Patents

Literature

177results about How to "Guaranteed not to fall off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Color jet printing machine and jet printing method

InactiveCN101367296AImprove ergonomicsLow costTypewritersPower drive mechanismsScreen printingAdhesion force

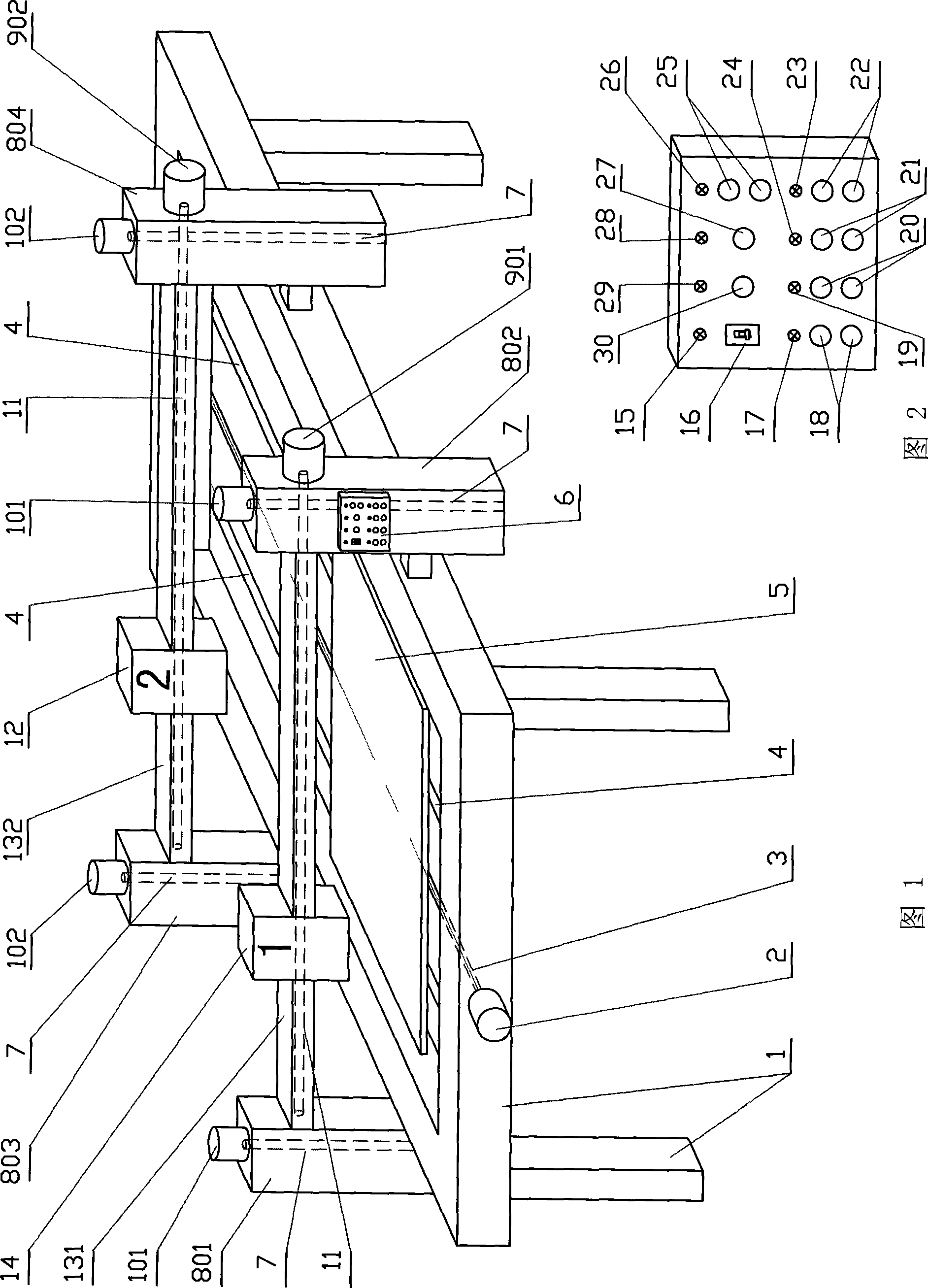

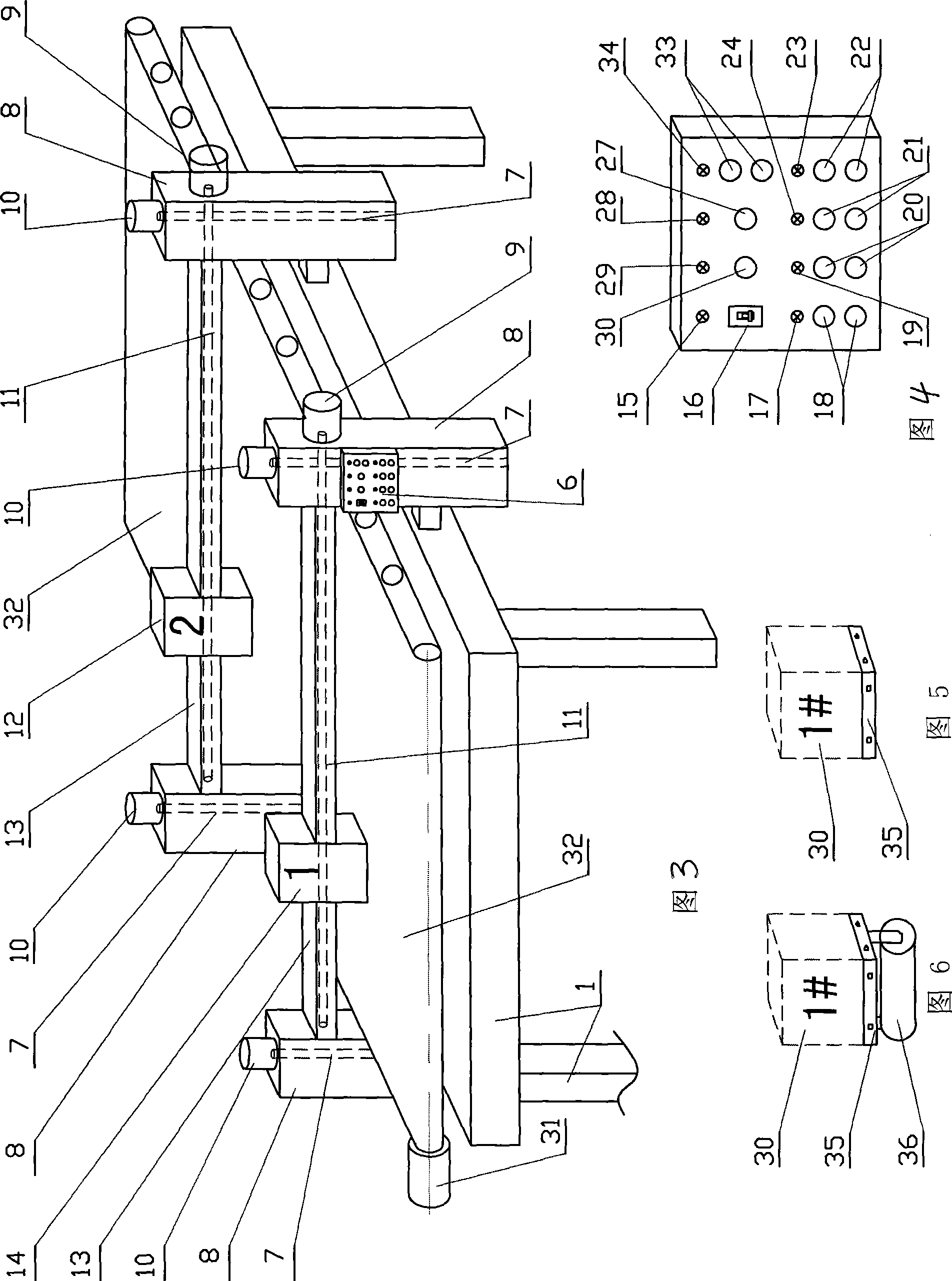

The invention relates to a color jet printer and a jet printing method thereof. The color jet printer comprises a machine frame, an upright post, a horizontal beam, a jet printing worktable and an electric cabinet, wherein the structure of the jet printing worktable comprises a parallelly traveling worktable and a rotary conveyer belt; textile to be printed is tiled on the parallelly traveling worktable or the rotary conveyer belt; and pattern areas of the textile are sprayed with white bottom layers by a computer programmed NO. 1 inking box and white bottom areas are sprayed with colored patterns by a computer programmed NO. 2 inking box. By utilization of the prior computer programmed color jet printing technology to perform jet printing of patterns on the textile such as T-shirts and so on or planar carriers, the jet printing method improves the work efficiency, reduces the cost and strengthens the viewing effect compared with the prior printing method. The white bottom layers are printed on the pattern areas of the textile at first and then sprayed with patterns, thereby the jet printing method can improve the adhesion force of the patterns and the textile, guarantee that the patterns are not fallen off and strengthen the jet printing effect of the patterns. Moreover, the white bottom layers of the textile can be respectively printed by the jet printing technique, the hot transfer printing technique or the silk-screen printing technique.

Owner:徐中九

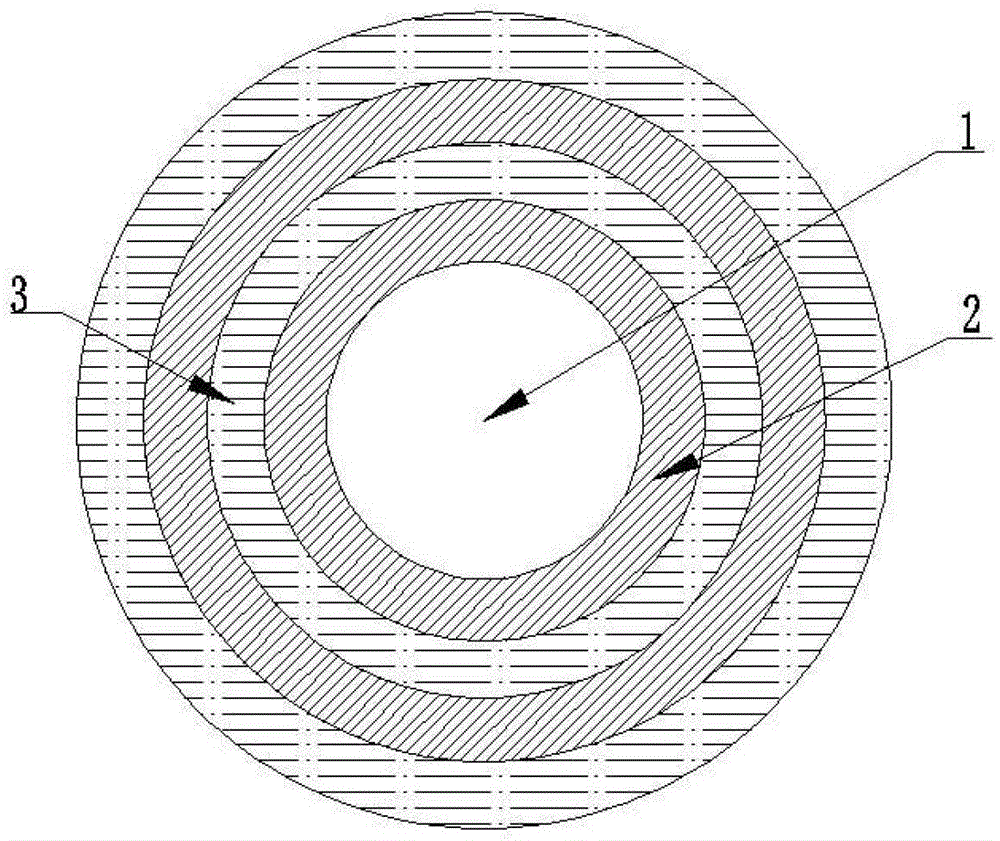

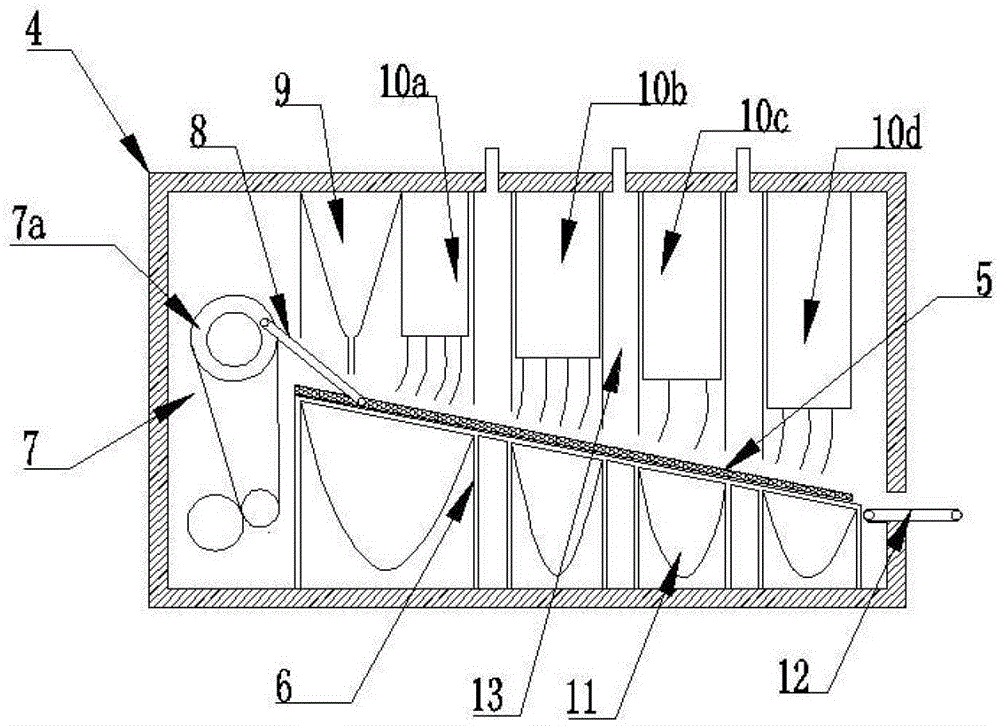

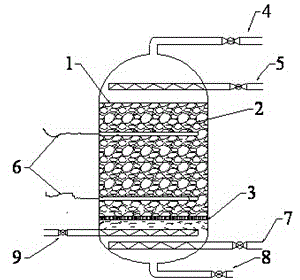

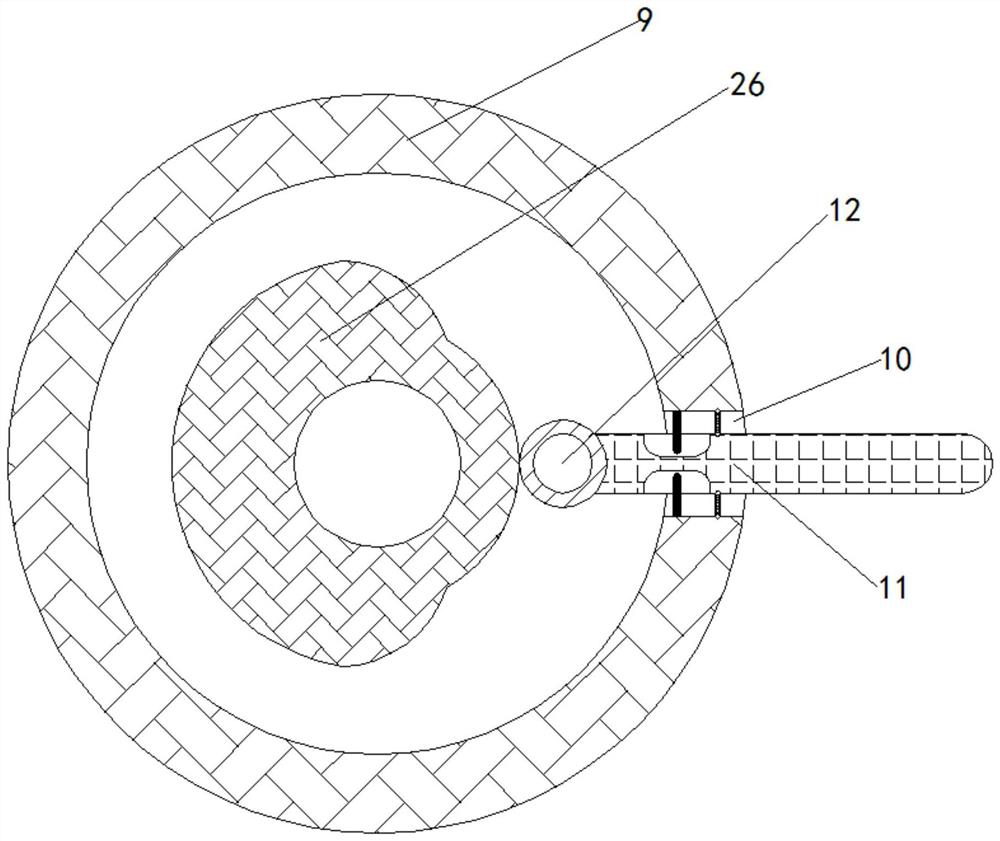

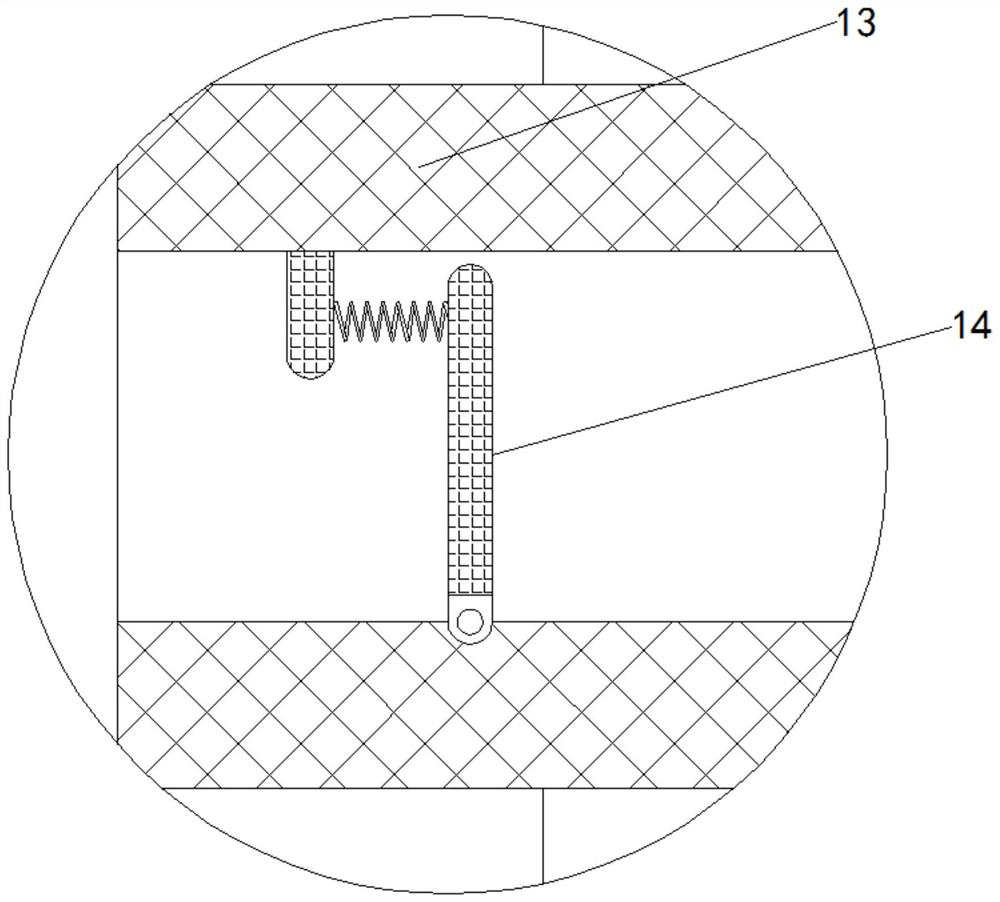

Large-particle slow/controlled-release fertilizer with multi-layer coating structure and coating equipment of fertilizer

ActiveCN102910978ABeautiful appearanceHave no ripsFertiliser formsFertilizer mixturesSoil scienceCaking

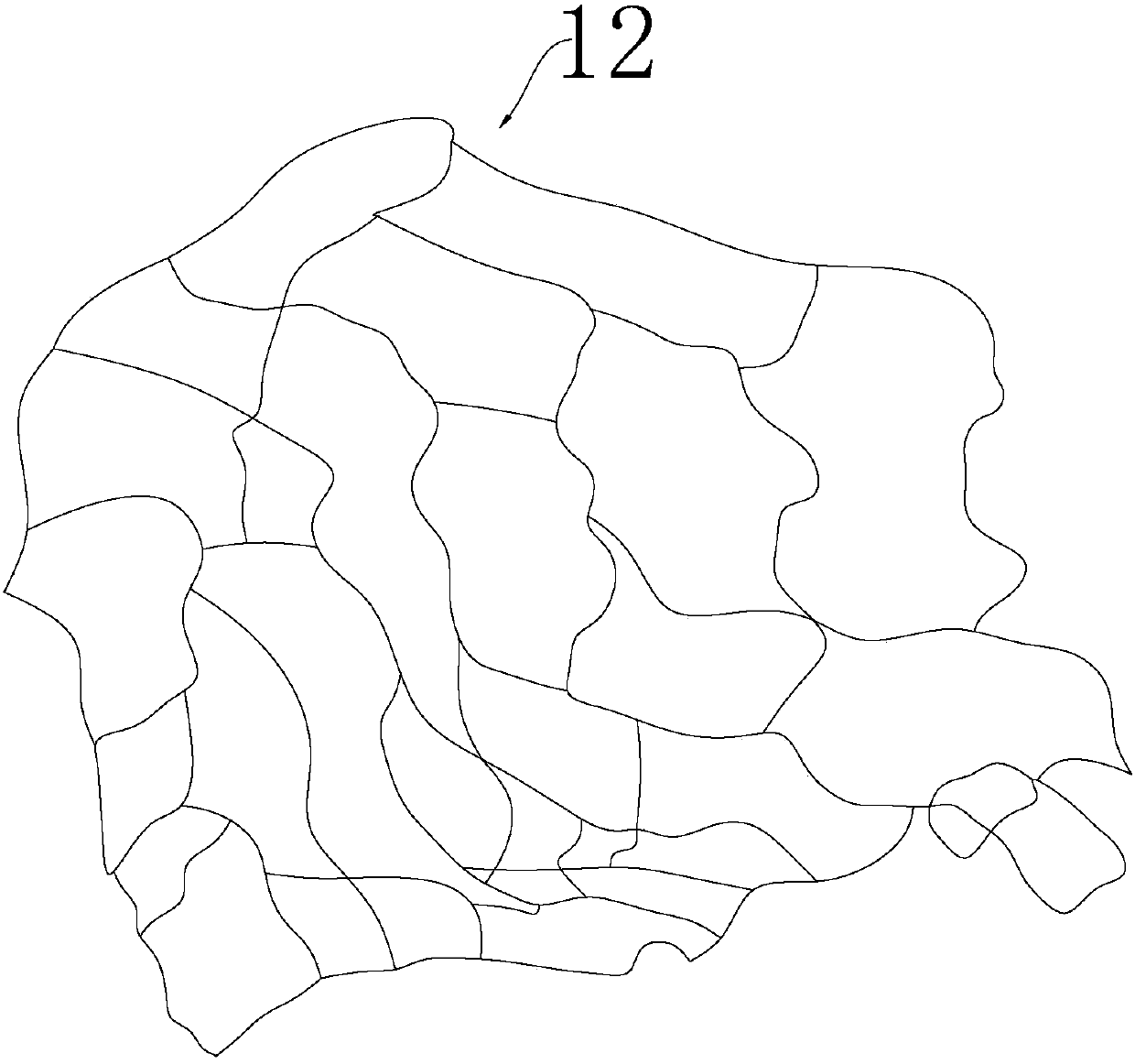

The invention relates to a large-particle slow / controlled-release fertilizer with a multi-layer coating structure and coating equipment of the fertilizer. According to the invention, a sulfur coating is coated outside the large-particle fertilizer, and a fertilizer coating is coated outside the sulfur coating. The coating equipment consists of a heating incubator, a screen and the like, wherein one end of the screen (5) is high, and the other end of the screen (5) is low; a particle funnel (9) and 2-10 spray boxes (10) are successively arranged above the screen (5) from the high end to the low end; 2-10 recovery tanks (11) are arranged under the screen (5) in turn from the high end to the low end; and the low end of the screen (5) is provided with a conveying belt (12). The obtained fertilizer can realize the different requirements of various growth periods on NPK elements through adjustment of fertilizer formula of each layer of coating, so that the sulfur coating is well ensured not to fall or be damaged; and simultaneously, the fertilizer has the advantages of beautiful appearance, no crack, no adhesion, no caking and the like.

Owner:CHONGQING JINMANDI FERTILIZER

Modified silicon dioxide powder/silicon dioxide nanofiber composite aerogel material and preparation method thereof

The invention provides a modified silicon dioxide powder / silicon dioxide nanofiber cross-gradient composite aerogel material and a preparation method thereof. The modified silicon dioxide powder / silicon dioxide nano fiber cross-gradient composite aerogel material is characterized in that silicon dioxide nano fibers serve as a three-dimensional framework structure of aerogel, modified nano silicondioxide powder is uniformly filled in gaps formed among single nano fibers, the whole composite material is divided into three layers of different nano silicon dioxide powder filling densities in thickness, and by the three-dimensional framework formed by the silicon dioxide nanofibers, good compression resilience and strength are achieved. The three-dimensional silicon dioxide powder / silicon dioxide nanofiber aerogel material has a bulk density of 10-1000 mg / cm<3> and the average pore size of 0.05-1000 mu m, a tensile strength of 20-50 kPa, and a compression resilience is greater than or equal to 85%. According to the inner structure of the obtained aerogel material, silicon dioxide powder is uniformly dispersed in meshes of a three-dimensional frame formed by silicon dioxide fibers, thefibers are mutually staggered and penetrated to form pores, the mechanical strength of the aerogel material is improved, meanwhile, the aerogel material has a high porosity and small pore size structure, and has wide application prospects in the fields of heat insulation, sound absorption, noise reduction and the like.

Owner:黄金龙

Electroplating or chemical-plating pretreatment method of aluminum alloy and application of electroplating or chemical-plating pretreatment method

ActiveCN105274545AImprove bindingUniform removalLiquid/solution decomposition chemical coatingChemical platingPretreatment method

The invention provides an electroplating or chemical-plating pretreatment method of aluminum alloy and a copper plating method of aluminum alloy. The pretreatment method which comprises the steps of chemical sand treatment, surface dust removal, primary zinc immersion, secondary zinc immersion and nickel preplating is adopted, a proper solution formula and proper technological parameters are selected, the binding force of a plating layer obtained later is increased, and it is ensured that the plating layer of copper or other metal is qualified after 280 DEG C welding. The pretreatment method is stable and suitable for cyaniding copper plating treatment of aluminum alloy materials and other kinds of electroplating and chemical-plating pretreatment of the aluminum alloy materials. A thermal shock experiment result shows that aluminum alloy parts can bear high temperature of 280 DEG C for 3 min without bubbling or peeling or falling off after being plated with copper through the method, and the pretreatment method can be applied to electroplating and chemical-plating processes of a large number of parts.

Owner:天津航空机电有限公司

Integral construction method for heat preservation and decoration of outer wall

The invention discloses an integral construction method for heat preservation and decoration of an outer wall, relating to the technical field of constructional engineering, in particular to a construction method for external heat insulation of an outer wall. The construction method comprises the following steps of: processing base level, dividing mesh and playing a line, cutting plate, mounting a bottom bracket, mounting a postposition bearing bracket, sticking plate materials, reinforcing mechanical fixing components, caulking, dividing joint to do waterproof sealing and coloring, repairing dividing-joints and repairing a whole body. The invention solves the difficult problems of hollowness, cracking, dropping, soaking and the like of architectural coating, and synchronously achieves the architectural effects of heat preservation, heat insulation, water resistance, decoration and the like.

Owner:华新建工集团有限公司

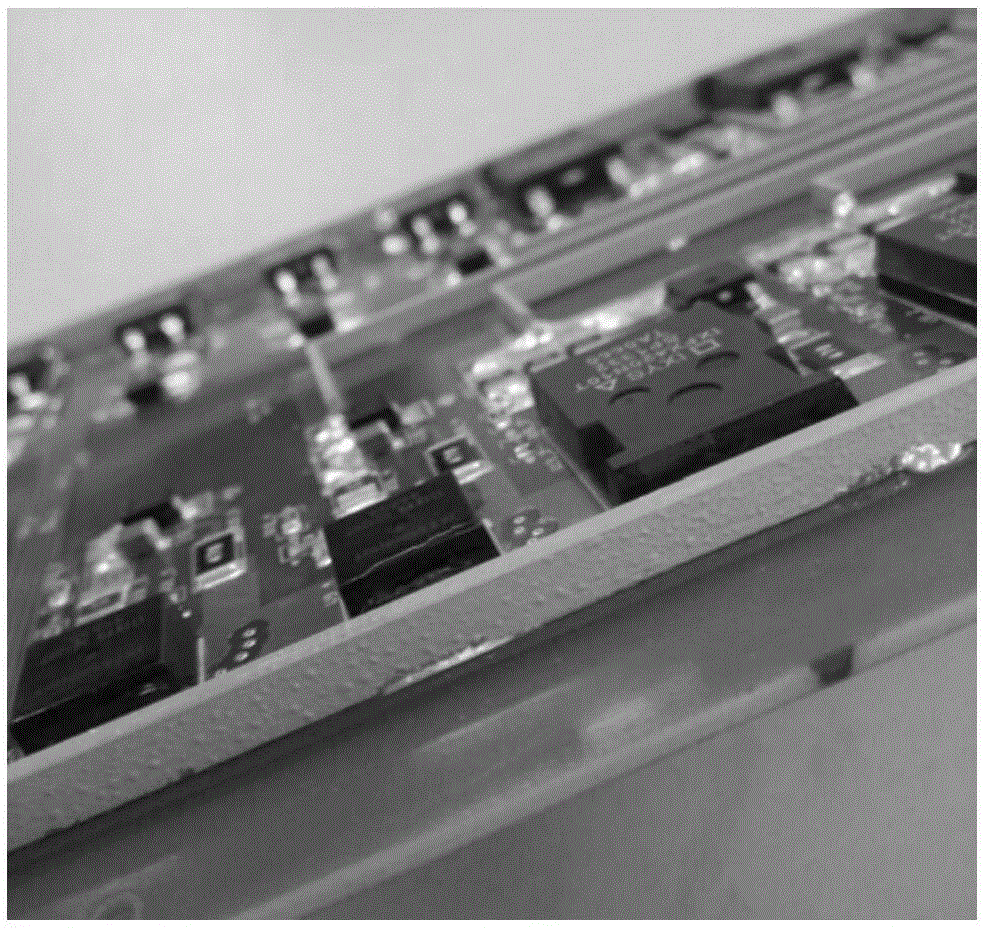

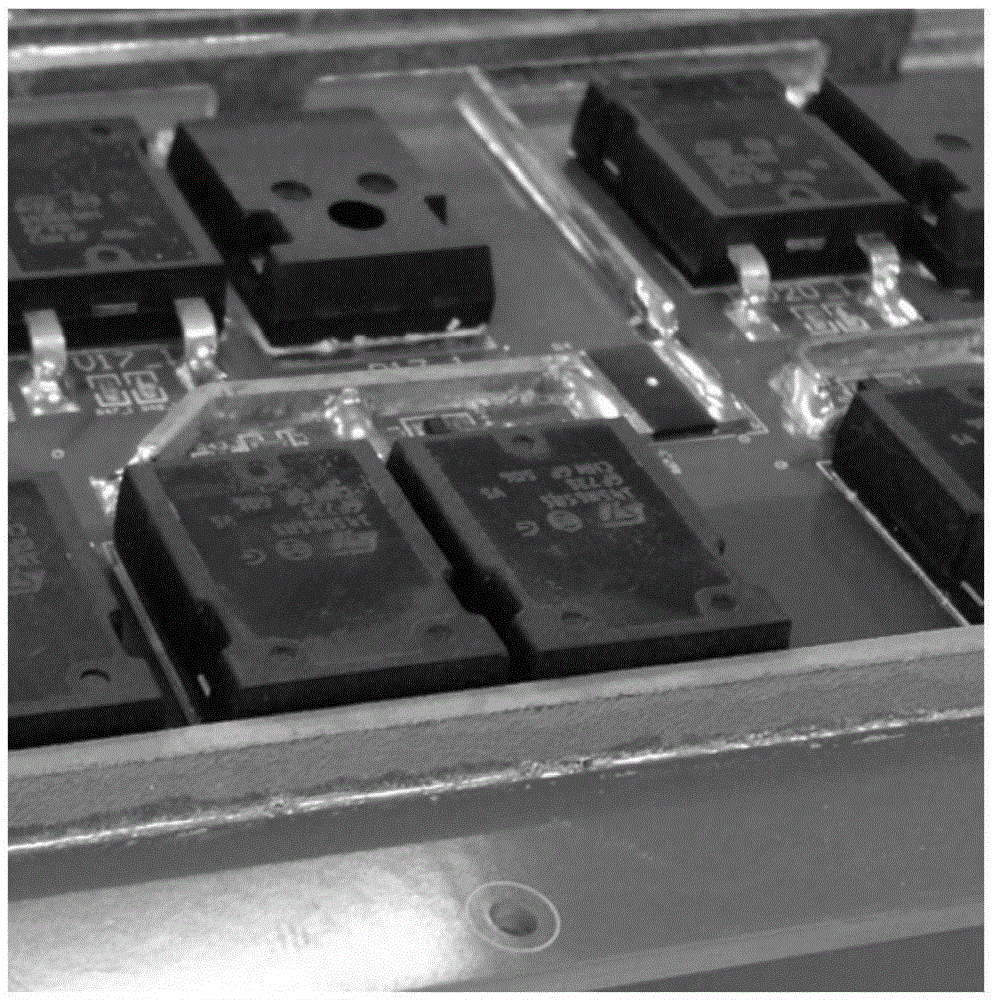

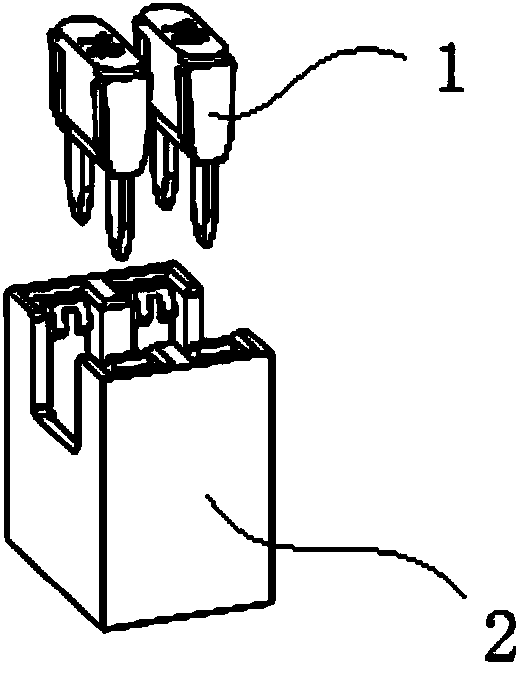

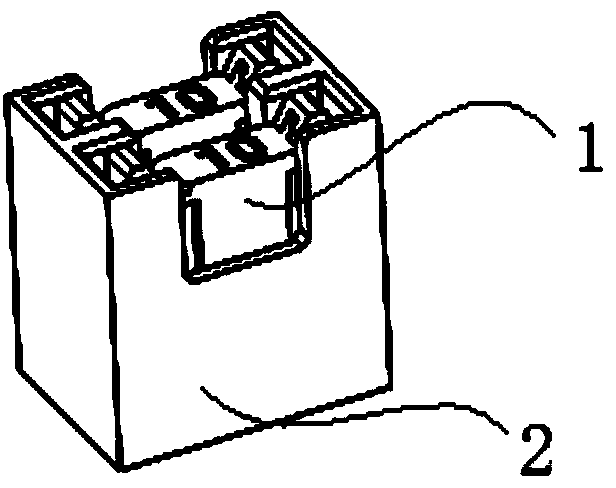

Fuse mounting structure

ActiveCN104392873AFixed and reliableAccurate and reliable positioningEmergency protective devicesEngineeringMechanical engineering

The invention provides a fuse mounting structure. The fuse mounting structure comprises an electric appliance box main body and a fuse holder, wherein slots are formed in the two sides of the electric appliance box main body; first bosses and second bosses are arranged inside the slots; the fuse holder comprises a fuse mounting part, clamping parts positioned on the two sides of the fuse mounting part, and two insertion parts positioned below the fuse mounting part; the insertion parts comprise sliding chutes with sealed upper ends and lower ends, and bulges protruded in the directions far away from the sliding chutes; the insertion parts of the fuse holder are inserted in the slots of the electric appliance box main body; the second bosses are positioned in the sliding chute; under the working condition, the first bosses are buckled with the bulges, and meanwhile the second bulges are not in contact with the lower ends of the sliding chutes; under the out-of-service condition, the first bosses squeeze the bulges to enable the insertion parts to be deformed towards the sliding chutes, and meanwhile the second bosses are in contact with the lower ends of the sliding chutes. The fuse mounting structure disclosed by the invention is convenient to operate and high in safety.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

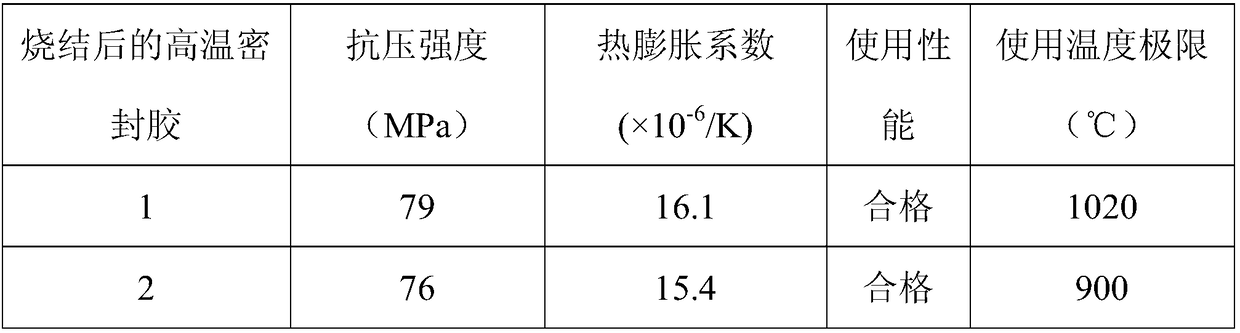

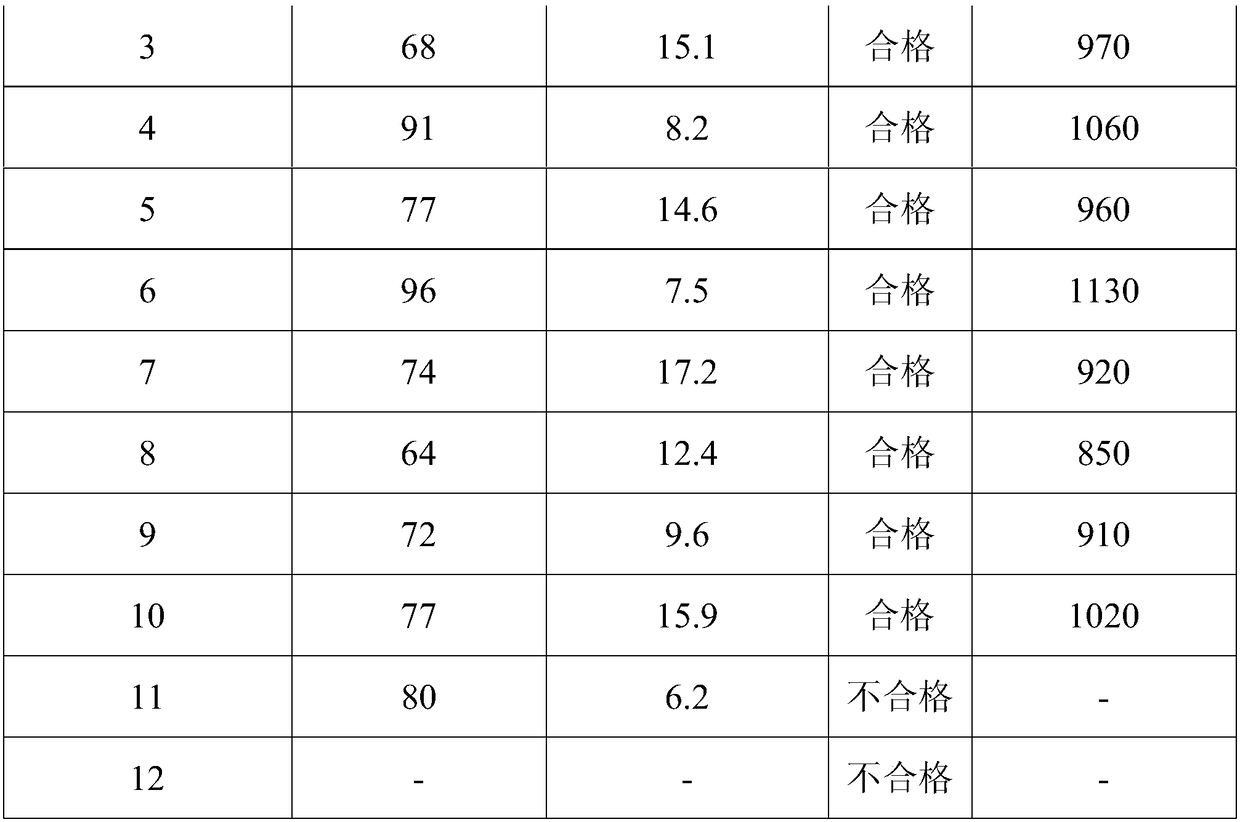

High-temperature sealing gum, and preparation method and application thereof

InactiveCN108219681AEvenly dispersedImprove adhesionNon-macromolecular adhesive additivesPretreated surfacesRoom temperatureThermal expansion

The invention relates to high-temperature sealing gum, which includes, by weight, 50-80 parts of glass powder, 5-40 parts of Ag / Cu alloy powder and 10-20 parts of a dispersant. The glass powder is prepared by crushing SiO2 glass and / or boron oxide glass. By adding the Ag / Cu alloy powder and the dispersant to the glass powder, the high-temperature sealing gum can seal or connect metal materials, ceramic materials or both, has excellent chemical stability and thermal stability, can effectively seal the material from room temperature to 1000 DEG C; meanwhile, after the high-temperature sealing gum is cured, thermal-expansion coefficient can be adjusted according to the content of oxides in the glass powder, ratio of silver in the Ag / Cu alloy powder and addition amount of the Ag / Cu alloy powder and can be changed optionally in the range of 7.3*10<-6> - 16.1*10<-6> / K, thus satisfying sealing demand on materials in different thermal-expansion coefficients.

Owner:上海穗杉实业股份有限公司

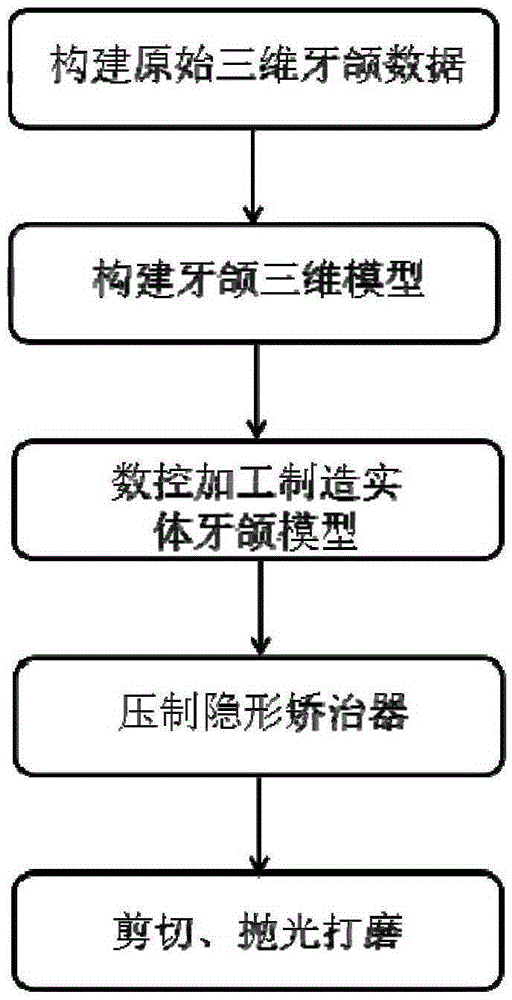

Manufacturing method of invisible correcting device and based on numerical control machining

InactiveCN105361963AImprove manufacturing precisionInhibit sheddingImpression capsOthrodonticsNumerical controlEpoxy

The invention discloses a manufacturing method of an invisible correcting device and based on numerical control machining. The manufacturing method includes: constructing original three-dimensional tooth jaw data; building tooth jaw three-dimensional models at 5-80 stages in total in the correcting process; using epoxy resin as a raw material; utilizing a numerical control machining method to machine the tooth jaw three-dimensional models to be solid tooth jaw models respectively; utilizing the solid tooth jaw models to press to form the invisible correcting device, shearing, polishing and then delivering the invisible correcting device to a patient to use. Through the method, the invisible correcting device manufactured reaches 0.005mm in accuracy, so that correcting effect is improved; light-cured resin which is expensive is not needed, and the raw material is recyclable, so that production cost is saved and the manufacturing method has a wide application prospect.

Owner:肖然 +1

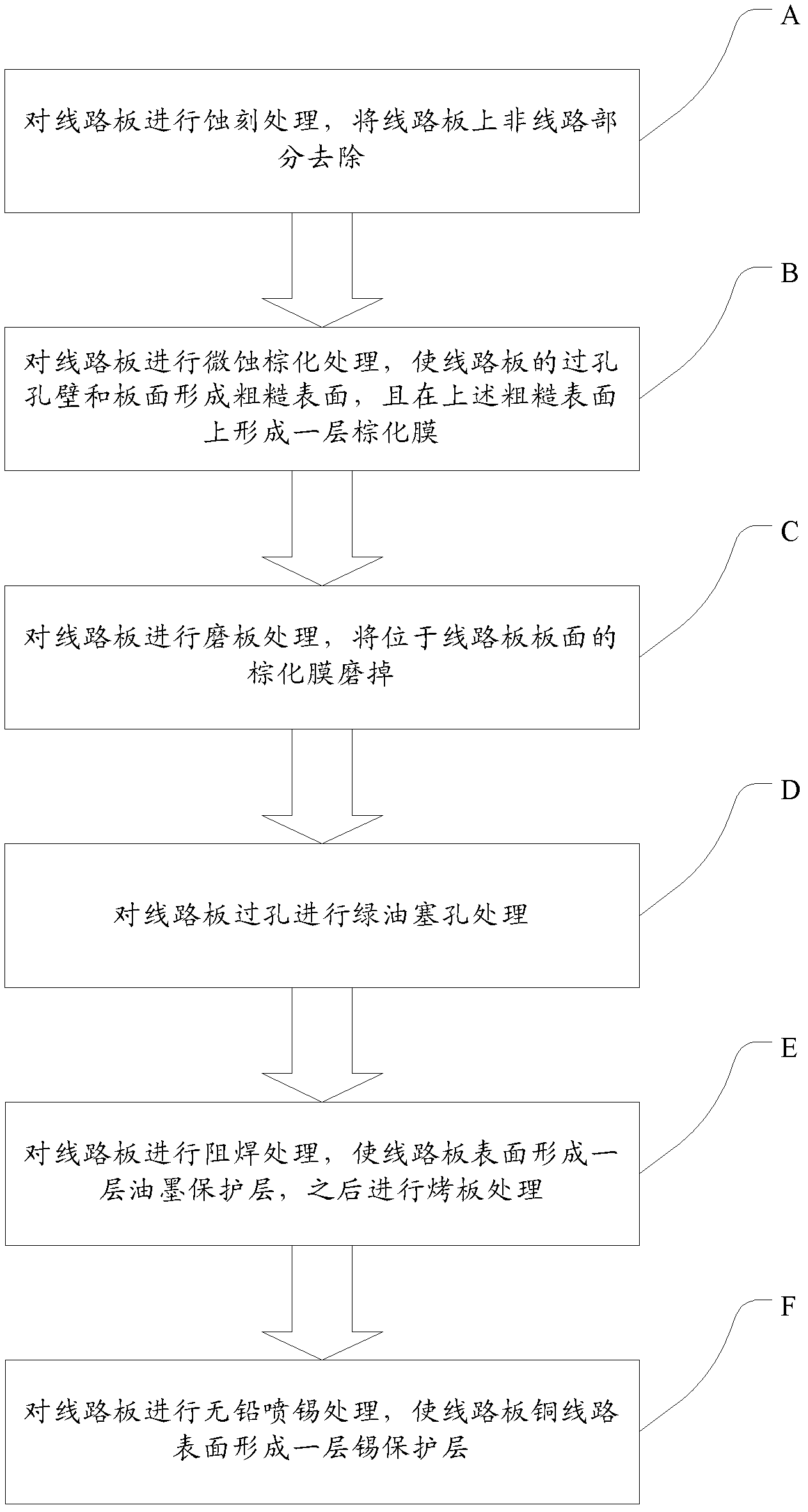

Method of preventing via hole from oil dropping in lead-free HASL process of circuit board

ActiveCN102883544AGuaranteed not to fall offThere will be no oil lossConductive pattern reinforcementPrinted element electric connection formationHot air solder levelingHigh heat

The invention discloses a method of preventing a via hole from oil dropping in the lead-free HASL (Hot Air Solder Leveling) process of a circuit board, which comprises the steps of etching, microetching and brownification, volcanic ash scrubbing, green oil jacking, solder resisting and lead-free HASL. According to the method, a microetching and brownification procedure is added after the etching, and a hole wall is subjected to micro coarsening to increase the adhesion of jacking green oil to the hole wall, thereby achieving the purpose of preventing the subsequent lead-free HASL technology from resulting in the oil dropping of the via hole due to high temperature. Compared with the prior art, the method solves the problem of oil dropping of the via hole in the green oil jacking in the lead-free HASL technology, the technology is simple, and the product quality is improved effectively.

Owner:SHENZHEN SUN & LYNN CIRCUITS

Adhesive bottom coating agent for improving metal-surface polyurethane elastomer coating adhesion of metal surface and preparation method of adhesive bottom sizing agent

InactiveCN107142006AImprove adhesionGuaranteed not to fall offPolyurea/polyurethane coatingsSolvent freeSolvent

The invention provides an adhesive bottom coating agent for improving metal-surface polyurethane elastomer coating adhesion and belongs to the field of adhesive bottom coating agents. The adhesive bottom coating agent is composed of a bottom coating agent base material and an accelerant, the bottom coating agent base material is composed of moisture-curing polyurethane resin, an adhesion promoter, a defoaming agent and an organic solvent, the moisture-curing polyurethane resin is a reaction product of diisocyanate with alcoholysis castor oil, and a bottom coating agent promoter is composed of a mixed catalyst of organic zinc with organic bismuth and the organic solvent; the bottom coating agent base material and the promoter are evenly and proportionally mixed and are applied to the surface of the base material by means of spraying, brushing, roll coating and the like, a solvent-free polyurethane elastomer is applied to the dried surface of the bottom coating agent after the surface is dried, and after 7 days of drying and curing, a solvent-free polyurethane elastomer coating has excellent adhesion strength on the metal surface.

Owner:硕投(武汉)高分子技术有限公司

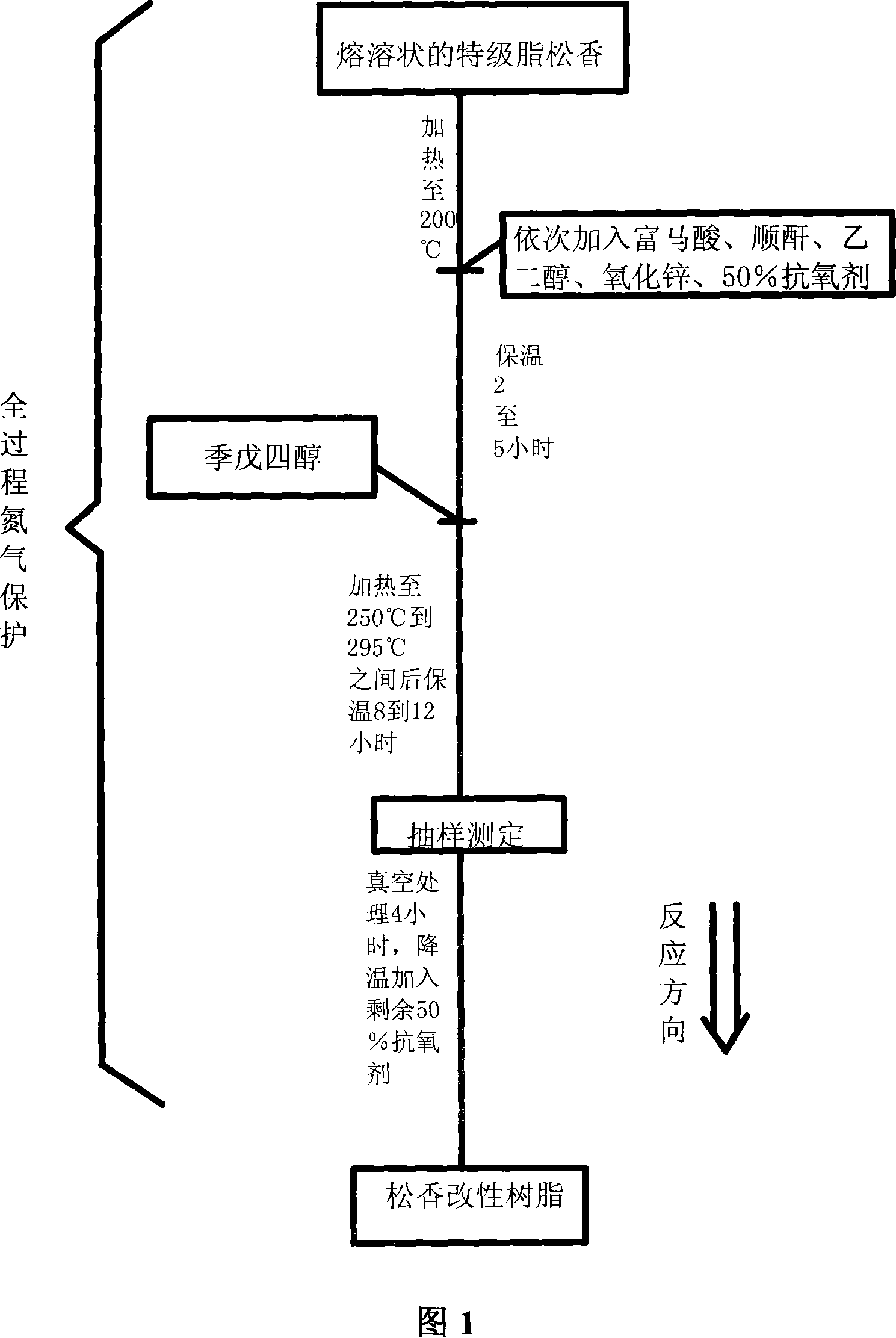

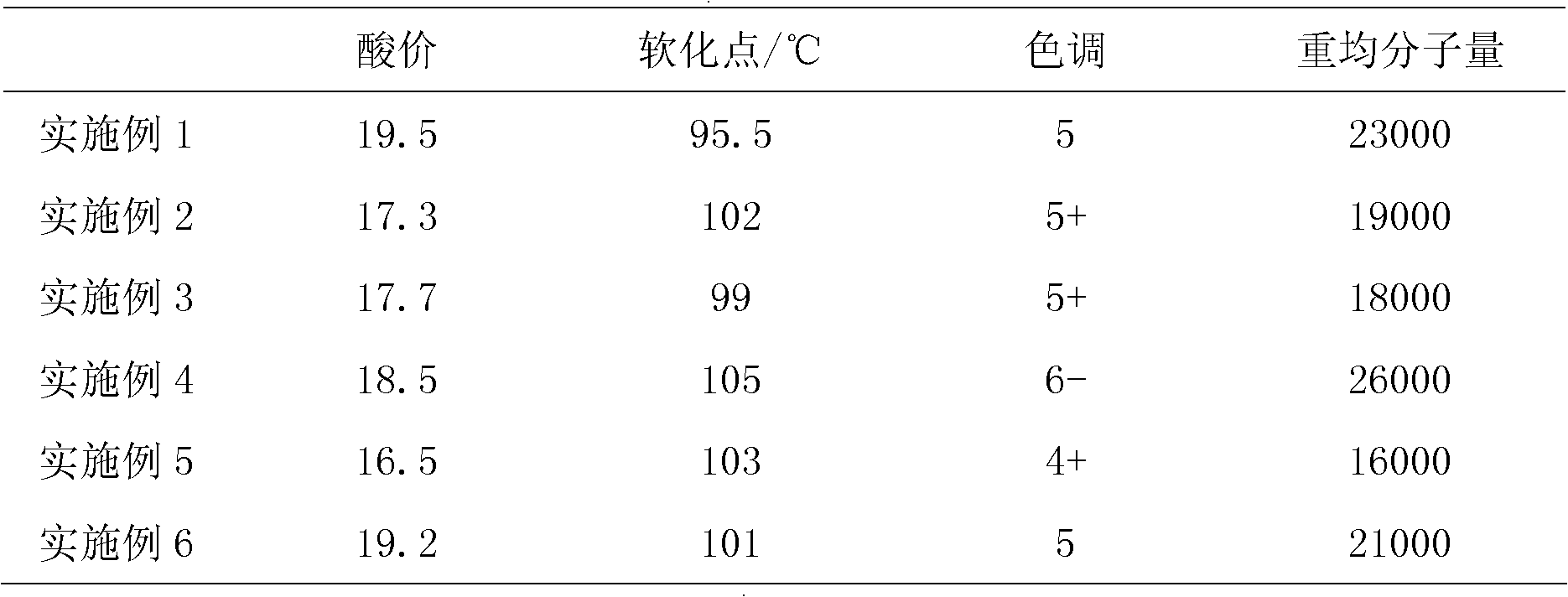

Rosin modified road guide line resin process flow and production formula

InactiveCN101033372ATo achieve the purpose of protectionSolve pollutionRosin coatingsTraffic signalsWeather resistanceRosin

The invention relates to a kind of road marking resin, which particularly relates to the road marking resin lipid-modified by the high-quality rosin to replace petroleum resin, acrylic or chlorinated rubber for solving the pollution problem. The material has excellent mobility of construction as well as anti-shed, light resistance, wear resistance, oxidation resistance, water-resistance, pressure resistance, filthy resistance, weather resistance and chemical resistance.

Owner:广西梧州金原树脂有限公司

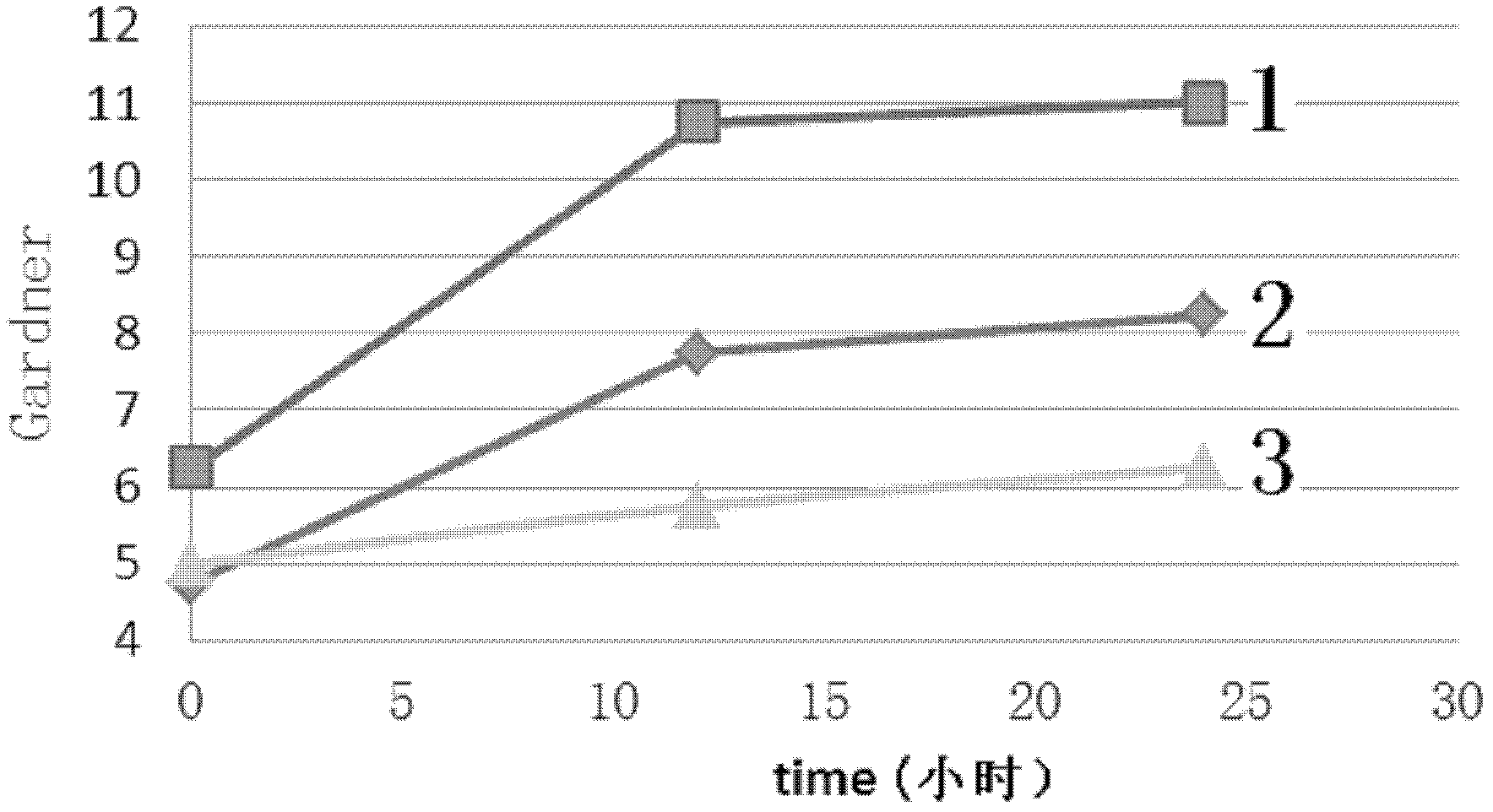

Rosin modified composite resin and preparation method

InactiveCN102532495AReduce dosageGood initial tackPolyester coatingsPolymer scienceResin-Based Composite

The invention discloses a rosin modified composite resin, which comprises the following raw materials in part by weight: 60 to 80 parts of rosin, 3 to 10 parts of conjugated polyprotic acid, conjugated polyanhydride or mixture of conjugated polyprotic acid and conjugated polyanhydride, 8 to 18 parts of polyol, 0.3 to 2 parts of pre-antioxidant, and 5 to 25 parts of vegetable oil, fatty acid or mixture of vegetable oil and fatty acid. The preparation method disclosed by the invention is to prepare rosin modified composite resin with high toughness, excellent film forming leveling property, high weather resistance and less pollution by subjecting raw materials to addition, esterification, ester exchange and other special modification reactions to increase the weather resistance and oxidation resistance of a resin structure. The preparation method can reduce production cost and environment pollution, and solve the problems of medium brittleness, poor leveling property, low weather resistance, and the like.

Owner:NANJING HALIMA CHEM

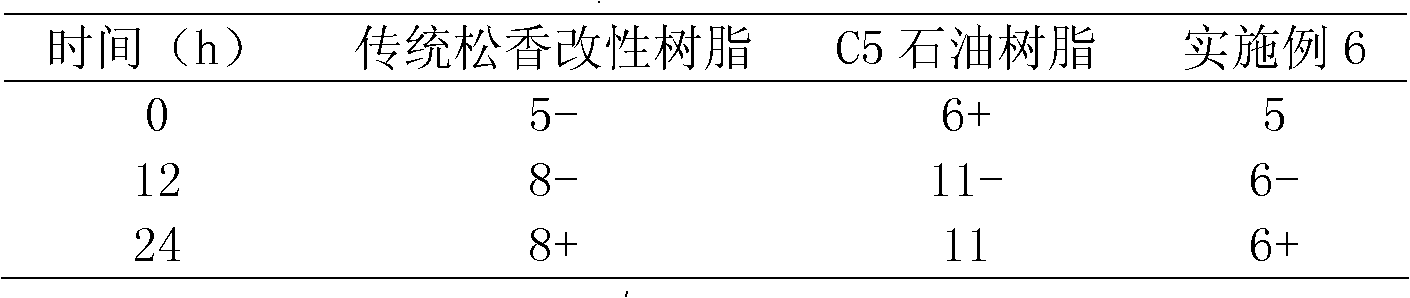

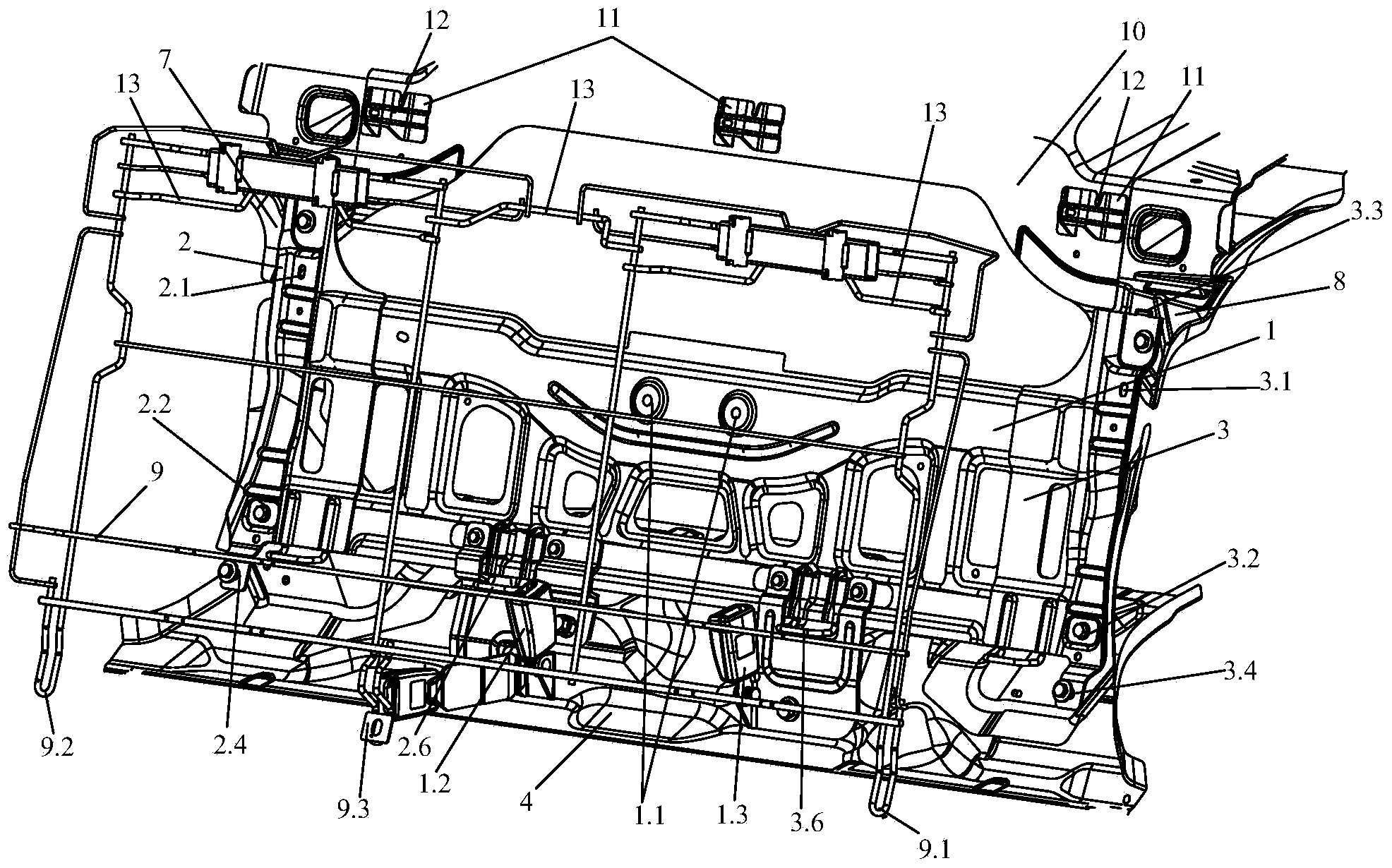

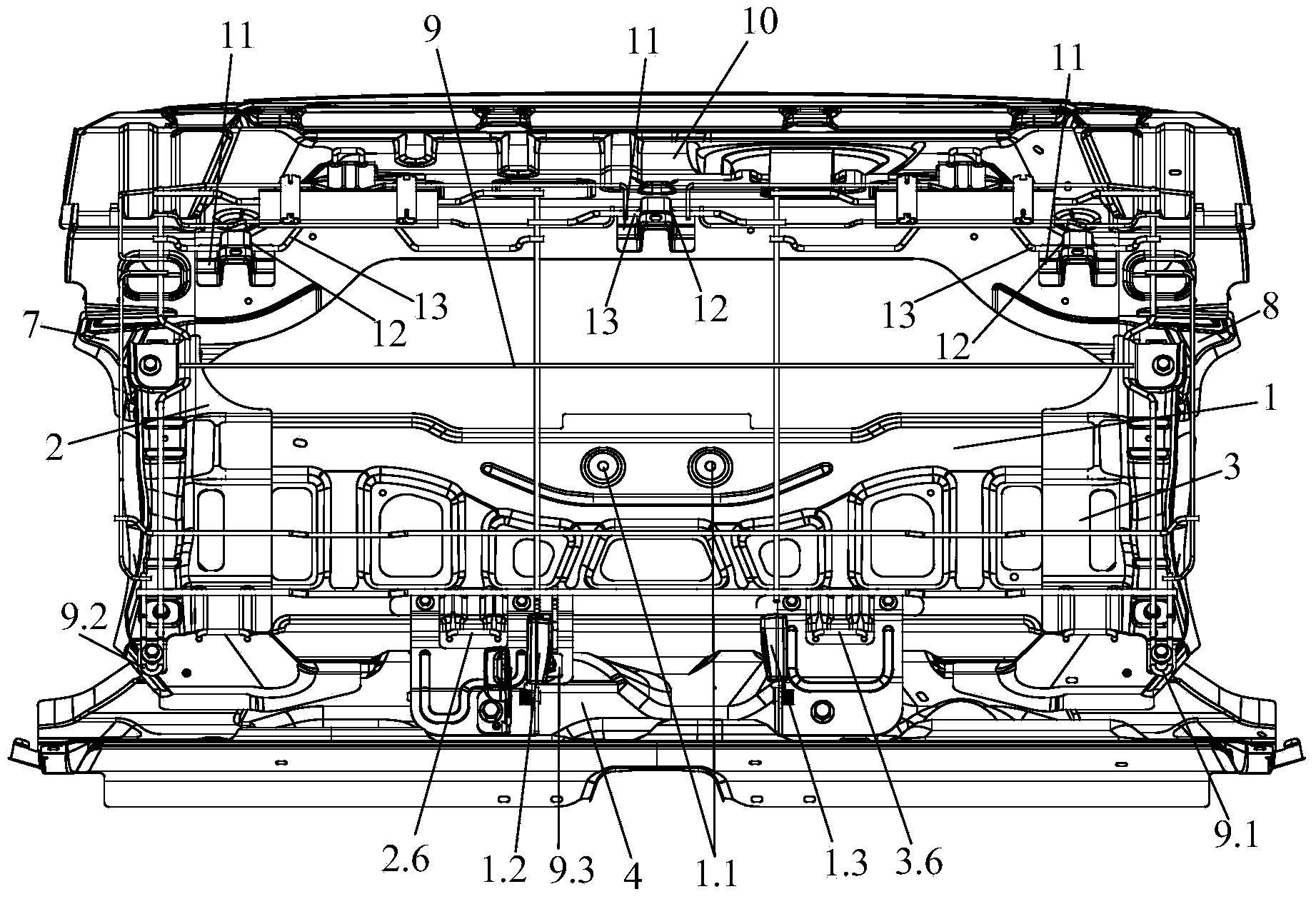

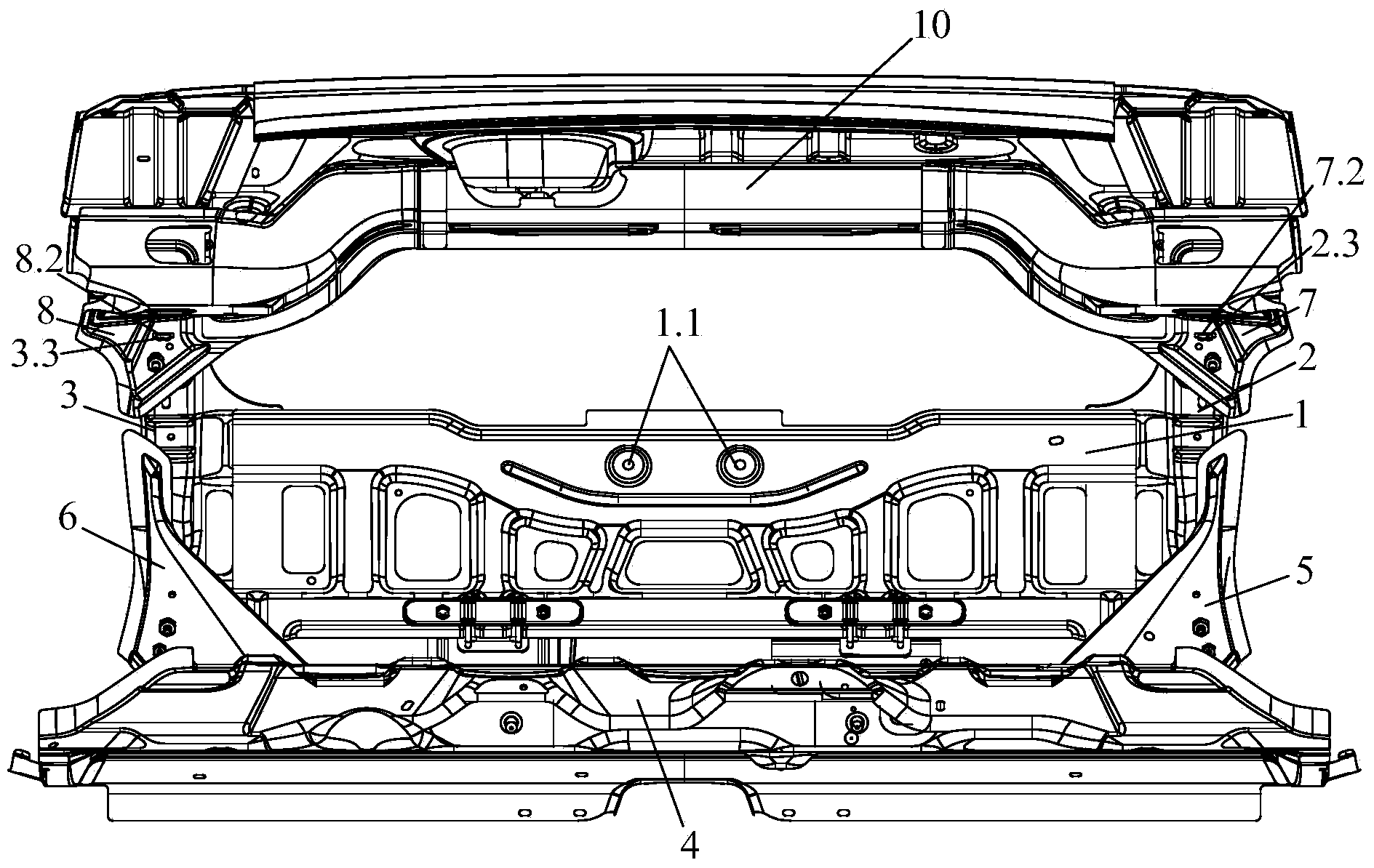

Split type structure of automobile backseat backrest framework and assembly method

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

Preparation method for metal-ceramic composite tube

InactiveCN101576178AGuaranteed not to fall offTightly boundRigid pipesElectrochemical machining apparatusCombustionCentrifugal force

The invention discloses a preparation method for a metal-ceramic composite tube, which comprises the steps of: 1, removing the oil stain of the inner wall of a metal tube; 2, removing the roll scale of the inner wall of the metal tube and exposing a fresh metal substrate; 3, filling the mixture of powder-shaped ceramic grains and a pyrophorus in the metal tube; 4 sealing the two ends of the tube the inside of which is fully filled with the ceramic grains and the pyrophorus, wherein one end of the tube is provided with a fuse lead in wire and the other end is provided with a waste gas exhaust hole; the fuse lead in wire and the pyrophorus are communicated; 5, clamping the metal tube and leading the metal tube to rotate at a certain rotational speed; 6, igniting the fuse lead in wire and then using the fuse lead in wire to ignite the pyrophorus to burn and give out heat to fuse the powder ceramic grains in the tube to be in a shape of a liquid which is closely adhered to the inner wall of the tube under the effect of a rotating centrifugal force and uniformly coated on the inner wall of the tube; and 7 grinding and finishing the inner hole of the tube. The method uses the heat generated by self-propagating combustion reaction to fuse the ceramic materials; the rotating centrifugal force leads the solid materials to be closely adhered to the wall of the tube to form a firm inner wall melting ceramic layer, thus ensuring the ceramic layer not to fall off in longer use and prolonging the service life of the ceramic layer.

Owner:CHONGQING UNIV OF TECH

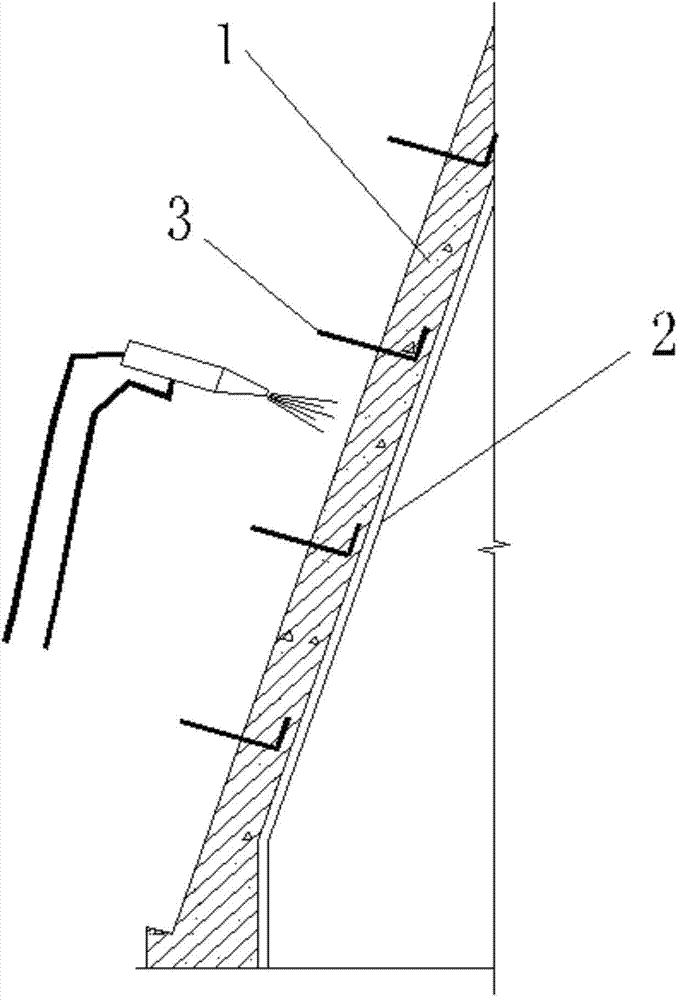

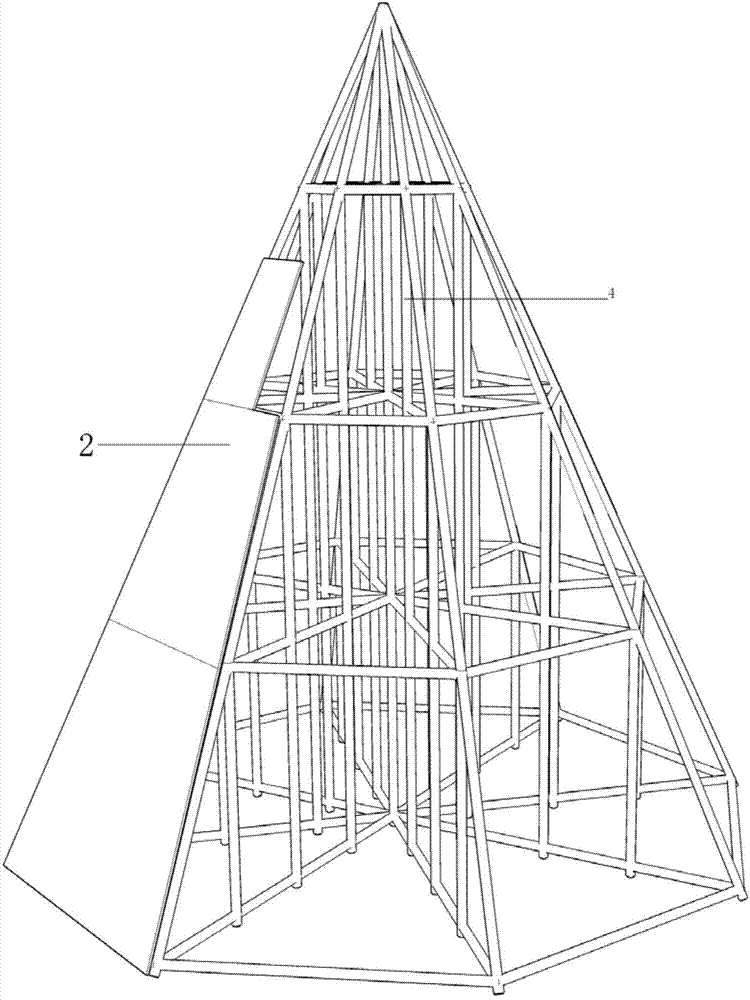

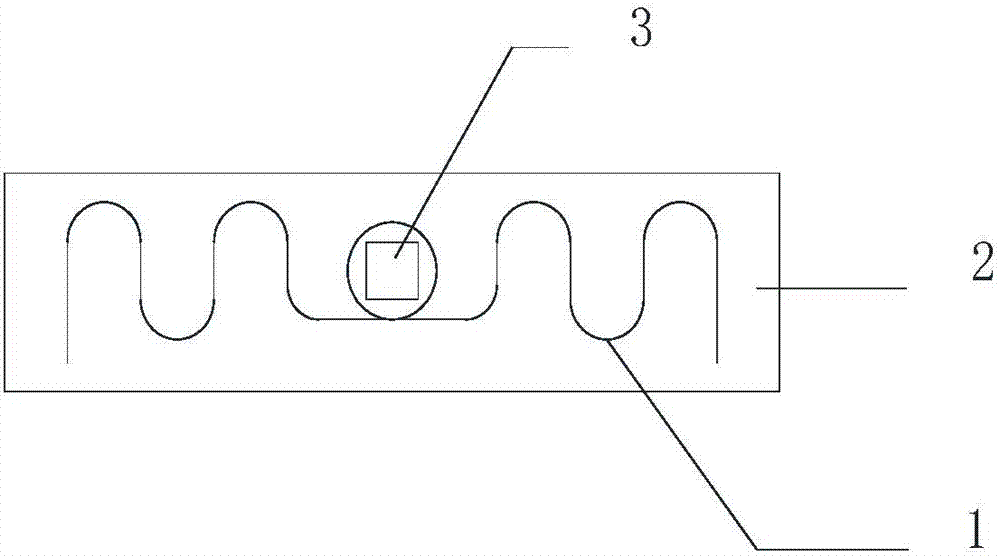

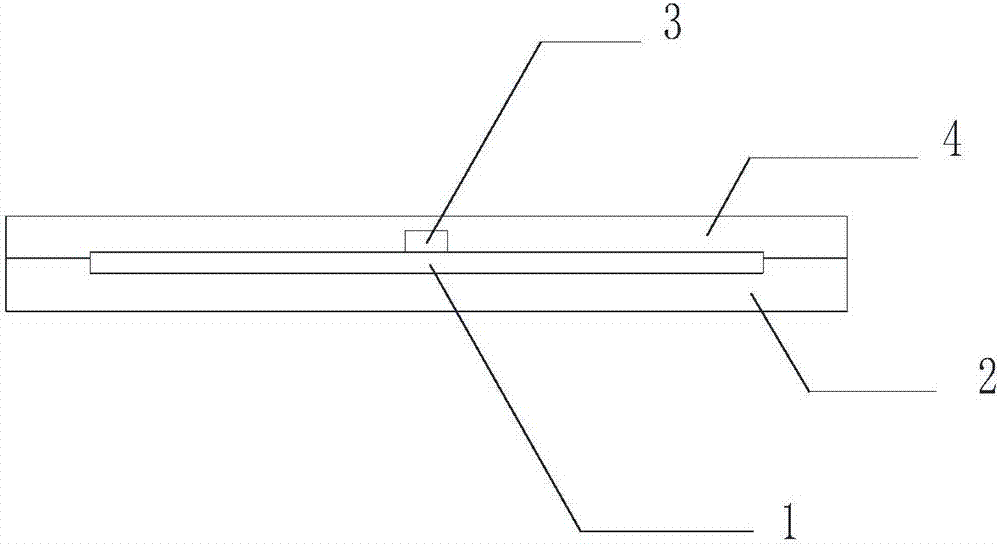

Concrete construction method for big-gradient sloping roof

ActiveCN103615076AShorten the construction periodReduce labor costsRoof covering using sealantsArchitectural engineeringRebar

The invention discloses a concrete construction method for a big-gradient sloping roof. At first, a bottom layer formwork module 2 of the big-gradient sloping roof is installed according to needs, roof panel steel bars are bound according to construction drawings and standard requirements, then sprayed concrete construction is carried out on the big-gradient sloping roof panel 1, the big-gradient sloping roof panel 1 comprises the sloping roof formwork module 2 and pre-buried L-shaped pulling ribs 3, the formwork module 2 is machined in advance to be formed and to be hoisted to a full space bearing frame 4, concrete is continuously sprayed and constructed at one time, construction quality of the concrete can be visually observed, and it is guaranteed that the interior of the concrete is dense; after roof concrete is renovated by means of cement mortar with the same proportion of the roof concrete through cleaning of dross on the surface layer, the concrete is square in appearance size, the exterior of the concrete is flat, and the interior of the concrete is solid.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

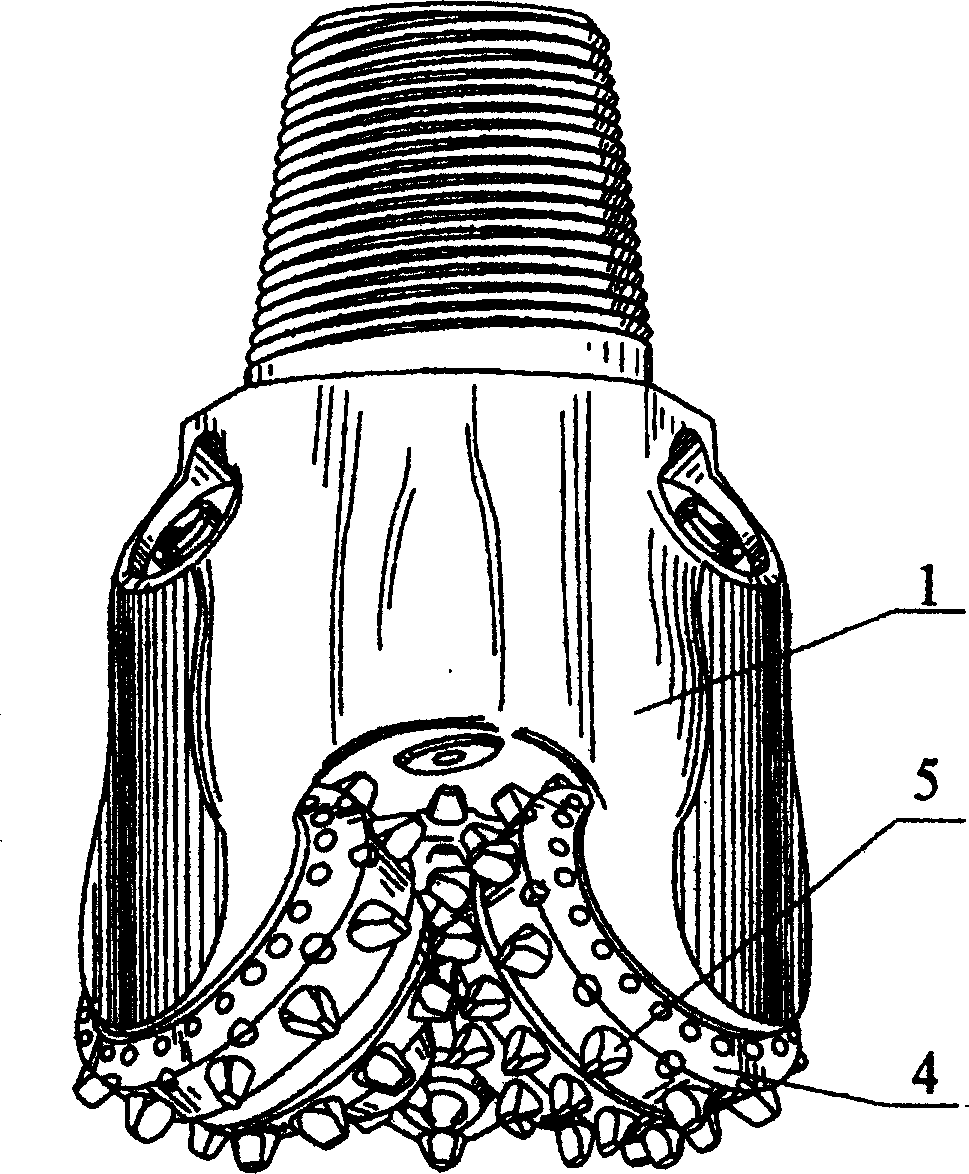

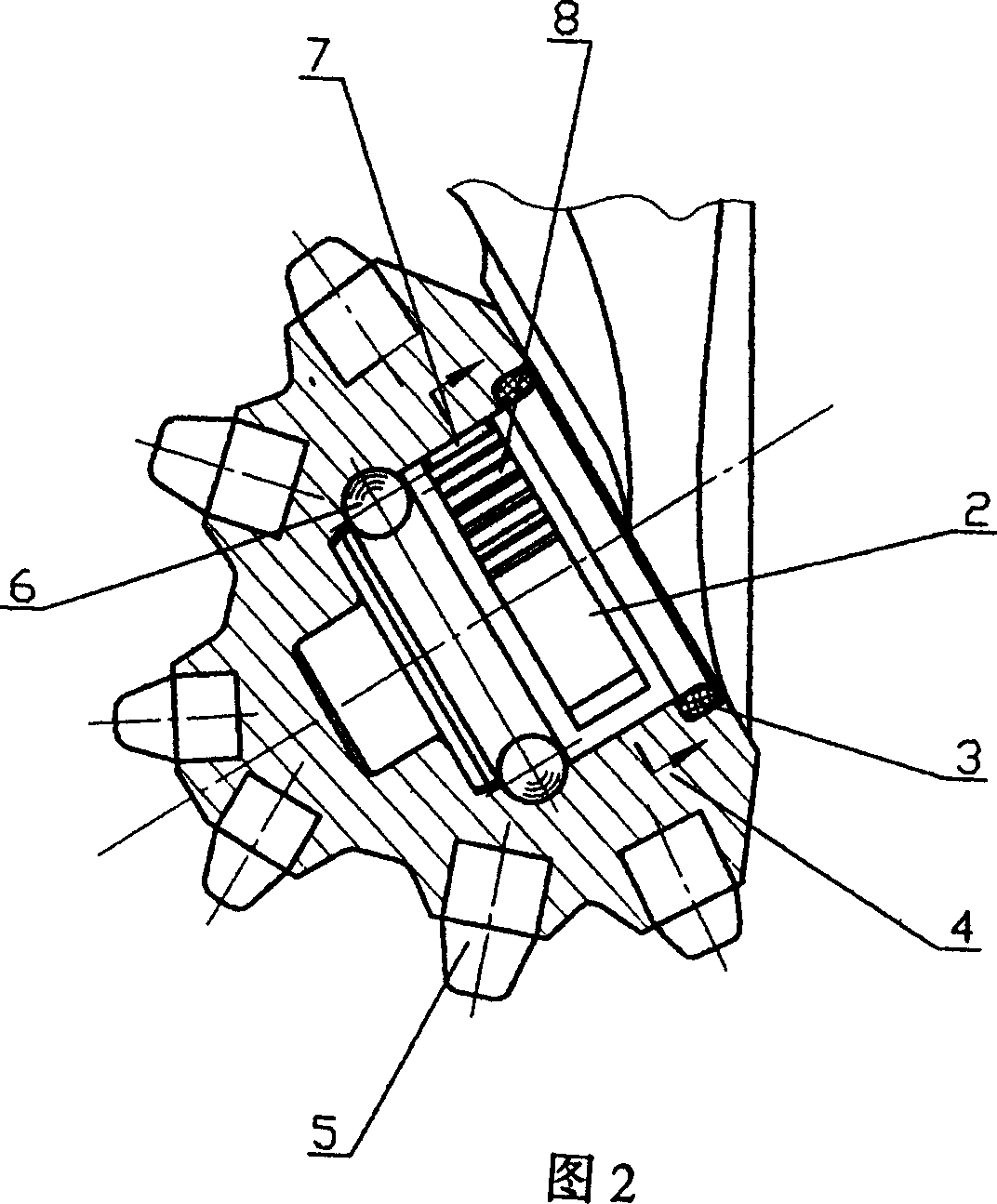

Roller bit with roller pull-off prevention alarm apparatus

The present invention relates to roller cutter bit and features an early warning device set on the toothed claw shaft neck for prevent pineapple from falling off. The device consists of circumferential rollaway nest, roller inside the nest and locking wedge. After the bearing pair is abrased to preset dangerous limit, the pineapple is clamped in the shaft neck, the working torque and speed of the roller cutter bit will change abruptly, so that the bit to be failed may be replaced timely. The present invention can prevent pineapple from falling off and lower well drilling cost, and the locking wedge in the device has great bearing capacity so that the present invention can meet the requirement of different work conditions, especially great drilling pressure.

Owner:SOUTHWEST PETROLEUM UNIV

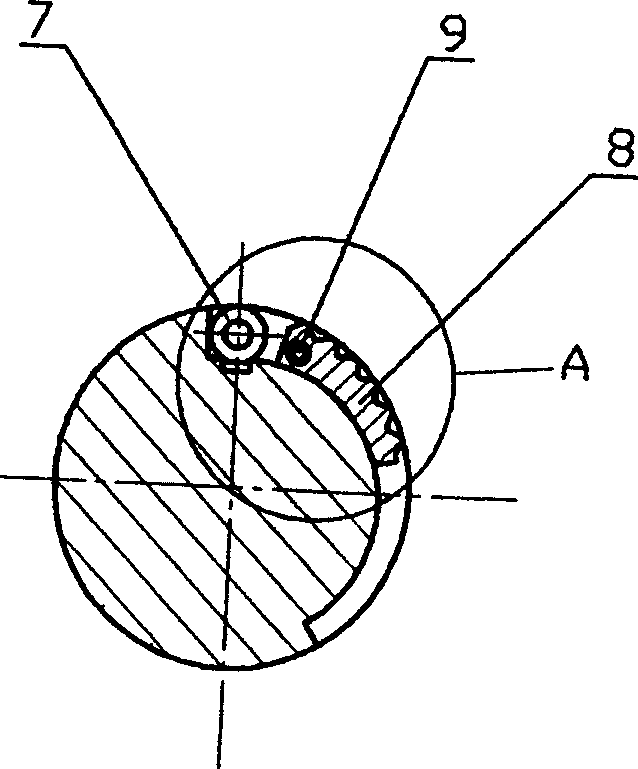

Method for purifying poisonous and harmful organic pollutants by using electromagnetic collaborative enhanced biological packed tower

ActiveCN104310571ALarge apertureIncrease productionTreatment by combined electrochemical biological processesWater contaminantsHigh concentrationOxygen

The invention discloses a device and method for purifying poisonous and harmful organic pollutants by using an electromagnetic collaborative enhanced biological packed tower, and belongs to the field of pollution control of difficultly treated high-concentration poisonous and harmful organic pollutants. The method for treating the poisonous and harmful organic pollutants, which is disclosed by the invention comprises the steps: domestication of a bactericide; preparation of reactor packing; biofilm formation of reactor packing; and treatment of poisonous and harmful organic pollutants. According to the method disclosed by the invention, the defect that the degradation efficiency is affected by concentrated falling easily caused by aging when the biofilm process runs are overcome by utilizing an electromagnetic collaborative technology; the bactericide with a rapid growth rate and high degradation efficiency of poisonous and harmful organic pollutants is cultured; meanwhile, the content of dissolved oxygen in a reactor system is improved, so that the mass transfer rate of matter in gas and liquid phases is enhanced, and thus the degradation reaction probability of the poisonous and harmful organic pollutants is increased, and the organic matter is fully purified.

Owner:KUNMING UNIV OF SCI & TECH

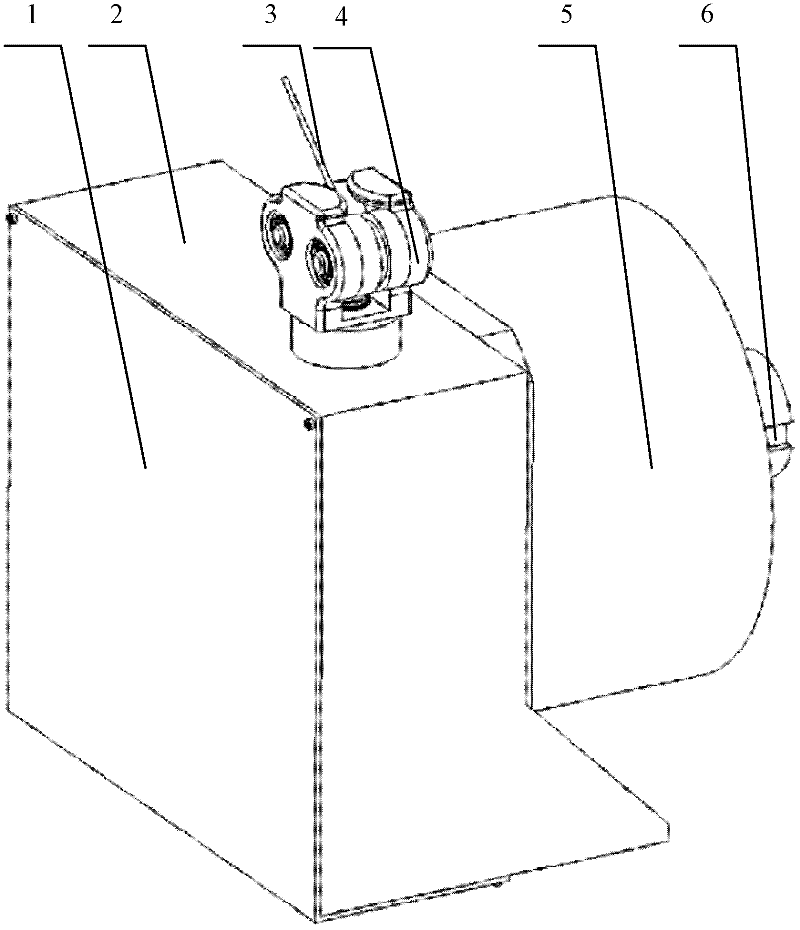

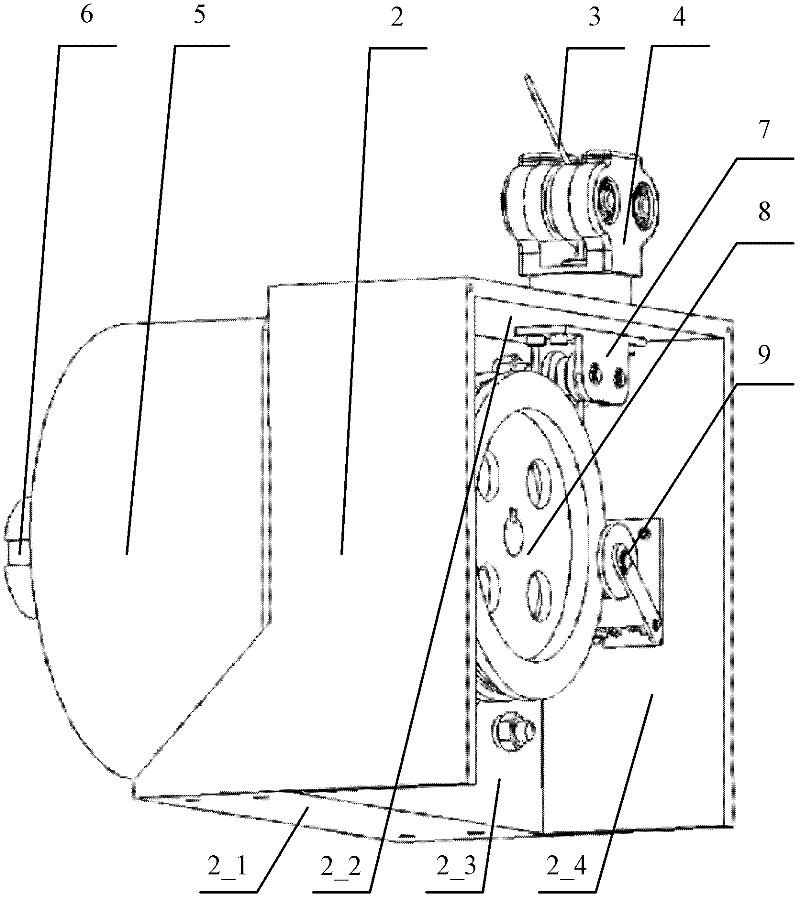

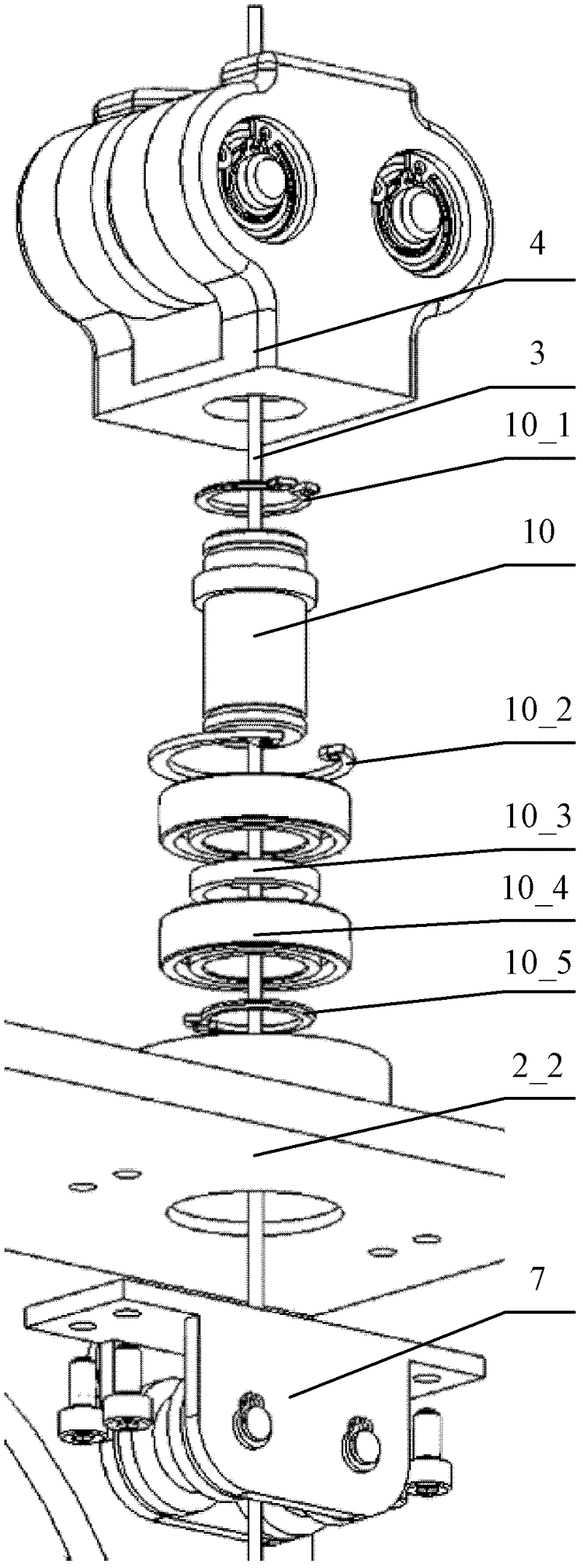

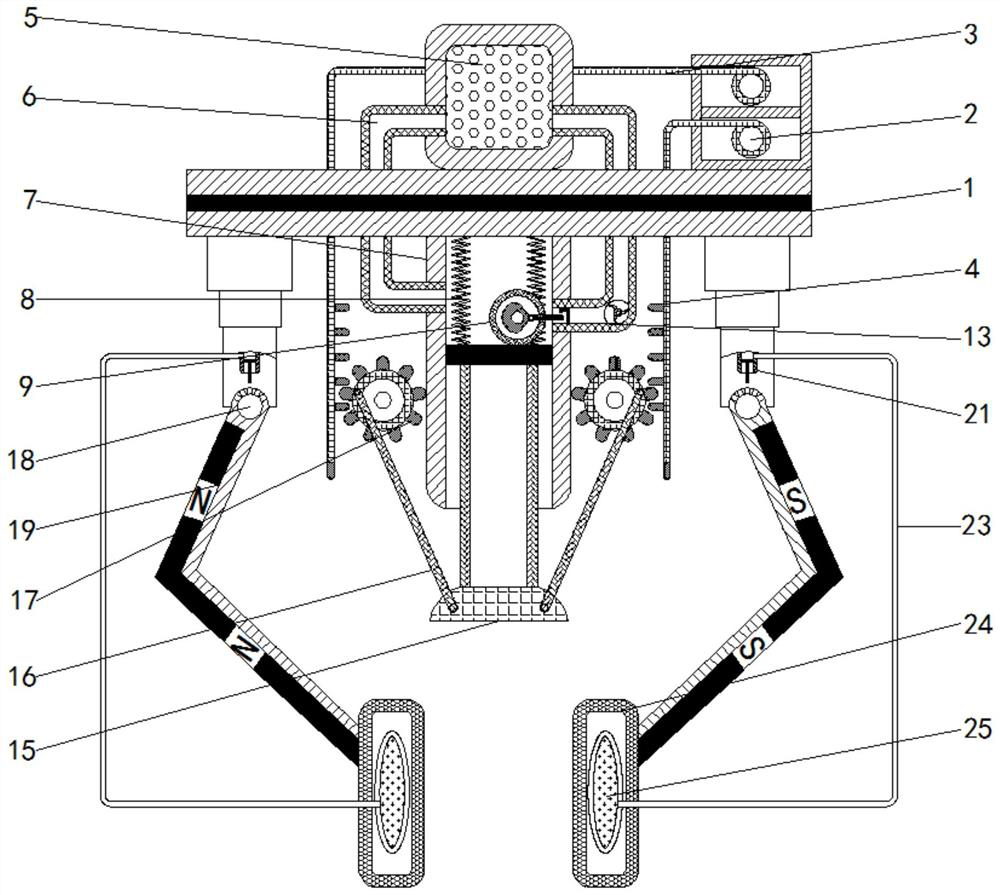

Flexible cable driving unit

InactiveCN102302835AGuaranteed not to fall offSmooth cable transmissionMuscle exercising devicesMulti degree of freedomFlexible cable

The invention aims to provide a flexible cable driving unit. The driving unit comprises a driving unit bracket, a revolving flexible cable guide device, a permanent magnet direct current moment motor, a fixed flexible cable guide device, a flexible cable traction wheel and a guide shaft, wherein the permanent magnet direct current moment motor is arranged outside the driving unit bracket; the flexible cable traction wheel is arranged in the driving unit bracket; an output shaft of the permanent magnet direct current moment motor is connected with the flexible cable traction wheel; the revolving flexible cable guide device is connected with the fixed flexible cable guide device through the guide shaft; the fixed flexible cable guide device is fixed in the driving unit bracket; the revolving flexible cable guide device and the guide shaft are arranged outside the driving unit bracket; and a flexible cable is wound on the flexible cable traction wheel and passes through the fixed flexible cable guide device, the guide shaft and the revolving flexible cable guide device. The flexible cable driving unit can drive the flexible cable in a spatial multi-degree-of-freedom mode, is modular,has a compact integral structure and light weight, and is convenient to transport, assemble and disassemble spatially.

Owner:HARBIN ENG UNIV

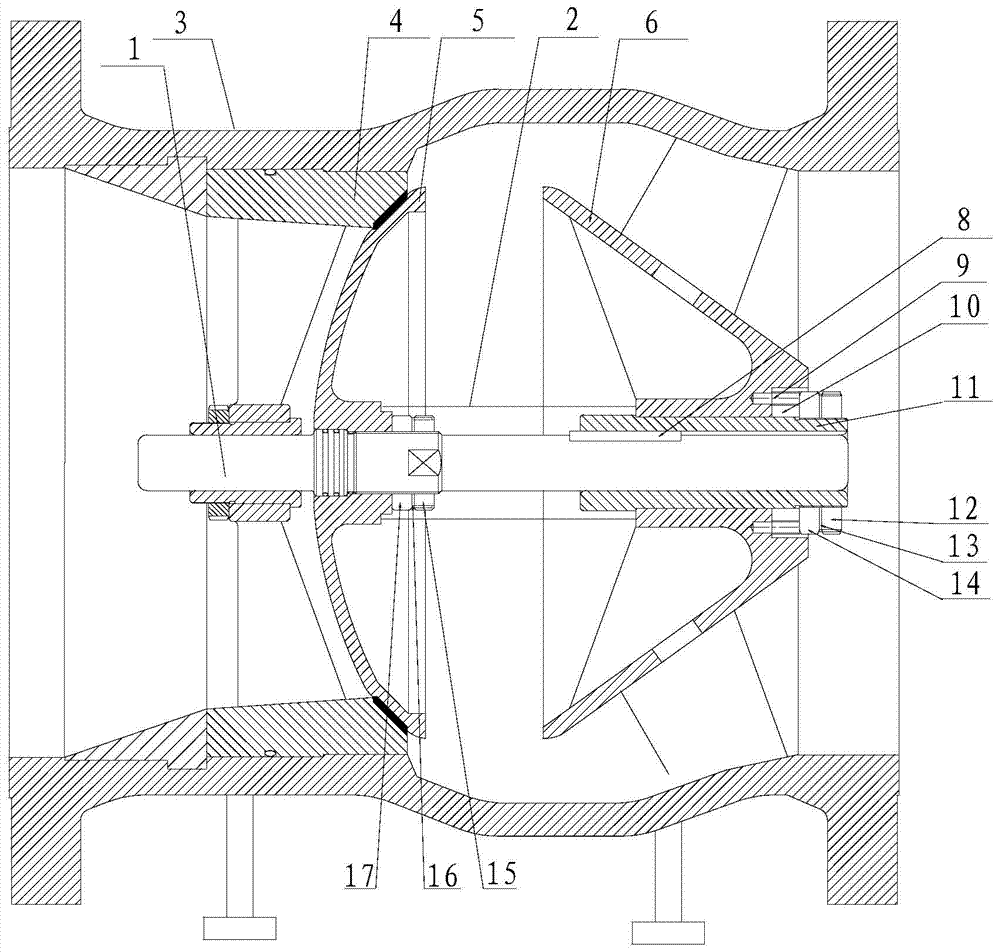

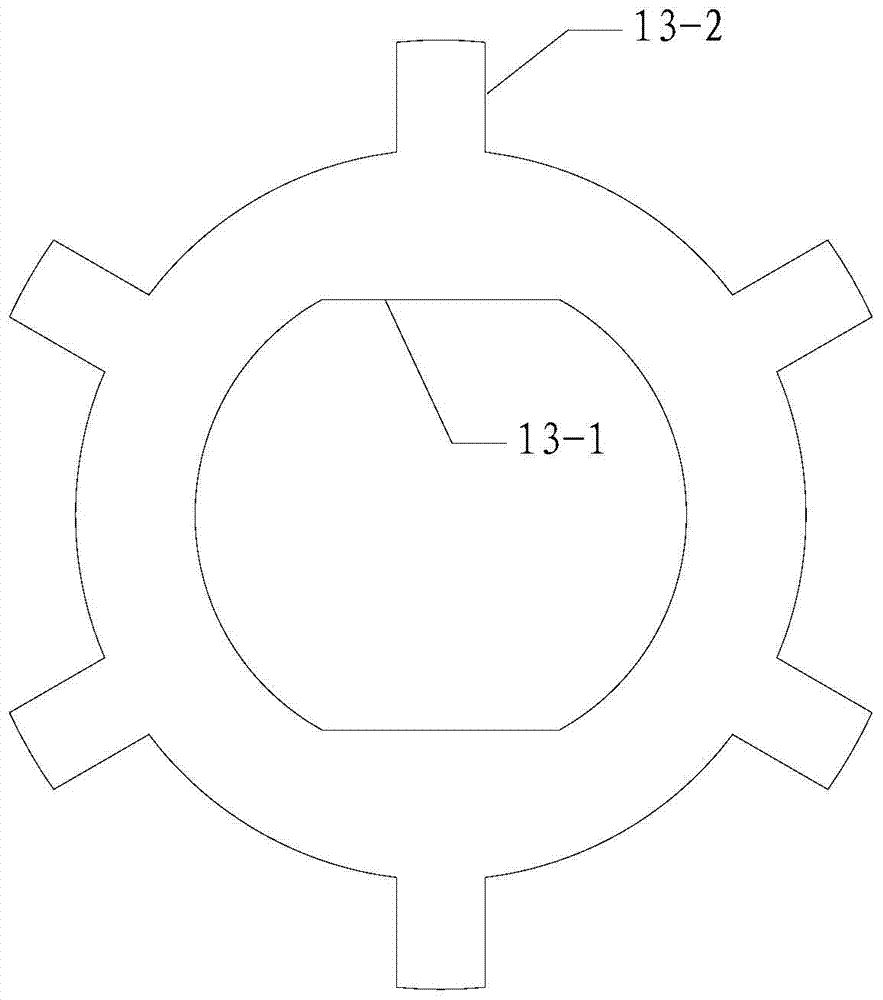

Axial-flow type check valve

ActiveCN104847932AInhibit sheddingAchieve absolute lockingCheck valvesLift valveEngineeringCheck valve

The invention discloses a valve structure, and particularly relates to an axial-flow type check valve. The axial-flow type check valve comprises a valve body, a valve rod, a valve seat, a valve clack, a valve sleeve, a bush, anti-falling locking nuts, thrust washers, closed locking nuts and a spring device. The anti-falling locking nuts comprise the first anti-falling locking nut and the second anti-falling locking nut. The thrust washers comprise the first thrust washer and the second thrust washer. The closed locking nuts comprise the first closed locking nut and the second closed locking nut. The axial-flow type check valve can achieve the effects that all the components of a valve element are prevented from falling and rotating and are resistant to vibrating and detachable, and the problems that the valve element of the axial-flow type check valve is prone to falling off and rotating, hard to maintain and the like are solved. Meanwhile, the use performance of valves of this kind is improved, and the service life of the valve is prolonged.

Owner:自贡新地佩尔阀门有限公司 +1

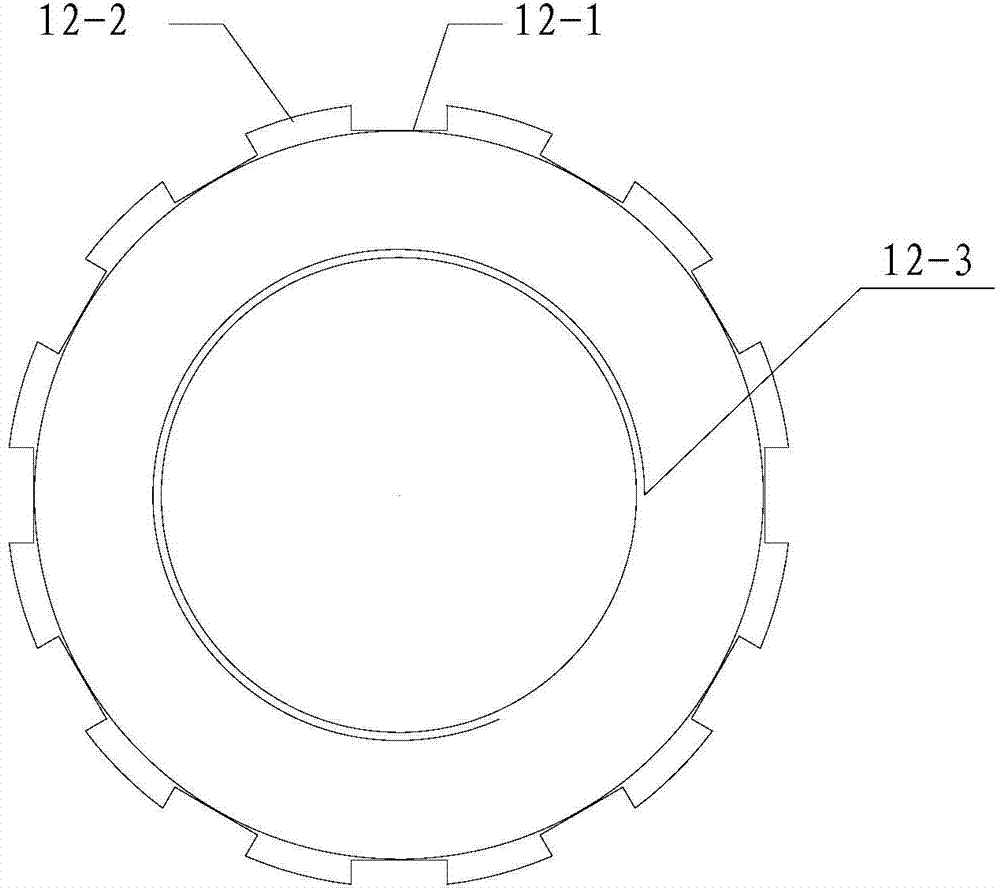

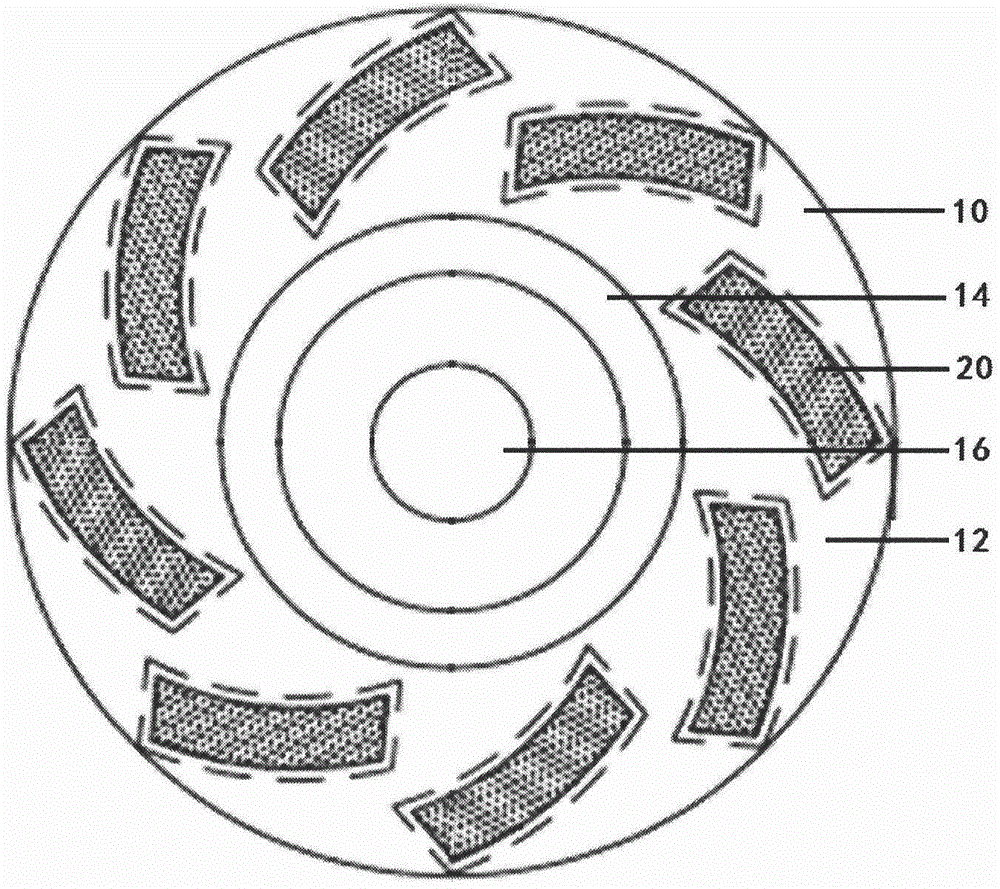

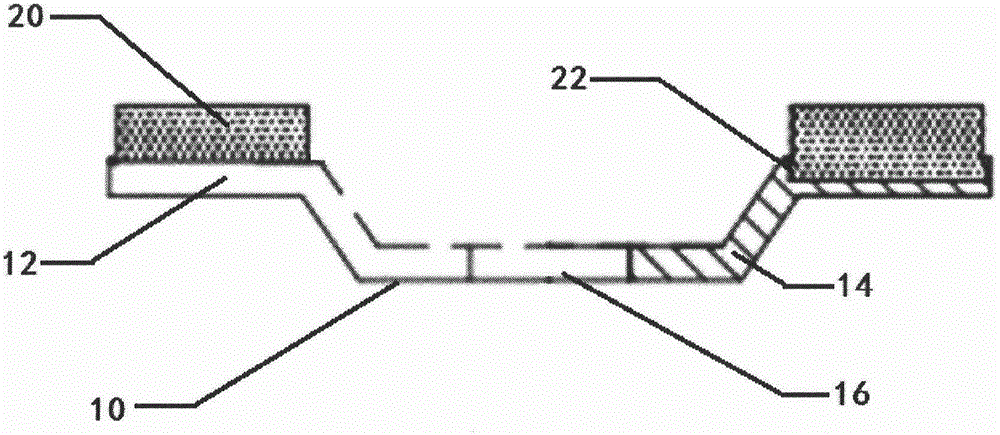

Light and efficient diamond grinding wheel

ActiveCN105014557AGuaranteed service lifeGuaranteed not to fall offBonded abrasive wheelsGrinding devicesDiamond cuttingAlloy

The invention relates to a light and efficient diamond grinding wheel, and belongs to the technical field of diamond cutting tools. The light and efficient diamond grinding wheel comprises an aluminum substrate and diamond tool bits. Outwards-extending protruding parts are arranged on the bottom edges of the diamond tool bits. The aluminum substrate comprises a grinding installation face. The diamond tool bits are arranged on the grinding installation face. The extending protruding parts are embedded in the grinding installation face. The light and efficient diamond grinding wheel is formed by high-strength alloy aluminum at a time, the bottoms of the diamond tool bits are embedded in the alloy aluminum, it is ensured that the tool bits do not fall in the use process, and therefore many subsequent procedures are reduced, silver solder is saved, the manufacturing cost is effectively reduced, the service life of the diamond grinding wheel is ensured as well, and the light and efficient diamond grinding wheel is particularly suitable for stone processing and concrete road face grinding.

Owner:JIANGSU FENGTAI TOOLS

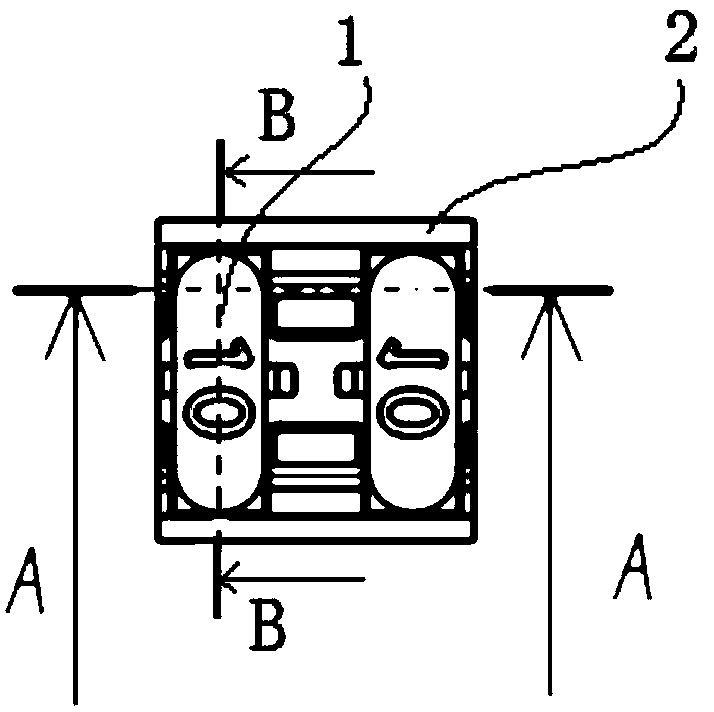

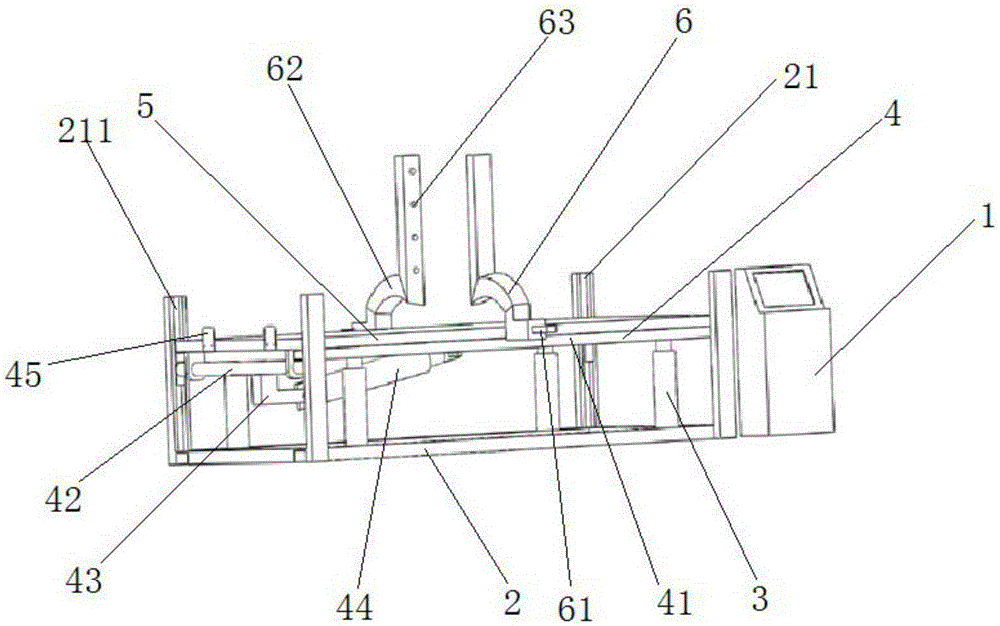

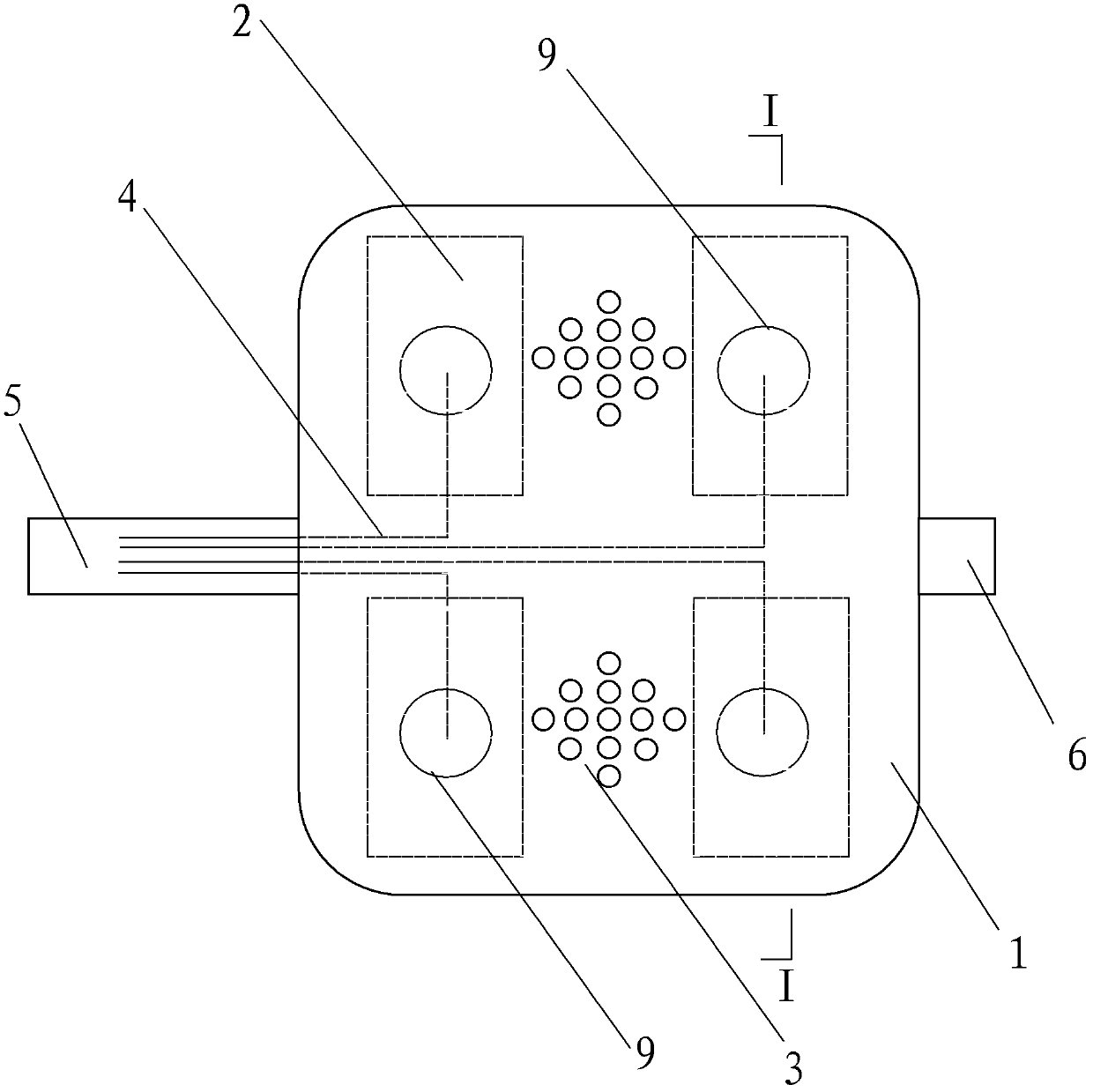

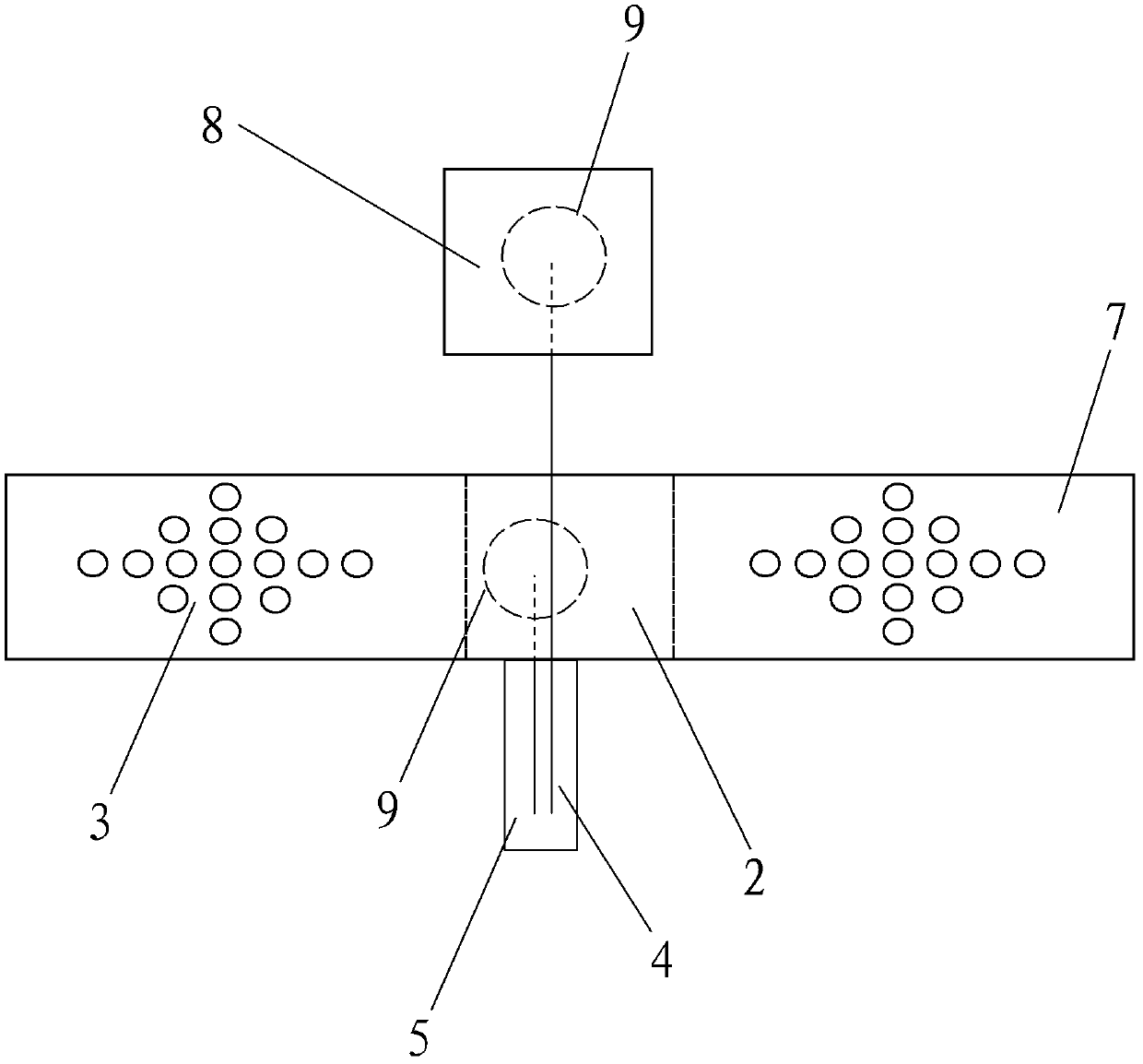

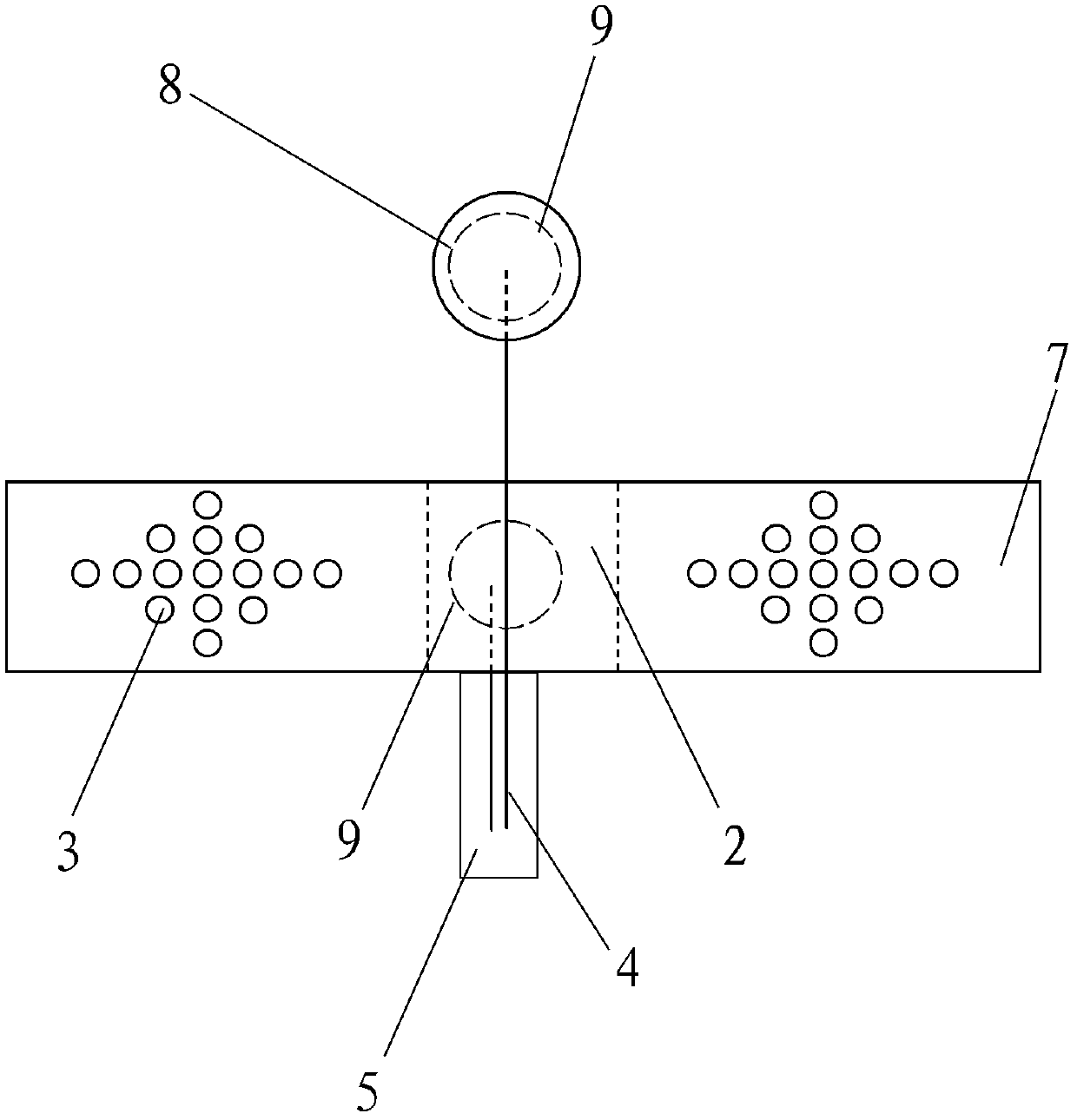

Power distribution cabinet assembling platform

The invention provides a power distribution cabinet assembling platform. The power distribution cabinet assembling platform includes an electric control cabinet, a base, lifting mechanisms, a turning mechanism, an operation platform and vertical arm mechanisms; supporting upright columns are connected onto the base; slide grooves are arranged on the supporting upright columns; the lifting mechanisms are vertically arranged at four corners of the base; the turning mechanism comprises a turning bracket, a rotating shaft, a connecting piece and a turning hydraulic jack, wherein the turning bracket is correspondingly clamped in the slide grooves in a sliding manner and is connected at the upper parts of the lifting mechanisms in a jacking manner, the rotating shaft is parallelly fixed at the lower part of the turning bracket and is clamped into the slide grooves in a sliding manner, and the turning hydraulic jack is connected at the middle of the turning bracket in a jacking manner through the connecting piece; the operation platform is fixed at the upper surface of the turning bracket; and the vertical arm mechanisms are arranged at two sides of the middle of the operation platform. With the power distribution cabinet assembling platform adopted, the positions of the side plates of a power distribution cabinet to be assembled can be determined, and complex steps for repeatedly adjusting a cabinet body to straighten the cabinet body in an assembling process can be omitted, and after the power distribution cabinet is assembled, the cabinet body of the power distribution cabinet can be automatically turned so as to be straightened, and manual lift can be omitted.

Owner:天津市建电实业有限公司

Machining method for sapphire window accessory of electronic product

ActiveCN104786377AGuaranteed not to fall offQuality improvementEdge grinding machinesFine working devicesSapphire windowClosed loop

The invention provides a machining method for a sapphire window accessory of an electronic product, and belongs to the technical field of electronic product screen machining. The technical problem that existing sapphire window accessories are machined by a tool one by one, and the machining efficiency is low is solved. The machining method for the sapphire window accessory of the electronic product comprises the steps that a sapphire crystal block is cut into a sapphire substrate, sapphire printing ink is used for printing a plurality of annular printing ink belts on the sapphire substrate, the printing ink is dried, then the sapphire substrate is placed in a clamp to be fixed, laser light is used for cutting the sapphire substrate into a plurality of annular sheet sapphire window accessories, finally, unqualified products are removed, and qualified finished products are taken out. According to the machining method, due to the fact that the multiple annular printing ink belts are printed on the sapphire substrate through the sapphire printing ink, a plurality of finished products can be obtained through cutting at a time, the production efficiency is improved, laser light can achieve closed-loop control, the laser cutting precision can be improved, and the finished product quality is improved.

Owner:ZHEJIANG XINGXING TECH CO LTD

UHF RFID label

PendingCN106960242ASolve the problem of intolerance to rubbingHigh bandwidthRecord carriers used with machinesRadio frequency circuitsEngineering

A UHF RFID label is disclosed and comprises a label chip, a radio frequency circuit and base material, wherein the radio frequency circuit is imbedded on the base material, the label chip is an on board chip, the label chip is placed in an inductance ring of the radio frequency circuit and is coupled to the radio frequency circuit, and a fixing layer used for wrapping the label chip and fixing the same on the base material is arranged on the label chip. According to the UHF RFID label, the radio frequency circuit is imbedded on the base material via wire imbedding technologies, poor consistency of product performance caused by tolerance of surface mounting technologies can be alleviated, the label chip is placed in the radio frequency circuit via a coupled mode in a disconnected manner, man-hours of workers can be prevented from being wasted by conventional lead pin welding technologies, bandwidth of the RFID label is increased, and application reliability of the RFID label in a whole solution can be increased.

Owner:HANGZHOU CENTURY TECH

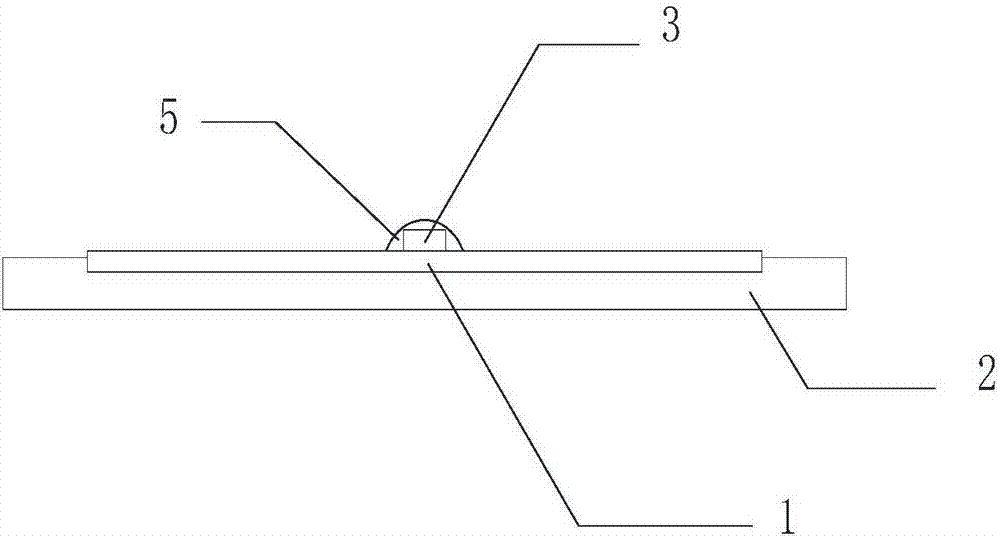

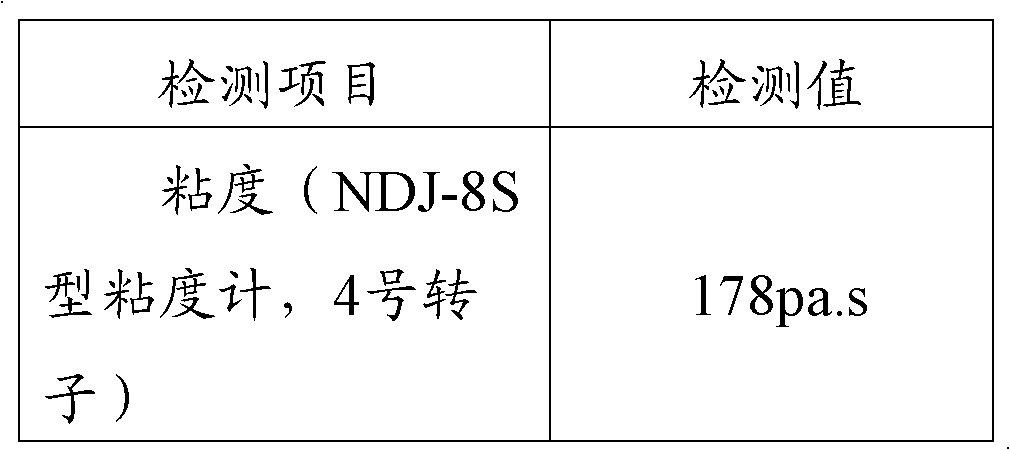

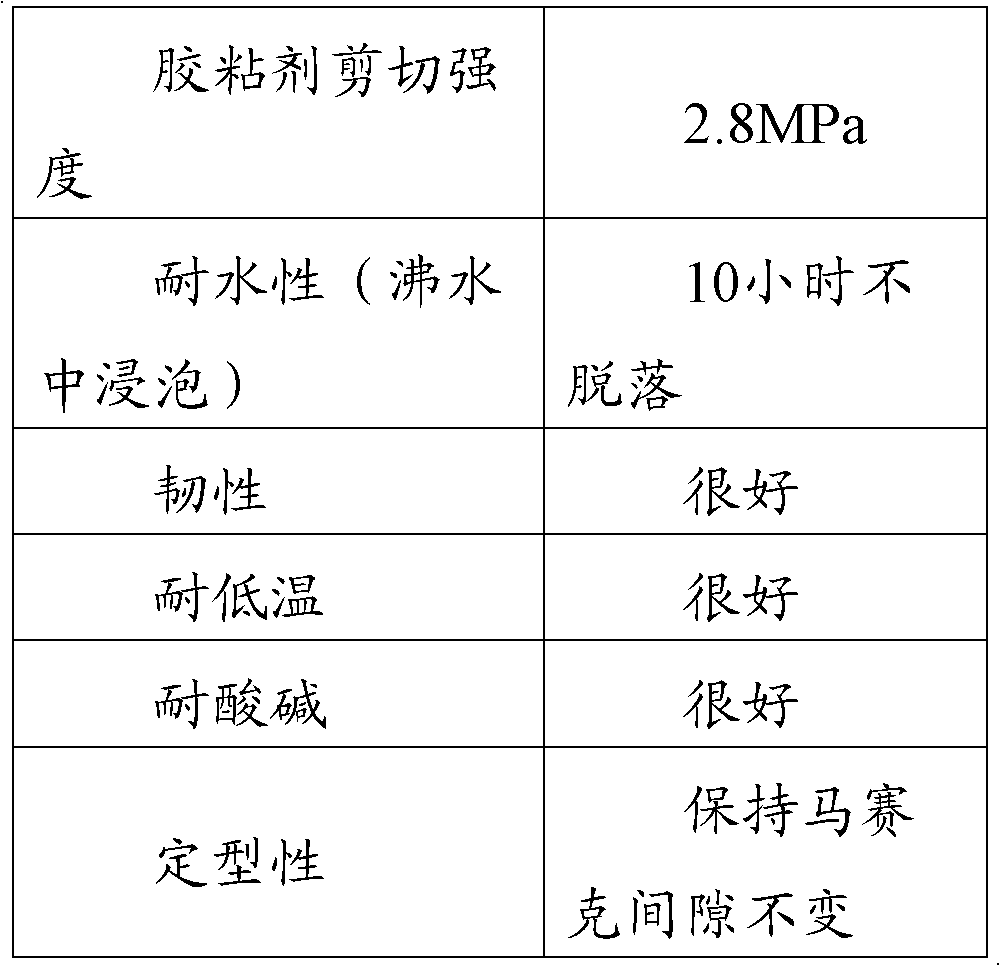

Dispensing adhesive agent for connection of mosaics and production process

InactiveCN103374314AImprove water resistanceGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPlasticizerPolyvinyl chloride

The invention discloses a dispensing adhesive agent for connection of mosaics and a production process. The adhesive agent comprises, by weight, 20%-30% of plasticizers, 18%-33% of polyvinyl chloride paste resins, 0.5%-2% of curing agents, 1.0%-12% of endcapped polyurethane prepolymers, 6%-13% of nano calcium carbonate, 3%-16% of heavy calcium carbonate, 3%-23% of calcite powder, 0.1%-1% of coupling agents, 0.3%-4.5% of heat stabilizers, 0.2%-6% of water-removal agents, 0.4%-1.8% of thixotropic agents and 0%-2% of diluents. The adhesive agent for connection of mosaics does not need base materials such as paper, silk screens and the like, has excellent water resistance and can raise the bonding strength of mosaics.

Owner:佛山市智韧新材料有限公司

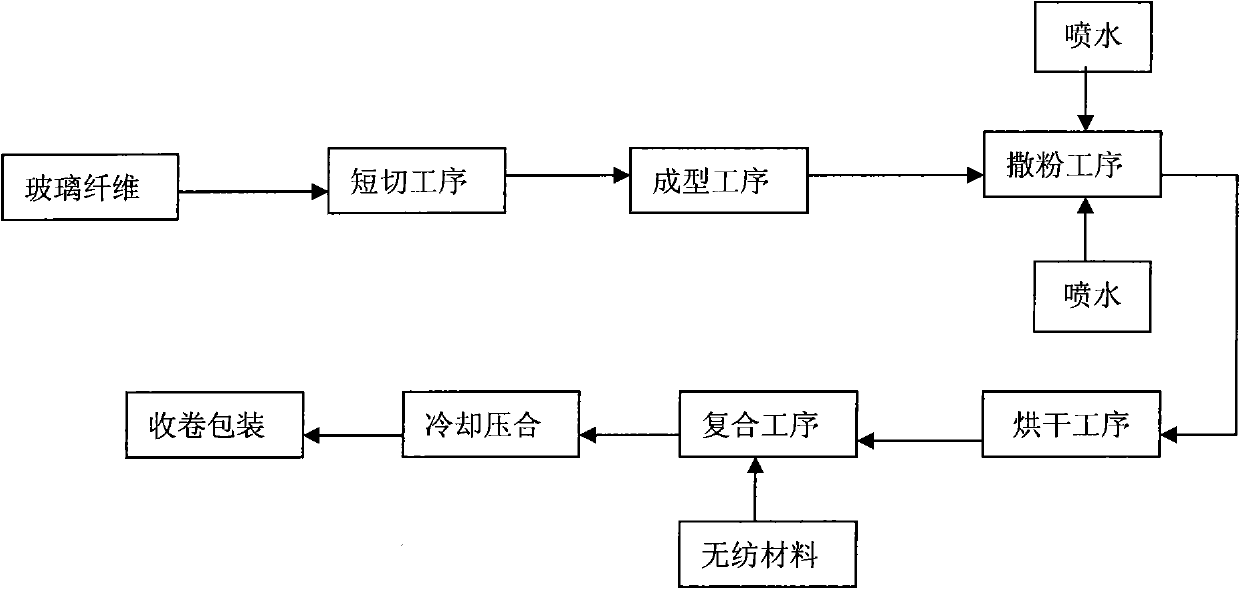

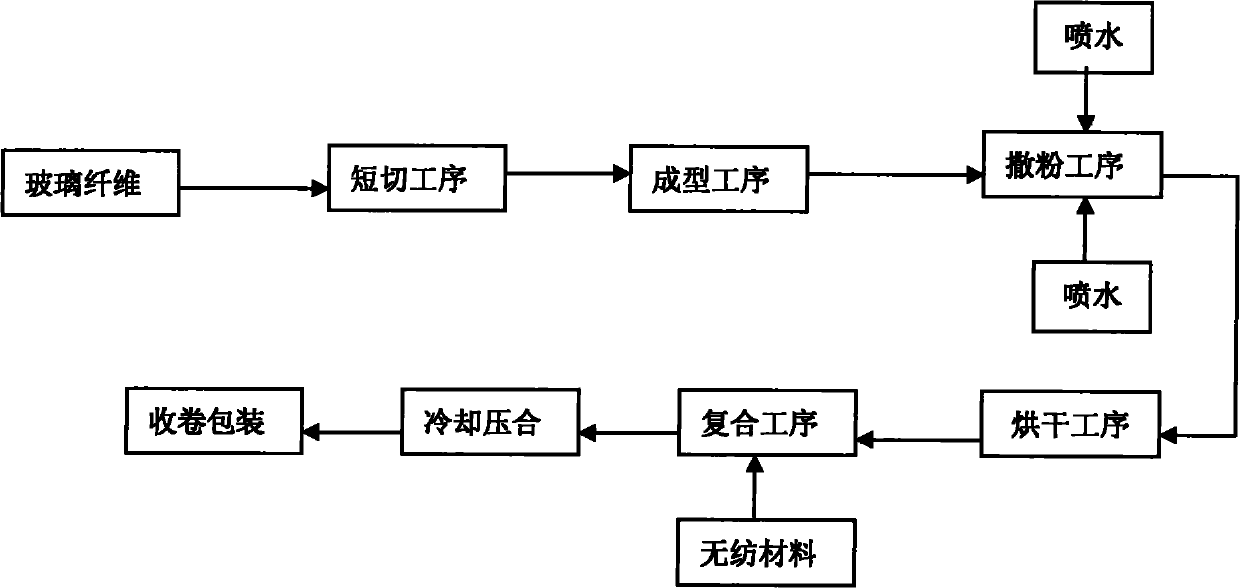

Method for preparing novel non-woven composite chopped strand mat

The invention relates to a method for preparing a novel non-woven composite chopped strand mat, which comprises the steps of: producing a non-woven composite material, producing a powder chopped strand mat and compositing the non-woven composite material with the chopped strand mat, wherein the first step comprises the procedures of uniformly coating high-viscosity thermoplastic emulsion on the surface of the non-woven material, and then drying and rolling; the second step comprises the procedures of chopping, forming, dusting and drying glass fiber; and the third step comprises the procedures of thermally pressing and compositing the non-woven composite material at a drying channel outlet of the chopped strand mat, controlling the hot-pressing temperature to be 120-180 DEG C and the thermally-pressing speed to be 3-5kgf / cm<2>, keeping thermal pressing for 5-10s, rapidly cooling, rolling and forming. The chopped strand mat prepared by using the method has smooth surface, tight gluing, does not generate arch cambers and wrinkles and shrinkage, is good in uniformity, and can directly enter a workshop for being thermally pressed on the roof, thus the working efficiency is improved and the cost is saved. Meanwhile, because multiple procedures of resin pasting and the like are reduced, the utilization rate is greatly improved and the secondary pollution is reduced.

Owner:JIANGSU CHANGHAI COMPOSITE MATERIALS CO LTD

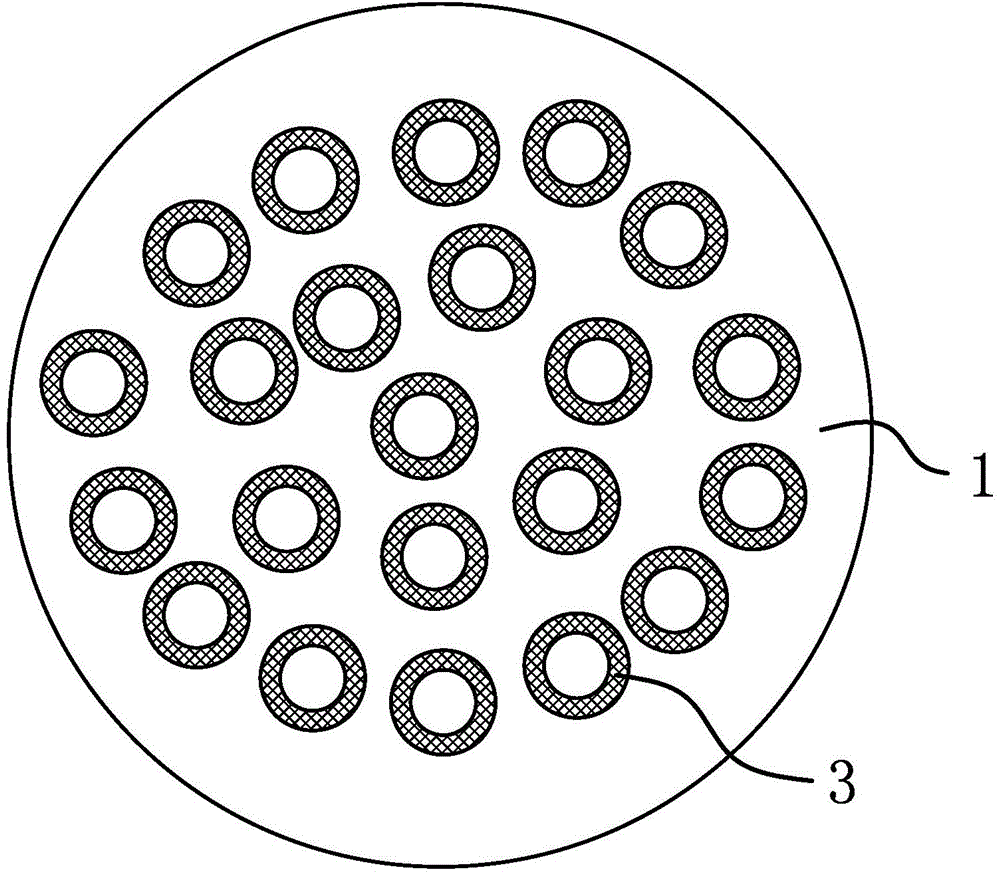

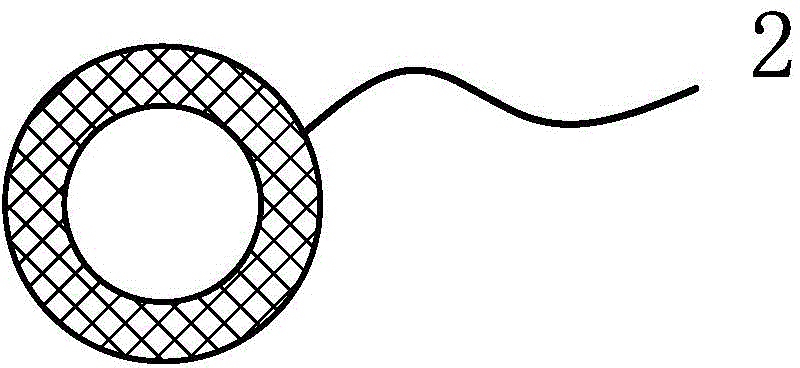

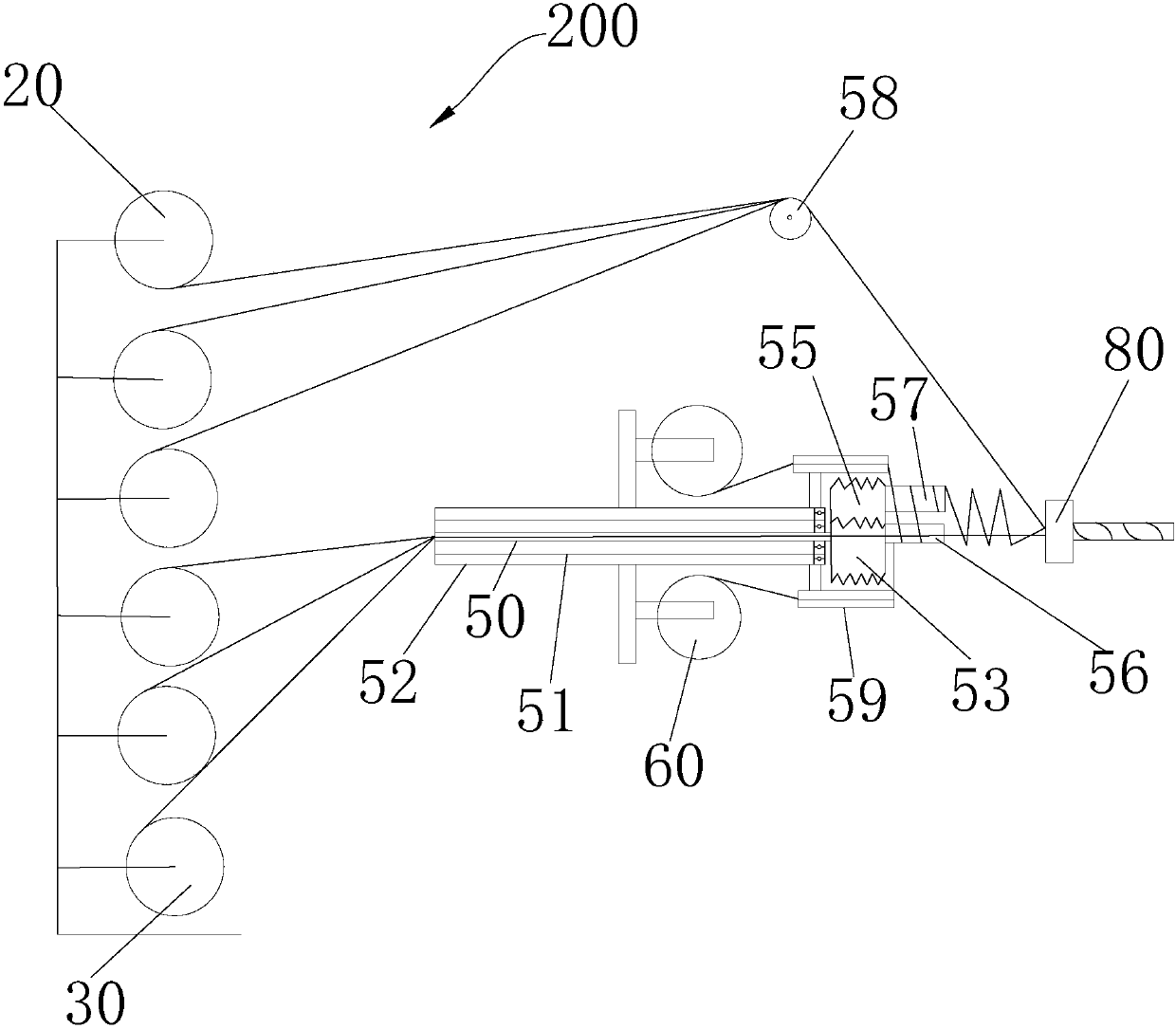

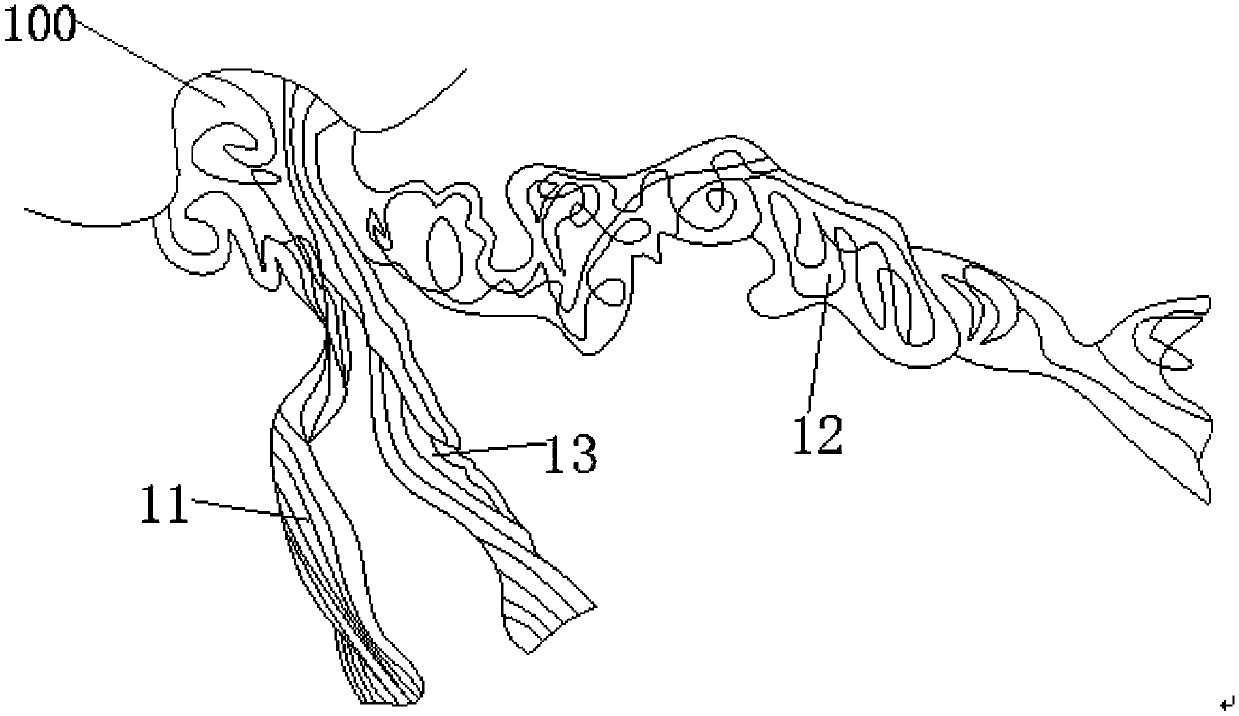

Production equipment of mussel attaching device

PendingCN107581113AGuaranteed not to fall offEasy to harvestClimate change adaptationPisciculture and aquariaYarnEngineering

The invention provides production equipment of a mussel attaching device. The equipment comprises a first set of yarn rollers, a second set of yarn rollers, a first rotating cylinder, a fixed cylinderwhich sleeves the first rotating cylinder, a second rotating cylinder which sleeves the fixing cylinder and synchronously rotates with the first rotating cylinder, a first gear fixed to the end of the first rotating cylinder, a spiral cylinder fixed to the end of the first gear, a second gear which is arranged above the first gear and is meshed with the first gear, a spiral rod fixed to the second gear, a third set of yarn rollers fixed outside the second rotating cylinder and a die head; a guide roller for guiding the yarns on the first set of yarn rollers to the die head is arranged on oneside of the first set of yarn rollers; the yarns of the second set of yarn rollers penetrates through the first rotating cylinder, the first gear and the spiral cylinder to the position of the die head; the end part of the second rotating cylinder is provided with a guide pipe for guiding the yarns on the third set of yarn rollers to the spiral cylinder and the spiral rod; and the spiral cylinderand the spiral rod are separately provided with a reverse thread groove. The mussel attaching device produced by the production equipment leaves attached spaces when the mussels grow mature, and prevents the mussels from falling off.

Owner:大连旅顺星汇绳网有限公司

Corrosion-resistant floor paint and preparation method thereof

InactiveCN110183912AHigh mechanical strengthGuaranteed not to fall offAnti-corrosive paintsPolyurea/polyurethane coatingsCross-linkActive agent

The invention discloses corrosion-resistant floor paint and a preparation method thereof, and belongs to the technical field of coatings. An adhesive for preparation can improve cohesive performance and adhesion strength and improve the bonding property between the floor paint and a wood floor, and then covalent crosslinking can be formed between the adhesive active agent and the floor, so that mechanical performance of the floor is improved, the floor paint can still be kept on the surface of the floor and does not fall off in a friction and wear process, and a protective layer is formed. Curing auxiliary resin for preparation enables the surface of the formed paint film to be smooth, and enable active components to be uniformly dispersed, so that cross-linking density of the floor paintis improved; F420 polyaspartic ester resin is added in a preparation process of the floor paint, so that ultraviolet aging resistance and wear resistance of the paint film are improved, durability ofthe paint film is improved, damage of the external environment to the paint film is reduced, and overall performance is improved. According to the invention, the problems of poor wear resistance and poor corrosion resistance of existing floor paint are solved.

Owner:陈卫国

Electrode conduction paster

InactiveCN103285508AEnsure close contactDoes not affect movementExternal electrodesStructural engineeringMetal sheet

The invention discloses an electrode conduction paster. The electrode conduction paster comprises non-woven cloth, a plurality of electrode plates, a plurality of flexible wires and a terminal junction box. The electrode conduction paster is characterized by further comprising a plurality of round copper sheets, wherein the round copper sheets are arranged among the electrode plates and the non-woven cloth and fixed on the non-woven cloth through the electrode plates; one ends of the flexible wires are welded in center holes of the round copper sheets, and the terminals of the flexible wires are integrated in the terminal junction box and connected with the signal output end of a physiotherapeutic instrument / therapeutic instrument through a line bank of the terminal junction box. The electrode conduction paster has the greatest advantage of enhancing tensile resistance of the flexible wires. Due to the fact that the flexible wires are welded on the round metal sheets, the tensile resistance of the flexible wires is greatly enhanced by virtue of the round metal sheets.

Owner:本然天地医疗科技(北京)有限公司

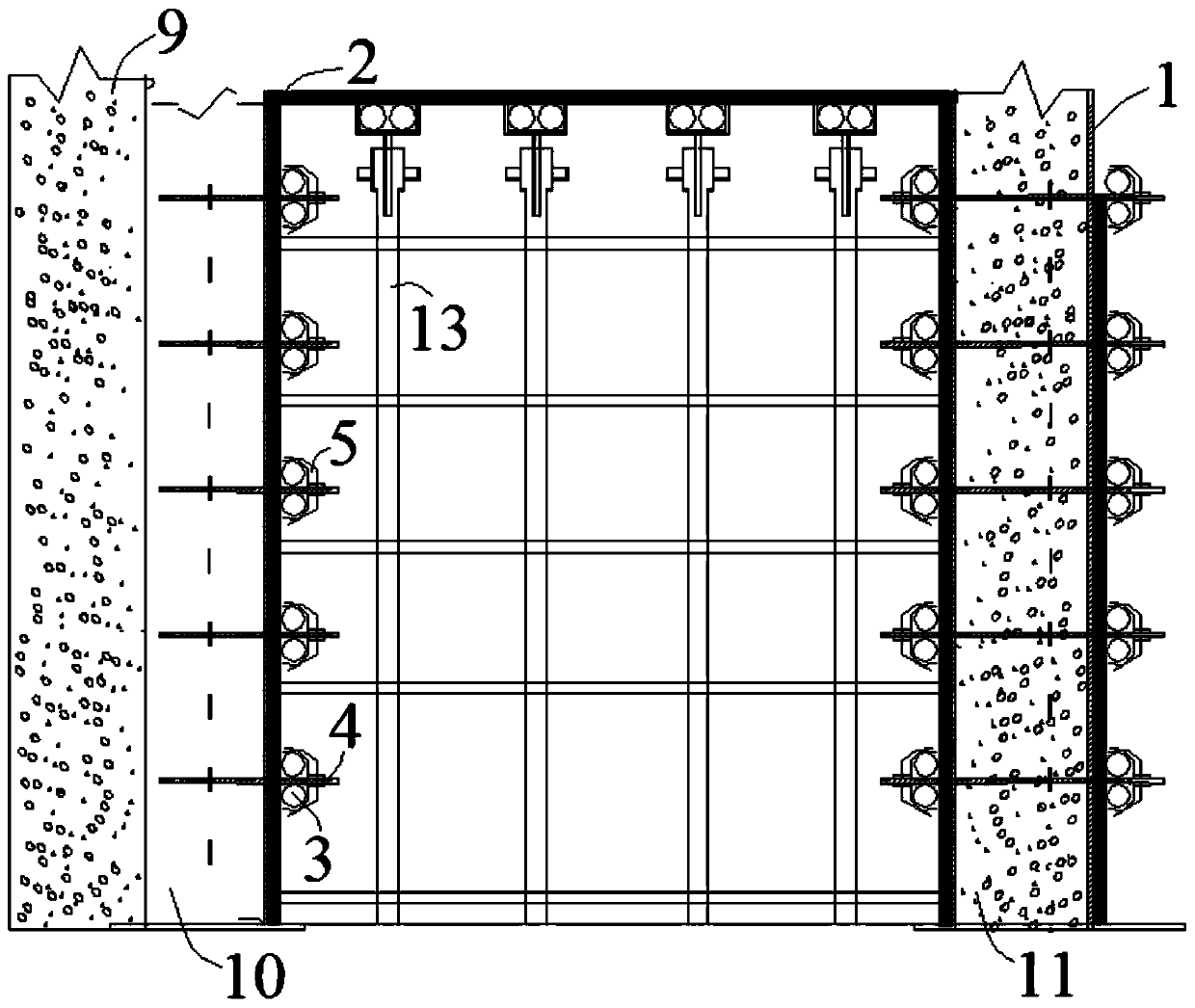

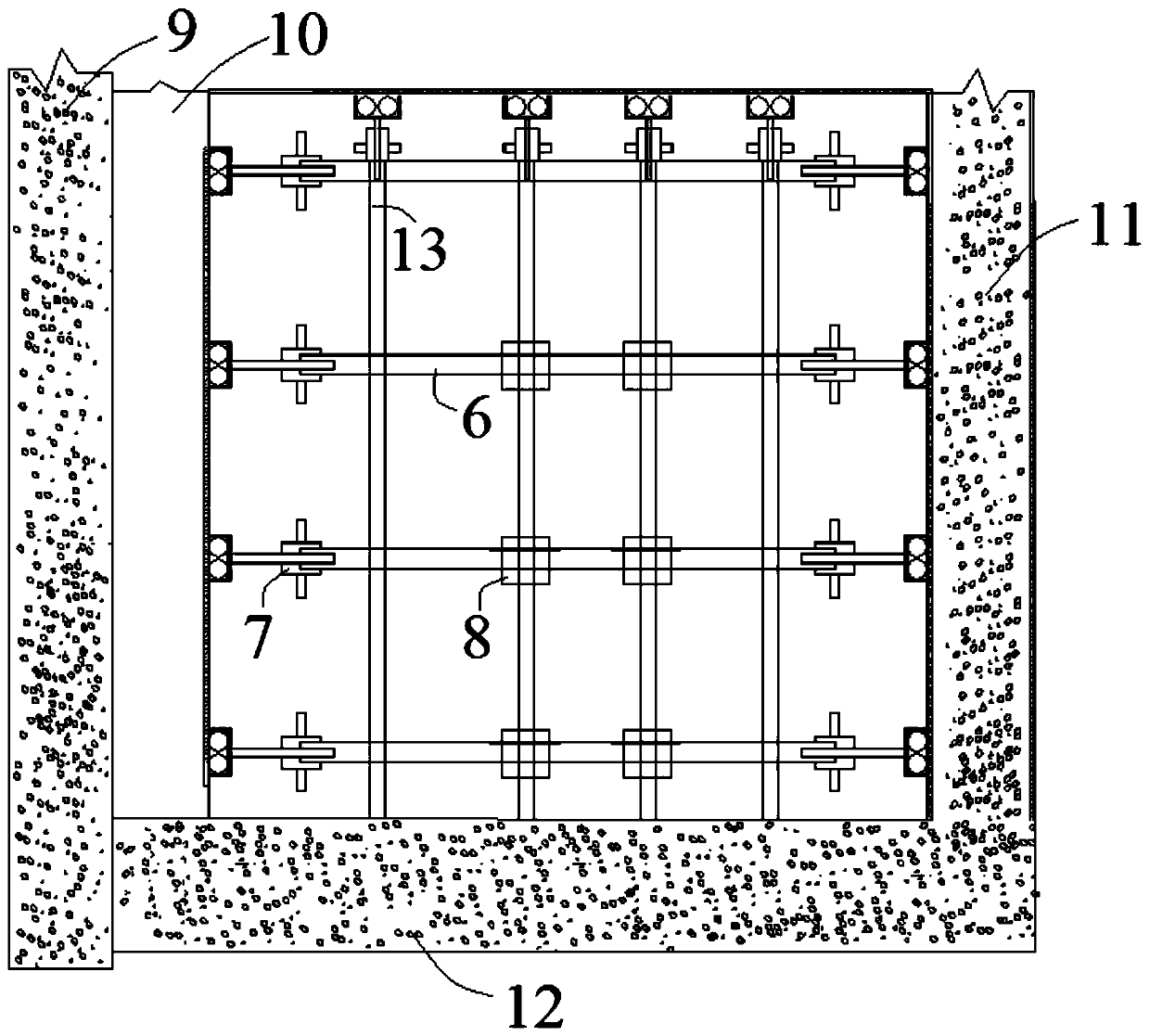

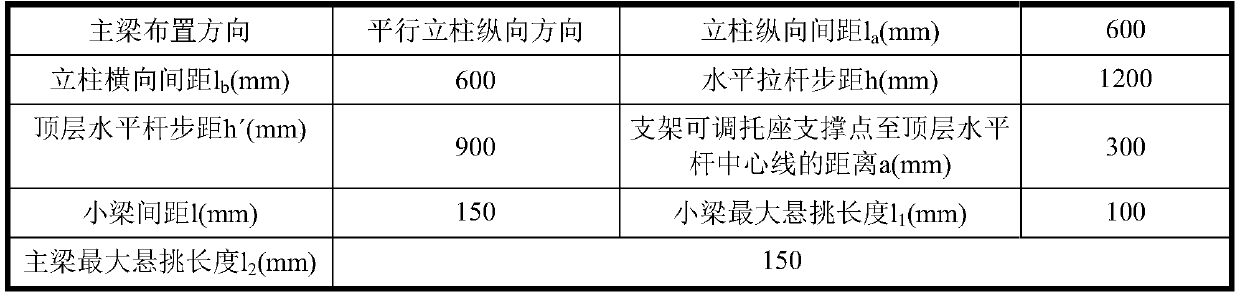

Internal supporting and reinforcing method for large-scale underground comprehensive pipe gallery wall plate without external mold

InactiveCN111364508ASimple structureEasy to buildArtificial islandsUnderwater structuresSupporting systemArchitectural engineering

The invention discloses an internal supporting and reinforcing method for a large-scale underground comprehensive pipe gallery wall plate without an external mold, and belongs to the field of buildingengineering. According to the supporting and reinforcing method provided by the invention, a bottom plate after the pipe gallery is formed is used as a foundation of an integral formwork supporting system, and when concrete of the bottom plate of the pipe gallery reaches 50% of the design strength, a socket plate buckle type steel pipe supporting system is used for erecting an inner supporting system of a formwork. A middle wall after the pipe gallery is formed is used as a foundation of a single-side formwork supporting system of an outer wall, when the concrete of an inner wall reaches 50%of design strength, a single-side formwork of the wall is reinforced by adopting a fastener type steel pipe system, and the fastener type steel pipe system consists of a fastening part and a supporting part. According to the supporting and reinforcing method disclosed by the invention, steel pipe materials are easy to obtain, the use is economic and reasonable, the construction cost can be reduced, the construction quality can be improved, the problem of reinforcing the underground comprehensive pipe gallery project wall plate without the external mold is solved, and the supporting and reinforcing method is safe, reliable and simple to apply.

Owner:CHINA MCC17 GRP

Industrial robot capable of adjusting gripper according to hardness degree of object

The invention relates to the technical field of industrial robots, and discloses an industrial robot capable of adjusting a gripper according to the hardness degree of an object. The industrial robotcomprises a cross beam, wherein clamping hands are movably arranged at the bottom of the cross beam, magnets are fixedly arranged inside the clamping hands, bolt openings are formed in the tops of theclamping hands, an air cylinder is fixedly arranged at the bottom of the cross beam, bolts are fixedly arranged at the bottom of the air cylinder, pressing pads are fixedly arranged at the bottoms ofthe clamping hands, and air bags are fixedly arranged inside the pressing pads. When a hydraulic cylinder extends out, due to the fact that the extending end of the hydraulic cylinder is made of a magnetic isolation material, the two clamping hands are prevented from being close to each other, and when the hydraulic cylinder is retracted, the clamping hands clamp the object, and after the clamping hands grasp the object, the air bags introduce air into the air cylinder, the air cylinder pushes out the bolts, the bolts enter the bolt openings, so that the object is prevented from falling off,and the effect that the object is prevented from falling off after being clamped is achieved.

Owner:广州钦丰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com