Far-infrared sapphire window protection screen for night vision

A protective screen and sapphire technology, applied in the direction of instruments, optics, layered products, etc., can solve the problems that the far-infrared coating structure cannot be realized, and achieve the effect of good transparency and uniform coating composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

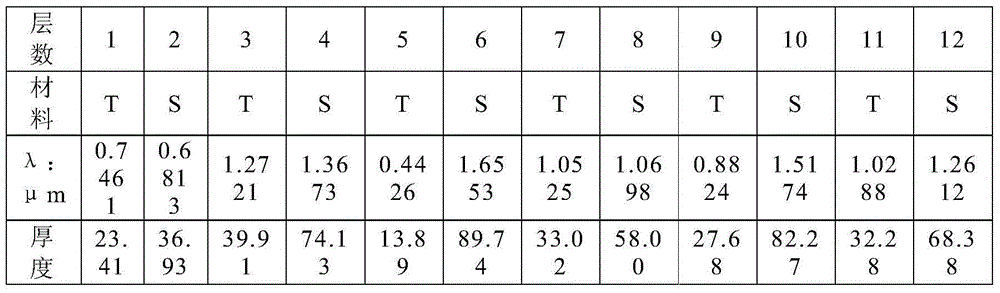

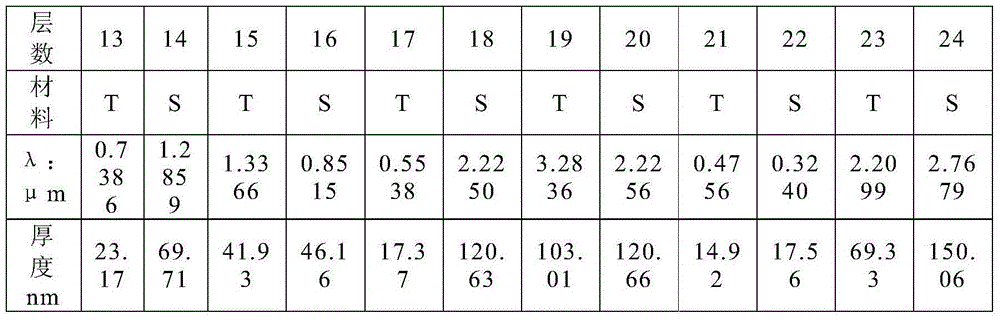

[0019] Such as figure 1 As shown, the sapphire window protection screen includes a substrate 1, the substrate 1 is sapphire, the side of the substrate 1 is coated with a multilayer film 2, and the multilayer film 2 is Ti 3 o 5 Plating and SiO 2 Plating layers are formed in combination. In this embodiment, the multilayer film 2 is an even-numbered layer, and Ti 3 o 5 Plating and SiO 2 The number of coating layers is the same, Ti 3 o 5 The plating layer is the first layer attached to the substrate 1 . Ti 3 o 5 Plating and SiO 2 The advantage of the same number of layers of coating is that SiO 2 The coating is the outermost layer, SiO 2 The coating is relatively hard and wear-resistant, Ti 3 o 5 The advantage of the plating being the innermost layer is that it combines better with sapphire and can comprehensively improve the cut-off effect. In this embodiment, the multilayer film 2 includes: 23.41nm thick Ti 3 o 5 Plating, 36.93nm thick SiO 2 Coating, 39.91nm thi...

Embodiment 2

[0029] The general content of this embodiment is the same as that of Embodiment 1, the difference is that, in this embodiment, the multilayer film 2 is an odd number of layers, Ti 3 o 5 Coating ratio SiO 2 The number of coating layers is one more, Ti 3 o 5 The coating is the first layer attached to the substrate 1, and the outermost layer of the multilayer film 2 is also Ti 3 o 5 plating. Ti 3 o 5 Plating and SiO 2 The advantage of the same number of coating layers is that Ti 3 o 5 Coating is the outermost layer, Ti3 o 5 Coating optical performance is good, Ti 3 o 5 The advantage of the plating being the innermost layer is that it combines better with sapphire and can comprehensively improve the cut-off effect. The multilayer film 2 includes: 23.41nm thick Ti 3 o 5 Plating, 36.93nm thick SiO 2 Coating, 39.91nm thick Ti 3 o 5 nm coating, 74.13nm thick SiO 2 Coating, 13.89nm thick Ti 3 o 5 Plating, 89.74nm thick SiO 2 Coating, 33.02nm thick Ti 3 o 5 Plati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com