Method for purifying n-butane by rectifying

A technology of n-butane and rectification, applied in chemical instruments and methods, distillation purification/separation, hydrocarbon purification/separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

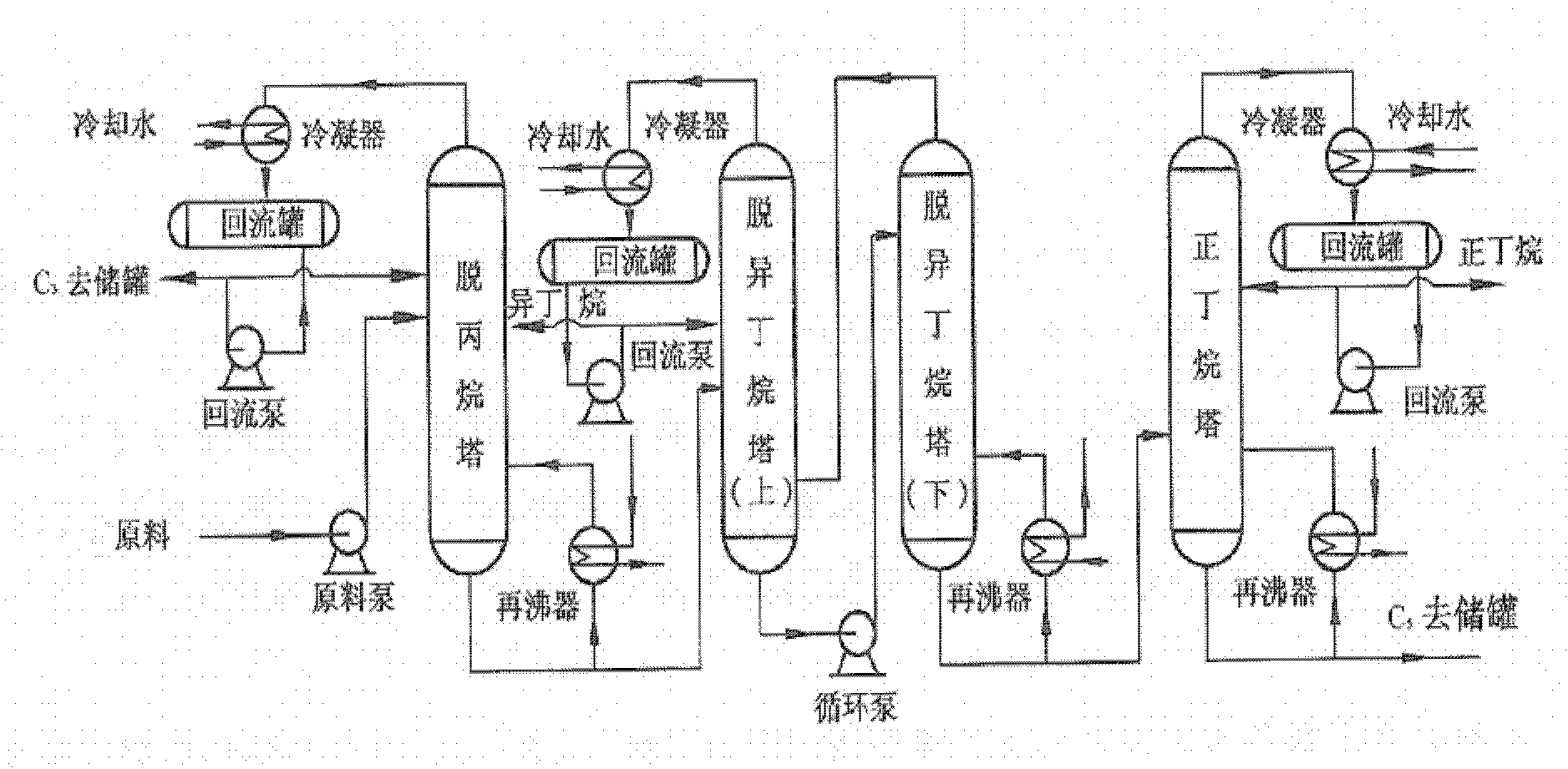

[0014] Hydrogenate C4 hydrocarbons, completely hydrogenate olefins and diolefins into n-butane and isobutane, and then separate the two by rectification to obtain n-butane with higher purity; among them, C4 hydrocarbons : Hydrogenation is a volume ratio of 1:0.1mol, see the technical process figure 1 .

Embodiment 2

[0016] Hydrogenate C4 hydrocarbons, completely hydrogenate olefins and diolefins into n-butane and isobutane, and then separate the two by rectification to obtain n-butane with higher purity; among them, C4 hydrocarbons : Hydrogenation is a volume ratio of 1:0.5mol, see the technical process figure 1 .

Embodiment 3

[0018] Hydrogenate C4 hydrocarbons, completely hydrogenate olefins and diolefins into n-butane and isobutane, and then separate the two by rectification to obtain n-butane with higher purity; among them, C4 hydrocarbons : The volume ratio of hydrogenation is 1:2mol, see the technical process figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com