Diamond energy transmission window for short millimeter wave traveling tubes and manufacturing method of diamond energy transmission window

A diamond and millimeter wave technology, applied in the field of diamond energy transmission window and its manufacturing, can solve the problems of high dielectric constant, poor matching performance, insufficient strength, etc., and achieve the effects of low reflection loss, stable working performance, and improved output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

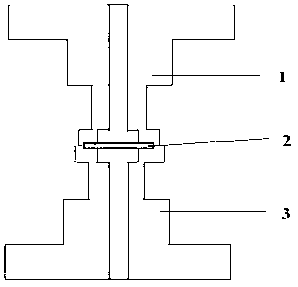

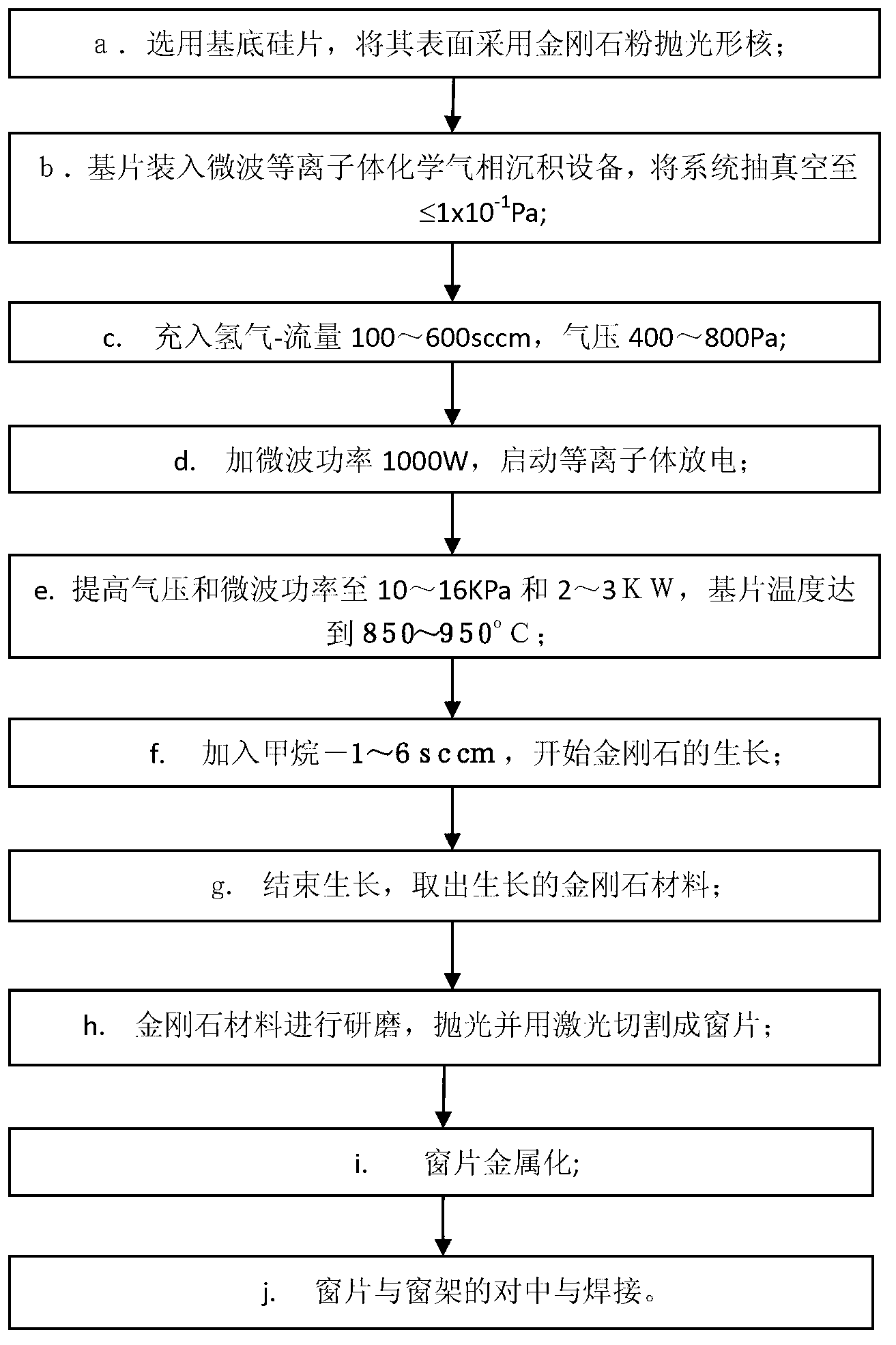

[0019] refer to figure 1 , showing a schematic diagram of a diamond energy transmission window for a W-band traveling wave tube. In the figure, component 2 is a diamond window, which is connected with the upper window frame 1 and the lower window frame 3 by brazing to form a vacuum seal. The preparation of the main component diamond window material is carried out according to the following steps:

[0020] a. Select the substrate silicon wafer, and polish the surface with diamond powder to nucleate;

[0021] b. The substrate is loaded into the microwave plasma chemical vapor deposition equipment, and the system is evacuated to ≤1x10 -1 Pa;

[0022] c. Filling with hydrogen gas - flow rate 100~600sccm, air pressure 400~800Pa;

[0023] d. Add microwave power of 1000W to start plasma discharge;

[0024] e. Increase the air pressure and microwave power to 10-16KPa and 2-3KW, and the substrate temperature reaches 850-950°C;

[0025] f. Add methane-1~6 sccm to start the growth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com