Method for adopting and combining adsorption and rectification for purifying n-butane

A technology of n-butane and rectification, applied in the direction of adsorption purification/separation, distillation purification/separation, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

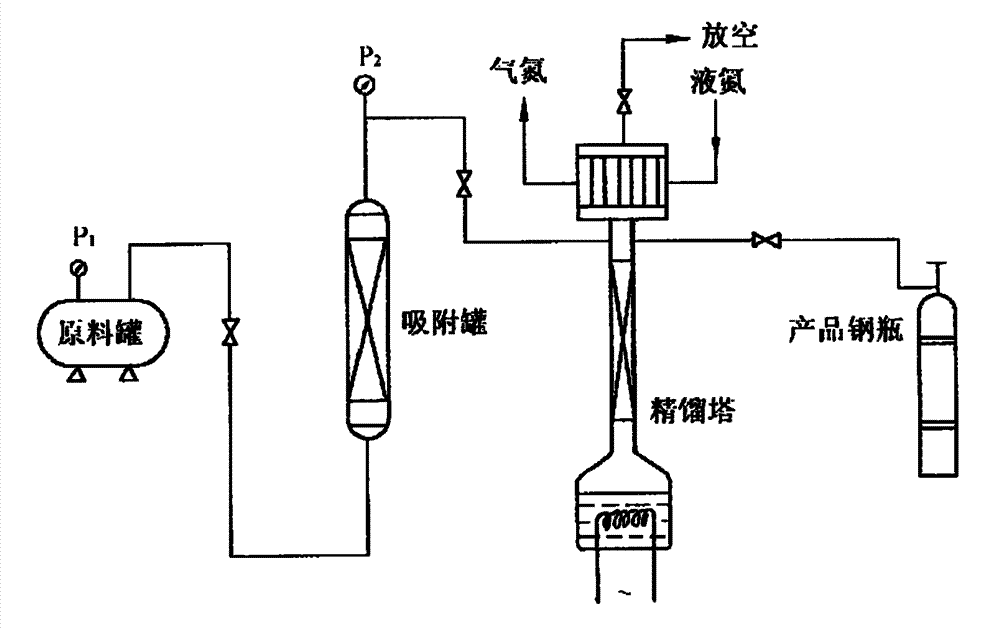

[0016] The n-butane raw material is passed through the adsorber equipped with NaX adsorbent, the rectification tower is evacuated, and then the outlet gas of the adsorber is fed into the tower at one time, and the temperature of the tower top is controlled by ice salt condensing agent, and the tower kettle Use a warm water bath to control the temperature. During operation, the temperature of the tower kettle is 50°C, and then adjust the water temperature of the tower kettle to maintain normal operation under total reflux. Every time it is balanced for a period of time, the balance gas is discharged from the analysis port on the top of the tower and analyzed. While maintaining the operation of the tower, the product in the tower kettle is filled into the steel cylinder. See the process for details. figure 1 .

Embodiment 2

[0018] The n-butane raw material is passed through the adsorber equipped with NaX adsorbent, the rectification tower is evacuated, and then the outlet gas of the adsorber is fed into the tower at one time, and the temperature of the tower top is controlled by ice salt condensing agent, and the tower kettle Use a warm water bath to control the temperature. During operation, the temperature of the tower kettle is 70°C, and then adjust the water temperature of the tower kettle to maintain normal operation under total reflux. Every time it is balanced for a period of time, the balance gas is discharged from the analysis port on the top of the tower and analyzed. While maintaining the operation of the tower, the product in the tower kettle is filled into the steel cylinder. See the process for details. figure 1 .

Embodiment 3

[0020] The n-butane raw material is passed through the adsorber equipped with NaX adsorbent, the rectification tower is evacuated, and then the outlet gas of the adsorber is fed into the tower at one time, and the temperature of the tower top is controlled by ice salt condensing agent, and the tower kettle Use a warm water bath to control the temperature. During operation, the temperature of the tower kettle is 80°C, and then adjust the water temperature of the tower kettle to maintain normal operation under total reflux. Every time it is balanced for a period of time, the balance gas is discharged from the analysis port on the top of the tower and analyzed. While maintaining the operation of the tower, the product in the tower kettle is filled into the steel cylinder. See the process for details. figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com