Purification method for butylene by chemical separation process

A technology for chemical separation, butene, applied in chemical instruments and methods, distillation purification/separation, hydrocarbon purification/separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

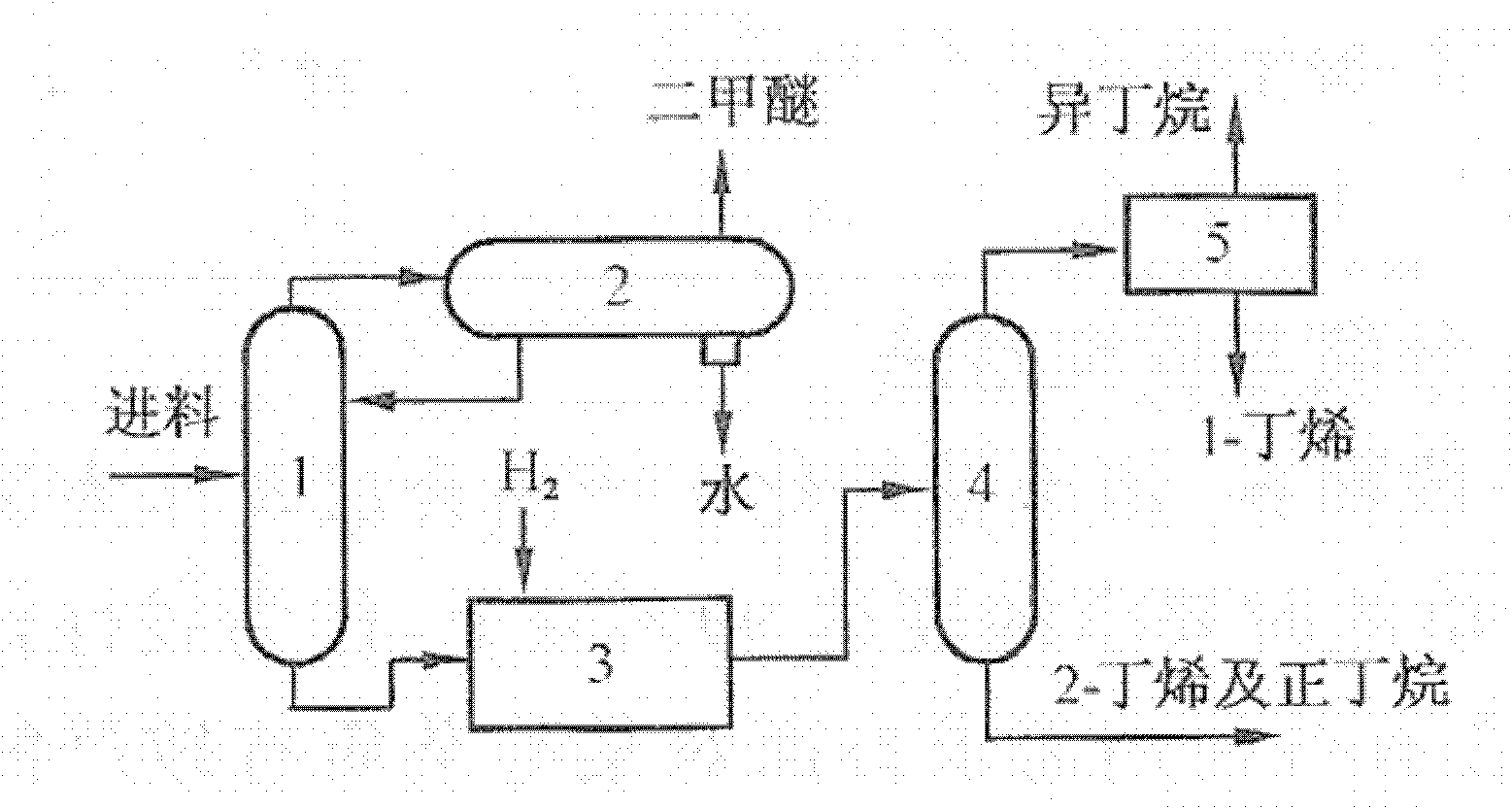

[0025] In the synthesis stage of methyl tert-butyl ether, two-stage reaction and methanol excess measures are adopted to improve the removal rate of isobutene. After removing isobutene, the C4 material is subjected to hydrogenation treatment to remove impurities such as butadiene, and then refined Distillation, the bottom of the tower is 2-butene and n-butane, and the overhead fraction is 1-butene and isobutane. The overhead fraction is extracted and distilled to separate isobutane, which obtains high-purity 1-butene, 1500 kg, see process flow figure 1 .

Embodiment 2

[0027] In the synthesis stage of methyl tert-butyl ether, two-stage reaction and methanol excess measures are adopted to improve the removal rate of isobutene. After removing isobutene, the C4 material is subjected to hydrogenation treatment to remove impurities such as butadiene, and then refined Distillation, the tower bottom is 2-butene and n-butane, the overhead fraction is 1-butene and isobutane, and the overhead fraction is extracted and distilled to separate isobutane, which obtains high-purity 1-butene, 2000 kg, see process flow figure 1 .

Embodiment 3

[0029] In the synthesis stage of methyl tert-butyl ether, two-stage reaction and methanol excess measures are adopted to improve the removal rate of isobutene. After removing isobutene, the C4 material is subjected to hydrogenation treatment to remove impurities such as butadiene, and then refined Distillation, the tower bottom is 2-butene and n-butane, and the overhead fraction is 1-butene and isobutane. The overhead fraction is extracted and distilled to separate isobutane to obtain high-purity 1-butene, 4000 kg, see process flow figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com