Patents

Literature

92 results about "Sapphire window" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High intensity light source

InactiveUS20060250090A9Improve life expectancyUnprecedented operating life expectancyElectric lighting sourcesStructural circuit elementsSapphire windowState of art

In one aspect the plasma lamp according to the present invention comprises a gas envelope that is constructed from ceramic material and a sapphire window rather than quartz. According to another aspect of the present invention, a plasma lamp comprises an RF structure for the radio wave radiation and an envelope for housing the excitation gas that are formed so as to constitute a single, integrated ceramic structure. According to yet another aspect of the present invention, the plasma lamp comprises a waveguide structure having solid material such as ceramic rather than air for the dielectric and a gas housing made of a combination of solid ceramic and a sapphire window. In this way, the separate quartz gas envelope and air-filled waveguide structure employed in the prior art are replaced by a single, integrated structure.

Owner:CERAVISION LTD

High temperature seal assembly for optical sensor

A seal assembly for an optical sensor employed in a high temperature environment is disclosed which includes an elongated metal guide tube having a distal end portion defining an open distal end and an inner rear wall, a sapphire window disposed within the distal end portion of the metal guide tube, the sapphire window having a rear end surface abutting the inner rear wall of the distal end portion of the metal guide tube, and a platinum mounting sleeve for securing the sapphire window to the metal guide tube, the platinum mounting sleeve having one portion joined to the metal guide tube and another portion joined to the sapphire window.

Owner:ROSEMOUNT AEROSPACE

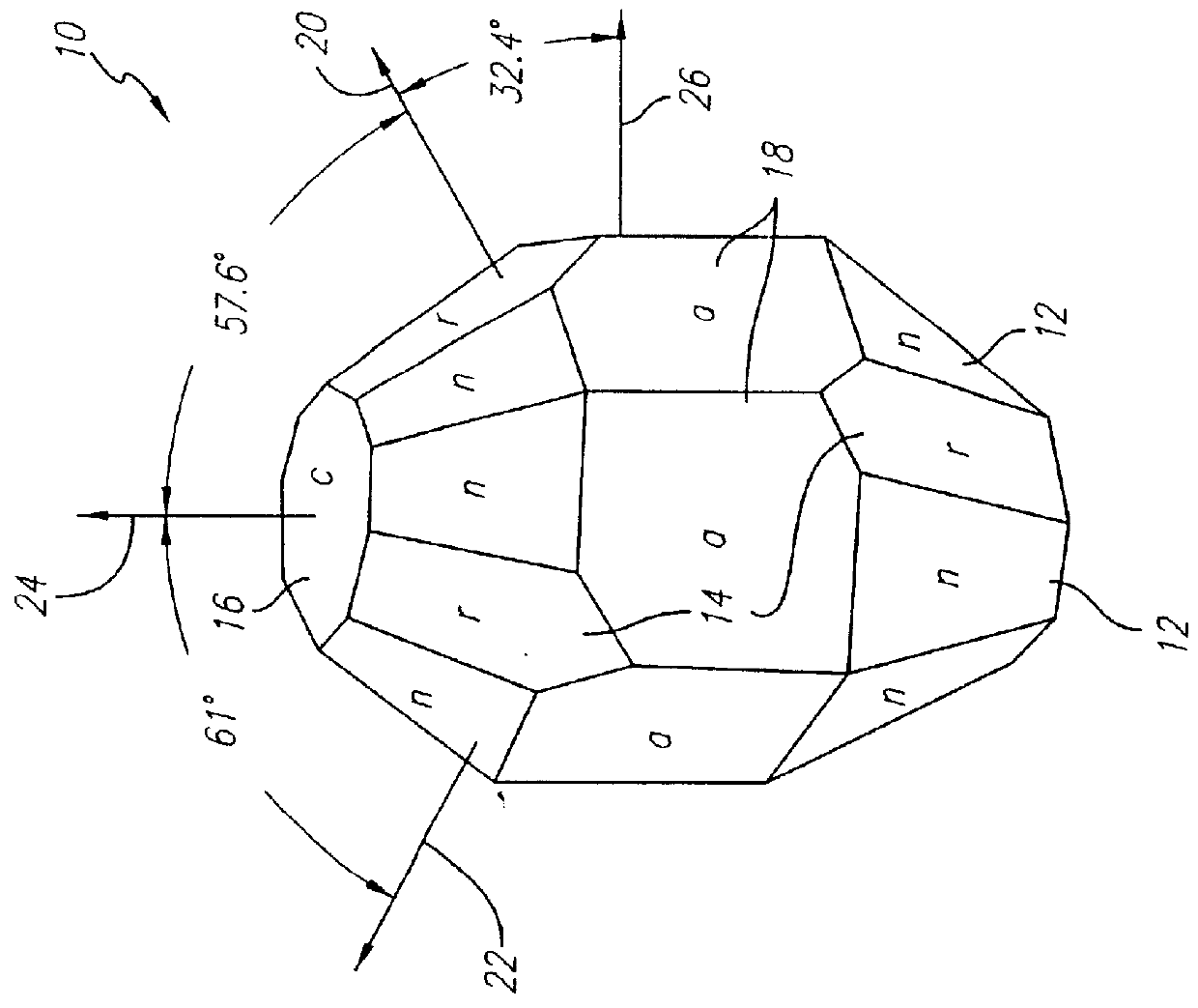

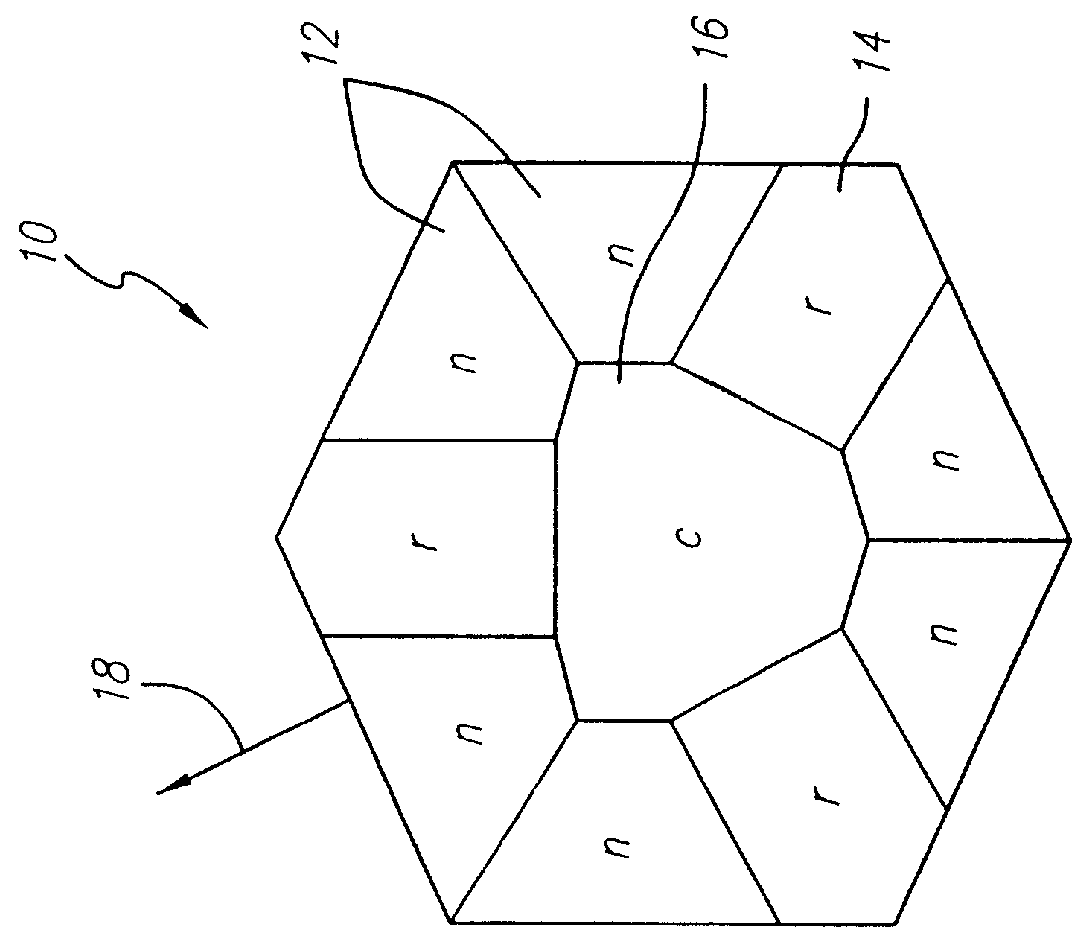

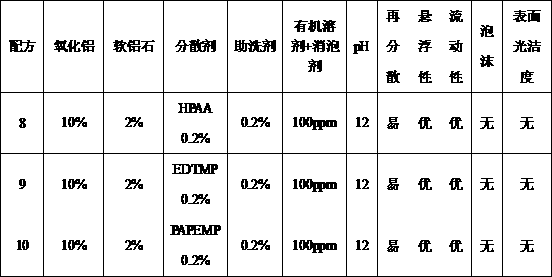

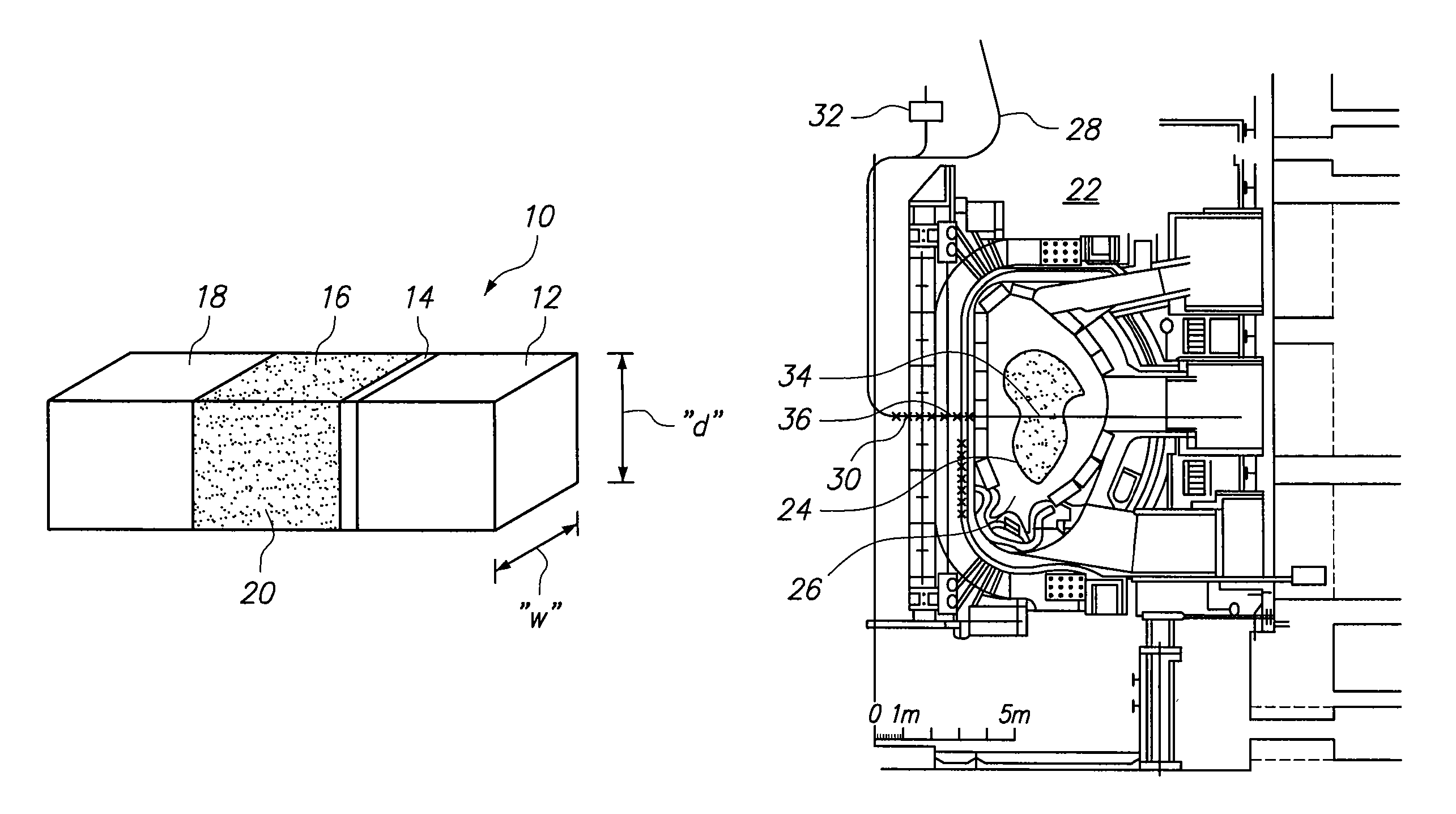

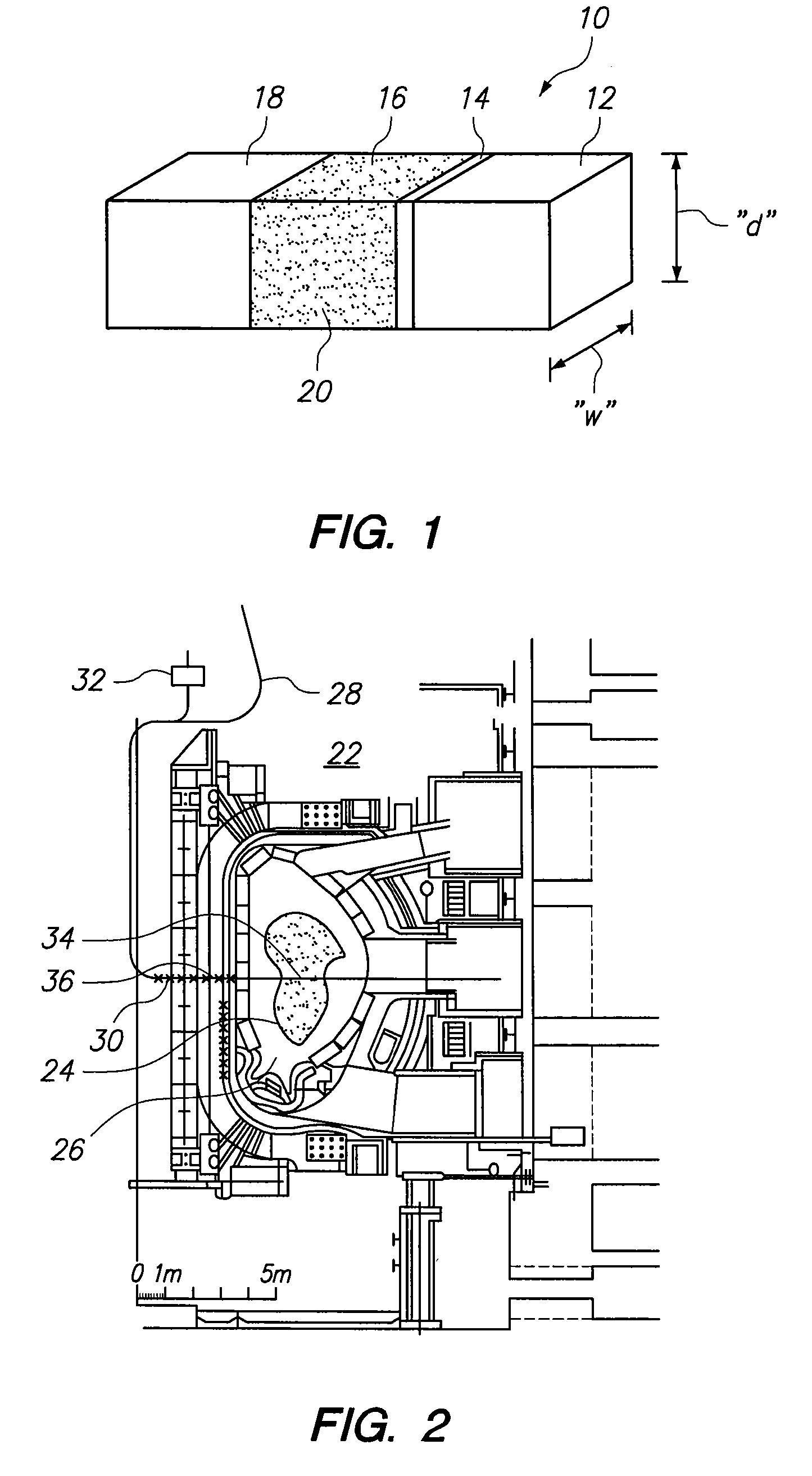

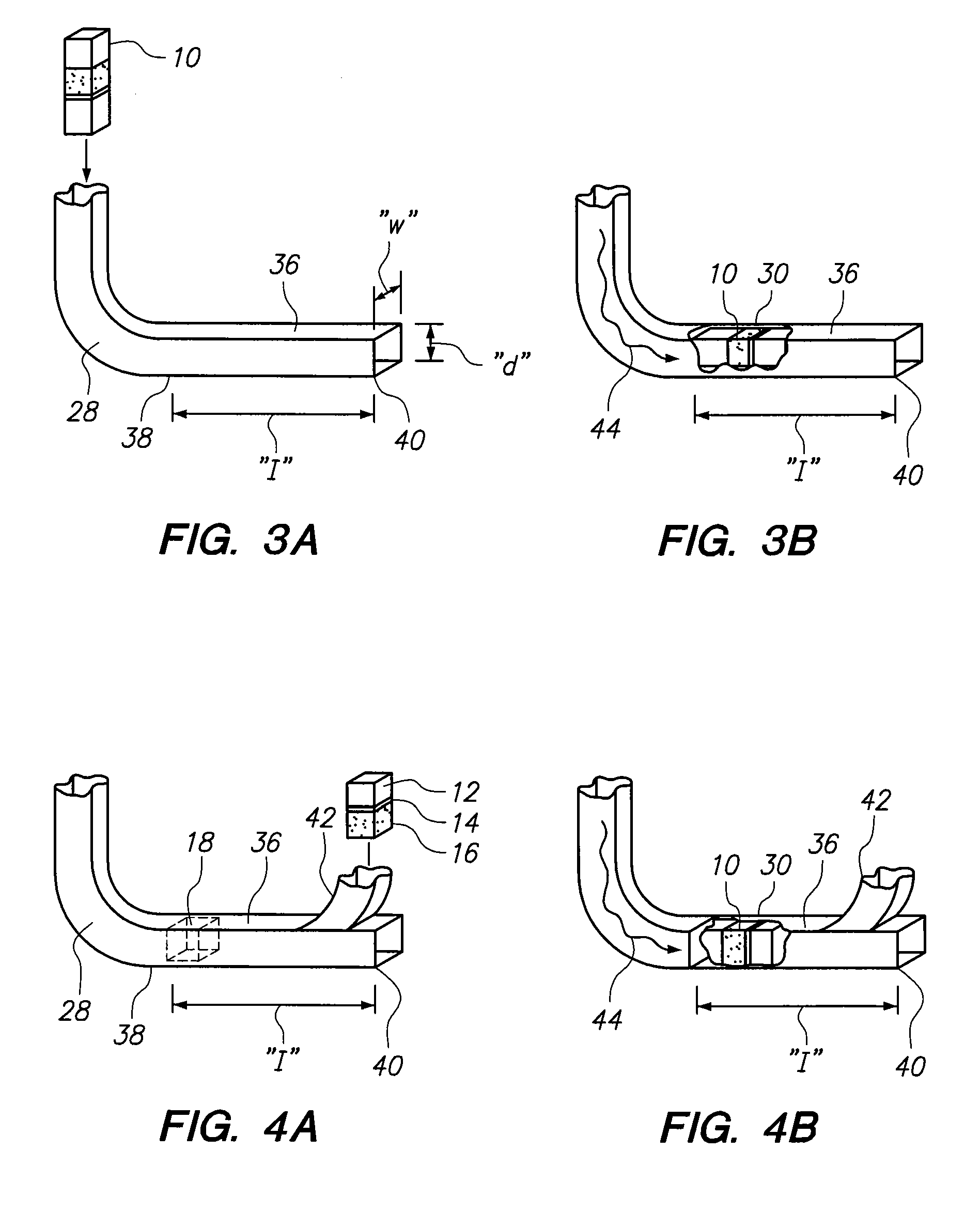

System and method for increasing the durability of a sapphire window in high stress environments

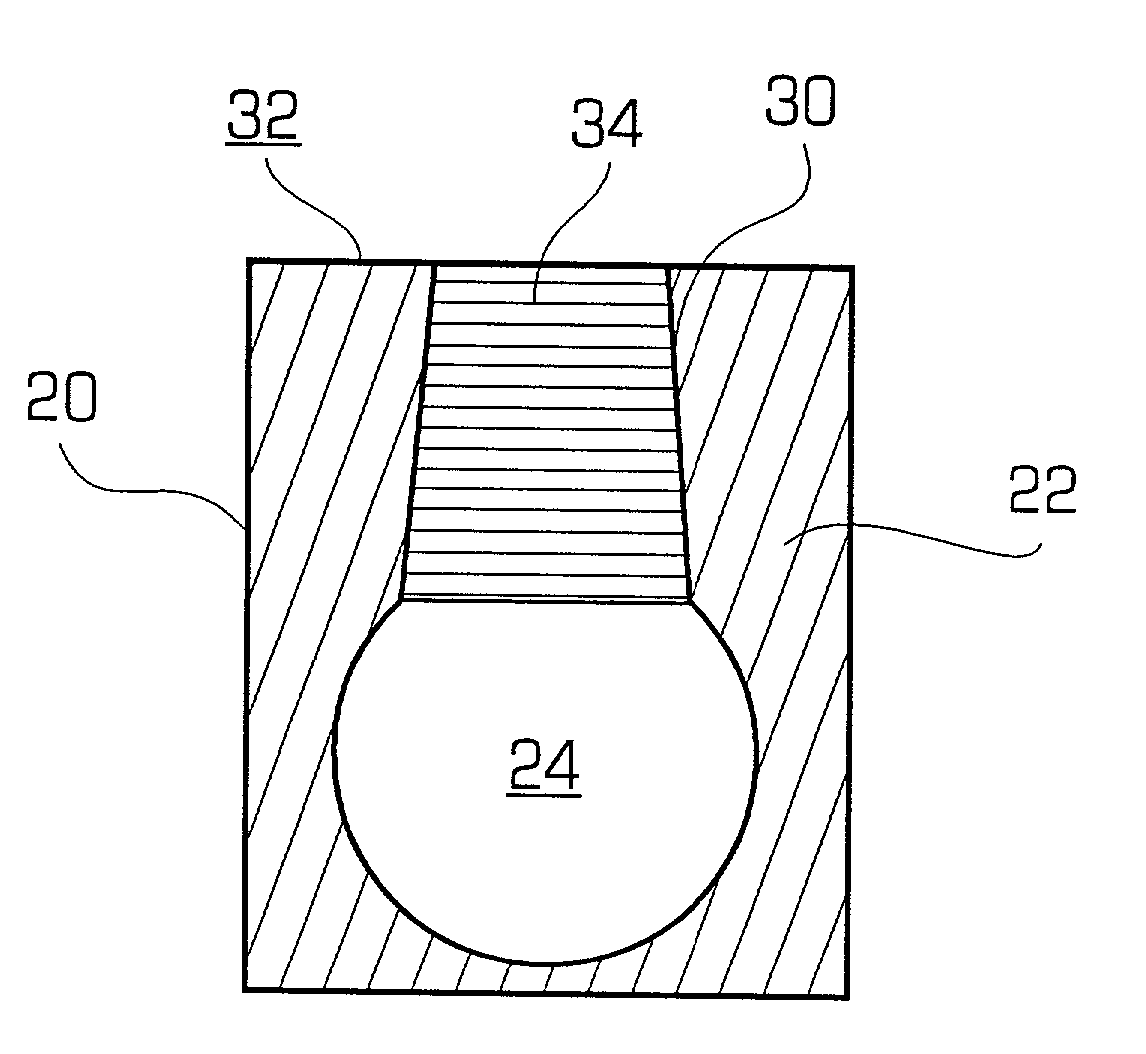

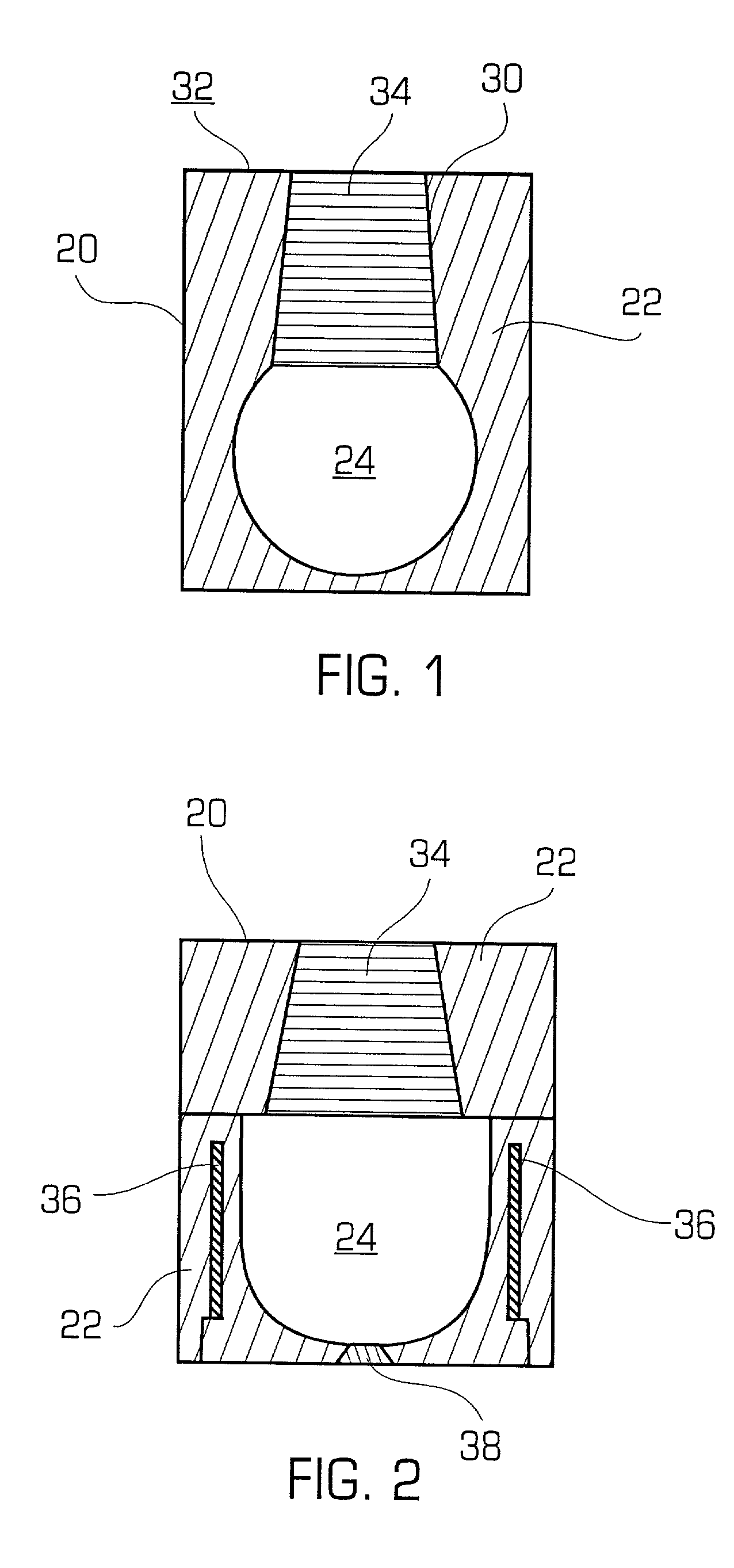

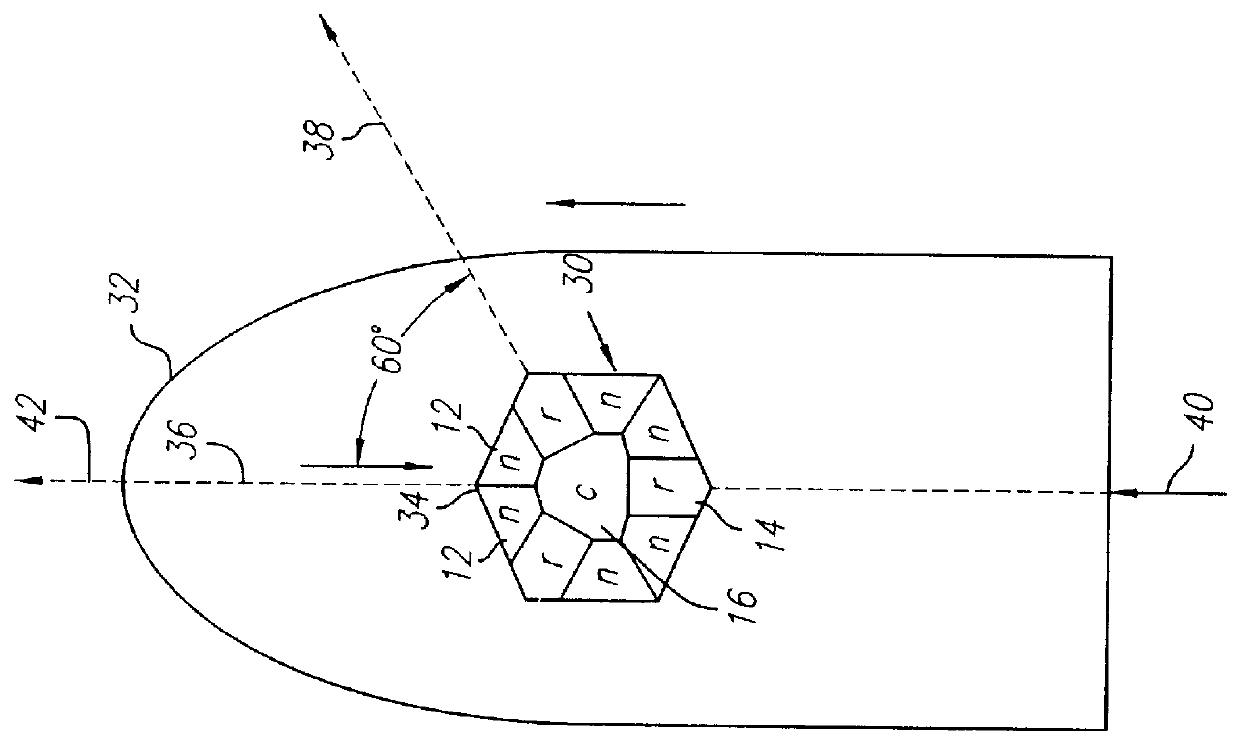

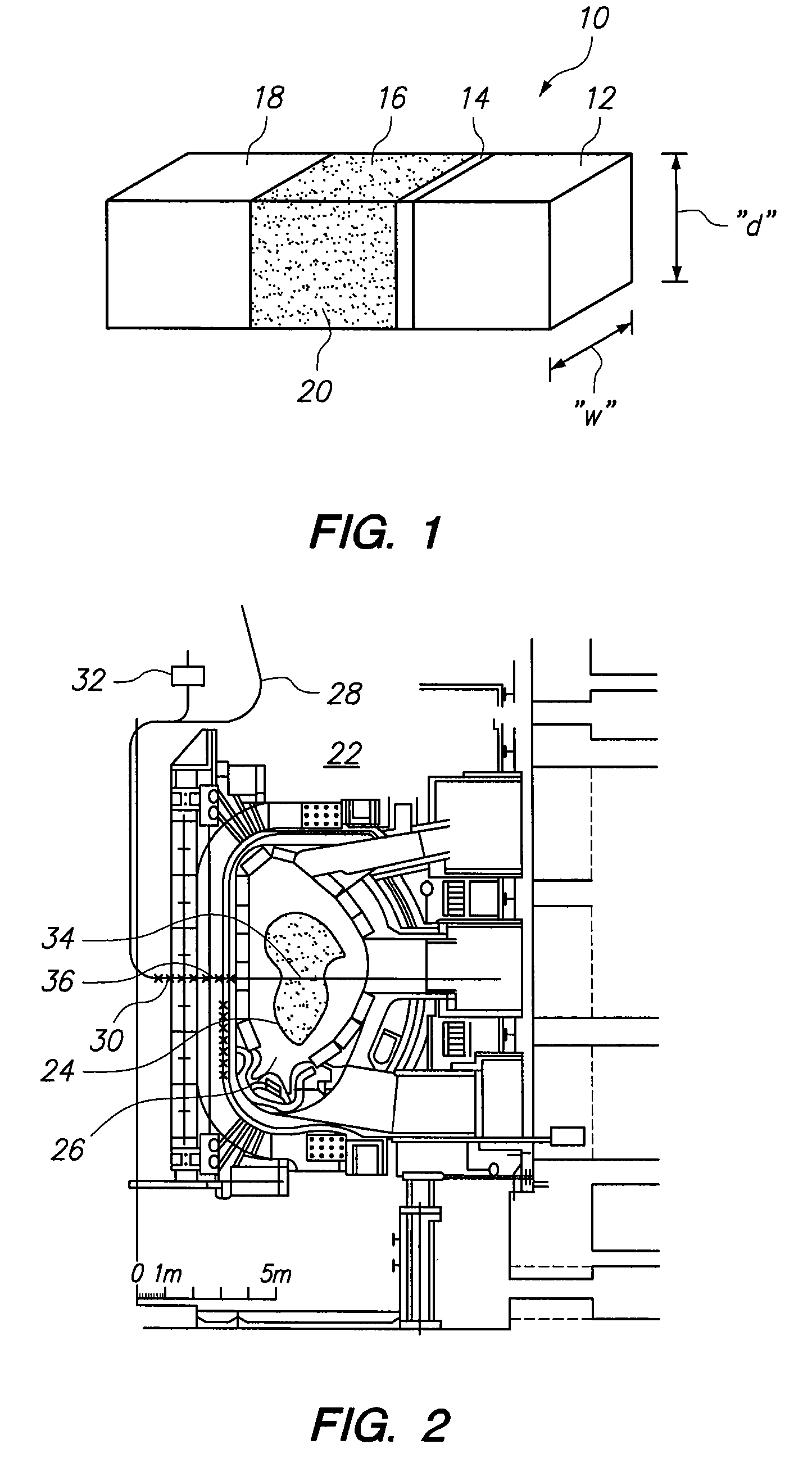

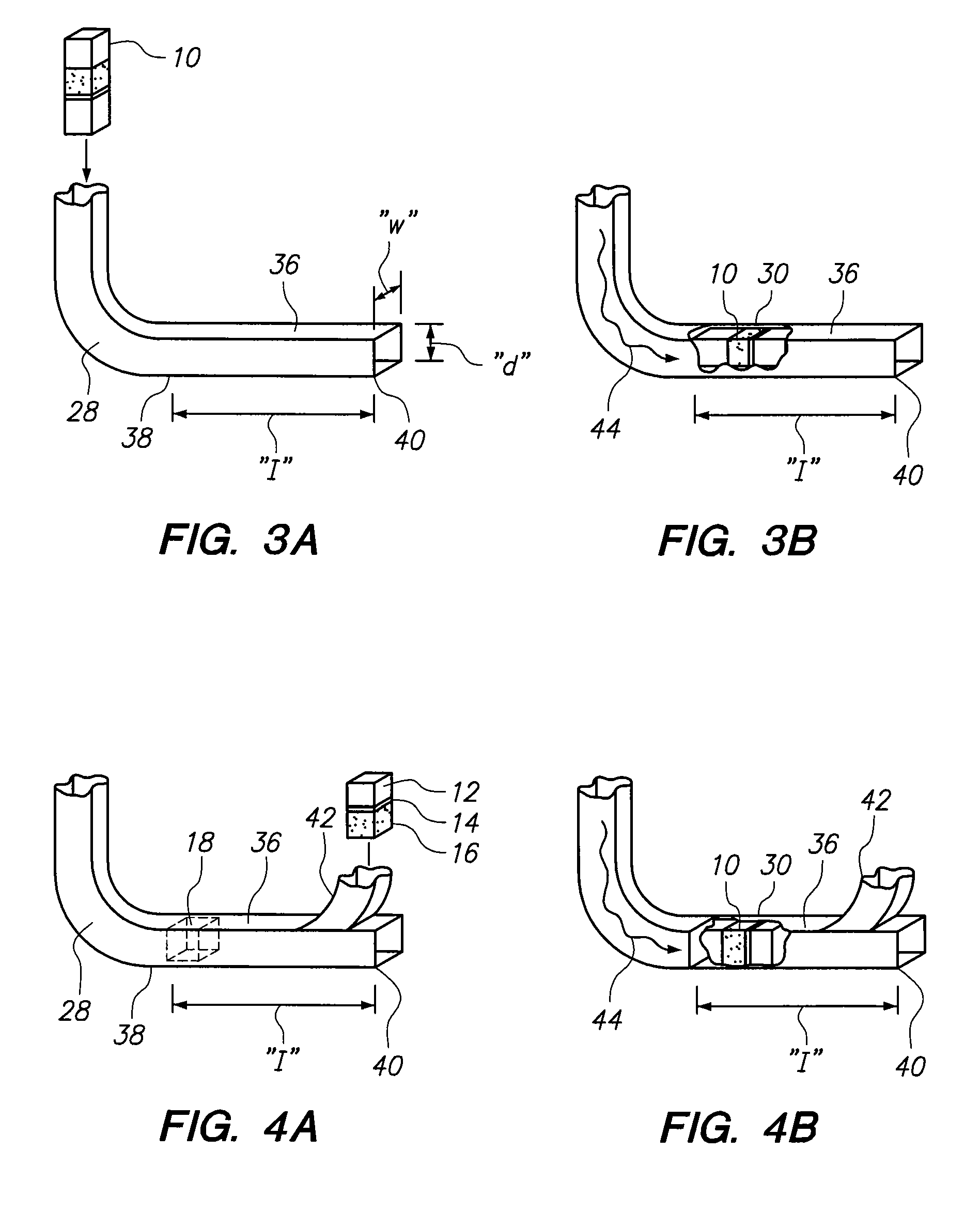

InactiveUS6123026ASelf-propelled projectilesSpacecraft guiding apparatusSapphire windowLattice plane

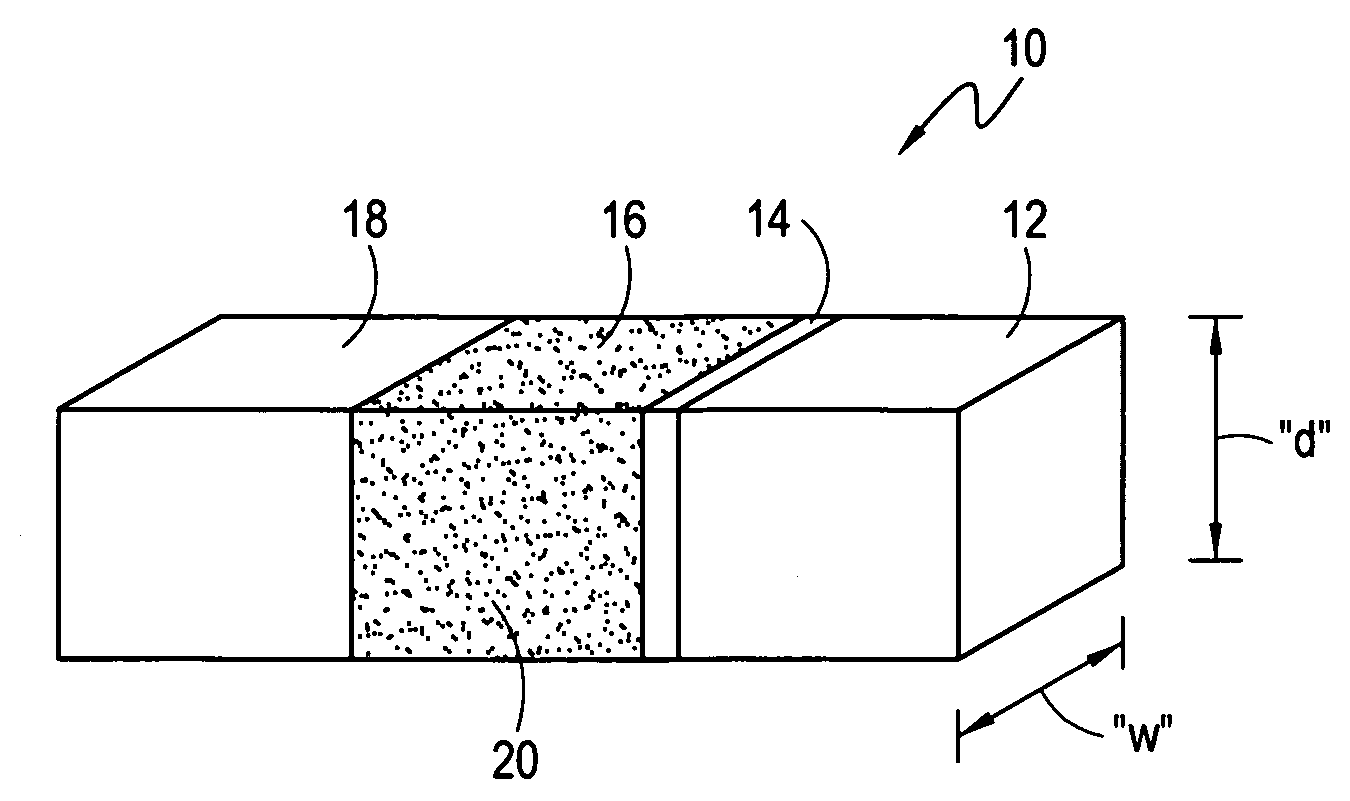

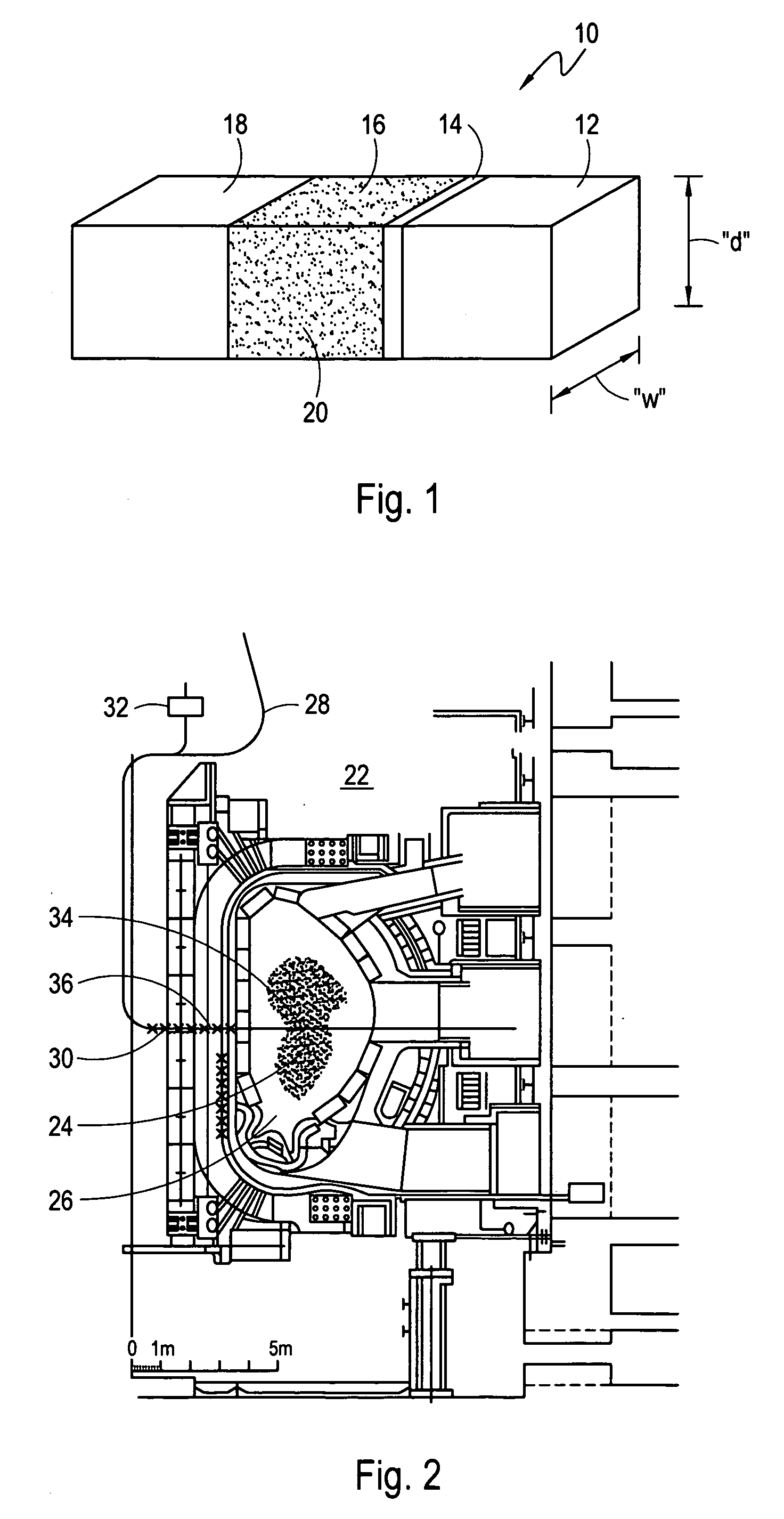

A dome assembly (50) adapted for use with a missile (32) having a longitudinal axis (42) parallel to a thrust vector thereof. The inventive dome (50) includes a crystal (30, 50) having a crystallographic structure that includes a plurality of planes (12, 14, 16), one of said planes (14) being more susceptible to failure than one or more of the other planes (12, 16). A surface around a missile sensor provides a place for mounting the crystal (30, 50) so that said plane susceptible to failure (14) faces approximately opposite to that of a positive velocity vector (34) of said missile (32). In a more specific embodiment, the crystal (30, 50) is a sapphire crystal (30, 50) having a crystallographic structure that includes positive n-planes (12), positive r-planes (14), and a c-plane (16). By design at nominal conditions, an r-plane (14) is approximately bisected by a plane formed by the normal of the c-plane (16) and a wind flow vector (36) parallel to a thrust vector of said missile (32). A turntable (not shown) orients the sensor dome (50) so that a first r-plane (14) faces leeward of impinging airflow (36) corresponding to the wind flow vector (36). An r-plane normal (38) of a second r-plane forms an angle of approximately 60 degrees with respect to impinging airflow (36) that is approximately parallel to the thrust vector of the missile (32). The turntable includes a motor (not shown) for strategically orienting the lattice planes (12, 14, 16) of the dome (50) so as to maximize the strength of the dome (50) with respect to applied stresses.

Owner:HUGHES ELECTRONICS

High temperature seal assembly for optical sensor

ActiveUS7987712B2Material analysis by optical meansGas turbine plantsSapphire windowEngineering physics

A seal assembly for an optical sensor employed in a high temperature environment is disclosed which includes an elongated metal guide tube having a distal end portion defining an open distal end and an inner rear wall, a sapphire window disposed within the distal end portion of the metal guide tube, the sapphire window having a rear end surface abutting the inner rear wall of the distal end portion of the metal guide tube, and a platinum mounting sleeve for securing the sapphire window to the metal guide tube, the platinum mounting sleeve having one portion joined to the metal guide tube and another portion joined to the sapphire window.

Owner:ROSEMOUNT AEROSPACE

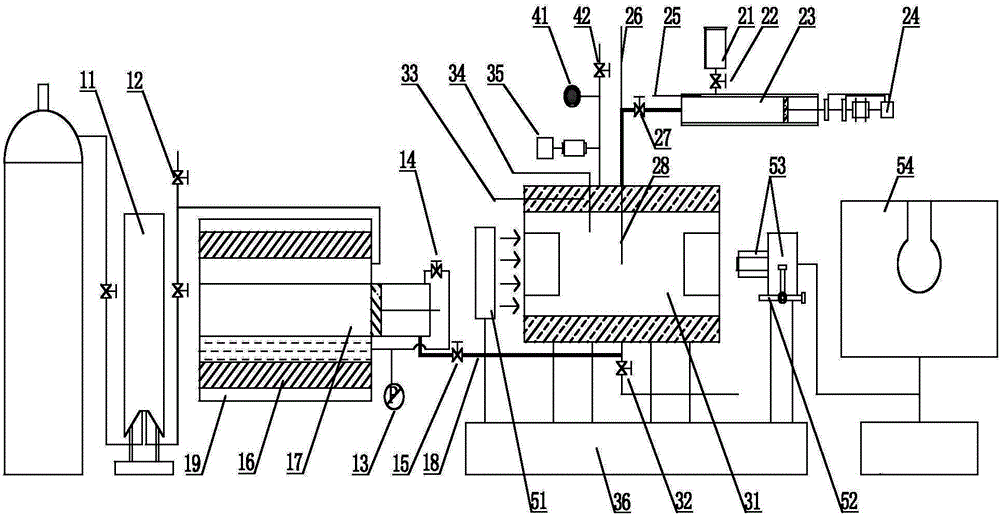

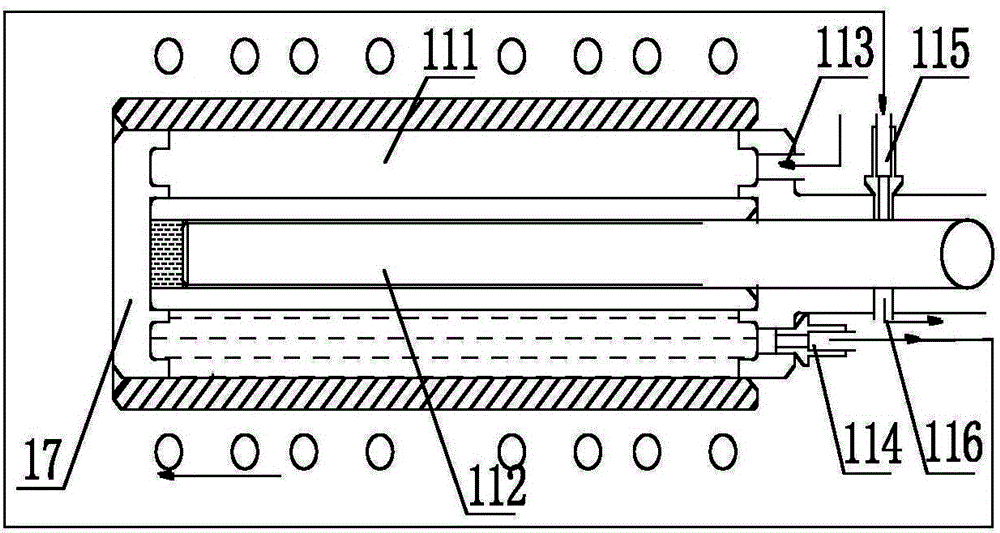

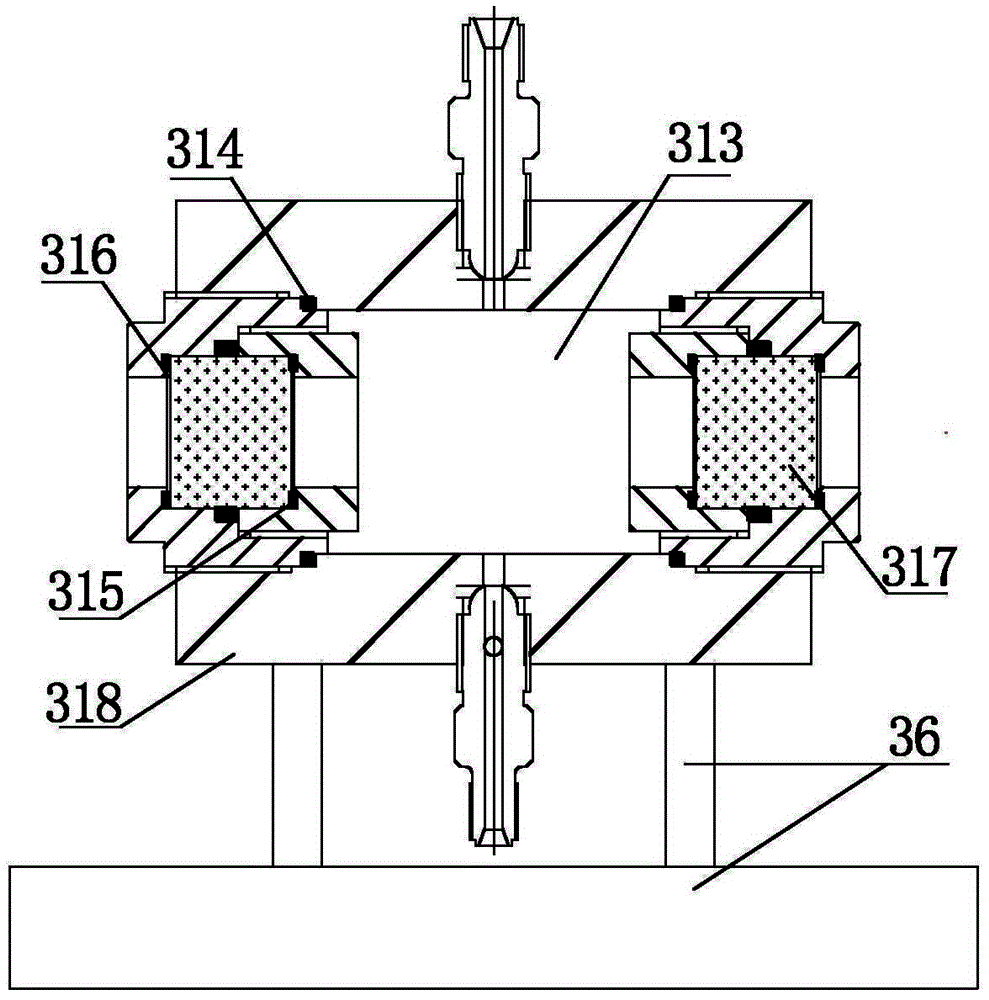

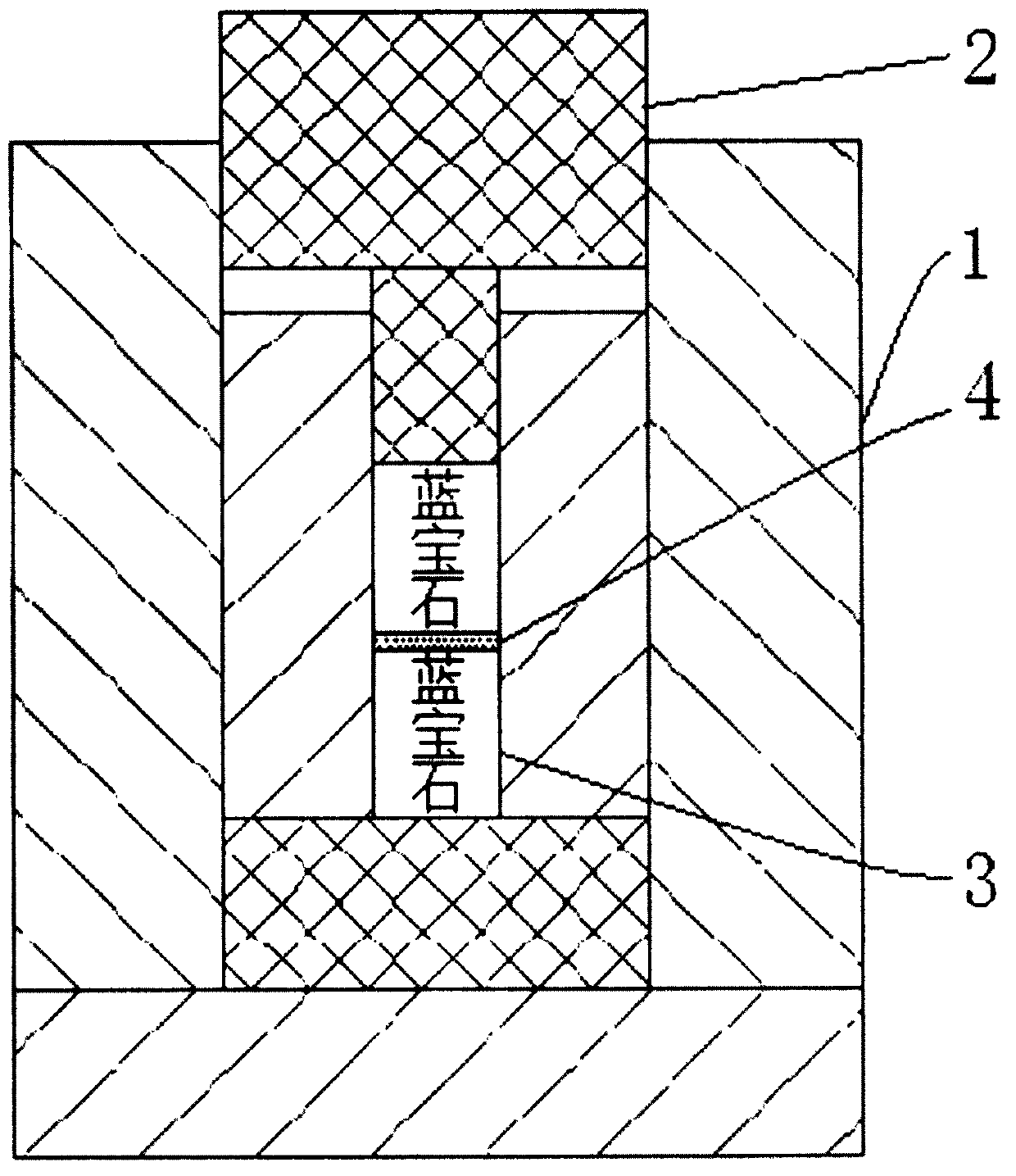

High-temperature and high-pressure interfacial tension measurement device and method

InactiveCN104155217ASolve the need for high pressure resistanceSolve high temperature resistanceSurface tension analysisSapphire windowMeasurement device

Owner:TIANJIN UNIV

Diamond energy transmission window for short millimeter wave traveling tubes and manufacturing method of diamond energy transmission window

ActiveCN103236390AIncrease output powerSuppression of reflection oscillationsTransit-tube coupling devicesCold cathode manufactureSapphire windowEngineering

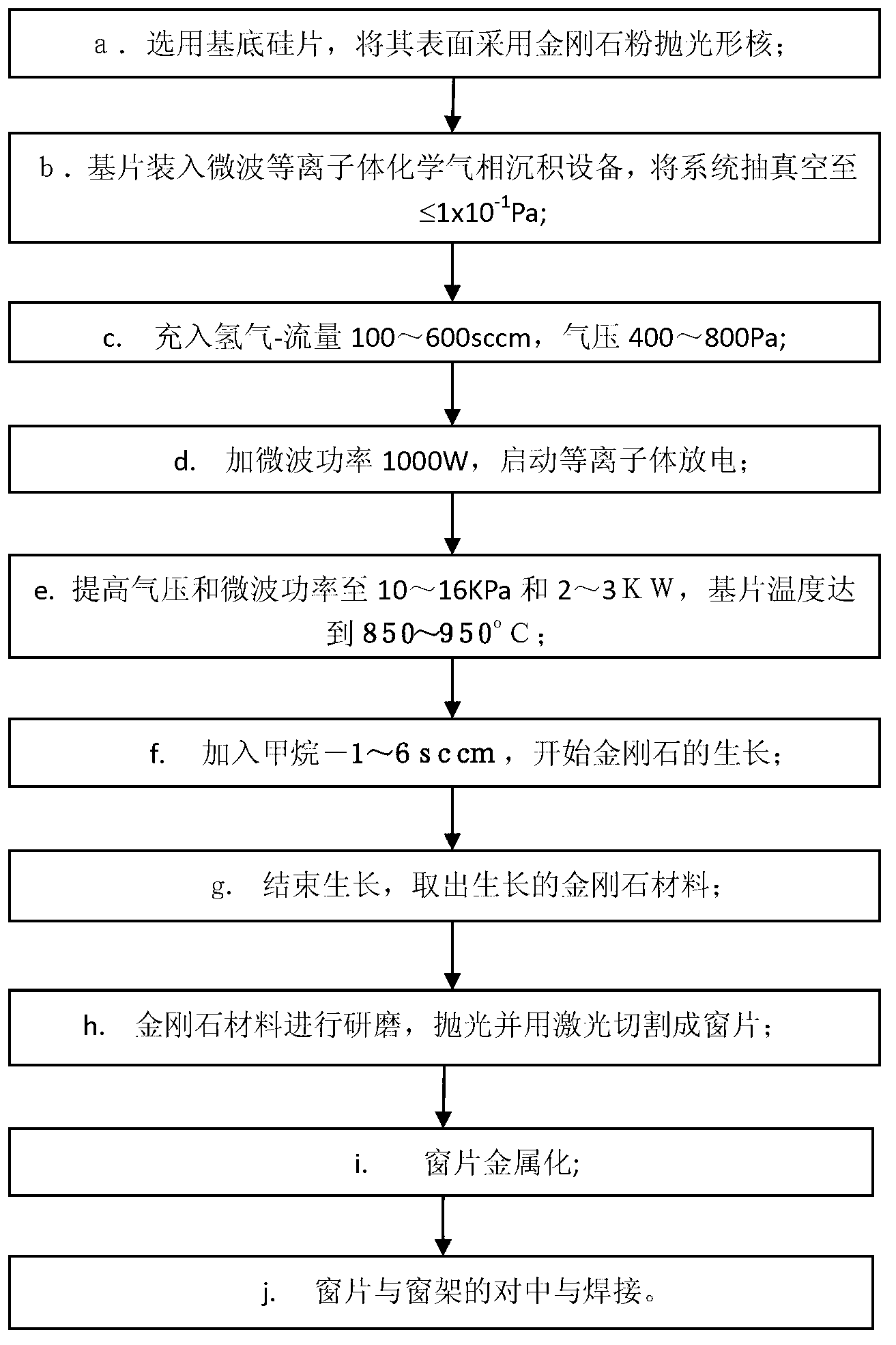

The invention discloses a diamond energy transmission window for short millimeter wave traveling tubes and a manufacturing method of the diamond energy transmission window and belongs to the technical field of vacuum electronics. The diamond energy transmission window comprises an energy transmission window leaf, a connecting wave guide and sealing window frames. The sealing window frames connected with the waveguide are symmetrically arranged on the upper and lower portion of the diamond energy transmission window, and the diamond window leaf is hermetically clamped between the window frames. The manufacturing method of the diamond energy transmission window includes: a, selecting a substrate silicon wafer; b, installing the substrate silicon wafer in a microwave plasma chemical vapor deposition device; c, inflating hydrogen gas; d, starting plasma discharging; e, increasing air pressure and microwave power and increasing substrate temperature to 850-950 DEG C; f, adding methane and starting growing diamond; g, finishing growing and taking out of diamond materials; h, grinding, polishing and cutting to obtain the window leaf by laser; i, metalizing the window leaf; and j, welding the window leaf and the window frames by centering. The diamond energy transmission window is superior to sapphire windows in both matching performance and transmission loss.

Owner:NO 12 RES INST OF CETC

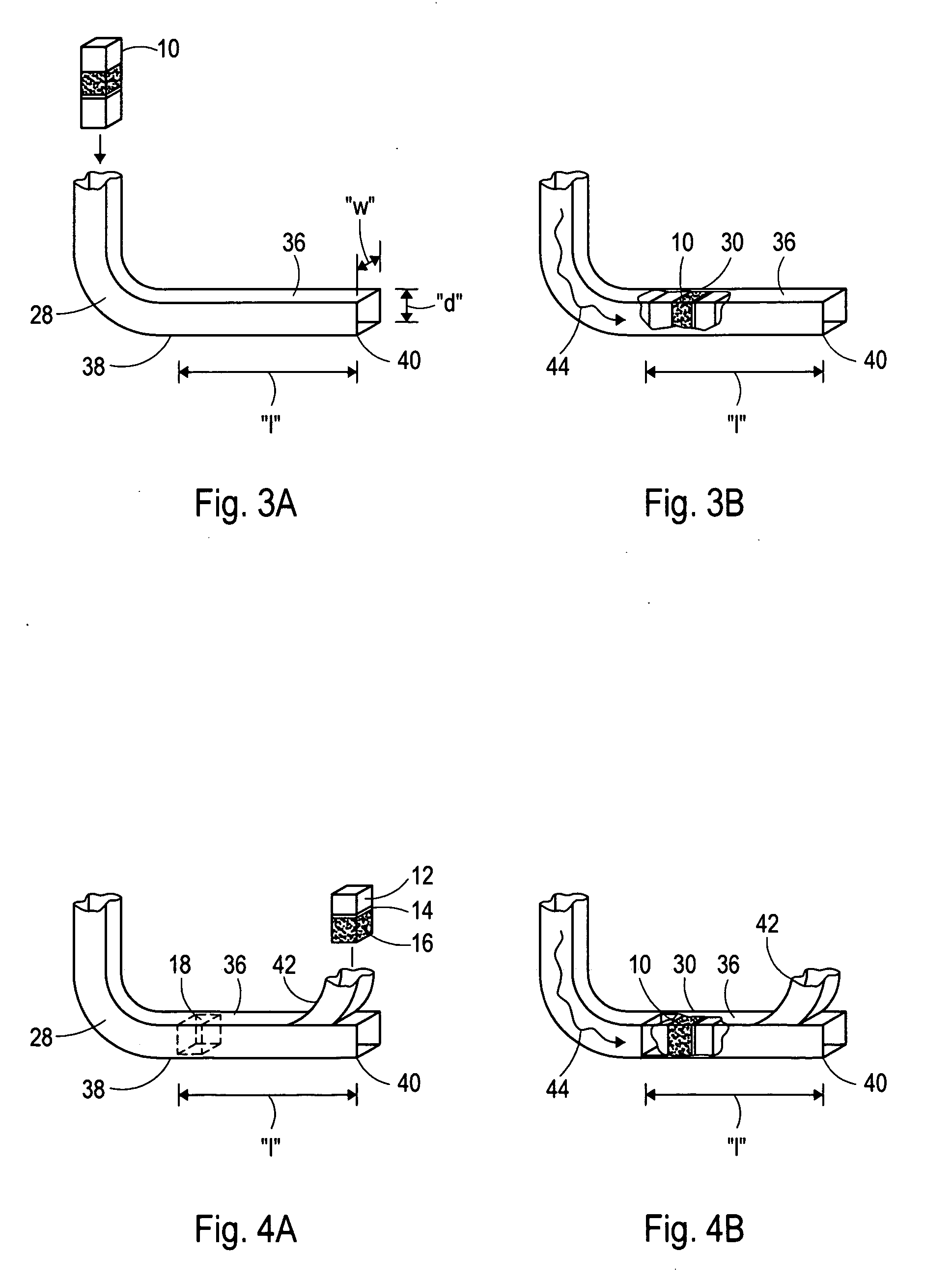

Apparatus and method for improved processing of food products

InactiveUS20130135608A1Eliminates collectionMaximizing intensityRadiation pyrometryScattering properties measurementsSapphire windowFood products

The light backscatter probe includes a housing carrying at least one optical transmission fiber and two optical reception or collecting fibers. The ends of the fibers are closed by a sapphire window. First and second light sources are provided for projecting incident light onto a product outside the sapphire window. The reception paths or fibers are located at different radial distances from the one optical transmission path to allow for measuring the coagulation of dairy products or determination of compositions of food products.

Owner:REFLECTRONICS

Flow cell for chemiluminescence analysis

InactiveUS8029730B1Withdrawing sample devicesChemiluminescene/bioluminescenceSapphire windowEngineering

A flow cell for chemiluminescence analysis. The flow cell has a flat, thin, opaque plate, with a groove machined into one side of the plate. An inlet port at the center, and an outlet port at the outside end of the groove pass through the plate, which is sandwiched between a flat sapphire window and a cell cap of a housing. The groove side faces the sapphire window, forming a flow channel with one wall being the sapphire window. A light detector is inserted into the housing until it butts up against that part of the housing holding the sapphire window, placing it very close to the generated light. The other side of the plate mates with inlet and outlet ports of the housing cap.

Owner:GLOBAL FIA

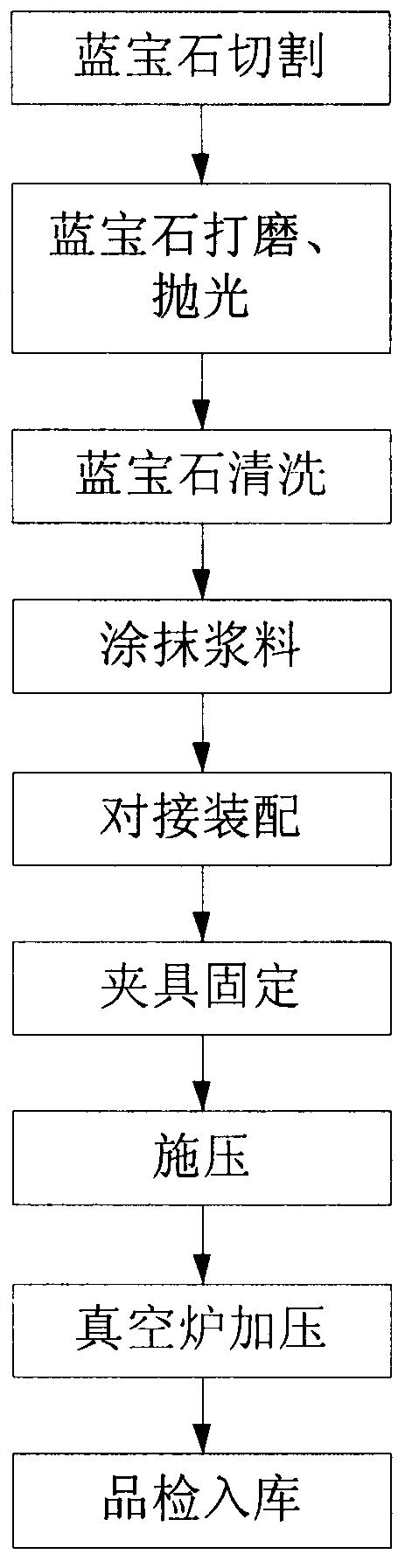

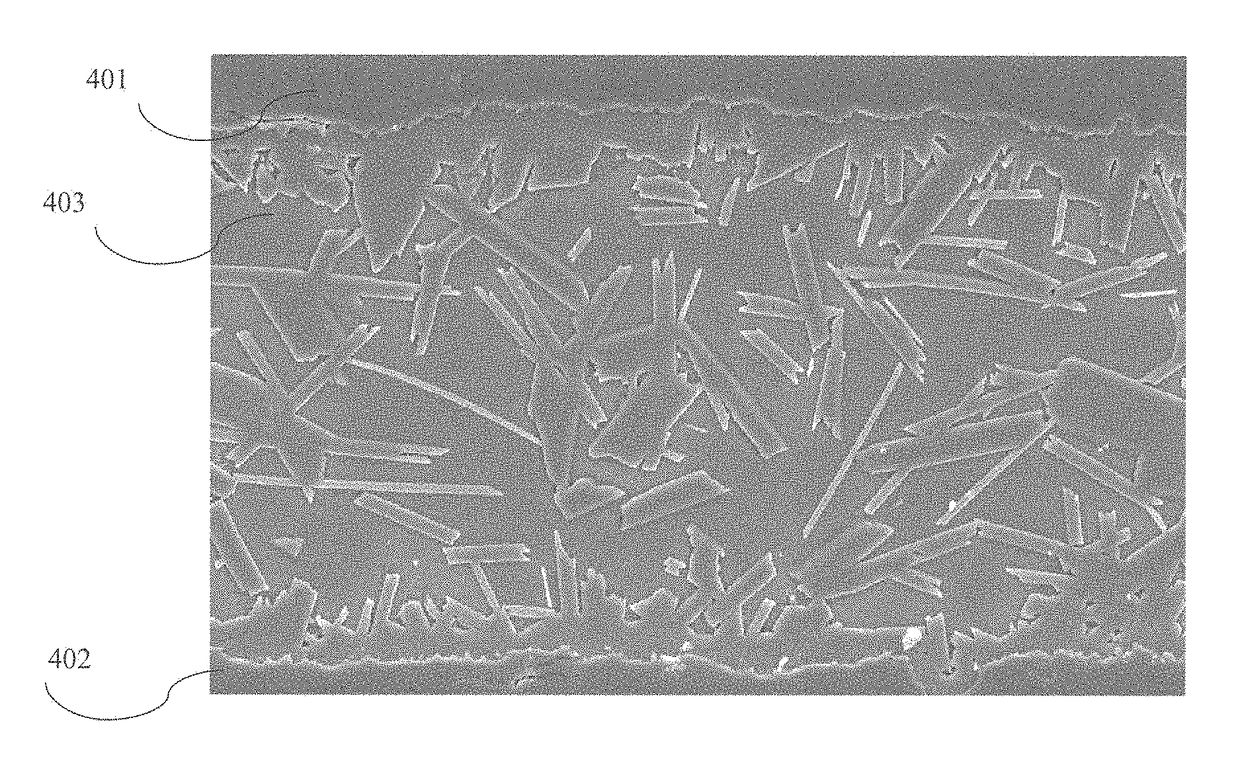

Sapphire splicing method, sapphire window and paste size

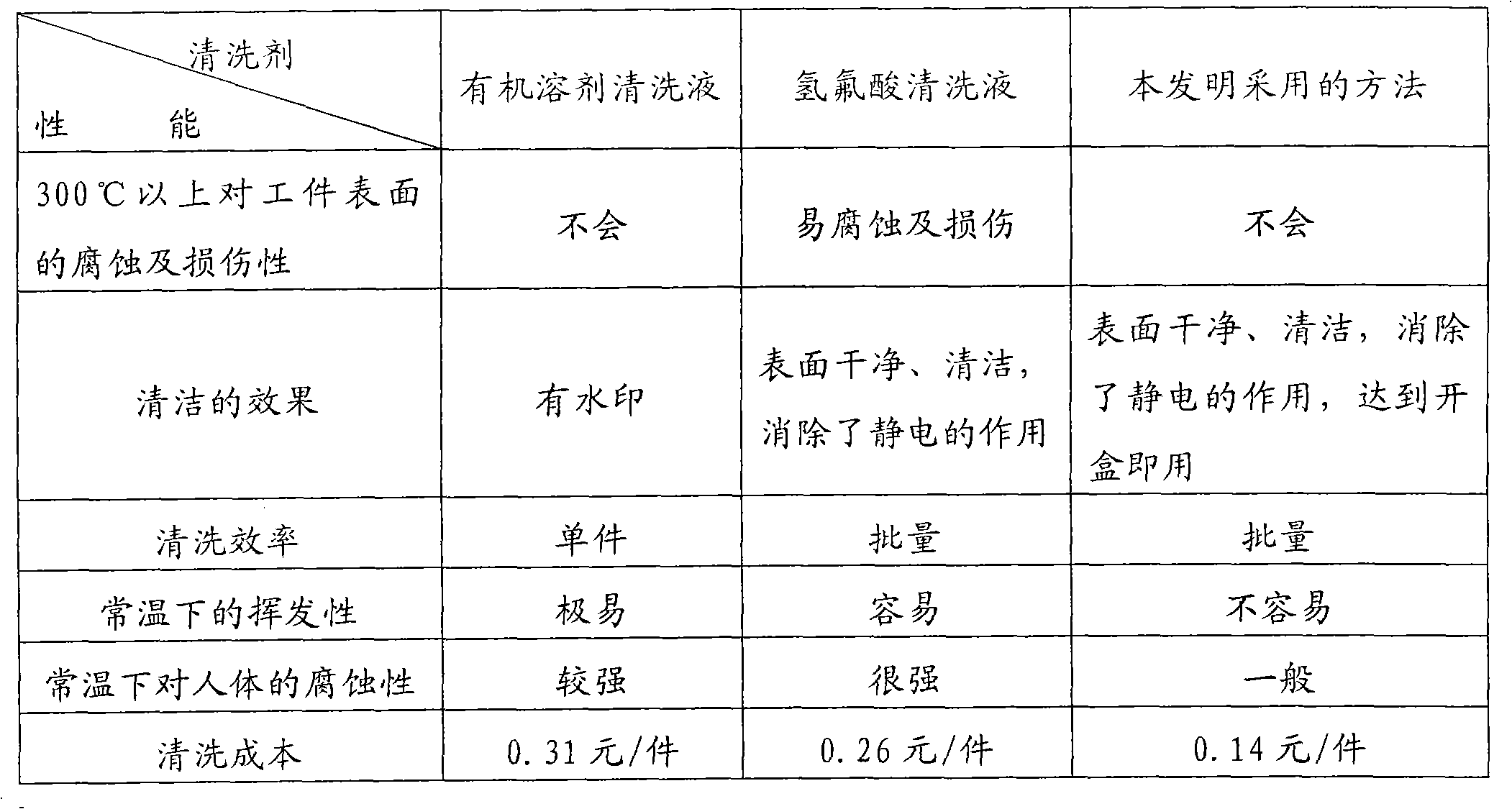

InactiveCN103103621ASolve the aperture requirements that are far from meeting many modern optical systemsAddresses aperture requirements that cannot meet many modern optical systemsAfter-treatment detailsSapphire windowOrganic solvent

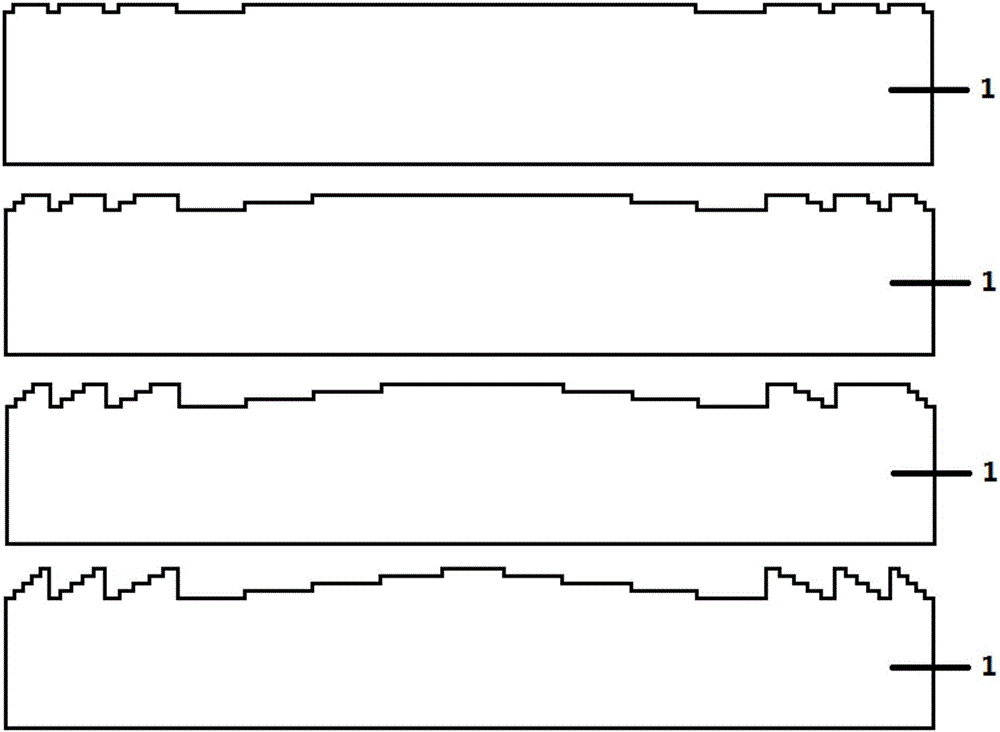

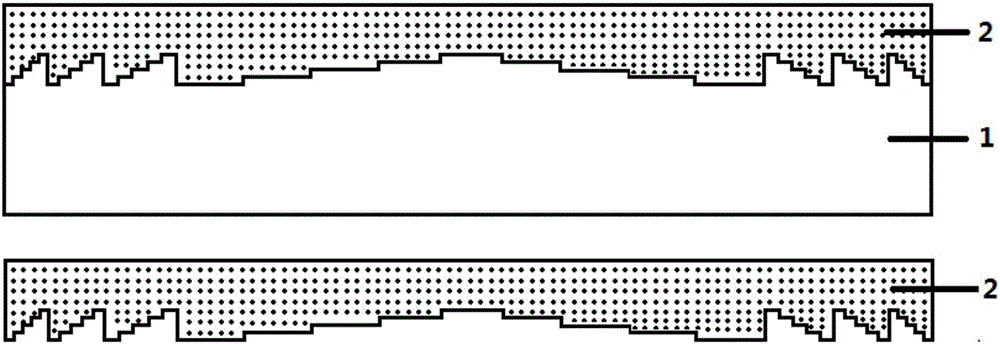

The invention discloses a sapphire splicing method, a sapphire window and a paste size. A sapphire splicing method comprises steps of: A, smearing the paste size on a combination surface of two pieces of sapphire crystal, wherein the paste size is formed by organic solvent mixed with a powder solder; B, splicing and fixing the two pieces of sapphire crystal; and C, pressurizing the spliced sapphire crystal in a vacuum furnace. The invention can effectively solve the problem that sapphire crystal plate and sapphire crystal block used in an optical window are limited by specifications of artificially grown sapphire crystal and fail to have size to satisfy the aperture requirements of many modern optical systems, in order to achieve the requirements; in addition, the invention employs mature technologies with relatively low cost in industrial practice, and produces sapphire window with large area from billet grown in small melt, so as to greatly reduce the cost of splicing.

Owner:无锡鼎晶光电科技有限公司

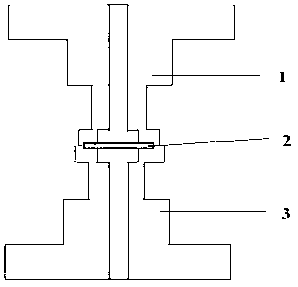

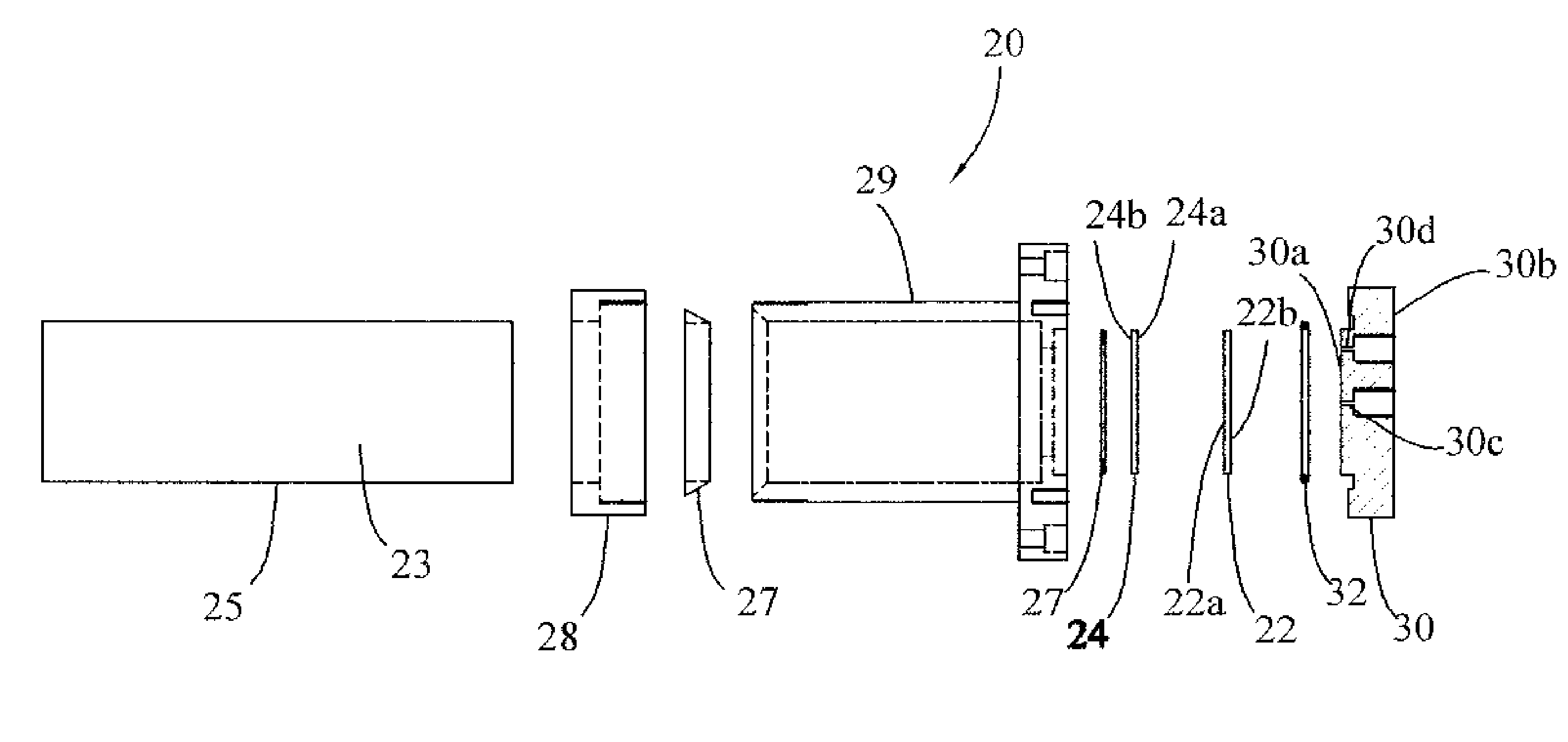

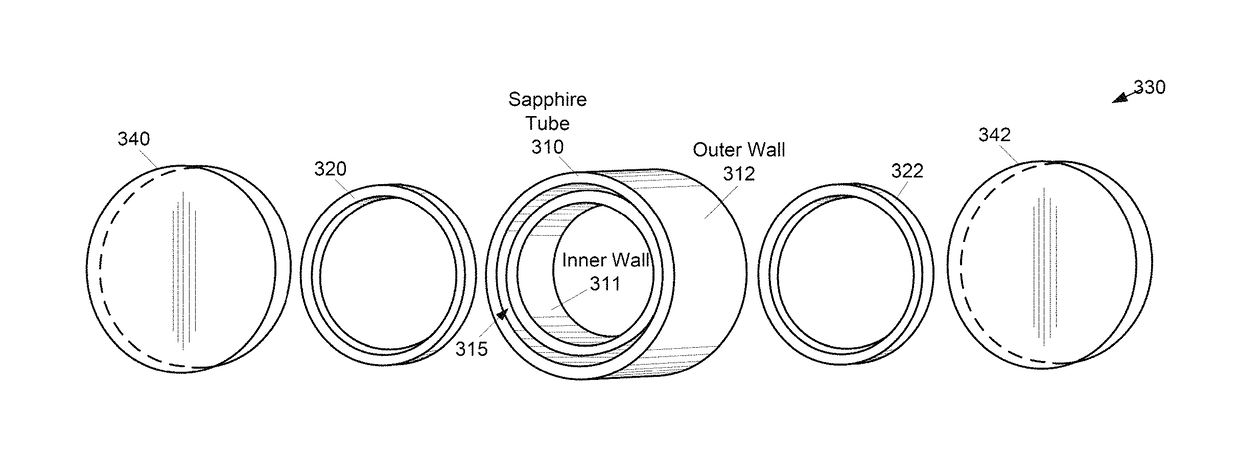

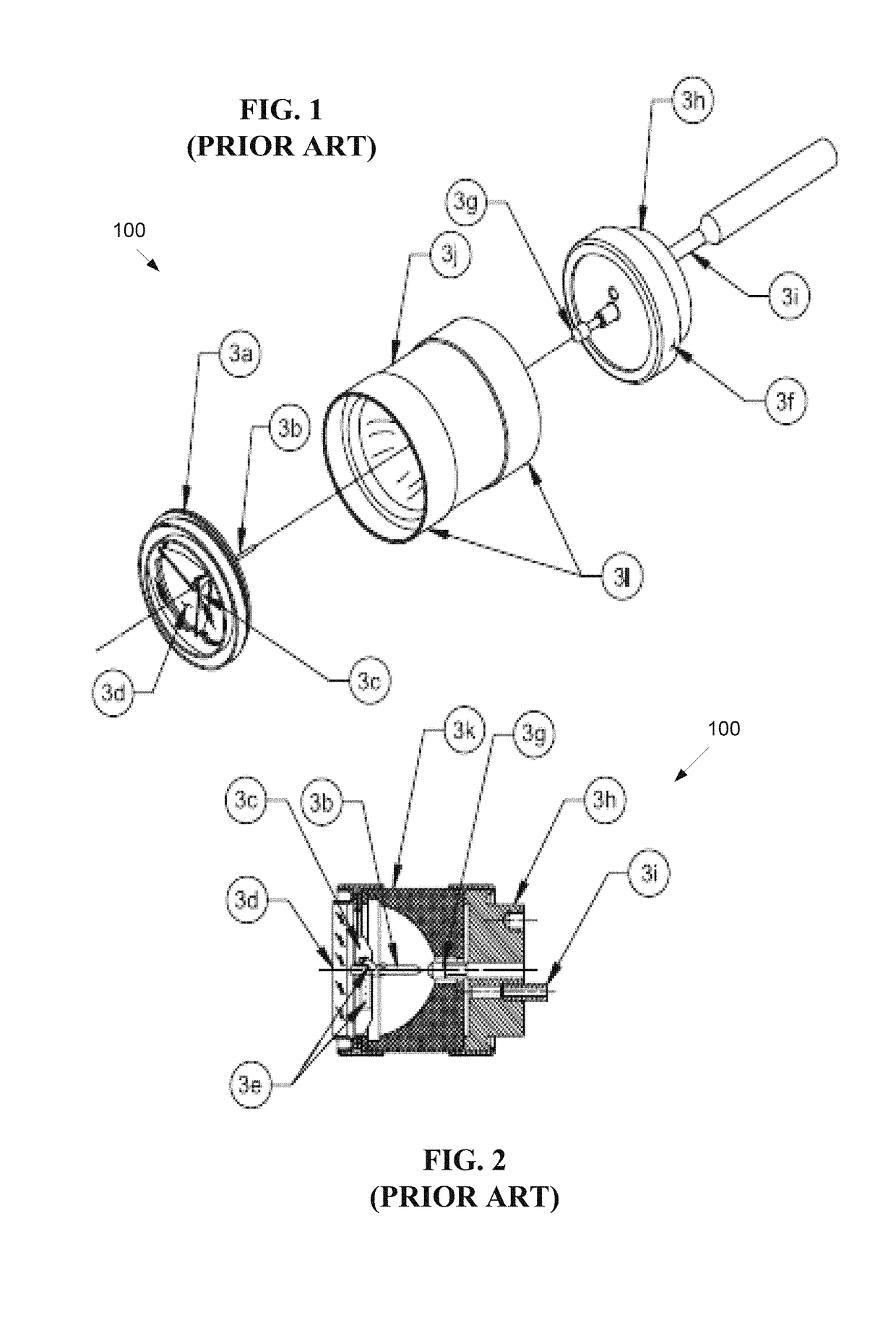

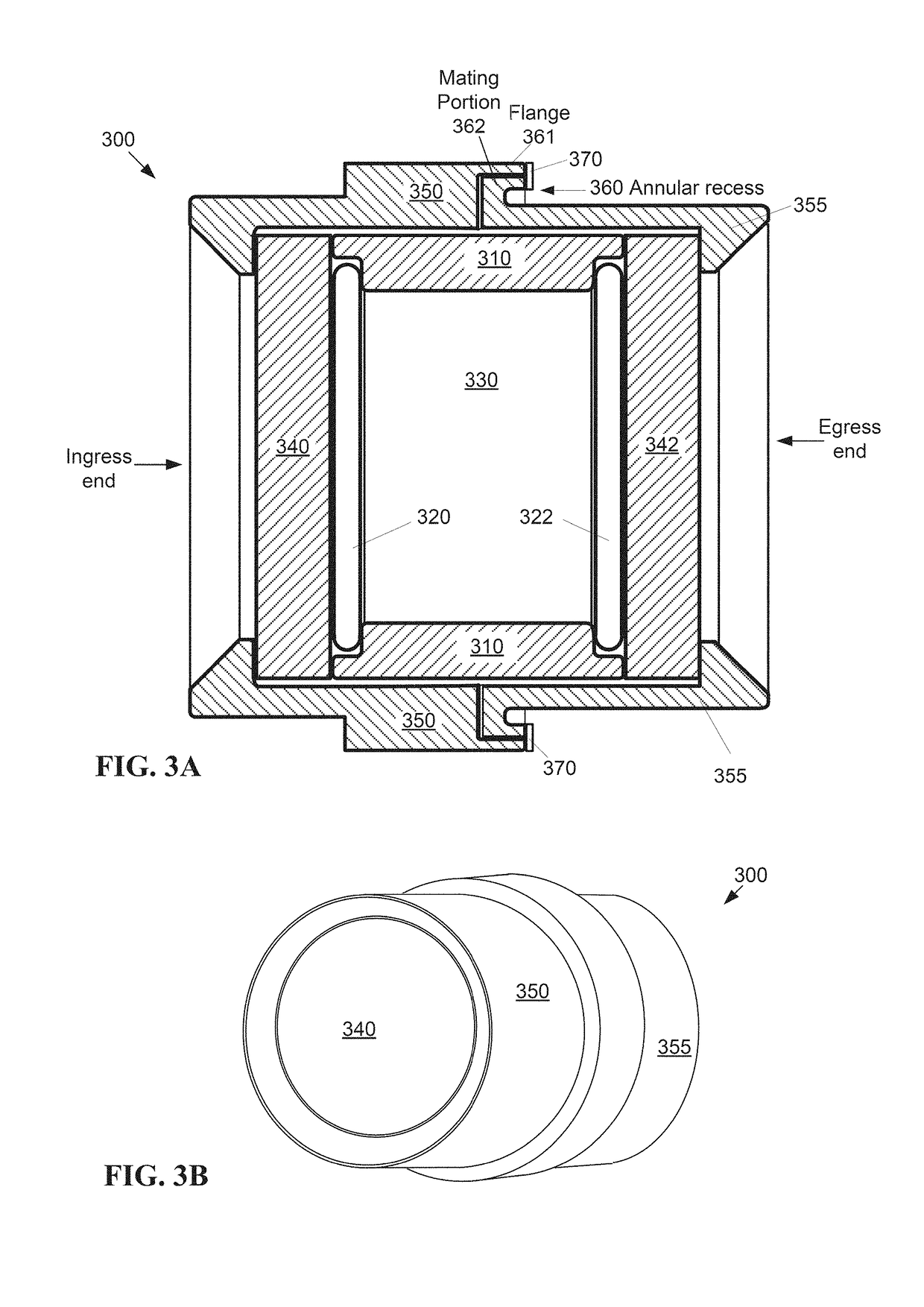

Mechanically sealed tube for laser sustained plasma lamp and production method for same

A laser sustained plasma lamp includes a mechanically sealed pressurized chamber assembly (330) configured to contain an ionizable material. The chamber assembly is bounded by a chamber tube (310), an ingress sapphire window (340), a first metal seal ring (320) configured to seal against the chamber tube ingress end and the ingress sapphire window, an egress sapphire window (342), and a second metal seal ring (322) configured to seal against the chamber tube egress end and the egress sapphire window. A mechanical clamping structure (350, 355) external to the chamber assembly is configured to clamp across at least a portion of the ingress sapphire window and the egress sapphire window. The ingress sapphire window and the egress sapphire window are not connected to the chamber tube via welding and / or brazing.

Owner:EXCELITAS TECH

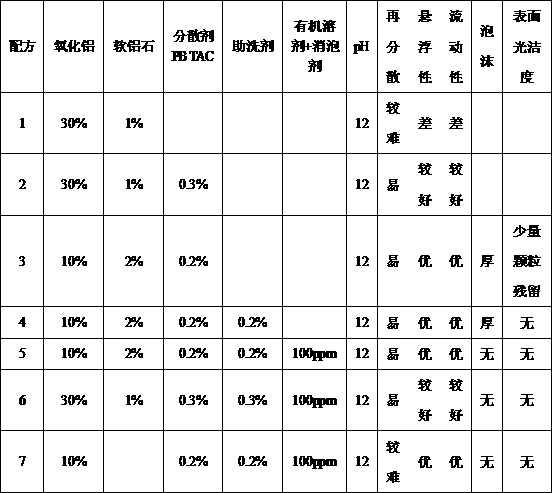

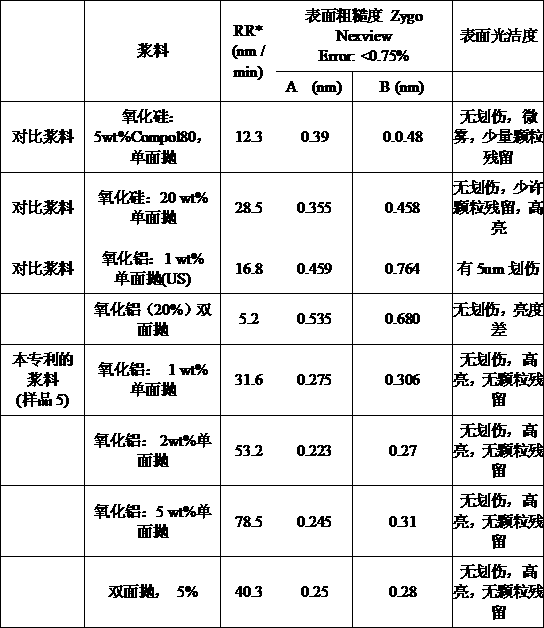

Aluminum oxide base polishing solution for sapphire substrate polishing and preparation method thereof

InactiveCN105950021ALow viscosityImprove liquidityPolishing compositions with abrasivesSapphire windowPhysical chemistry

The invention discloses a polishing solution of an aluminum oxide base sapphire substrate or a sapphire window piece. The polishing solution is characterized in that an alpha-type aluminum oxide grinding material with the specification of 0.01-1.5 micrometers, a dispersing agent containing organic phosphoric micromolecules, a builder, one or more organic solvents and antifoaming agents and the like are adopted, and the pH value is 10-14. The polishing solution has the better suspension dispersibility and mobility, and the high polishing efficiency, finish degree and roughness and can meet the technical requirement of polishing of the sapphire substrate material and the window piece.

Owner:苏州溶煋新材料科技有限公司

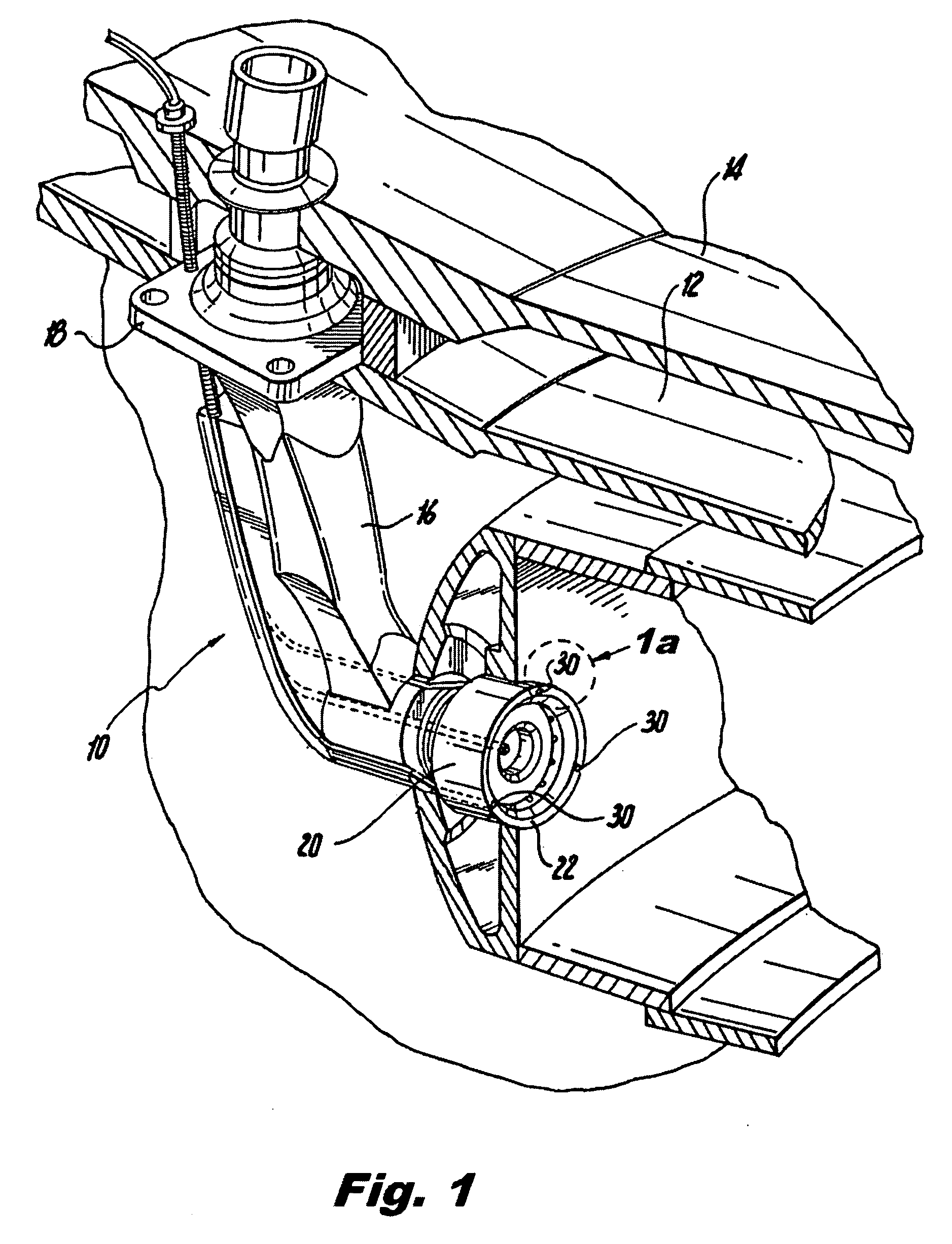

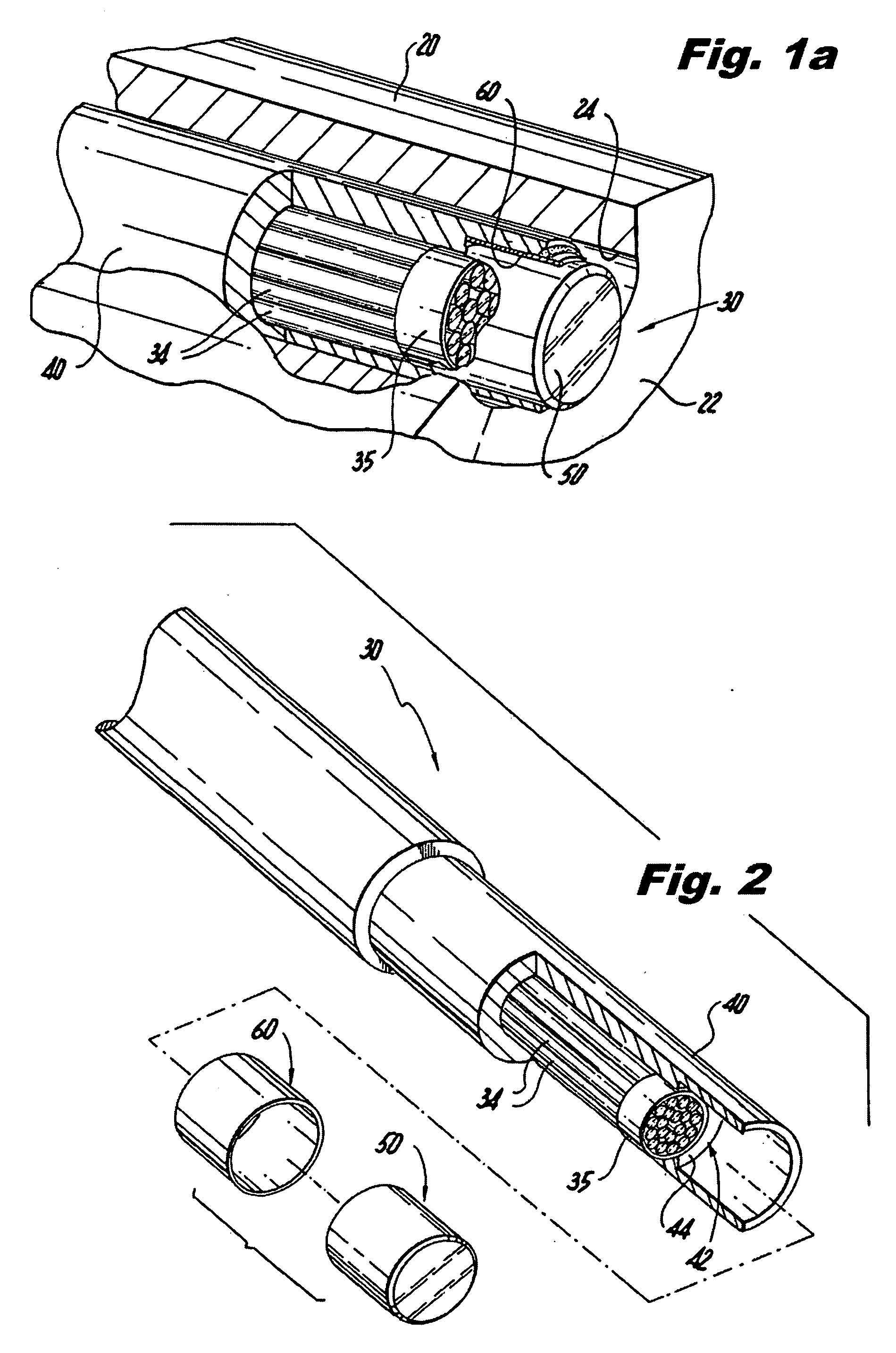

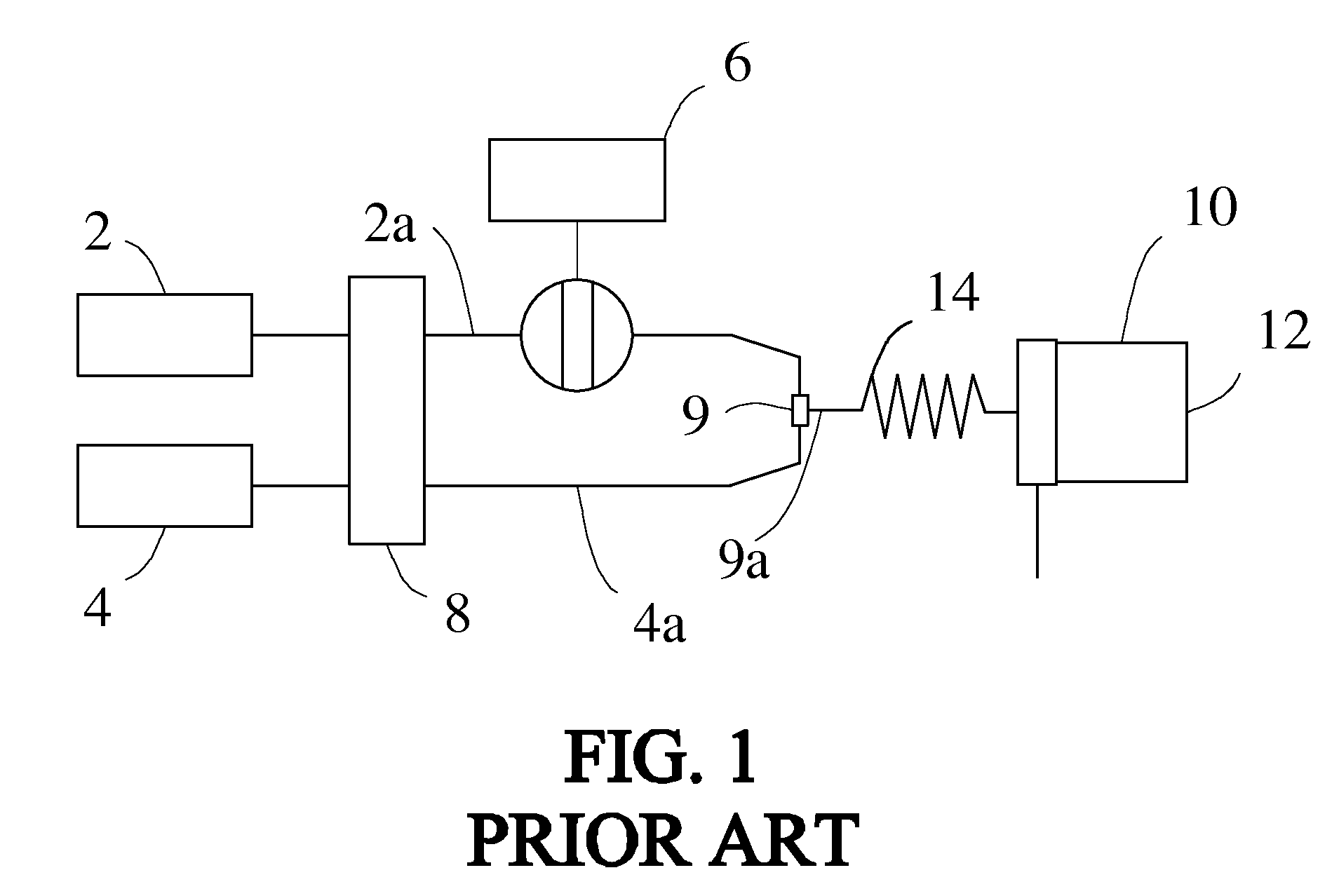

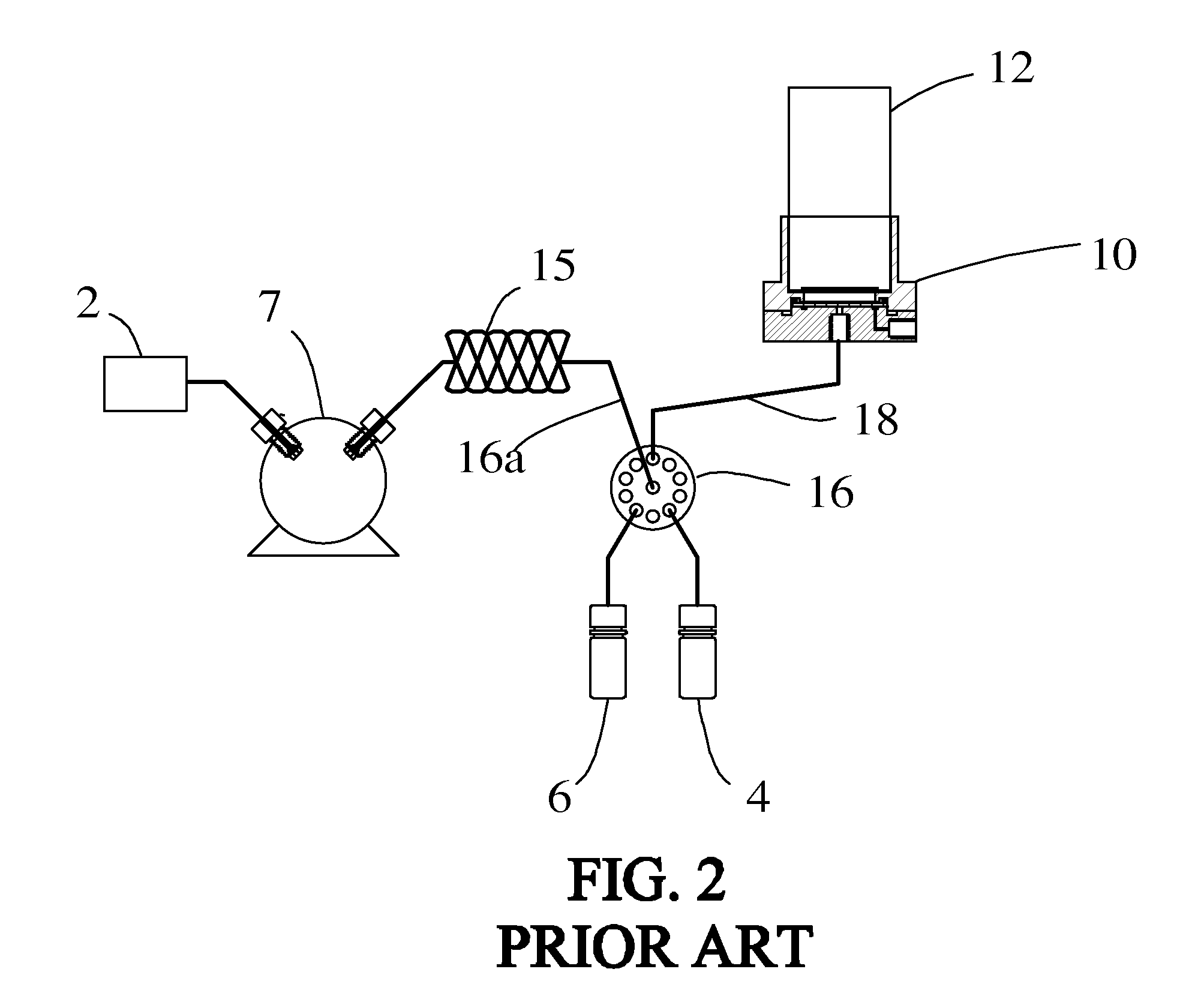

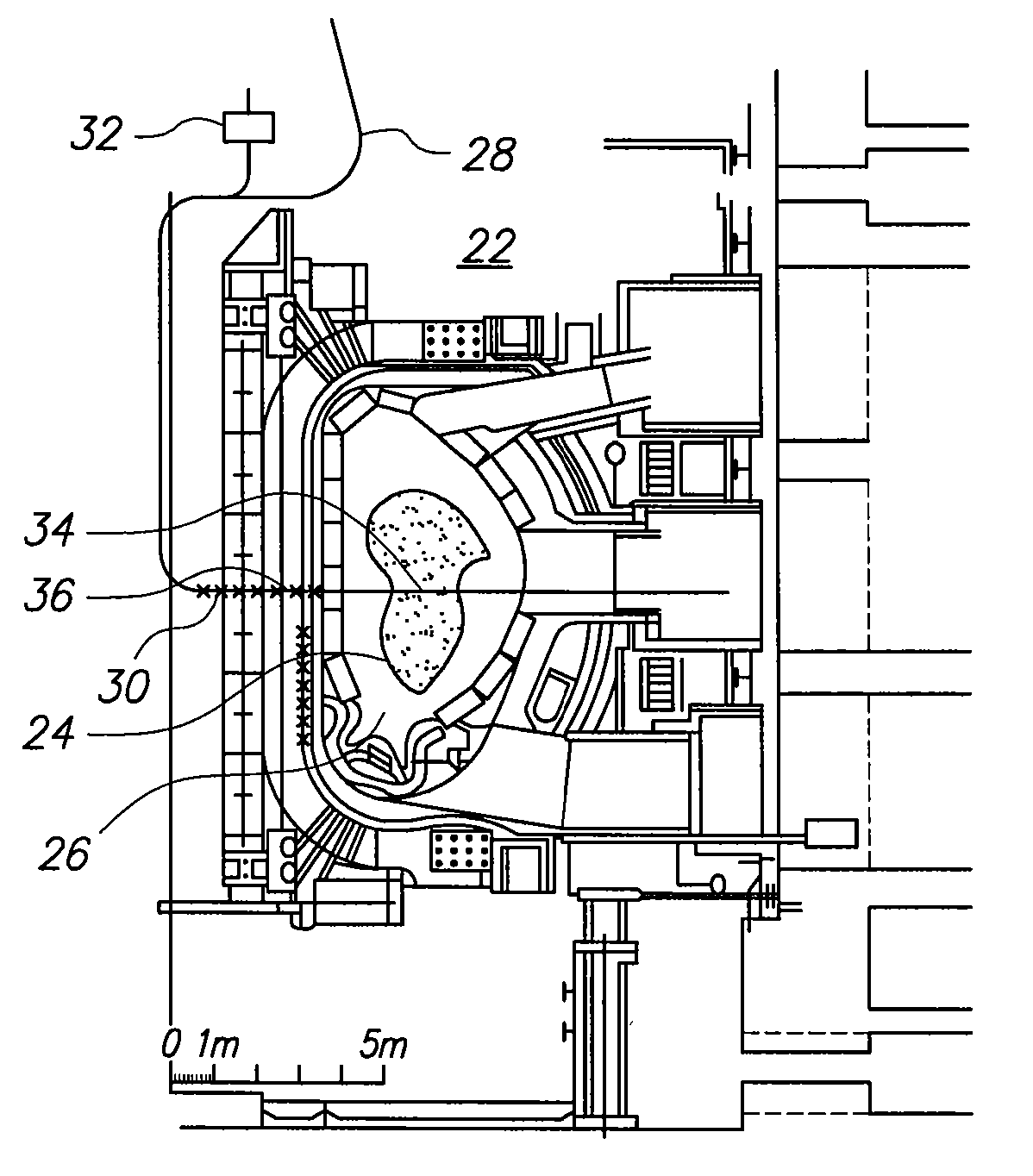

Microwave-powered pellet accelerator

ActiveUS7831008B2Easy to evaporateNuclear energy generationDirect voltage acceleratorsSapphire windowMicrowave

A system for fueling a plasma includes a gyrotron for radiating microwave energy into a waveguide. Also included is a module having a deuterium-tritium (DT) fuel pellet, a diamond, quartz or sapphire window, and a pusher medium located between the pellet and window that is made of frozen deuterium (D2) and metallic particles. With the module in the waveguide, the gyrotron is activated. Radiation from the gyrotron is then directed into the waveguide and through the window to cause the inducement of current in the metal particles, causing the particles to become hot. The absorbed microwave energy is then transferred to the pusher medium by conduction resulting in a gaseous expansion of the pusher medium. This ejects the pellet from the waveguide and into the plasma.

Owner:GENERAL ATOMICS

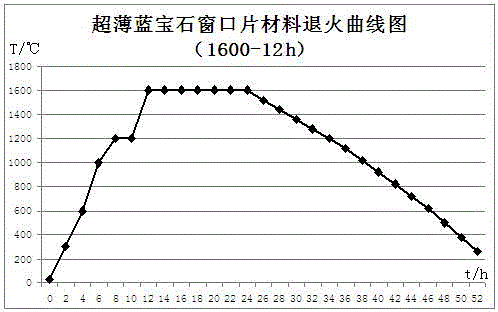

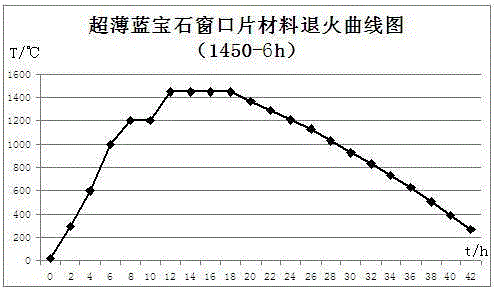

Processing method of large-sized sapphire ultrathin double-side-polished diaphragm

ActiveCN106181747AImprove pass rateEasy to operateAfter-treatment detailsPolishing machinesSapphire windowFirst pass yield

The invention relates to a processing method of a large-sized sapphire ultrathin double-side-polished diaphragm. The method comprises steps as follows: (1) a sapphire crystal bar is cut into a sapphire diaphragm; (2) smoothing treatment is performed to protect edges; (3) annealing processing is performed at the annealing temperature of 1,450 DEG C; (4) coarse grinding processing of double-side grinding is performed; (5) secondary annealing processing is performed at the annealing temperature of 1,600 DEG C; (6) fine grinding processing of double-side grinding is performed; (7) ultrasonic cleaning is performed; (8) polishing is performed by the aid of a silica sapphire polishing liquid in a double-side polishing machine; (9) the sapphire double-side-polished diaphragm is obtained through ultrasonic cleaning. The method has the characteristics that the method is convenient to operate, the first pass yield is high, no diaphragm breakage occurs in the grinding process and the like, and is applicable to processing of sapphire double-side-polished diaphragms which have diameters being 4 inches and 6 inches and thicknesses ranging from 0.20 mm to 0.25 mm.

Owner:TUNGHSU GRP

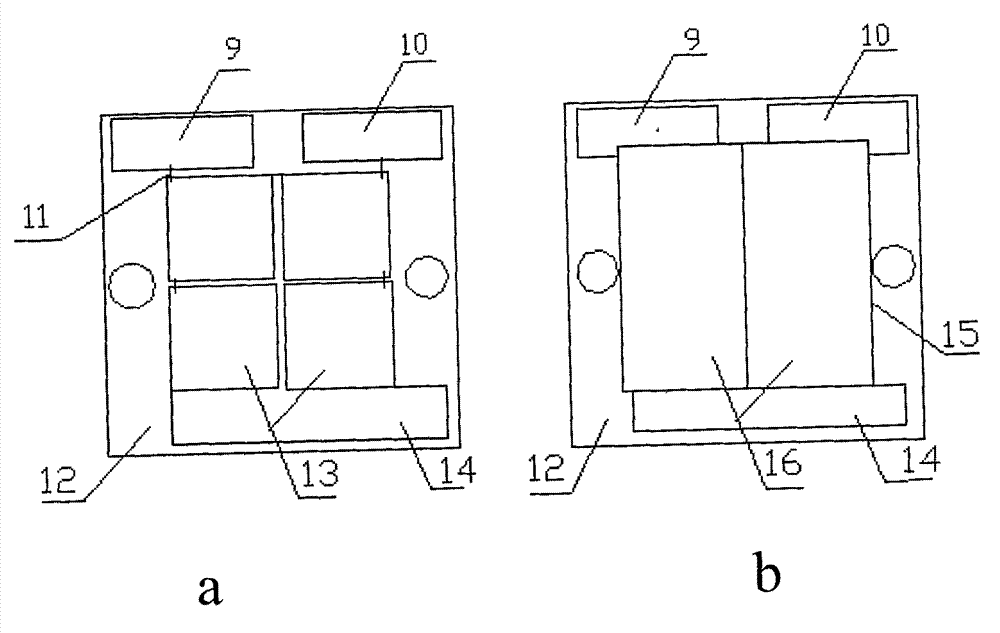

Sample collection and preparation device for collecting near infrared spectrum of coal powder on line

InactiveCN104330380ARelatively denseGood repeatabilityWithdrawing sample devicesMaterial analysis by optical meansSapphire windowDifferential pressure

The invention discloses a sample collection and preparation device for collecting a near infrared spectrum of coal powder on line. The sample collection and preparation device comprises a shell box body, a sample processing unit assembled in the shell box body and a system control unit. The defect that relevant equipment is easily affected by relevant factors such as the compactness, temperature and surface flatness of a material when collecting the near infrared spectrum of a powdered substance is overcome. The sample collection and preparation device is characterized in that a pressure sensor is mounted on a sample collection pipe in the sample processing unit; an approach temperature sensor, a sapphire window and a near infrared standard reference plate are mounted on a coal powder sample preparation device; the coal powder temperature is automatically adjusted by the system control unit by controlling the cold air amount, and the coal powder compactness is automatically adjusted by controlling the pressure difference between compressed air and a coal powder pipeline; furthermore, the device also has a function of automatically catching outside samples. Compared with a product of the same type, the sample collection and preparation device is reasonable in structural design, and can be used for obviously improving the repetitiveness and stability of near infrared spectrum collection and thus ensuring the accuracy of on-line near infrared coal quality detection.

Owner:NORTHEASTERN UNIV

Alkaline cleaning technology for sapphire diaphragm

InactiveCN106391548AImprove cleanlinessImprove securityCleaning using liquidsSapphire windowEngineering

The invention provides an alkaline cleaning technology for a sapphire diaphragm. A sapphire workpiece is made into a double-face polished sapphire sheet through cutting, grinding and polishing firstly, and then, the double-face polished sapphire sheet is finally cleaned. The steps are simple, and preparing is convenient. The whole cleaning process comprises cleaning through an alkalescence environment-friendly cleaning agent two times and cleaning through ultra-pure water five times. Compared with an original cleaning technology, the alkaline cleaning technology is used for conducting cleaning and is more environment-friendly, the chip cleanliness degree is high, and safety is high; and meanwhile, cost is low, and safety and environment-friendliness are achieved.

Owner:江苏吉星新材料有限公司

Sapphire infrared window cleaning agent and preparation method

InactiveCN101875886AQuality assuranceGuaranteed surface finishInorganic non-surface-active detergent compositionsSapphire windowSurface finish

The invention relates to a sapphire infrared window cleaning agent and a preparation method. The sapphire infrared window cleaning agent is characterized by comprising 1472-1840 parts by weight of concentrated sulfuric acid, 300-500 parts by weight of potassium dichromate and 4000-5500 parts by weight of water. When used to clean a sapphire window, the cleaning agent is non-corrosive on human body at normal temperature because the cleaning agent is not volatile easily, thus the cleaning agent has safe and convenient use without corroding and damaging polishing surfaces in the cleaning process and can ensure that the surface quality and the surface finish quality of the sapphire infrared window are not damaged.

Owner:CHONGQING CHUANYI AUTOMATION

Colorimetry-based test device for magnesium and magnesium alloy ignition temperature and use method of test device

InactiveCN102865930AIncrease in sizeSimple structureRadiation pyrometryAnalysis by thermal excitationSapphire windowMeasuring instrument

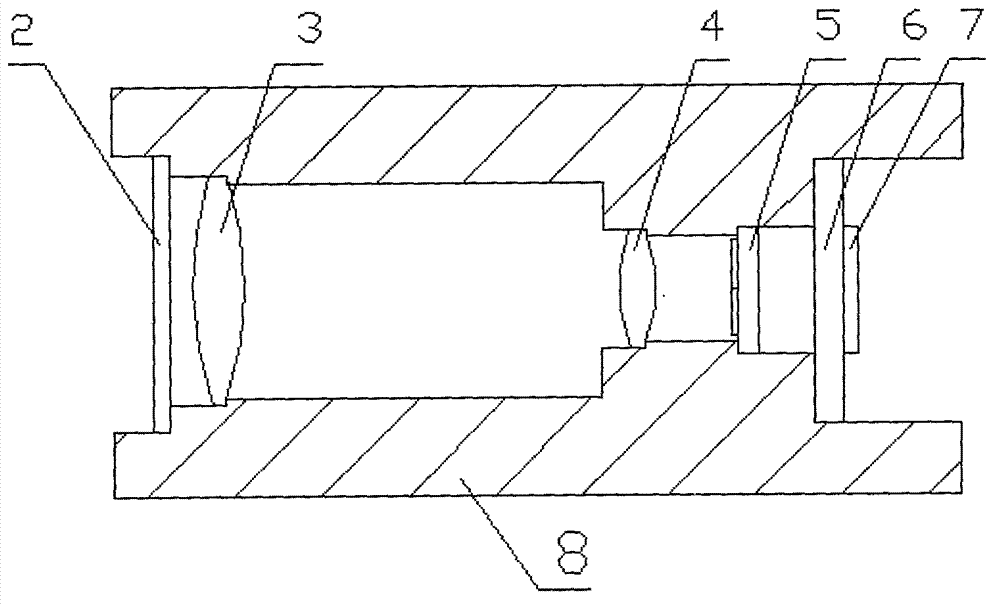

The invention discloses a colorimetry-based test device for magnesium and magnesium alloy ignition temperature and a use method of the test device and belongs to the technical field of optical engineering and sensors. The test device comprises a metal housing, a sapphire window, an object lens, a field lens, a two-quadrant detector, a conditioning circuit and an interface circuit, wherein the sapphire window, the object lens, the field lens, the two-quadrant detector, the conditioning circuit and the interface circuit are arranged inside the metal housing, the two-quadrant detector is used for detecting spectral wavelengths of the magnesium and magnesium alloy ignition temperature, and the test has the advantages of being simple in design structure, small in volume, light in weight, convenient to use, long in service life, reliable in measurement and the like. The use method of the test device comprises that a standard temperature-measurement measuring instrument is used for conducting static calibration for the colorimetry-based test device for the magnesium and magnesium alloy ignition temperature, the measurement accuracy and measurement the reliability are guaranteed due to the fact that the static calibration is conducted before use, then the standard temperature-measurement measuring instrument and the test device test the temperature of an object to be tested together, test results are compared, and the test results for the magnesium and magnesium alloy ignition temperature are reliable and accurate. The test device and the use method are worth using and popularizing.

Owner:ZHONGBEI UNIV

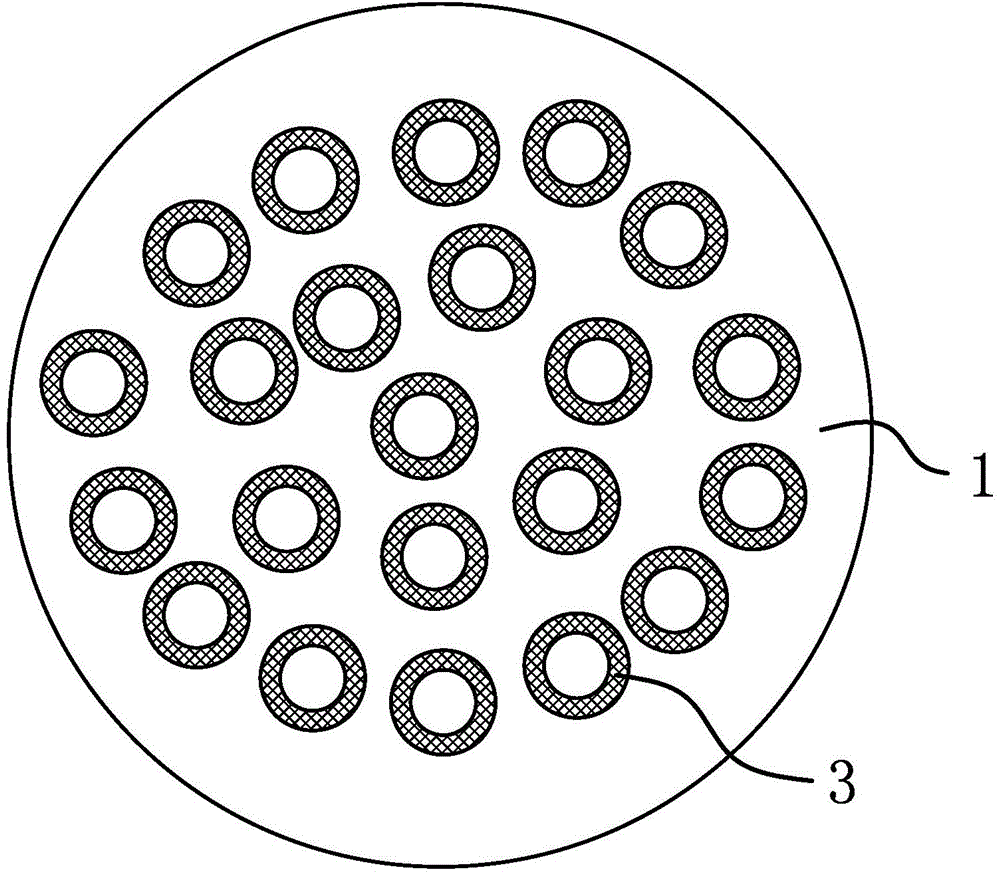

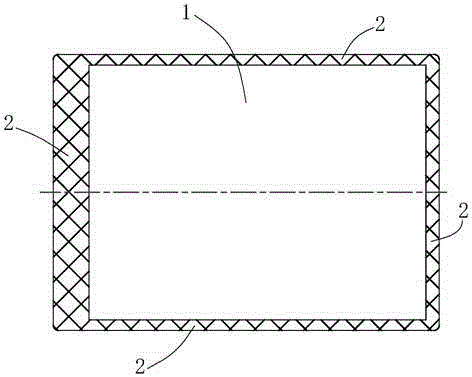

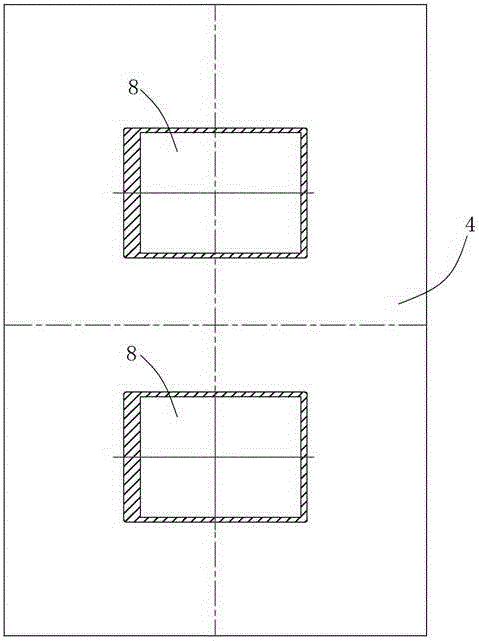

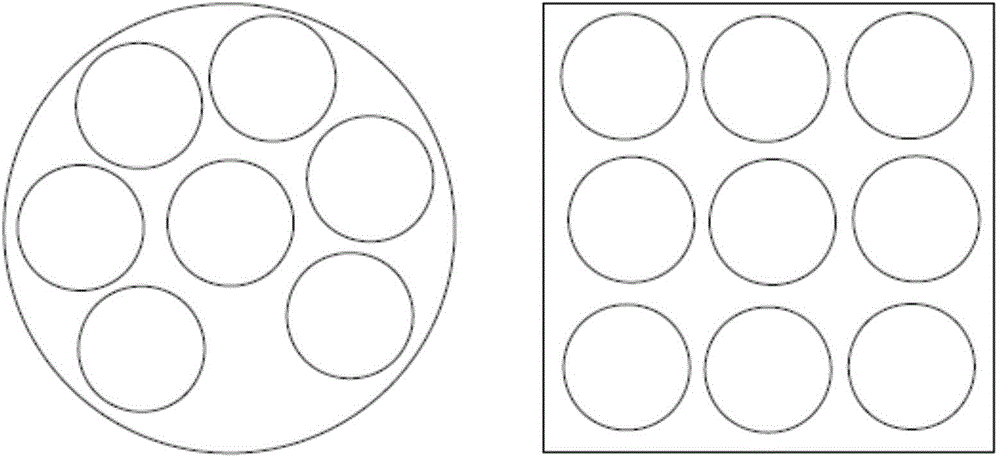

Machining method for sapphire window accessory of electronic product

ActiveCN104786377AGuaranteed not to fall offQuality improvementEdge grinding machinesFine working devicesSapphire windowClosed loop

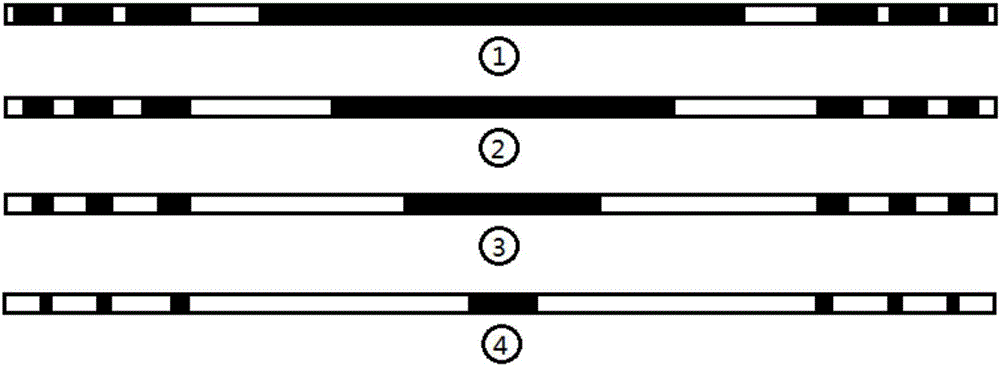

The invention provides a machining method for a sapphire window accessory of an electronic product, and belongs to the technical field of electronic product screen machining. The technical problem that existing sapphire window accessories are machined by a tool one by one, and the machining efficiency is low is solved. The machining method for the sapphire window accessory of the electronic product comprises the steps that a sapphire crystal block is cut into a sapphire substrate, sapphire printing ink is used for printing a plurality of annular printing ink belts on the sapphire substrate, the printing ink is dried, then the sapphire substrate is placed in a clamp to be fixed, laser light is used for cutting the sapphire substrate into a plurality of annular sheet sapphire window accessories, finally, unqualified products are removed, and qualified finished products are taken out. According to the machining method, due to the fact that the multiple annular printing ink belts are printed on the sapphire substrate through the sapphire printing ink, a plurality of finished products can be obtained through cutting at a time, the production efficiency is improved, laser light can achieve closed-loop control, the laser cutting precision can be improved, and the finished product quality is improved.

Owner:ZHEJIANG XINGXING TECH CO LTD

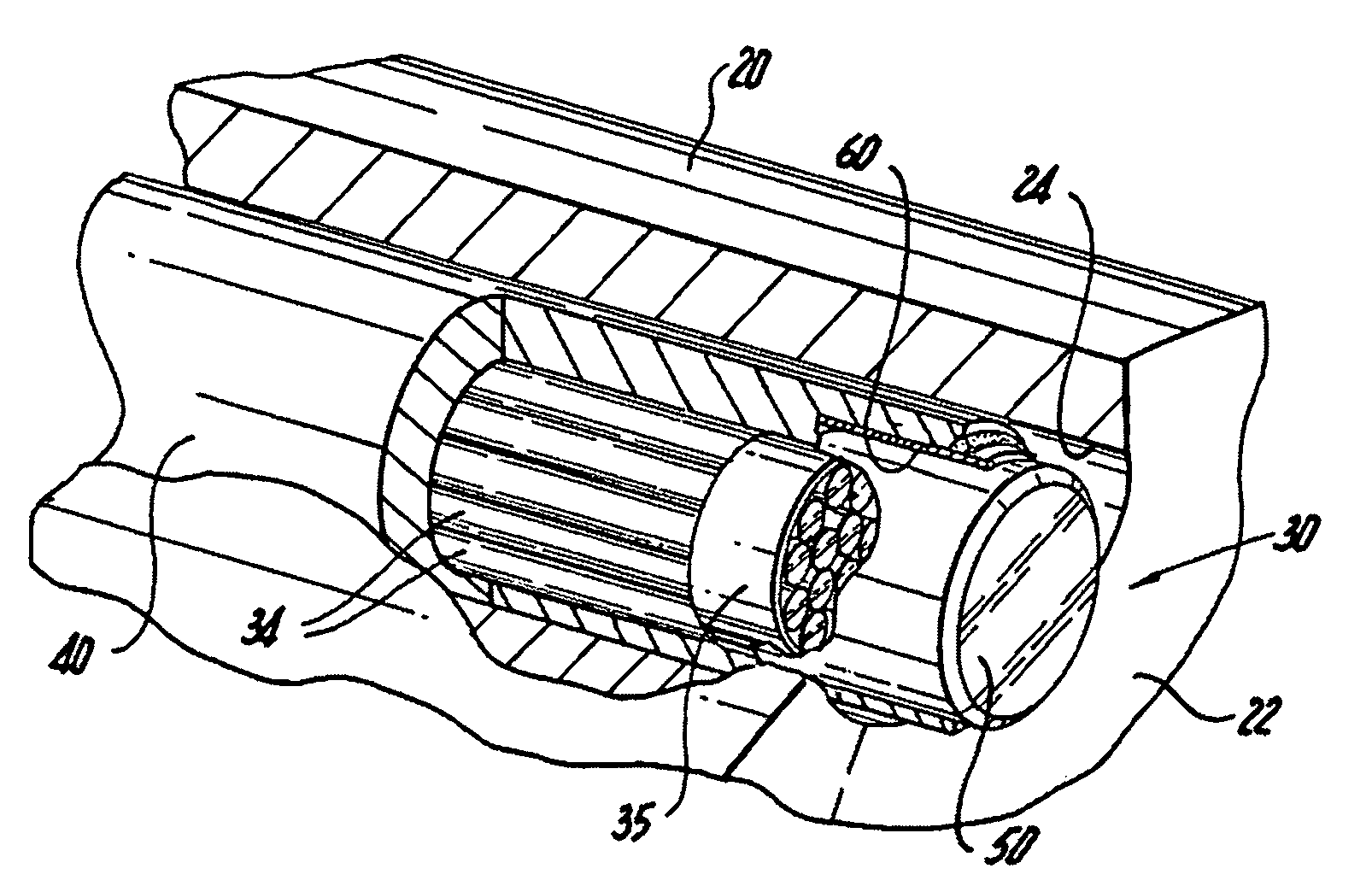

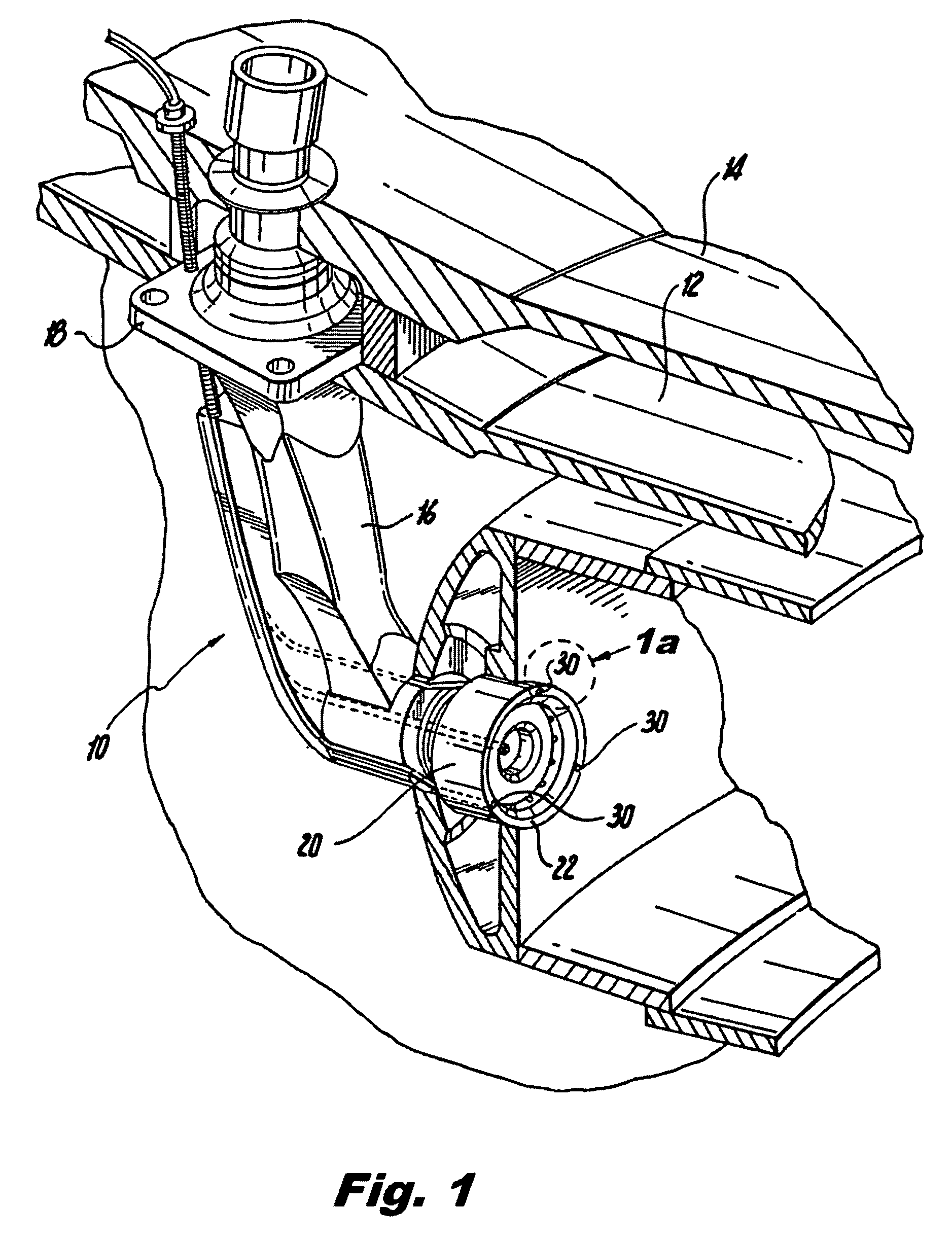

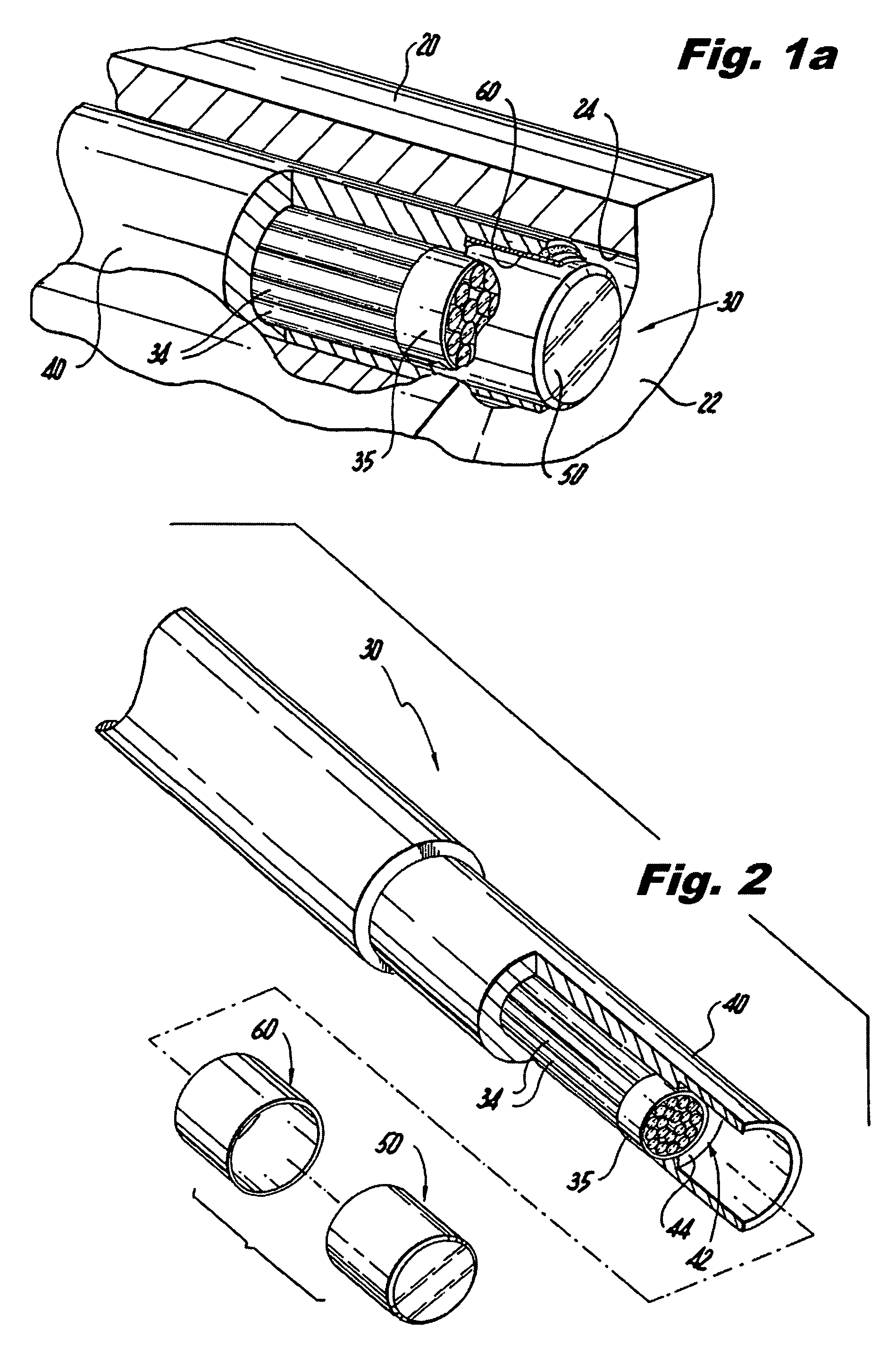

Microwave-powered pellet accelerator

ActiveUS20090028282A1Easy to evaporateNuclear energy generationDirect voltage acceleratorsSapphire windowMicrowave

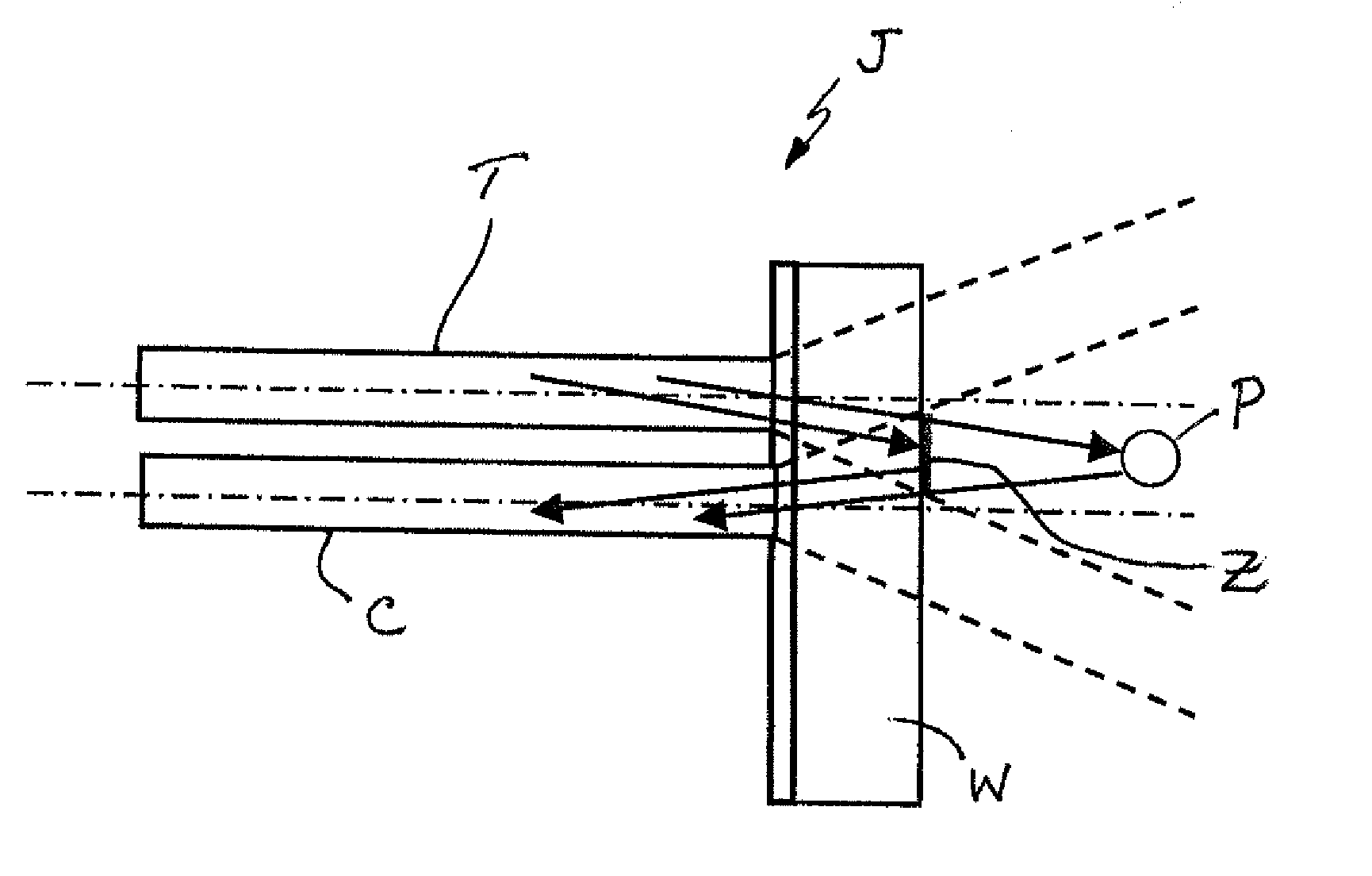

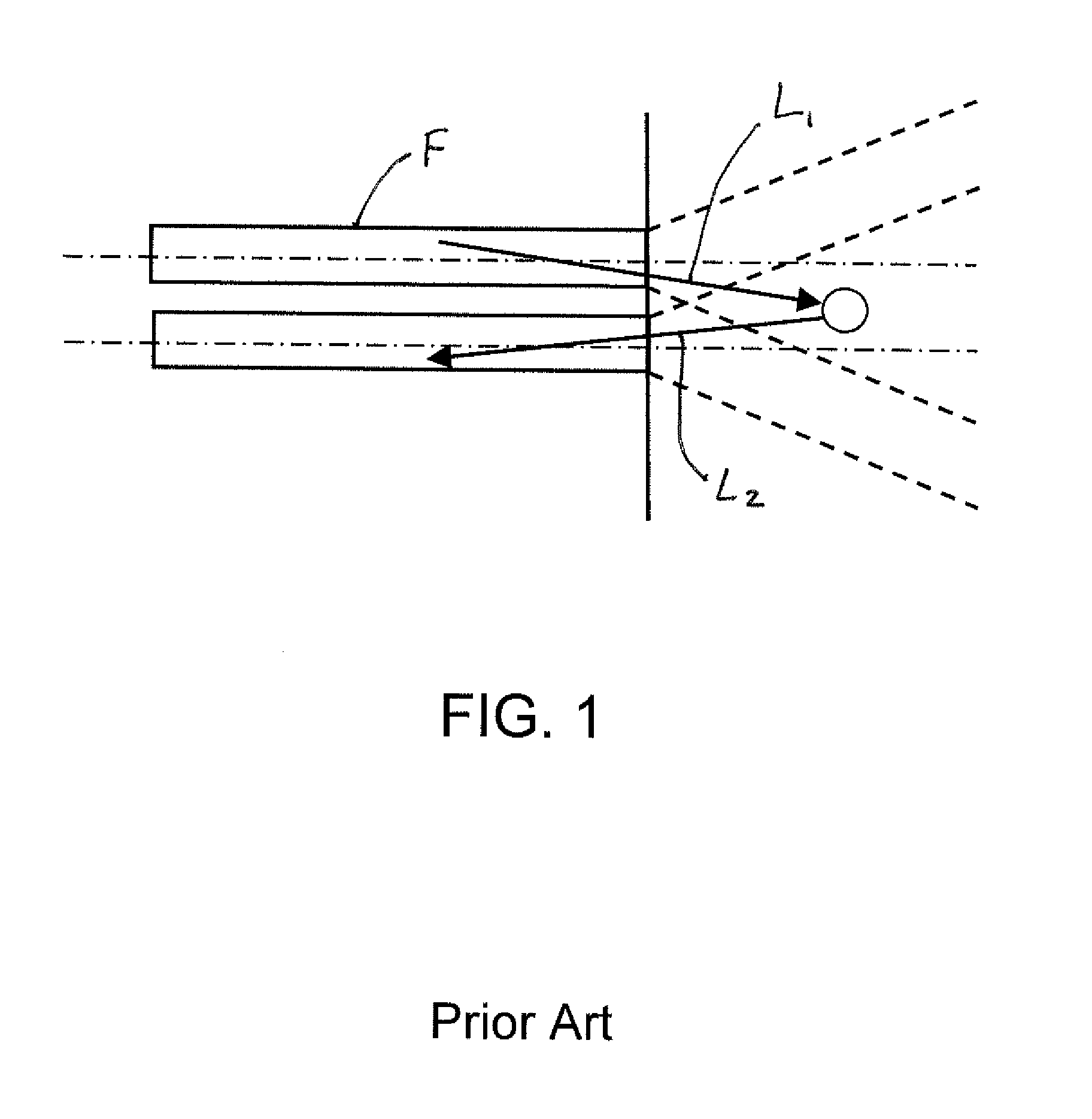

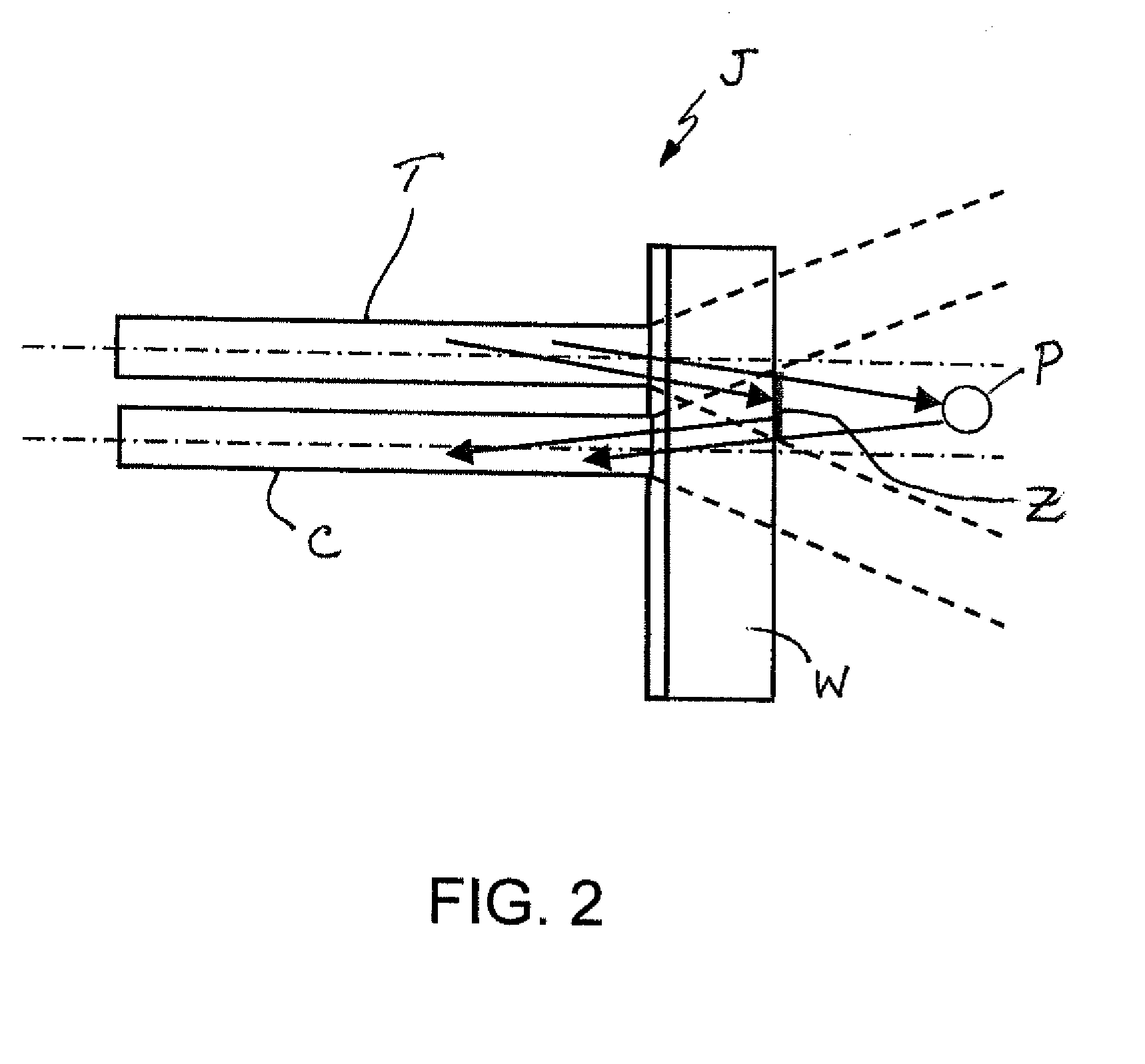

A system for fueling a plasma includes a gyrotron for radiating microwave energy into a waveguide. Also included is a module having a deuterium-tritium (DT) fuel pellet, a diamond, quartz or sapphire window, and a pusher medium located between the pellet and window that is made of frozen deuterium (D2) and metallic particles. With the module in the waveguide, the gyrotron is activated. Radiation from the gyrotron is then directed into the waveguide and through the window to cause the inducement of current in the metal particles, causing the particles to become hot. The absorbed microwave energy is then transferred to the pusher medium by conduction resulting in a gaseous expansion of the pusher medium. This ejects the pellet from the waveguide and into the plasma.

Owner:GENERAL ATOMICS

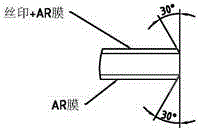

Formation method for thin-layer border of sapphire window

ActiveCN106274103AEliminate limitationsTroubleshoot difficult transformationsTelevision system detailsPattern printingSapphire windowScreen printing

The invention provides a formation method for a thin-layer border of a sapphire window of a high-end mobile phone or camera. According to the formation method, a coated laser engraving process is replaced by a precise silk-screen printing process. The formation method comprises the following steps: cleaning up a sapphire window substrate (3) by virtue of an ultrasonic cleaning process before printing; fixing the sapphire window substrate (3) to be machined onto a substrate location fixture during the printing, locating a movable frame by virtue of a silk-screen printing screen plate, and preparing a silk-screen printing ink from a silicon-free ink stock solution with the same brand, a curing agent and a diluting agent; roasting the sapphire window substrate (3) in a roasting box after the printing. According to the formation method, various colours are quite convenient to change during machining for the border of the sapphire window, and can be changed only through adjusting the colour of the ink and changing the ratio of the curing agent to the diluting agent.

Owner:NINGBO YONGXIN OPTICS

Method and apparatus for measuring emissivity and density of crude oil

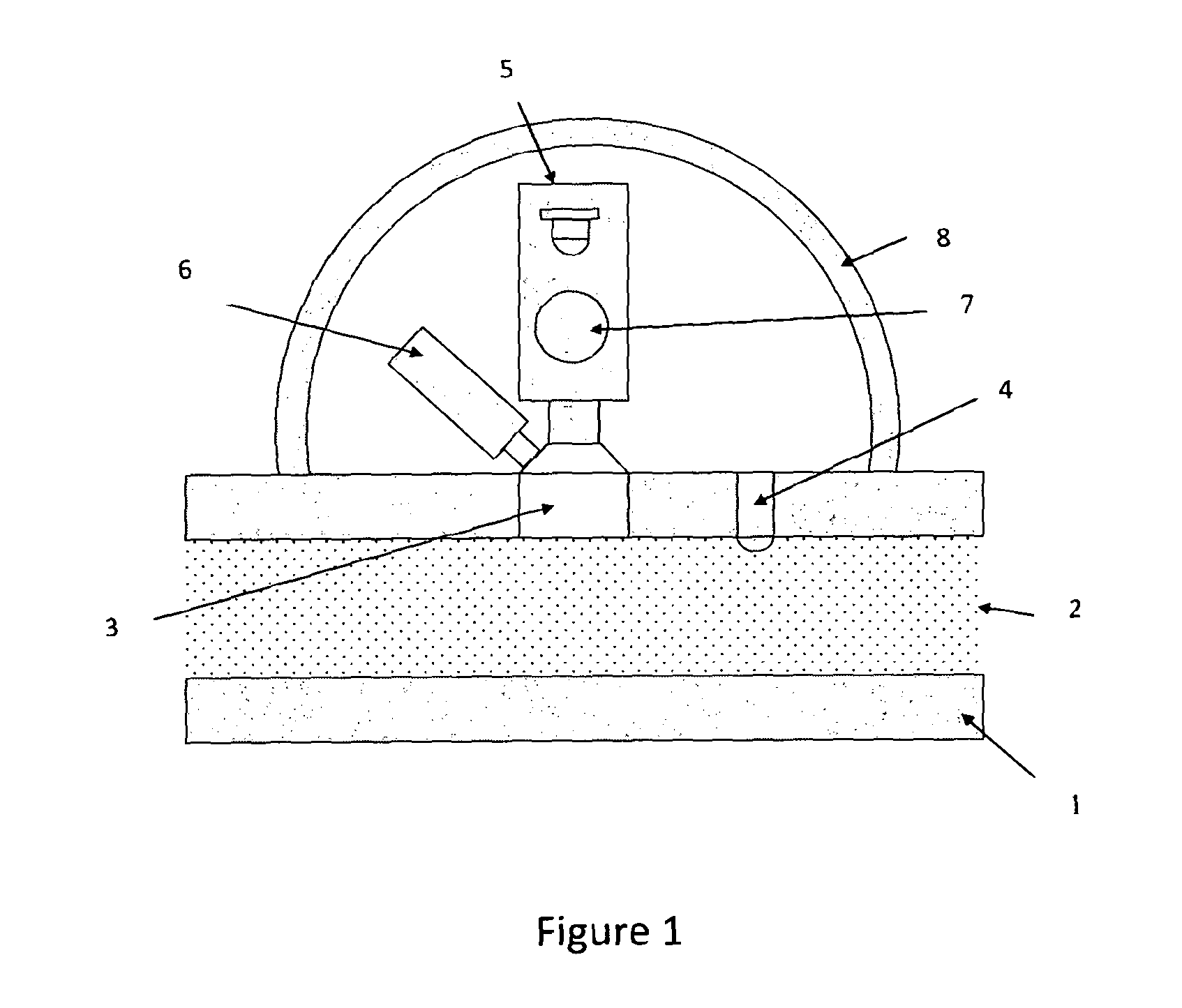

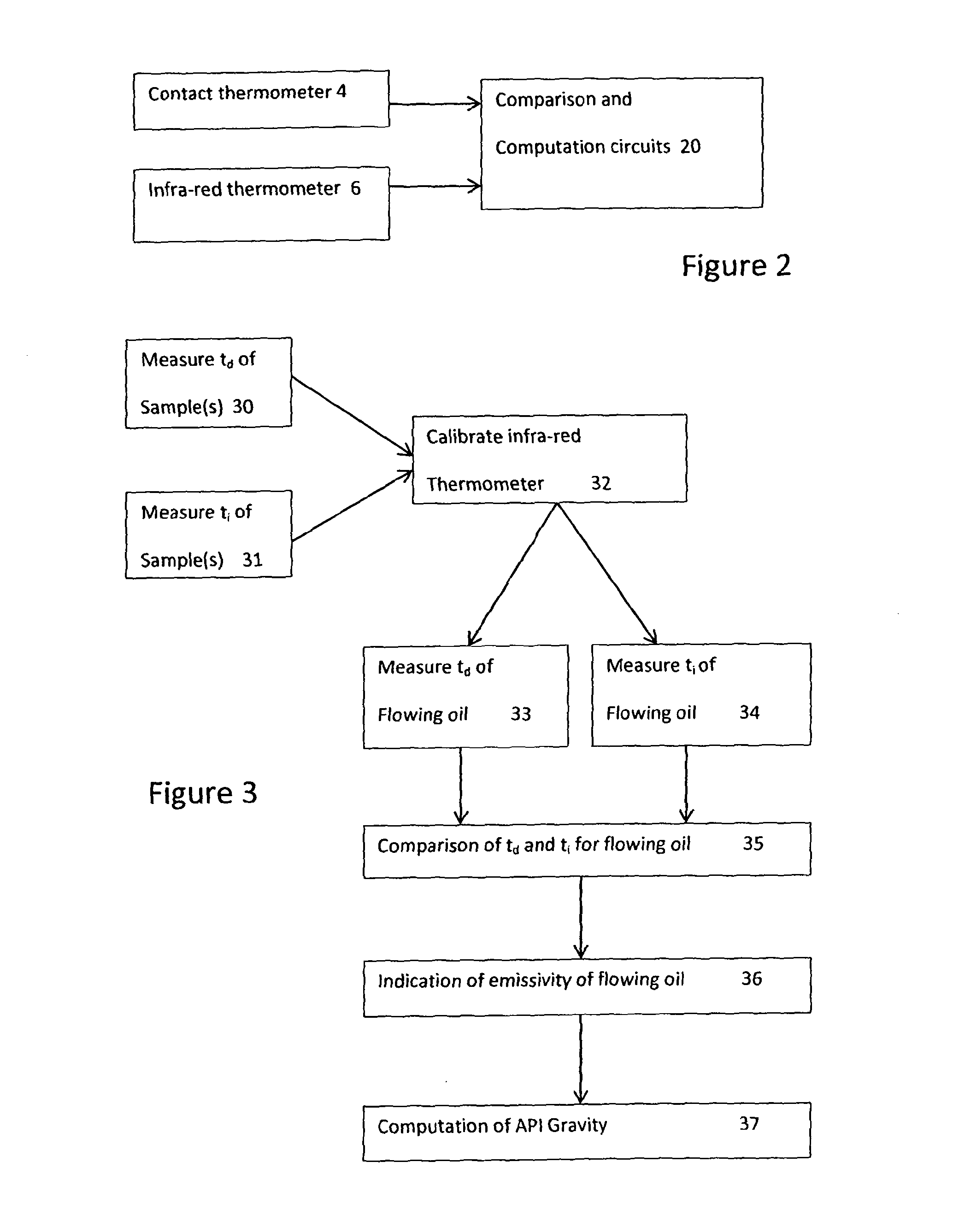

InactiveUS20150139273A1High tensile strengthHigh modulusTemperature measurement of flowing materialsSensing heat from liquidsSapphire windowEmissivity

Apparatus for use in the measurement of the API gravity of crude oil, comprises a conduit (1)for the oil, a thermo-couple (4) in the conduit for measuring temperature of the oil in contact therewith, a sapphire window (3) in the conduit, an infrared thermometer (5,6) for the measurement of the temperature of the oil through the window, and means (20) for comparing the measurements of temperature made by the thermometers to obtain a measure of the emissivity of the crude oil and thereby its API gravity.

Owner:AKER SOLUTIONS LTD

Microwave-powered pellet accelerator

InactiveUS20070092050A1Effective interactionHigh radiation outputPlasma techniqueThermonuclear fusion reactorSapphire windowGyroscope

A system for fueling a tokamak includes a gyrotron for radiating microwave energy into a waveguide. Also included is a module having a deutritium-tritium (DT) fuel pellet, a diamond / sapphire window, and a pusher medium located between the pellet and window that is made of frozen deuterium (D2) and metallic particles. With the module in the waveguide, the gyrotron is activated. Radiation from the gyrotron is then directed into the waveguide and through the window to cause a gaseous expansion of the pusher medium. This ejects the pellet from the waveguide and into the plasma of the tokamak.

Owner:GENERAL ATOMICS

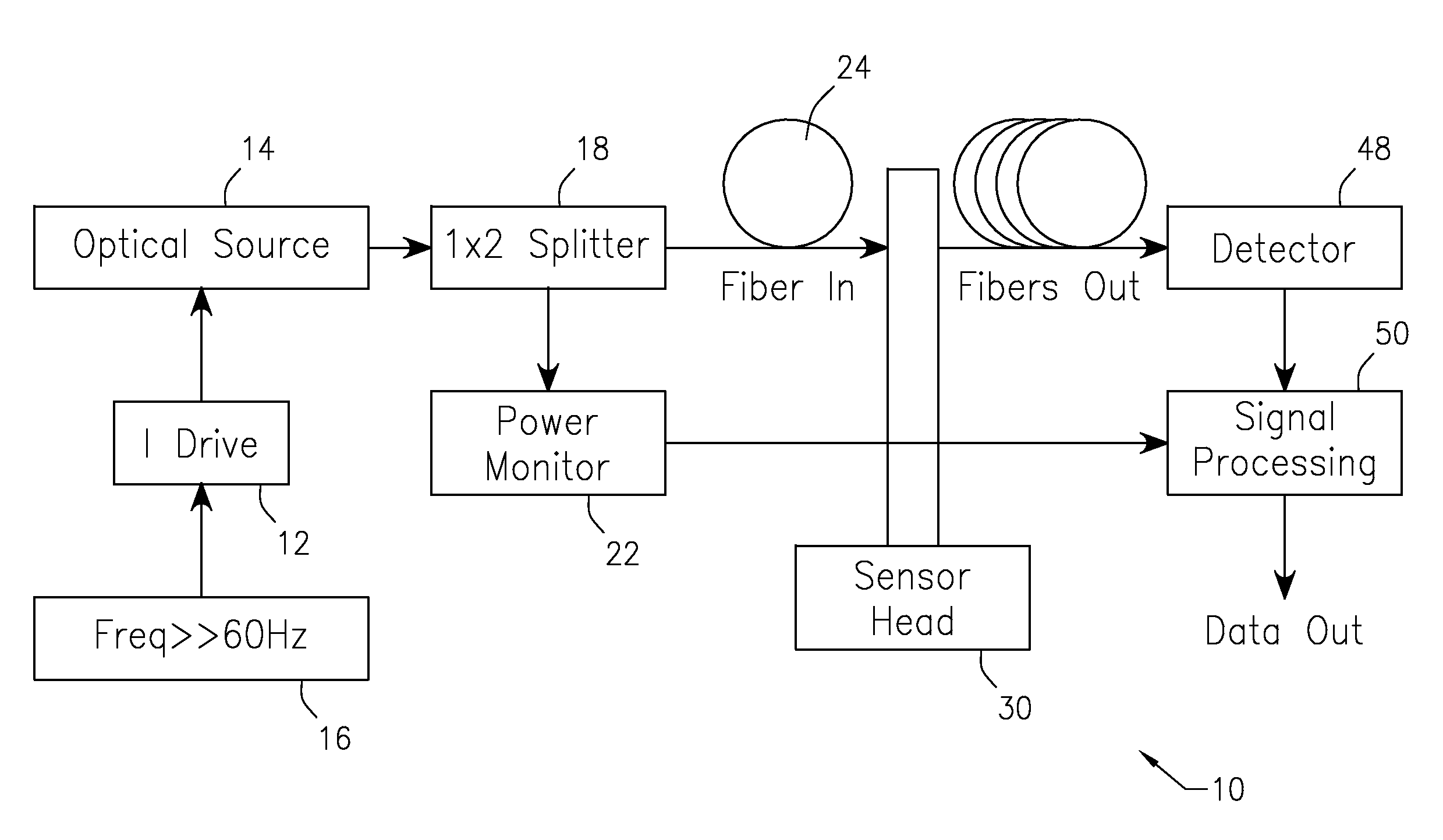

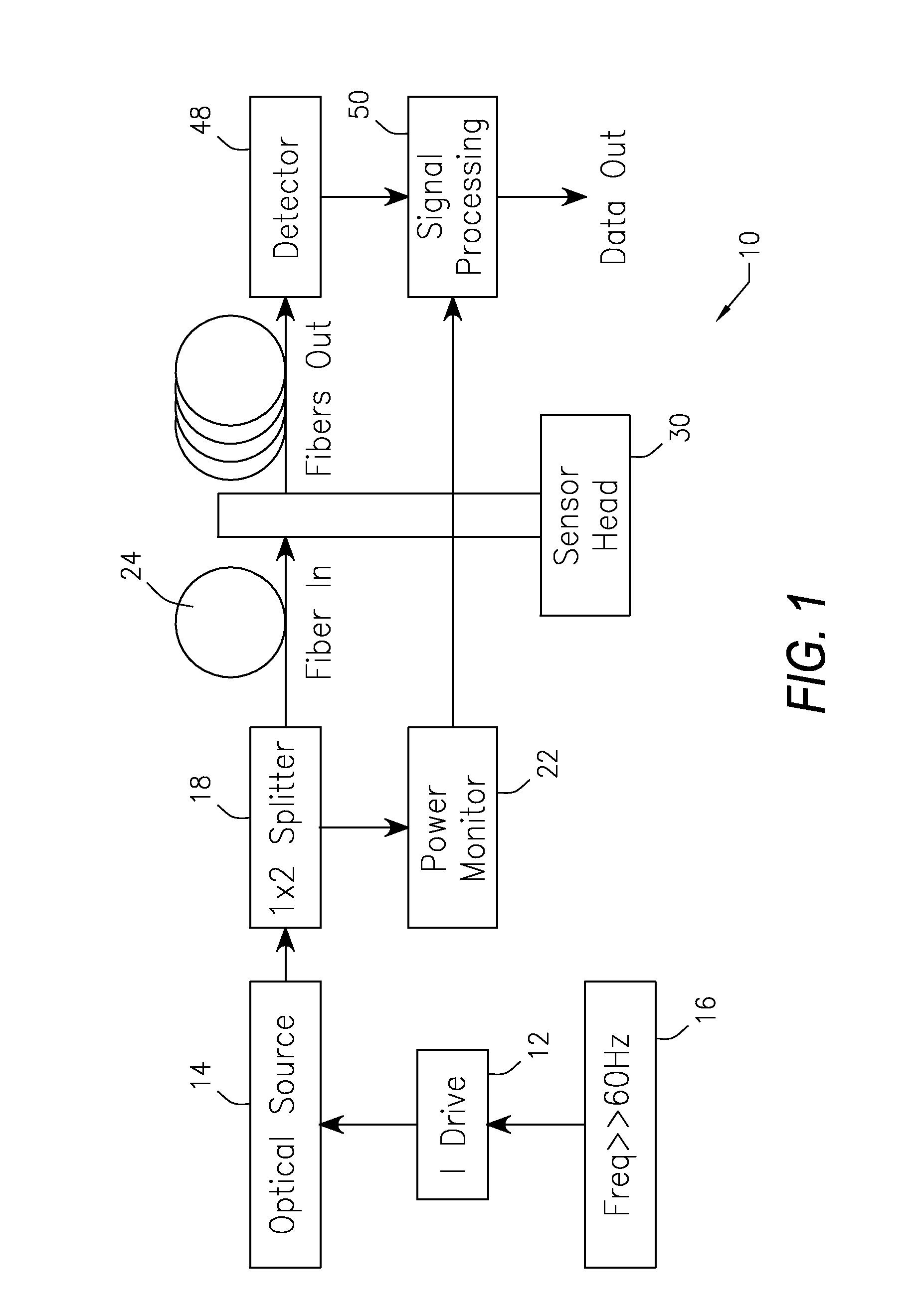

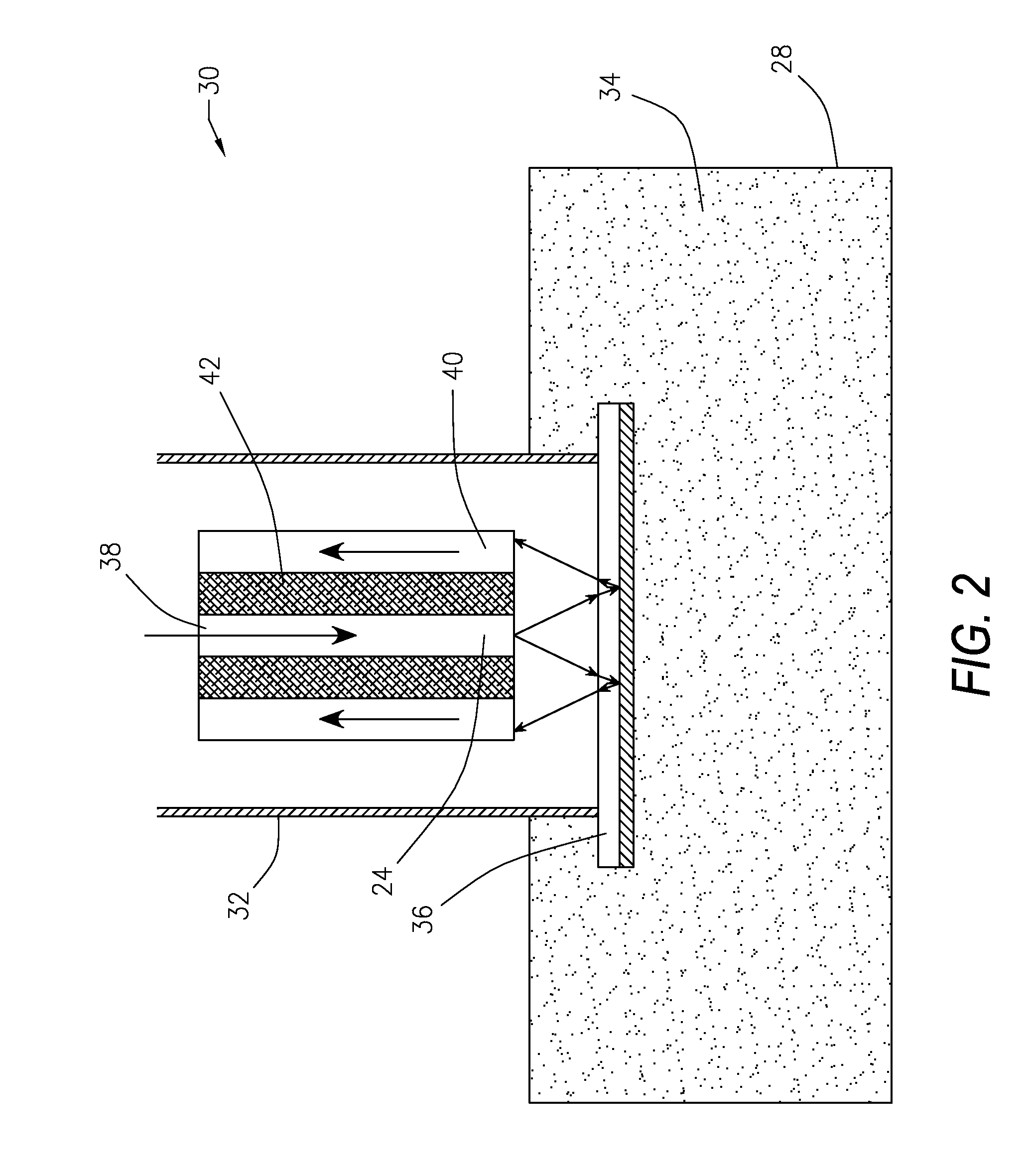

Optical pH sensor

ActiveUS7961327B1Photometry using reference valueScattering properties measurementsSapphire windowFiber

A method to sense pH of a fluid and an optical pH sensor. The method includes the steps of supplying at least a portion of an optical source through an input fiber. The optical source is passed through a sensor head having a sapphire window to a fluid. Optical power reflected from the fluid is collected in a plurality of output fibers in the sensor head. The reflected optical power in the output fibers in the sensor head is thereafter converted to an electrical signal which is used to determine the pH of the fluid.

Owner:BOVAIRD

Method for producing fresnel lens on sapphire window and application of fresnel lens

ActiveCN105742176AFocusingLarge Optical Fill FactorSemiconductor/solid-state device manufacturingLensSapphire windowFresnel lens

The invention provides a method for producing a fresnel lens on a sapphire window. According to the method, a silicon wafer is firstly designed by a binary optical principle to etch a mask; accurate nested etching is carried out on the surface of the silicon wafer to form a fresnel lens structure; an imprinted template is produced through the etched silicon wafer; and the fresnel lens is produced on the sapphire window through an imprint method and an etching process. Good transmittance of the sapphire window to ultraviolet rays is utilized; and the produced fresnel lens can effectively focus the ultraviolet rays in an ultraviolet ray absorption region of an ultraviolet detector, so that the detection range of the ultraviolet detector is increased; and the sensitivity is improved.

Owner:袁永刚

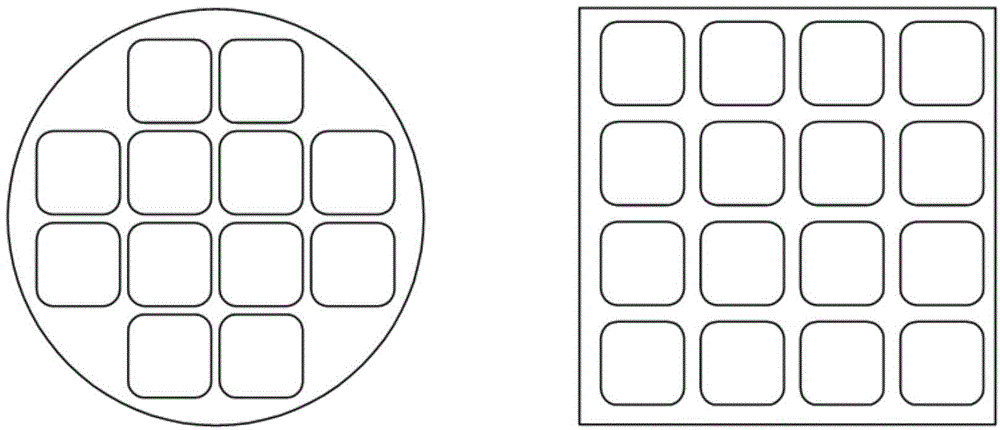

Sapphire diaphragm thinning machining method achieved through double-faced grinding pad

InactiveCN106466808AReduce wearImprove appearance qualityOther chemical processesLapping toolsSapphire windowPunching

The invention provides a sapphire diaphragm thinning machining method achieved through a double-faced grinding pad. The method comprises the steps of diaphragm manufacturing, pad installing and placing and punching, diamond grinding liquid preparing, diamond grinding liquid adding, grinding, grinding liquid recycling and the like. According to the method, the steps are simple, and preparation is convenient; by adopting the machining method of cooperating the polyurethane pad with diamond grinding liquid and utilizing the characteristics that the polyurethane pad is low in hardness and has many small holes in the surface, diamond particles can be inlaid into the surface in the grinding process, abrasion of the diamond particles to the wafer surface is effectively reduced, the machining efficiency is effectively improved, the wafer appearance quality is improved, the cost is greatly reduced, and recycling is achieved.

Owner:江苏吉星新材料有限公司

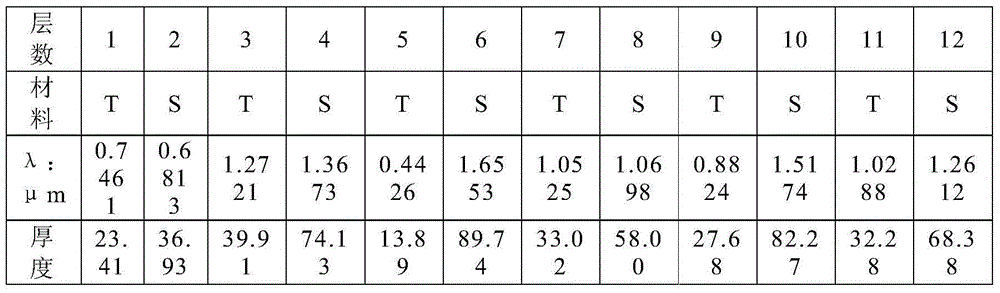

Far-infrared sapphire window protection screen for night vision

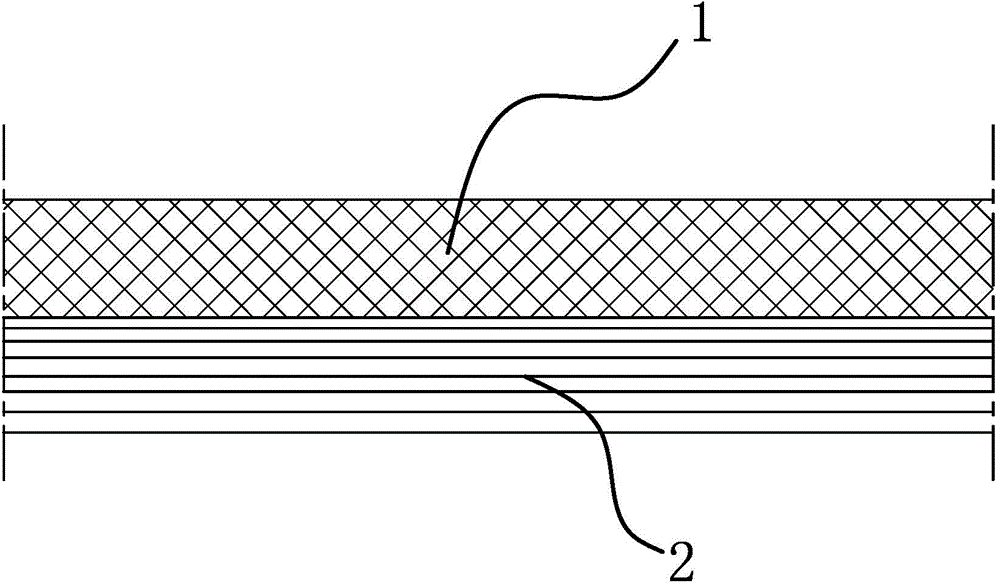

ActiveCN104536067AHigh transparencyGood optical performanceLayered productsOptical filtersCompound aNight vision

The invention provides a far-infrared sapphire window protection screen for night vision, and belongs to the technical field of optical equipment. The technical problems that far-infrared rays cannot permeate a coating film structure of the existing protection screen and the like are solved. The far-infrared sapphire window protection screen for night vision comprises a substrate made from sapphire, wherein the side of the substrate is coated by a multilayer film, and the multilayer film is formed by compounding a Ti3O5 coating with an SiO2 coating; high permeability is realized by the multilayer film at a visible light waveband from 420nm to 720nm, the cut-off is realized by the multilayer film at a waveband below 400nm, the cut-off is realized by the multilayer film at a near-infrared waveband from 720nm to 1100nm, and the high permeability is realized by the multilayer film at a far-infrared waveband above 1100nm. The far-infrared sapphire window protection screen for night vision provided by the invention has the advantages of stable optical properties, relatively low cost, good transparency, uniform coating components, realization of selective cut-off of light rays at different wavebands and the like.

Owner:ZHEJIANG XINGXING TECH CO LTD

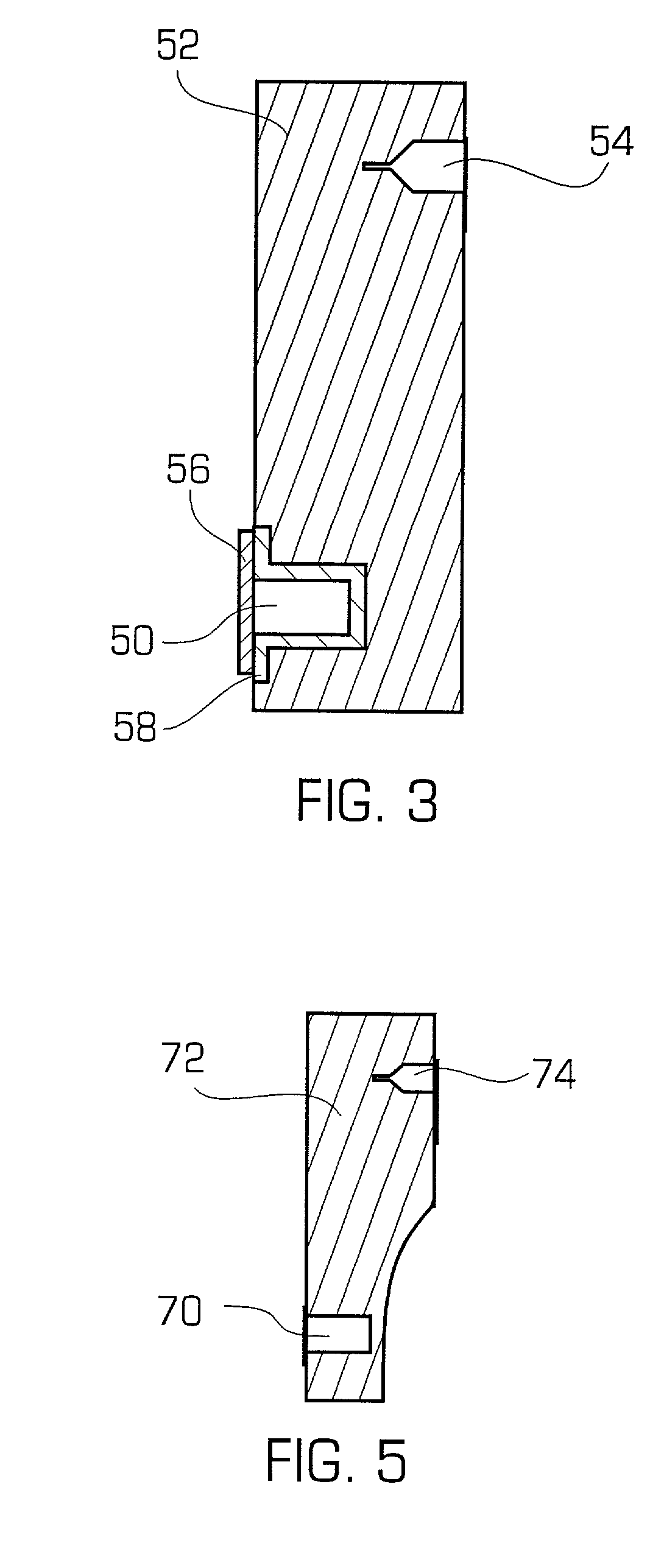

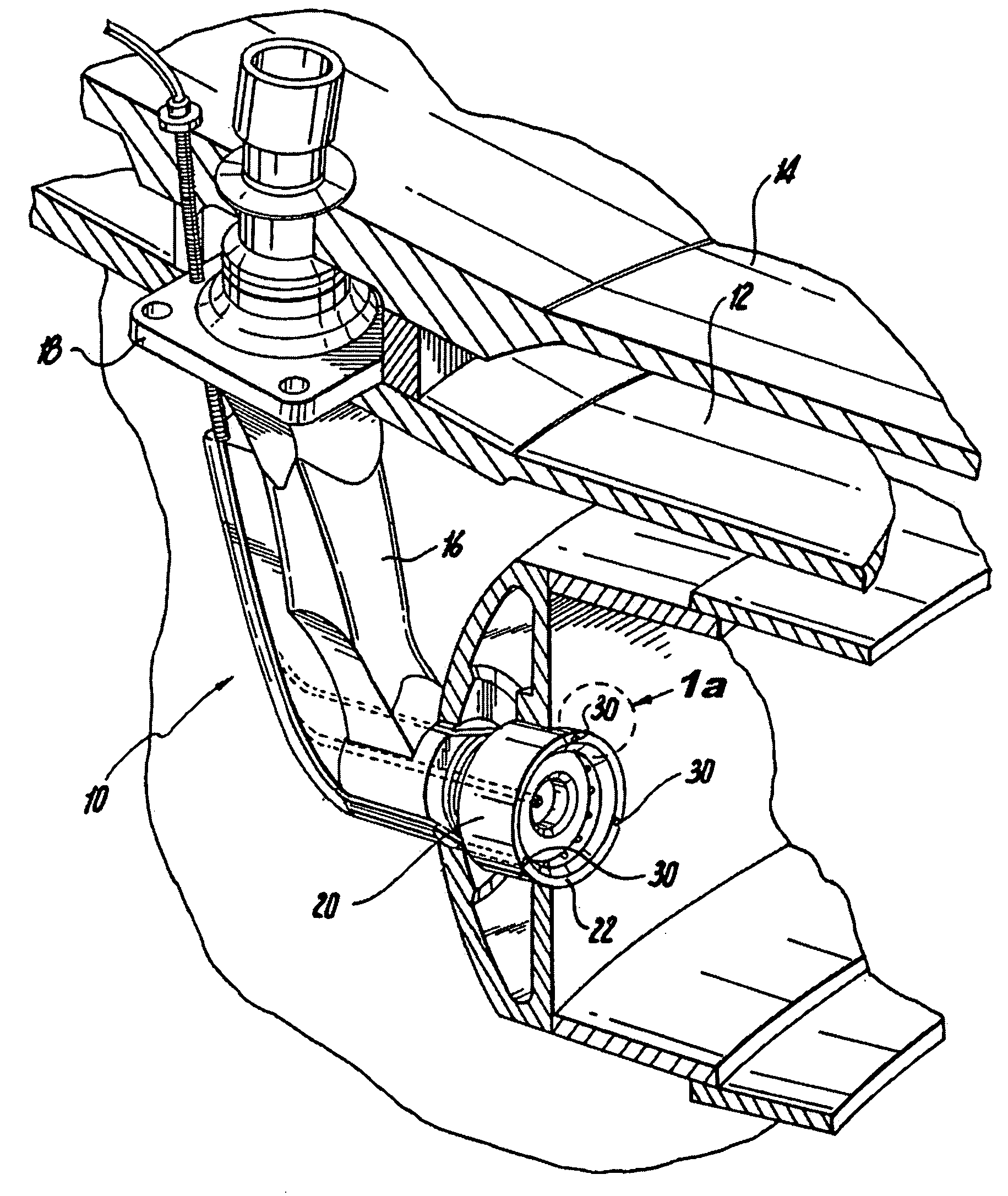

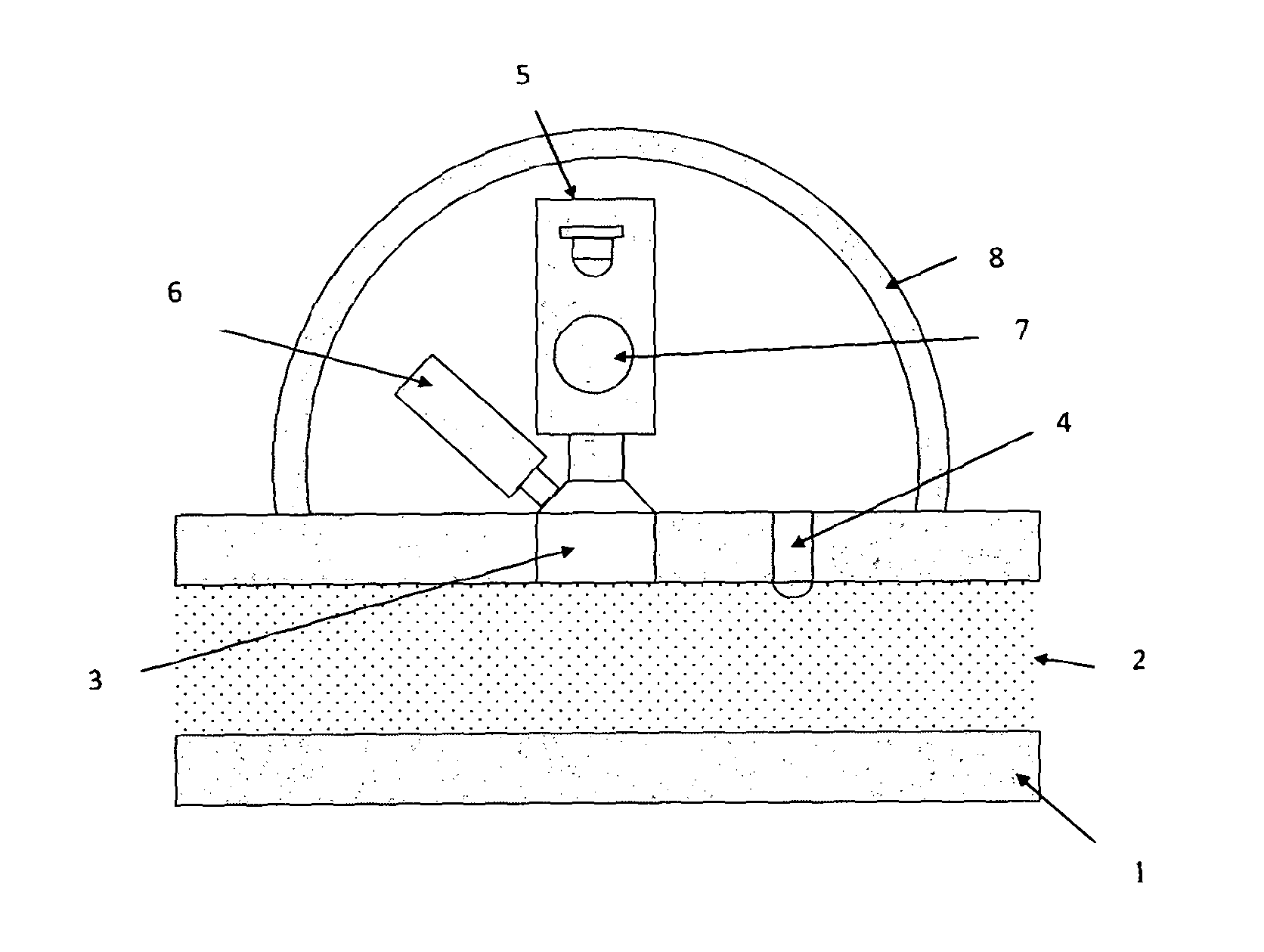

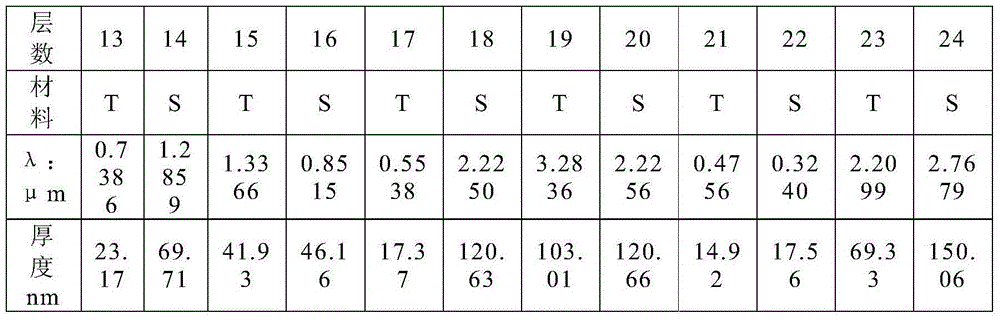

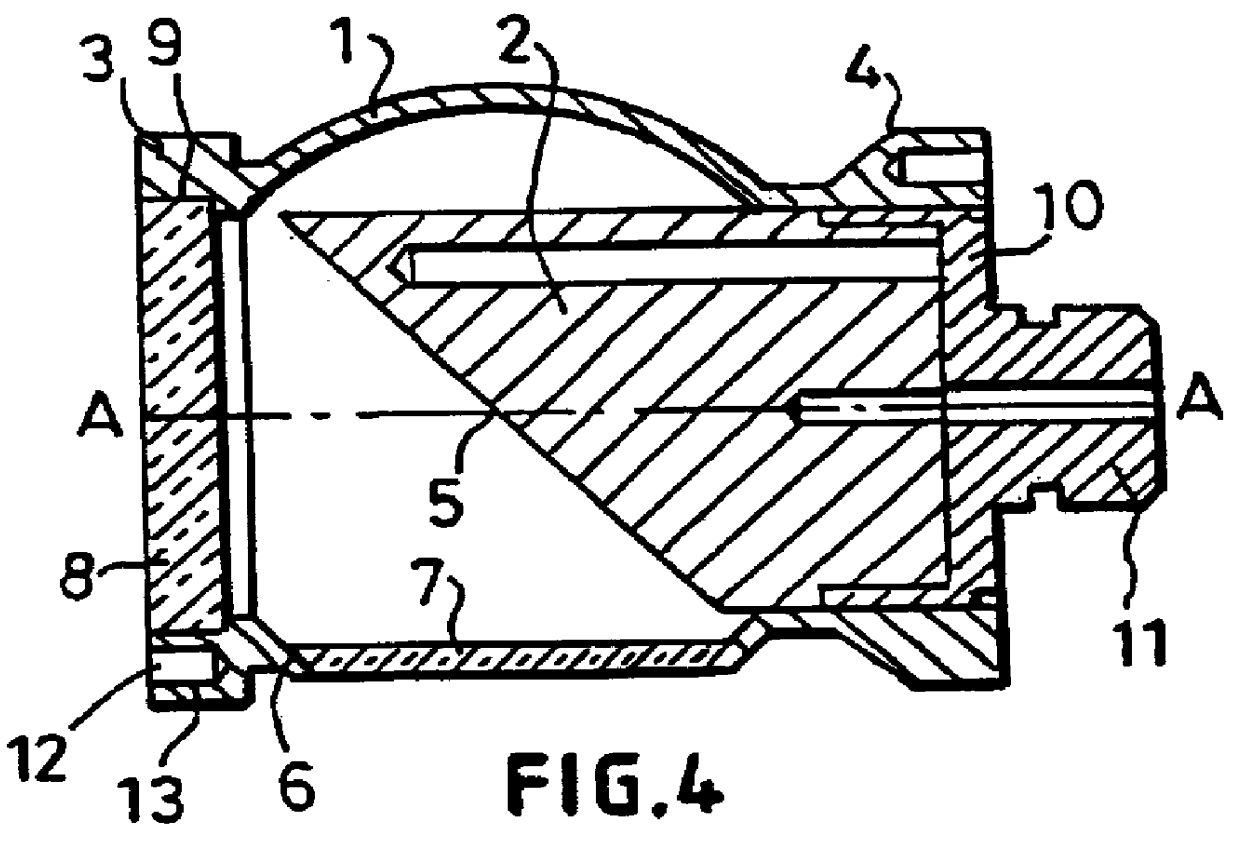

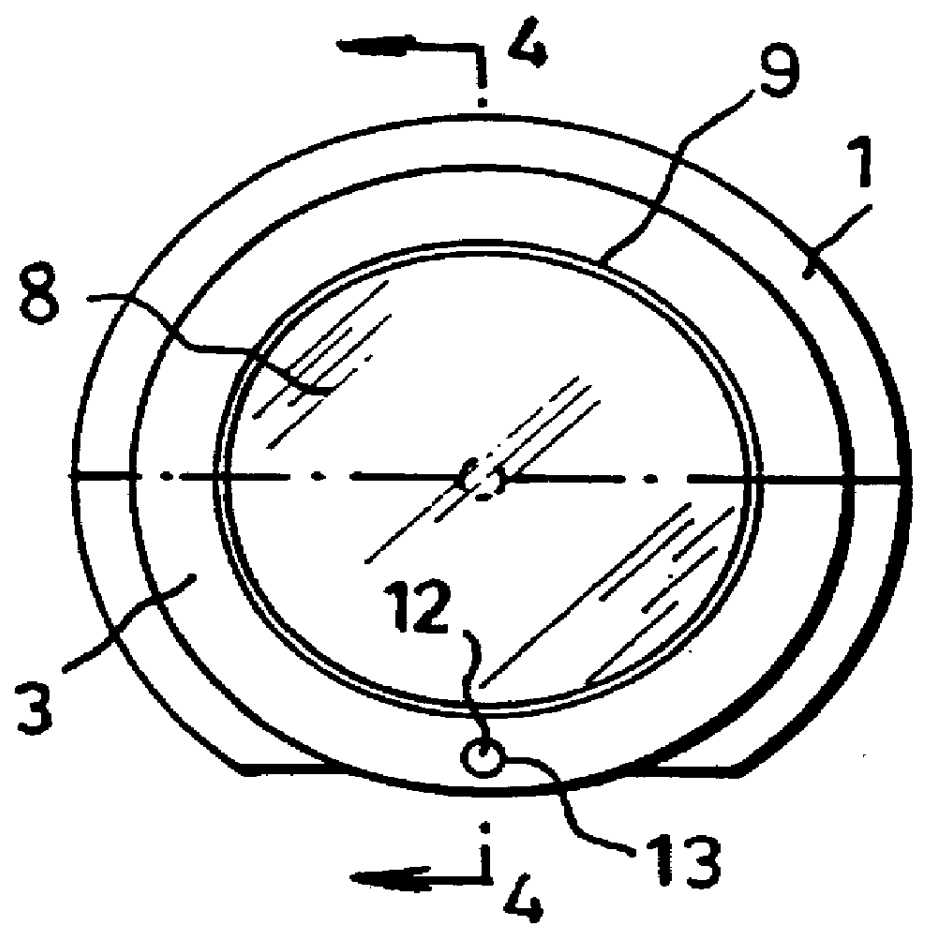

Rotary mirror assembly having spherical housing

A rotatable mirror assembly is described comprising a spherical housing (1) rotatable about an axis (A). The housing contains a mirror (2) bonded in the rear end of the housing. The housing at the front of mirror (2) has a flange (3) while a second enlarged flange (4) is formed at the rear of the mirror (2) the front of the mirror (2) has a sloping end face (5) at an angle of 45.degree. of the rotary axis (A) which fives toward an opening (6) in the side of the housing (1). The opening (6) in a first embodiment is closed by an optically flat sapphire window (7) bonded into the opening (6) and in a second embodiment has a curved lens (17) mounted in the aperture. The improved assemblies reduce noise generation of high speed rotating mirrors and prevent the deposit of small particles of dust on the mirror surface.

Owner:THE GSI GRP LLC

Sapphire and machining method thereof

The invention discloses a sapphire machining method. The method comprises the steps that a sapphire crystal is cut into a cuboid-shaped diamond, at least the upper bottom face and the lower bottom face of the cuboid-shaped diamond are square, and the side length of the square is 50-60 mm; the diamond is cut into a plurality of square base tabs with the identical or different thicknesses, and the side length of the upper bottom face and the side length of the lower bottom face of each base tab is the same as that of the upper bottom face and that of the lower bottom face of the diamond. Each square base tab is cut into a plurality of window pieces. The upper bottom face and the lower bottom face of each window piece is square or round, the thickness of each window piece is the same as that of each base tab, the side length of the bottom faces of each square base tab is 4-5 times the side length or the diameter of the bottom faces of each window piece, and equal to the sum of the side length or the diameter of the bottom faces of each window piece and the machining allowance of 1-5 mm. The sapphire machining method can effectively increase the utilization rate of a sapphire material, the use cost of the sapphire window pieces is reduced to the maximum, and the sapphire machining method can be widely used in production of the sapphire window pieces.

Owner:CHONGQING SILIAN OPTOELECTRONICS SCI & TECH

Infrared detector packaging assembly and infrared detector with same

PendingCN114093954AImprove performance and stabilitySemiconductor devicesSapphire windowCompressive resistance

The invention provides an infrared detector packaging assembly and an infrared detector with same; the infrared detector packaging assembly comprises a shell assembly, a chip and a lead ring, the shell assembly defines a cavity, the chip is arranged in the cavity, a lead ring frame forms a constituent part of the shell assembly, and the chip is electrically connected with the lead ring. And the chip is electrically led out from the cavity. The shell assembly is a low-expansion alloy part, a window communicated with the cavity is formed in the shell assembly, and the window is covered with a sapphire window piece. According to the infrared detector packaging assembly, packaging is carried out in a tube shell mode, and the structure is compact. The shell assembly adopts a low-expansion alloy part, and has excellent mechanical strength, thermal conductivity and air tightness at low temperature. Moreover, the thermal expansion coefficient of the shell assembly of the low-expansion alloy piece at low temperature is close to that of the sapphire window piece, the stress of the sapphire window piece at low temperature can be effectively reduced; in addition, the sapphire window piece is high in compressive strength and can achieve high transmittance.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com