Flexible cable driving unit

A driving unit and flexible cable drive technology, which is applied in sports accessories, muscle training equipment, gymnastic equipment, etc., can solve the problems of large friction loss of the driving flexible cable, easy oscillation and falling off of the flexible cable, and achieve small transmission damping of the flexible cable, The effect of expanding the scope of work and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

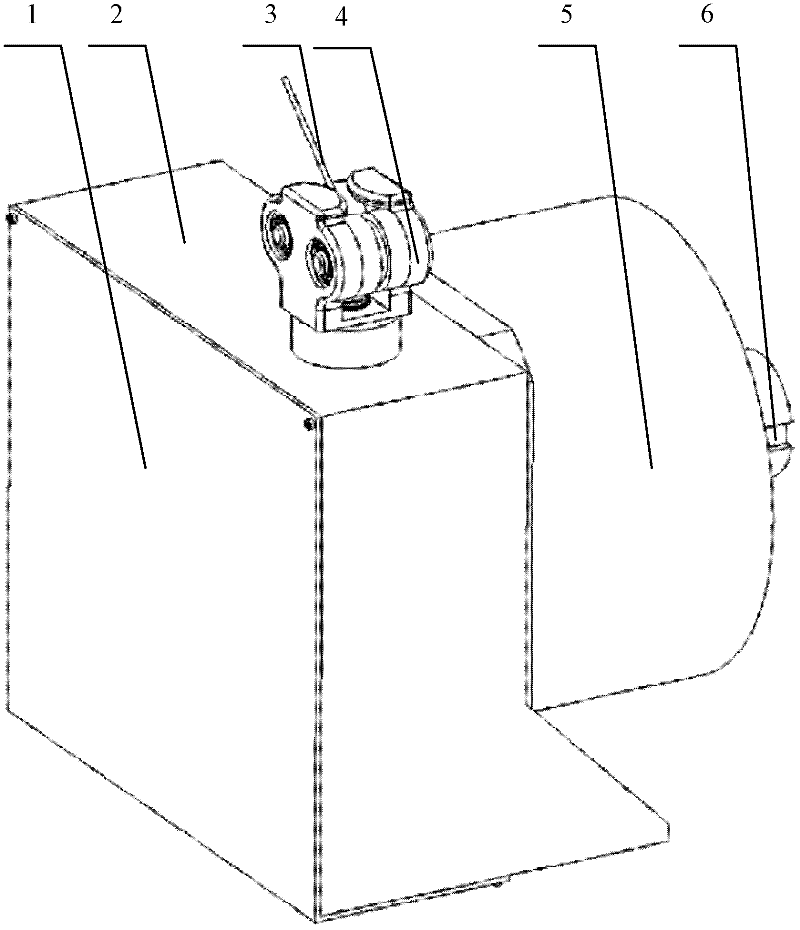

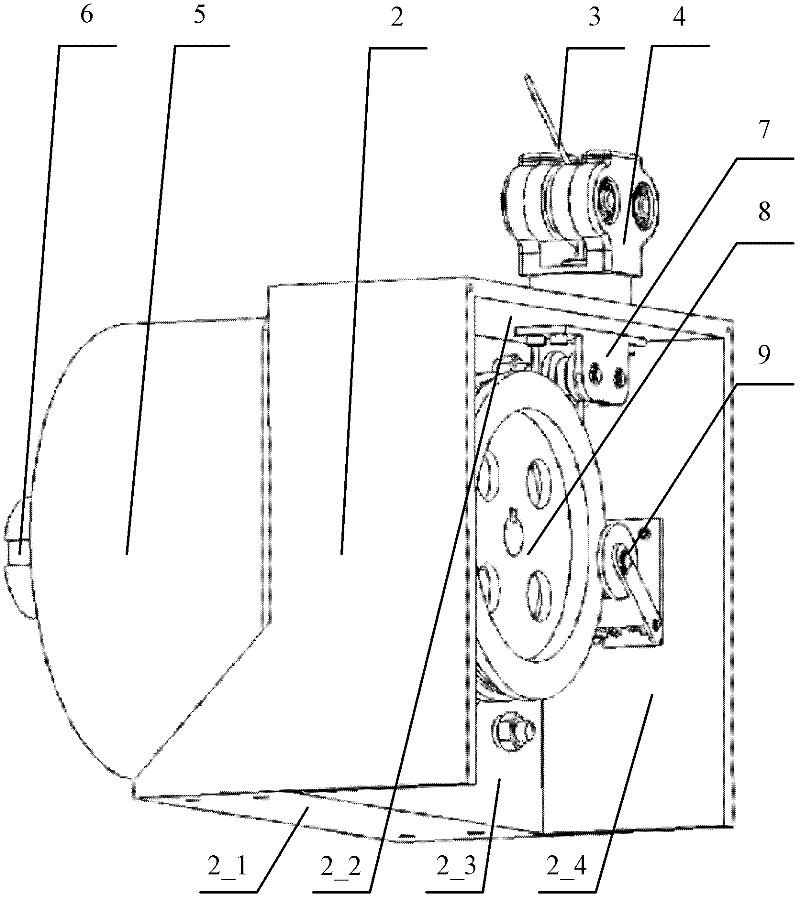

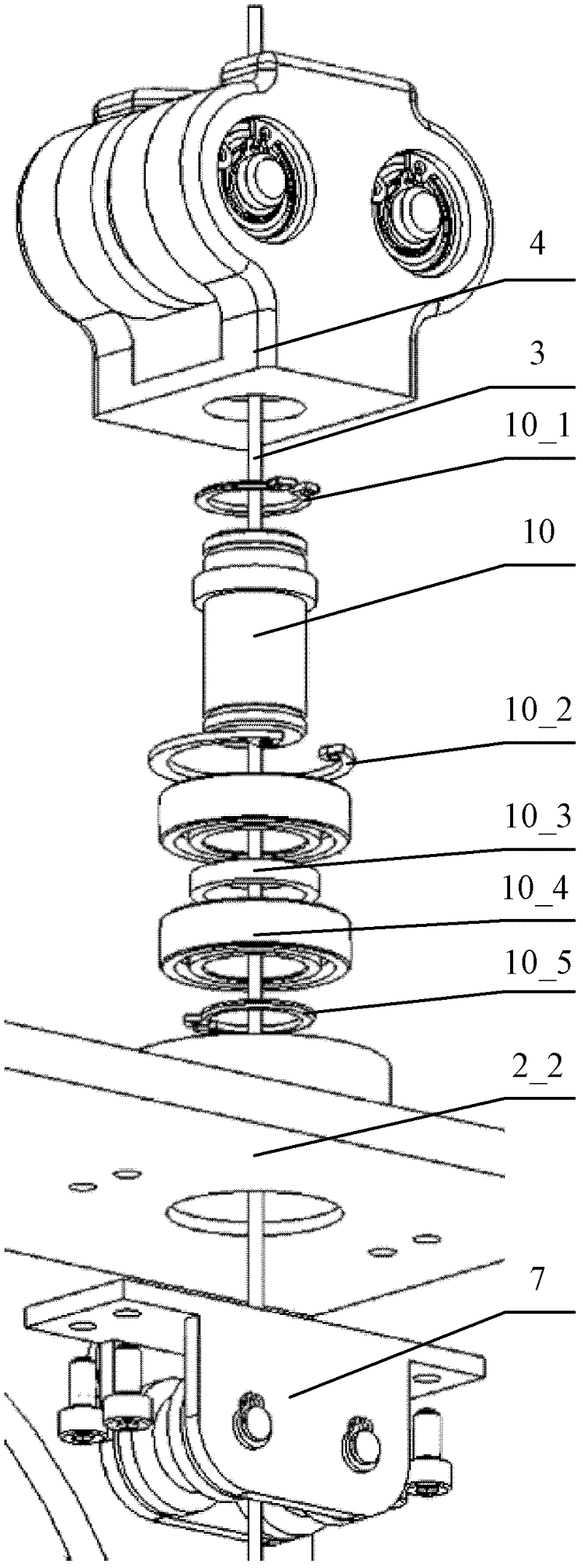

[0024] combine Figures 1 to 6 , the overall assembly diagram of the flexible cable driving unit of the present invention is as follows figure 1 As shown, the internal assembly diagram of the flexible cable drive unit is shown in figure 2 As shown: the flexible cable drive unit consists of drive unit protective cover 1, drive unit bracket 2, flexible cable 3, turnover flexible cable guide device 4, permanent magnet DC torque motor 5, photoelectric encoder 6, fixed flexible cable guide device 7, flexible cable Cable pulley 8, anti-loosening damping device 9 and guide shaft 10 form. Described drive unit bracket 2 is made up of drive unit fixed frame 2_1, guide device fixed frame 2_2, motor fixed frame 2_3 and drive unit side wall 2_4 four parts.

[0025] The assembly between the revolving cable guide 4, the fixed cable guide 7, the guide shaft 10 and the guide f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com