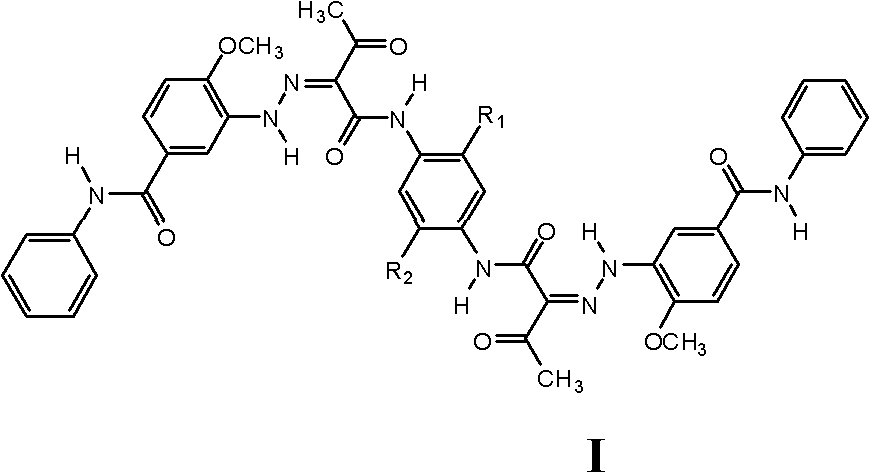

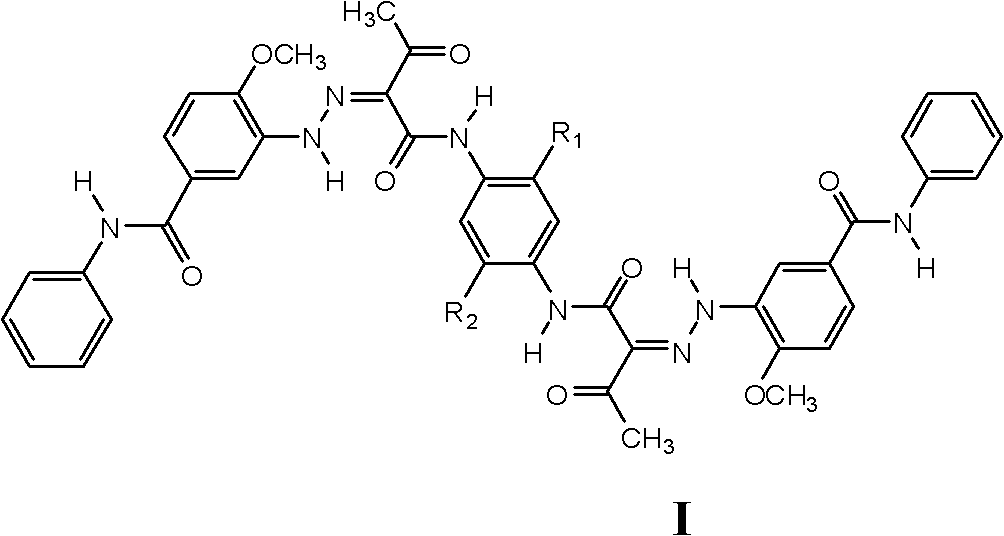

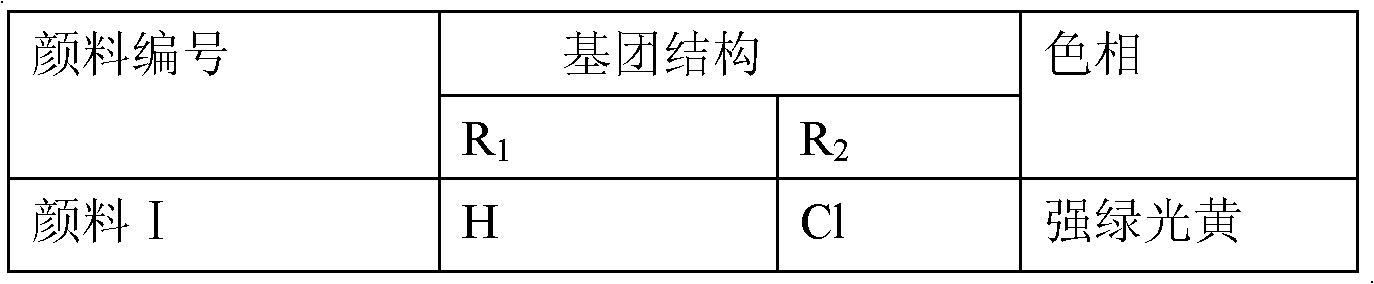

Strong green light yellow disazo organic pigment

A technology of organic pigments and disazo, applied in the field of organic pigments, can solve the problems of red color and high price of pigments, achieve high tinting strength, moderate price, and reduce usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The synthesis of embodiment 1 pigment I

[0037]Disperse 24.2 parts of red base KD in 100 ml of water and 34.5 parts of 32% hydrochloric acid at room temperature. Dissolve 6.96 parts of sodium nitrite in 30 ml of water. To 100 ml of water at 15°C, add the red base KD suspension and sodium nitrite aqueous solution at the same time to obtain a transparent light yellow diazonium salt solution. Add water to dilute to 300 parts, keep a slight excess of sodium nitrite, and wait for coupling.

[0038] Dissolve 16.1 parts of 2-chloro-1.4-bisacetoacetamido-p-phenylenediamine in 250 parts of water containing 4.2 parts of sodium hydroxide, filter, collect the mother liquor, and add water to adjust to 300 parts.

[0039] Add 14 parts of sodium acetate and 0.2 parts of emulsifier EL-40 to 200 parts of water, add the diazo component and the coupling component to the buffer system at the same time at 15 ° C, add it in about 2 hours, stir for 30 minutes, and heat up To 50°C, keep wa...

Embodiment 2

[0042] Using sodium phosphate and sodium dihydrogen phosphate instead of sodium acetate as a buffer, the operation steps of Example 1 were repeated to obtain 39.5 grams of pigment samples.

Embodiment 3

[0043] The synthesis of embodiment 3 pigment III

[0044] Diazo component and preparation are the same as in Example 1.

[0045] Dissolve 17.2 parts of 2-chloro-5-methyl-1.4-bisacetoacetamido-p-phenylenediamine in 250 parts of hot water containing 4.4 parts of sodium hydroxide, filter, collect the mother liquor, and add water to adjust to 300 parts.

[0046] Add 12 parts of sodium bicarbonate to 200 parts of water to prepare a buffer system, add the diazo component and the coupling component to the buffer system at the same time at 15 ° C, add it in about 2 hours, stir for 30 minutes, and detect the weight with H acid Nitrogen salts are all gone. Heat up to 95°C, keep warm for 2 hours, filter, and wash with water. Take the filter cake and add about 600 parts of DMF, stir and raise the temperature to reflux for 3 hours. Cool down to 30°C, filter, recover the DMF mother liquor, wash with water, and dry. Get about 41.3 grams of pigment dry product.

[0047] Compared with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com