Method for preparing novel non-woven composite chopped strand mat

A chopped strand mat, a new type of technology, applied in the direction of textiles and papermaking, etc., can solve the problems of poor sticking effect, waste of working time, uneven sticking, etc., and achieve the effect of increased strength, tight fit and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

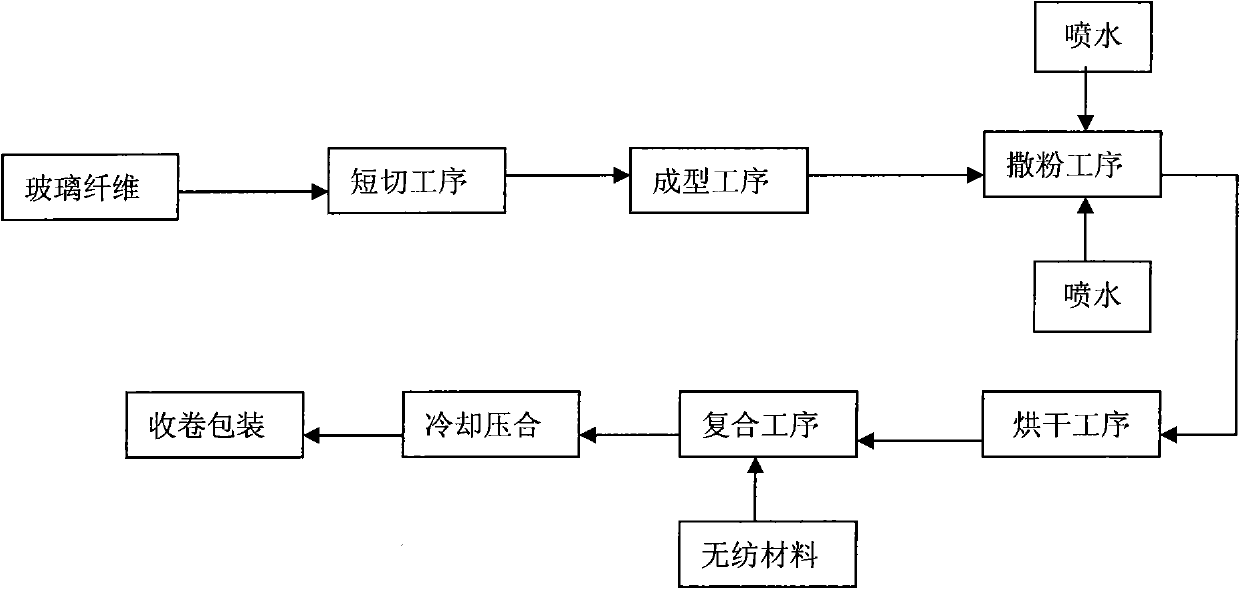

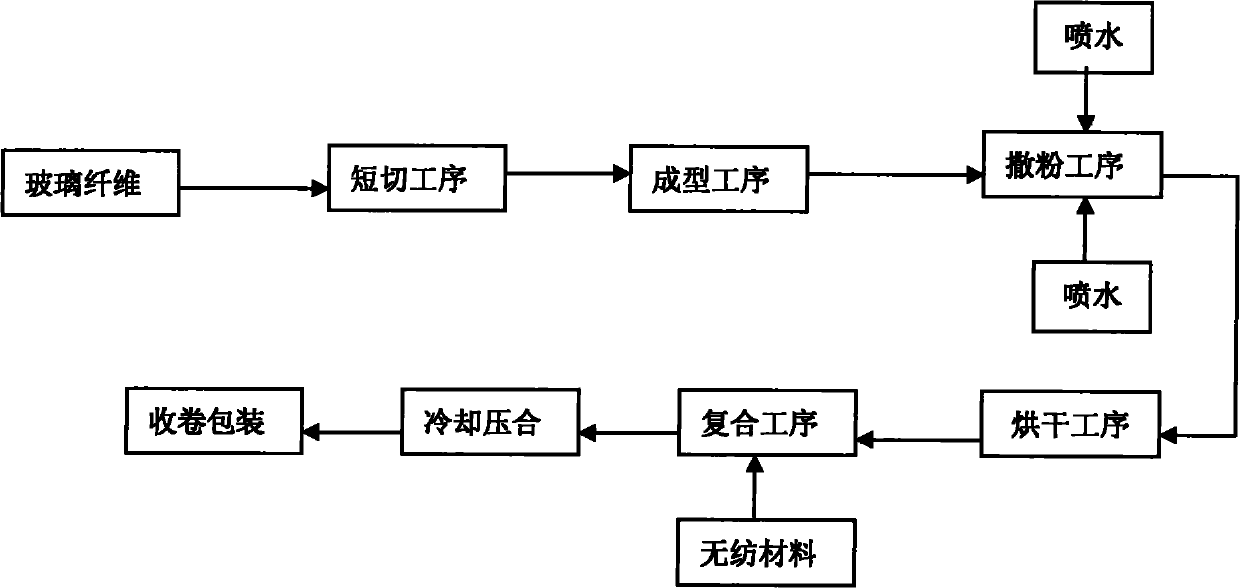

[0013] A kind of preparation method of novel non-woven composite chopped strand mat, carries out according to the following steps:

[0014] a) Production of non-woven composite materials

[0015] The polyvinyl chloride emulsion emulsified by the OP-1 emulsifier is used, and 0.5% of the total weight of polyvinyl alcohol and acrylic acid mixed thickener are added for mixing and stirring to prepare a high-viscosity viscous emulsion. Then apply the scraping technology, so that the thermoplastic emulsion is uniformly scraped on the surface of the non-woven material and the decorative paper material, and then dried and rolled to form a composite non-woven material and decorative paper material. Among them, the thickness of emulsion scrape coating is 3 or 5 or 7 or 8g / m 2 ;

[0016] Technical indicators of thermoplastic emulsion: solid content: ≥36%; PVC content: ≥97%; use viscosity: 3000-5000mpaS; emulsion secondary melting point: 100-180℃.

[0017] b) Powder chopped strand mat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com