Anti-gravity three-phase separator

A three-phase separator and anti-gravity technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of easily damaged graphite and diamond, poor environment, and poor separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

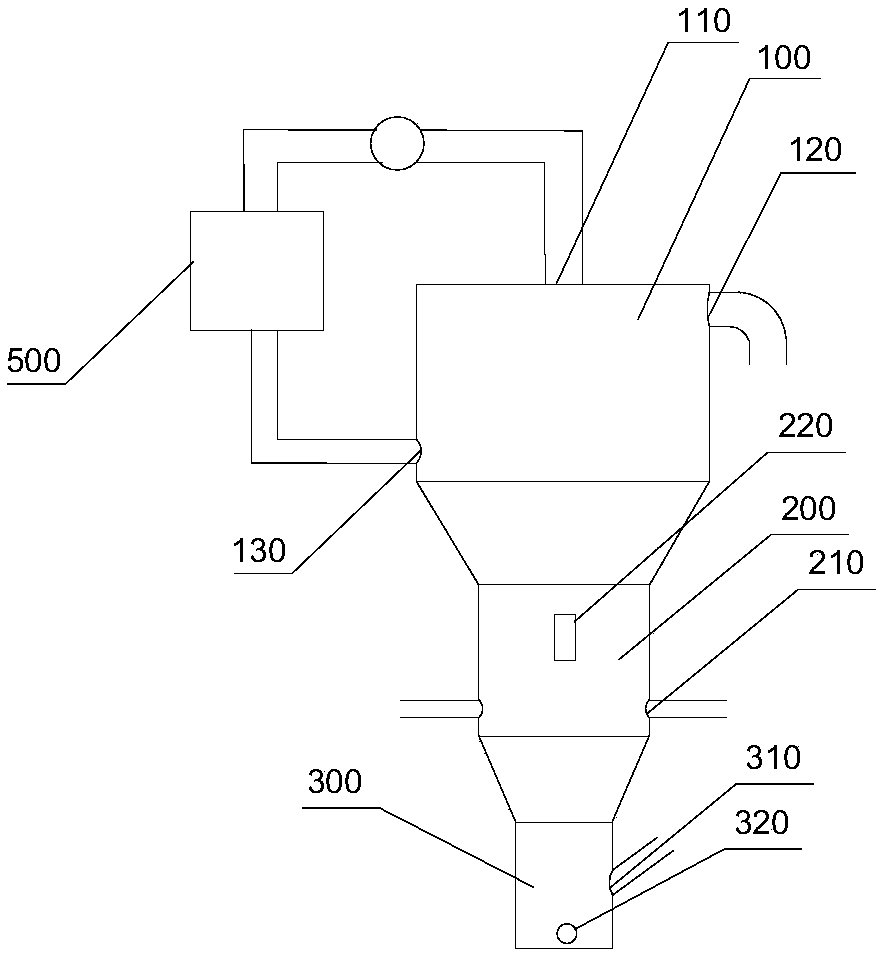

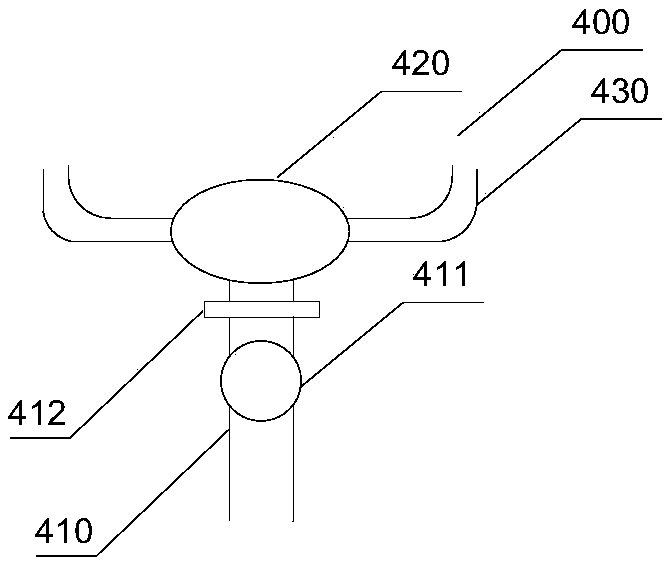

[0020] combine figure 1 and figure 2 , which describes a specific embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

[0021] Such as figure 1 and figure 2 As shown, a kind of anti-gravity three-phase separator, from top to bottom successively comprises upper section separation column 100, middle section separation column 200 and lower section separation column 300, described upper section separation column 100 and middle section separation column 200, middle section separation column 200 and The lower separation column 300 is connected by a conical hopper, the axes of the upper separation column 100, the middle separation column 200 and the lower separation column 300 are coincident, the diameter of the upper separation column 100 is larger than that of the middle separation column 200, and the diameter of the middle separation column 200 is larger than that of the lower separation column. Column 300; the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com