Machining method for sapphire window accessory of electronic product

A processing method and technology for electronic products, applied in stone processing equipment, metal processing equipment, fine working devices, etc., can solve the problems of inability to meet modern production, low processing efficiency, etc., to improve the quality of finished products, improve production efficiency, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

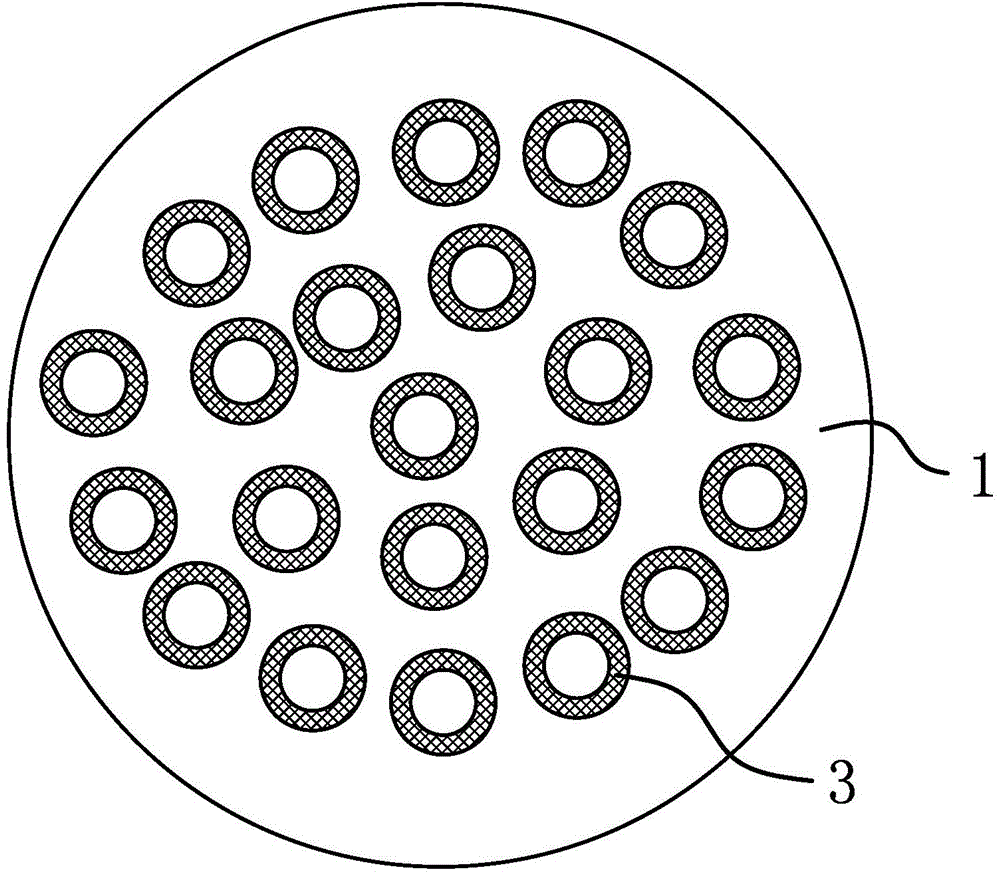

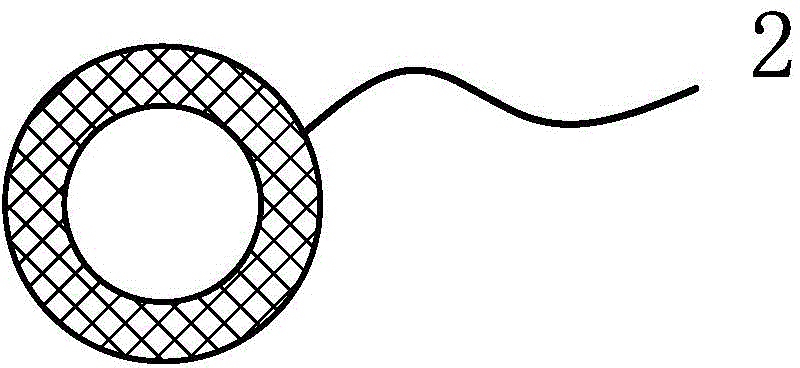

[0027] Such as figure 1 and figure 2 As shown, the sapphire window fitting 2 is in the shape of an annular sheet, and the processing method comprises the following steps:

[0028] a. Pretreatment: cutting the sapphire crystal ingot into a sheet-shaped sapphire substrate 1; in step a, first put the block-shaped sapphire crystal ingot into a wire cutting machine for wire cutting, and cut the sapphire crystal ingot into flakes by wire cutting the sapphire substrate 1; put the roughly machined sapphire substrate 1 into the grinder, chamfer the edge of the sapphire substrate 1 with a diamond cutter, and finely grind the outer contour of the chamfered sapphire substrate 1 with a diamond cutter. The cutting fluid is injected during the fine grinding process, and the temperature is maintained at 30°C-60°C by continuously injecting the cutting fluid. The use of wire cutting for blank processing can make full use of the advantages of low processing cost and fast processing speed of w...

Embodiment 2

[0036]The general content of this embodiment is the same as that of Embodiment 1, except that in this embodiment, in step b, the sapphire substrate 1 is first covered with printing paper, and a ring-shaped annular groove is pre-cut on the printing paper. Sapphire ink is brushed on the printing paper, and the sapphire ink passes through the annular groove and is printed on the sapphire substrate 1 . The printing paper can be used repeatedly, and the annular groove can accurately print the corresponding annular ink ribbon 3 on the sapphire substrate 1 with high precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com