Solid-liquid method of silicon wafer cutting fluid

A technology of solid-liquid separation and cutting fluid, which is applied in the direction of lubricating compositions, etc., can solve the problems such as the difficulty of separating solid particles such as fine silicon chips, and achieve the effects of low production cost, simple process flow, and accelerated sedimentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

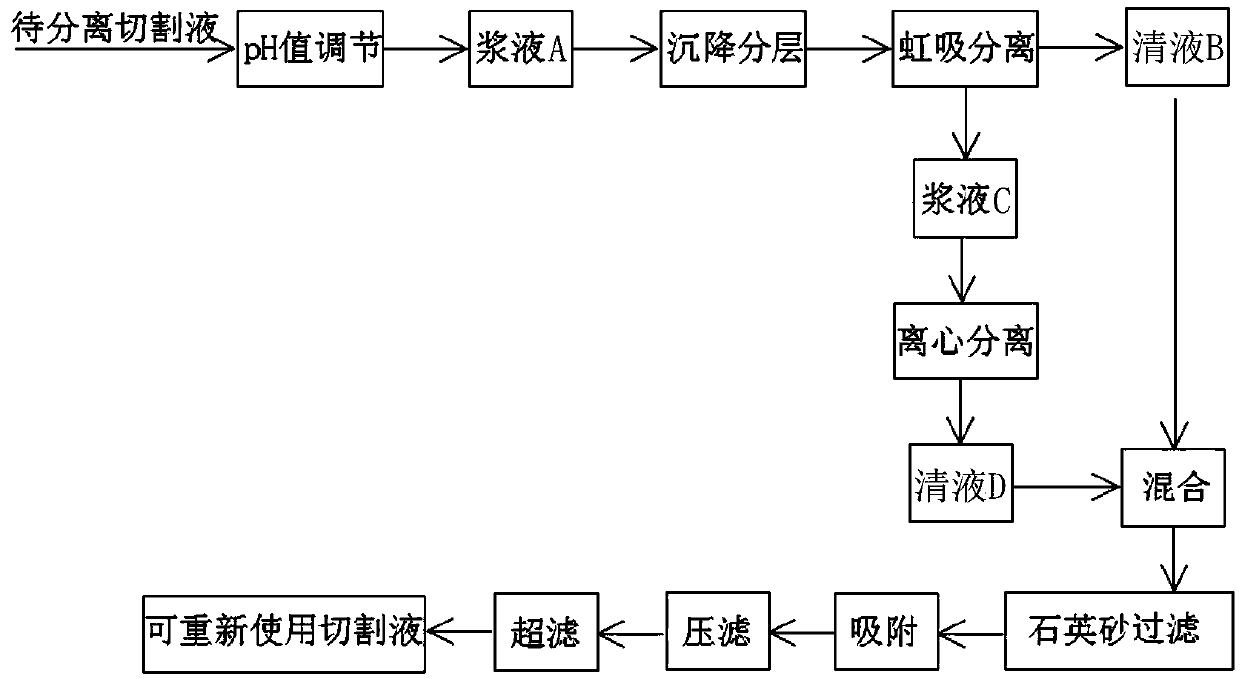

[0029] Example 1: A kind of solid-liquid separation method of crystal silicon wafer cutting liquid, see figure 1 , including the following steps:

[0030] (1) pH value adjustment: adjust the pH value of the cutting fluid to be separated to 8.5 to obtain weakly alkaline slurry A;

[0031] (2) Sedimentation and stratification: Let the slurry A stand for 16 hours to allow the solid particles to settle and form stratification with the liquid in it;

[0032] (3) Siphon separation: use siphon to extract the supernatant liquid after sedimentation and stratification, the siphon pressure is 0.03MPa, and separate the supernatant liquid B and the remaining slurry C; the siphon separation method can adopt the lifting siphon method to ensure The siphon is required for the layered interface of different heights, and the siphon tube is a U-shaped tube with an upward opening in the supernatant, which can avoid the inhalation of solid particles in the lower layer;

[0033] (4) Centrifuga...

Embodiment 2

[0039] The crystalline silicon wafer cutting fluid to be separated from solid and liquid is processed in the same manner as in Example 1, the difference being that in the quartz sand filtration process, pressurized filtration is adopted, so that the uniformly mixed liquid is filtered at a filtration pressure of 0.3 MPa. Filtration is performed under pressure through a bed of quartz sand media.

Embodiment 3

[0041] The crystal silicon wafer cutting fluid to be separated from solid-liquid was treated in the same manner as in Example 1, except that: during the adsorption process, an adsorbent was added to the filtrate E, and its pH value was adjusted to 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com