Waste aluminum and plastic separating and recycling process

A technology for separating and recycling aluminum and plastic, which is applied in the field of aluminum and plastic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

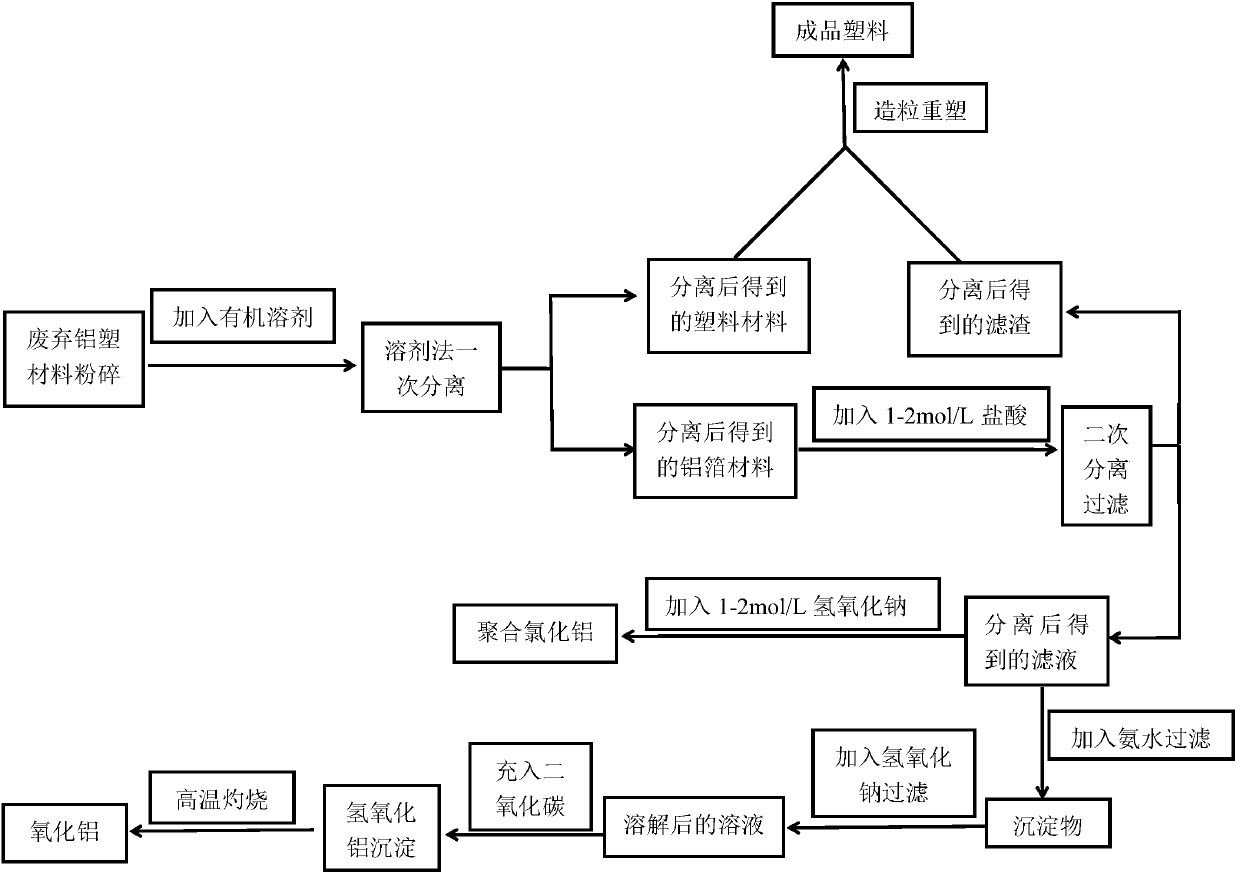

Image

Examples

Embodiment 1

[0021] A process for separating and recycling waste aluminum and plastic, the specific steps are as follows:

[0022] Step 1: Put the discarded aluminum-plastic composite packaging materials into a crushing and cutting machine and crush them into granules, then put the crushed aluminum-plastic materials into a mixing bucket, put toluene in the mixing bucket until the aluminum-plastic materials are completely submerged, and then After stirring for 8 hours at 500 rpm, the plastic material floating on the surface of the organic solvent and the aluminum foil material deposited at the bottom of the mixing tank were cleaned with water respectively;

[0023] Step 2: The cleaned plastic material is dried and then granulated and reshaped to obtain the finished plastic. The aluminum foil material deposited at the bottom of the mixing tank is dried and put into the reaction vessel for secondary separation;

[0024] Step 3: Add 2mol / L hydrochloric acid solution into the reaction vessel, w...

Embodiment 2

[0029] A process for separating and recycling waste aluminum and plastic, the specific steps are as follows:

[0030] Step 1: Put the discarded aluminum-plastic composite packaging materials into a crushing and cutting machine and crush them into granules, then put the crushed aluminum-plastic materials into a mixing bucket, put acetone in the mixing bucket until the aluminum-plastic materials are completely submerged, and then After stirring for 2 hours at 200 rpm, the plastic material floating on the surface of the organic solvent and the aluminum foil material deposited at the bottom of the mixing tank were cleaned with water respectively;

[0031] Step 2: The cleaned plastic material is dried and then granulated and reshaped to obtain the finished plastic. The aluminum foil material deposited at the bottom of the mixing tank is dried and put into the reaction vessel for secondary separation;

[0032] Step 3: Add 1mol / L hydrochloric acid solution into the reaction vessel, w...

Embodiment 3

[0037] A process for separating and recycling waste aluminum and plastic, the specific steps are as follows:

[0038] Step 1: Put the discarded aluminum-plastic composite packaging materials into a crushing and cutting machine and crush them into granules, then put the crushed aluminum-plastic materials into a mixing bucket, put chloroform in the mixing bucket until the aluminum-plastic materials are completely submerged, After stirring for 6 hours at 300 rpm, the plastic material floating on the surface of the organic solvent and the aluminum foil material deposited at the bottom of the mixing tank were cleaned with water respectively;

[0039] Step 2: The cleaned plastic material is dried and then granulated and reshaped to obtain the finished plastic. The aluminum foil material deposited at the bottom of the mixing tank is dried and put into the reaction vessel for secondary separation;

[0040] Step 3: Add 1.5mol / L hydrochloric acid solution into the reaction vessel, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com