Method for producing fresnel lens on sapphire window and application of fresnel lens

A Fresnel lens and sapphire technology, applied in the field of optical components, can solve the problems of reduced detection range and sensitivity impact of ultraviolet detectors, and achieve the effect of large optical fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment includes the following steps:

[0026] In the first step, according to the chip size of the ultraviolet detector, determine the size and focal length of the Fresnel lens, design the layout and determine the etching depth.

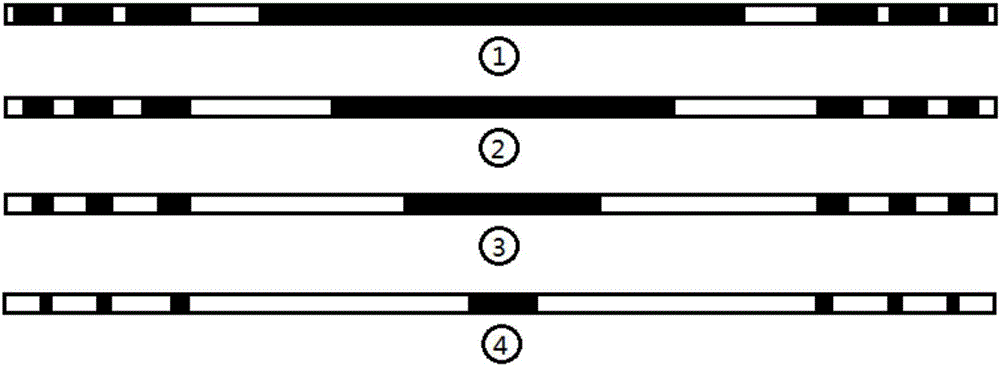

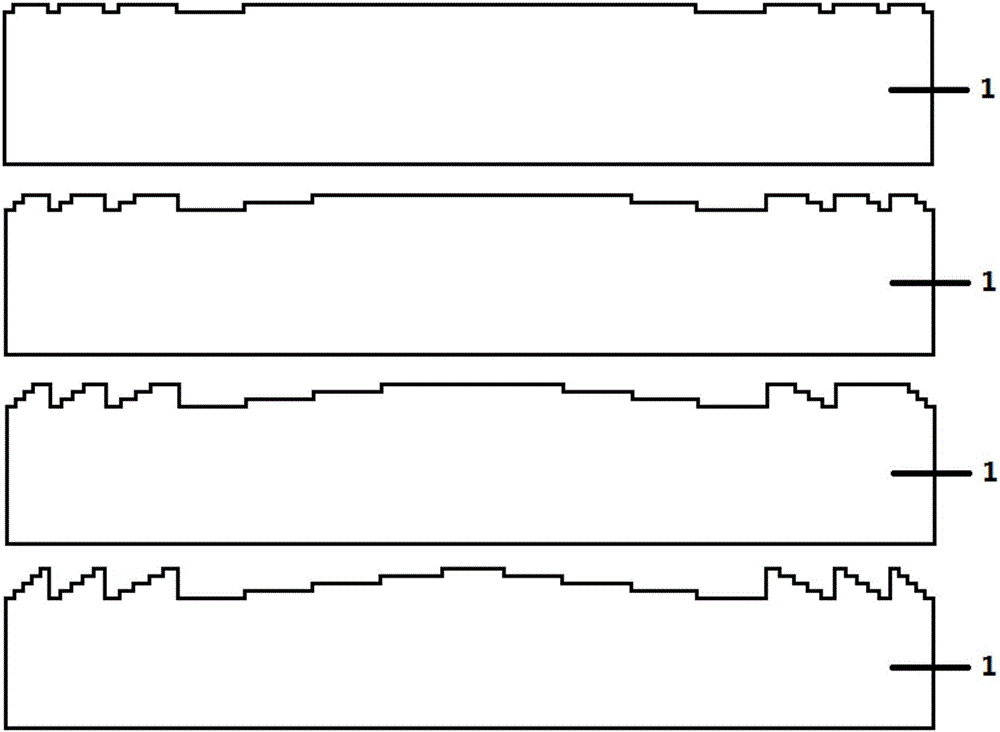

[0027] The second step is to etch a specific pattern on the silicon wafer by using reactive ion etching Si micromachining technology. The four etching depths are equal, each etching is 280nm, and the total step height is 1.12μm, so that UV protection can be achieved. focus function.

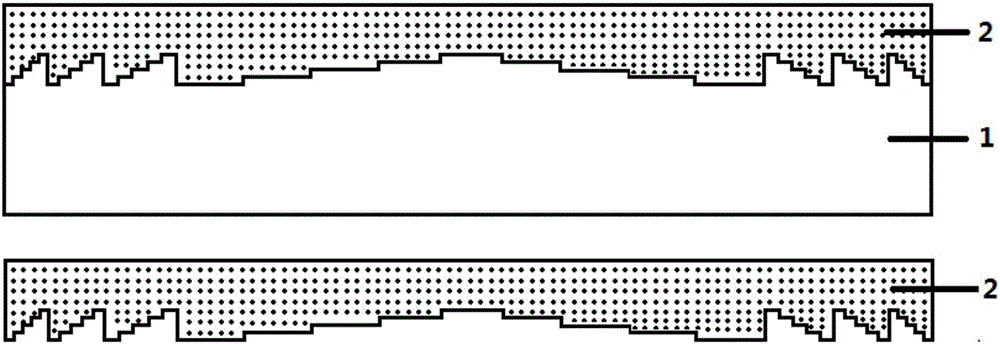

[0028] In the third step, an imprint template is prepared from the above-mentioned silicon wafer with the Fresnel lens structure.

[0029] In the fourth step, after the photoresist is spin-coated on the sapphire window, the above-mentioned imprint template is used for imprinting, and then an etching process is performed to form a sapphire window with a Fresnel lens structure.

[0030] The ultraviolet detectors include but are not limited to: GaN, SiC, ...

Embodiment 2

[0037] This embodiment includes the following steps:

[0038] In the first step, according to the chip size of the ultraviolet detector, determine the size and focal length of the Fresnel lens, design the layout and determine the etching depth.

[0039] In the second step, a specific pattern is etched on the silicon wafer using reactive ion etching Si micromachining technology. focus function.

[0040] In the third step, an imprint template is prepared from the above-mentioned silicon wafer with the Fresnel lens structure.

[0041] In the fourth step, after the photoresist is spin-coated on the sapphire window, the above-mentioned imprint template is used for imprinting, and then an etching process is performed to form a sapphire window with a Fresnel lens structure.

[0042] The ultraviolet detectors include but are not limited to: GaN, SiC, Al x Ga 1-x N, CdS, ZnO, diamond and other UV detectors.

[0043] In the process of dry etching a silicon wafer with a four-layer m...

Embodiment 3

[0049] This embodiment includes the following steps:

[0050] In the first step, according to the chip size of the ultraviolet detector, determine the size and focal length of the Fresnel lens, design the layout and determine the etching depth.

[0051] In the second step, a specific pattern is etched on the silicon wafer using the reactive ion etching Si micromachining process. The depth of the four etchings is equal, each etching is 400nm, and the total step height is 1.6μm, so that the UV radiation can be realized. focus function.

[0052] In the third step, an imprint template is prepared from the above-mentioned silicon wafer with the Fresnel lens structure.

[0053] In the fourth step, after the photoresist is spin-coated on the sapphire window, the above-mentioned imprint template is used for imprinting, and then an etching process is performed to form a sapphire window with a Fresnel lens structure.

[0054] The ultraviolet detectors include but are not limited to: G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com