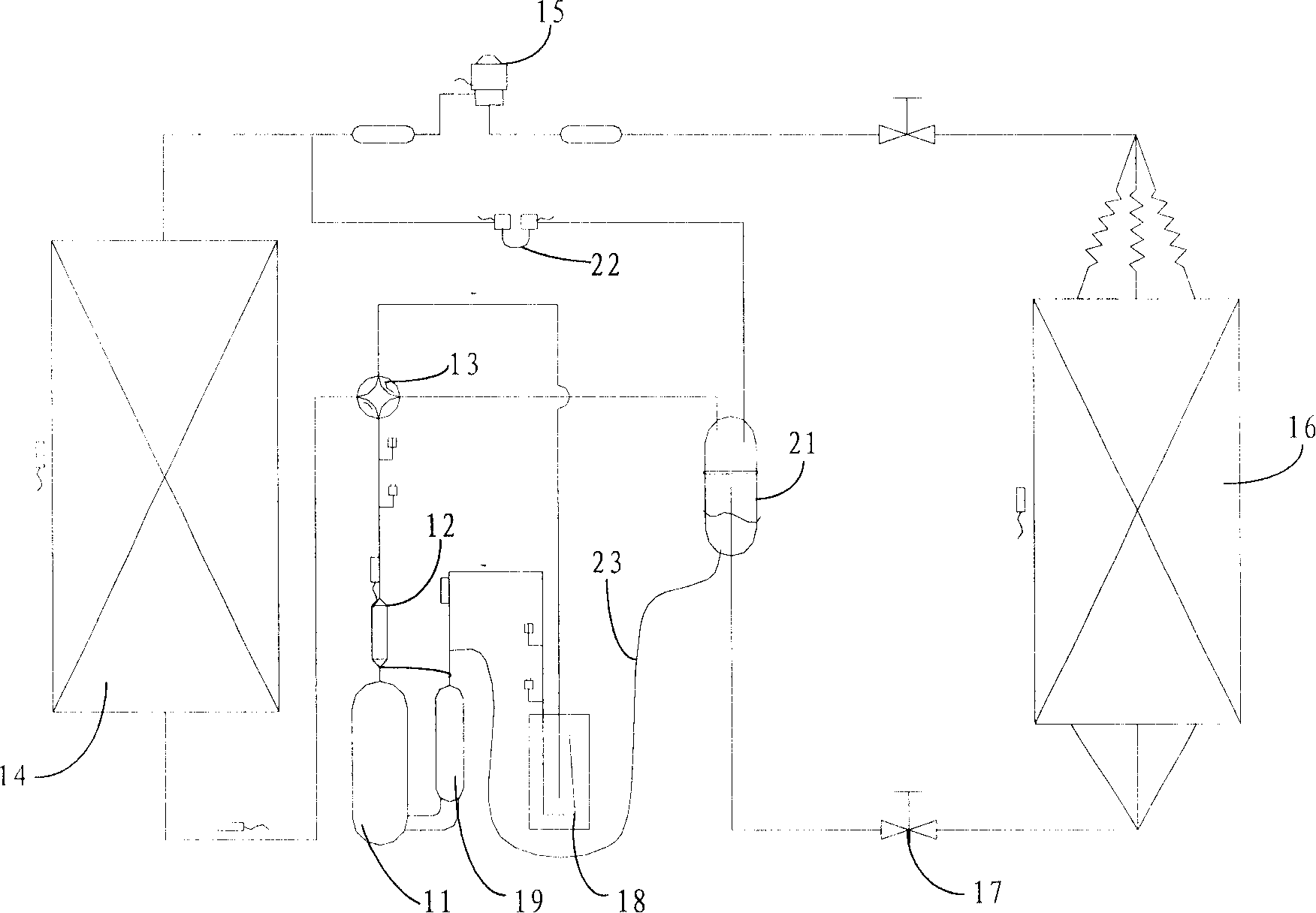

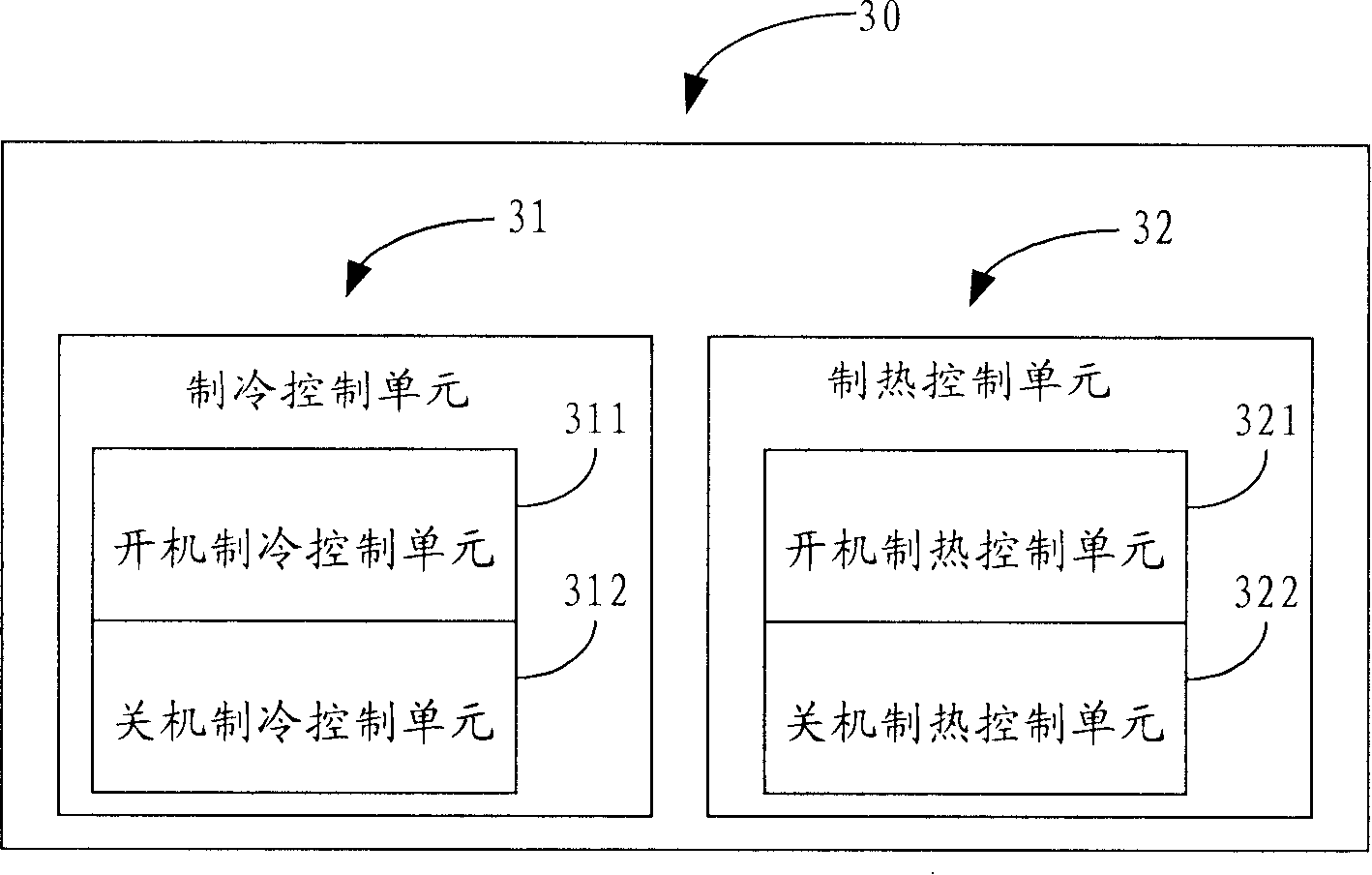

InactiveCN101178272AImprove work performanceEasy to separateCompressorRefrigeration safety arrangementFour-way valveSolenoid valve

The invention discloses an oil-return system used for an air conditioner, comprising a compressor, a four-way valve, a condenser, an expansion valve, an evaporator, an air-side check valve, as well as an oil separator, a solenoid valve and an oil-return capillary. The oil separator is connected with the four-way valve and the evaporator. The solenoid valve is connected with the oil separator and the condenser. The oil-return capillary is connected with the oil separator and the compressor. When the air conditioner works, the invention can effectively separate the oil from cooling mediums to enhance the working efficiency of the air conditioner, which can further eliminate noises and avoid the happening of cooling liquid returning.

Owner:HAIER GRP CORP +1

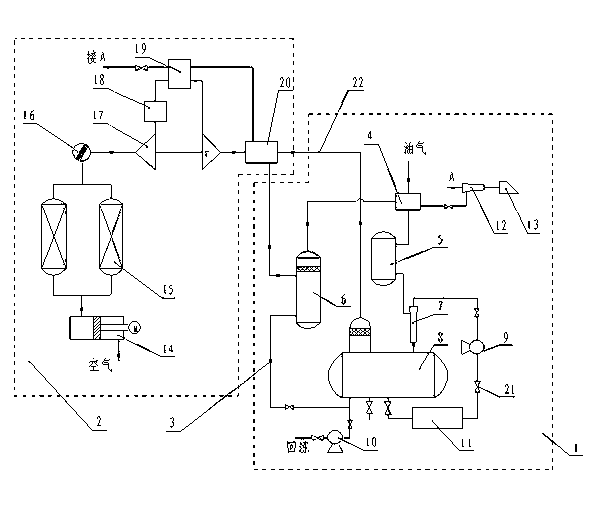

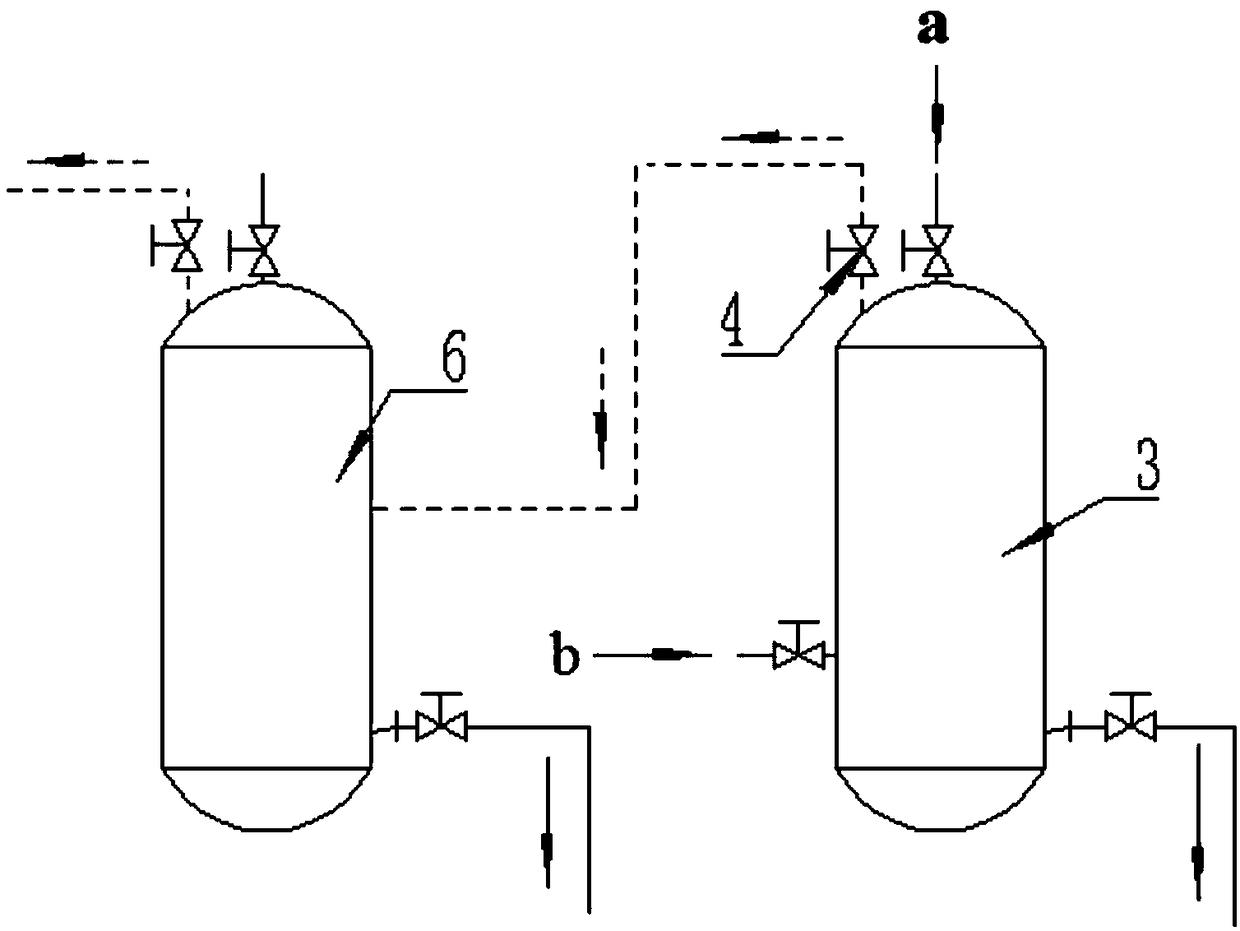

Evaporable petroleum gas adsorption condensation and comprehensive recovery device

InactiveCN103215060AOvercoming low recovery ratesOvercoming emissions non-complianceLiquid hydrocarbon mixture recoveryTurboexpanderFront and back ends

An evaporable petroleum gas adsorption condensation and comprehensive recovery device for loss control and pollution reduction during the storage and transportation of gasoline and light-weight oil includes an adsorption system and a condensation system, wherein a secondary separator, a liquid gas jet pump and an absorber are arranged in the adsorption system; an air compressor, a turbine expansion engine and a heat exchanger are arranged in the condensation system; the liquid gas jet pump is connected with the absorber; the absorber is connected with a main heat exchanger; the main heat exchanger is connected with the absorber through the secondary separator; the air compressor and the main heat exchanger are arranged at the front end and the rear end of the turbine expansion engine respectively; the air compressor produces delivery pressure; the turbine expansion engine refrigerates air; and the air serving as a cold source refrigerates the petroleum gas. According to the invention, lean oil inside the absorber is used for absorbing hydrocarbon materials of the petroleum gas, and the main heat exchanger and the secondary separator are used for processing the petroleum gas, so that the recovery rate is improved, and discharge meeting the standard is realized; and the evaporable petroleum gas adsorption condensation and comprehensive recovery device is widely applied to petroleum gas recovery during the transshipment of gasoline and light-weight oil, and has the advantages of higher recovery rate, tail gas discharge meeting the standard, simple and reasonable structure as well as safe and reliable operation.

Owner:XIANGYANG HANGLI ELECTROMECHANICAL TECH DEV

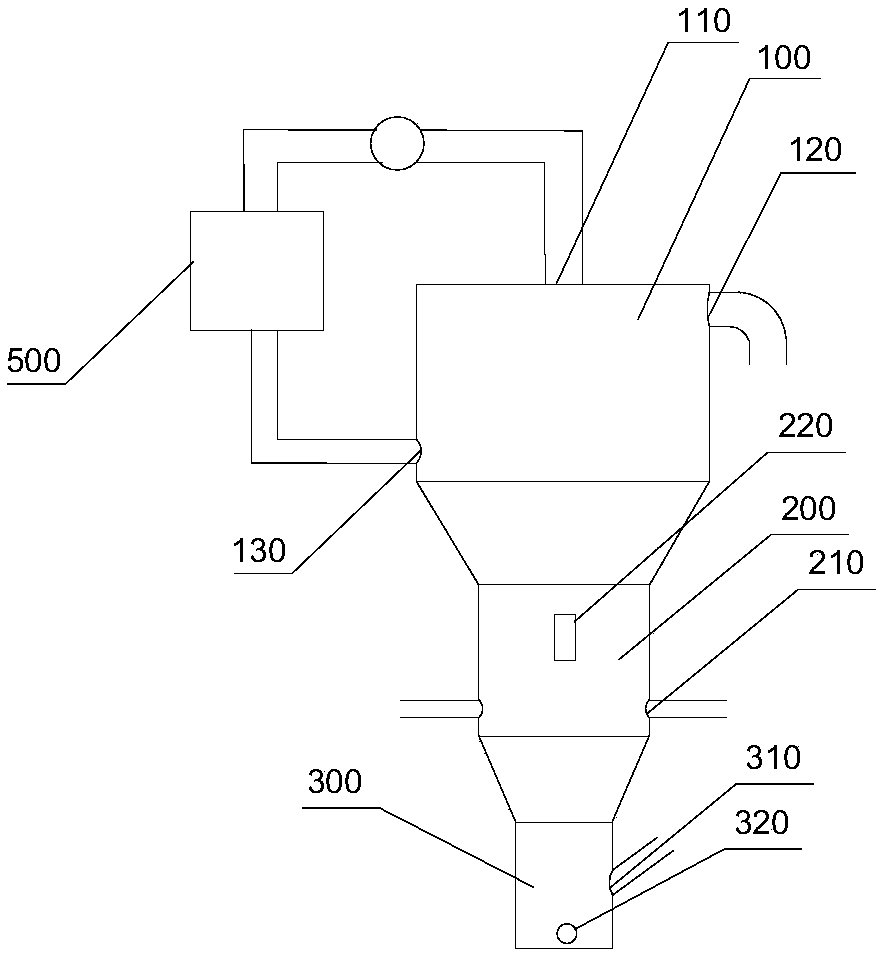

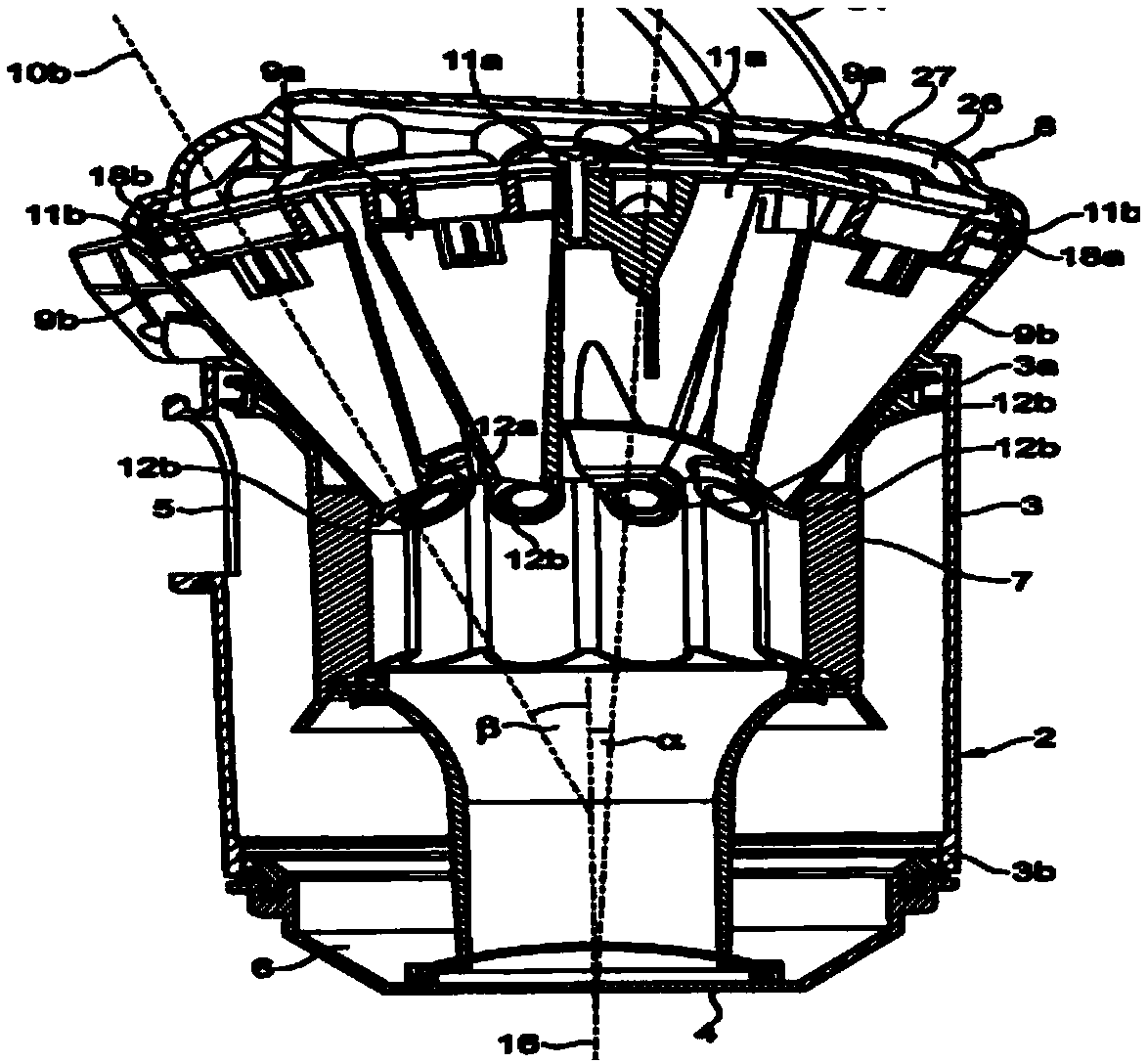

Anti-gravity three-phase separator

PendingCN108686825AEasy to separateAchieve secondary separationGrain treatmentsWet separationAnti-gravityThree-phase

The invention belongs to the technical field of separating devices, and discloses an anti-gravity three-phase separator. The problem that the separation effect of existing separating devices for separating graphite and diamond still needs to be improved in the prior art is solved. The anti-gravity three-phase separator comprises an upper section separation column, a middle section separation column and a lower section separation column, wherein the upper section separation column, the middle section separation column and the lower section separation column are connected from top to bottom andthe diameters of the upper section separation column, the middle section separation column and the lower section separation column decrease in sequence. A slurry inlet is formed in the top of the upper section separation column, a graphite powder overflow opening and a graphite coarse particle discharge outlet are formed in the positions, close to the top and bottom, of the outer wall of the uppersection separation column, and the graphite powder overflow opening and the graphite coarse particle discharge outlet are located at two sides of an axis of the upper section separation column. Two primary water inlets symmetrically formed in two sides of the axis of the middle section separation column are formed in the outer wall of the middle section separation column. The bottom of the lowersection separation column is closed, and diamond discharge opening and two secondary water inlets are separately formed in the positions, close to the bottom and at the bottom, of the outer wall of the lower section separation column, and the two secondary water inlets are symmetrically formed in two sides of the axis of the lower section separation column. The anti-gravity three-phase separator has a good separation effect on the graphite and the diamond.

Owner:无锡新迈自动化系统工程有限公司

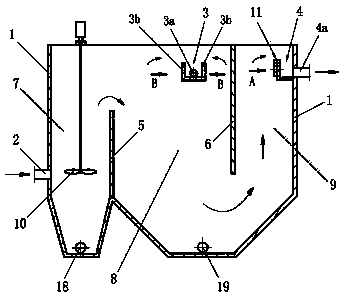

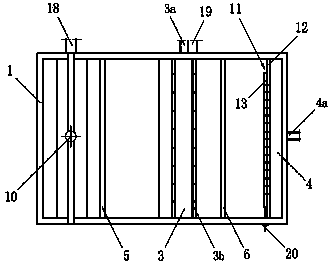

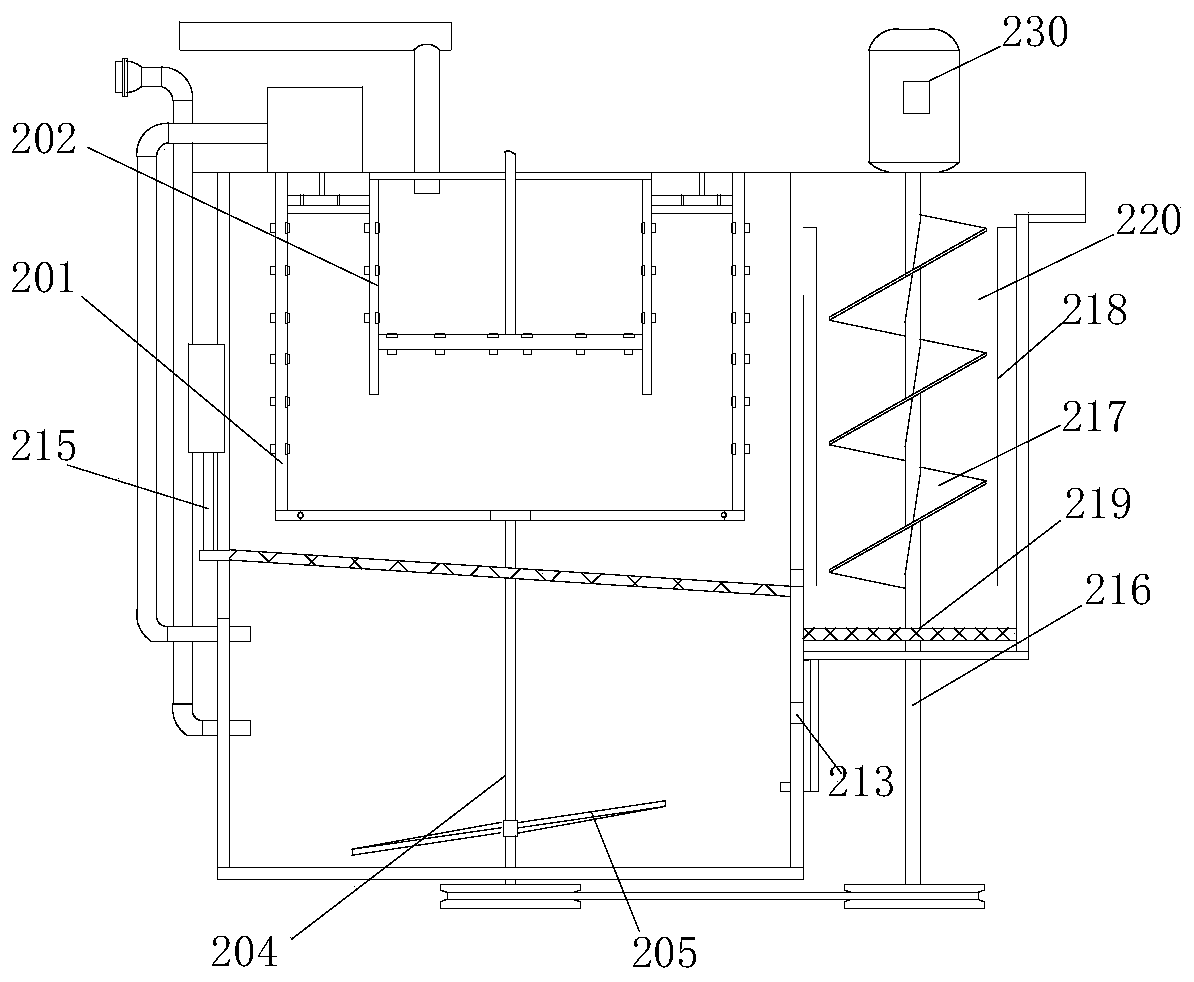

Dissolved air flotation tank

PendingCN107324432ASmall footprintLow costWaste water treatment from quariesWater/sewage treatment by centrifugal separationSeparation technologyEnvironmental engineering

A dissolved air flotation tank comprises a tank body, an upper head, a lower head, a pack mounting rack and a conical barrel, wherein coalescent pack and a taper tube are arranged on the pack mounting rack, a blowdown pipe is arranged on the lower side of the taper tube, an outer barrel is arranged on the upper side of the taper tube, an inner barrel is arranged in the outer barrel, a cyclone water inlet pipe is welded tangentially on the side wall of the inner barrel, an insertion pipe is inserted in the cyclone water inlet pipe and connected with a static mixer and a water inlet, a dross outlet is formed in the upper head of the tank body, and the blowdown pipe is arranged on the lower head of the tank body; a closed water purification area is formed between the conical barrel and the lower head, a plurality of water distribution square tubes communicating the tank body with the water purification area are arranged uniformly on the lower surface of the conical barrel; the water purification area is provided with a water outlet in the side wall of the tank body. An air flotation technology, a cyclone separation technology and a coalescence-separation technology are combined, and the dissolved air flotation tank further has the advantages of occupying small area and being low in cost, high in oil removal efficiency, simple and convenient to operate and high in reliability.

Owner:ZHEJIANG JINLONG AUTOMATIC CONTROL EQUIP

Environment-friendly dredging device

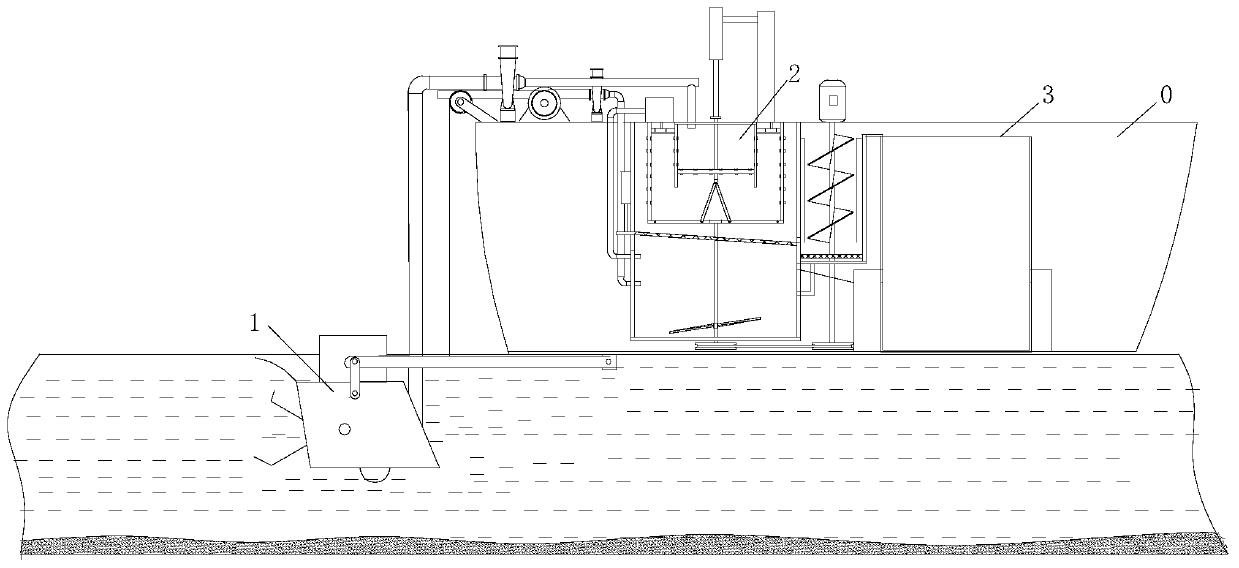

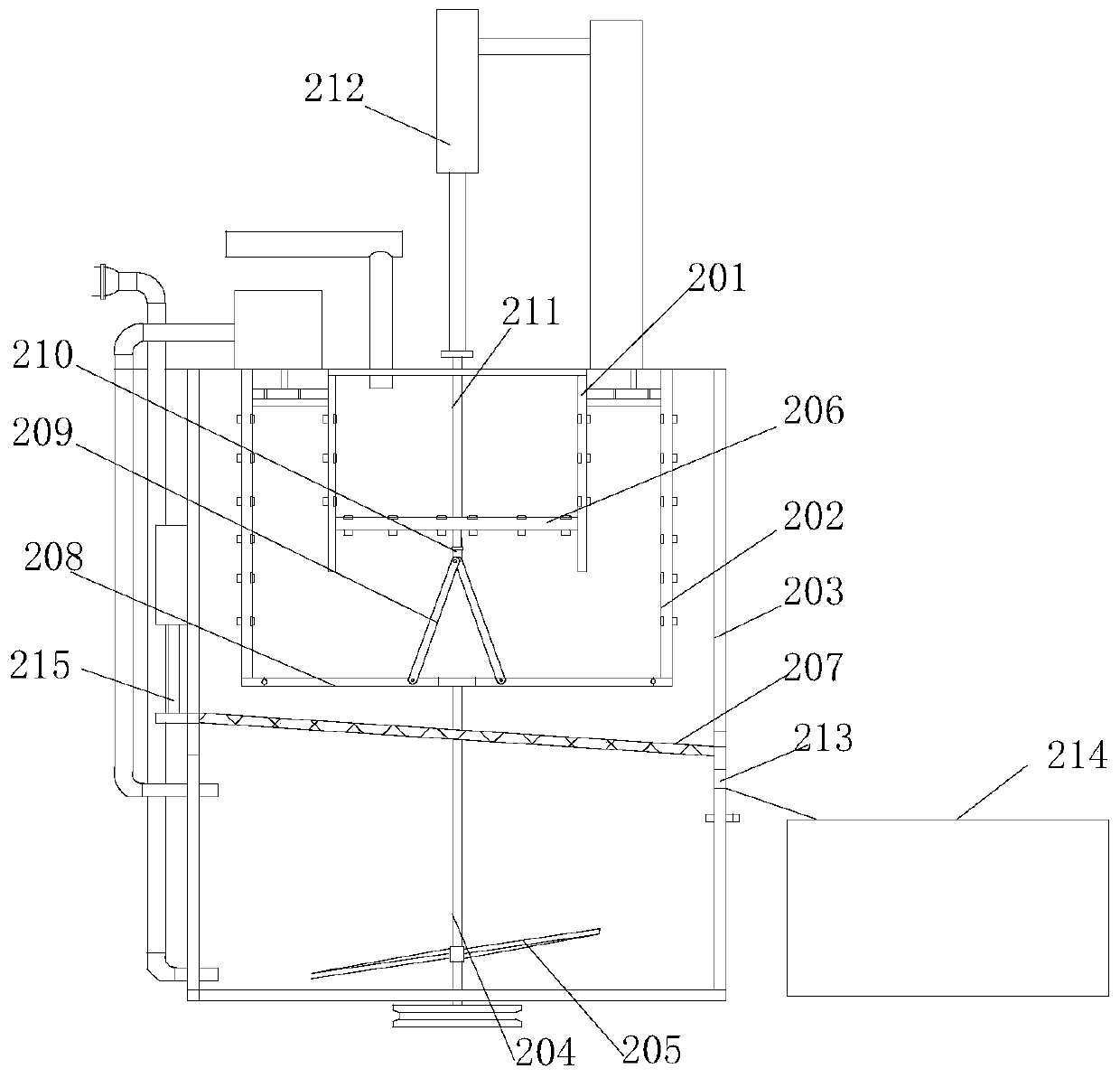

ActiveCN109853656AWork effectively for a long timeGuarantee dredging efficiencyMechanical machines/dredgersSludgeSpiral blade

The invention relates to an environment-friendly dredging device. A dredging unit comprises a silt loosening mechanism and a silt pump; a sludge separation unit comprises an outer box body, a first inner box body and a second inner box body which are arranged on a ship body; the sludge separation unit further comprises a dewatering box, and spiral blades are arranged in the dewatering box; the ship body is also provided with a water pump and a chemical tank, and a water inlet of the water pump extends into the bottom of the outer box body through a water pipe; deodorizing liquid is contained in the chemical tank, and a liquid outlet of the chemical tank extends into the bottom of the outer box body through a liquid outlet pipe; and the first inner box body, the second inner box body, a stirring paddle and the spiral blades are all driven to rotate through a transmission mechanism. The environment-friendly dredging device is capable of automatically removing silt at the river bottom orthe lake bottom, is also capable of filtering and dewatering the silt, and has the technical effects of simple operation, high working efficiency, energy conservation and environmental friendliness.

Owner:天津市雷升科技有限公司

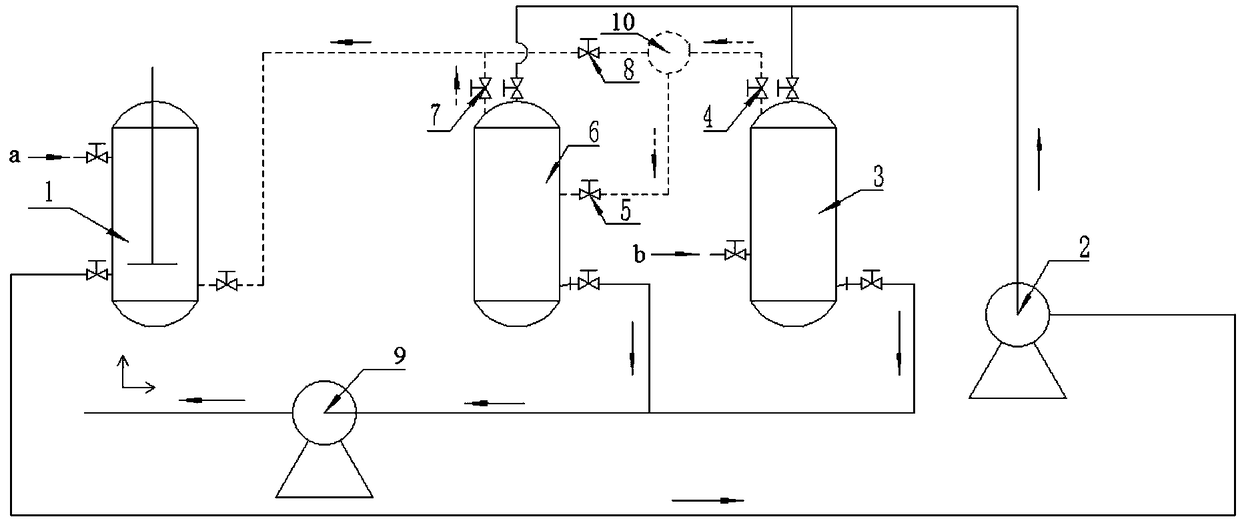

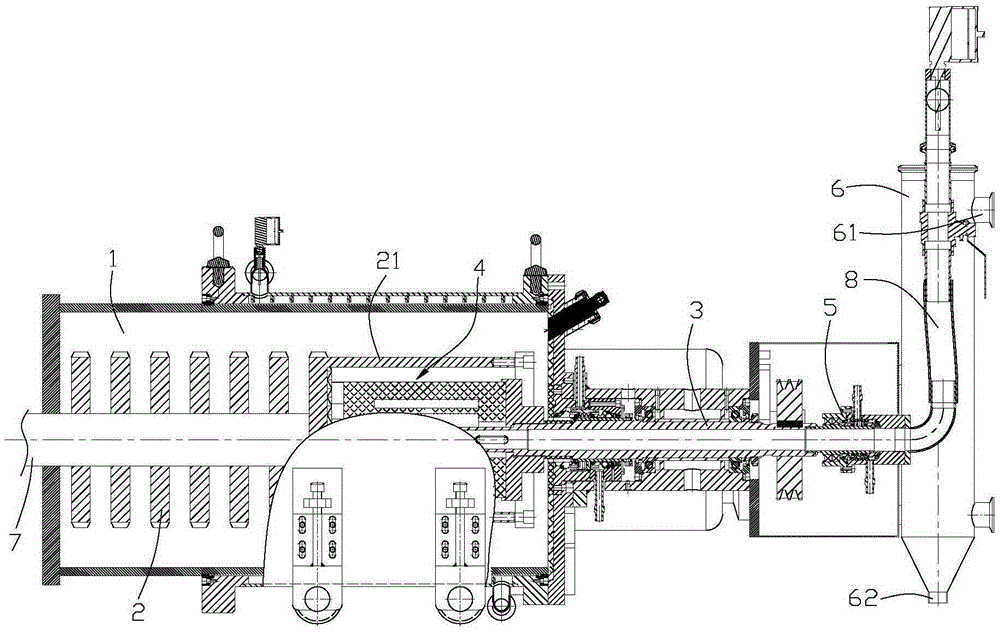

Pyrohydrolysis flash separation device, pyrohydrolysis flash separation technology, pyrohydrolysis system and pyrohydrolysis technology

PendingCN108840548ASmall pressure fluctuationsReduce vibrationSludge treatment by thermal conditioningSludge treatment by pyrolysisTreatment needRelief valve

The invention discloses a pyrohydrolysis flash separation device, a pyrohydrolysis flash separation technology, a pyrohydrolysis system and a pyrohydrolysis technology. The pyrohydrolysis flash separation device comprises a pyrohydrolysis reaction tank and a gas-liquid separation tank which are communicated through a pipe, wherein a pressure relief valve is arranged on the pipe therebetween. By the pyrohydrolysis flash separation technology, the pyrohydrolysis flash separation device is used for flash separation. The pyrohydrolysis system comprises a slurrying tank, a mud inlet pump, the pyrohydrolysis reaction tank and the gas-liquid separation tank which are sequentially communicated end to end through pipes; the pressure relief valve is arranged on the pipe between the pyrohydrolysis reaction tank and the gas-liquid separation tank. By the pyrohydrolysis technology, the pyrohydrolysis system is used for pyrohydrolysis. The pyrohydrolysis flash separation device and the pyrohydrolysis system have the advantages of small floor area, low production cost, a high safety production factor and the like, and the pyrohydrolysis flash separation technology and the pyrohydrolysis technology have the advantages of a simple process, easy operation, high treatment efficiency, a good gas-liquid separation effect and the like, so that actual treatment needs can be met and an application prospect is very good.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

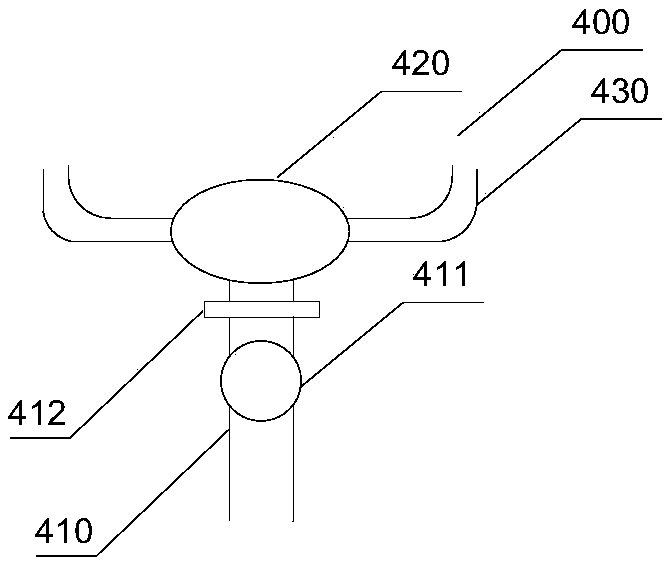

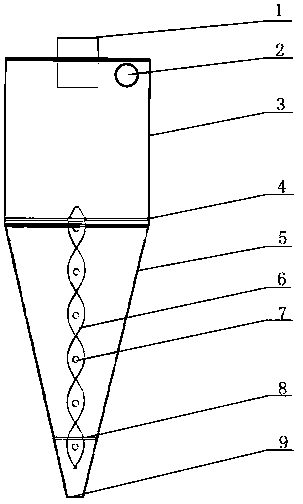

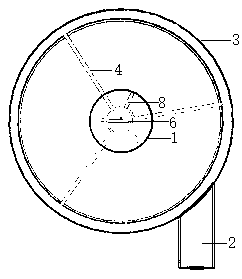

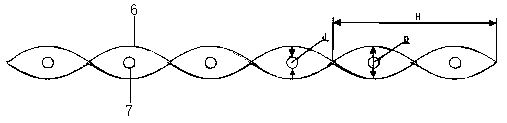

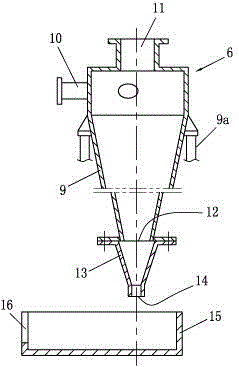

Cyclone separator for natural gas hydrate exploitation silt

ActiveCN109488262AEnhance the strength of internal swirlAchieve secondary separationConstructionsFluid removalCycloneEngineering

The invention discloses a cyclone separator for natural gas hydrate exploitation silt. A separator body comprises a cylindrical barrel body and a conical barrel body, wherein an overflowing opening isformed in the top of the cylindrical barrel body; a feeding opening is formed in a side wall of the cylindrical barrel body; a bottom flow opening is formed in the bottom of the conical barrel body;a band is longitudinally arranged in the separator body and is positioned at the axis of the separator; the top of the band is fixedly connected with the cylindrical barrel body through a fixing support on the band; and the bottom end of the band is fixedly connected with the conical barrel body through a band lower fixing support. The separator is simple in structure, convenient to mount, low inprocessing cost, wide in application range and high in separation efficiency, and is suitable for separating silt in a natural gas hydrate exploitation process; by the built-in band, the strength of inner swirling flow is enhanced, and secondary separation is realized favorably; the flowing stability of an inner swirling flow region is improved, and safe running of the system is facilitated; by the band, a zero-flow-speed envelope line moves outwards, and loss of the hydrate is reduced favorably; and by a flow hole, a channel is provided for floating up of central gas, and running faults caused by air resistance are avoided.

Owner:CHANGZHOU UNIV

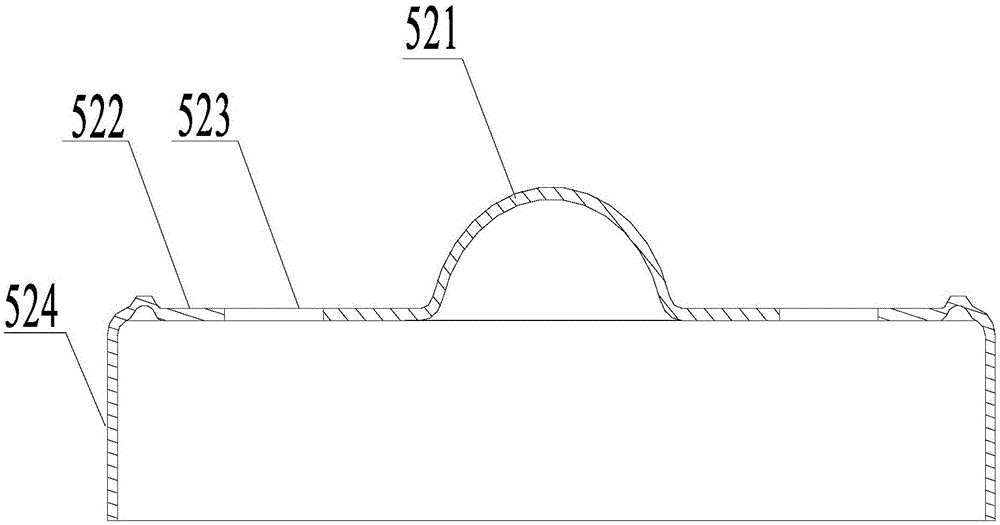

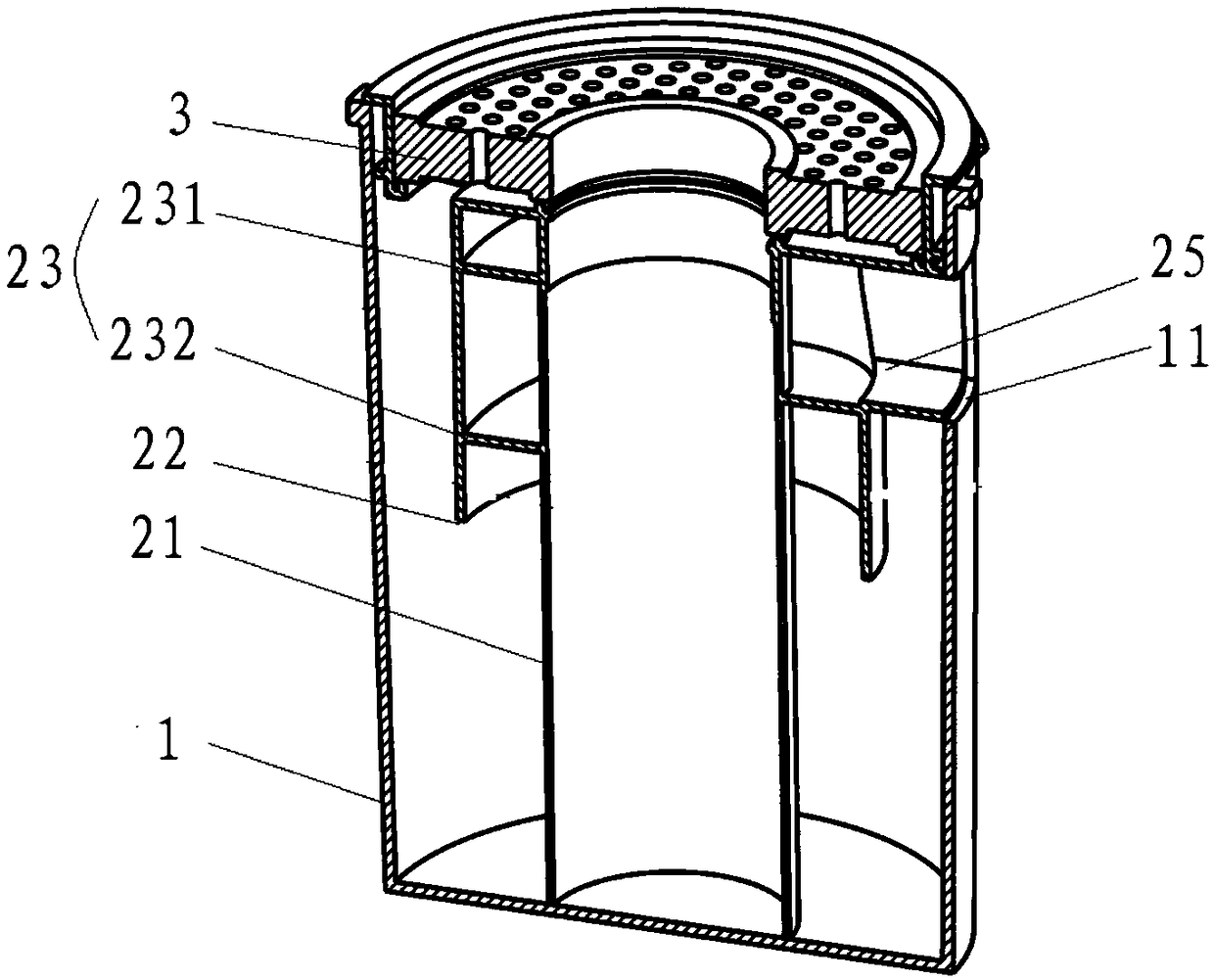

Liquid dispenser filter screen assembly and liquid dispenser

ActiveCN106322866AReduce the possibilityPrevent liquid shockRefrigeration componentsRefrigerantEngineering

The invention relates to the technical field of liquid dispensers, in particular to a liquid dispenser filter screen assembly and a liquid dispenser. The liquid dispenser filter screen assembly comprises a filter screen support, wherein the filter screen support comprises a connecting plate, a through hole is formed in the middle of the connecting plate, a central supporting plate is arranged at the central position of the through hole, an air inlet channel is formed between the outer edge of the central supporting plate and the inner edge of the connecting plate, an upper filter screen is arranged above the filter screen support, a lower filter screen is arranged below the filter screen support, and a connecting port is connected to the lower filter screen. The upper filter screen covers the central supporting plate and the air inlet channel, the edge of the upper filter screen is connected with the top of the connecting plate, the lower filter screen covers the central supporting plate, and the edge of the lower filter screen is connected with the bottom of the central supporting plate. The liquid dispenser filter screen assembly is provided with the upper filter screen and the lower filter screen respectively on the filter screen support and is provided with two ways of filtration, a gas-liquid mixed refrigerant is successively subjected to two times of filtration, secondary separation of liquid refrigerant is achieved, the possibility that the liquid refrigerant enters a compressor is greatly reduced, liquid impact can be effectively prevented, and the quality of the compressor can be improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Intelligent garbage classification robot

InactiveCN103464380AImprove classification efficiencyReduce sorting costsSortingControl systemCoupling

An intelligent garbage classification robot comprises a garbage separation device and a garbage classification device, the garbage separation device is formed by a garbage bucket and a crank rocking bar mechanism, the garbage bucket comprises a garbage baffle board, a baseboard, side boards, a laser transmitting tube I, metal proximity switches, a laser receiver I, a partition board, a metal proximity switch support, a rotation shaft, a steering engine I, a garbage separating column jack and a garbage separating column, the crank rocking bar mechanism comprises a shaft coupling, a crank I, a direct current deceleration motor I and a connecting rod, and the garbage classification device comprises a direct current deceleration motor II, transmission shafts, driving sprocket wheels, a control system, driven sprocket wheels, garbage boxes, a laser transmitting tube II, a solar board, a camera support, chain boards, a camera, a support body, a laser receiver II, a driven gear, a driving gear, a vertical support, a steering engine II, a crank II, slide rails and a slide block. The robot has the advantages of intelligence, high classification efficiency, environmental protection, low price and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

Waterway gas rapid automatic removing device

PendingCN108726618AQuick removalAchieve a separationPreparing sample for investigationWater/sewage treatment by degassingMicro bubbleEngineering

The invention discloses a waterway gas rapid automatic removing device. The waterway gas rapid automatic removing device is used for removing a large of micro bubbles generated in flowing process of liquid in pipelines or existing in liquid, avoiding generation of cavities and even blasting in high pressure pipelines, and improving liquid detection accuracy. The waterway gas rapid automatic removing device comprises a protective housing, a pressure reducing pipe, a water film generator, a gas discharging assembly, and a floating assembly; the waterway gas rapid automatic removing device is capable of realizing two times of gas liquid separation operation based on negative pressure and gravitational acceleration principles, and bubbles in water can be removed automatically and quickly without pipeline pressure release. Interacting of the separated gas and liquid is achieved, opening and closing of the gas discharging assembly is adopted, so that smooth and rapid gas discharge is realized, and influences on removing effect caused by long time accumulation of gas and liquid in the protective housing are avoided.

Owner:河北科瑞达仪器科技股份有限公司

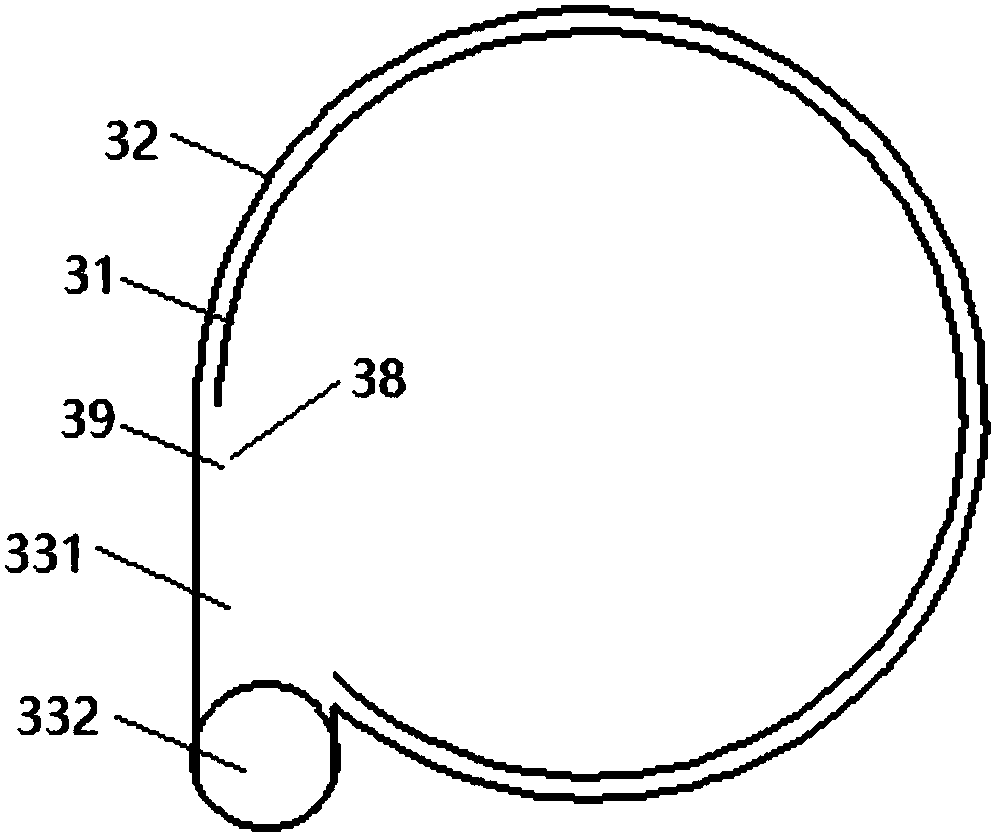

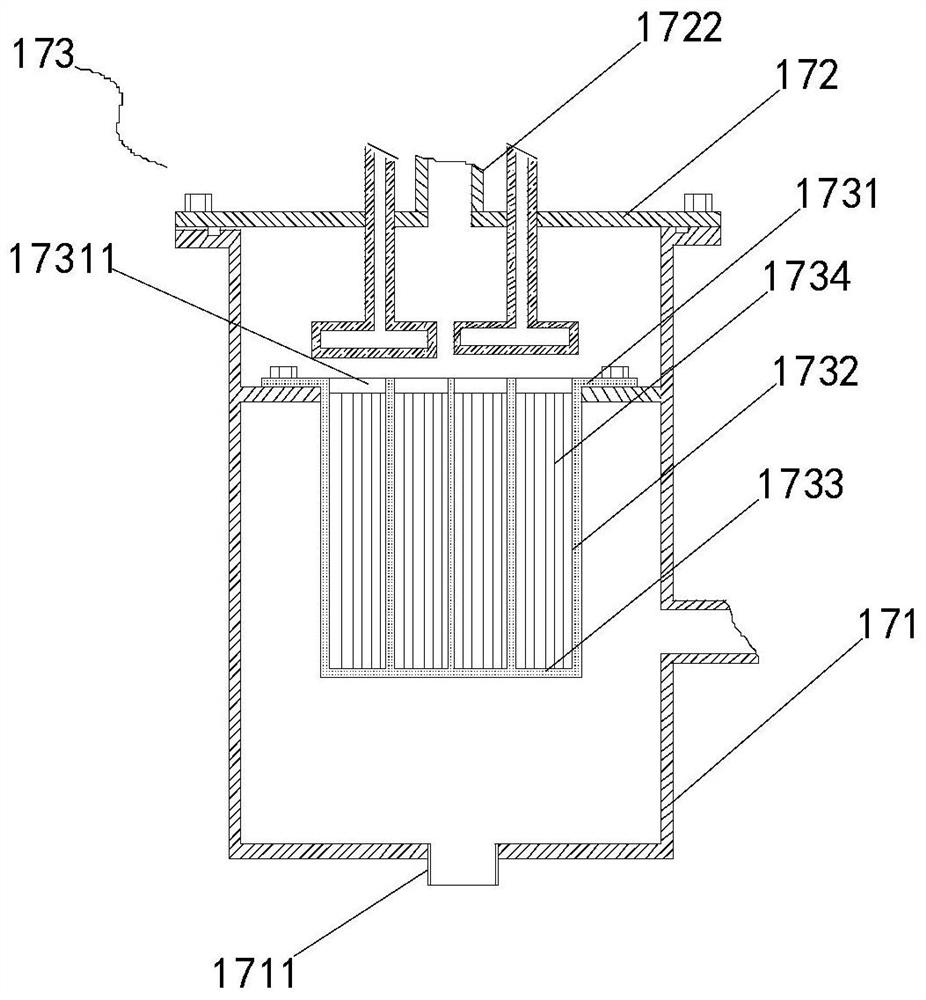

Screen-free type intelligent nanometer grinding system

InactiveCN105396650AIncrease productionExcellent performanceGrain treatmentsFeed pressurePressure - action

The invention relates to the field of dispersing and grinding equipment, in particular to a screen-free type intelligent nanometer grinding system. The screen-free type intelligent nanometer grinding system comprises a grinding cavity and a grinding rotor. One end of a discharging hollow shaft extends into the grinding cavity; a rotary separation device is installed on the discharging hollow shaft; materials inside the grinding cavity are ground through the grinding rotor and flow to the periphery of the rotary separation device; large-particle materials and grinding beads inside the grinding cavity are thrown out of the rotary separation device under the centrifugal action of the rotary separation device, and small-particle materials overcome centrifugal force under the feeding pressure action to enter the rotary separation device, the discharging hollow shaft and a subsidence and filter transfer container. The structure of an existing screen type separation device is completely abandoned, strong centrifugal force generated when the separation device rotates throws grinding media outwards namely the grinding beads and the large-particle materials, and the small-particle materials overcome centrifugal force under the feeding pressure action to enter the discharging hollow shaft and the subsidence and filter transfer container from a vortex groove, and therefore products with smaller particles are obtained.

Owner:PUHLER GUANGDONG SMART NANO TECH CO LTD

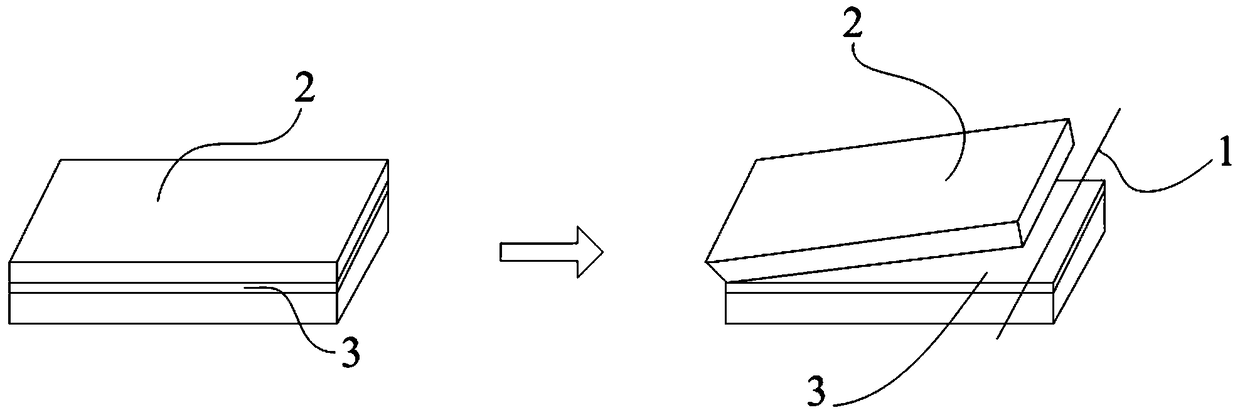

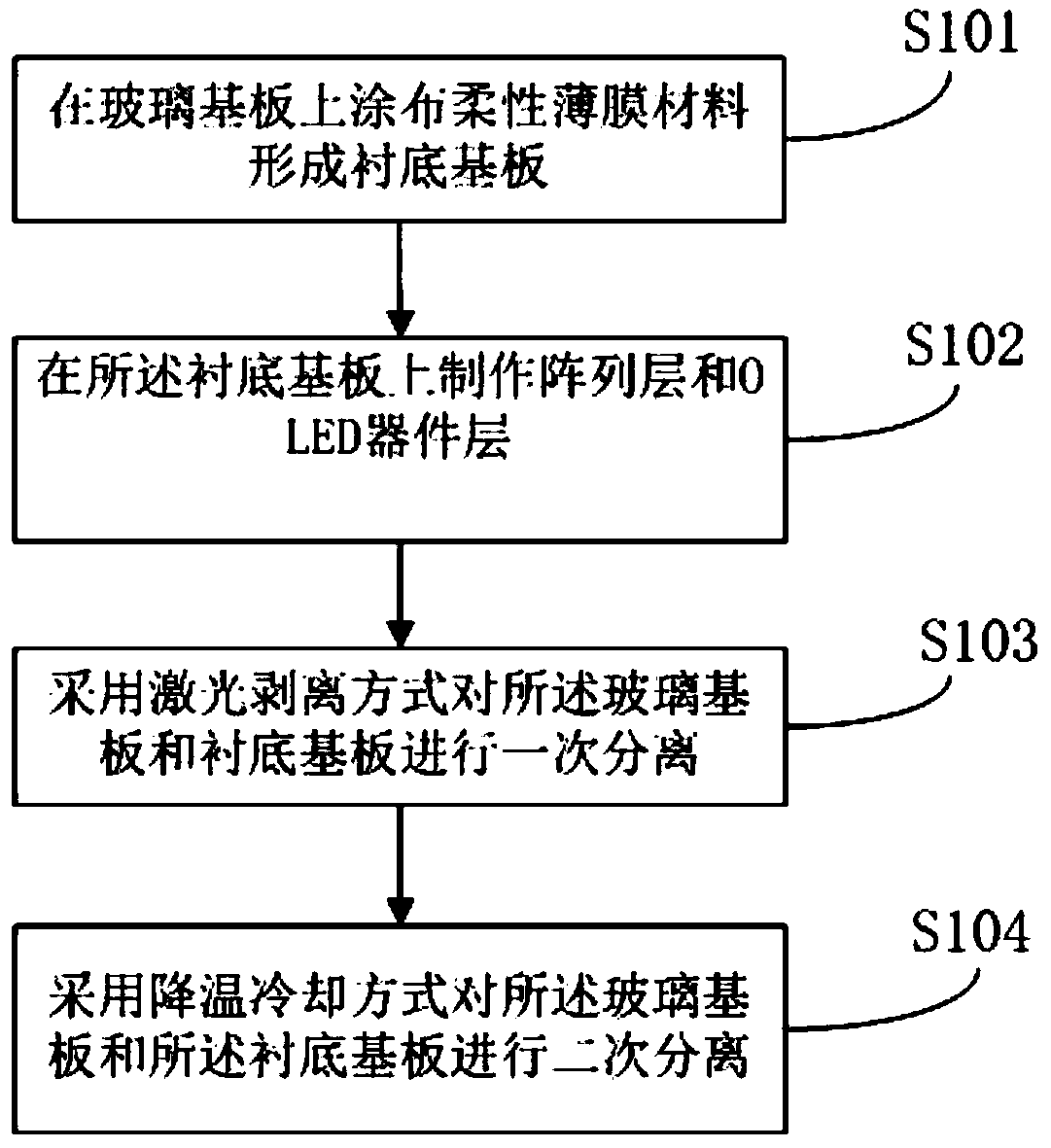

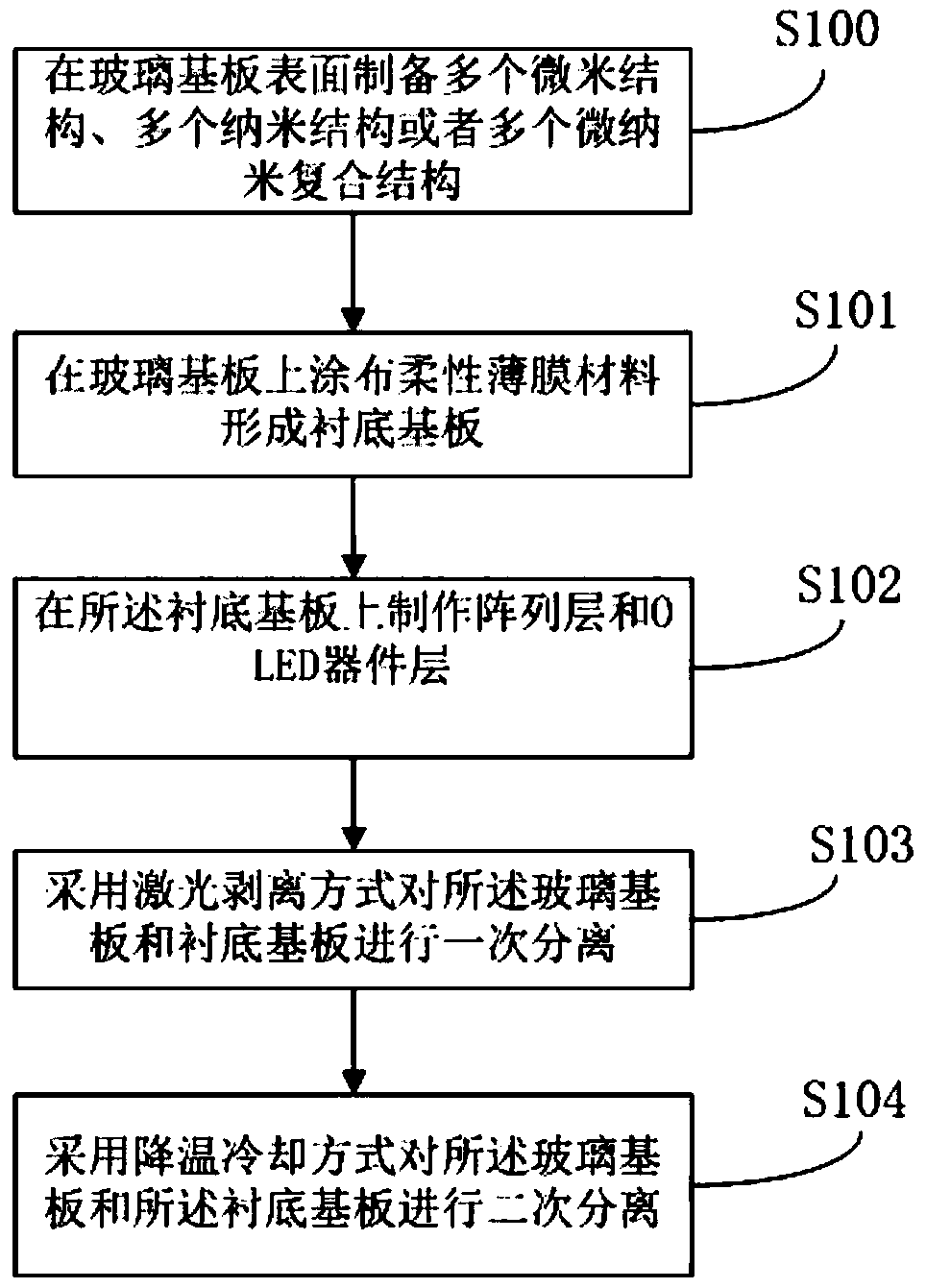

A flexible display panel and a manufacturing method thereof

InactiveCN109087998AAchieve secondary separationAvoid pulling damageFinal product manufactureSolid-state devicesSeparation processFlexible display

A method for manufacturing a flexible display panel includes coating a glass substrate with a flexible thin film material to form a substrate; fabricating an array layer and an OLED device layer on the substrate; using a laser stripping method to carry out primary separation between that glass substrate and the substrate; using a cooling mode to perform secondary separation between the glass substrate and the substrate. The invention can complete the separation of the glass substrate and the substrate without contacting the substrate, and effectively prevents the substrate from being damaged in the separation process. The invention also provides a flexible display panel manufactured by the method.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Steam rapid diffuser

PendingCN109974105AEvenly distributedShorten the absorption distanceCondensate preventionLighting and heating apparatusEngineeringAir conditioning

The invention discloses a steam rapid diffuser. The steam rapid diffuser comprises a gas collecting chamber, a dry steam chamber and a condensed water chamber which are sequentially separated from topto bottom, a steam-water separator and a plurality of steam distribution branch pipes which are connected between the gas collecting chamber and the condensed water chamber, and a steam distributionheader which is arranged at the upper part of the gas collecting chamber. One end of the steam distribution header is provided with a steam inlet, a plurality of nozzles are uniformly distributed on the potions, located in the dry steam chamber, of the steam distribution branch pipes, and a condensed water outlet is arranged at the bottom of the condensed water chamber. According to the steam rapid diffuser, in the flowing process of steam in the steam distribution branch pipes, only pure dry steam with the highest temperature located at the central parts of the steam distribution branch pipescan be sprayed out from the plurality of nozzles, so that it is ensured that only dry steam can be captured; and through the plurality of the nozzles, the steam is enabled to be evenly distributed, thereby greatly shortening the steam absorption distance and ensuring the shortest steam trail in the air conditioning box.

Owner:STLAILE TIANJIN CLEANROOM EQUIP

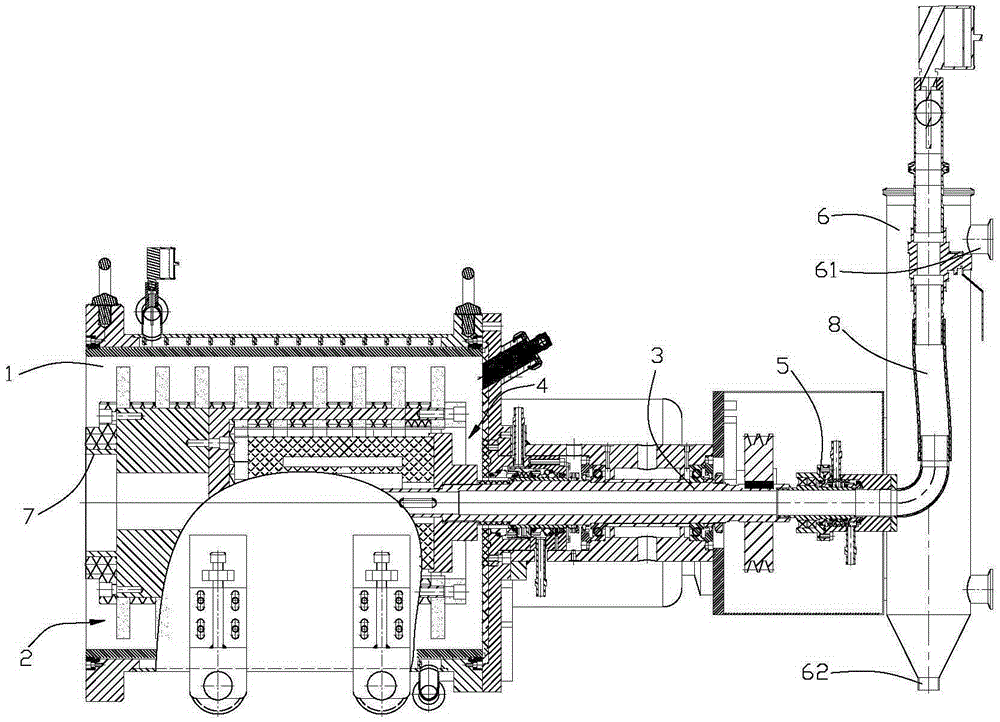

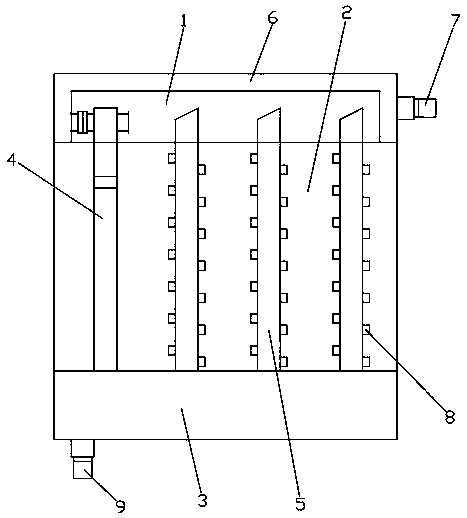

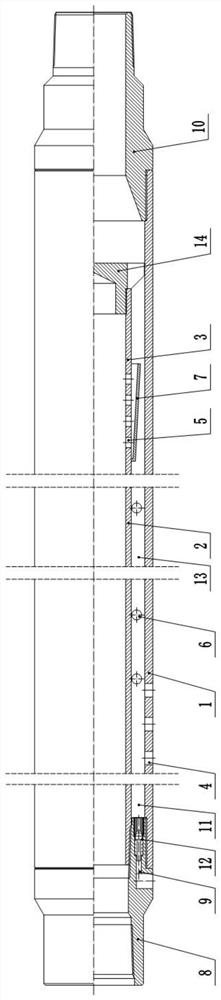

Multifunctional sand-prevention oil-gas separator

PendingCN112145134AAchieve a separationAchieve secondary separationFluid removalMechanical engineeringMechanics

The invention discloses a multifunctional sand-prevention oil-gas separator. The oil-gas separator comprises an outer pipe, a central pipe and a flow dividing pipe, wherein the central pipe is fixedlyconnected with the flow dividing pipe, and the central pipe and the flow dividing pipe are arranged inside the outer pipe in a sleeved mode; a plurality of sucking and screening holes are formed in the pipe wall of the front end of the outer pipe, the flow dividing pipe corresponds to the rear end of the outer pipe, and liquid inlet holes are formed in the pipe wall of the flow dividing pipe; andspiral sheets are arranged between the central pipe and the outer pipe, and a flow dividing umbrella is arranged between the flow dividing pipe and the outer pipe. According to the multifunctional sand-prevention oil-gas separator, the spiral sheets are adopted for spiral separation, and the flow dividing umbrella is adopted for slip effect separation, so that the two-stage separation effect of liquid flow in the pipe circulation process is achieved, and the oil-gas separator is novel in structure, simple and reliable.

Owner:西安东鑫石油机械有限公司

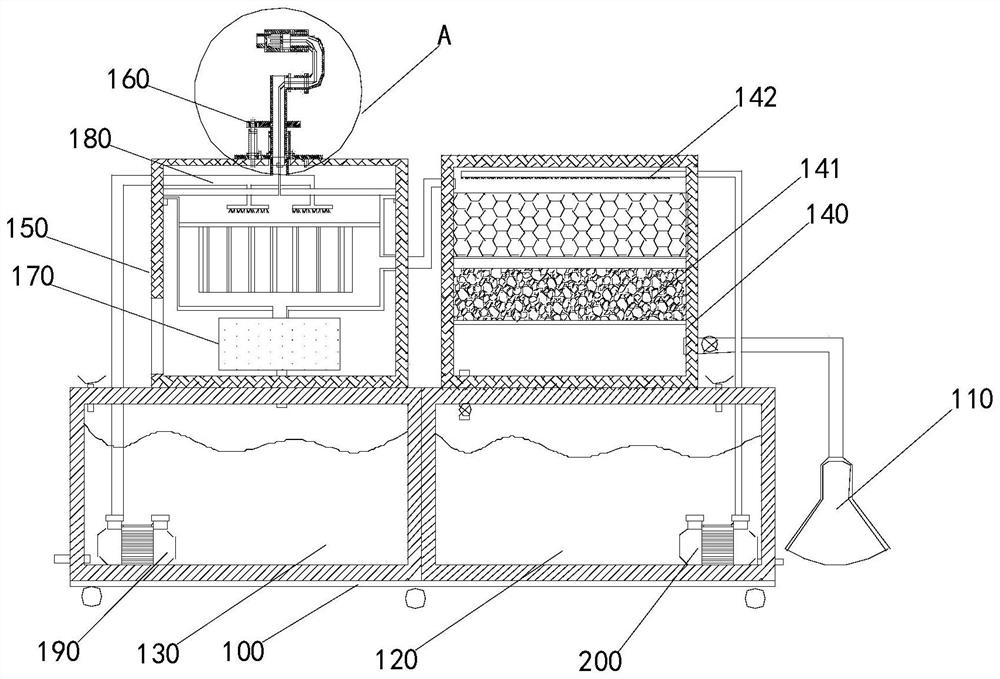

Zero-emission reusing device for paper-making wastewater for fireworks paper

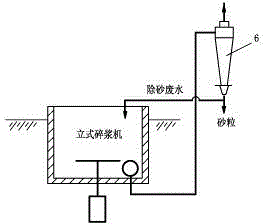

ActiveCN104480765AEfficient removalSatisfy productivityWater/sewage treatment by centrifugal separationPulp liquor regenerationFireworksWastewater

The invention discloses a zero-emission reusing device for paper-making wastewater for fireworks paper. An outlet of a wastewater conveying member (1) is communicated with a pulper; a discharge opening of a screening wastewater pool (2) is communicated with the wastewater conveying member; the discharge opening of a sheet forming wastewater pool (3) is communicated with the wastewater conveying member; the discharge opening of a squeezing wastewater pool (4) is communicated with the wastewater conveying member; a first wastewater outlet for providing dilution water (5) to a paper pulp dilution pool is formed in the sheet forming wastewater pool; the first wastewater outlet is formed in the lower part of a side wall of the sheet forming wastewater pool, and is communicated with the lower part of the paper pulp dilution pool; the discharge opening capable of playing a control role in a paper pulp liquid level in the paper pulp dilution pool is formed in the upper part of the other side wall of the sheet forming wastewater pool; a paper pulp sand remover (6) is arranged; and pulping wastewater is communicated with the pulper via the wastewater outlet of the paper pulp sand remover. According to the zero-emission reusing device disclosed by the invention, sand grains in the pulped paper pulp can be effectively removed; the reuse quality of the sand-removing wastewater is improved; and the zero-emission reusing device has the characteristics of being relatively reasonable in structure, practical and the like.

Owner:钟立福

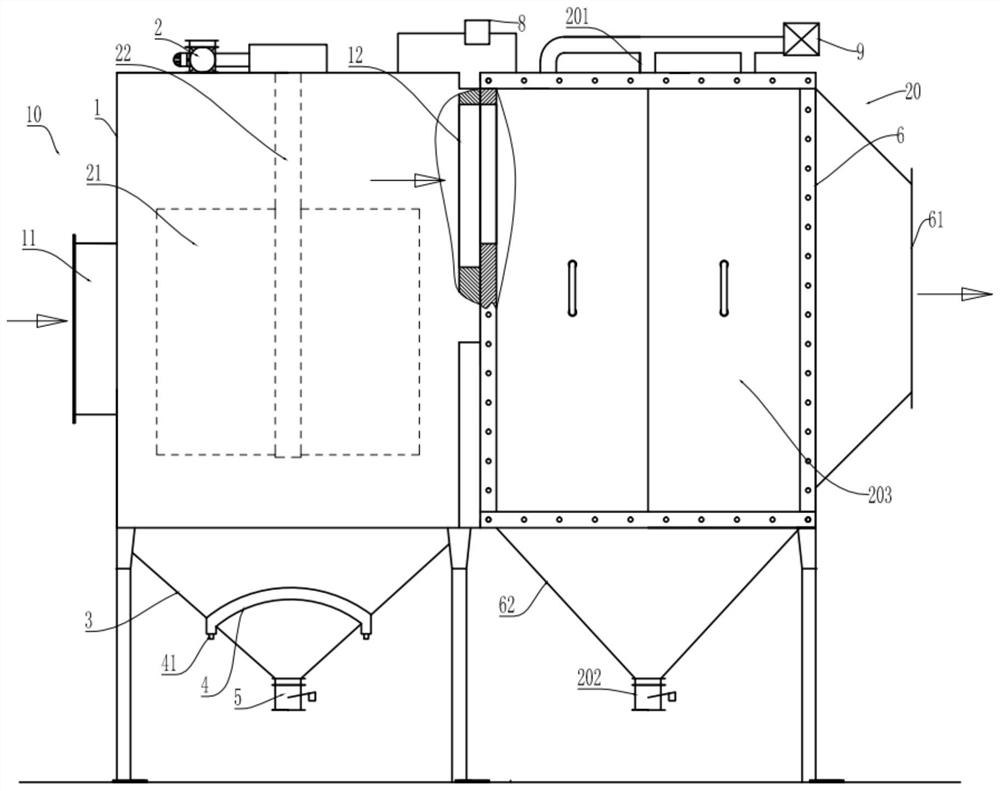

Oil-containing smoke intercepting equipment

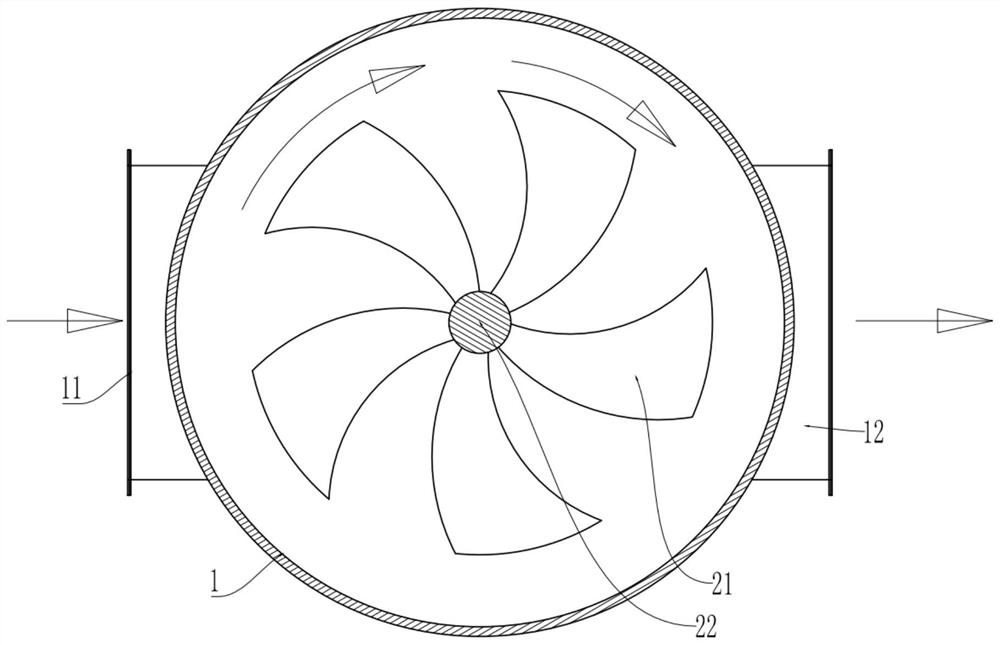

PendingCN113731057AReduce oil contentImplement interceptionHuman health protectionGas treatmentDust controlOil mist

The invention relates to the technical field of oil-smoke separation, and particularly discloses oil-containing smoke intercepting equipment which comprises an oil-smoke separation unit, the oil-smoke separation unit comprises a separation chamber, the separation chamber comprises an air inlet and an air outlet, the oil-smoke separation unit further comprises a rotator, the output end of the rotator is connected with blades, and the blades are located in the separation chamber; after the rotator drives the blades to rotate, smoke entering from the air inlet can impact the inner wall of the separation chamber and then is discharged from the air outlet; the equipment further comprises an oil filtering unit, the oil filtering unit comprises a filtering plate for intercepting oil mist, the input end of the oil filtering unit is communicated with the air outlet of the separation chamber, and the output end of the oil filtering unit is connected with a cloth bag dust removal and purification equipment. According to the scheme, oil mist in waste gas is separated twice through the oil-smoke separation unit and the oil filtering unit, the oil content in the waste gas is greatly reduced, and the problems that in the prior art, after the waste gas enters cloth bag dust removal and purification equipment, a bag is pasted, dust removal is difficult, and the running resistance of the equipment is increased are solved.

Owner:重庆华光环境工程设备有限公司

Separation method of mineral elements

The mineral element separating process includes the following steps: crushing, sieving, grinding, grading, initial sorting in type-II laminating machine, and eliminating impurity and purification in type-I laminating machine. The present invention has smart structure and wide separation range, can separate mineral elements with specific weight difference within 0.5, and makes it possible to treat tail mineral and dregs to realize comprehensive utilization.

Owner:周涛

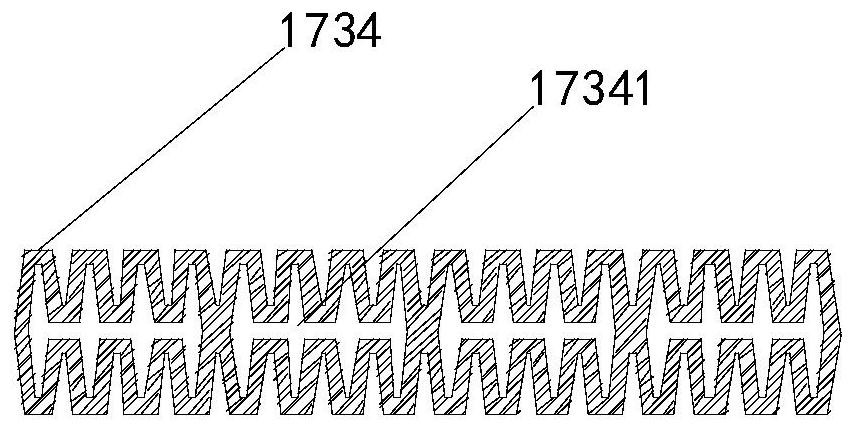

Spiral dust-gas separation device and gas purification device

The invention provides a spiral dust-gas separation device and a gas purification device. The spiral dust-gas separation device comprises a cup body and a separator; the separator comprises an upper flow guiding vane, a lower flow guiding vane, an inner pipe and an outer pipe, wherein the upper flow guiding vane and the lower flow guiding vane are parallel to each other and spiral downward; a first guiding passage is arranged between the outer wall of the separator and the inner wall of the cup body; the outer pipe, the inner pipe, the upper flow guiding vane and the lower flow guiding vane jointly form a second guiding passage. Through the arrangement of the first guiding passage and the second guiding passage, secondary separation of airflow containing dust is achieved, a better effectof separating the dust from gas is achieved, the spiral dust-gas separation device only comprises the cup body and the separator, the cup body can be sleeved with the separator to achieve the separation, and the structure is simple and compact.

Owner:GREE ELECTRIC APPLIANCES INC

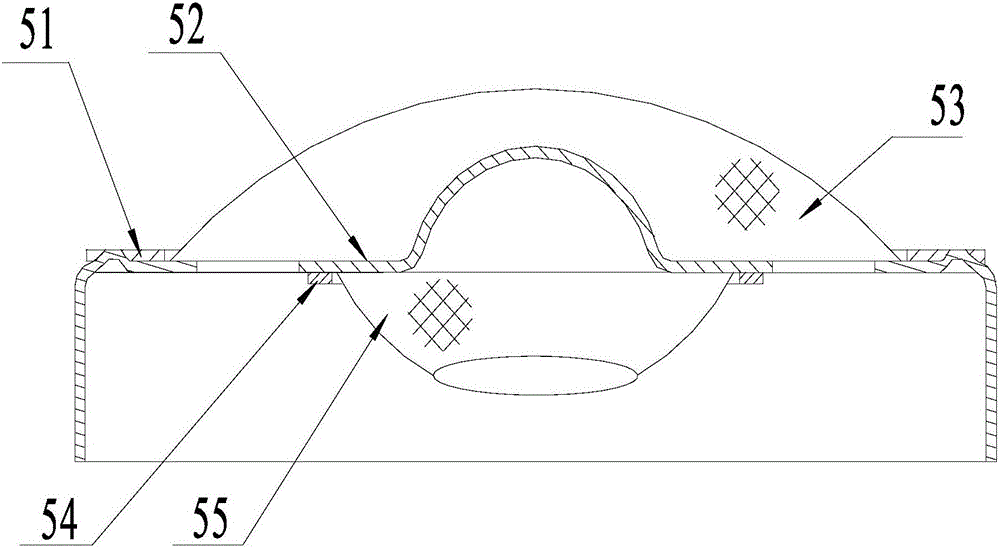

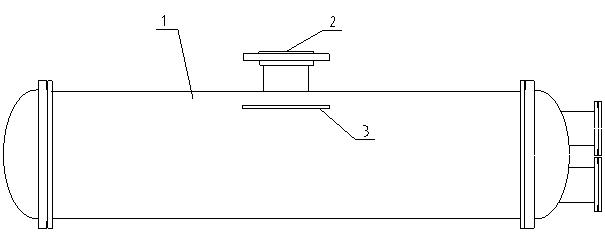

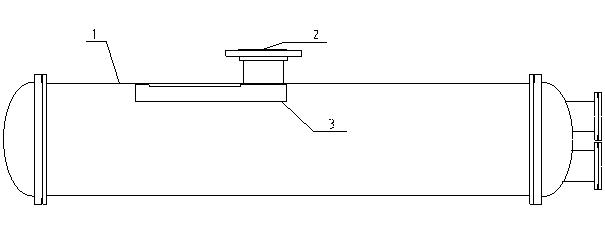

Flooded type evaporator structure

InactiveCN102003851AAchieve secondary separationAvoid inhalationRefrigeration componentsEngineeringRefrigerant

The invention relates to a flooded type evaporator structure, comprising a horizontal cylindrical evaporator body, wherein the upper wall in the middle of a cylindrical shell is fixedly provided with a gaseous refrigerant outlet pipe penetrating through the shell wall, a groove shape liquid baffle plate is fixedly arranged below the position of a gaseous refrigerant outlet pipe, and a backflow hole is arranged on a bottom plate of a groove. The inlet of the gaseous refrigerant outlet pipe is covered by the groove shape liquid baffle plate, the side wall of the groove shape liquid baffle plate is ought to be further provided with an inlet hole for a gaseous refrigerant and a liquid refrigerant or gas-liquid mixed refrigerant, and the inlet hole is round or oblong. The invention has the advantages of skillful design, simple and smooth structure and high practicability, by changing a simple flat panel into a semi-closed groove shape and by virtue of the gravity of liquid, the secondary separation of the gas-liquid mixture of the refrigerant is naturally realized in the groove shape liquid baffle plate, and the separated liquid refrigerant drips from the backflow hole at the bottom and evaporates again, therefore the liquid refrigerant is prevented from being sucked into a compressor.

Owner:广州联合冷热设备有限公司

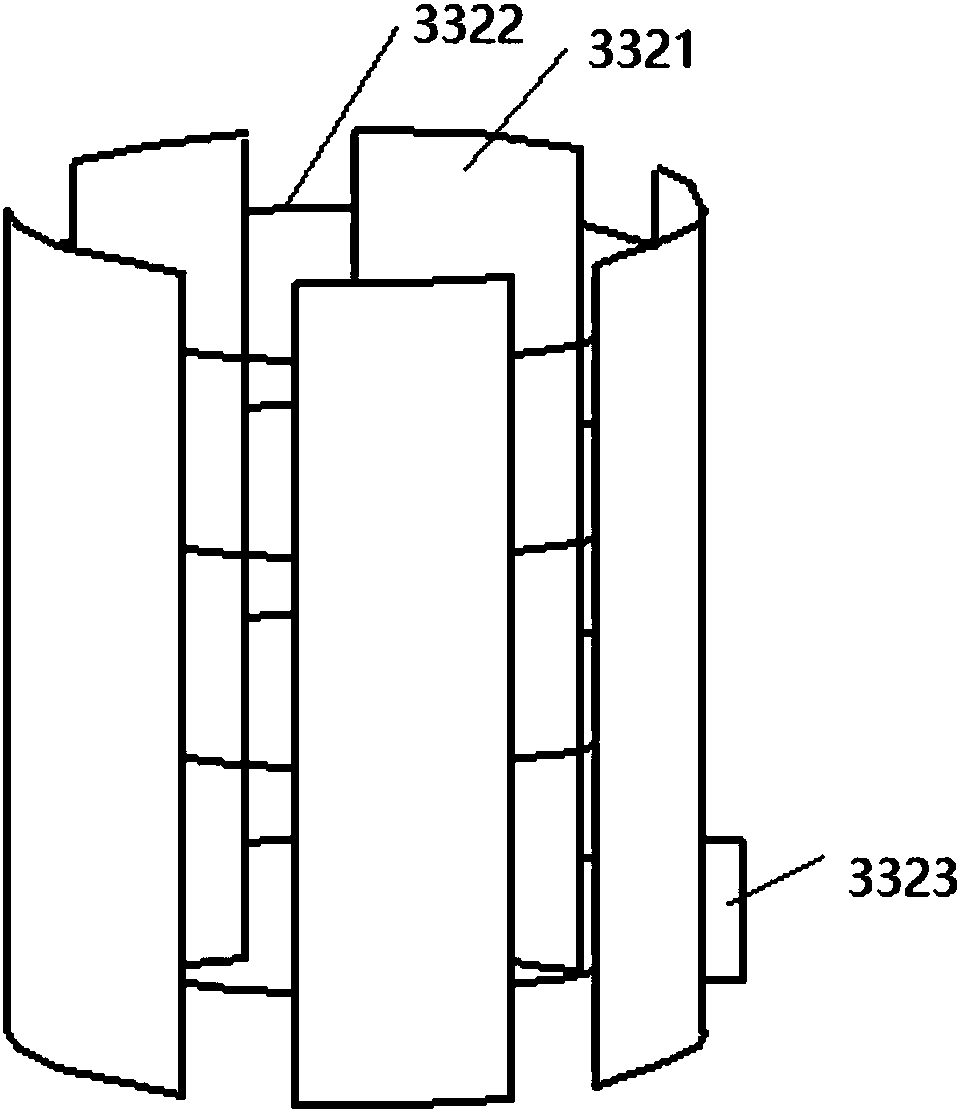

Corn threshing machine

The invention discloses a corn thresher, comprising: a frame; a threshing device, which is fixed horizontally on the frame; a feeding device, which is fixed above the The cylinder and the outer cylinder, the inner cylinder and the outer cylinder are provided with a first opening and a second opening that only allow one ear of corn to pass through vertically; the connecting column is vertically arranged at the bottom of the inner cylinder, and the connecting column is passed through the motor Drive the inner cylinder to rotate; the connecting passage includes a hollow cuboid section and a cylindrical section, one end of the hollow cuboid section is tangent to the lower part of the outer cylinder and communicates with the second opening; the cylindrical section communicates with the other end of the hollow cuboid section, and communicates with the hollow The two sides of the cuboid section are tangent, the lower end of the cylindrical section extends downwards to communicate with the threshing barrel, and the bottom of the cylindrical section is provided with a plurality of protrusions; the cylinder is arranged directly above the cylindrical section. The invention has the advantages of high applicability, good threshing effect, small threshing loss, high yield of corn kernels and the like.

Owner:蓝妙田

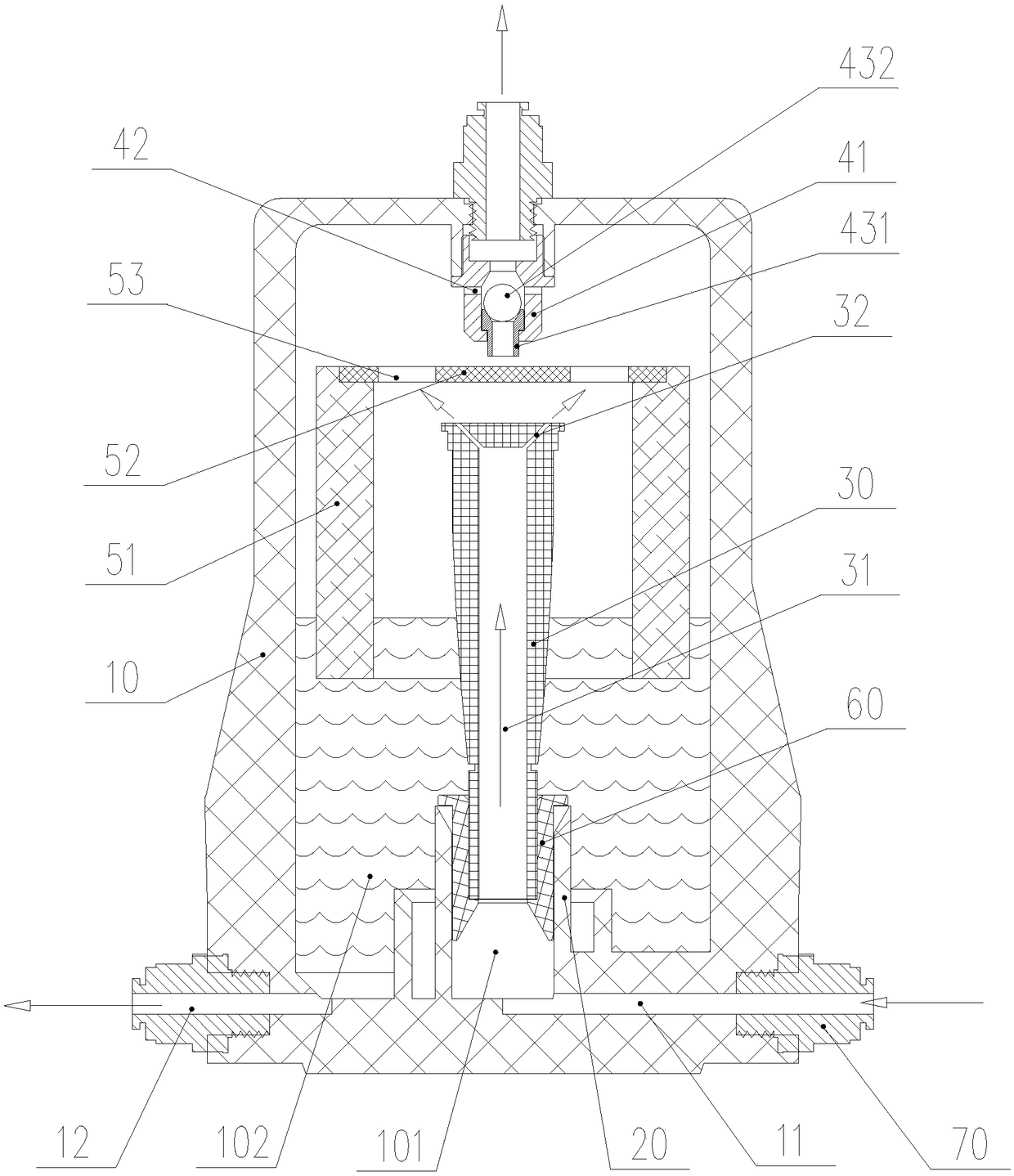

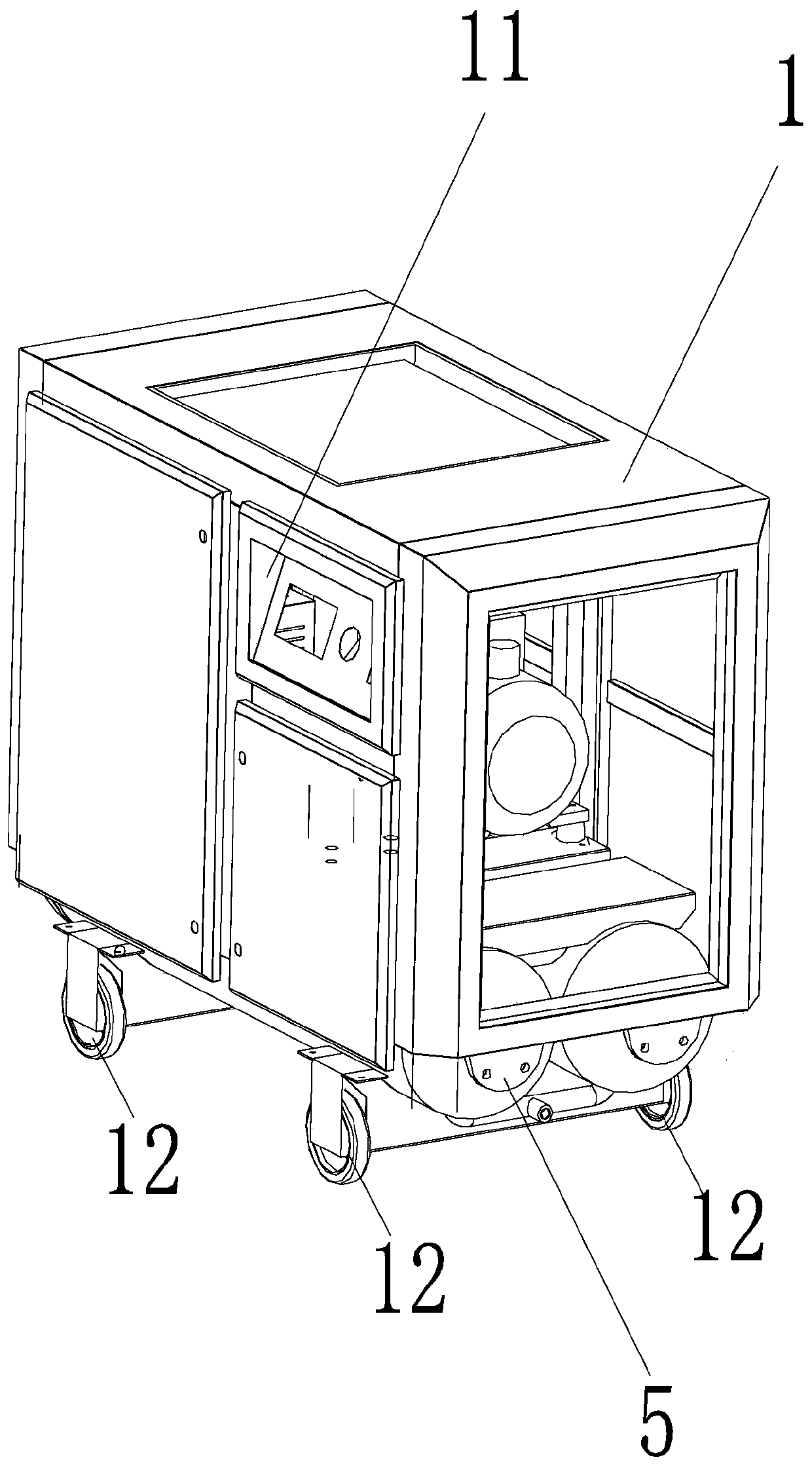

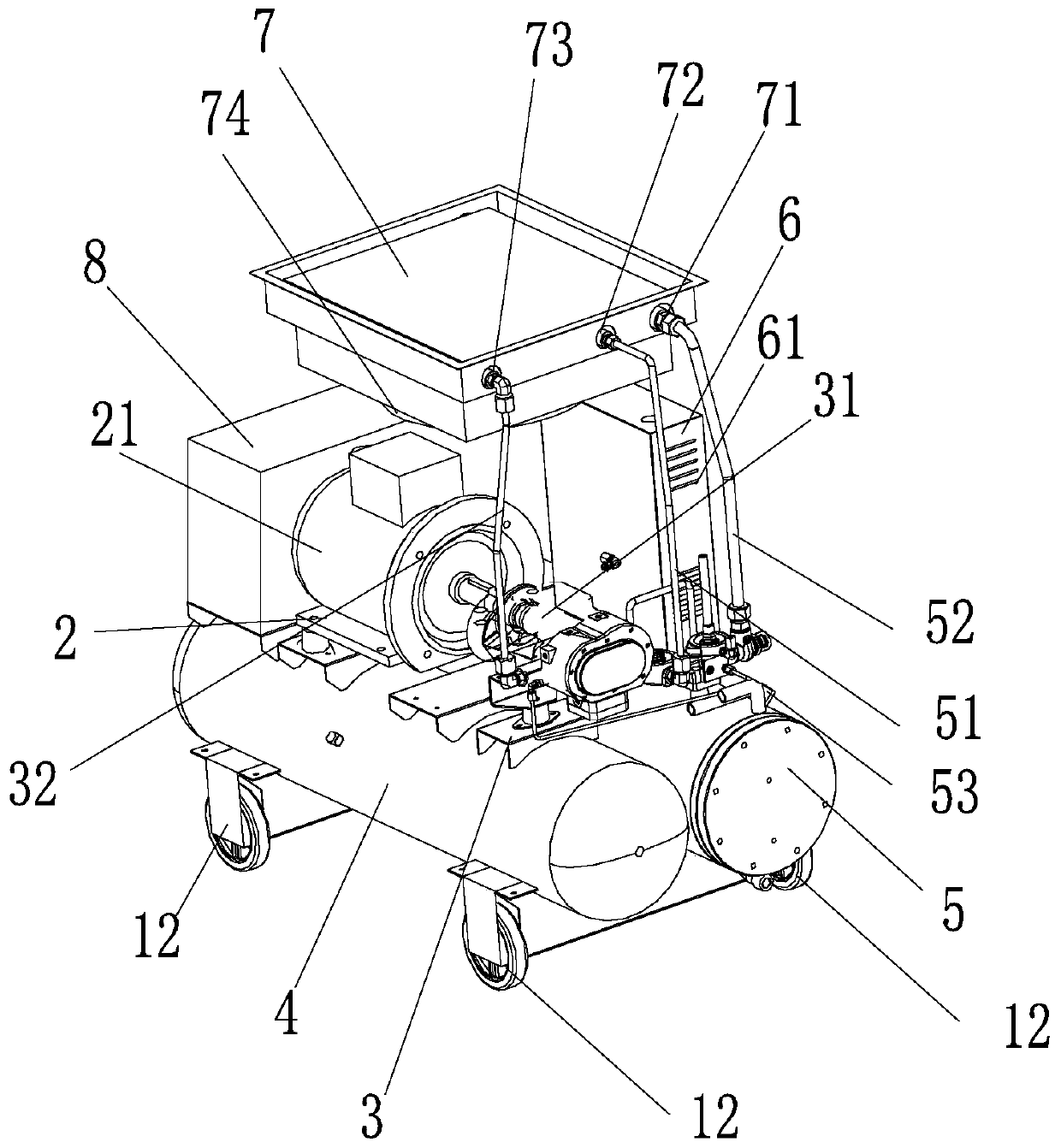

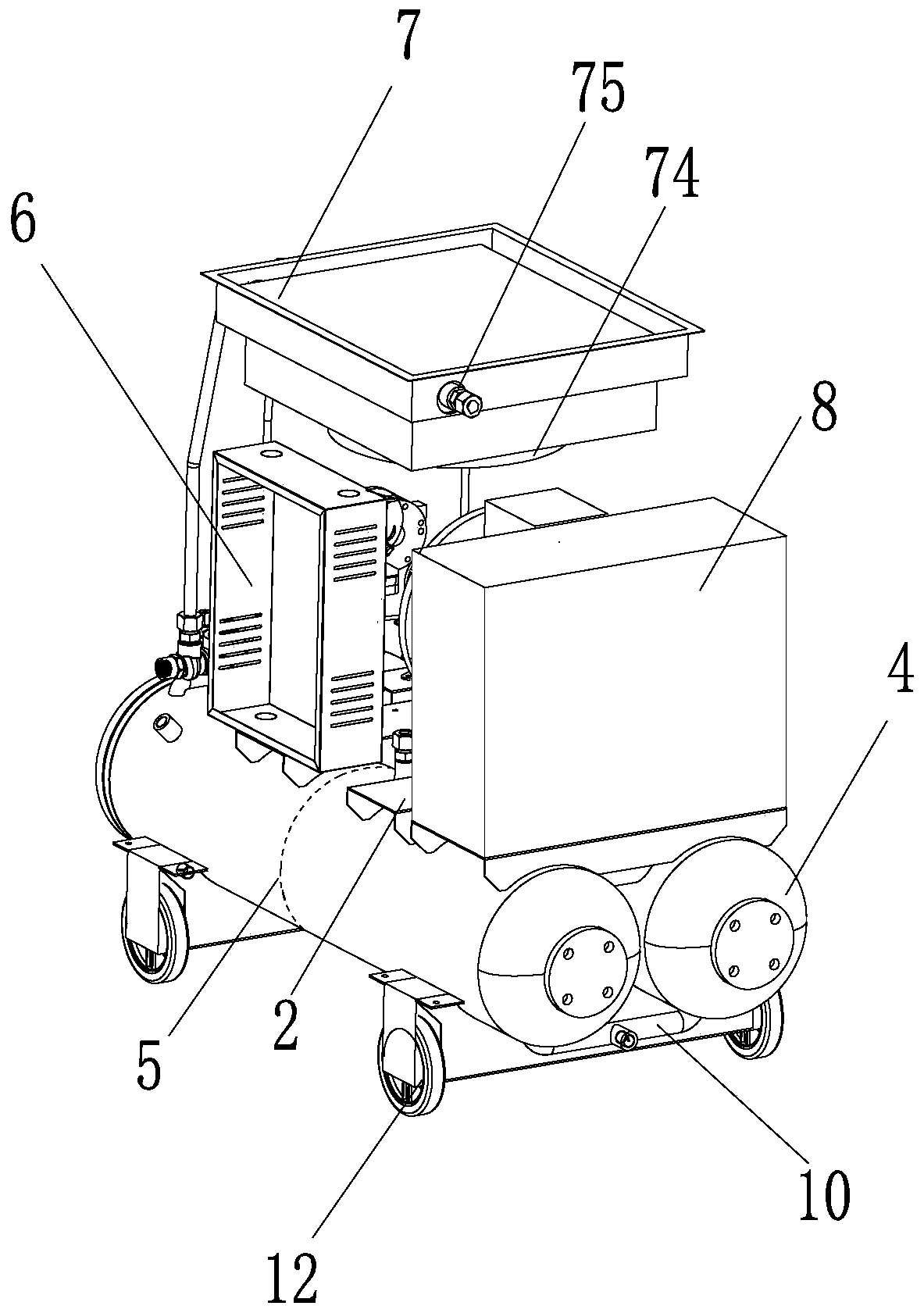

Compact oil-gas secondary separated air compressor

PendingCN109869313AImprove compression efficiencySmall footprintRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsAir compressionPermanent magnet motor

The invention relates to a compact oil-gas secondary separated air compressor. The compact oil-gas secondary separated air compressor comprises a machine frame, wherein a gas storage tank and an oil-gas separation barrel are arranged on the bottom end surface of the machine frame, a gas return pipe is arranged at the front end of the gas storage tank, two supporting plates are arranged on the upper surface of the gas storage tank and the oil-gas separation barrel, a permanent magnet motor and a cold dryer are arranged on the upper surfaces of the two supporting plates respectively, a bearing plate is arranged on the upper surface of the gas storage tank, a double-screw main machine is arranged on the upper surface of the bearing plate, an oil return pipe is arranged on the left side of thedouble-screw main machine, the output end of the permanent magnet motor is connected with the double-screw main machine, an electric control box is arranged above the oil-gas separation barrel, the upper surface of the oil-gas separation barrel is provided with an air outlet pipe and an oil outlet pipe, the upper surface of the oil-gas separation barrel is also provided with a cooling device, andthe right side wall of the cooling device is sequentially provided with an oil return pipe opening, an air inlet pipe opening and an oil inlet pipe opening from left to right. The structure is smallin occupied area, space resources are saved, and movement can be realized; and heat can be dissipated through heat dissipation holes, and the gas storage tank is combined with the oil-gas separation barrel, so that secondary separation is realized, and the air compression efficiency is improved.

Owner:江西智奇压缩机有限公司

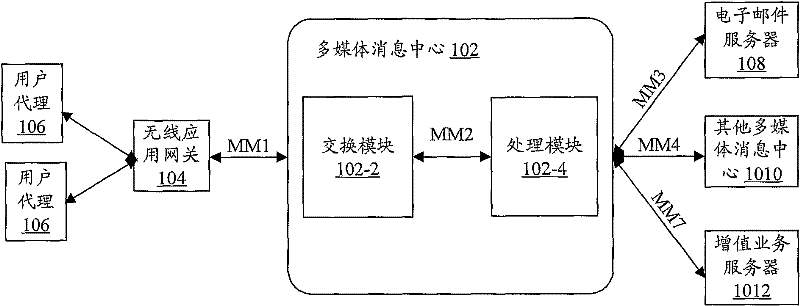

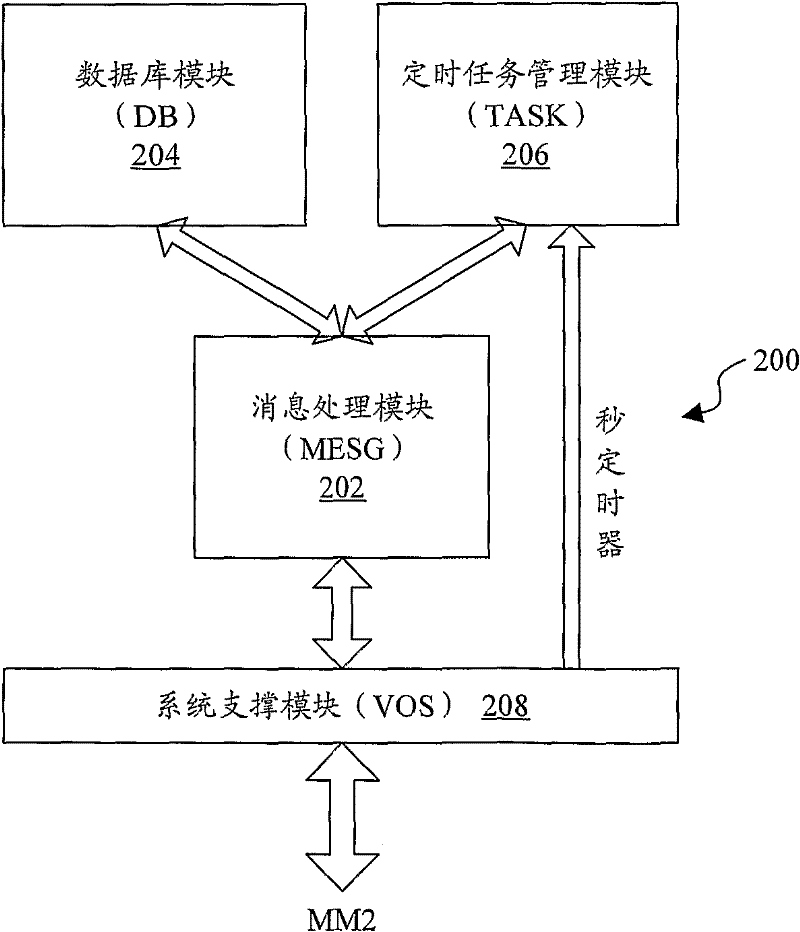

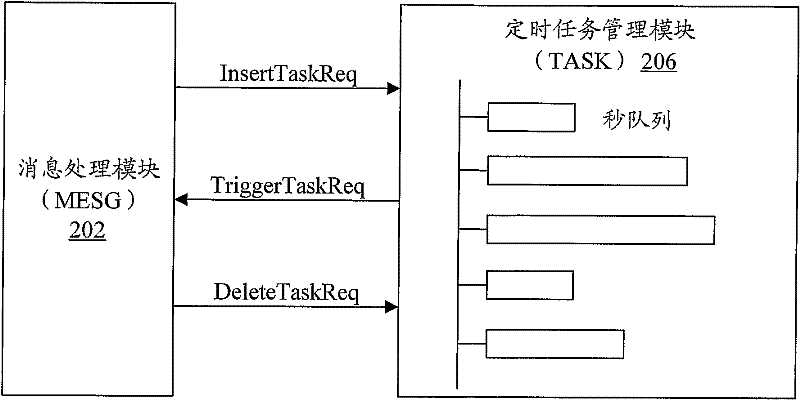

System and method for processing multimedia information timing task

InactiveCN101467406BAchieve secondary separationConvenient and flexible function expansionData switching networksProcess moduleMessage processing

A system and a method for processing timing task of multimedia message are disclosed. The multimedia message timing task processing system includes: a message processing module for receiving signaling and calling a database module interface and timing task management module interface to complete the process of message; a database module for storing control message, generating control information and returning it to the message process module; a timing task management module for storing and triggering the timing task information; wherein, the message process module extracts the timing task information from the control information and stores in the timing task management module, the timing task management module triggers the message process module according to given time to process the timing task. The system and method can manage the multimedia message timing task completely, and process the timing task with high efficiency and instantaneity.

Owner:ZTE CORP

Safety tank on oil outlet pipe of oil well oil pouring tank

InactiveCN103935949APrevent dissipationAvoid fire hazardLiquid transferring devicesOil wellNatural gas

The invention relates to a safety tank on an oil outlet pipe of an oil well oil pouring tank. A tank body of the safety tank is divided into a left tank body area and a right tank body area through an interlayer, and a crude oil flowing gap is reserved in the lower end of the interlayer; the upper portion of one tank body area is sequentially provided with an oil inlet pipe and an exhaust pipe from the interlayer to the outside, the other end of the exhaust pipe is inserted into a chimney of the oil well oil pouring tank, the oil inlet pipe is in threaded connection with the oil outlet pipe of the oil well oil pouring tank, electric stirring blades are arranged in the oil inlet pipe, the lower portion of a pipe orifice, in the tank body, of the oil outlet pipe is provided with a guide plate arranged obliquely, and the bottom of the other tank body area is provided with an oil outlet pipe connected with an oil inlet pipe of an oil pouring tank vehicle oil tank. The safety tank is arranged between the oil well oil pouring tank and the oil pouring tank vehicle oil tank, natural gas in crude oil can be separated in a two-stage mode, the separated natural gas is exhausted into the multi-functional tank chimney as soon as possible and effectively prevented from dispersing, possible fire danger in the oil pouring process is avoided, and the oil pouring tank is simple in structure, high in operability, safe, reliable and convenient to popularize and use.

Owner:无棣华信石油技术服务有限公司

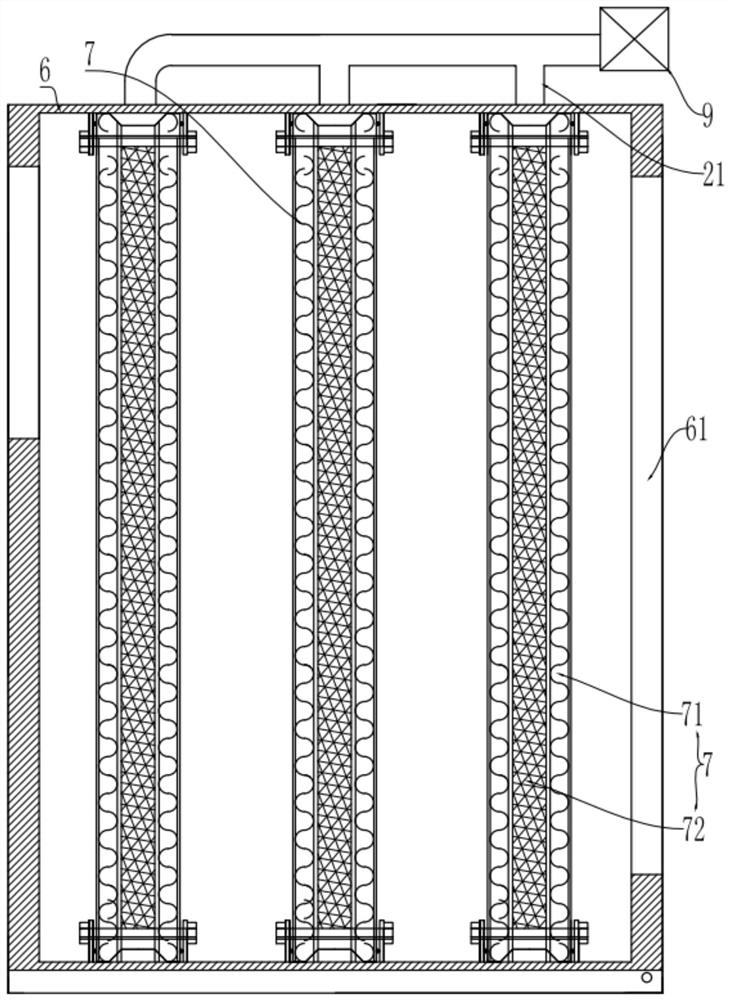

Environment-friendly dust removal equipment

InactiveCN113398701AEasy to useRealize secondary filtrationHuman health protectionCombination devicesDust controlEnvironmental engineering

The invention discloses environment-friendly dust removal equipment which comprises a base, a dust collecting mechanism, a first circulating water tank, a second circulating water tank, a first dust removal box, a second dust removal box and a spraying mechanism, a filler assembly is arranged in the first dust removal box, the second dust removal box is arranged on the second circulating water tank, and a dust-gas separation mechanism is arranged in the second dust removal box; and the second dust removal box is provided with a second leaching assembly above the dust-gas separation mechanism, and the spraying mechanism is fixed above the second dust removal box and communicates with the dust-gas separation mechanism. The environment-friendly dust removing equipment is used for removing dust existing in a factory workshop, the dust is absorbed by a workbench or a dust area through the dust collecting mechanism, firstly, the dust is adsorbed and filtered through the filler assembly, the dust-gas separation mechanism can achieve secondary filtering of residual dust in air, and the dust-gas separation mechanism can achieve secondary filtering of the residual dust in the air; and then the clean air is subjected to spraying treatment through the spraying mechanism, spraying and dust falling can be further conducted on dust in a factory workshop, and the dust problem can be effectively solved.

Owner:蚌埠科睿达机械设计有限公司

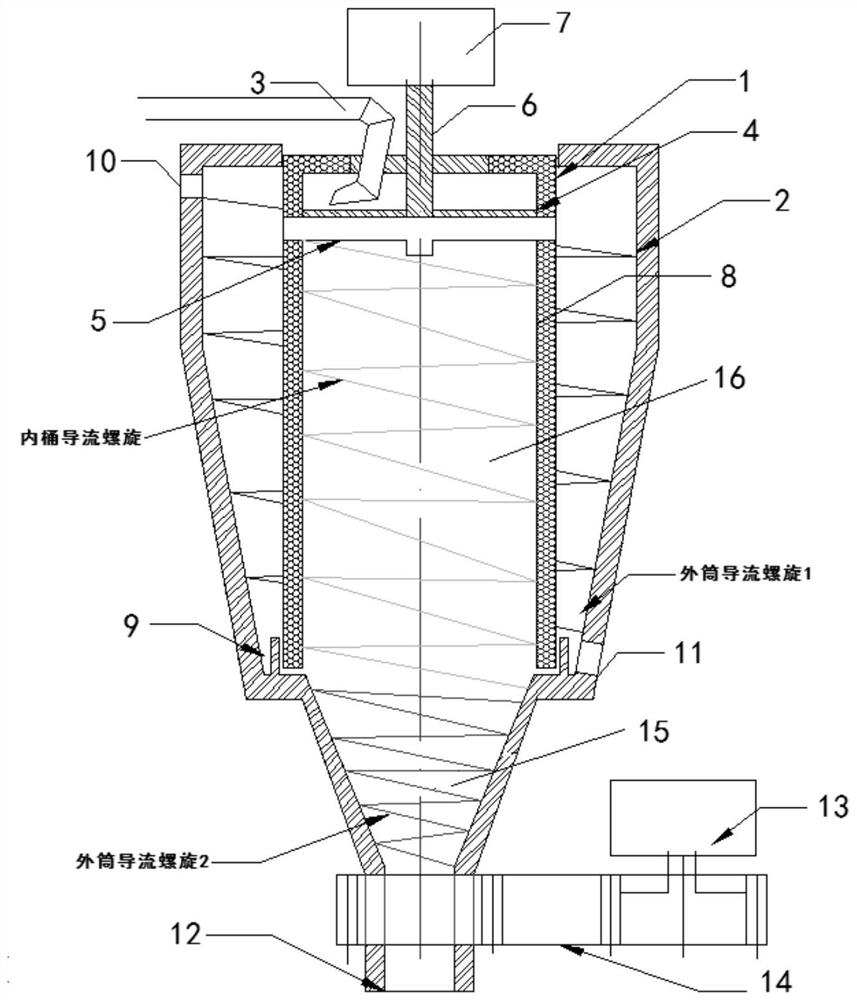

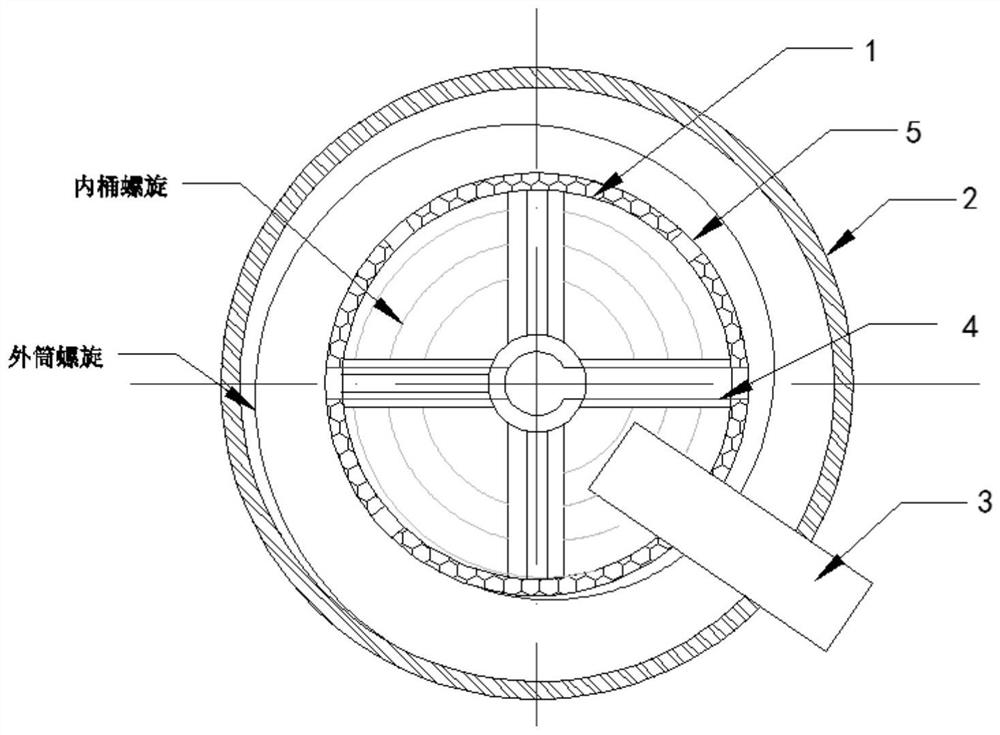

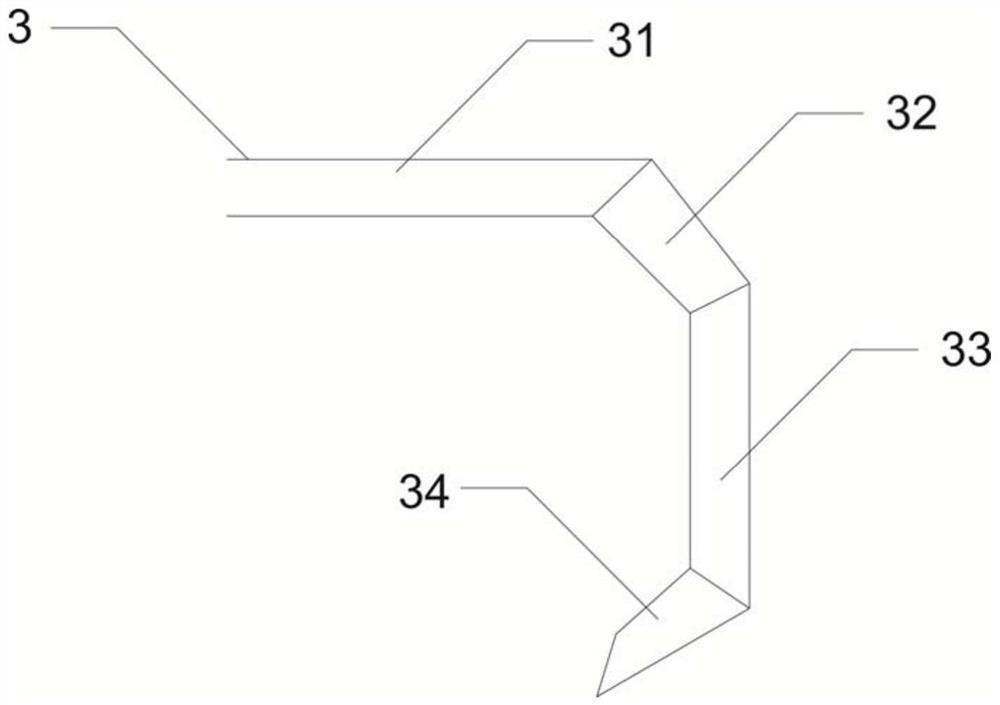

Multi-stage centrifugal concentration treatment device for waste slurry and use method thereof

ActiveCN113351379AAchieving primary separationAchieve secondary separationSludge treatmentReversed direction vortexElectric machineDrive shaft

The invention discloses a multi-stage centrifugal concentration treatment device for waste slurry and a use method thereof. The device comprises an inner barrel and an outer barrel, the inner barrel is located in the outer barrel, a connecting rod is arranged on the upper portion of the inner barrel, the connecting rod is connected with a transmission shaft of a first rotating motor, a feeding mechanism is arranged on the top of the inner barrel, an inner barrel rotational flow outlet is formed in the upper portion of the inner barrel, a barrel body of the inner barrel is of a mesh structure, the outer barrel comprises an outer barrel upper portion, an outer barrel middle portion and an outer barrel lower portion, the outer barrel upper portion is provided with a clear water outlet, the outer barrel middle portion is provided with a waste slurry outlet, the outer barrel lower portion is provided with a waste slurry residue outlet, and the outer barrel is connected with a second rotating motor through a transmission device. The device has the characteristics of small occupied area, low cost, low energy consumption, high solid-liquid separation efficiency and easy operation in a use process; and according to the device, multi-stage separation of the waste slurry can be realized, different waste slurry products are obtained, high-efficiency and high-quality separation of the waste slurry is realized, and the disposal level, the utilization rate and the added value of the waste slurry are improved.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com