Formation method for thin-layer border of sapphire window

A sapphire and thin-layer technology, which is applied in the printing of special types of printed matter, post-processing of printing, and parts of color TVs, etc. It can solve the problems of long etching time, inability to repair, and difficulty in color conversion, etc., to achieve The effect of large randomness of color, reduced cost, and variety of colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] the following to Figure 1 to Figure 7 The specific embodiments of the present invention are shown in detail.

[0040] For the convenience of expression, in this patent application document, the sapphire window as the workpiece of the present invention is referred to as

[0041] The sapphire window substrate, number 3 in the figure, is called the sapphire window after the finished product, number 1 in the figure.

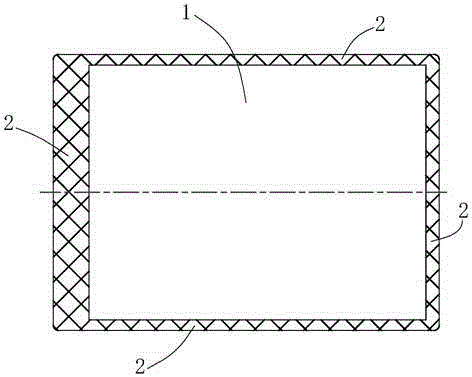

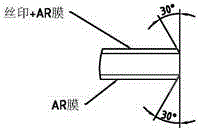

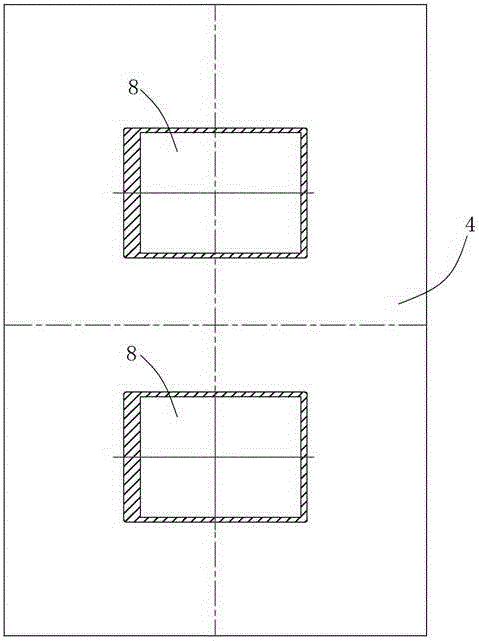

[0042] The present invention is to figure 1 , figure 2 The peripheral region of one side of the sapphire window substrate 3 shown in the figure forms a thin layer frame, which becomes as shown image 3 , Figure 4 , Figure 5Sapphire window shown. The sapphire window substrate 3 is a transparent plate with a thickness of about 1mm. image 3 The peripheral area of the B side in , needs to form a thin layer frame. The present invention replaces the coating laser engraving process with a precision screen printing process, and on one side of the sapphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com