Internal supporting and reinforcing method for large-scale underground comprehensive pipe gallery wall plate without external mold

A comprehensive pipe gallery and large-scale technology, which is applied in the field of internal support and reinforcement of large-scale underground comprehensive pipe gallery without external formwork and wall panels, can solve the problems of inconvenient movement, inflexible construction, and heavy weight of triangular steel pipe trusses, etc. Quality and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, a large-scale underground comprehensive pipe gallery has no external formwork and wall plate internal support reinforcement method, and its specific steps are:

[0038] Step 1. Concrete the bottom plate 12 of the pipe gallery:

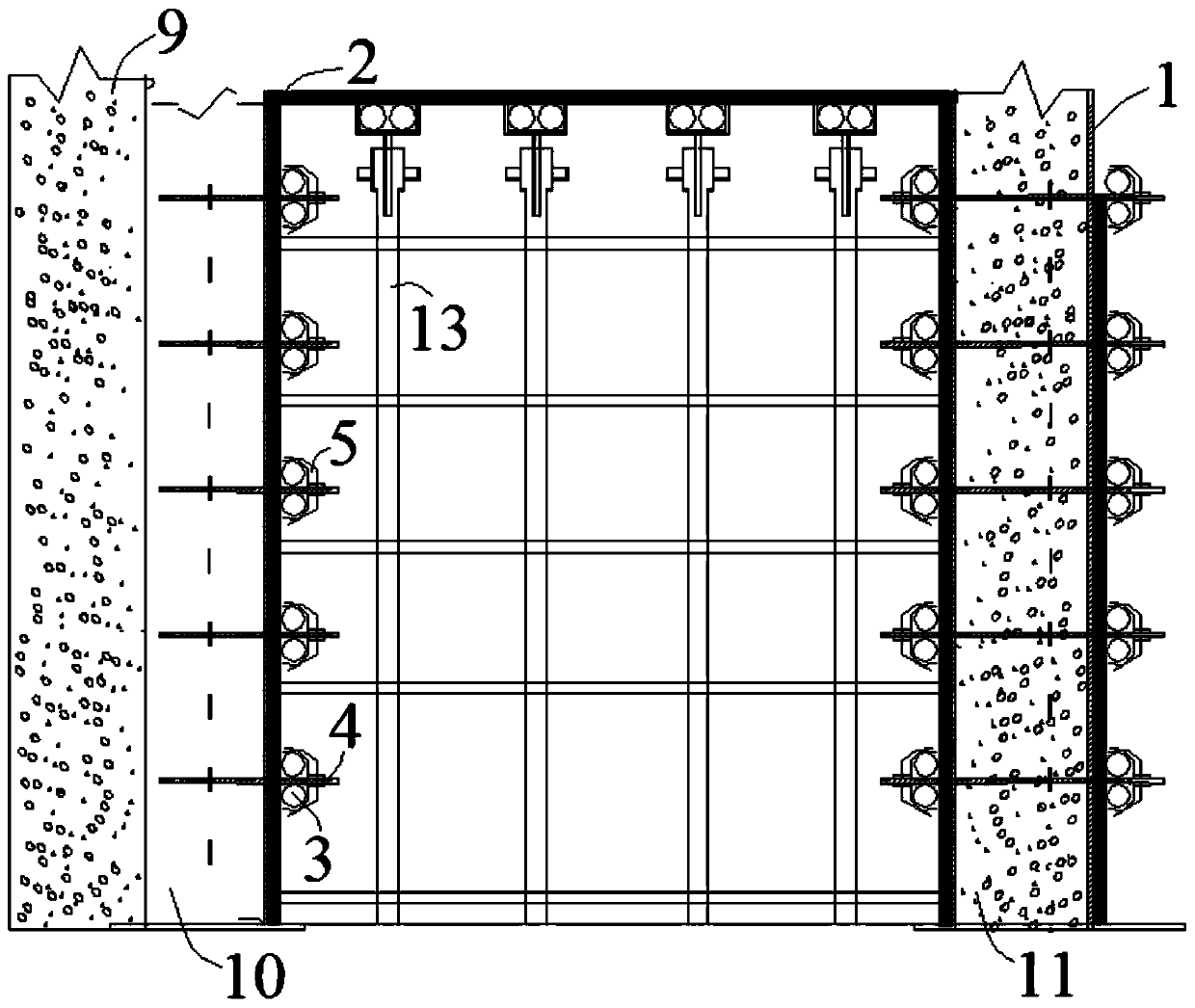

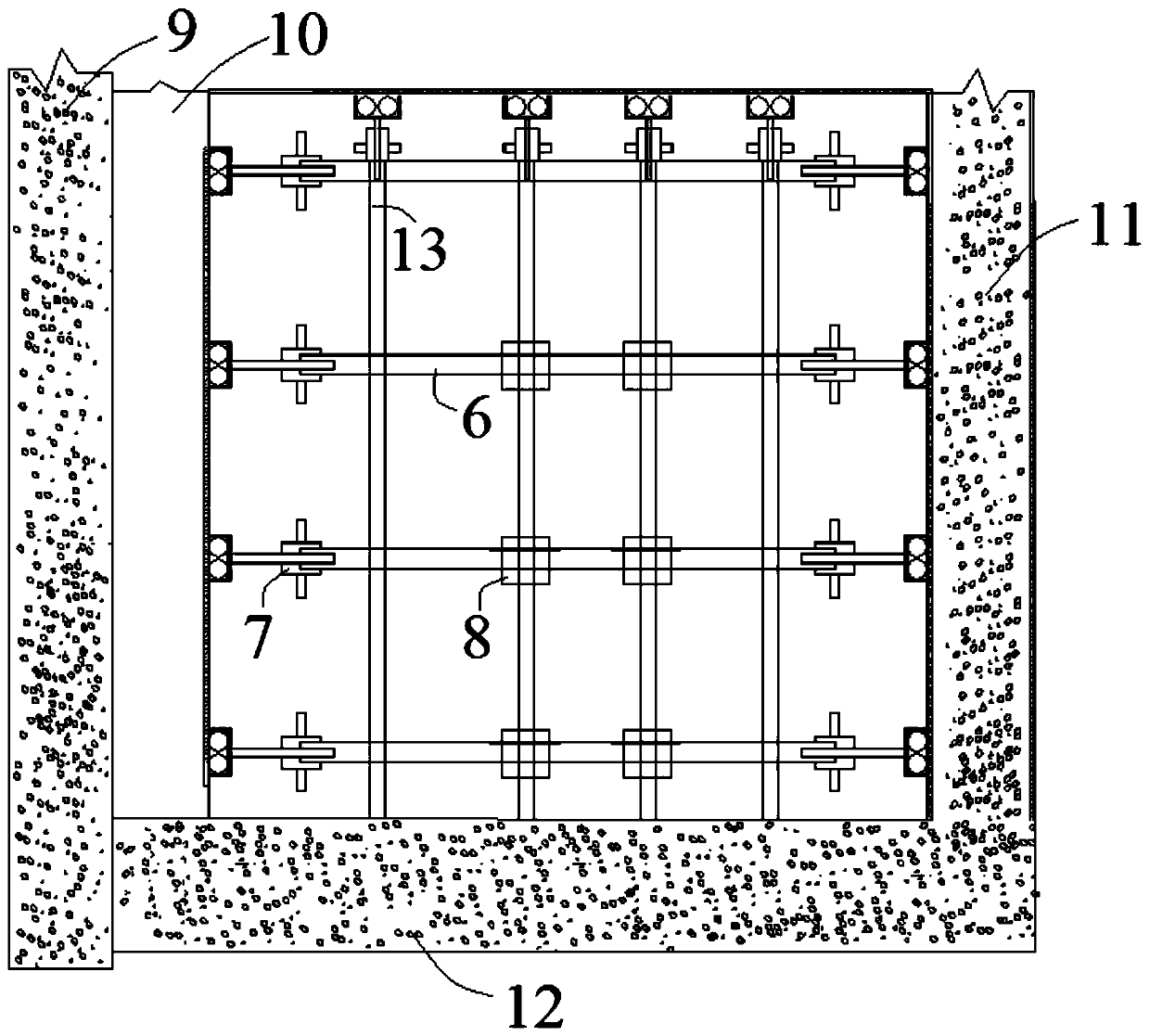

[0039] to combine figure 1 According to the requirements of the design drawings, the bottom plate 12 of the pipe gallery formed by pouring concrete is used as the foundation of the support system of the overall formwork 1.

[0040] Step 2. Install the inner and outer walls and roof formwork 1 on the basis of the bottom plate 12 of the pipe gallery, and set up a socket-type buckle-type steel pipe support system:

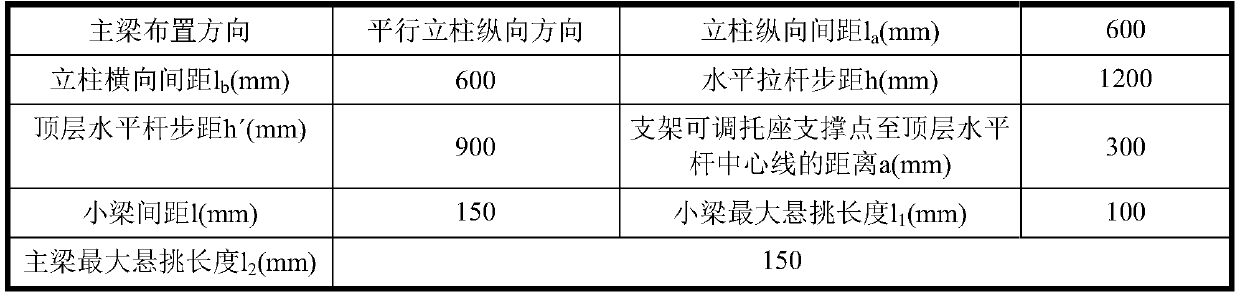

[0041] to combine figure 2 , according to the requirements of the design drawings and specifications, when the concrete strength reaches 1.2N / m 2 In order to make the foundation of the internal support system stable and safe, and to do a good job of protecting the finished concrete of the bottom plate 12, when th...

Embodiment 2

[0052] Xi'an City's underground comprehensive pipe gallery construction PPP project II bid section, using the underground comprehensive pipe gallery project without external formwork wall plate support reinforcement method proposed by the present invention, realized the underground comprehensive pipe gallery project without external formwork wall plate support reinforcement method, Until the completion of all the construction of the corridor structure. This method is used to strengthen the formwork on one side to avoid the problem of formwork expansion, and the verticality of the wall is good, and the use effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com