Method for comprehensively extracting lithium, potassium and boron from oilfield brine

A comprehensive extraction, lithium potassium boron technology, applied in chemical instruments and methods, boron compounds, boron oxide compounds, etc., to achieve the effect of low cost, economic benefits and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

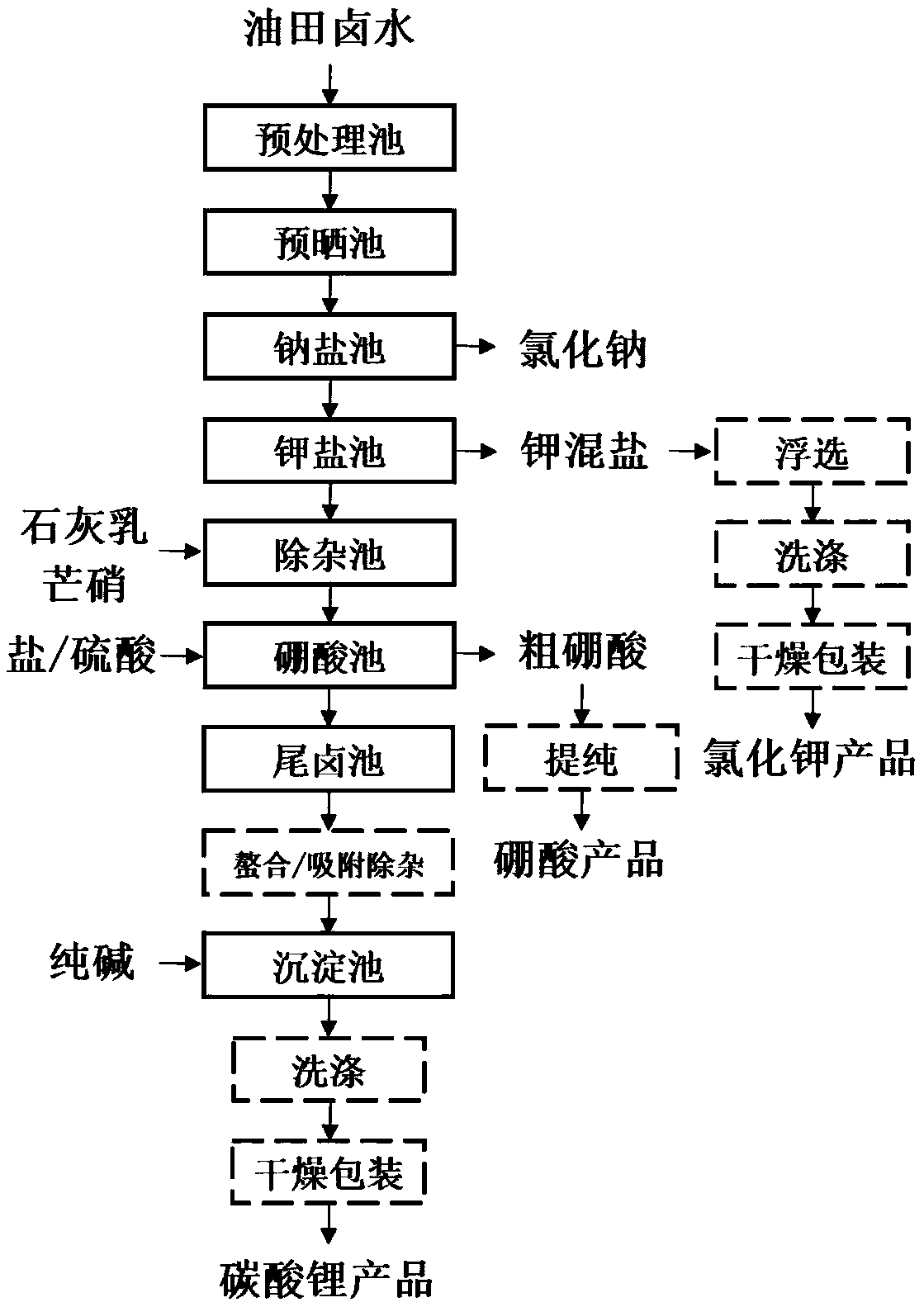

[0056] A method for comprehensively extracting lithium, potassium and boron from oil field brine, specifically including the following steps, the process flow is as follows figure 1 Shown:

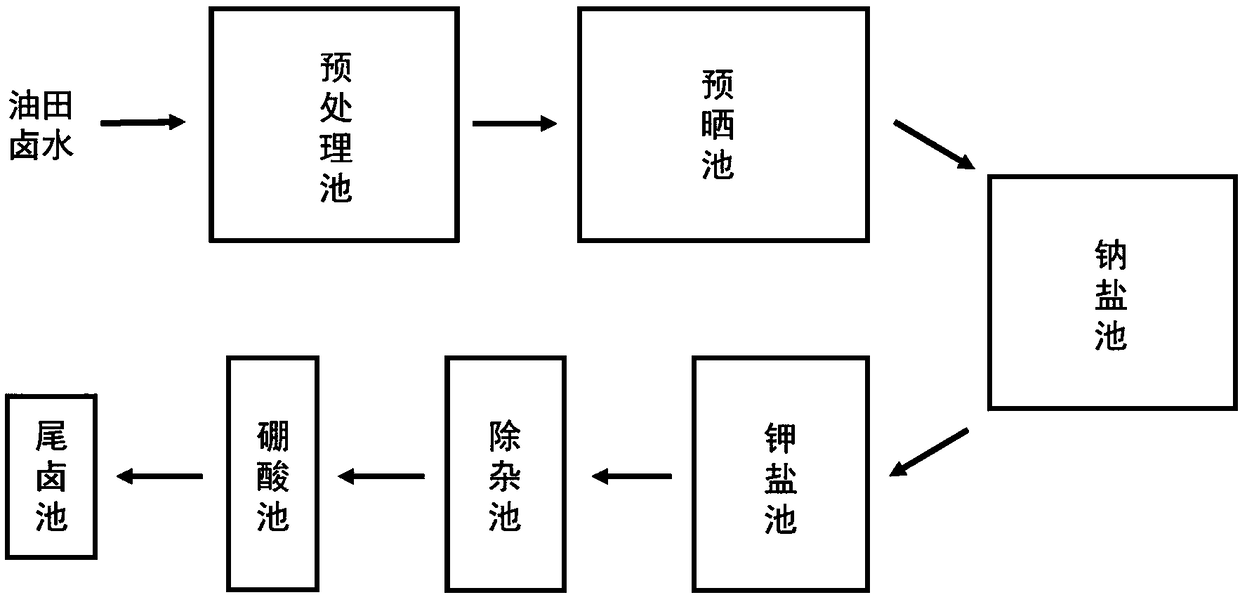

[0057] 1) Set up the pretreatment pool, pre-sunning pool, sodium salt pool, potash salt pool, impurity removal pool, boric acid pool and tail brine pool in sequence, such as figure 2 Shown

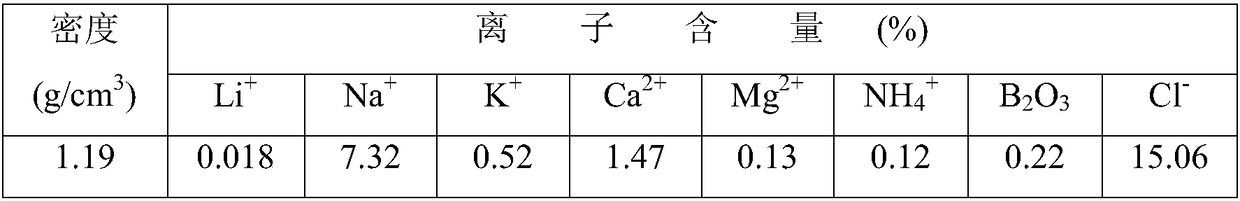

[0058] 2) Take the brine from an oilfield in Qinghai (see Table 1 below for the chemical composition of brine), pump it into the pretreatment tank, naturally settle the mud and sand, and separate oil and water with an oil-water separator to obtain clarified pretreated oilfield brine;

[0059] Table 1 Chemical composition of oil field brine

[0060]

[0061] 3) Pour the pre-treated oilfield brine obtained in step 2) into the pre-tanning tank for natural evaporation in the sun. + When it is close to saturation, it is poured into a sodium salt bath to crystallize sodium chloride, and the liquid phase weight of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com