Patents

Literature

52 results about "Chemical separation method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

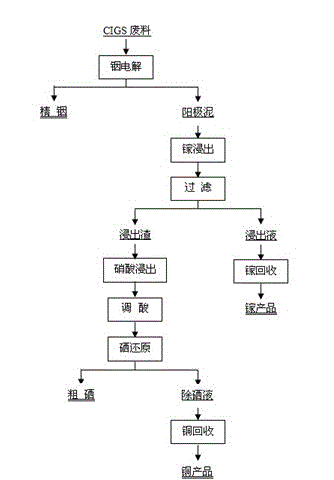

Method for recovering copper, indium, gallium and selenium

ActiveCN104018186ASimple methodEasy to recyclePhotography auxillary processesProcess efficiency improvementMaterials preparationIndium

The invention provides a method for recovering copper, indium, gallium and selenium. The method comprises the following steps of: recovering the indium by carrying out electrolysis by taking a CIGS (Copper Indium Gallium Selenium) waste material as an anode; recovering the gallium by leaching precipitates, namely anode mud and the like, and electrodepositing leach liquor; respectively recovering the selenium and the copper by pickling leached residues, regulating alkali into acid and then respectively adding reducing agents. The method provided by the invention is simple. According to the method, the recovered indium, copper and gallium can be recycled in CIGS target material preparation. The method provided by the invention can be used for respectively separating and recovering gallium, copper and selenium by carrying out the electrolysis by using the CIGS waste material as the anode, directly electrodepositing indium and then using a conventional chemical separation method, thereby being an excellent method capable of extremely easily and efficiently recovering the high-purity indium and gallium. In industrial production, the recovery rate of indium is more than 99%, the grade of refined indium achieves 99.995%, the recovery rate of copper achieves 98.8%, the recovery rate of gallium is more than 98.5%, and the recovery rate of selenium achieves 98%.

Owner:ZHUZHOU SMELTER GRP

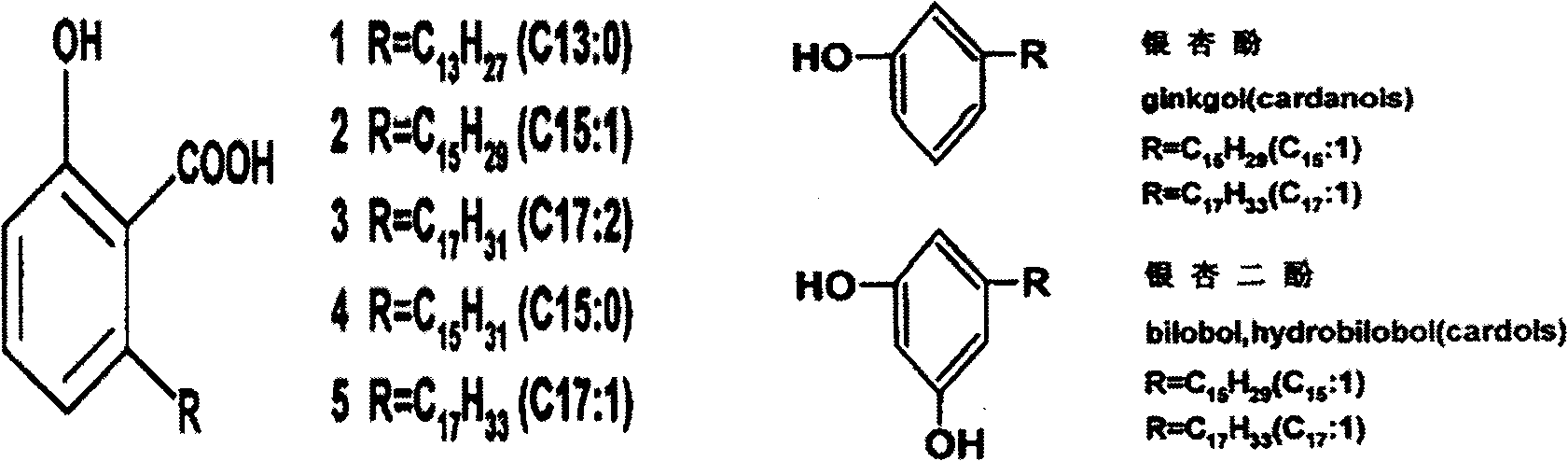

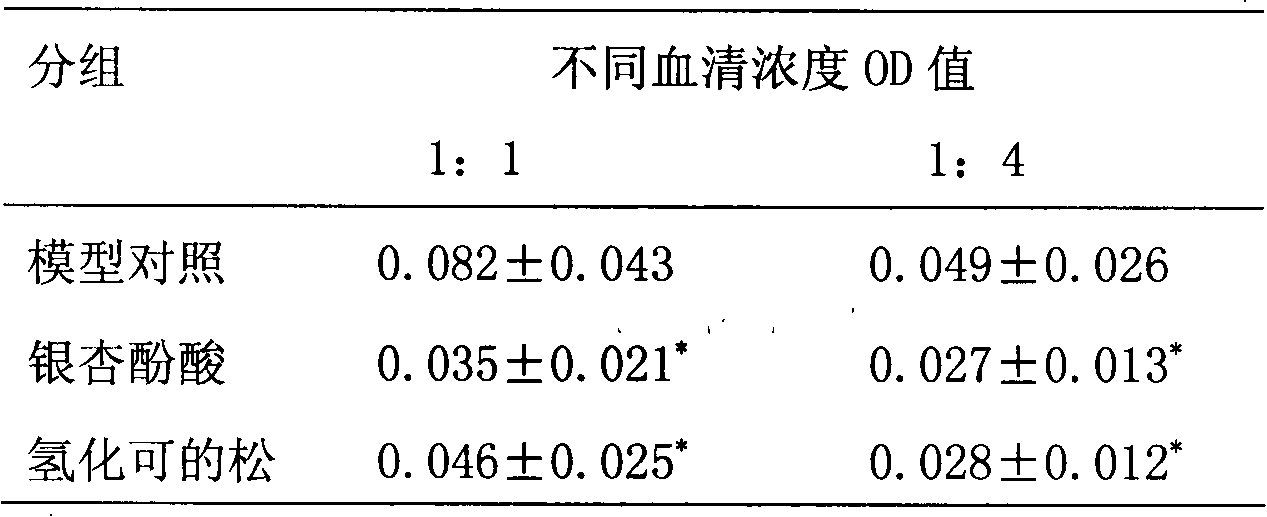

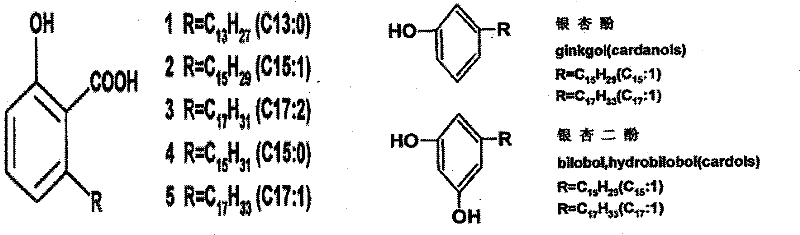

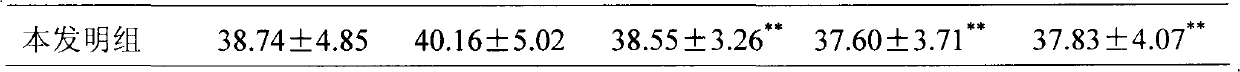

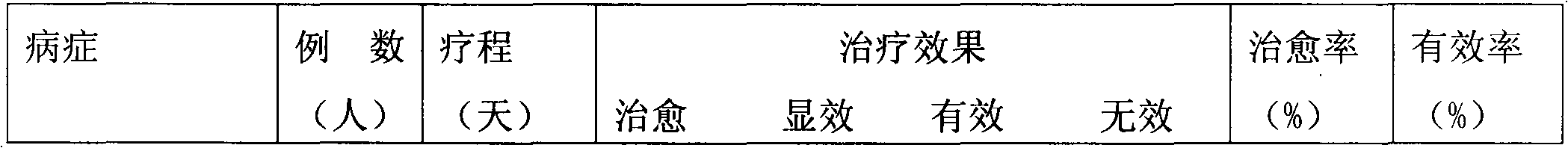

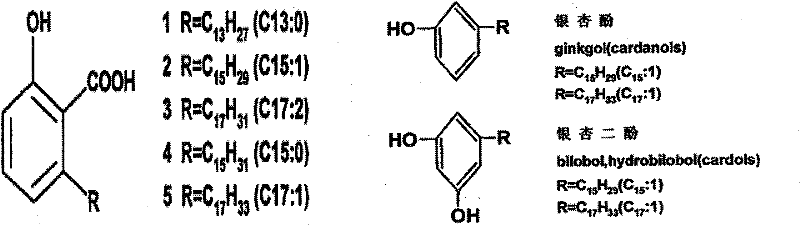

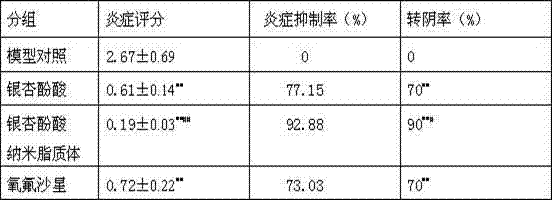

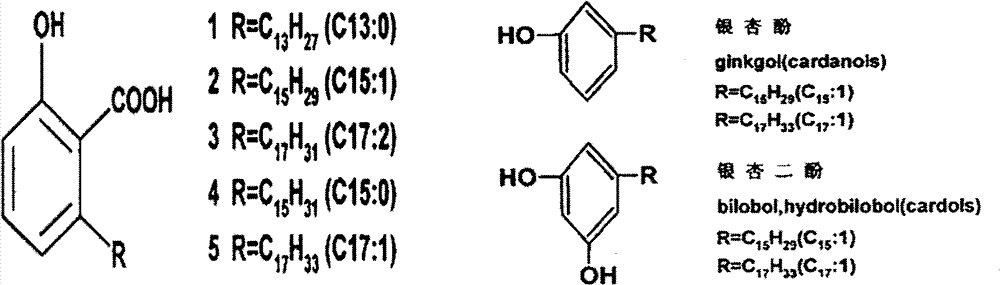

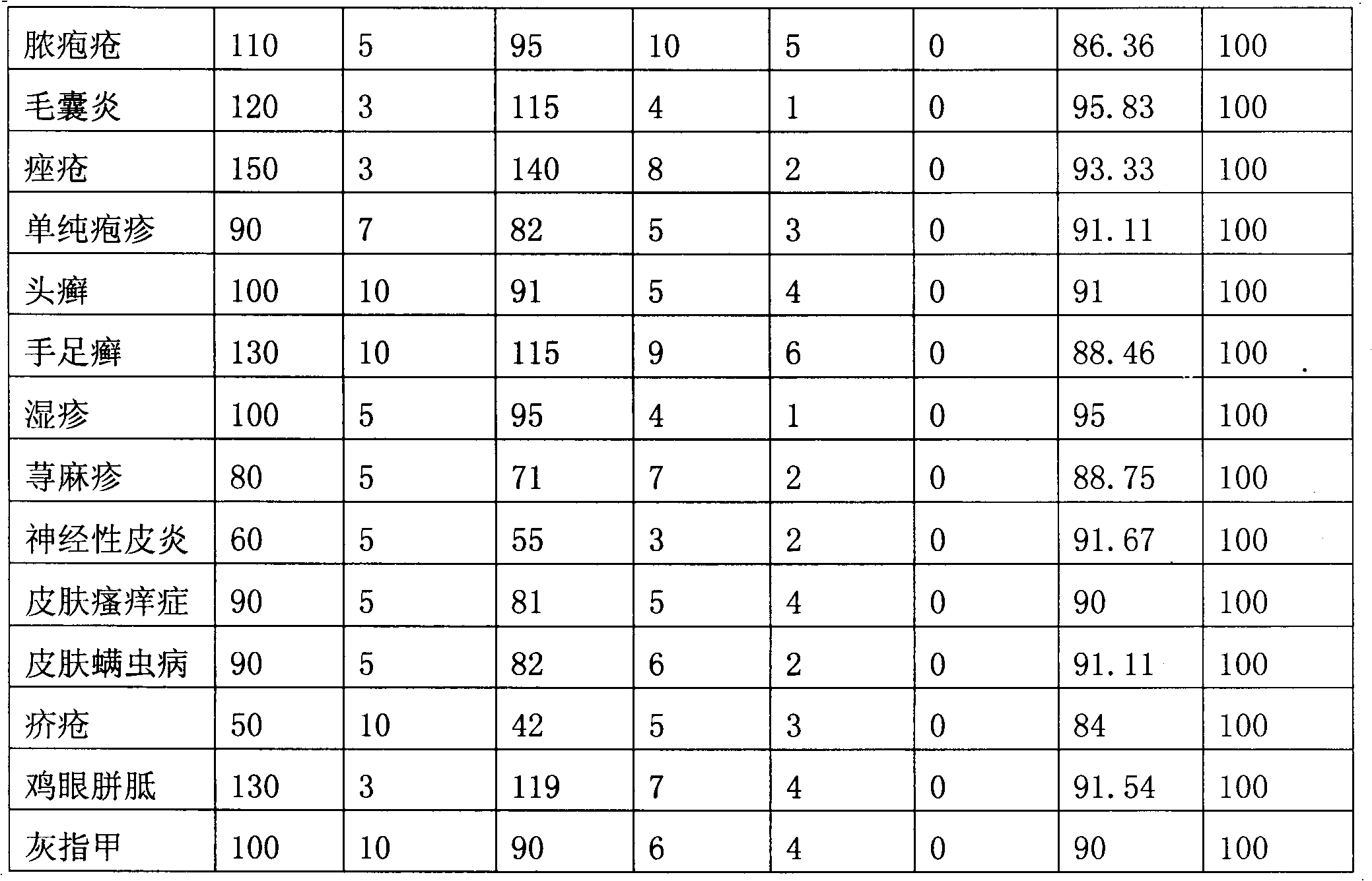

Application of ginkgolic acid in preparation of external preparation for treating dermatopathy

ActiveCN102319272ASignificant effectNo adverse reactionAntimycoticsAntipyreticSide effectDisinfectant

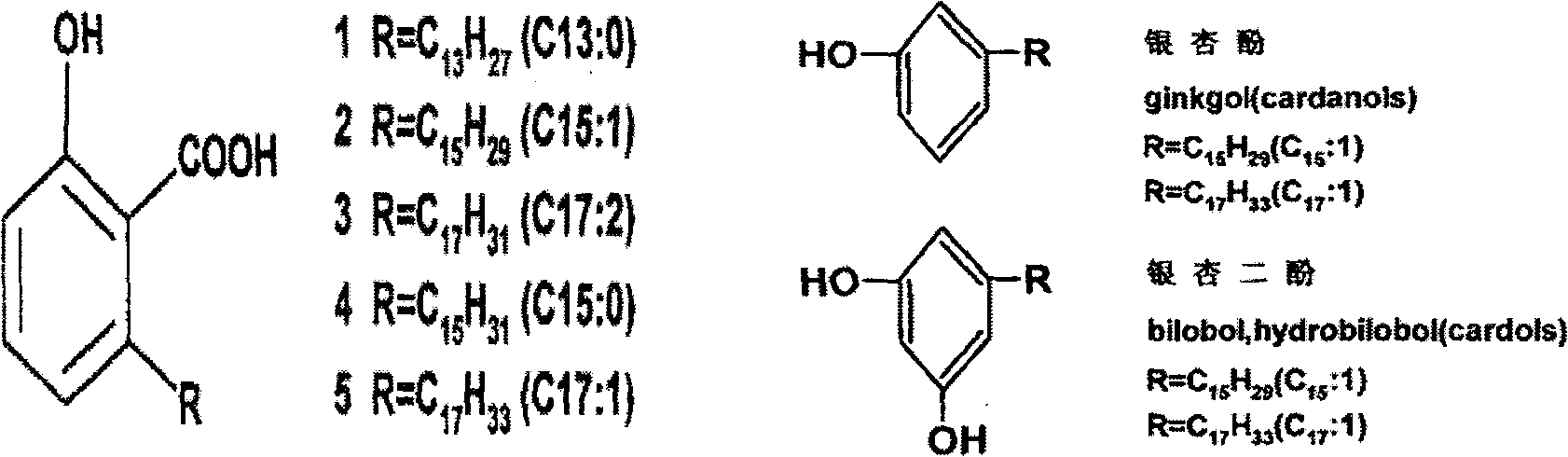

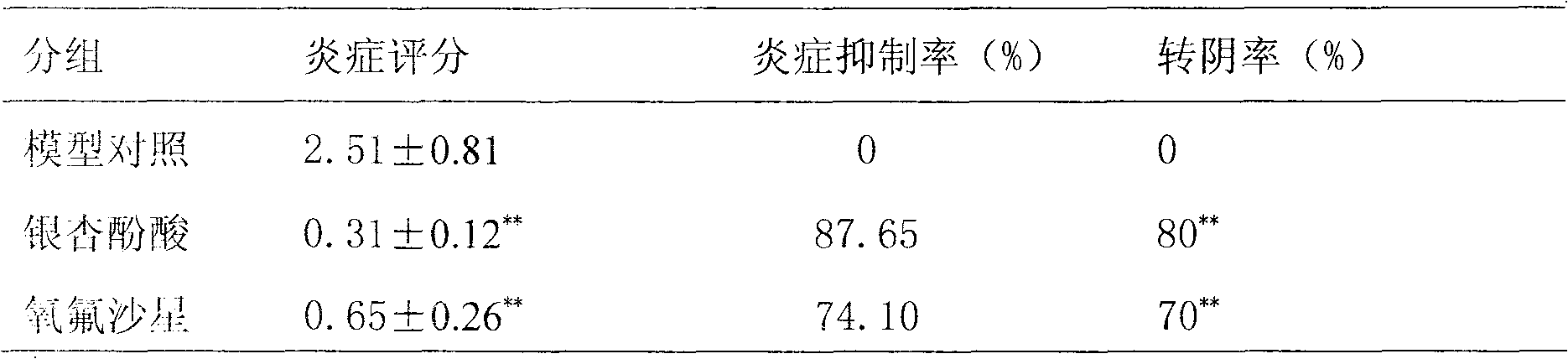

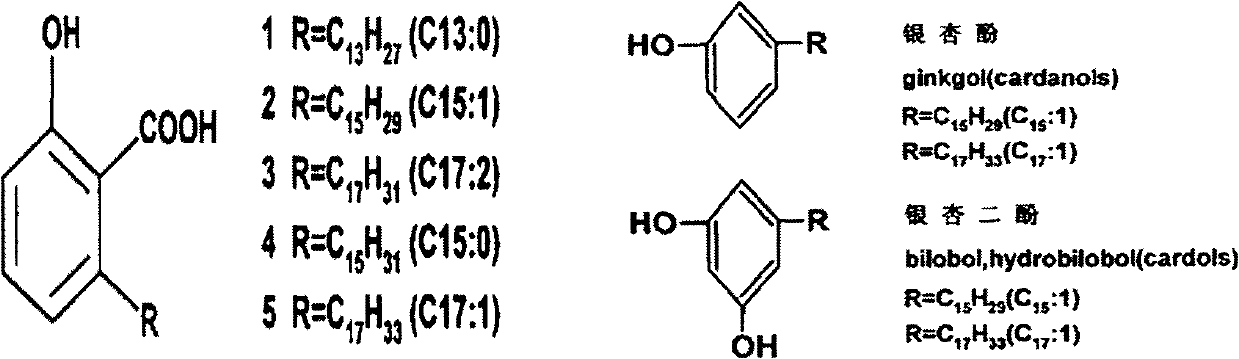

The invention relates to an application of ginkgolic acid in preparation of an external preparation for treating dermatopathy. The ginkgolic acid comprises ginkgoic acid, ginkgol, ginkgo diphenol, and the like, and can be obtained from extracts of leaves, fruit, exopleura, and rhizome of ginkgo by a chemical separation method. The dermatopathy is infectious, inflammatory, allergic or anaphylactic dermatopathy. External preparations of ginkgolic acid-containing medicaments, cosmetics, or disinfectants for treating dermatopathy comprises 0.001-80% (by weight) of ginkgolic acid, and pharmaceutically common external preparation substrates or acceptable carriers; the preparation has any pharmaceutical dosage form. Pharmacological experimental research shows that the preparation of the invention has significant effect of anti-infection of skin resident pathogens, anti-inflammation, antianaphylaxis, anti-allergy, analgesia, itching relief, and wound heal promotion. Clinical trials show that the preparation of the invention has significant treatment effect on various dermatopathy, has an effective rate of up to 100%, is safe and has no side effect.

Owner:王青

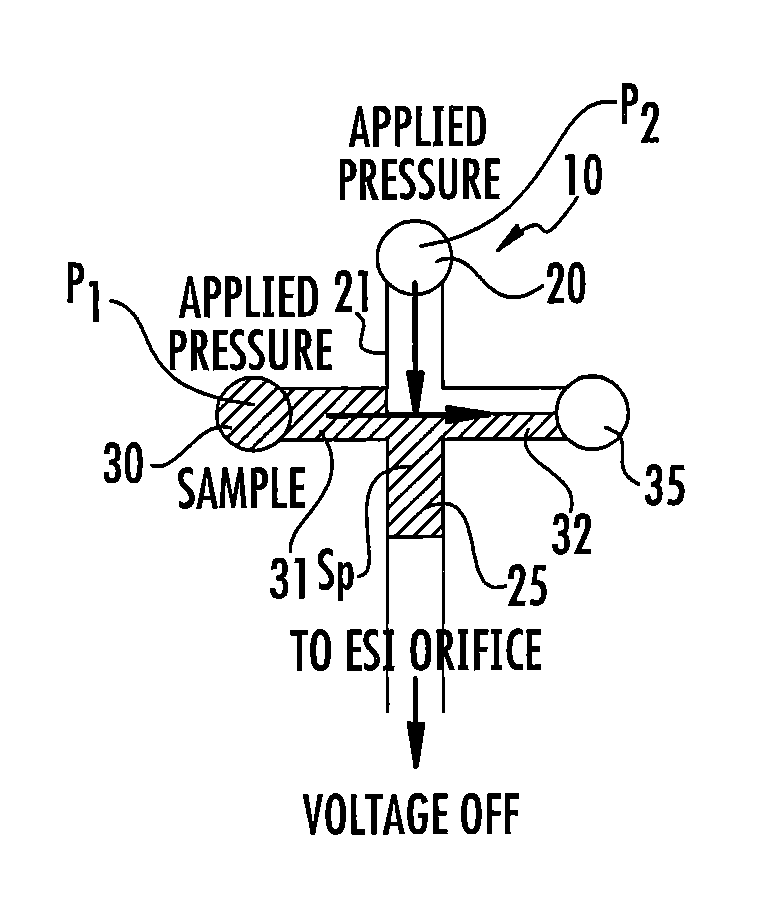

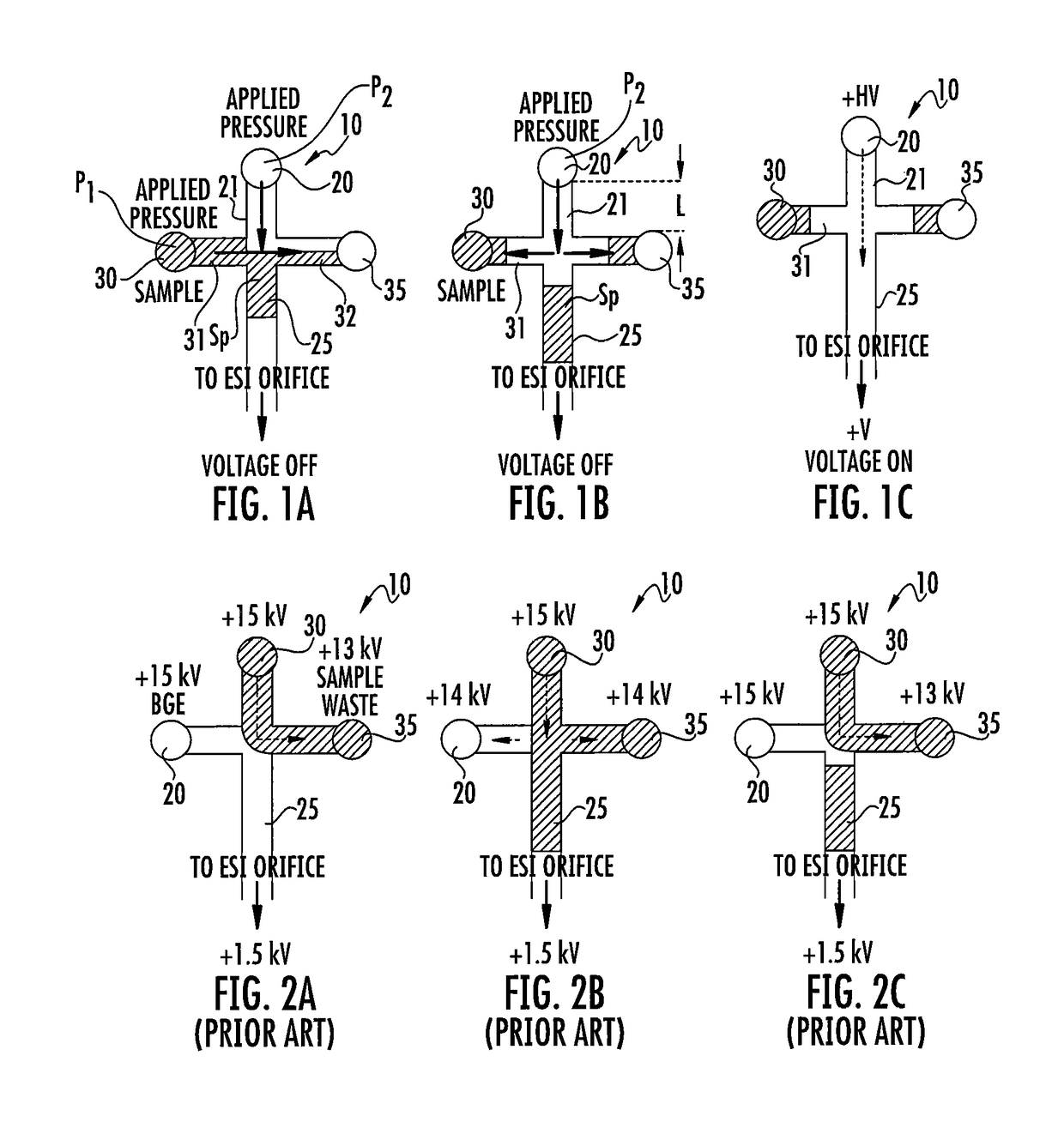

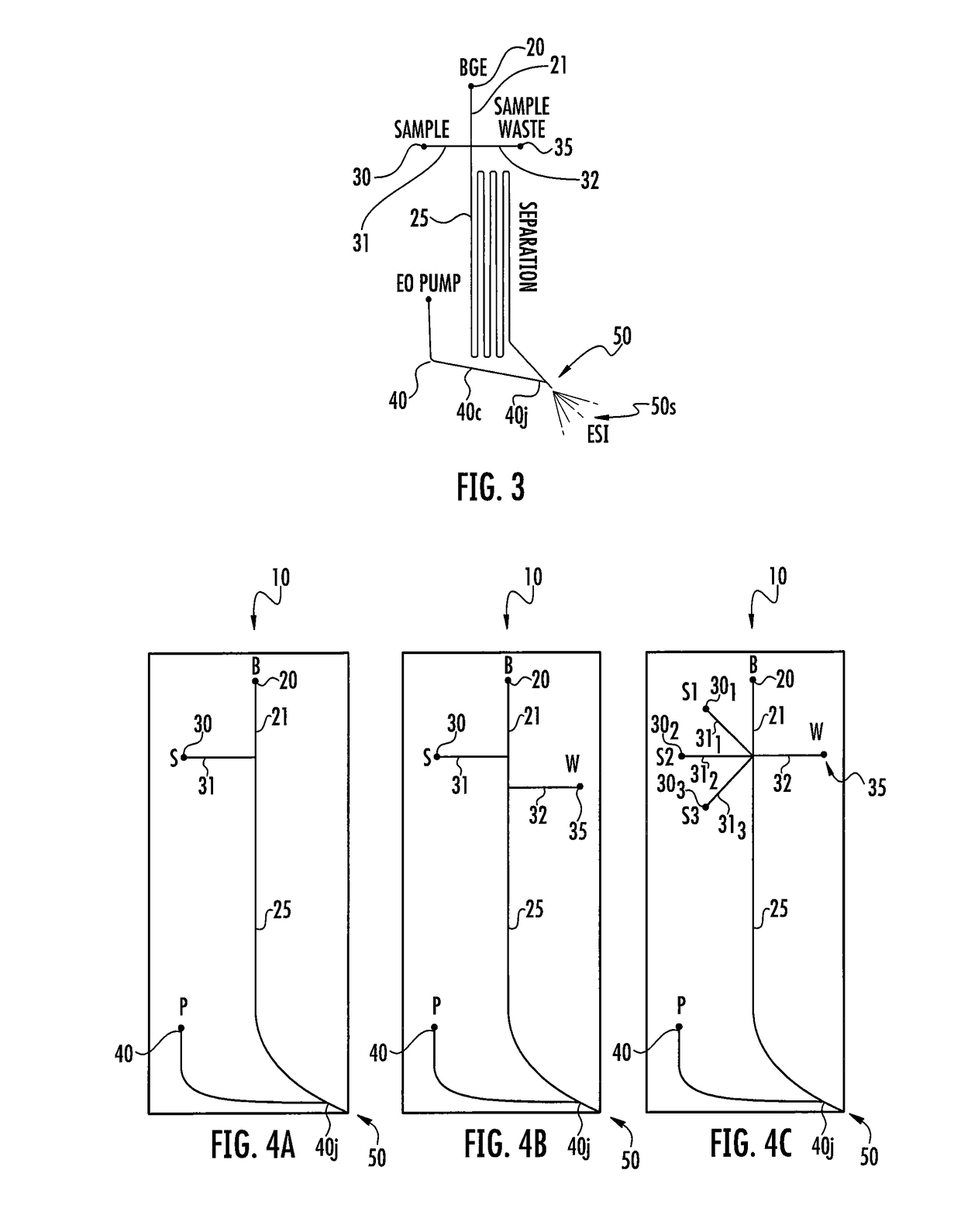

Pressure driven microfluidic injection for chemical separations

ActiveUS9606082B2Accurate volumeComponent separationMaterial analysis by electric/magnetic meansPressure.driveEngineering

Methods that allow independently applied pressures to a BGE reservoir and a sample reservoir for pressure-driven injection that can inject a discrete sample plug into a separation channel that does not require voltage applied to the sample reservoir and can allow for in-channel focusing methods to be used. The methods are particularly suitable for use with a mass spectrometer.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

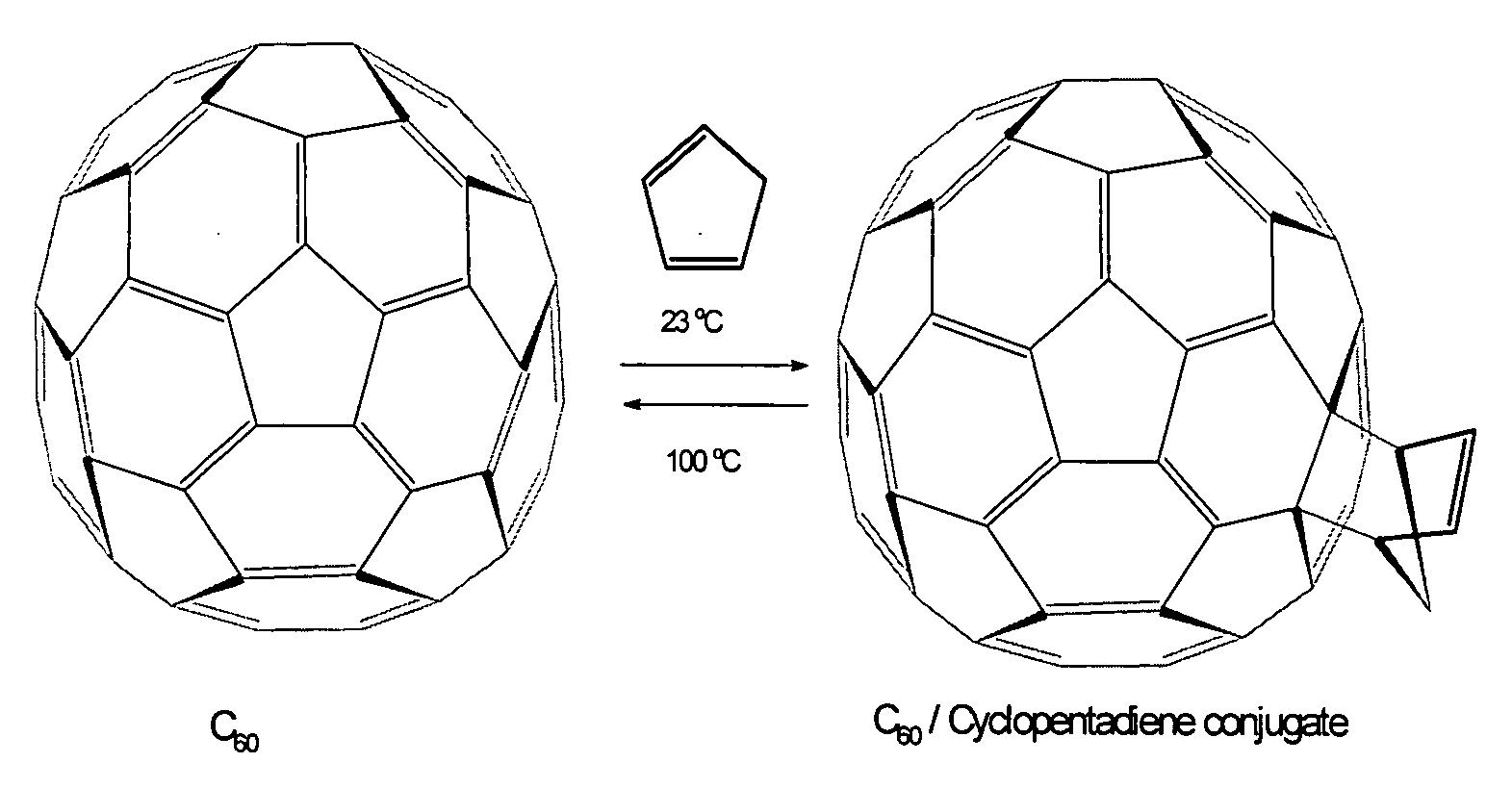

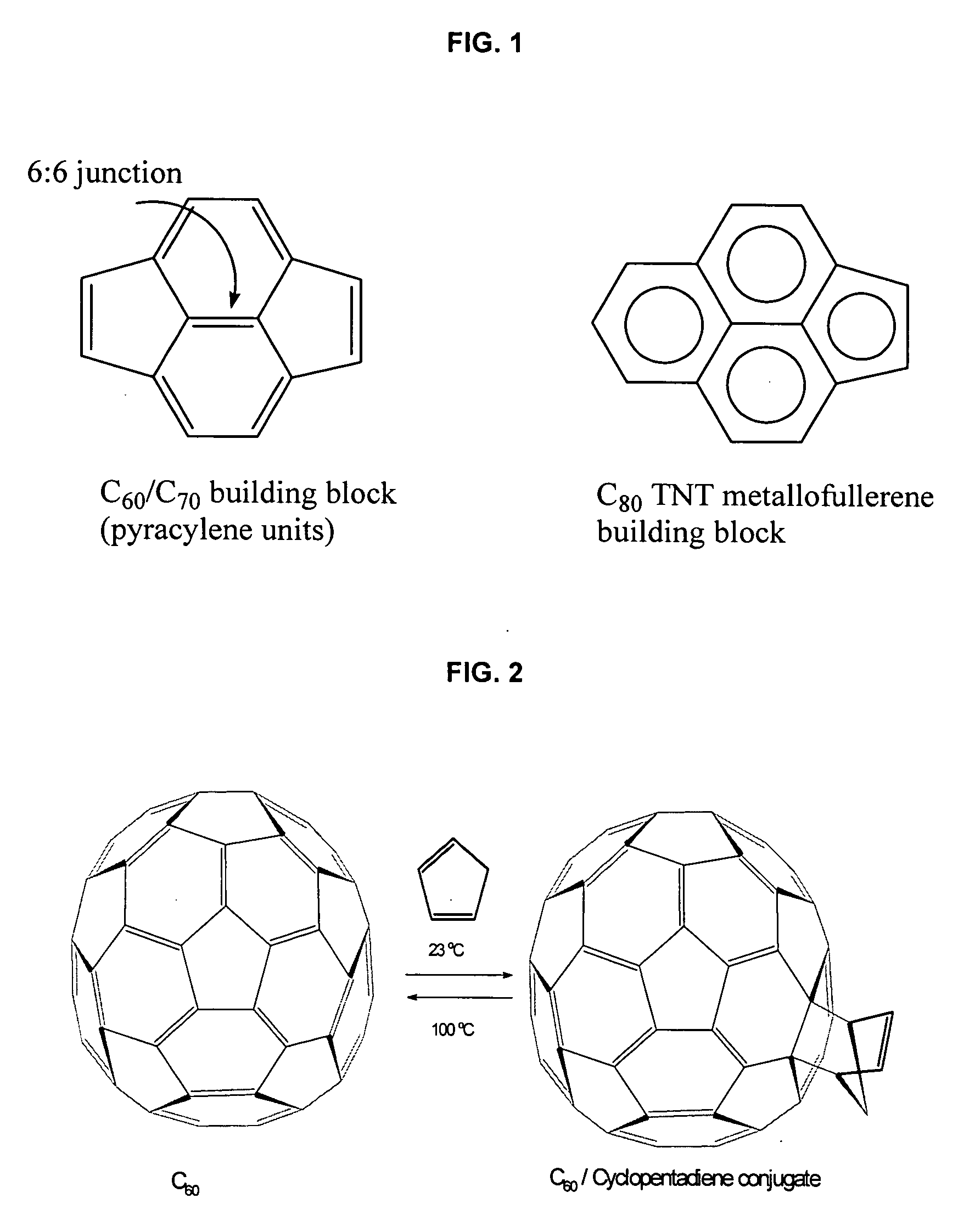

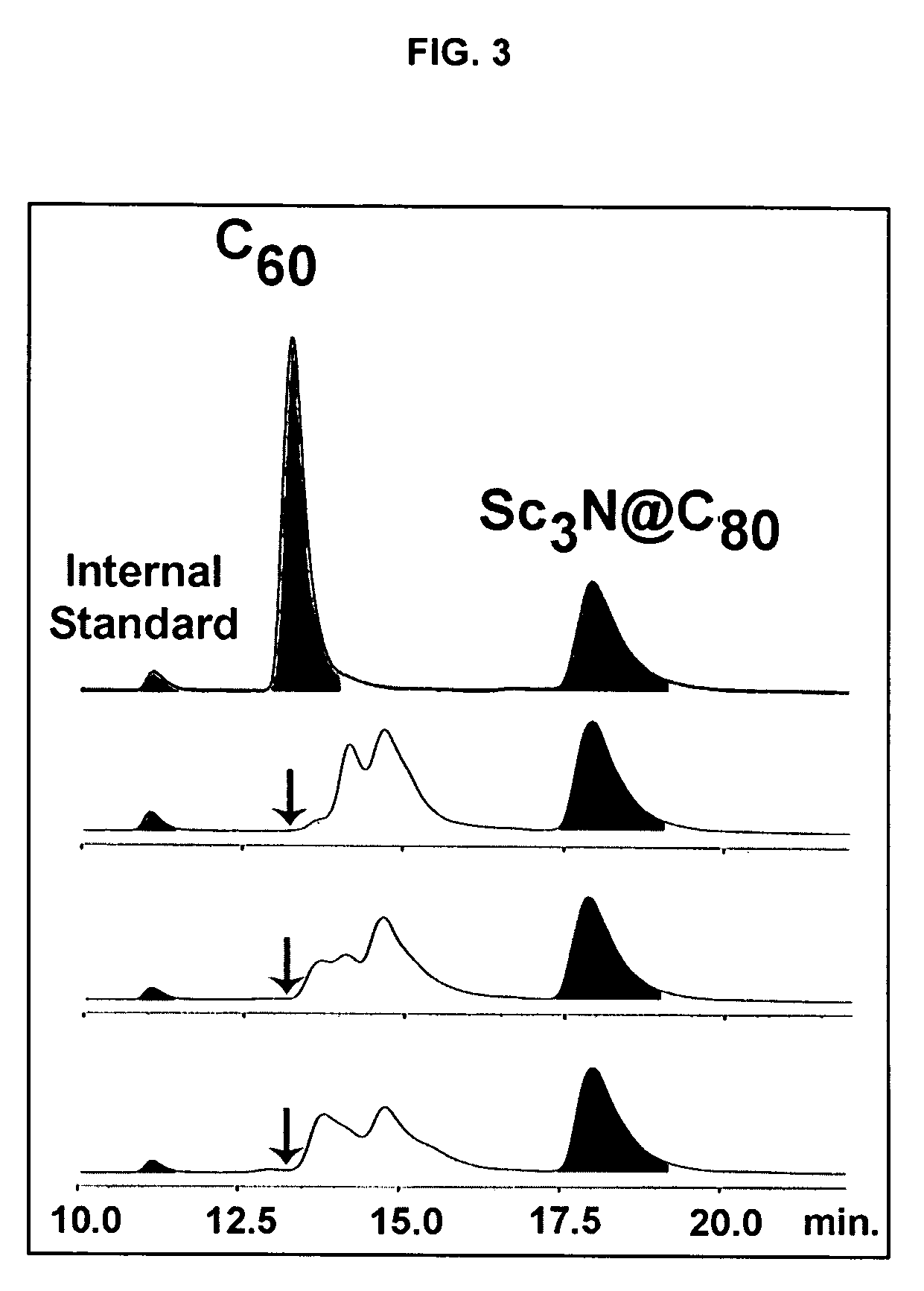

Chemical separation method for fullerenes

A method for separating two types of fullerene molecules in a mixture can comprise: contacting a mixture comprising different fullerenes with a reagent that reacts at different rates or to a different extent with different types of fullerenes in the mixture and separating the fullerenes based upon the extent of reaction between the fullerene and the reagent.

Owner:LUNA INNOVATIONS

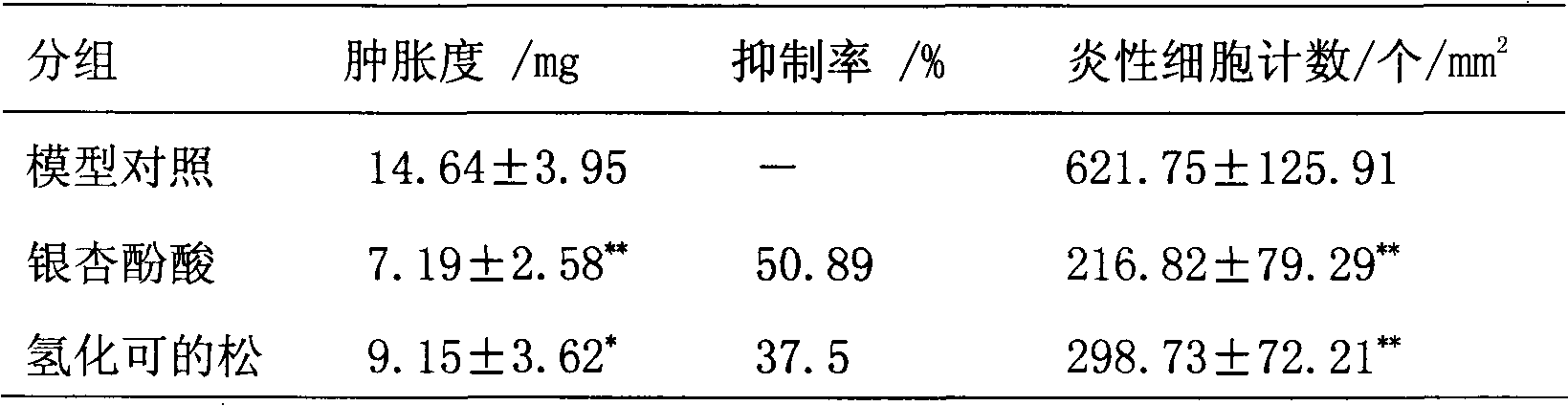

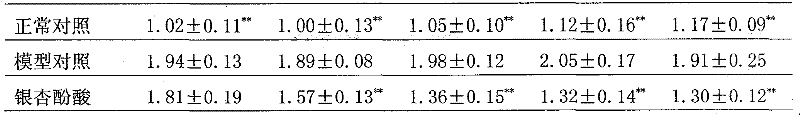

Application of ginkgolic acid in treating arthritis

InactiveCN102641278AGood treatment effectImprove joint swellingBiocideSalicyclic acid active ingredientsSide effectRhizome

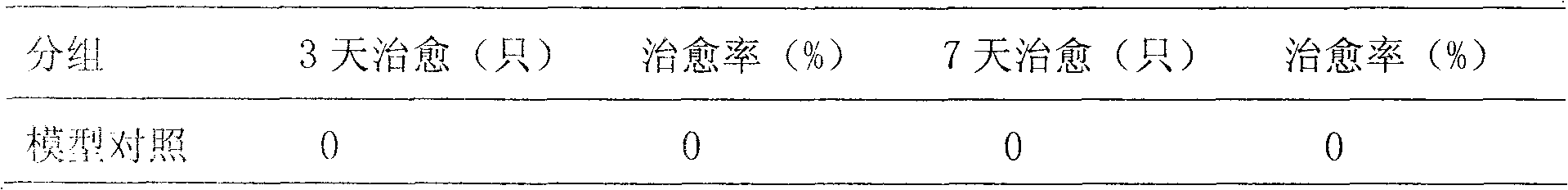

The invention relates to the application of ginkgolic acid in treating arthritis. The ginkgolic acid comprises ginkgoic acid, ginkgol, ginkgoic diphenol and the like and can be obtained from the extracts of the parts of the leaves, the fruits, the episperms, the rhizomes and the like of gingkoes by a chemical separation method. The arthritis is rheumatoid arthritis, chronic infectious arthritis, gouty arthritis, osteoarthritis and the like. A medicine, a medical appliance or a disinfector preparation which contains the ginkgolic acid and is used for treating the arthritis contains 0.001 to 80 percent of ginkgolic acid (calculated according to weight percent) and an external preparation substrate or an acceptable carrier which is generally used pharmaceutically; and the preparation is any external preparation formulation which is given pharmaceutically. The research of a pharmacological experiment shows that the ginkgolic acid has the favorable actions of improving arthrocele, relieving joint injury and suppressing local inflammation to an animal model with the arthritis. Clinical trial shows that the ginkgolic acid has an obvious therapeutic action to each type of arthritis, and the effective rate reaches more than 90 percent. In use, the ginkgolic acid is safe and has no side effect.

Owner:王青

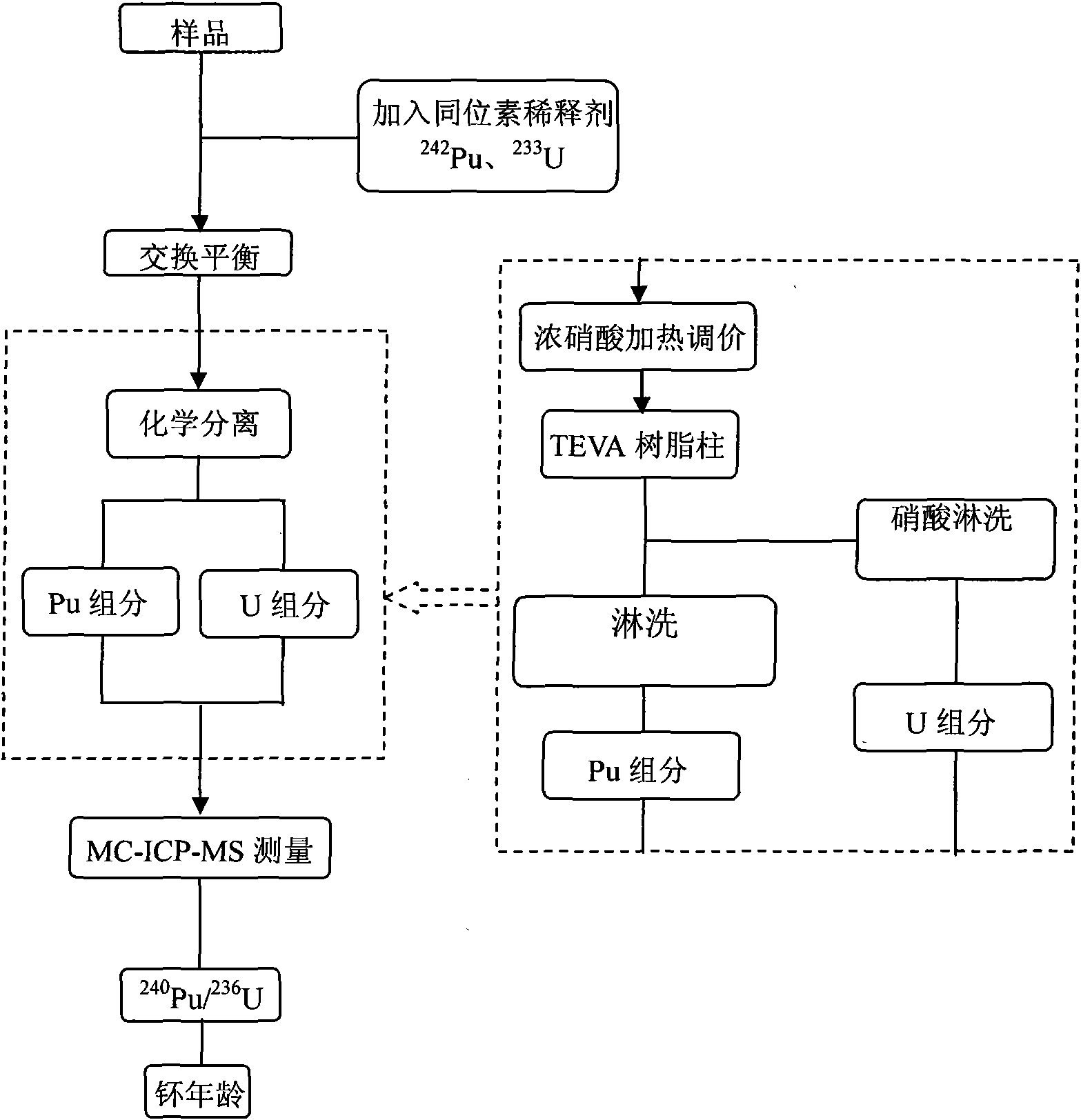

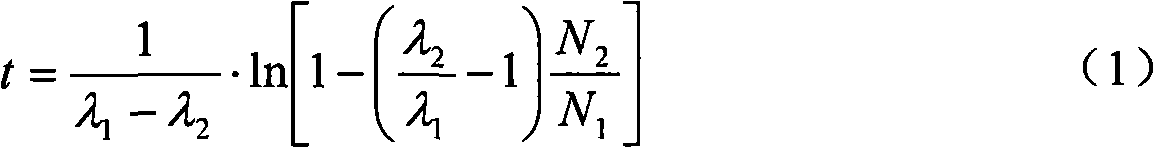

Determination method of plutonium age in trace plutonium sample

ActiveCN101561417AShort analysis timeSimple chemical separation processMaterial analysis by electric/magnetic meansChemical separationInductively coupled plasma

The invention discloses a determination method of plutonium age in a trace plutonium sample. The method comprises the following steps of: adding plutonium and the isotopic diluents of daughter uranium thereof, namely, Pu and U, in the sample; adding concentrated nitric acid for heating and price adjustment; and then loading a TEVA resin column, using a chemical separation method to respectively obtain a Pu component and a U component, and using a multi-receiving inductive coupling plasma mass spectrometry to measure the Pu component and the Am component respectively to obtain the values of Pu / Pu and U / U . According to the amount of the added diluents, the value of Pu / U is calculated and substituted into the age-calculating formula to obtain the age of plutonium. The deviation between the age measured by the method and the reference value is within 5%.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

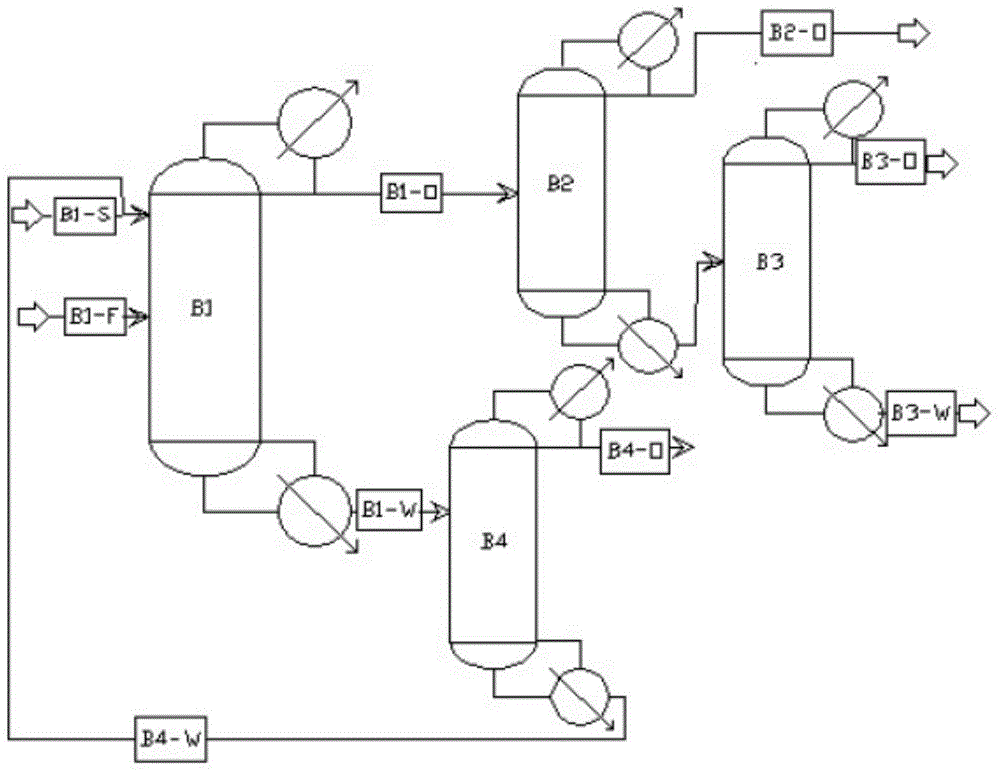

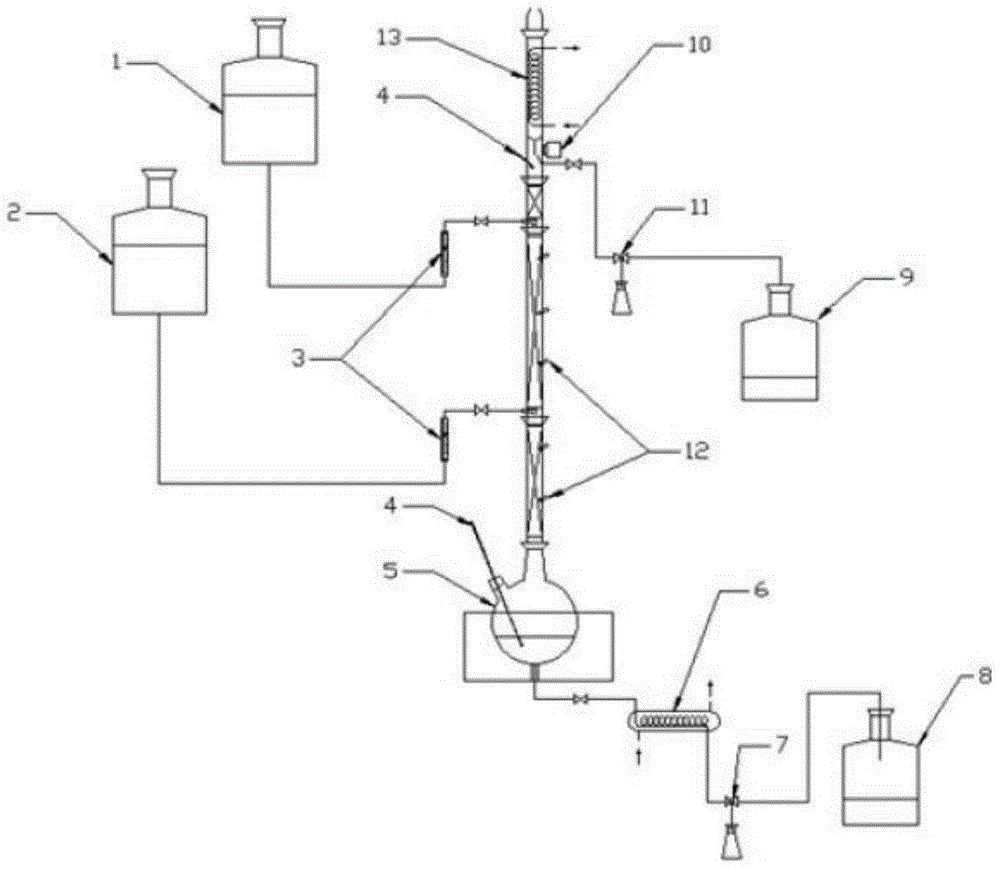

Method for separating mixed alcohol-water by continuous extractive rectification

InactiveCN105418370ABroaden your optionsEasy to industrializeOrganic compound preparationHydroxy compound preparationIsobutanolSolvent

The present invention relates to a method for separating mixed alcohol-water by continuous extractive rectification, and relates to a chemical separation method, i.e. a method for separating mixed alcohol-water by continuous extractive rectification with water mixtures such as ethanol, n-propanol and isobutanol. The method comprises the steps: combining extractive rectification with general rectification, and gradually separating the mixed alcohol and the water by using a combined sub-step separation method of multiple towers so as to recover and obtain a component with high purity; achieving separation of the mixed alcohol and the water in an extractive rectification tower B1 by using ethylene glycol as an extractant, wherein atmospheric rectification is used in the tower with a reflux ratio of 1:1 to 10:1, the mixed alcohol is obtained from the tower top, and the solvent and the water are obtain from the tower bottom; recovering most of the solvent in a solvent recovery tower B4 for recycling; and after allowing the mixed alcohol to pass through towers B2 and B3, effectively separating the mixed alcohol, respectively. The method provided by the invention combines extractive rectification with general rectification, breaks azeotropy between alcohol and water by using an extractant, and recovers components with relatively high purity step by step by using multi-tower continuous separation, so that the method has higher economic and environmental benefits.

Owner:海安华达石油仪器有限公司

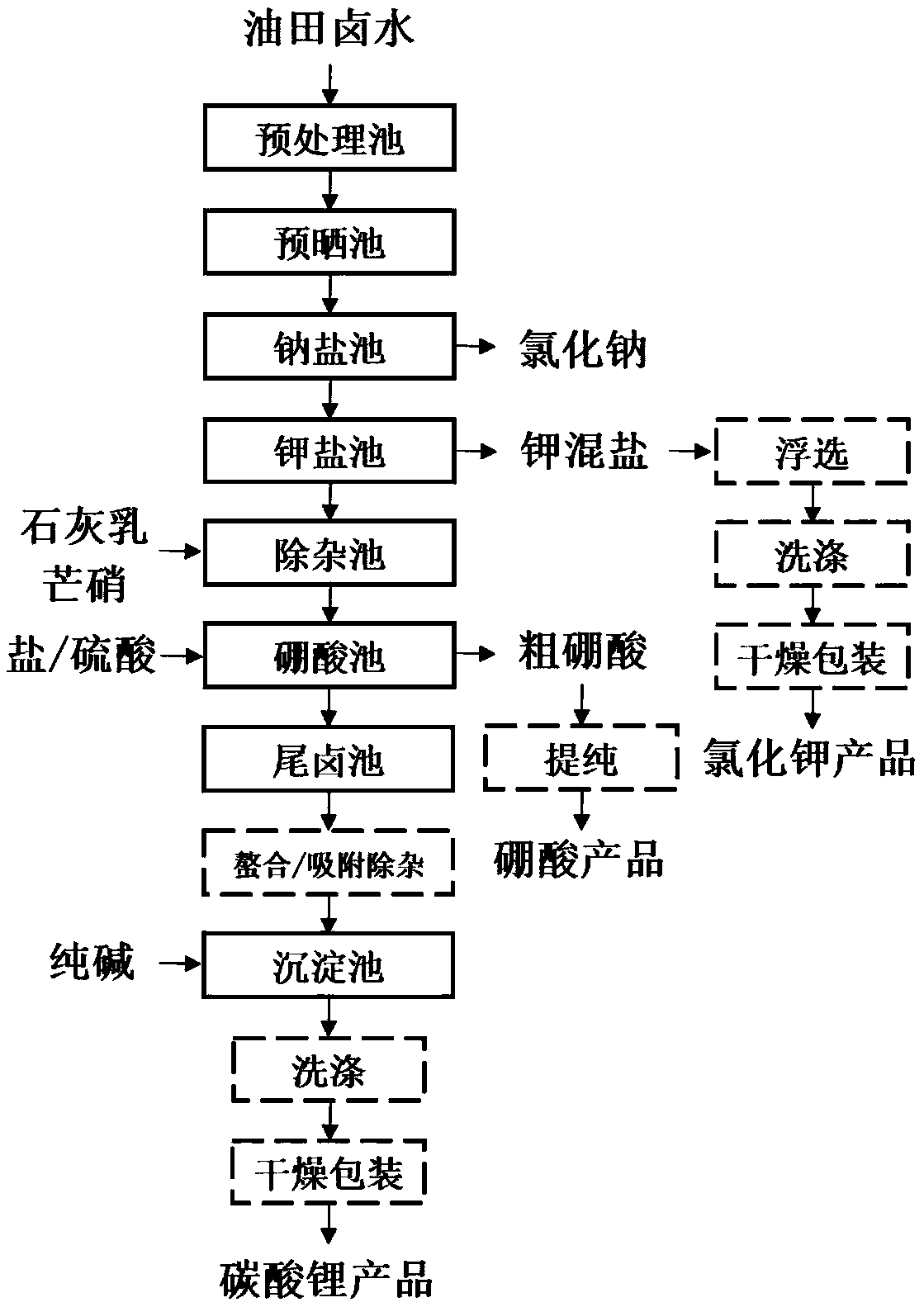

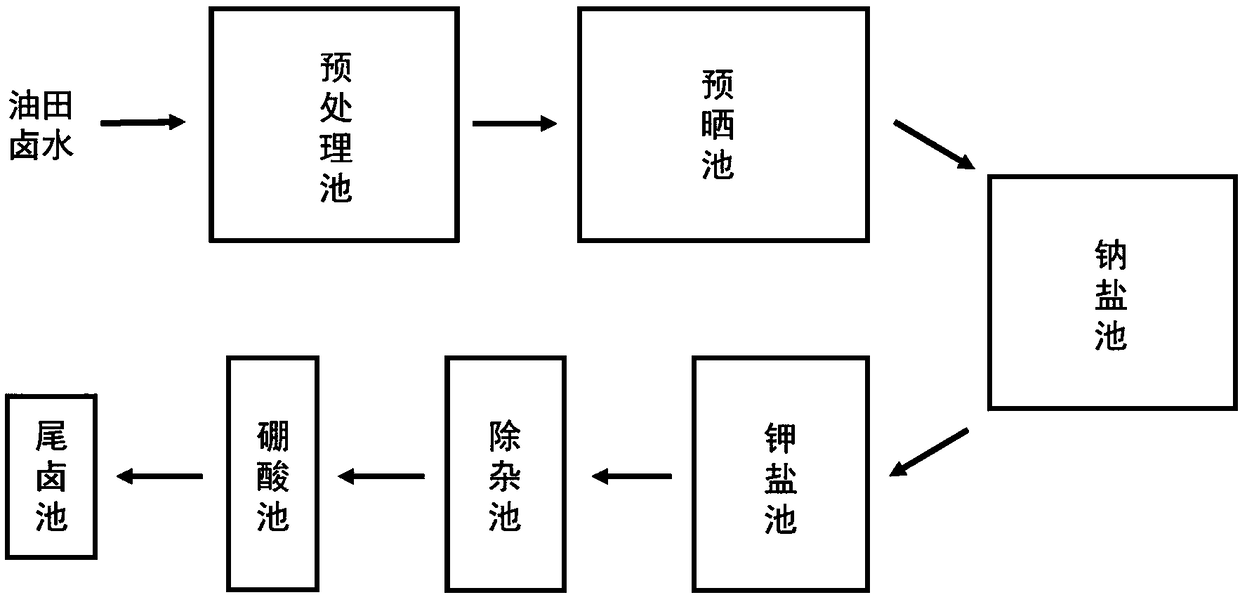

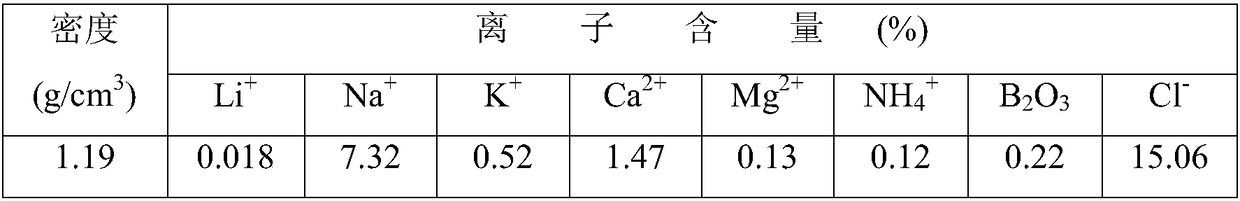

Method for comprehensively extracting lithium, potassium and boron from oilfield brine

ActiveCN108584995AMake up for the shortageLow costAlkali metal chloridesBoron-oxygen compoundsPotassiumMirabilite

The invention discloses a method for comprehensively extracting lithium, potassium and boron from oilfield brine. The method includes the steps of conducting preprocessing, conducting evaporative crystallization to separate out sodium salt to obtain a sodium extraction mother solution, conducting evaporative crystallization on the sodium extraction mother solution to separate out sylvite to obtaina potassium extraction mother solution, conducting impurity removal on the potassium extraction mother solution through lime milk and mirabilite to obtain an impurity-removed potassium extraction mother solution, adding hydrochloric acid or sulfuric acid to the impurity-removed potassium extraction mother solution to obtain coarse boric acid and a coarse lithium-containing mother solution, conducting evaporative concentration on the coarse lithium-containing mother solution, conducting chelation or adsorption and purification impurity removal to obtain a refined lithium-rich mother solution,and adding alkali to the refined lithium-rich mother solution for depositing and washing to obtain coarse lithium carbonate. The salt pan technology and the chemical separation method are applied in the separation and extraction process of resources such as lithium, potassium and boron in the oilfield brine, the practical low-cost economic benefits and social value can be created, a new brine resource comprehensive utilization approach can be created, and the method has great significance in making up the shortage of resources such as lithium, potassium and boron in China.

Owner:INST OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

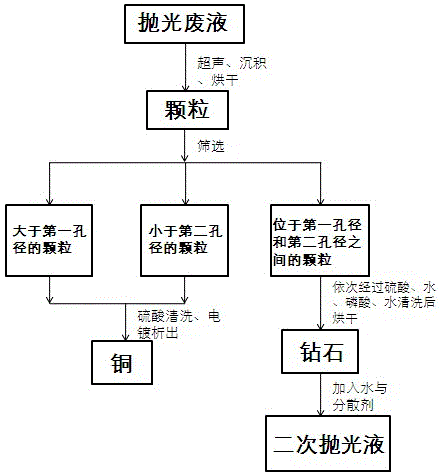

Recovery method of sapphire polishing waste liquid

The invention discloses a recovery method of sapphire polishing waste liquid. The waste liquid contains copper scraps for polishing a copper disc and diamond in polishing liquid and is recovered in combination with vibrating screen separation and chemical separation methods, an electroplating method and other methods; the copper and the diamond in the waste liquid are extracted, so that the production cost is favorably reduced.

Owner:FUJIAN JING AN OPTOELECTRONICS CO LTD

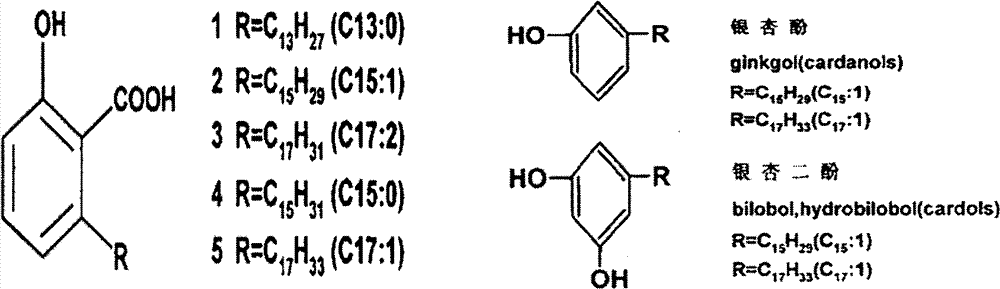

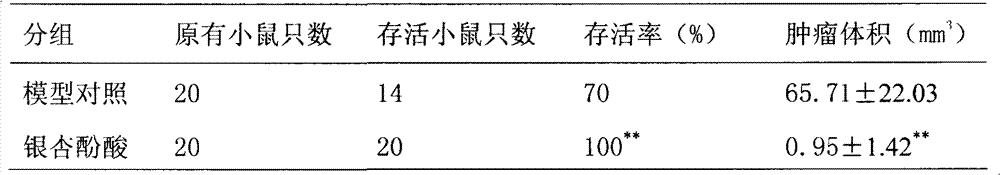

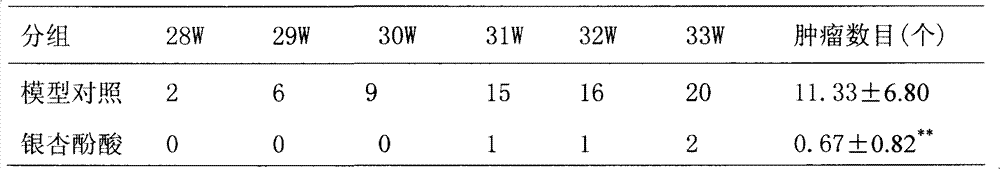

Use of ginkgolic acids in preparation of external preparation for treating cutaneous tumors

InactiveCN102846677AInhibitionInhibit tumor growthSalicyclic acid active ingredientsHydroxy compound active ingredientsSide effectCancer cell

The invention relates to a use of ginkgolic acids in preparation of an external preparation for treating cutaneous tumors. The ginkgolic acids comprise ginkgolic acid, bilobol and ginkgol and can be extracted from leaves, fruits, testa and rootstocks of gingko by a chemical separation method. A ginkgolic acid-containing external preparation for treating cutaneous tumors comprises 0.001 to 80wt% of ginkgolic acids and a pharmaceutically used common external preparation matrix or pharmaceutically acceptable carriers. The ginkgolic acid-containing external preparation for treating cutaneous tumors is an external dosage form defined by all pharmaceutics. A pharmacological experiment research shows that ginkgolic acids have effects of inhibiting cutaneous tumor generation, cutaneous cancer cell propagation and tumor growth and improving a survival rate, are safe and have no side-effect and a good clinical application prospect.

Owner:王青

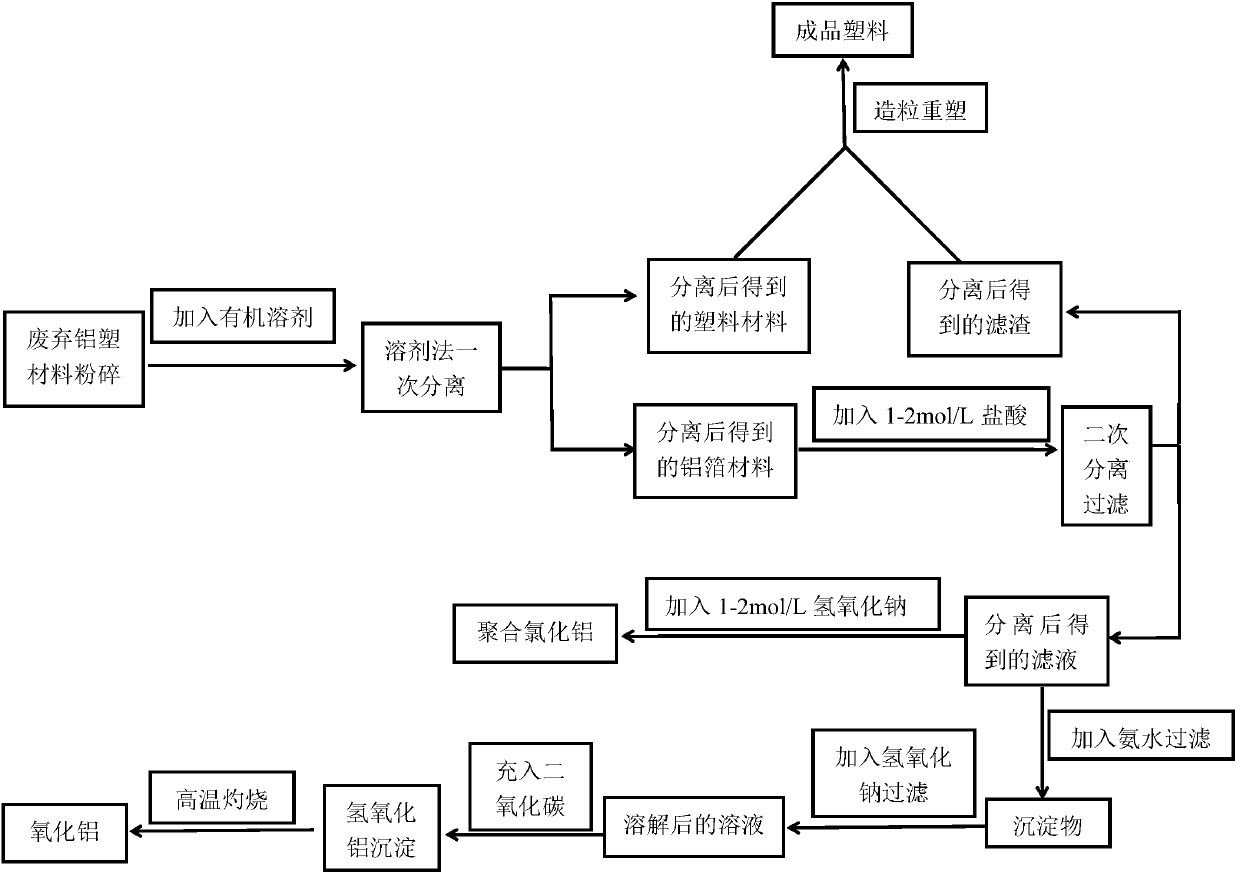

Waste aluminum and plastic separating and recycling process

ActiveCN107599234AEasy to separateRealize multi-field applicationsPlastic recyclingOrganic solventEngineering

The invention discloses a waste aluminum and plastic separating and recycling process which comprises the specific steps of: inputting a waste aluminum plastic composite packaging material into a crushing cutter to be crushed to particles, then putting the crushed aluminum plastic material in a stirring barrel, putting an organic solvent in the stirring barrel till the aluminum plastic material isfully immersed, stirring the mixture at a rotating speed of 200-500 r / min for 2-8h, and separately washing a plastic material floating on the surface of the organic solvent and an aluminum foil material precipitated in the bottom of the stirring barrel with clean water; pelletting and remolding the cleaned dry plastic material to obtain a finished plastic, and putting the dried aluminum foil material precipitated in the bottom of the stirring barrel in a reaction container for secondary separation; and adding a 1-2mol / L hydrochloric acid solution into the reaction container, stirring the mixture for 2-5h at 30-70 DEG C, filtering and washing the mixture to obtain a filtrate for later use, and pelletting and remolding the filter residues and the plastic material separated in the step 1 together. By combining an organic solvent method and a chemical separating method to achieve separation, the method is thorough in separation and the product is wide in application field.

Owner:ANHUI TENGYUE ALUMINUM PLASTIC

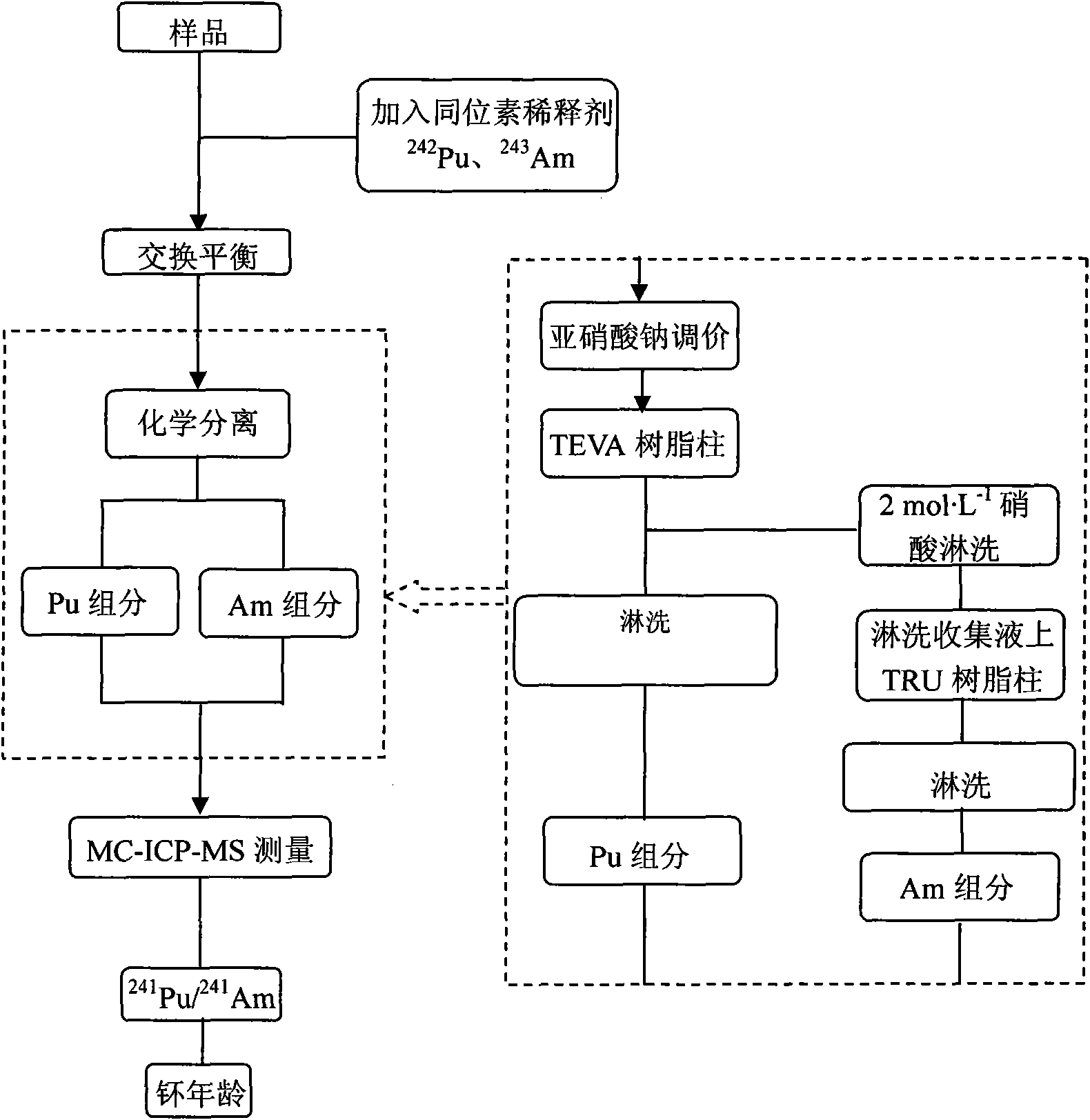

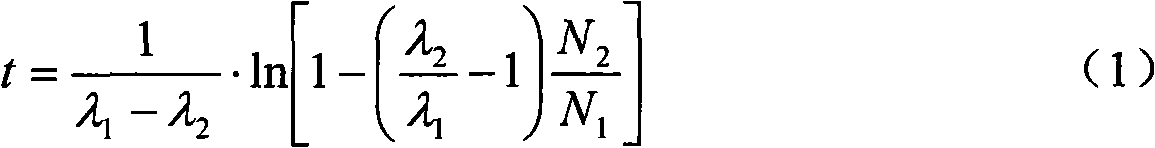

Determination method of plutonium age in trace plutonium sample

ActiveCN101561418AShort analysis timeSimple chemical separation processMaterial analysis by electric/magnetic meansInductively coupled plasmaChemical separation

The invention discloses a determination method of plutonium age in a trace plutonium sample. The method comprises the following steps of: adding plutonium and the isotopic diluents of daughter americium thereof, namely, Pu and Am, in the sample; adding sodium nitrite for price adjustment; and then loading a TEVA resin column, using a chemical separation method to respectively obtain a Pu component and an Am component, and using a multi-receiving inductive coupling plasma mass spectrometry to measure the Pu component and the Am component respectively to obtain the values of Pu / Pu and Am / Am . According to the amount of the added diluents, the value of Pu / Am is calculated and substituted in the age-calculating formula to obtain the age of plutonium. The deviation between the age measured by the method and the reference value is within 5%.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

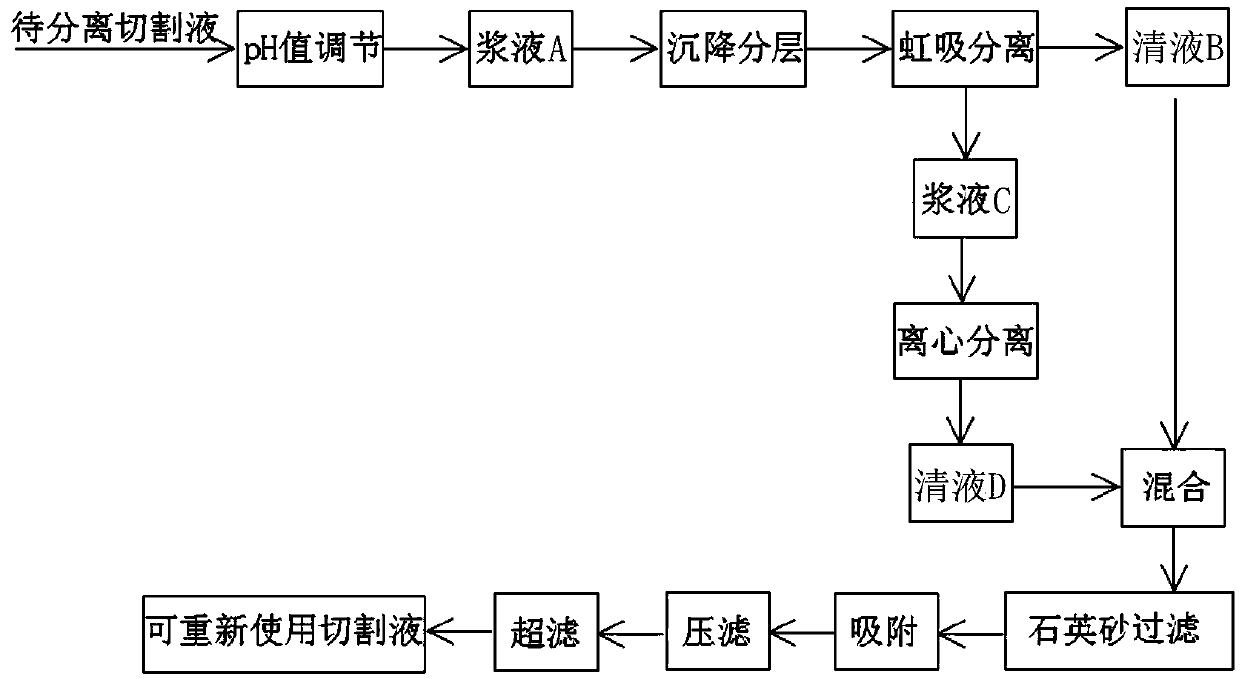

Solid-liquid method of silicon wafer cutting fluid

The invention relates to a solid-liquid method of silicon wafer cutting fluid, aiming to solve the problem that fine solid particles in the cutting fluid are difficult to separate. The solid-liquid method comprises the following steps: firstly regulating the pH value of the cutting fluid to 8-9, then standing for 10-20 hours for settlement and layering, then performing siphon separation to obtain supernatant under siphon pressure of 0.01-0.05MPa, evenly mixing the supernatant together with a liquid which is obtained from centrifugally separating lower-layer slurry at high speed, leading the obtained mixture to quartz sand for filtering, then adding an adsorbant for adsorption, performing pressure filtering and ultrafiltration to finally realize the solid-liquid separation of the cutting fluid. The method has the characteristics that the separation of solid and liquid is thorough and the separated cutting fluid can be repeatedly used, the generation of reactive gas in a chemical separation method and the adverse effect on the environment and production safety can be avoided.

Owner:KAIFENG WANSHENGXIN MATERIALS

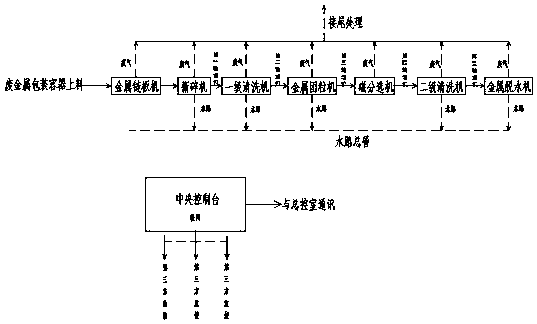

Waste metal packaging container intelligent harmless treatment and resource recycling process

ActiveCN110560448AAchieve volume reduction effectThe size is easy to controlSolid waste disposalWastewaterChemical separation

The invention discloses a waste metal packaging container intelligent harmless treatment and resource recycling process comprising the following steps of (1) feeding, (2) tearing, (3) first-grade cleaning, (4) granulation, (5) sorting, (6) second-grade cleaning, (7) dehydration, (8) waste gas treatment, (9) wastewater recycling treatment and (10) system control. Various dangerous packaging containers are broken, cleaned and recycled in a concentrated mode, an advanced breaking technology is adopted, materials are effectively cut under a normal temperature state, a material volume reduction effect is achieved, the treated materials are controllable in size, metal is separated from other materials through physical and chemical separation methods, and the recycling rate is increased.

Owner:常熟市首誉机械有限公司

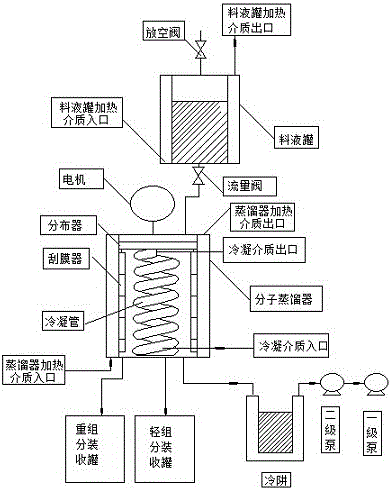

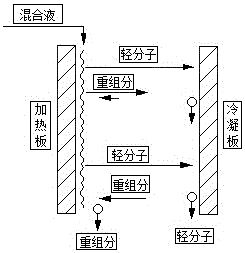

Method for extracting high-purity flaxseed oil by aid of molecular distillation processes

InactiveCN105695093AHigh degree of separationHigh product yieldFatty acids production/refiningFatty-oils/fats refiningSeparation technologyDistillation

The invention relates to the technical field of food processing, in particular to a method for extracting high-purity flaxseed oil by the aid of molecular distillation processes.The method includes steps of 1), carrying out primary molecular distillation; 2), carrying out secondary molecular distillation to obtain the high-purity flaxseed oil with a high-purity alpha-linolenic acid product index and higher than or equal to 90% of alpha-linolenic acid.Compared with the traditional chemical separation method, the method for extracting the high-purity flaxseed oil by the aid of the molecular distillation processes has the advantages that molecular distillation is a purely physical procedure, accordingly, large quantities of solvents can be saved, and environmental pollution can be decreased; the content of alpha-linolenic acid in products can be increased, new impurities and toxic substances can be prevented, natural properties of raw materials can be kept, and accordingly molecular distillation which is a modern separation technology has a certain industrialization prospect in the aspect of extracting alpha-linolenic acid from flaxseed oil.

Owner:QINGHAI FLAXSEED BIOTECH CO LTD

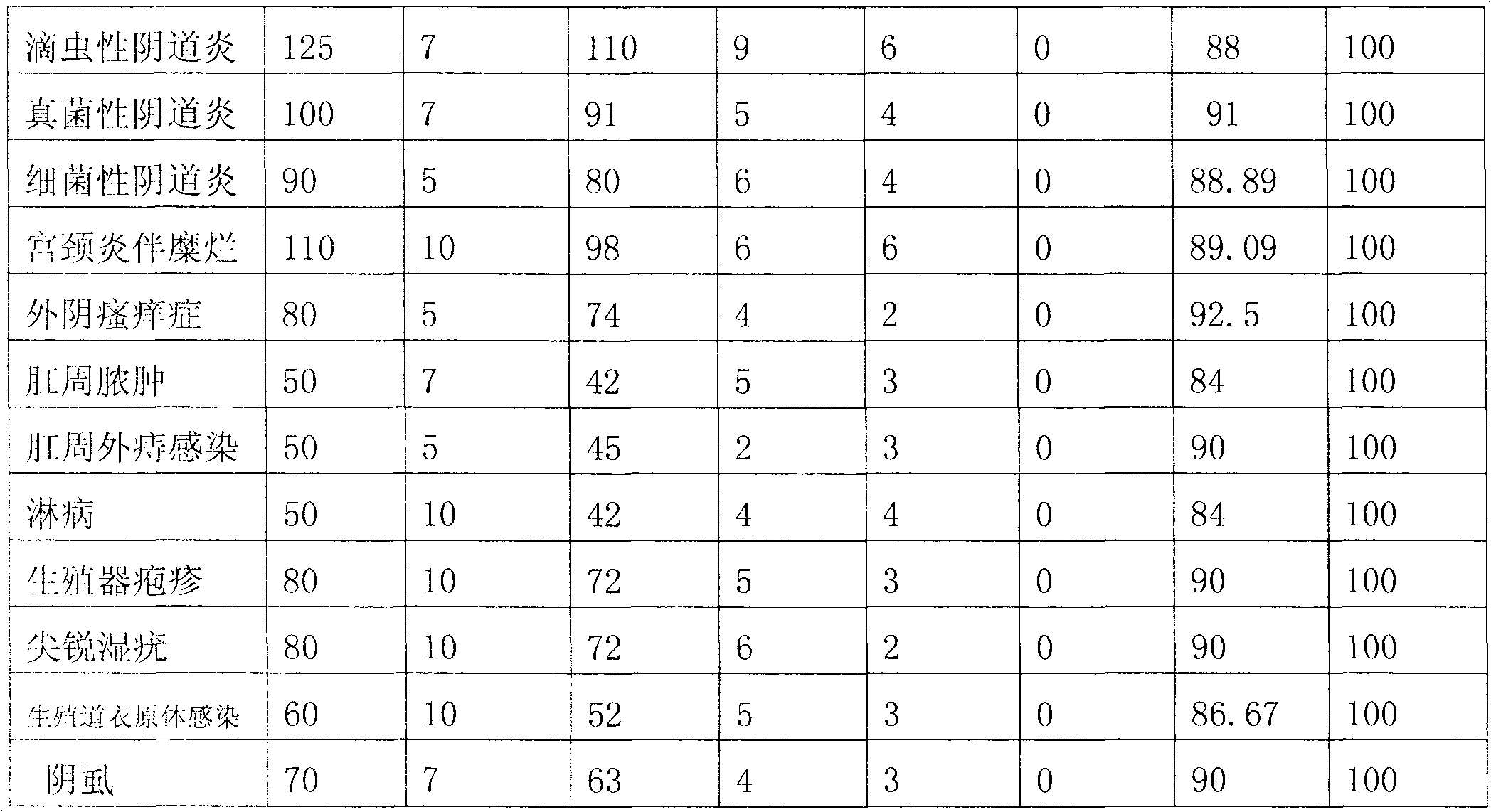

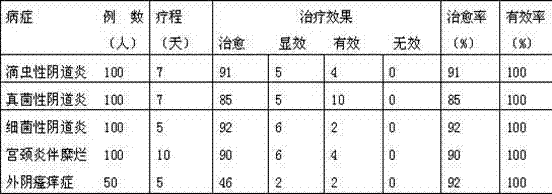

Purpose of ginkgolic acid in preparing external preparation for treating venereal disease, gynopathy and perianal disease

InactiveCN102349935AGood treatment effectSignificant effectSalicyclic acid active ingredientsHydroxy compound active ingredientsSide effectDisinfectant

The invention relates to purpose of ginkgolic acid in preparing external preparations for treating venereal diseases, gynopathy and perianal diseases. The ginkgolic acid comprises ginkgolic acid, ginkgol, ginkgo dipenol, etc., and can be obtained from extractives of ginkgo leaf, fruit, episperm and rhizome through a chemical separation method. The venereal diseases comprise infectious and inflammatory genital diseases. A medicament, a disinfectant or external preparation containing ginkgolic acid for treating venereal diseases, gynopathy and perianal diseases comprises 0.001-80wt% of ginkgolic acid and a pharmaceutically common used external preparation matrix or a pharmaceutically accepted carrier, wherein the preparation is any pharmaceutical external dosage form. Pharmacological tests show that the preparation of the invention has substantial effects of killing resident pathogens on or surrounding genitals, resisting inflammation, relieving pain and itching. Clinic trials show that the preparation of the invention has outstanding curative effects on a plurality of venereal diseases, gynopathy and perianal diseases and an effective rate of 100%, and is safe for usage without side effect.

Owner:王青

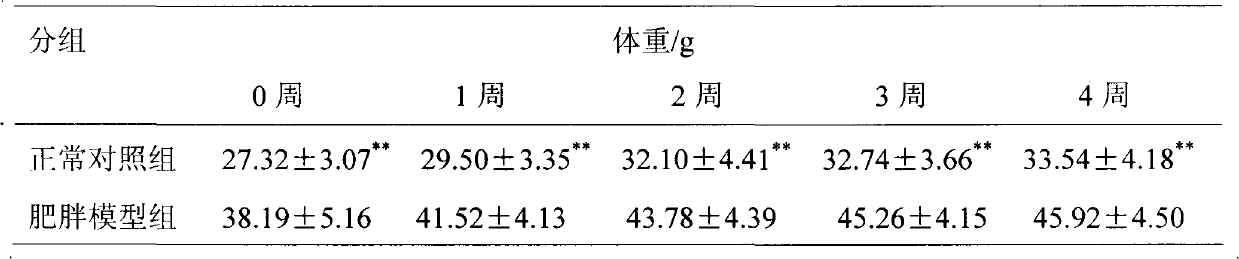

Application of ginkgolic acid in weight losing

InactiveCN102846678ALose weightObvious weight loss effectSalicyclic acid active ingredientsCosmetic preparationsMedicineBlood sugar

The invention relates to application of ginkgolic acid in weight losing. The ginkgolic acid comprises ginkgolic acid, ginkgol and bilobol and can be obtained from extracts of such parts of the gingko as leaves, fruits, testae and rootstalks by a chemical separation method. A weight reducing medicament or cosmetic contains 0.001-80% of ginkgolic acid by weight percent and pharmaceutically common external preparation substrates or acceptable carriers. The preparation is any one pharmaceutically called external dosage form. Pharmacological experiment studies show that the preparation has the functions of reducing weight, body fat and adipocyte quantity and volume and has the effect of reducing blood sugar and blood fat. Trial results of fat people show that the preparation has the functions of reducing weight and removing fat, is obvious in weight reducing effect, is safe to use and has no effects.

Owner:王青

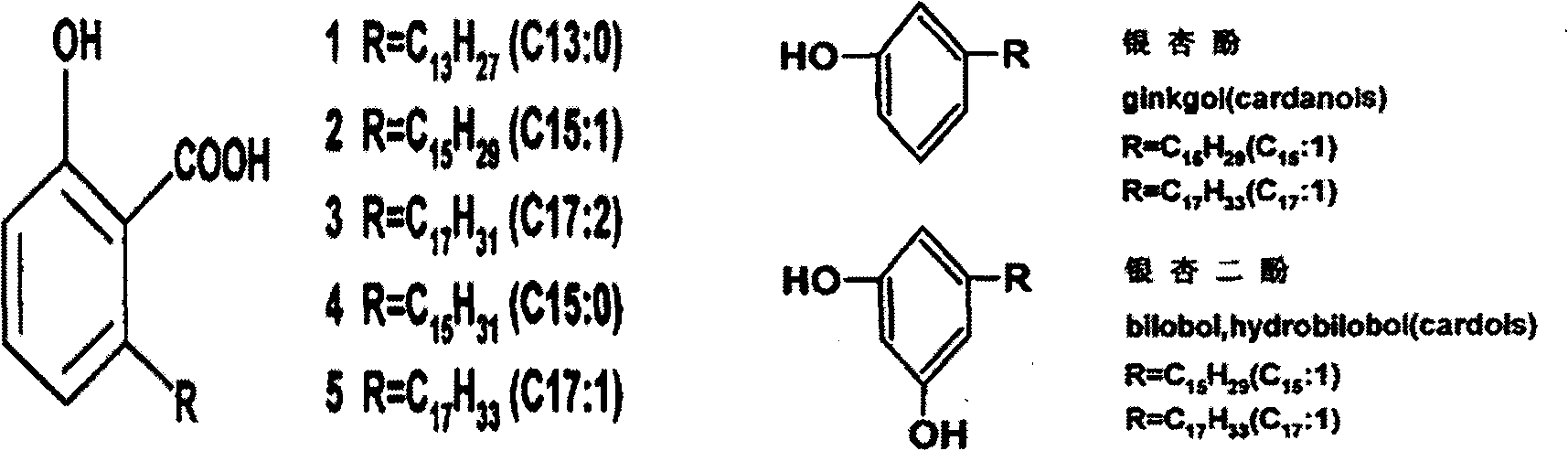

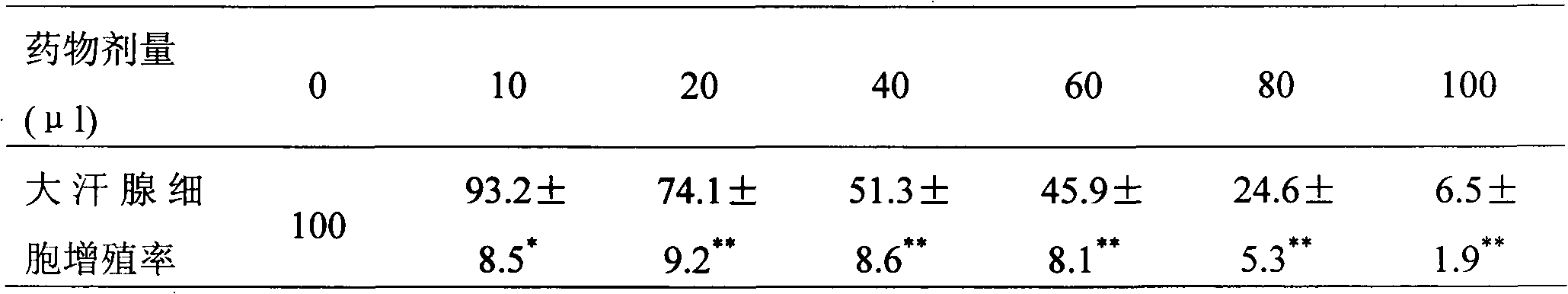

Application of gingkolic acid in preparation of external preparation for treating osmidrosis

ActiveCN102349919AInhibition of secretionDoes not affect sweat gland functionSalicyclic acid active ingredientsCosmetic preparationsSide effectTrial drug

The invention relates to application of gingkolic acid in preparation of an external preparation for treating osmidrosis. The gingkolic acid comprises ginkgoic acid, ginkgol, ginkgo diphenol and the like, and can be extracted from leaf, fruit, external exotesta, rhizome and other parts of ginkgo through a chemical separation method. The osmidrosis includes the osmidrosis of axillary part, foot part, perineum and other parts. The drug, cosmetic or disinfectant external preparation containing gingkolic acid for treating osmidrosis contains 0.001-80wt% of gingkolic acid and a pharmaceutically common external preparation matrix or acceptable carrier; and the preparation is any one pharmaceutically external dosage form. Pharmacological experiment researches show that the external preparation has the effects of inhibiting the growth and propagation of bacteria on skin surface and permeating into skin to destroy large sudoriferous gland, and inhibiting the generation of free fatty acid, ammonia nitrogen compound and other smelling substances in sweat. Clinical trial shows that the external preparation has significant treatment effect on the osmidrosis, has effective rate up to 100%, is safe to use and has no side effect.

Owner:王青

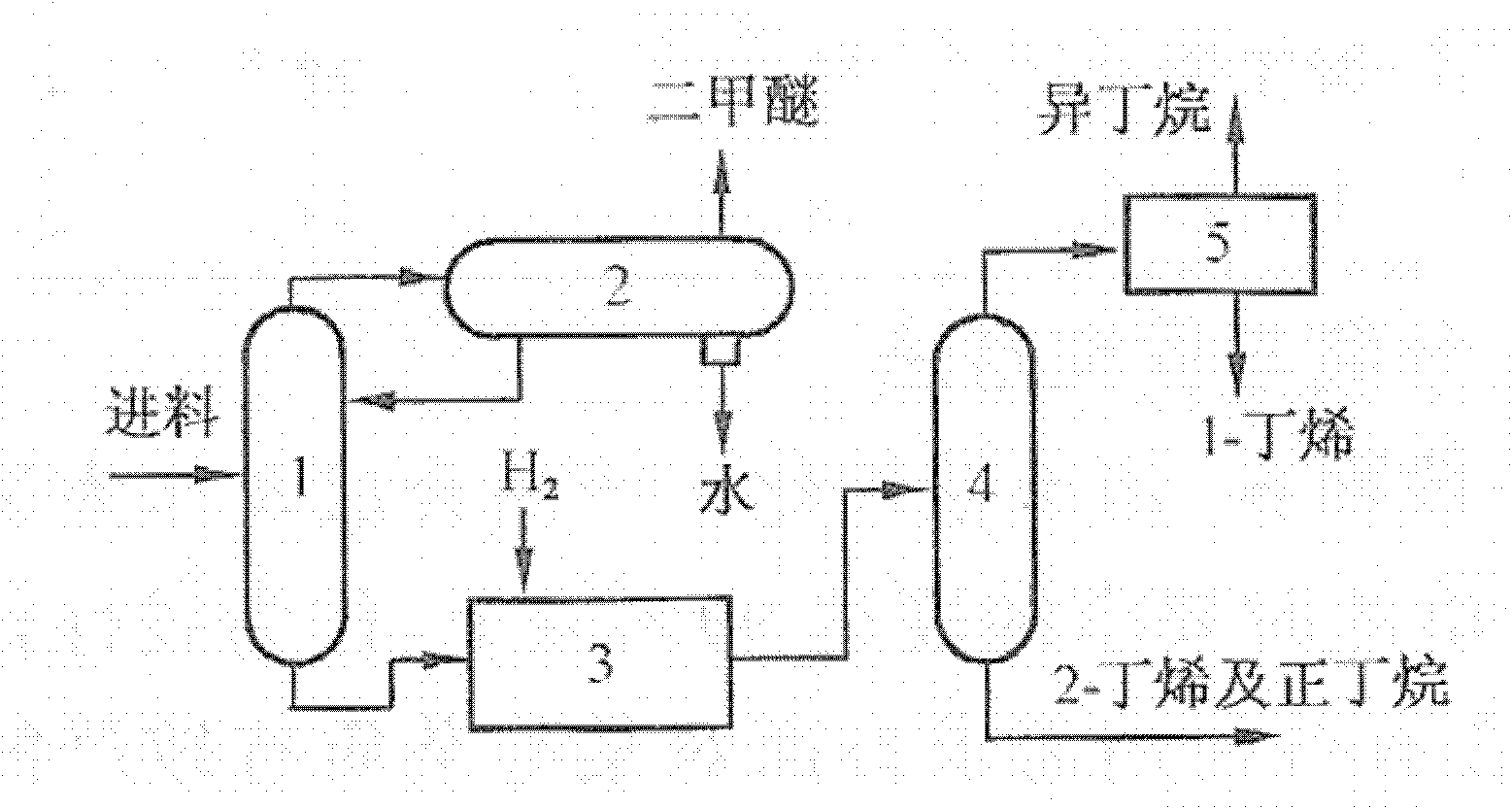

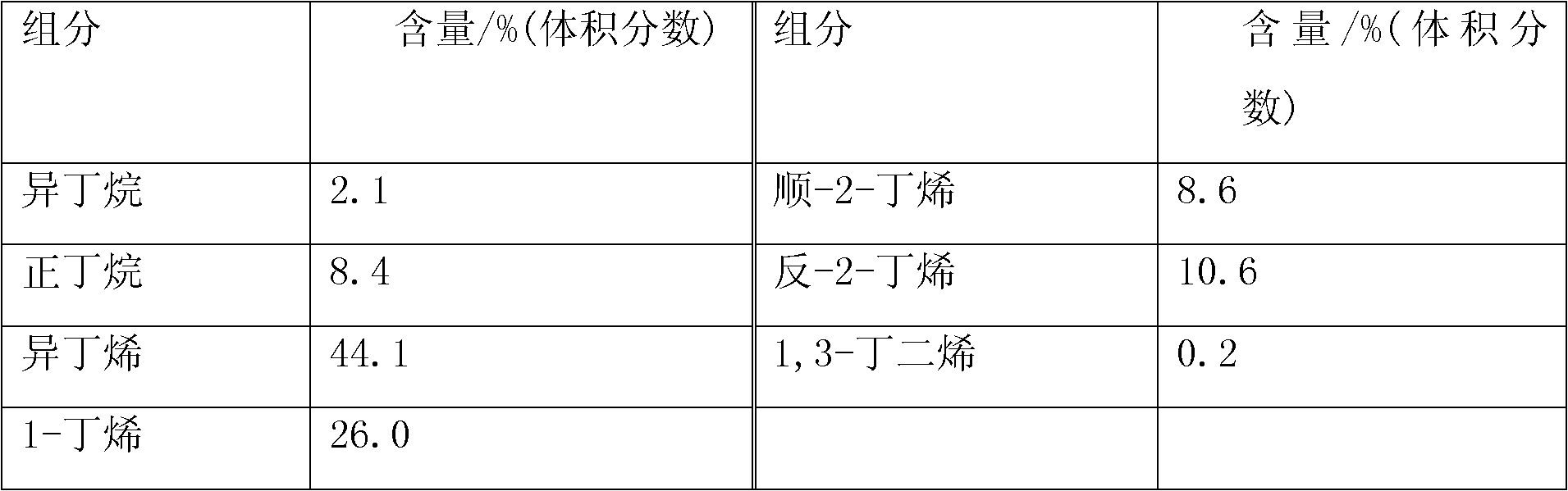

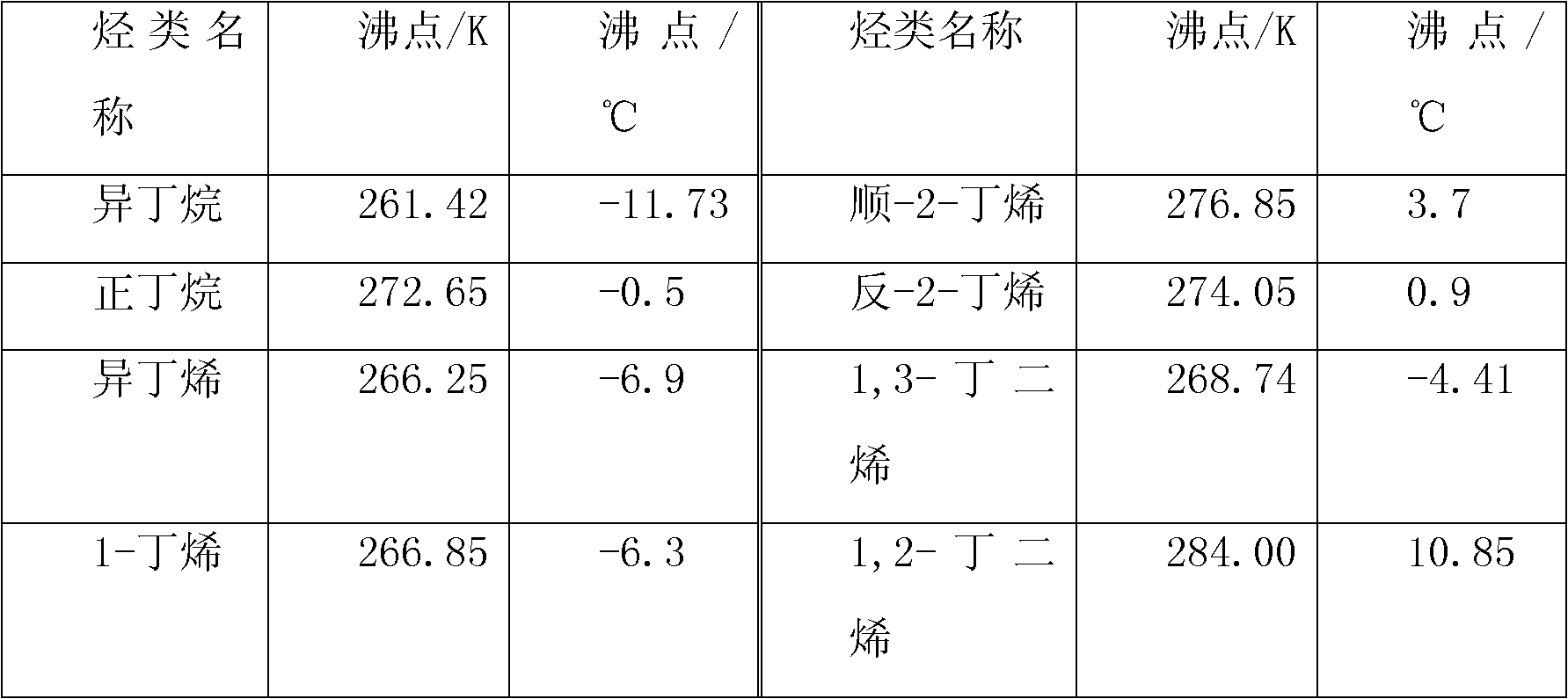

Purification method for butylene by chemical separation process

InactiveCN102249837ASolve the problem of producing high-purity n-butaneIncrease productivityDistillation purification/separationHydrocarbonsButenePurification methods

The invention discloses a purification method for butylene by a chemical separation process. The method is characterized in that: such measures as a two-stage reaction and excess methanol have already been employed at the synthetic phase of methyl tertiary butyl ether so as to improve the removal rate of isobutene; C4 materials which have been deprived of isobutene are subjected to hydrotreatment to remove impurities like butadiene and then to rectification; tower bottoms are 2-butylene and n-butane, while overhead fractions are 1-butylene and isobutene; the overhead fractions are subjected to extractive distillation to separate isobutene, and therefore high purity 1-butylene is obtained. The invention has the advantages of reasonable technology and simple preparation, and is the simplest ideal technology for preparing butylene.

Owner:TIANJIN TAIHENG GASES

Method for recovering mercury from waste mercury catalyst

InactiveCN109082529AEfficient recyclingPromote recoveryProcess efficiency improvementSolubilityLow speed

The invention discloses a method for recovering mercury from a waste mercury catalyst. The method comprises the following steps that (1) through the water solubility of HgCl2, the waste mercury catalyst is pretreated through water, the leaching reaction time is 80.0-90.0 min, the leaching reaction temperature is 50.0-80.0 DEG C, the liquid-solid ratio is (20.0:1.0)-(10.0:1.0), the magnetic stirring speed is 200.0 r / min, the pH value is 0.5-1.5, and at this time, the leaching rate of Hg2+ in the waste mercury catalyst is 85.5-93.2%; and (2) a leaching solution containing the Hg2+ is filtered bythe step (1), a suitable flow carrier, surfactant and solvent are selected, emulsion is made under high-speed stirring and mixing, and low-speed stirring for mass transfer is conducted with an external water phase containing the Hg2+ for a period of time. According to the method, an emulsion membrane system is adopted as a chemical separation method for recovering the mercury, the advantages of high efficiency, environmental protection, new type, easy operation and good selectivity are achieved, meanwhile, the operation flow is short, the operating conditions are mild, the operation cost andthe equipment cost are low, and the mercury in the waste mercury catalyst can be efficiently and quickly recovered.

Owner:TONGREN UNIV

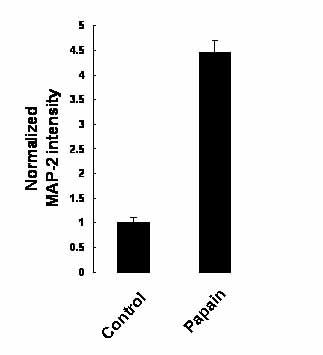

Mechanical separation method of neurons of adult mice

InactiveCN102660506AThe method is simpleEasy to separateNervous system cellsChemical separationNeural zone

The invention which relates to the biomedicine field discloses a mechanical separation method of neurons of adult mice. The method comprises the following steps: making the adult mice's brain tissue slices with the thickness of 350-375mum in an ice bath tissue culture solution with an electronic vibration slicer, preserving for 30-60min at room temperature, putting the brain tissue slices into a papain-containing tissue culture solution under aseptic conditions, controlling the temperature at 32.2-35.3DEG C, maintaining the temperature for 30min, placing the brain slices in a cell culture dish containing an HEPES buffer solution, selecting a neural region needing separation, and separating neurons through using a cell separator; and screening healthy neurons. The method of the invention, which allows a primary culture chemical separation method to be integrated into mechanical cell separation and the brain slices to be preprocessed with the papain, makes the healthy neurons of adult and aged mice to be obtained through the mechanical separation, and has the advantages of simplicity, convenience, and substantial separation effect.

Owner:ZHEJIANG UNIV

Applications of gingko extractive in preparing external preparation for treating venereal disease, gynecopathy and perianal diseases

InactiveCN102302524AGood treatment effectEasy to useAntibacterial agentsAntimycoticsSide effectTreatment effect

The invention relates to applications of a gingko extractive in preparing an external preparation for treating venereal disease, gynecopathy and perianal diseases. The gingko extractive can be obtained from extractives of the parts of leaves, fruit, testa, rhizome and the like of gingko through a chemical separation method, and the extractive solvents can be organic solvents of alcohol, water, ethyl ether, petroleum ether and the like. The venereal disease is infectious and inflammatory genital disease. The medicament and disinfectant external preparation containing the gingko extractive for treating venereal disease, gynecopathy and perianal diseases comprises 0.001-80% of gingko extractive (in percentage by weight) and pharmaceutically common external preparation media or acceptable carriers; and the preparation is any external dosage form in pharmaceutics. The clinical test result shows that the gingko extractive provided by the invention has an obvious treatment effect on multiple venereal diseases, gynecopathy and perianal diseases, the effective rate can reach 100%, and the gingko extractive is safe and has no toxic and side effects in use.

Owner:王青

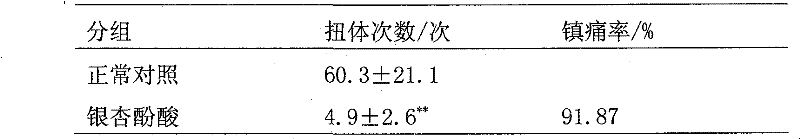

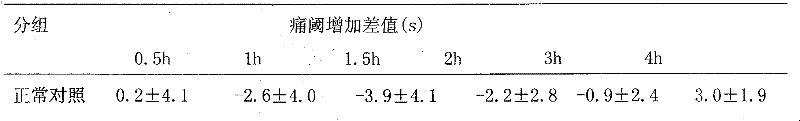

Application of ginkgolic acid in pain alleviation

InactiveCN102641309AGood inhibitory effectRaise pain thresholdNervous disorderAntipyreticSide effectDisinfectant

The invention relates to application of ginkgolic acid in pain alleviation. The ginkgolic acid comprises ginkgo acid, ginkgol, ginkgo diphenol and the like, and can be obtained from an extract of leaves, fruits, testa, rhizomes and the like of ginkgo by a chemical separation method. The pain comprises nerve pain, bone pain, muscle pain, tendon ligament pain, cancer pain and the like. A medicament, a medical instrument, a cosmetic or a disinfectant containing the ginkgolic acid and having a purpose of alleviating pain contains 0.001 to 80 weight percent of ginkgolic acid and pharmaceutically common external preparation matrix or acceptable carrier; and the preparation is any one of pharmaceutical external formulations. Pharmacological experimental research shows that the ginkgolic acid has an obvious effect of improving pain threshold on pain response caused by physical, chemical and cancerous stimulus. Clinical trials show that the ginkgolic acid has a remarkable alleviating effect on various pains and is predominant in curative effect, the effective rate reaches over 95 percent, and the ginkgolic acid is safe in use and does not have side effect.

Owner:王青

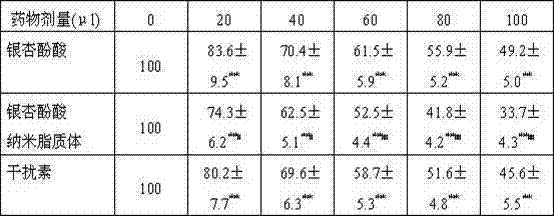

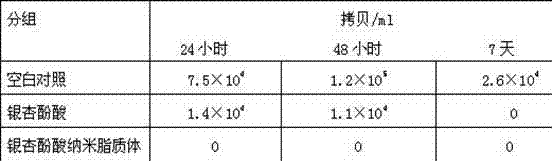

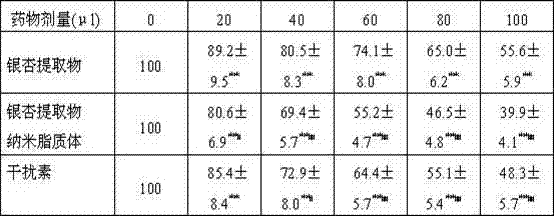

Application of ginkgolic acid nanometer liposome in treatment of gynecological diseases and venereal diseases

InactiveCN103751105AGood treatment effectPrevent proliferationAntibacterial agentsSalicyclic acid active ingredientsDiseasePharmacometrics

The invention relates to a use of ginkgolic acid nanometer liposome in preparation of external application preparations for treatment of gynecological diseases and venereal diseases. According to the present invention, the ginkgolic acid can be obtained from extracts of the exopleura part of gingko through a chemical separation method; the ginkgolic acid nanometer liposome is prepared by using a film ultrasound-high pressure homogenization method; the gynecological diseases are infectious and inflammatory genitalia diseases; the drug or the disinfectant external application preparation containing the ginkgolic acid nanometer liposome and provided for treatment of gynecological diseases and venereal diseases contains 0.001-80% of the ginkgolic acid nanometer liposome and a pharmaceutically and commonly used external application preparation substrate or an acceptable carrier; the preparation is the any one external application formulation in the pharmacy; and results of pharmacology studies and clinical trials show that the ginkgolic acid nanometer liposome provides prominent treatment effects for a variety of gynecological diseases and venereal diseases, wherein the effective rate is 100%, and characteristics of safe use and no side effect are provided.

Owner:王青

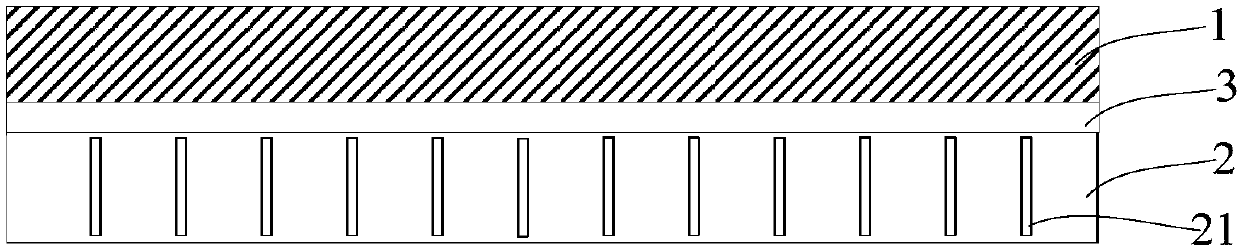

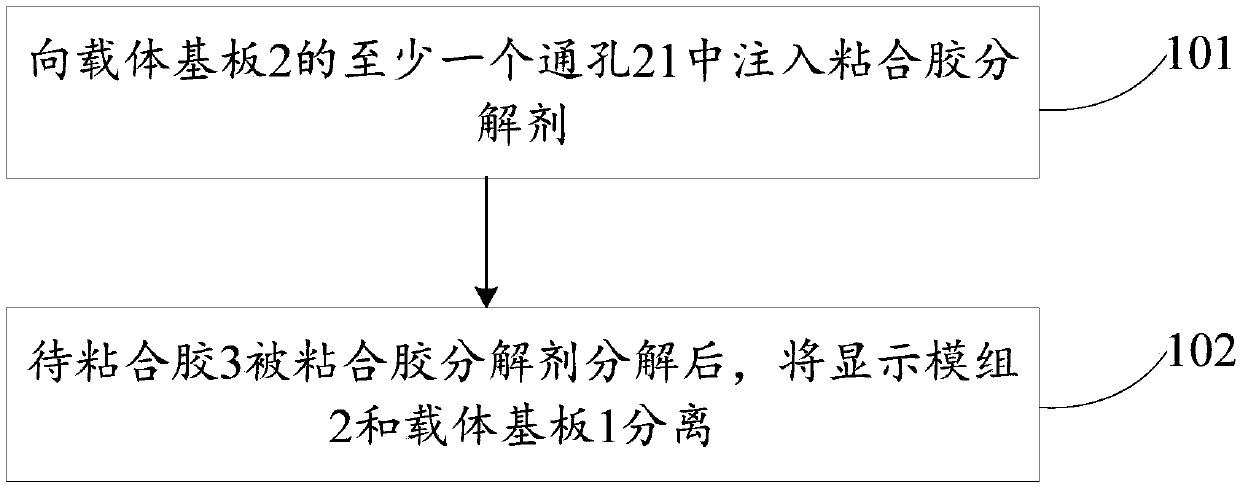

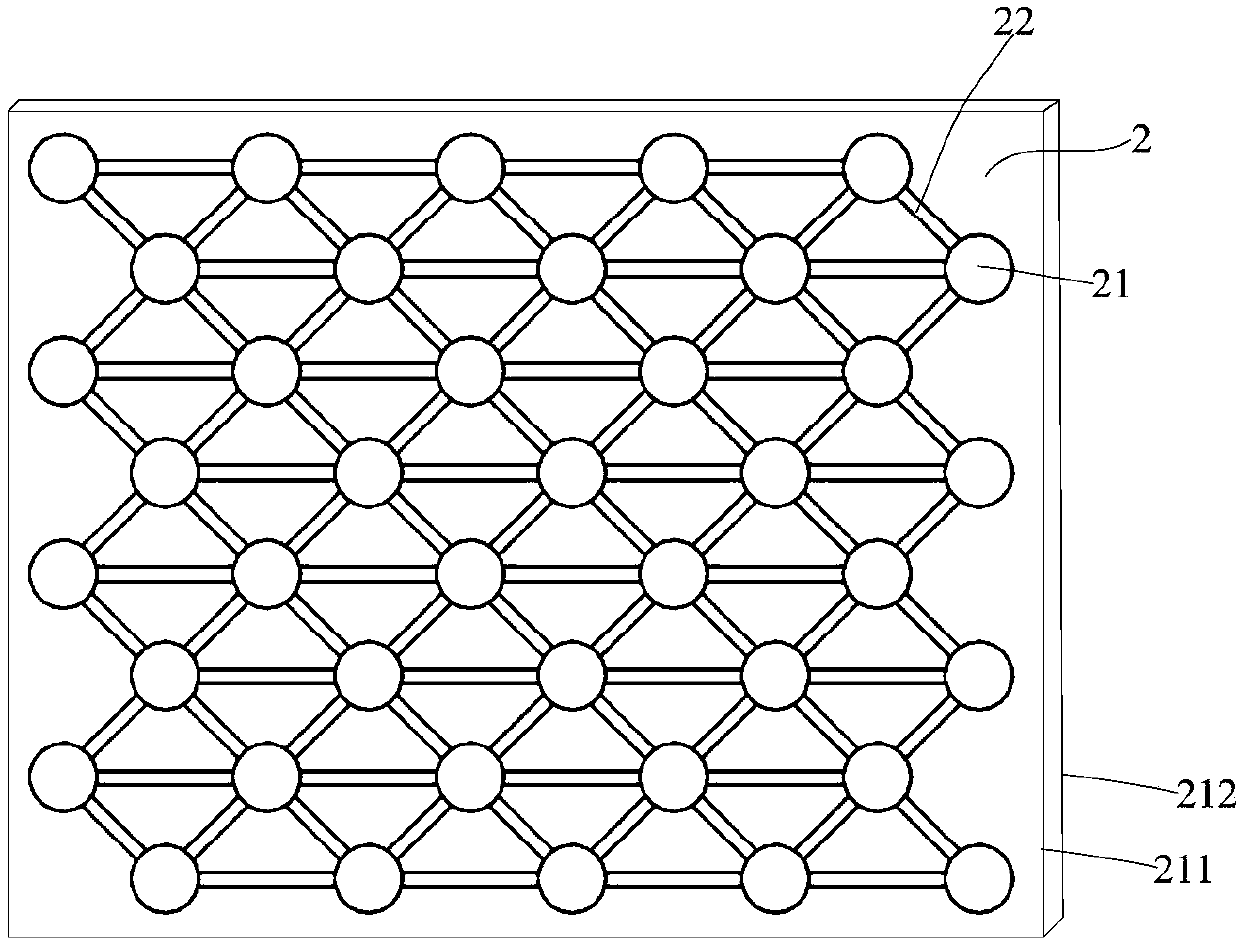

Method for separating display module group from carrier substrate

ActiveCN107808927AReduce alignment accuracy requirementsImprove flatnessSolid-state devicesSemiconductor/solid-state device manufacturingChemical reactionDecomposition

The invention provides a method for separating a display module group from a carrier substrate. The display module group and the carrier substrate are bonded together by an adhesive. The carrier substrate comprises a plurality of through holes. The separation method includes: adhesive glue disintegrants are injected into a plurality of through holes of the carrier substrate; and after decomposition of the adhesive glue by the adhesive glue disintegrants, the display module group and the carrier substrate are separated. According to the embodiment of the invention, the adhesive glue disintegrants are injected into the through holes and the adhesive glue disintegrants are in contact with the adhesive glue to produce chemical reaction, so that the activity of the adhesive glue is reduced andthus the display module group is easy to separate from the carrier substrate. Compared with the conventional physical separation method, the chemical separation method based on the chemical reaction between the adhesive glue disintegrants and the adhesive glue enables the display module group to be protected from being damaged by the physical separation force; and the difficulty of bonding betweenthe carrier substrate and the display module group is also reduced.

Owner:YUNGU GUAN TECH CO LTD

Application of gingko extract nanometer liposome in gynecological disease treatment

InactiveCN103751230AGood treatment effectPrevent proliferationAntibacterial agentsAntimycoticsSide effectTreatment effect

The invention relates to a use of gingko extract nanometer liposome in preparation of external application preparations for gynecological disease treatment. According to the present invention, the gingko extract can be obtained from extracts of leaf, fruit, rhizome and other parts of gingko through a chemical separation method; the gingko extract nanometer liposome is prepared by using a film ultrasound-high pressure homogenization method; the drug, the cosmetic or the disinfectant external application preparation containing the gingko extract nanometer liposome and provided for gynecological disease treatment contains 0.001-80% of the gingko extract nanometer liposome and a pharmaceutically and commonly used external application preparation substrate or an acceptable carrier; the preparation is the any one external application formulation in the pharmacy; and results of pharmacology studies and clinical trials show that the gingko extract nanometer liposome provides significant treatment effects for a variety of gynecological diseases, and has characteristics of safe use and no side effect.

Owner:王青

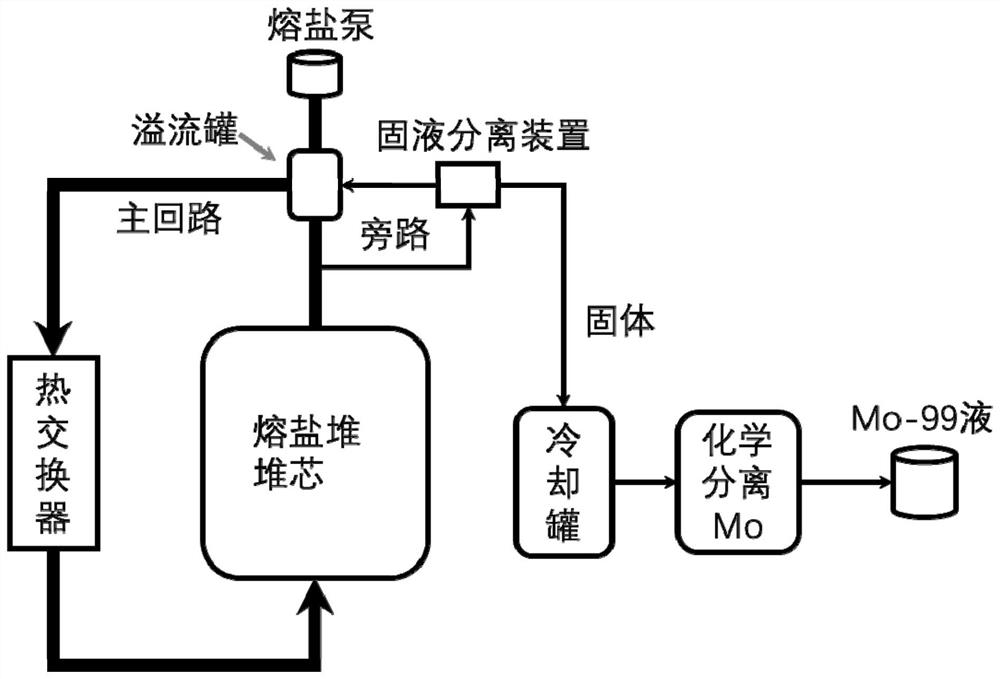

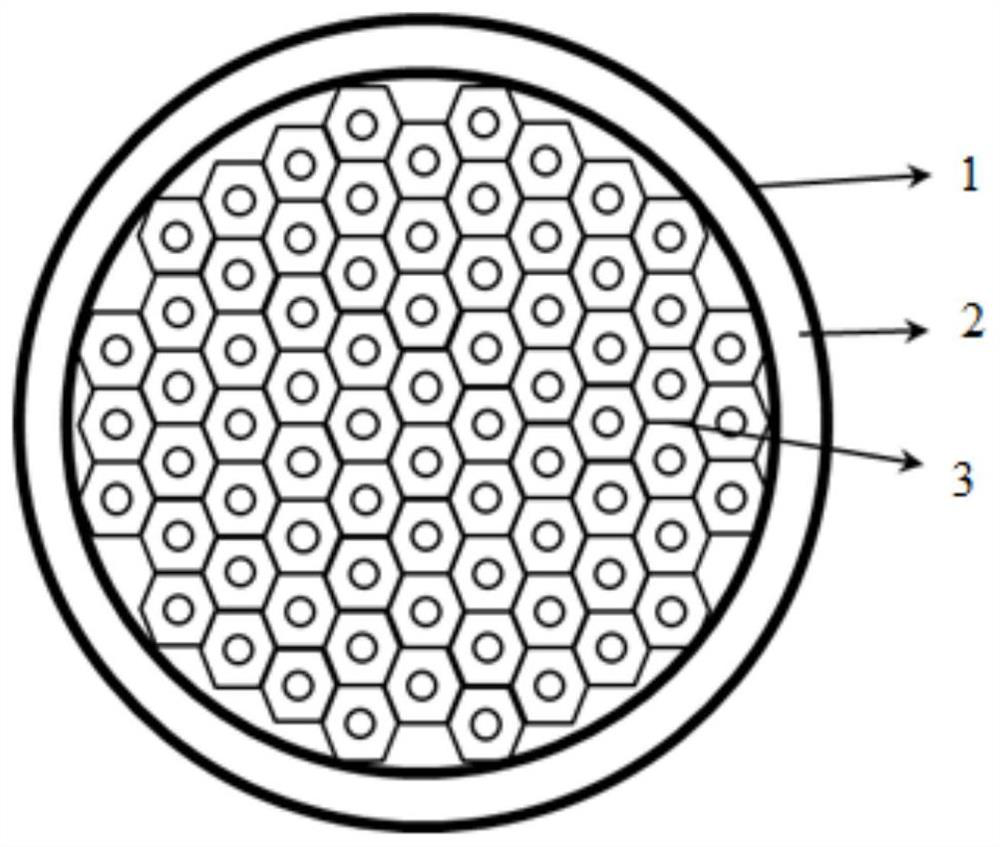

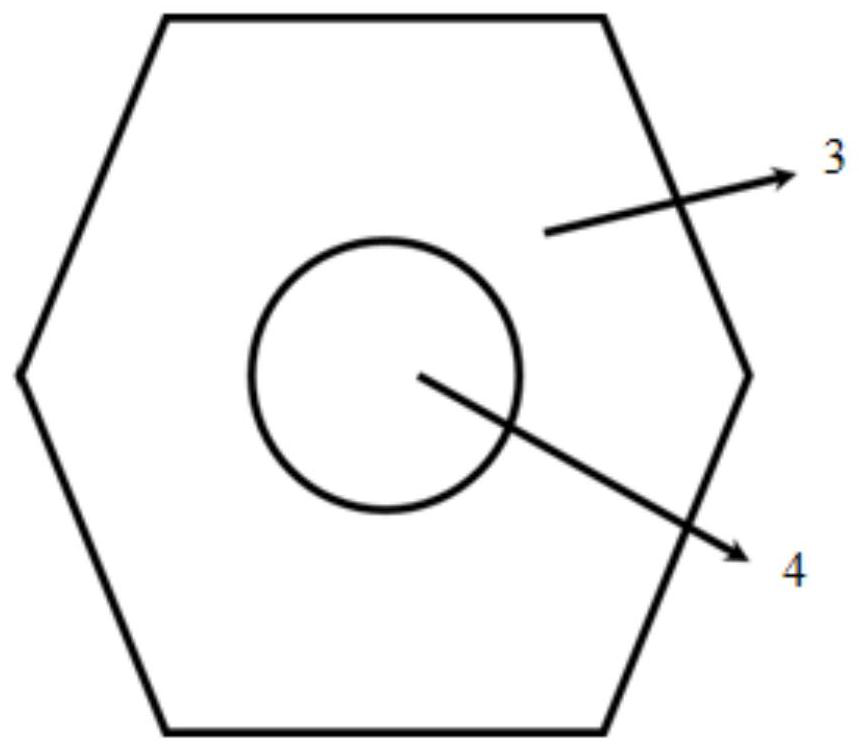

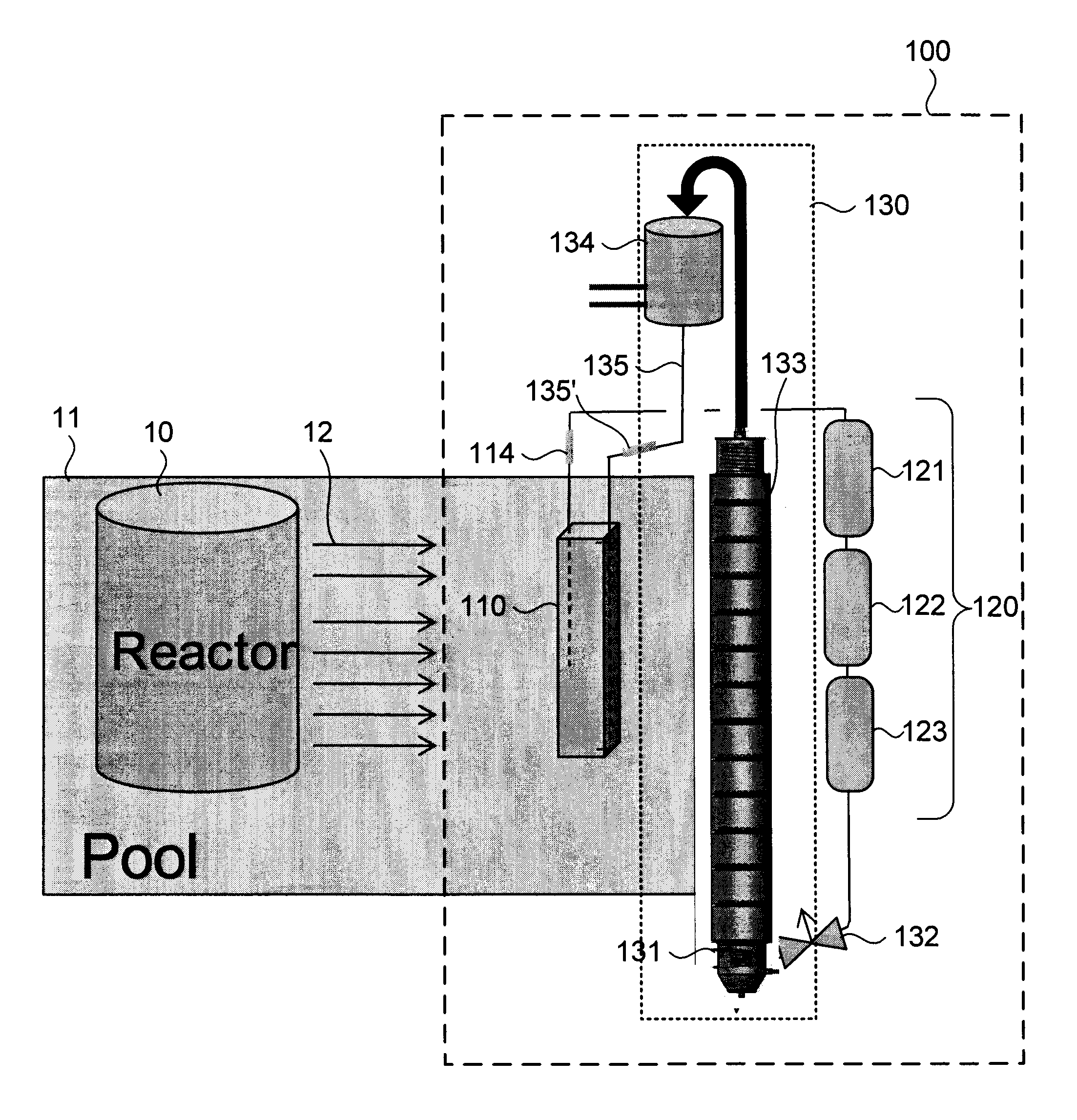

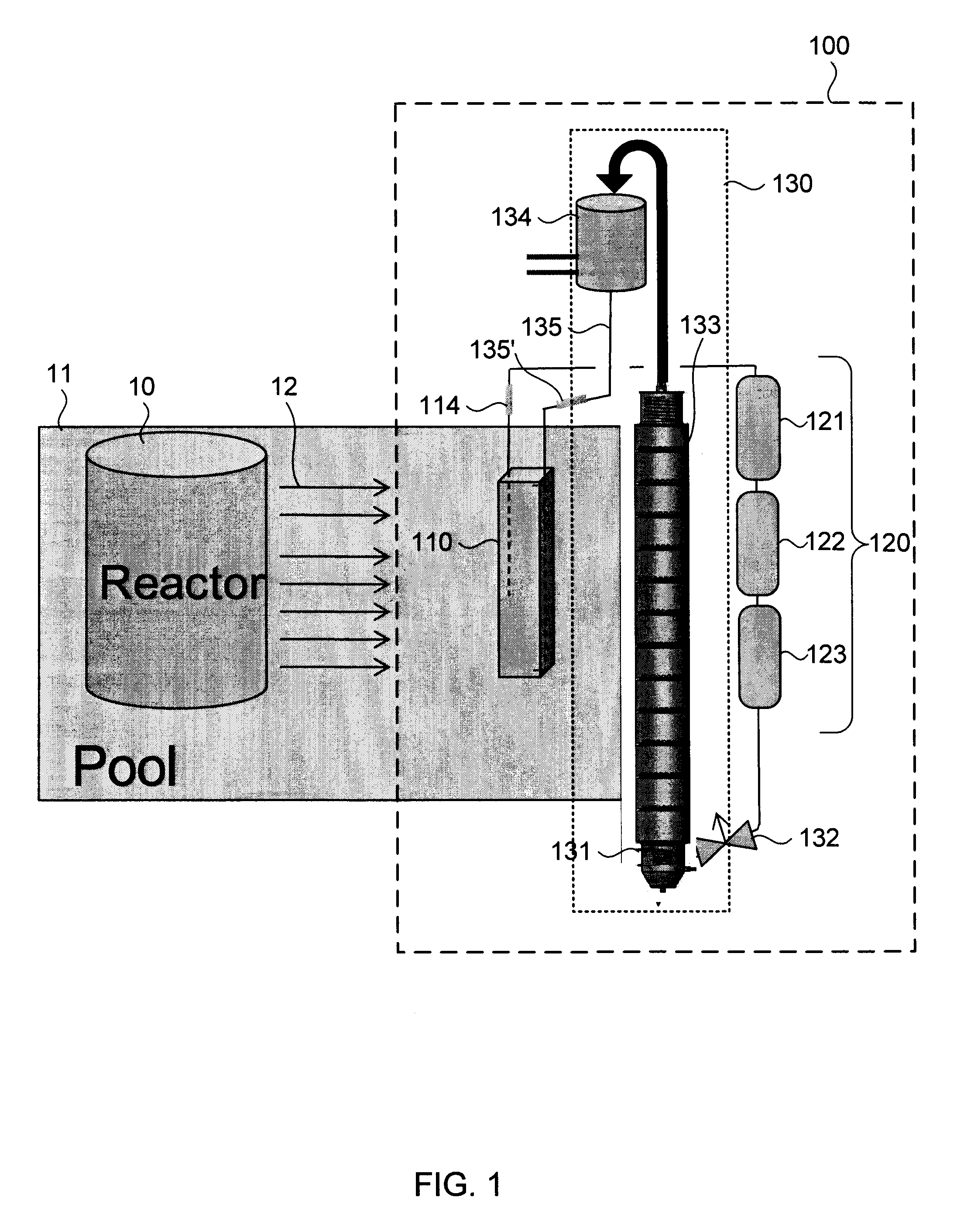

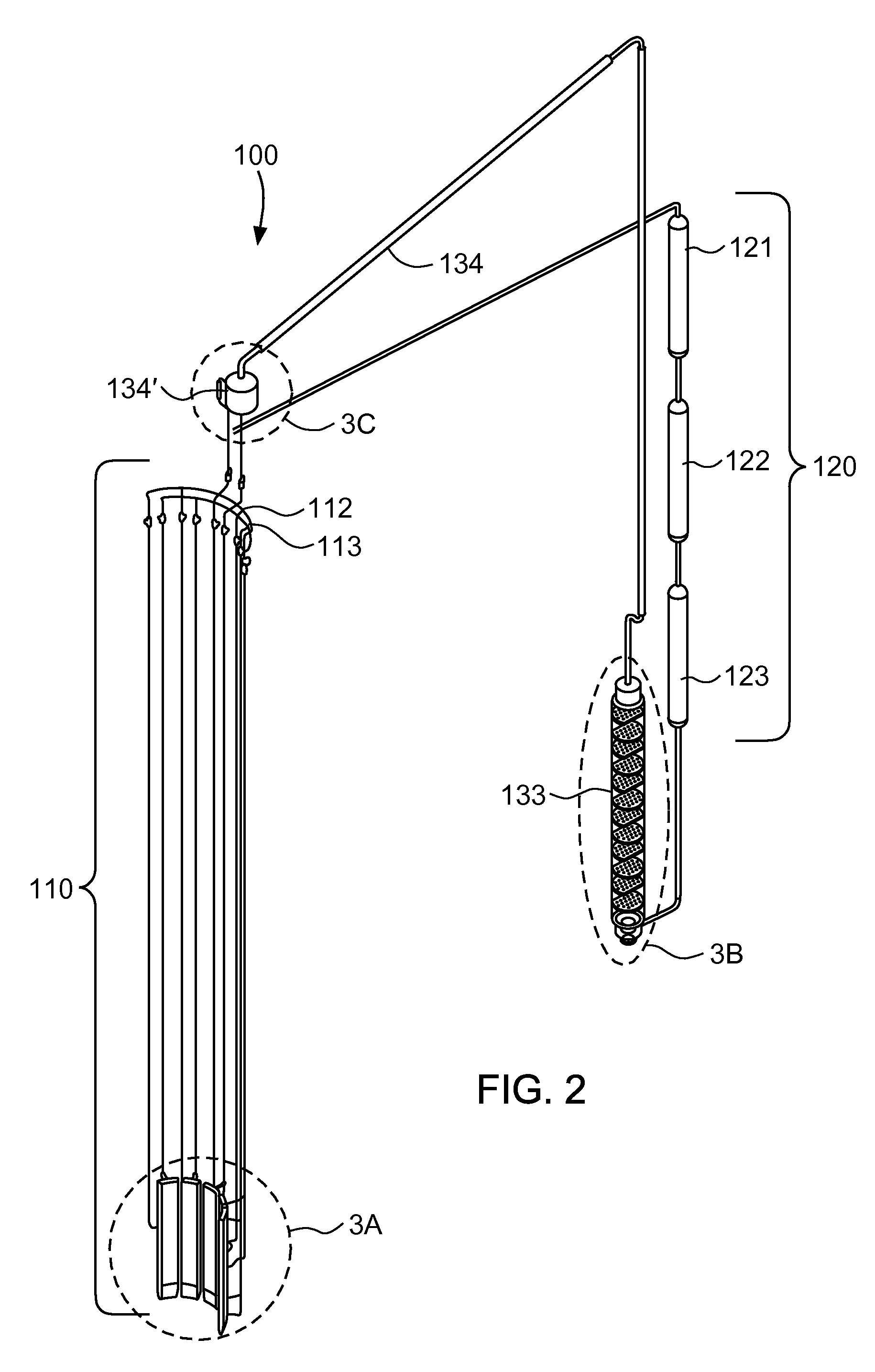

Method and system for producing Mo-99 through liquid molten salt reactor

ActiveCN112863725AIncrease productivityIncrease profitConversion outside reactor/acceleratorsNuclear energy generationEngineeringChemical separation

The invention provides a method and a system for producing Mo-99 by using a liquid molten salt reactor. The method comprises the following steps: providing a liquid molten salt reactor, wherein a plurality of graphite moderation assemblies containing channels are arranged in the reactor core, the channels of the graphite moderation assemblies are filled with molten salt composed of low-enriched uranium and base salt, and Mo-99 is generated by fission in the liquid molten salt reactor. When the liquid molten salt reactor runs, an on-line solid-liquid separation method is adopted to separate indissolvable solid fission products on line, then a cooling method is adopted to reduce the radioactive activity of the indissolvable solid fission products, and finally a chemical separation method is adopted to separate and recover Mo-99 from the indissolvable solid fission products, so that the preparation of Mo-99 is realized. According to the invention, the production efficiency is improved, operation is convenient and fast, the economic cost is low, the fuel demand quantity is low, the radioactive shielding requirement is low, and the current Mo-99 supply demand problem can be effectively solved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

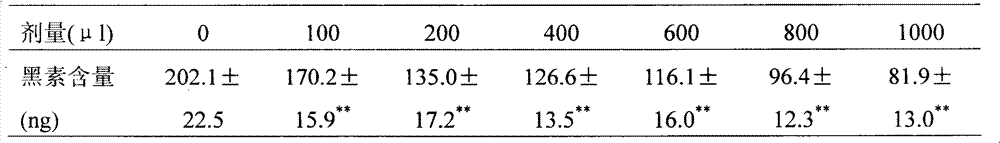

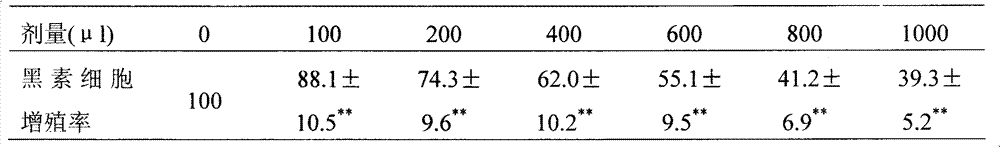

Application of ginkgolic acid in skin whitening, freckle removing and resurfacing

InactiveCN102846501APrevent proliferationPromote apoptosisCosmetic preparationsHydroxy compound active ingredientsSide effectApoptosis

The invention relates to application of ginkgolic acid in skin whitening, freckle removing and resurfacing. The ginkgolic acid comprises ginkgolic acid, ginkgol and bilobol and can be obtained from the extracts of such parts of the gingko as leaves, fruits, testae and rootstalks by a chemical separation method. A medicament or cosmetic which contains ginkgolic acid and is used for skin whitening, freckle removing and resurfacing contains 0.001-80% by weight of ginkgolic acid and pharmaceutically common external preparation substrates or acceptable carriers, wherein the preparation is any one pharmaceutically called external dosage form. Pharmacological experiment studies show that the preparation has the effect of inhibiting the activity of tyrosinase and melanogenesis in the skin, can obviously promote proliferation of keratinocytes and apoptosis and has obvious skin whitening, freckle removing and resurfacing effects. Clinical trials show that the preparation has obvious effects of improving the preventing dark yellow complexion and facial pigmentation, is one hundred percent in effective rate, is safe to use and does not have side effects.

Owner:王青

Application of ginkgo extractive in preparing external preparation capable of treating skin disease

InactiveCN102247411AGood treatment effectGood effectGinkgophyta medical ingredientsDermatological disorderSide effectSkin irritation

The invention relates to an application of ginkgo extractive in preparing external preparation capable of treating skin diseases. The ginkgo extractive can be obtained from extractives of ginkgo leaves, fruits, testa, roots, stems and other positions with a chemical separation method. Extraction solvents can be organic solvents, such as ethanol, water, aether, sherwood oil and the like. The skin disease is infectious, inflammatory, allergic reaction or allergic dermatitis. The drug, cosmetics or disinfector external preparations containing ginkgo extractives contains 0.001-80wt% of ginkgo extractive, pharmaceutically commonly-used external preparation or acceptable carrier. The preparation is any external preparation of pharmacy. The local irritation test researches to show that the ginkgo extractive is safe, is free from adverse reaction, such as skin irritation, allergy and the like. The trial result of patients with clinical infectious or anaphylactic skin diseases proves that the ginkgo extractive has obvious treating effect on various skin diseases, and the effective rate is 100%, and the ginkgo extractive is safe to use and has no side effect.

Owner:王青

Systems and methods for efficiently preparing plutonium-238 with high isotopic purity

InactiveUS9196389B2Efficient preparationInhibit side effectsSpecific isotope recoveryPlutonium halidesNuclear reactorIsotope

A method for preparing plutonium-238 (Pu-238) includes using a nuclear reactor in irradiating a liquid containing a neptunium-237 (Np-237) based compound with neutrons to convert a portion of the Np-237 based compound to a Np-238 based compound; retaining the liquid containing the resulting mixture for a sufficient amount of time for the Np-238 based compound to at least partially convert to a Pu-238 based compound; and separating the Pu-238 based compound from the neptunium based compounds using fractional distillation or a chemical separation method.

Owner:GENERAL ATOMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com