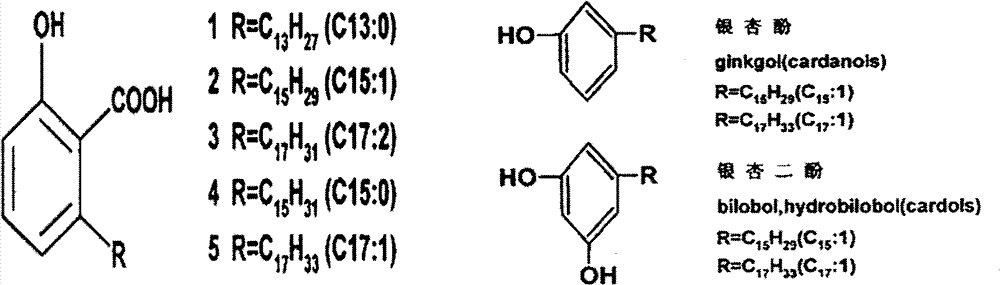

Application of ginkgolic acid in skin whitening, freckle removing and resurfacing

A ginkgolic acid, whitening and freckle-removing technology, which is applied in the field of therapeutic cosmetics and biomedicine, can solve problems such as human health damage, achieve the effects of promoting proliferation, inhibiting melanin production, and using it without side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

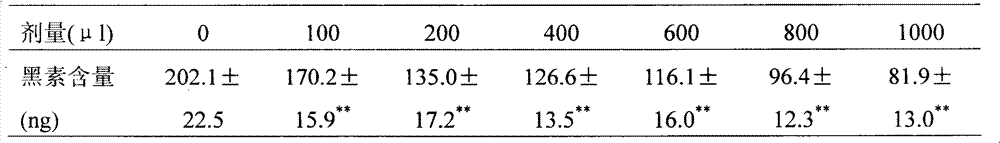

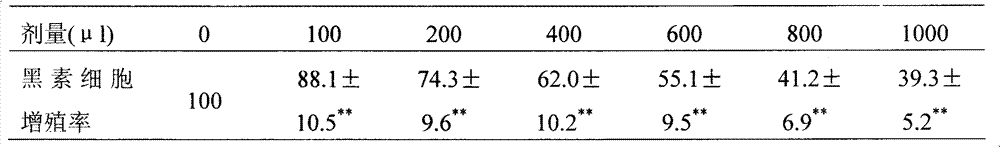

Examples

Embodiment 1

[0019] The extraction process of ginkgolic acid from the ginkgo biloba exocarp is as follows: the ginkgo biloba exocarp is peeled off, dried, and crushed with a grinder. Accurately weigh a certain amount of crushed Ginkgo biloba exocarp, add 80% ethanol with a material-to-liquid ratio of 1:6 (W / V), stir and extract twice at a water bath temperature of 60°C, each extraction time is 4 hours , (Note: After adding liquid, seal the mouth of the beaker with plastic wrap to prevent the evaporation of ethanol). After the leaching is finished, use a suction filter to collect the filtrate. Concentrate the filtrate with a vacuum rotary evaporator under the conditions of a temperature of 55°C, a pressure of 0.008-0.009 MPa, and concentration under reduced pressure. It was dried in vacuum at 60°C to obtain the ginkgolic acid extract. The properties were: light brown extract, slightly odor, soluble in alcohol, insoluble in water; weighed and determined the ginkgolic acid content (mg / g).

[0...

Embodiment 2

[0025] The extraction process of ginkgo phenolic acid in ginkgo fruit is as follows: peel the ginkgo fruit and put it into a tissue crusher to crush. Accurately weigh a certain amount of crushed ginkgo, add 80% ethanol with a material-to-liquid ratio of 1:10 (W / V), stir and extract twice at a water bath temperature of 60°C, each extraction time is 4 hours, (Note : After adding liquid, seal the mouth of the beaker with plastic wrap to prevent the evaporation of ethanol). After the extraction, centrifuge (5000 rpm, 15 minutes), and take the supernatant. Concentrate the supernatant with a vacuum rotary evaporator at a temperature of 55°C, a pressure of 0.008-0.009MPa, concentrate under reduced pressure, and vacuum-dry at 60°C to obtain ginkgolic acid extract. The properties are: light brown extract, slightly smelly , Soluble in alcohol, insoluble in water. Weigh and determine the content of ginkgolic acid (mg / g).

[0026] Ginkgo phenolic acid content determination: the same as in...

Embodiment 3

[0030] The extraction process of ginkgo phenolic acid in ginkgo biloba leaves is as follows: the ginkgo biloba leaves are cut into small pieces and placed in a crusher to crush them. Accurately weigh a certain amount of crushed ginkgo leaves, add 80% ethanol with a material-to-liquid ratio of 1:6 (W / V), stir and extract twice at a water bath temperature of 60°C, each extraction time is 4 hours, ( Note: After adding liquid, seal the mouth of the beaker with plastic wrap to prevent the evaporation of ethanol). After the extraction, centrifuge (5000 rpm, 15 minutes), and take the supernatant. Concentrate the supernatant with a vacuum rotary evaporator at a temperature of 55°C, a pressure of 0.008-0.009MPa, concentrate under reduced pressure, and vacuum-dry at 60°C to obtain ginkgolic acid extract. The properties are: light brown extract, slightly smelly , Soluble in alcohol, insoluble in water. Weigh and determine the content of ginkgolic acid (mg / g).

[0031] Ginkgo phenolic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com