A kind of heat-resistant high-solid content water-based polyurethane emulsion and its preparation method and application

A technology of water-based polyurethane with high solid content, applied in the field of polyurethane materials, can solve problems such as difficulty and achieve good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

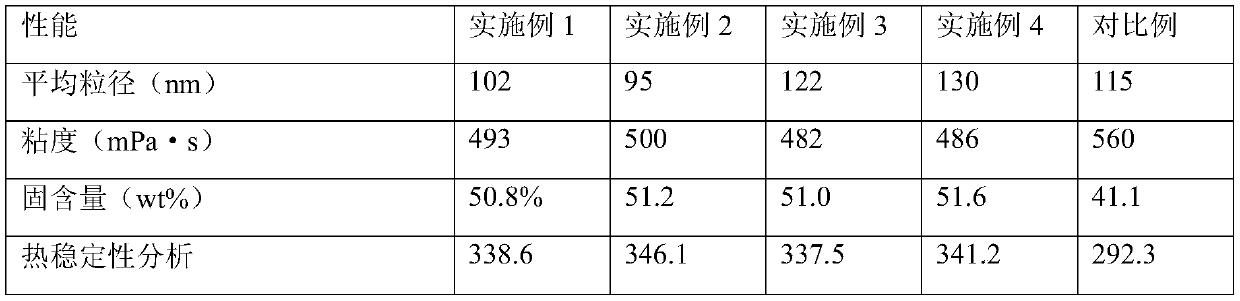

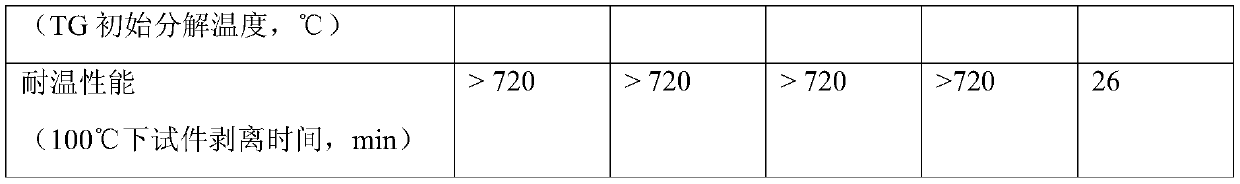

Examples

Embodiment 1

[0036] (1) Preparation of prepolymer: Add 80.0 g of PCL with a molecular weight of 2000 into a 500 mL four-necked flask equipped with a stirrer, a thermometer and a condenser tube, heat and melt, then add 35.0 g of IPDI while blowing nitrogen, and heat it at 80 ° C. The reaction was carried out for 130 minutes to obtain a polyurethane prepolymer whose terminal group was -NCO group.

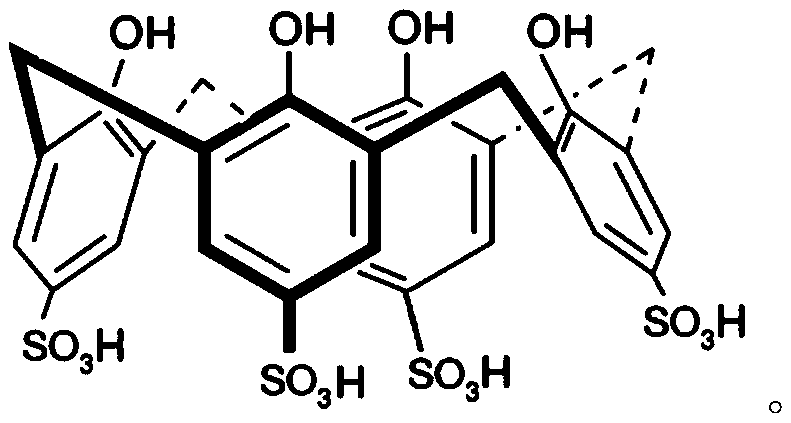

[0037] (2) Dilution and chain extension of the prepolymer: the temperature of the prepolymer obtained in the previous step was lowered to 65°C, and 198.3g butanone was added to reduce the viscosity of the system, then a mixed solution of 6.5g BDO and 15g butanone was added, and 5.1 The mixture of gC4AS and 15g butanone was continued to react at 65° C. for 90 minutes to obtain a polyurethane prepolymer solution.

[0038] (3) Neutralization, emulsification and solvent removal: Cool the prepolymer solution obtained in the previous step to 35°C, add 123mL deionized water with 1.10g NaOH dissolved in i...

Embodiment 2

[0040] (1) Preparation of prepolymer: Add 50.0g of PBA and 25.0g of PPG with a molecular weight of 2000 into a 500mL four-necked flask equipped with a stirrer, a thermometer and a condenser tube, heat and melt, and then add IPDI while flowing nitrogen. 37.0 g was reacted at 85° C. for 120 min to obtain a polyurethane prepolymer whose end group is -NCO group.

[0041] (2) Dilution and chain extension of the prepolymer: the temperature of the prepolymer obtained in the previous step was lowered to 55°C, and 221.4g of butanone was added to reduce the viscosity of the system, then a mixed solution of 7.2g of BDO and 15g of butanone was added, and 6.6 The mixture of gC4AS and 15g butanone was continued to react at 65°C for 120min to prepare a polyurethane prepolymer solution.

[0042] (3) Neutralization, emulsification and solvent removal: Cool the prepolymer solution obtained in the previous step to 30°C, add 121mL deionized water with 1.42g NaOH dissolved in it, Next, neutralize...

Embodiment 3

[0044] (1) Preparation of prepolymer: Add 42.0g of PCDL and 28.0g of PTMG with a molecular weight of 2000 into a 500mL four-necked flask equipped with a stirrer, a thermometer and a condenser tube, heat and melt, and then add 40.0 g IPDI, reacted at 75°C for 150min to prepare a polyurethane prepolymer whose end group is -NCO group.

[0045] (2) Dilution and chain extension of the prepolymer: the temperature of the prepolymer obtained in the previous step was lowered to 60°C, and 173.5g butanone was added to reduce the viscosity of the system, then a mixed solution of 8.8g BDO and 15g butanone was added, and 4.5 The mixture of gC4AS and 15g butanone was continued to react at 65°C for 60min to prepare a polyurethane prepolymer solution.

[0046] (3) Neutralization, emulsification and solvent removal: Cool the prepolymer solution obtained in the previous step to 40°C, add 120mL of deionized water with 0.97g NaOH dissolved in it, Next, neutralize and emulsify for 20 minutes. Fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com