N-butane extraction method by adsorption separation

A technology of adsorption separation and n-butane, applied in the direction of adsorption purification/separation, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

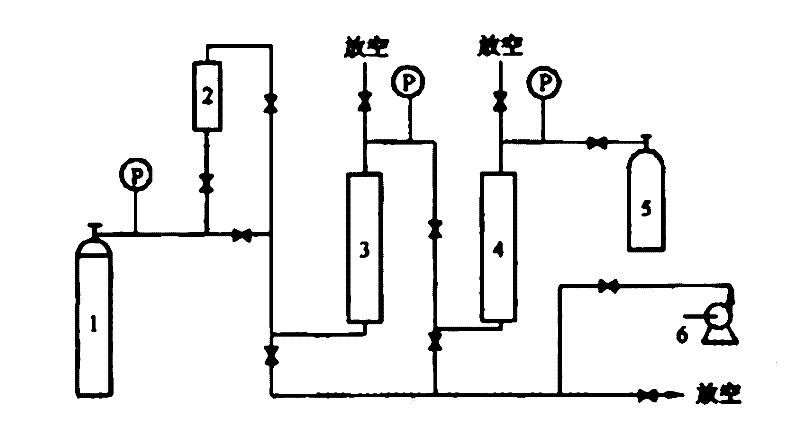

[0020] Under the protection of pure hydrogen or pure nitrogen, n-butane, isobutane, and propane are separated, and high-purity n-butane is adsorbed and retained in the adsorption phase, and then the molecular sieve is heated or assisted by nitrogen purging to make n-butane The high-purity n-butane product can be obtained by collecting the desorbed gas, and the product purity is 99.5%. see details figure 1 .

Embodiment 2

[0022] Under the protection of pure hydrogen or pure nitrogen, n-butane, isobutane, and propane are separated, and high-purity n-butane is adsorbed and retained in the adsorption phase, and then the molecular sieve is heated or assisted by nitrogen purging to make n-butane desorption of alkane, and the high-purity n-butane product can be obtained by collecting the desorption gas. The product purity is 99.8%. For details, see figure 1 .

Embodiment 3

[0024] Under the protection of pure hydrogen or pure nitrogen, n-butane, isobutane, and propane are separated, and high-purity n-butane is adsorbed and retained in the adsorption phase, and then the molecular sieve is heated or assisted by nitrogen purging to make n-butane desorption of alkanes, and the high-purity n-butane product can be obtained by collecting the desorption gas. The product purity is 99.5%. For details, see figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com