Patents

Literature

357 results about "Permanent magnet direct current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

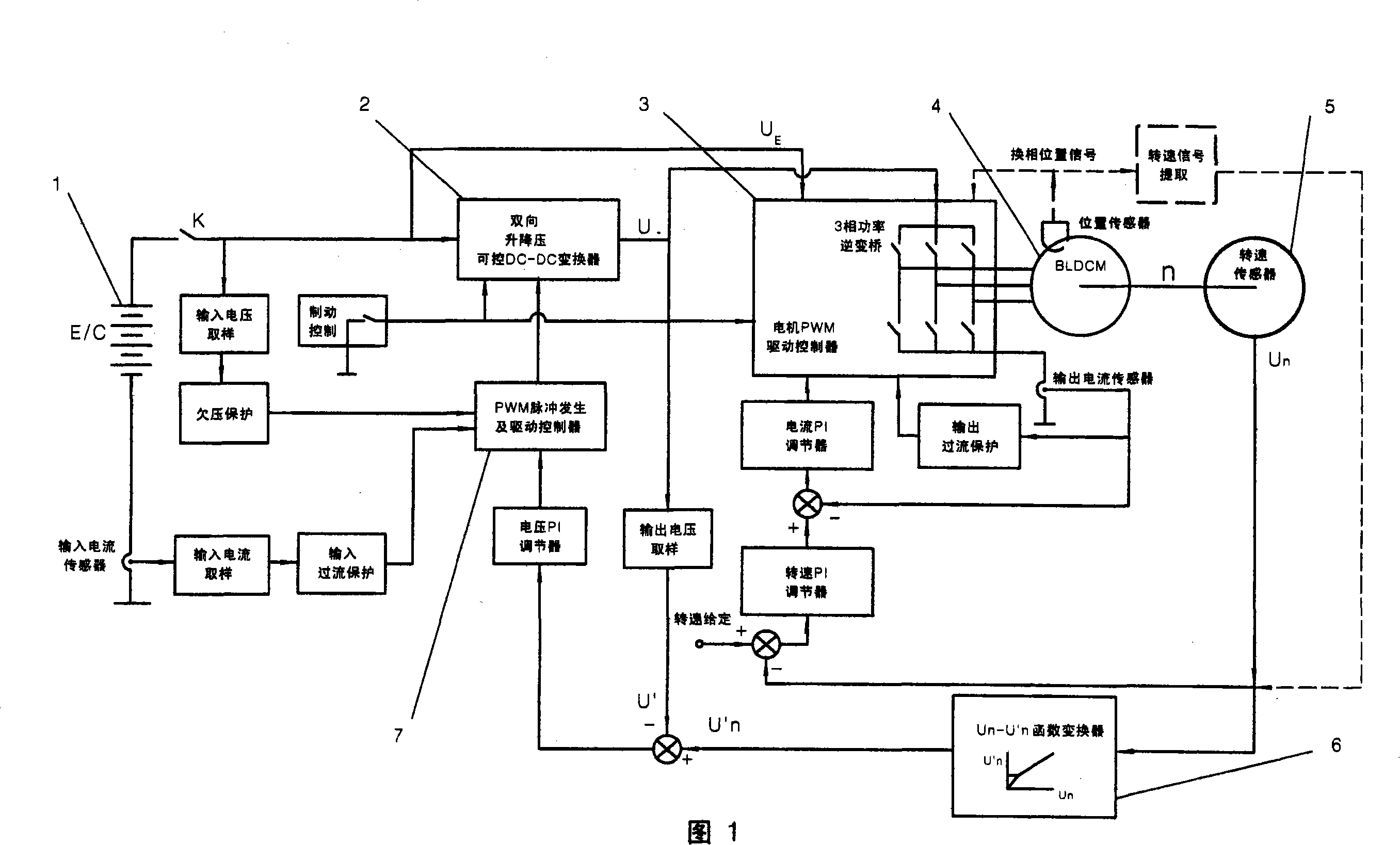

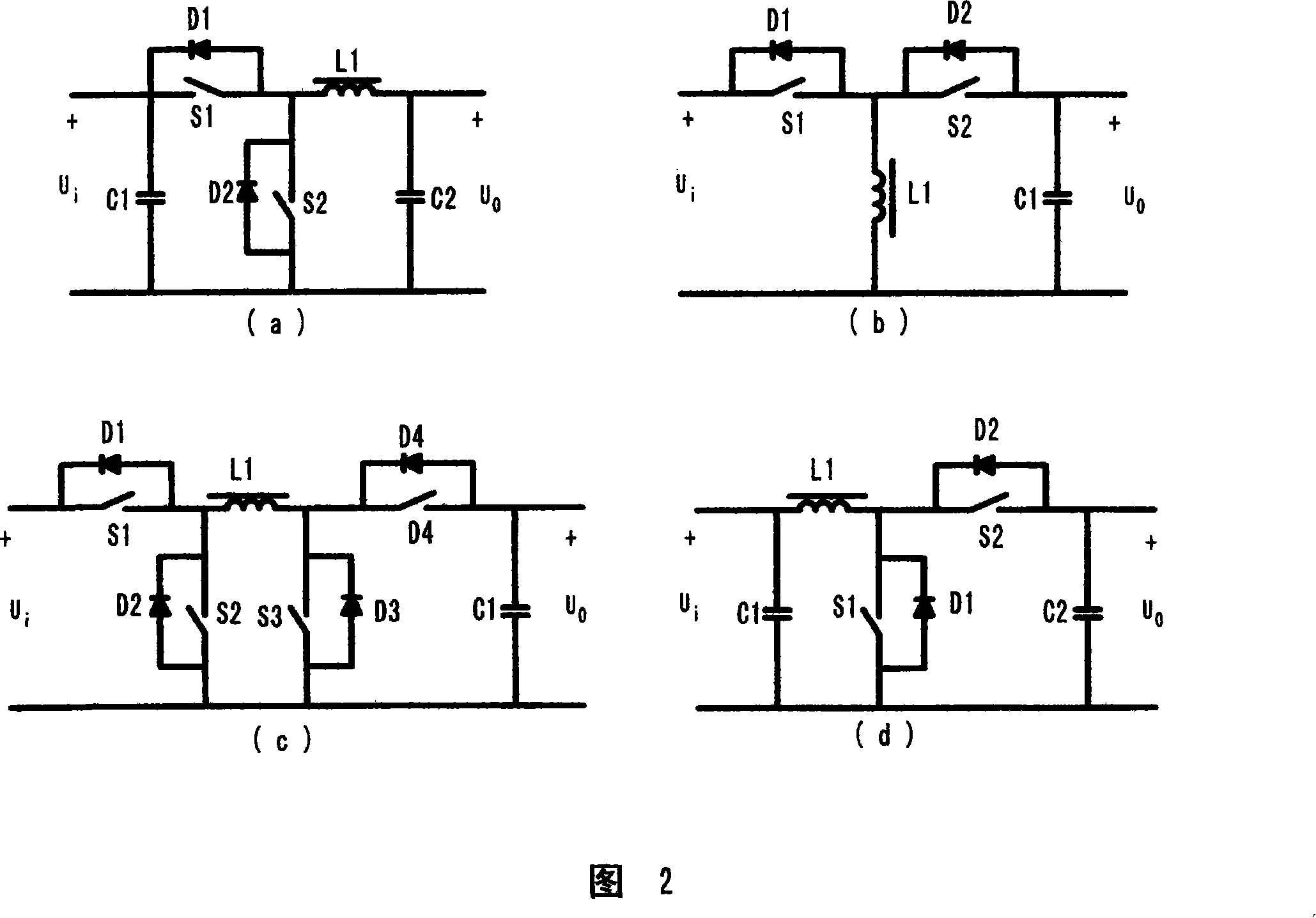

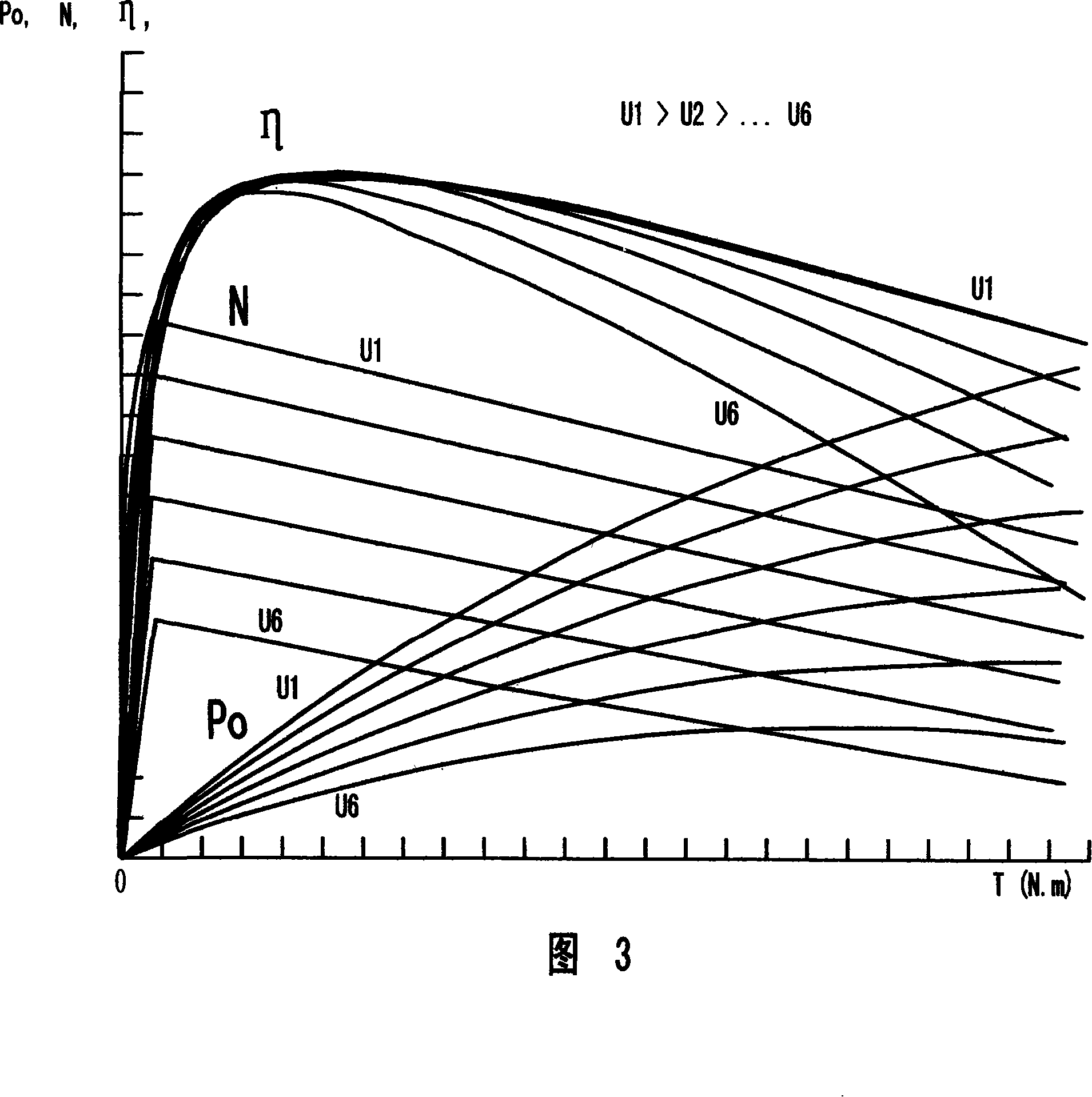

Permanent-magnet DC motor drive control system with approximate constant power pulling motor characteristics

InactiveCN101159422AIncreased complexityIncrease manufacturing costSingle motor speed/torque controlMechanical energy handlingCapacitanceBrushless motors

A permanent-magnetic DC motor bearing similar characteristics with the constant power pulling motor, in particular a new drive control system for brushless motor adopts new technologies of full electronic drive control and DC-DC transducer. The motor can generate great drive torque, i.e. high tractive force, climbing ability and better acceleration performance with low power consumption, and eliminate the needs for improvement to the motor structure, complication, high manufacture cost or weak magnetic control; the motor may further gain such performance as high speed, wide speed regulation and infinite variable speed under light load; the total voltage of the battery and the number of single series of connection can be reduced; controllable electric brake can be realized through fully utilizing the energy feedback during sliding and braking. The new system can significantly improve the kinetic performance, safety and reliability of electric vehicles and remarkably reduce operating costs, with ideal characteristics expected in various electric vehicles powered by rechargeable battery or / and super capacitance as well as significantly expanded work scope and capacity for conventional electrically driven system.

Owner:李平 +1

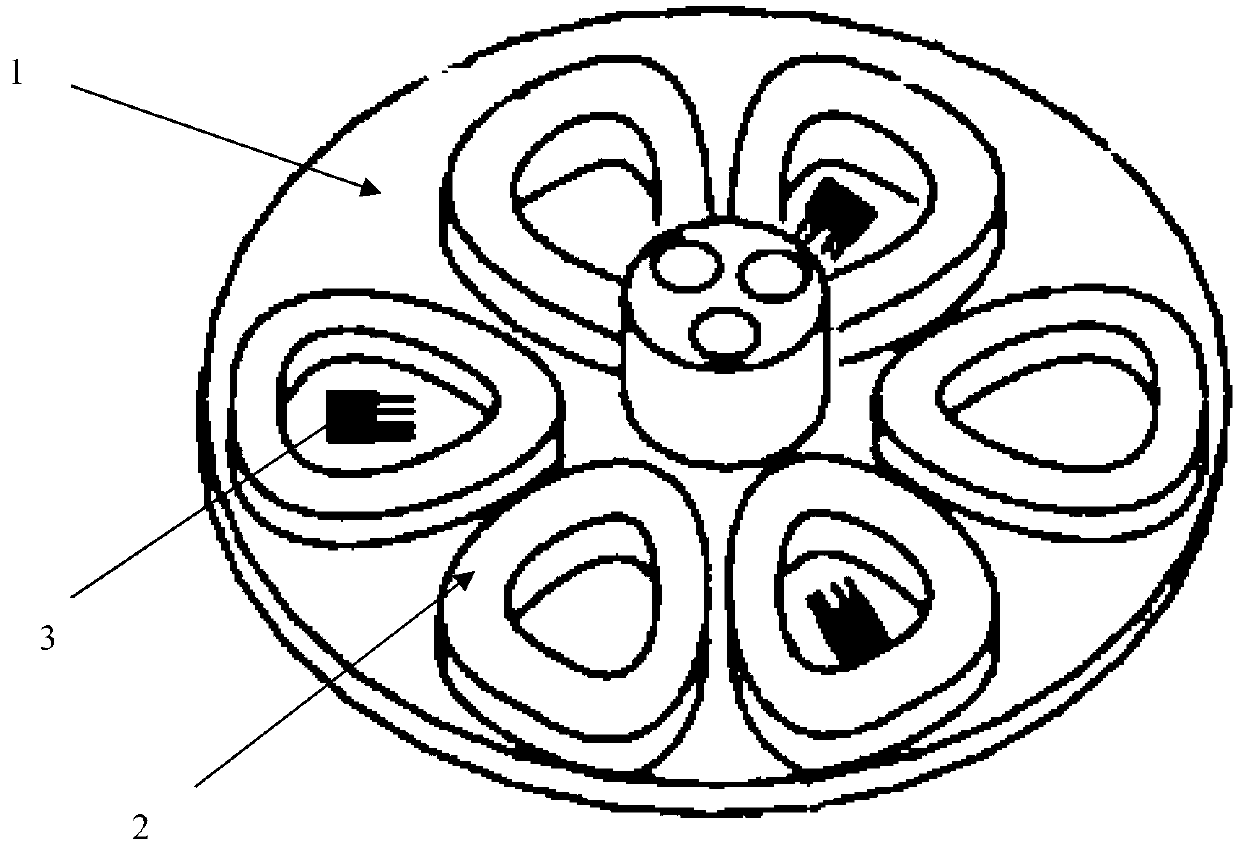

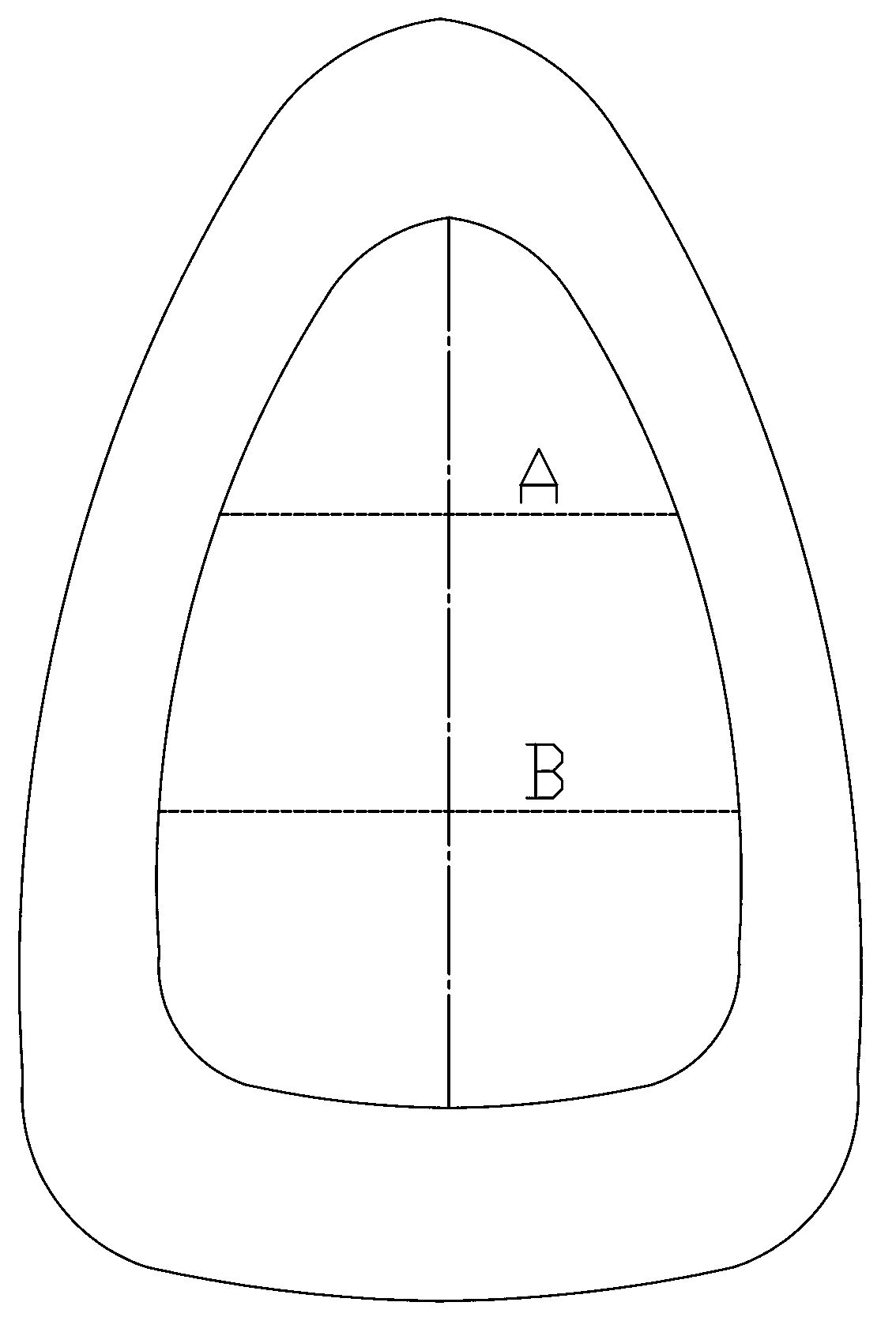

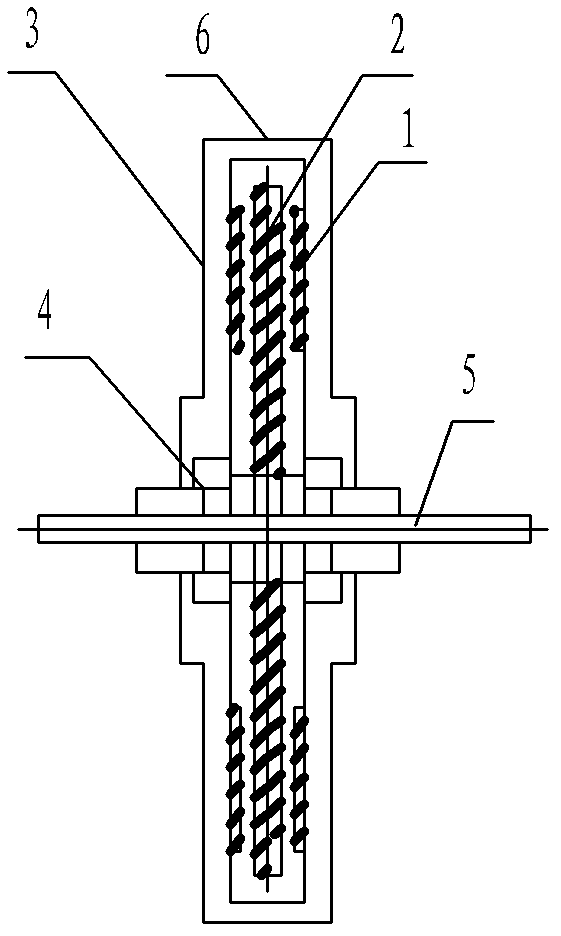

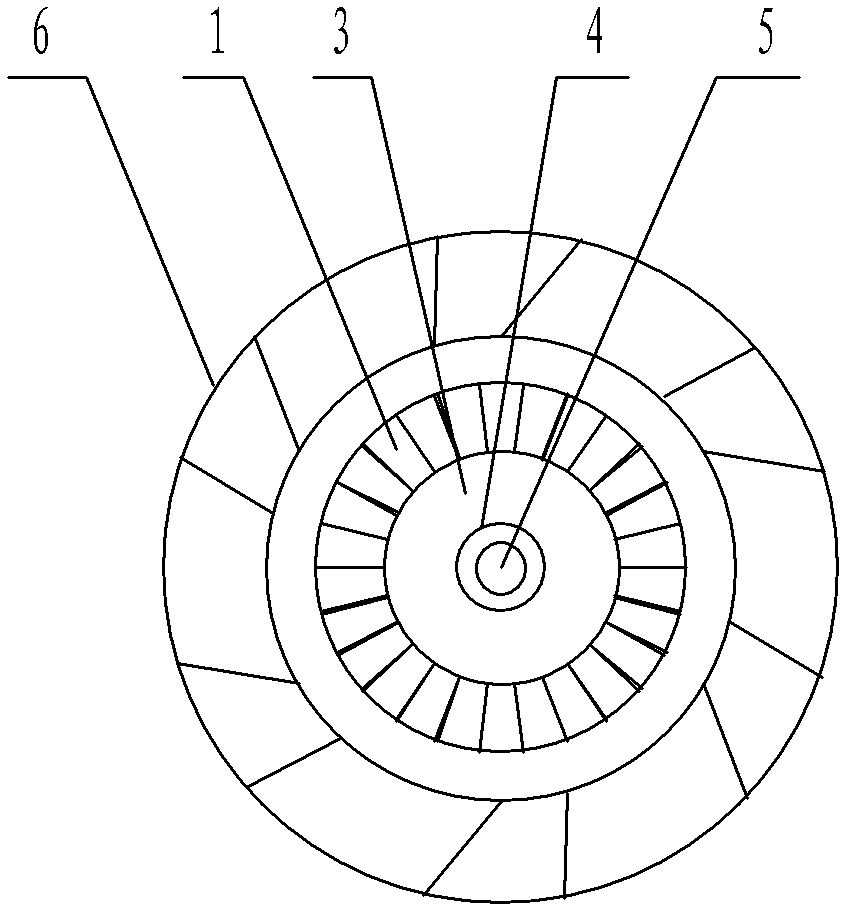

Disc type iron-core-free permanent magnet direct current (PMDC) motor

InactiveCN103124128AAxial dimension shortCompact structureSynchronous machines with stationary armatures and rotating magnetsWindings conductor shape/form/constructionElectricityElectric machine

The invention relates to a disc type iron-core-free PMDC motor. The disc type iron-core-free PMDC motor comprises a middle stator and rotors which are installed on a spindle and in disc shapes, disc surfaces are arranged parallelly and correspondingly, gap flux densities on two sides of the stator are the same, the stator comprises an iron-core-free rolled annular winding which is placed axially, and a magnetic line of force passes gaps and the winding axially; and each rotor is a disc composed of a magnetic conducting disc for accommodating magnetic steel and an aluminum case, a permanent magnet is bonded on the magnetic conducting disc in an N and S alternating mode, and polarities of magnetic steel corresponding to the rotors up and down are opposite. The disc type iron-core-free PMDC motor is characterized in that the annular winding is an axial symmetry conical ring composed of a plurality of sections of arcs, the central axis points to the axis of the stator, and the tip of the conical ring is close to the axis of the stator. The magneto-electricity conversion efficiency of the motor is improved by above 10%.

Owner:浙江义阳光电科技有限公司

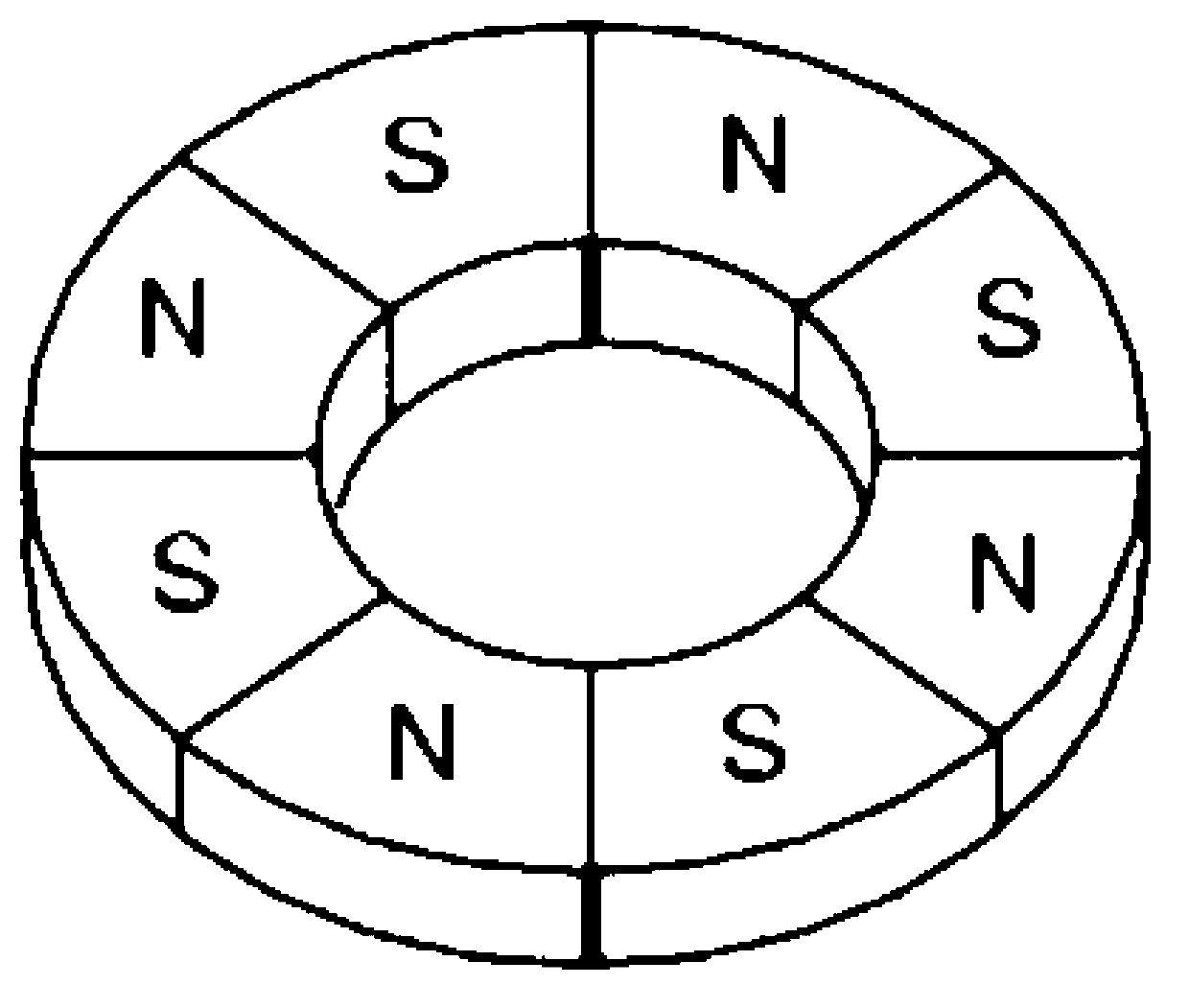

Method of magnetizing a ring-shaped magnet

InactiveUS6080352AAvoid missingLow costOther chemical processesInorganic material magnetismDetentMagnetization

A brushless permanent-magnet direct current motor has a permanent magnet which is magnetized to create an offset angle between detent and mutual torques for providing sufficient starting torque for all relative orientations between the stator and the rotor of the motor. This is accomplished by providing a permanent magnet in which the global magnetization of the magnet has been disrupted by the application of a local magnetic field to a portion of the magnet, thereby to provide a magnetic anomaly in the global magnetization. Also, a method of magnetization of the magnet is described.

Owner:SEAGATE TECH LLC

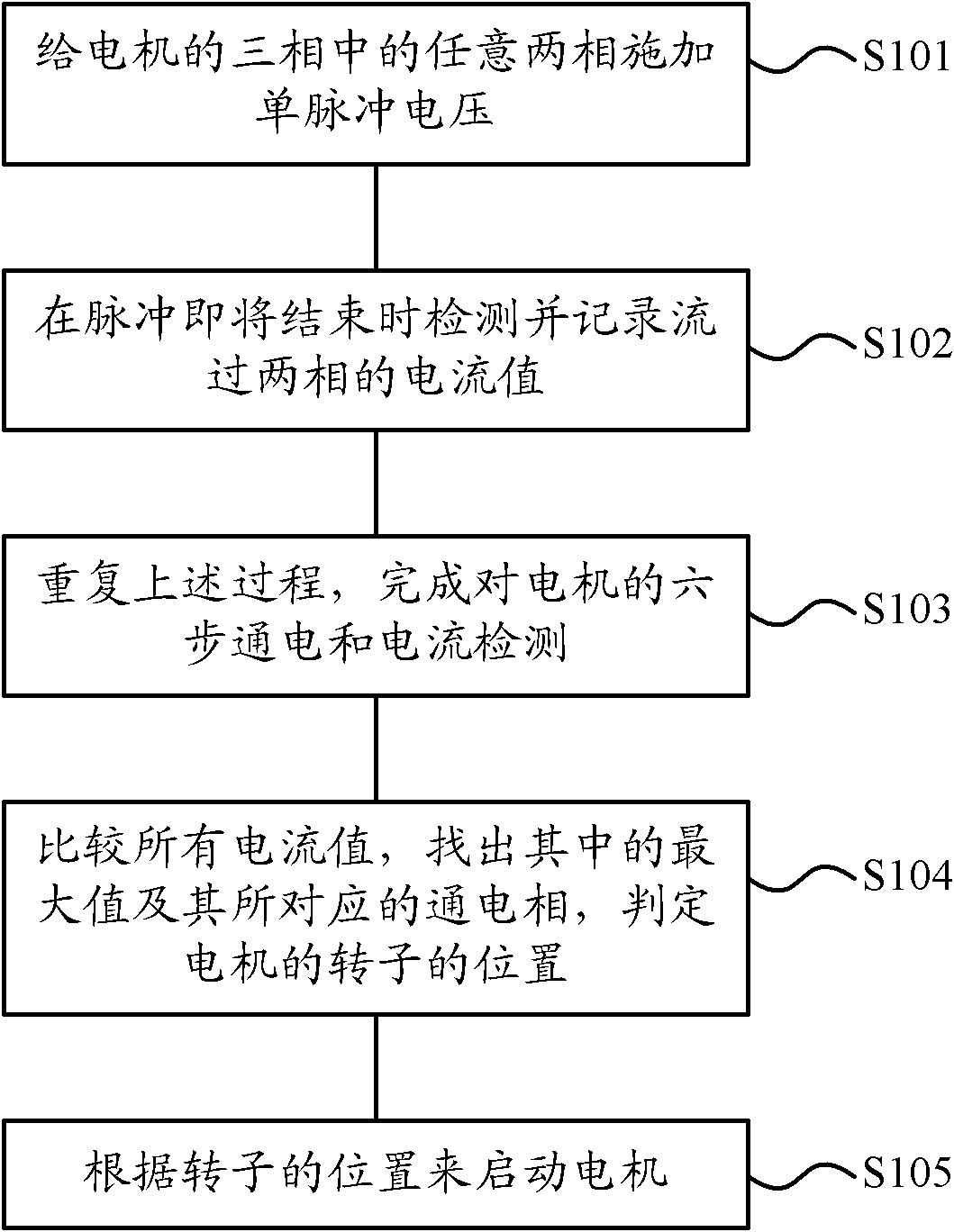

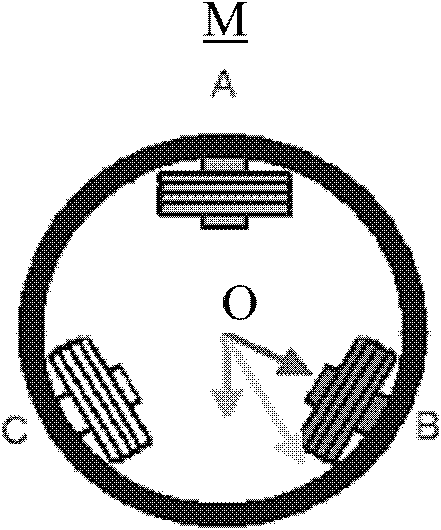

Startup method and startup device of permanent magnet direct current brushless hall-less motor

InactiveCN101977001ASmooth and reliable start-up processEasy to implementStarter arrangementsElectric machineThree-phase

The invention provides a startup method of a permanent magnet direct current brushless hall-less motor, which comprises the following steps of: applying single-pulse voltage on any two phases of three phases of the motor; detecting and recording the value of the current passing through the two phases when the pulse is about to end; repeating the previous process to finish six-step energization and current detection of the motor; comparing all current values, finding out the maximal value and a corresponding energization phase, and judging the position of a rotor of the motor; and starting the motor according to the position of the rotor. Correspondingly, the invention also provides a startup device of the permanent magnet direct current brushless hall-less motor. By using the startup method and the startup device, forcible positioning is not necessary when determining the position of the rotor before the motor is started, the application range of the motor is not influenced, the motor is not impacted when started, and the starting process is smooth and reliable. Besides, the motor is powered on and detected based on the current condition without extra hardware resources, the startup method and the startup device are simple to implement and have low cost, and the starting speed of the motor is quick.

Owner:SINO WEALTH ELECTRONICS

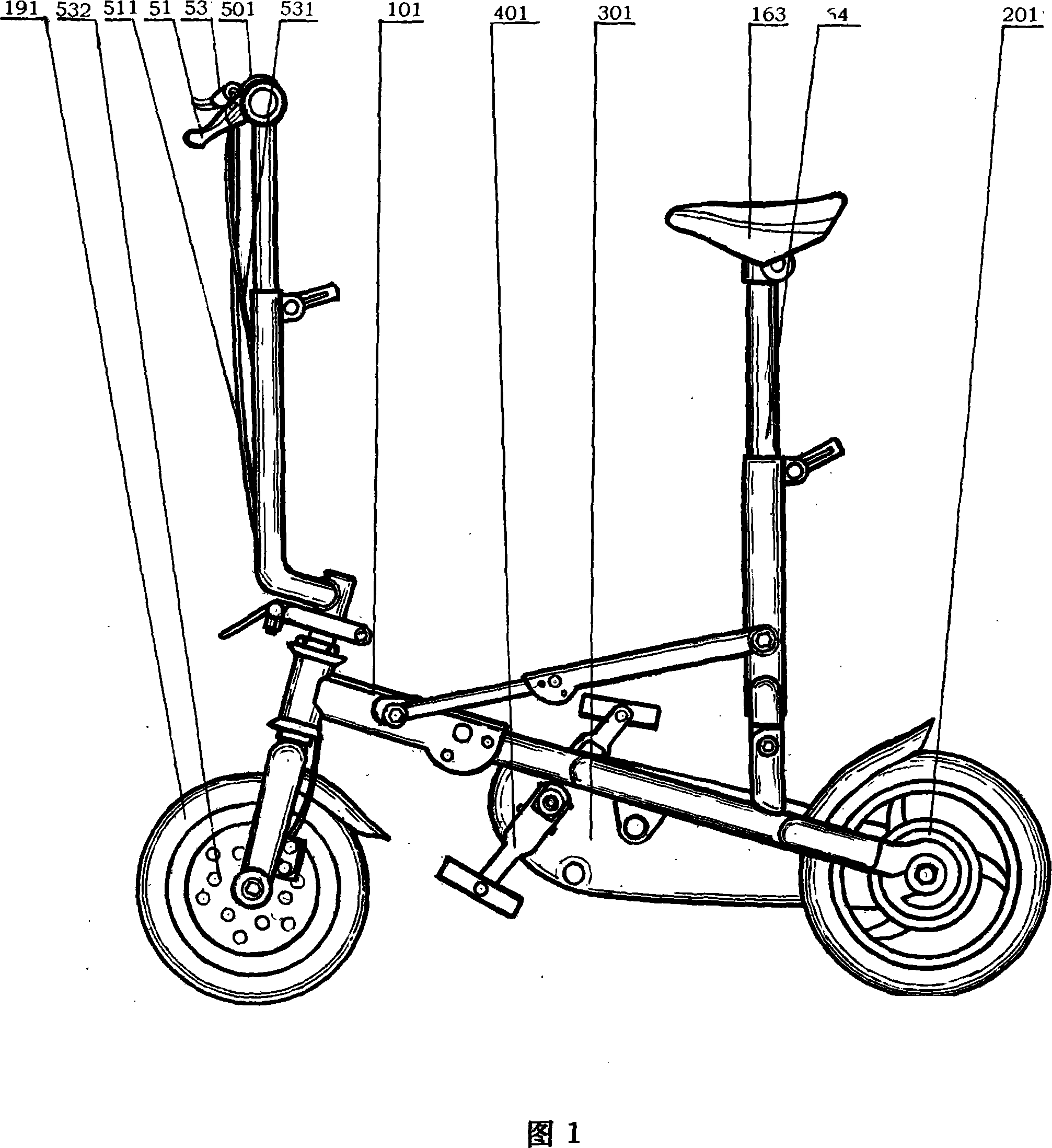

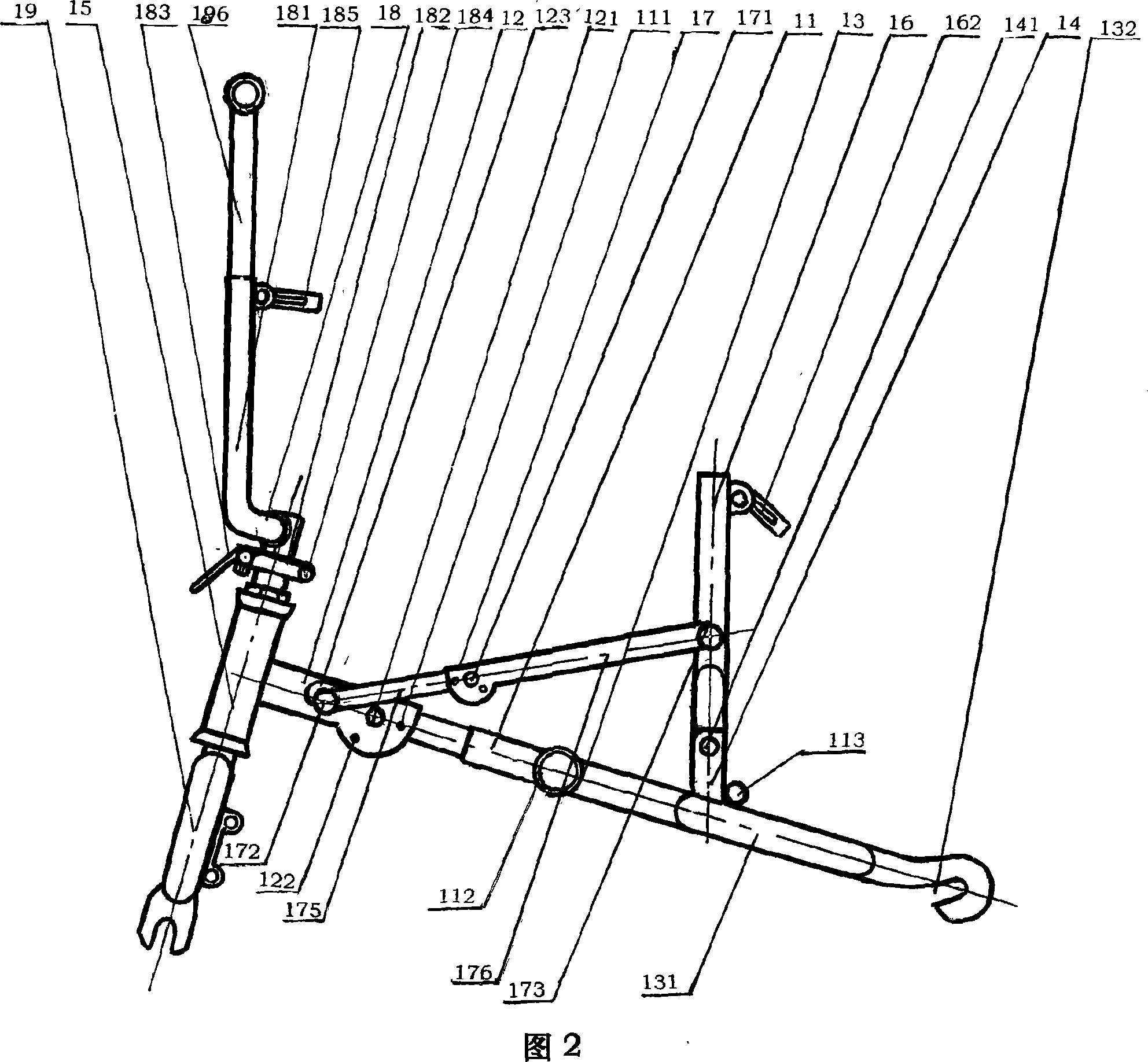

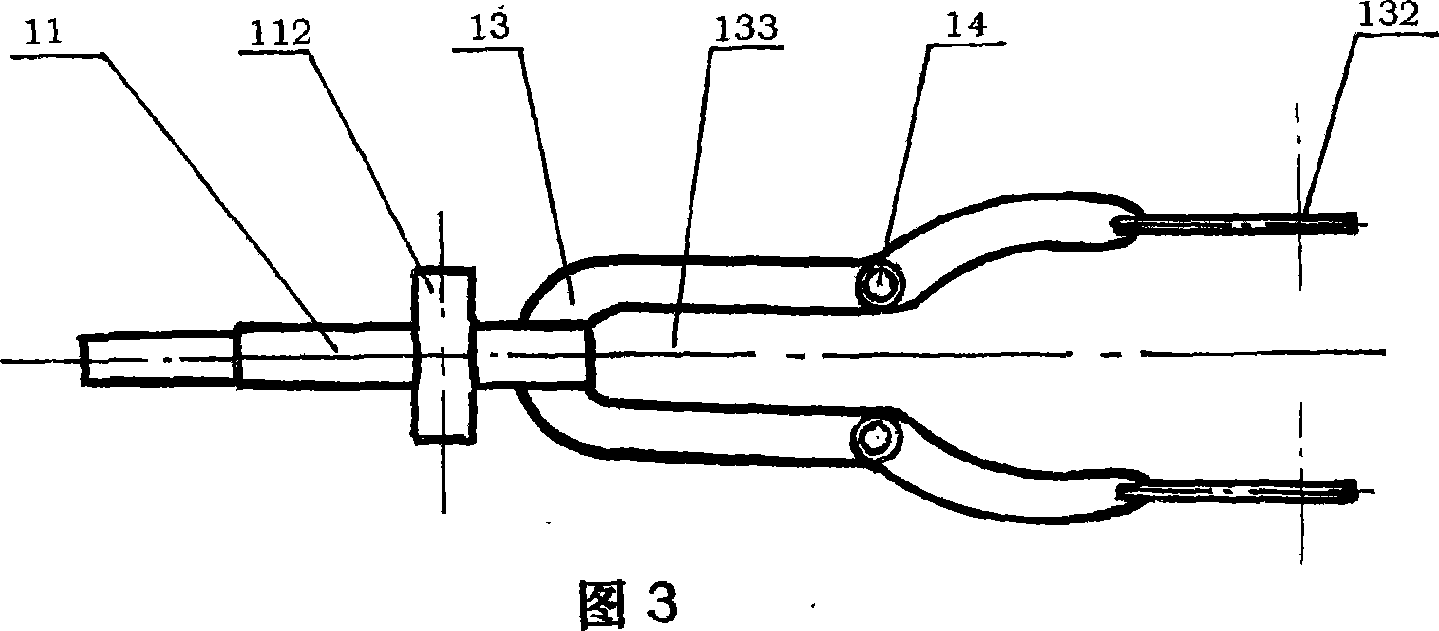

Portable mini electric bicycle

InactiveCN101032990ALess materialSmall folding areaElectric propulsion mountingFoldable cyclesElectronic controllerDrive wheel

The portable mini electric bicycle consists of one inner rotating embedded foldable frame, light energy saving electric hubs, one mixed tooth-chain driving mechanism, one turnable crank and one control system with hidden string. The inner rotating embedded foldable frame consists of main beam, folding frame with T-joint, forked beam, front fork, U-shaped combined handlebar, seat beam on the vertical beam and bracing boom; the light energy saving electric hub consists of disk type permanent magnetic DC motor, bearing cover plate, internal gear and driving wheel; the mixed tooth-chain driving mechanism consists of main gear, flywheel, middle gear and protecting cover; the turnable crank consists of crank seat, turnable crank and resetting spring mechanism and the control system consists of control compartment, accumulator, electronic controller, speed regulating handle, braking handle, power cord and braking thread.

Owner:GUOKE WEIMABEIJING TECH

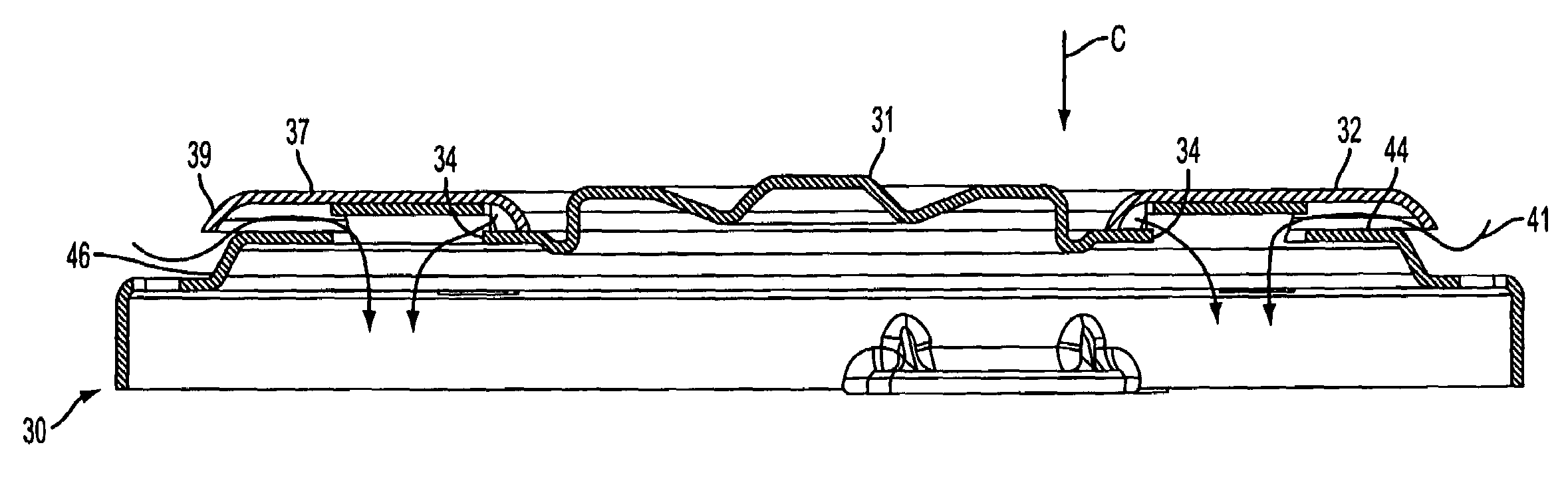

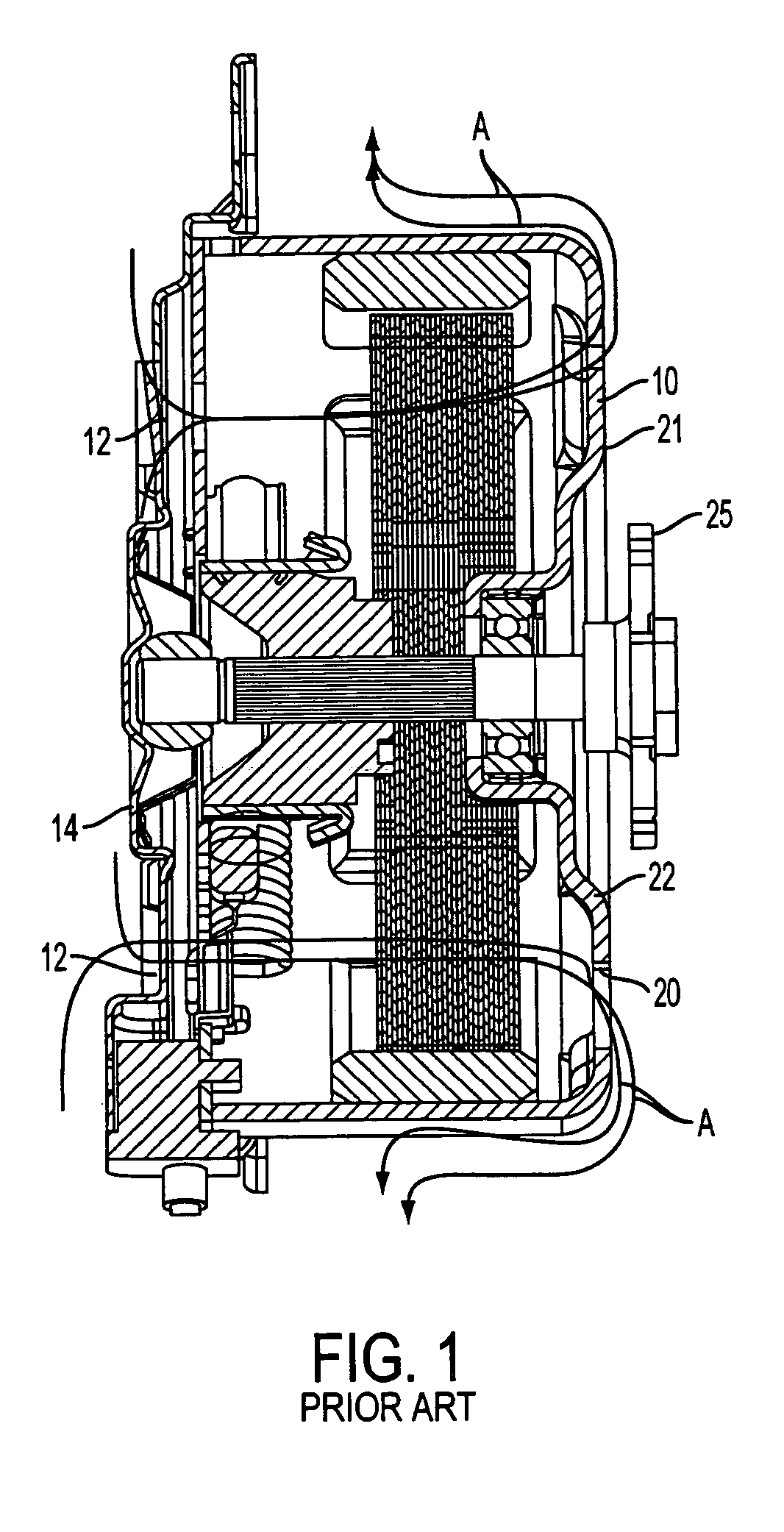

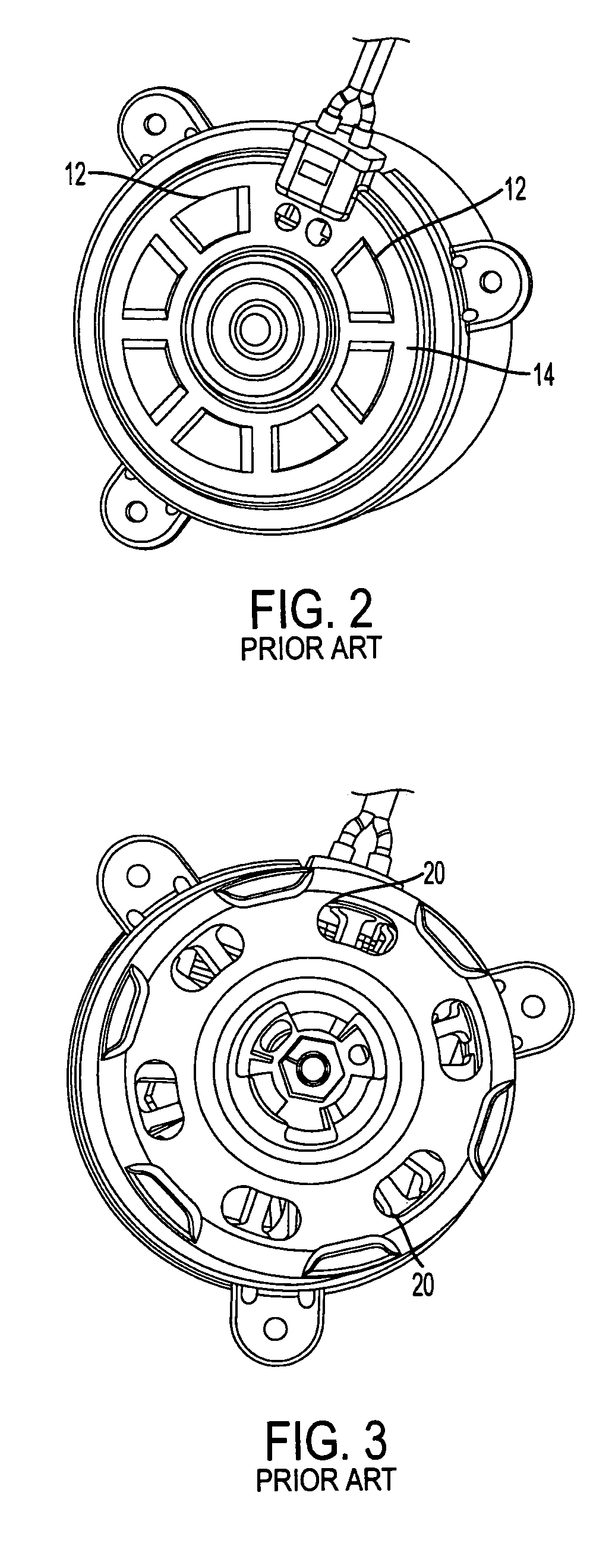

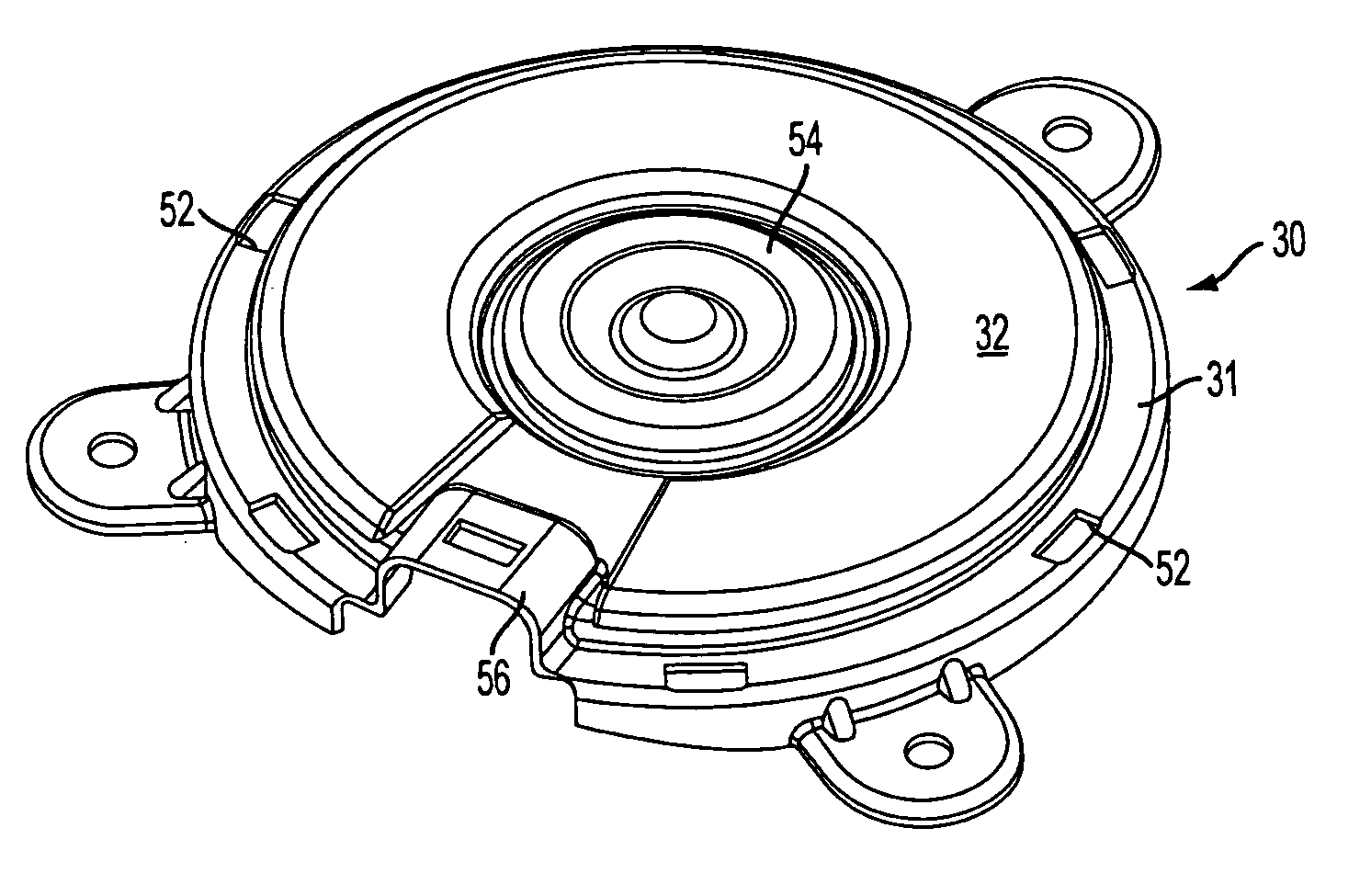

Vented end cap with integrated splash shield for permanent magnet DC motor

ActiveUS7034416B2Cooling/ventillation arrangementSupports/enclosures/casingsForeign matterEngineering

A permanent magnet D.C. electric motor 36 includes a motor housing 29 having first and second ends. The second end 42 is substantially closed and has an end of a shaft 35 extending there from. The second end includes vent holes 20 therein. The first end 27 is substantially open. An end cap 31 closes the first end of the housing. The end cap 31 has venting holes 34 therein for permitting air to pass there-through to cool the motor. A splash shield 32 is integral with the end cap 31 and covers the venting holes 34 in such a manner to limit foreign matter from entering the venting holes while permitting air to flow through the venting holes.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

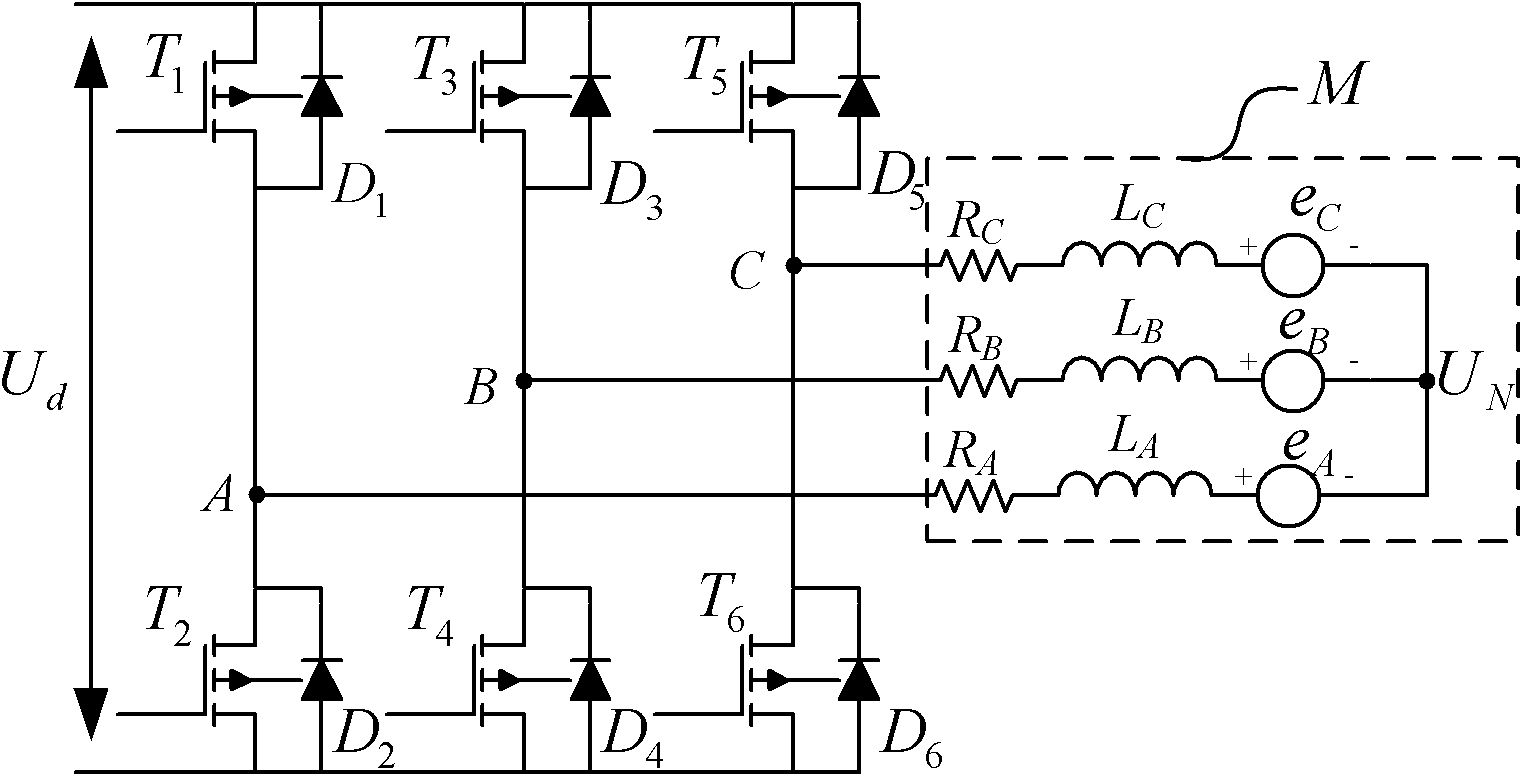

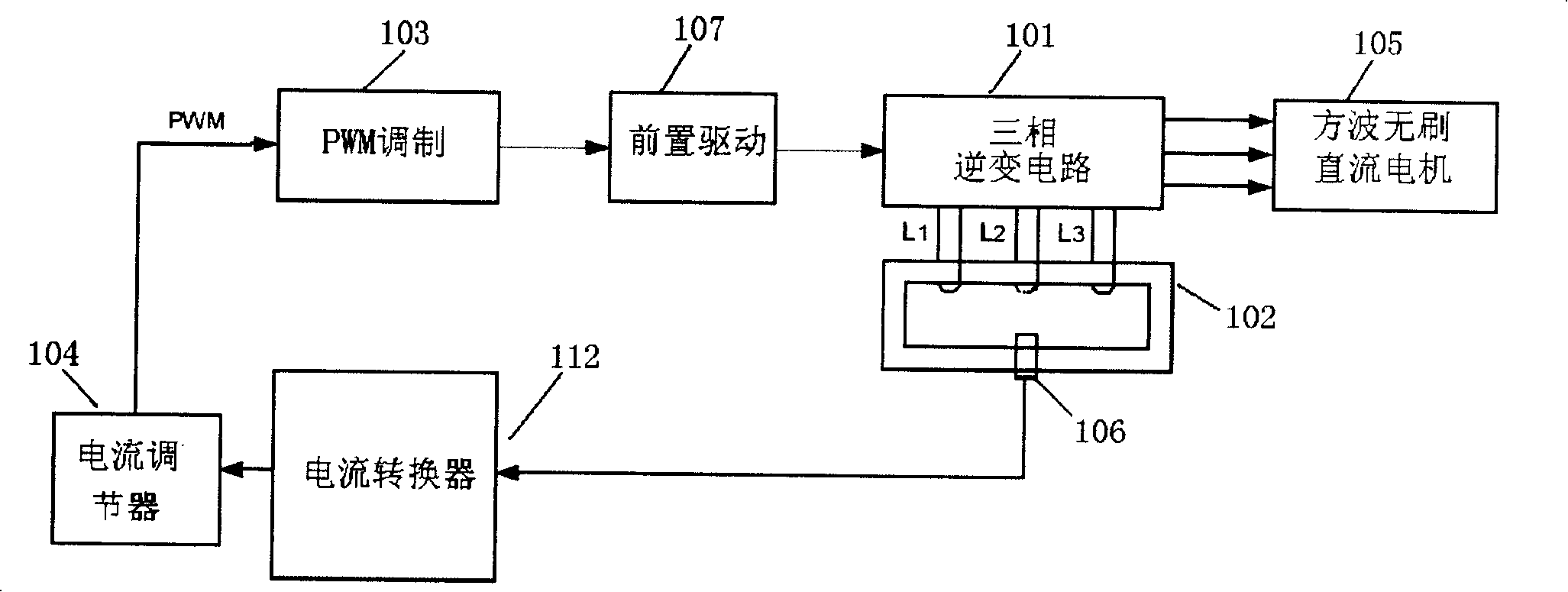

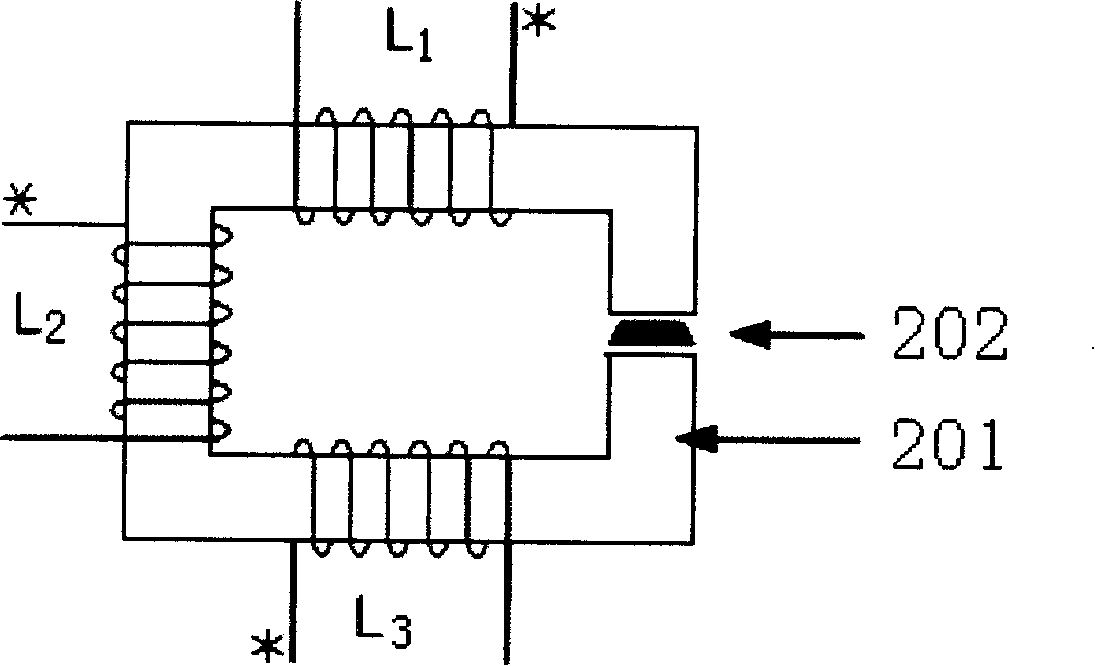

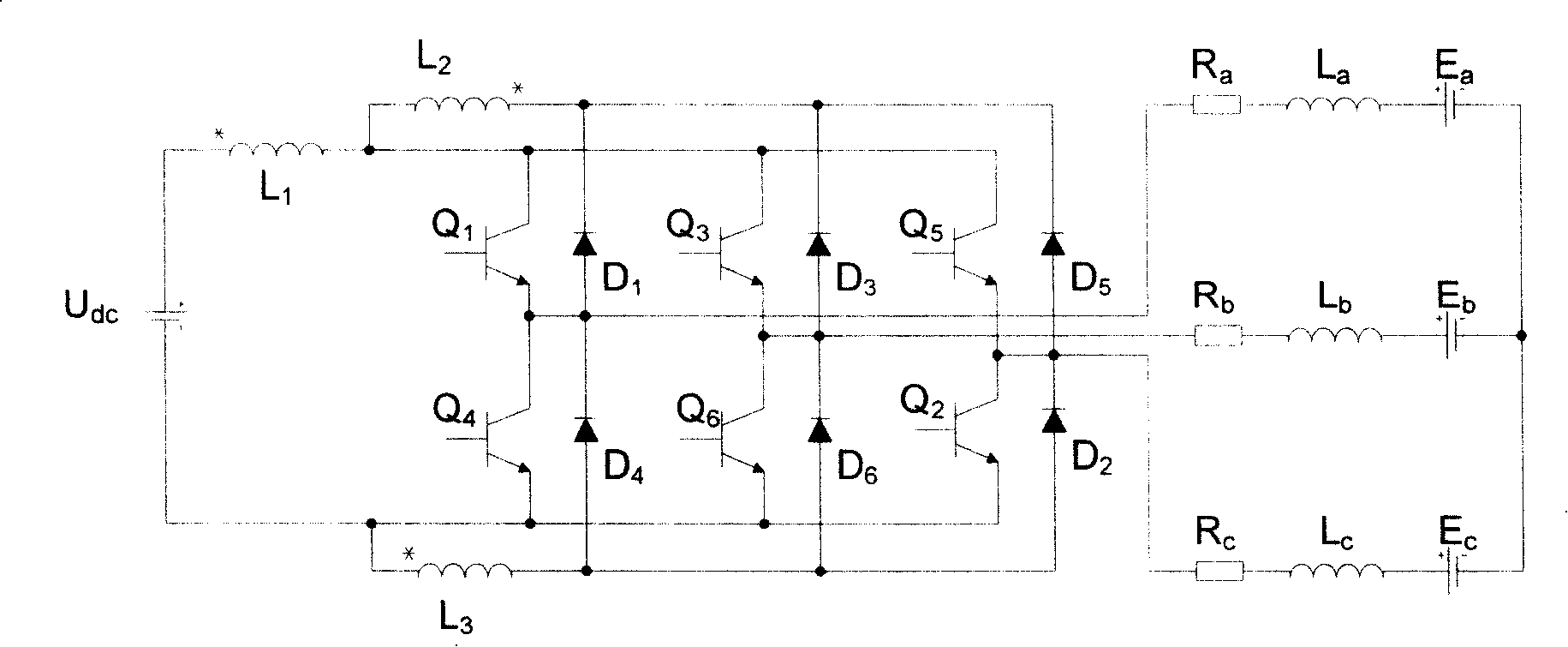

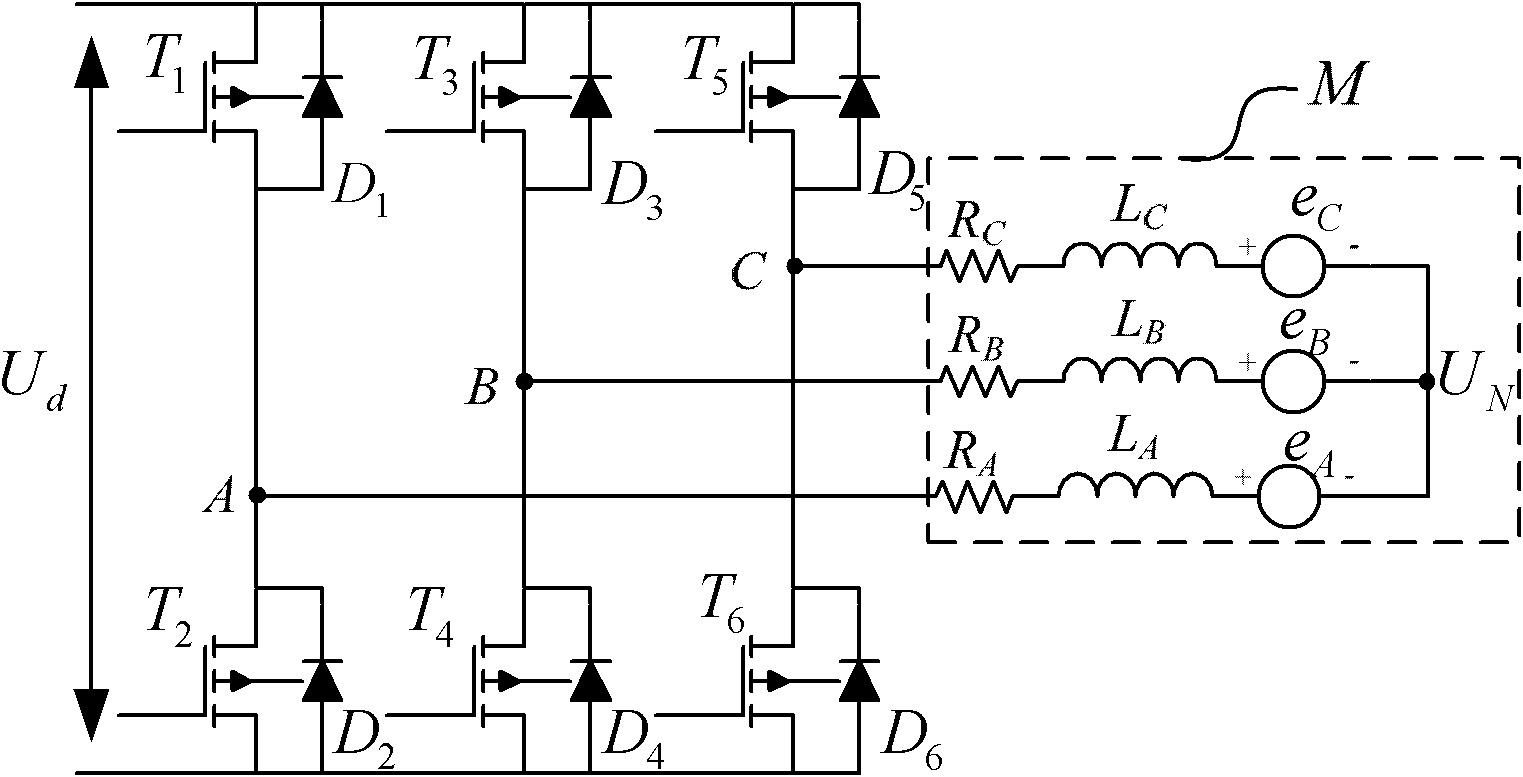

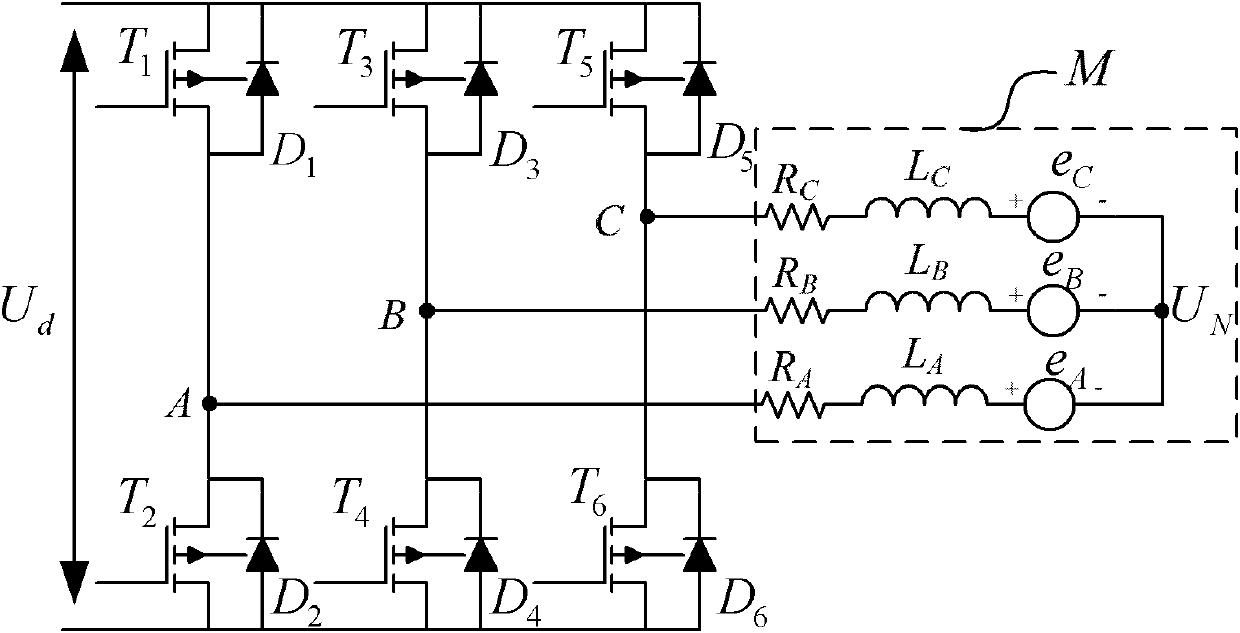

Control system and control method of brushless DC motor

ActiveCN101227163ASolve the problem of current closed-loop controlIncrease dynamicsSingle motor speed/torque controlAc-dc conversionPhase currentsLoop control

The invention relates to the controlling technique of a three-phase direct current motor, which aims at solving the problem that the existing technique can not realize good electric current closed-loop control of a three-phase square-wave brushless direct current motor. The invention provides a novel proposal for realizing electric current closed-loop control of the square-wave brushless permanent magnet direct current motor, particularly comprises a brushless direct current motor controlling system, a controlling method and a corresponding inversing module. The cathodes of freewheeling diodes D1, D3, D5 are independent from each input end of self switch pipe and mutually connected in parallel to a sample-taking coil L2, and / or the anodes of freewheeling diodes D4, D6, D2 are independent from each output end of self switch pipe and mutually connected in parallel to a sample-taking coil L3. The invention can adopt a single resultant current sensing device to completely continuously take sample of three-phase electric current when the motor is conducted and freewheeled, and continuous closed-loop control can be carried out to three-phase electric current by a single electric current closed-loop regulating device, and therefore, dynamic and static index of the motor are greatly increased.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

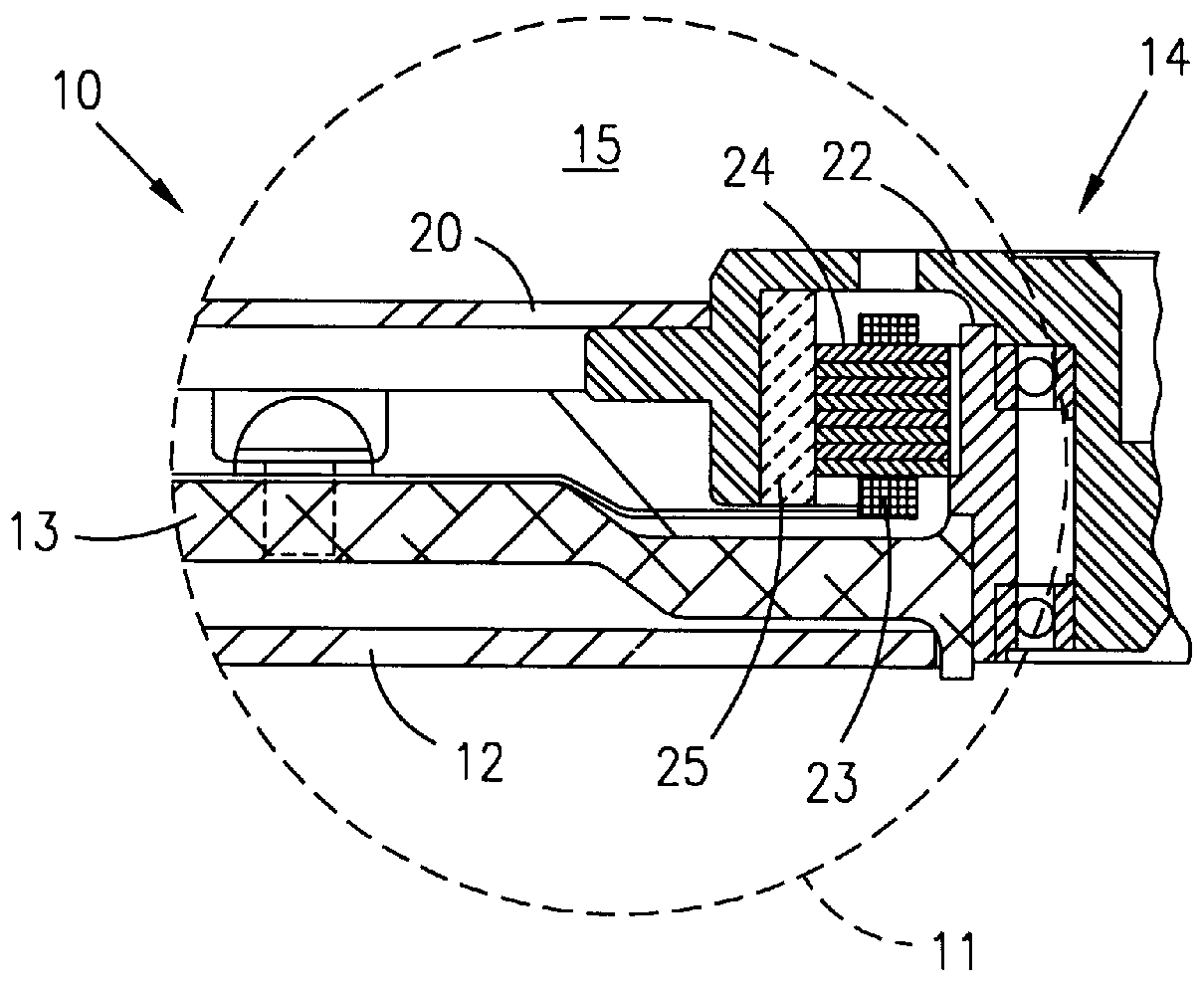

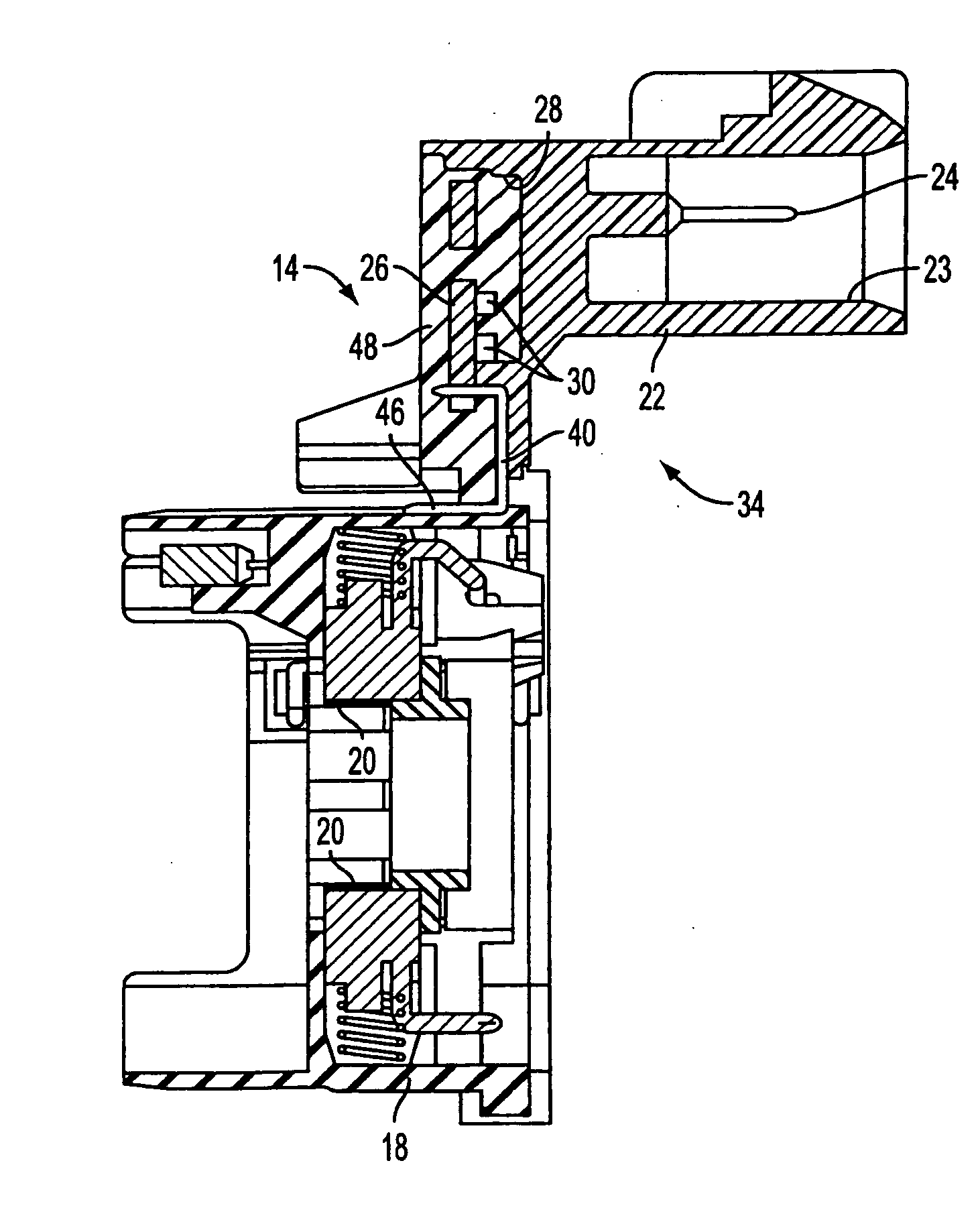

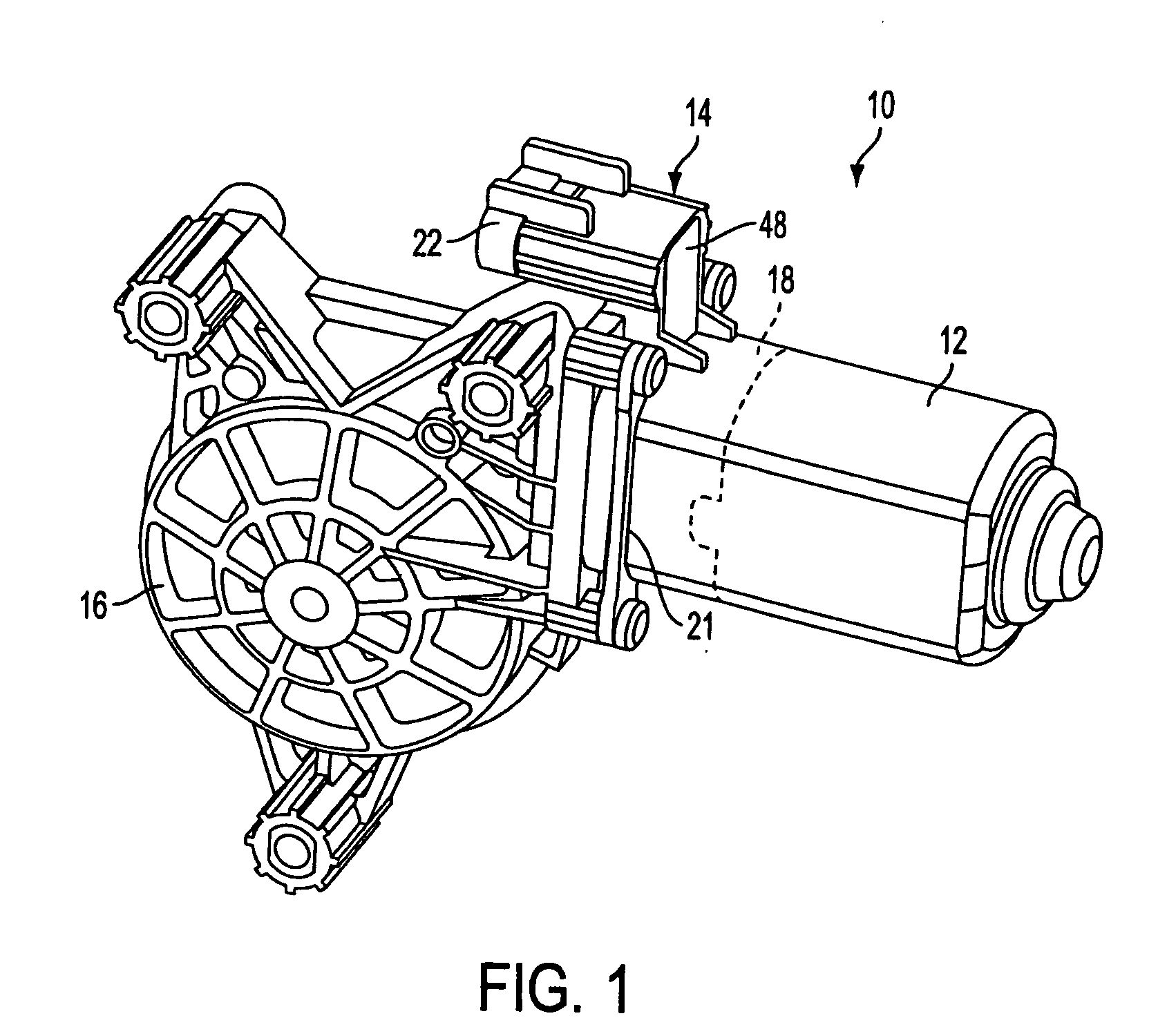

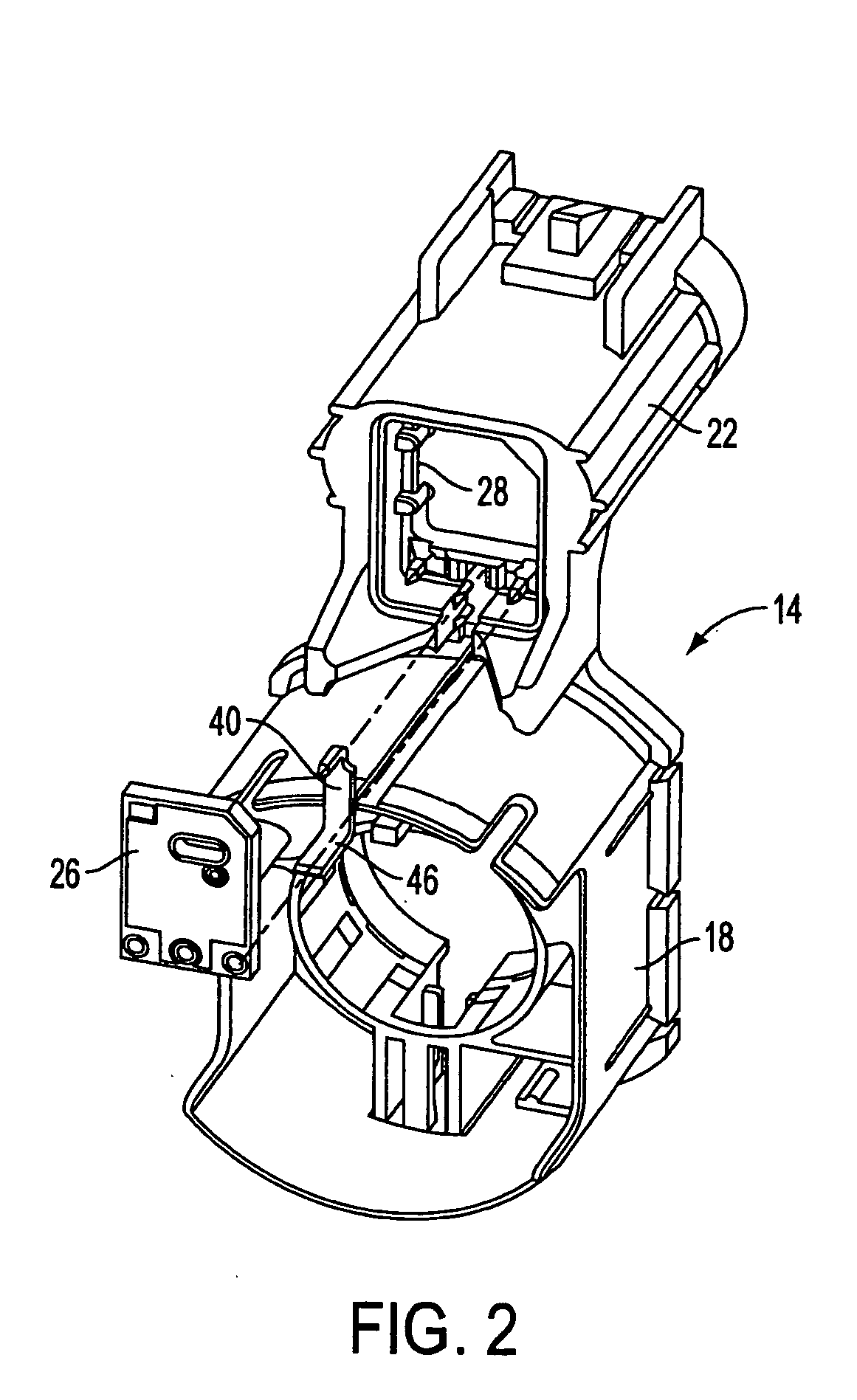

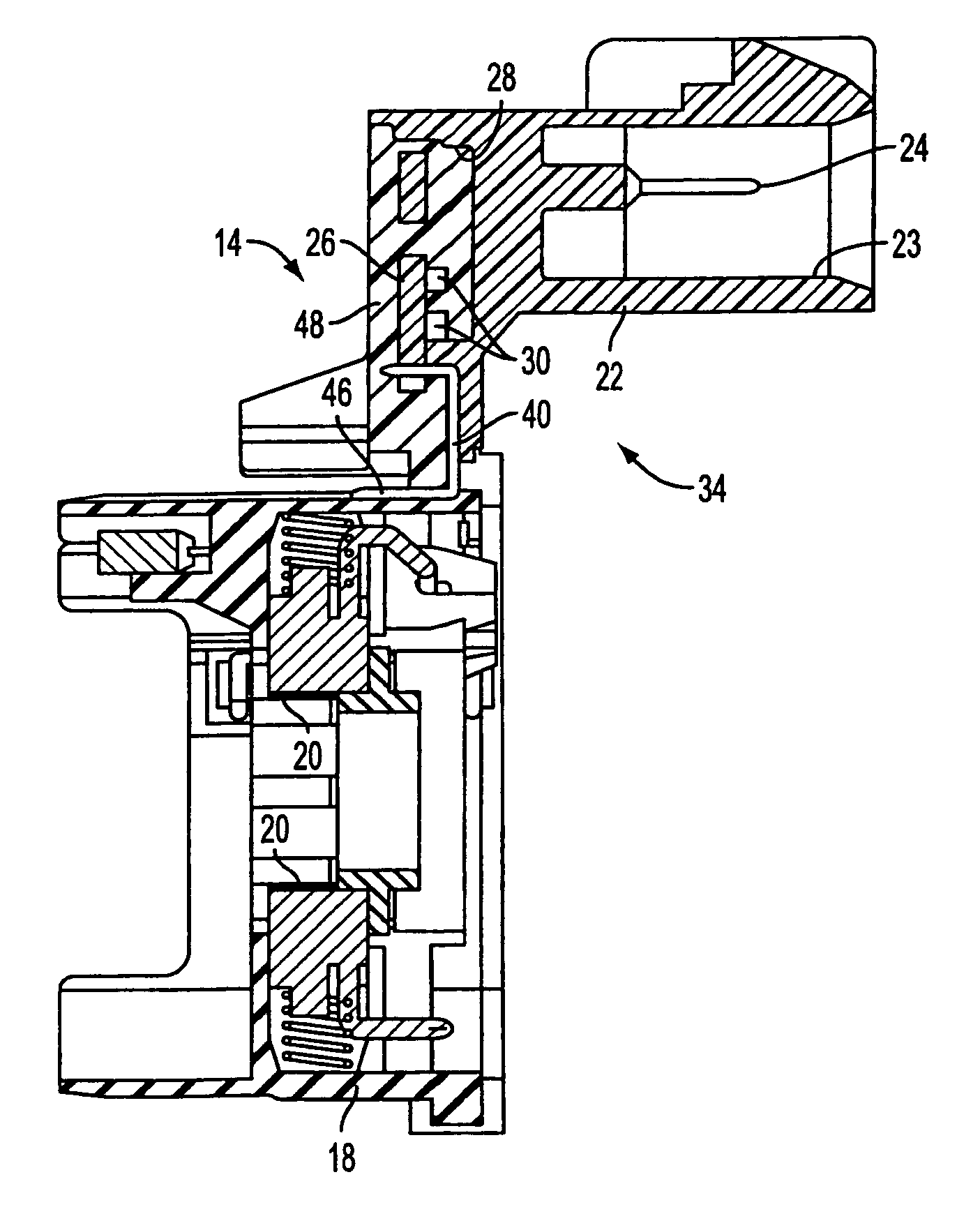

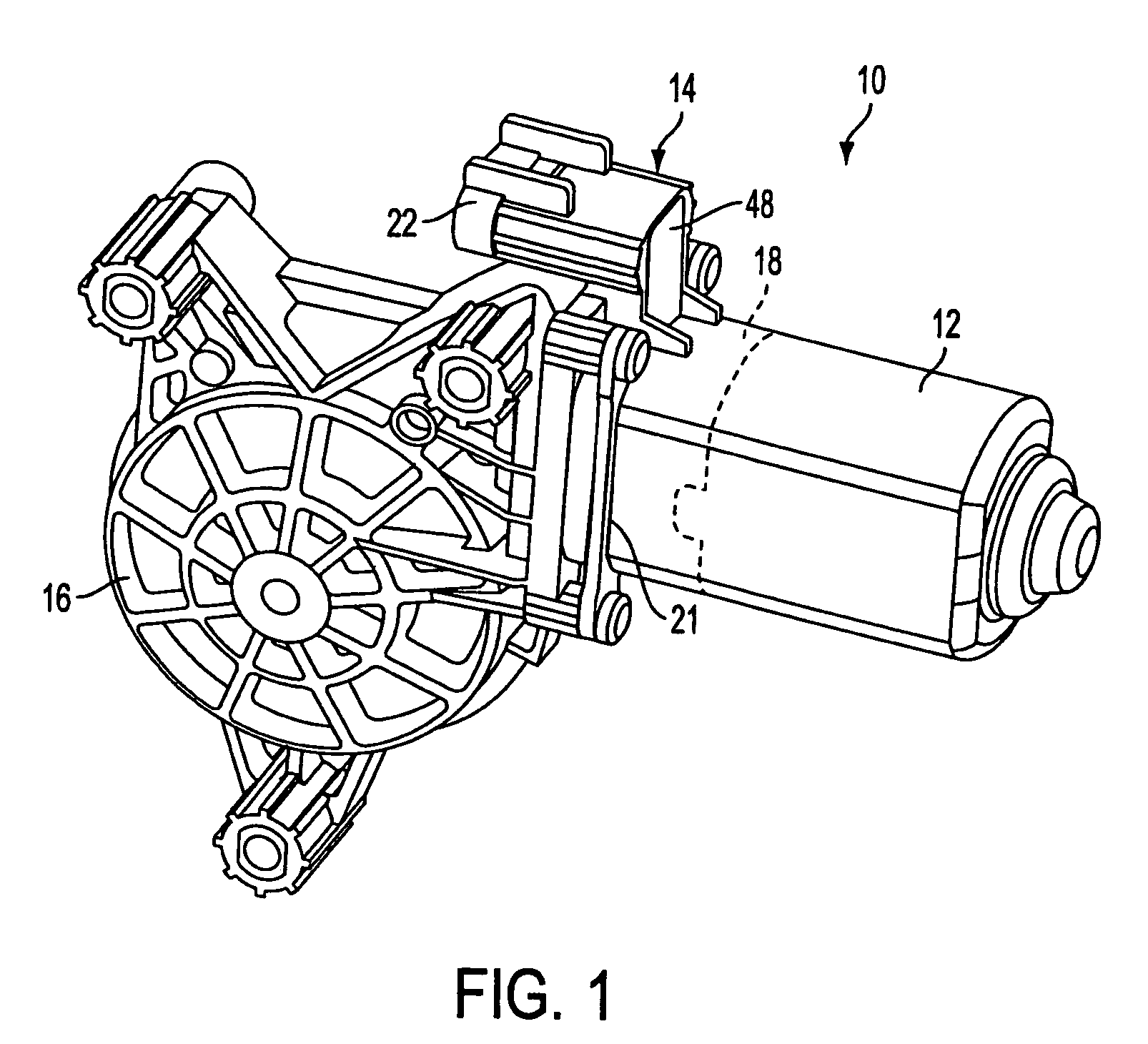

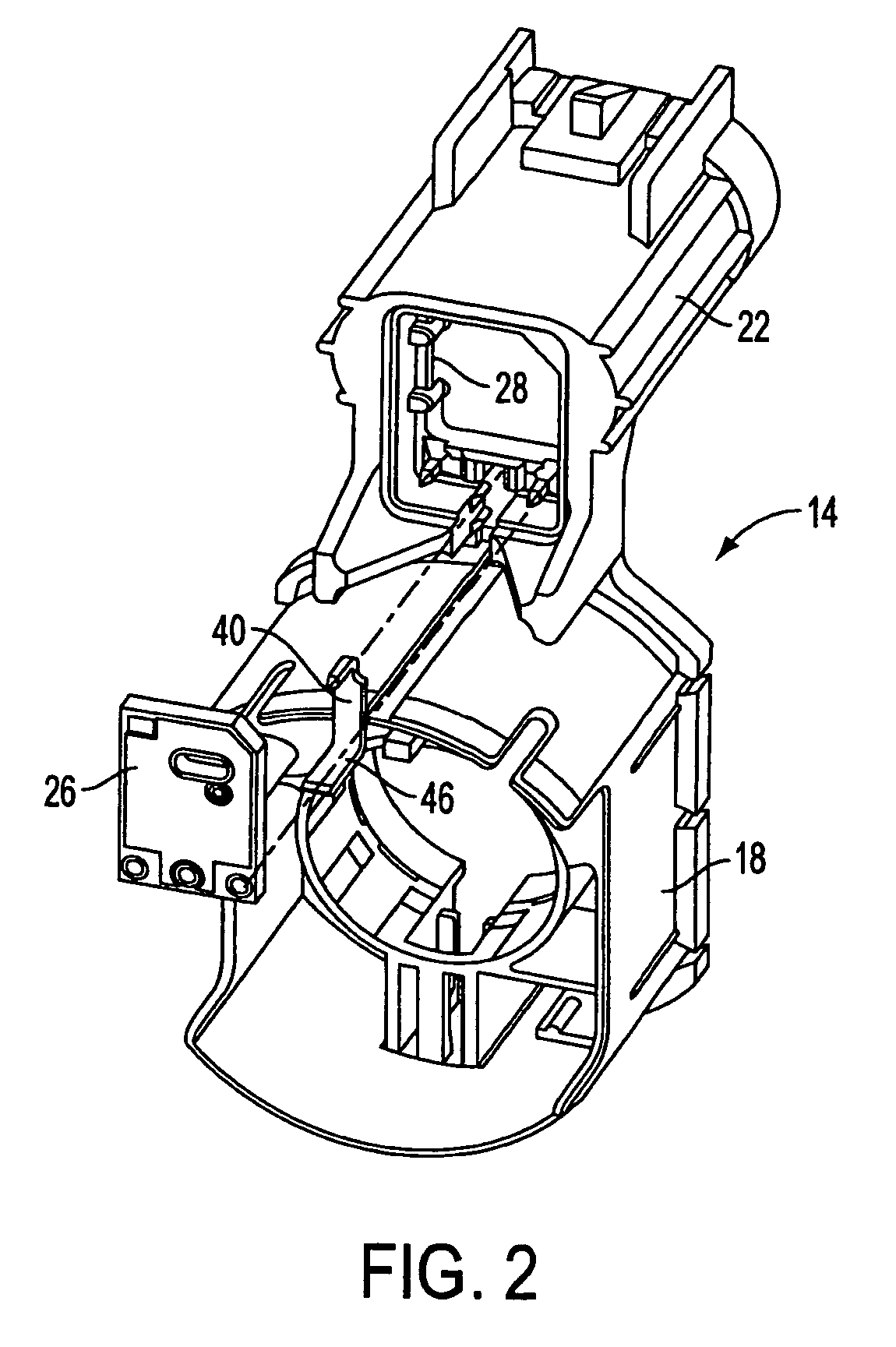

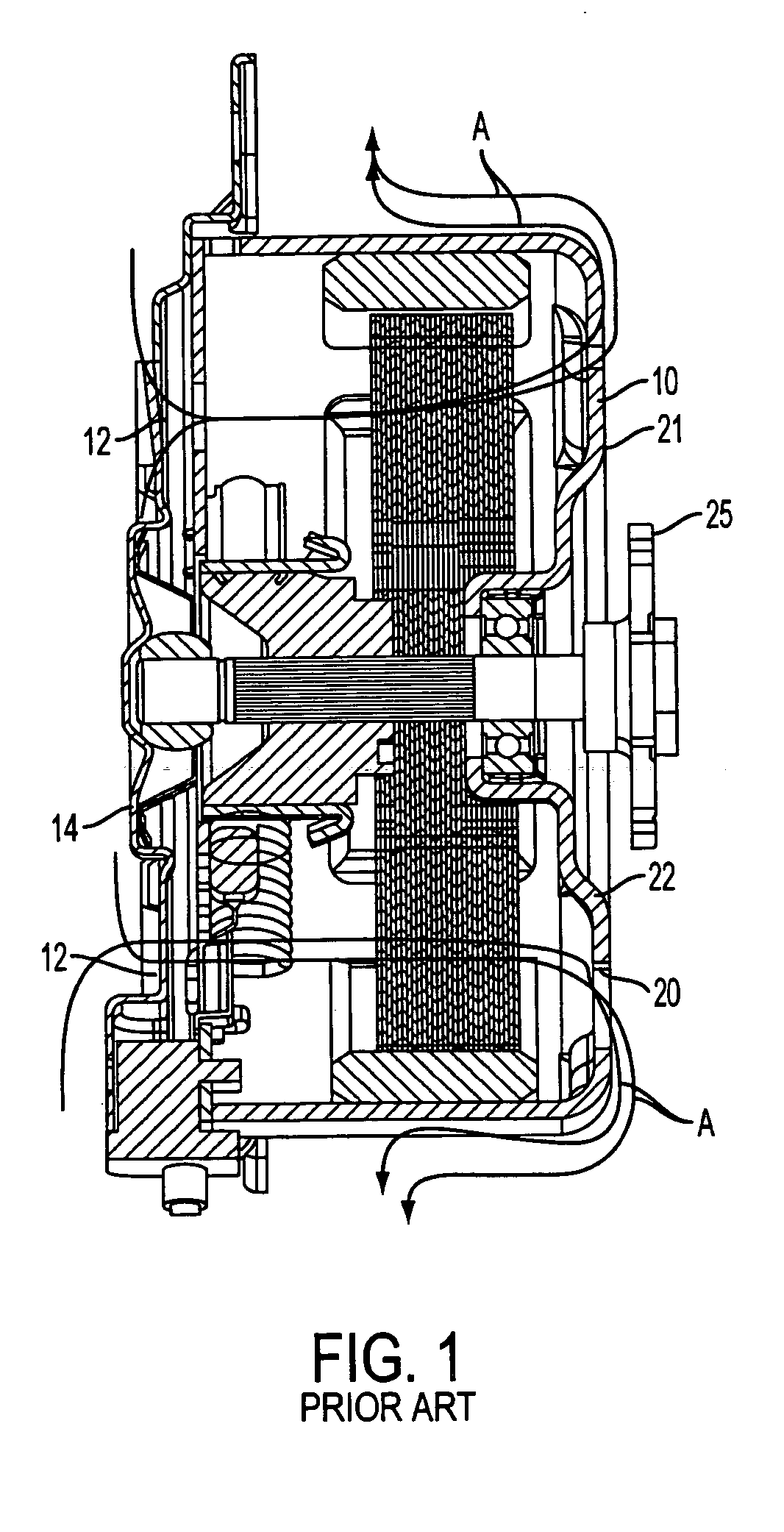

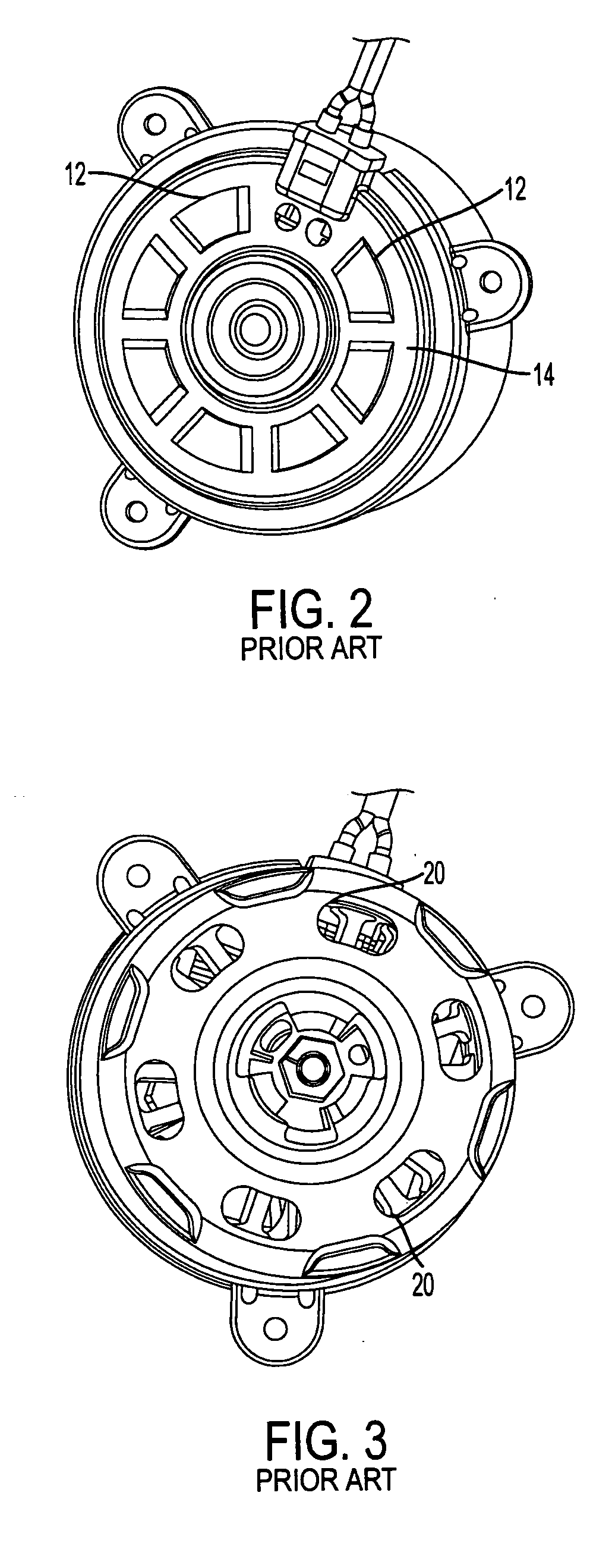

EMI suppression in permanent magnet DC motors having PCB outside motor in connector and overmolded

InactiveUS20050189829A1EMI suppressionRotary current collectorMagnetic/electric field screeningElectromagnetic interferenceEngineering

A permanent magnet DC motor 10 having electromagnetic interference (EMI) suppression includes a metal motor housing 12 and a brush card assembly 34. The brush card assembly includes brushes 20 and leads 24 constructed and arranged to be coupled with a source of power to power the motor. A brush card housing 14 has a first portion 18 housing the brushes and a second portion 22, integral with the first portion, and housing the leads. A printed circuit board 26 is mounted with respect to the second portion of the housing and carries at least one electromagnetic interference (EMI) suppression component 30 constructed and arranged to suppress EMI generated by the motor. The leads are electrically connected to the printed circuit board so that current can be provided through the printed circuit board to the brushes. A contact member 40 is electrically connected between the printed circuit board and the metal motor housing so that the at least one EMI suppression component couples the brushes to the metal motor housing thereby causing the metal motor housing to become an AC ground and EMI shield.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

EMI suppression in permanent magnet DC motors having PCB outside motor in connector and overmolded

InactiveUS6992414B2Rotary current collectorMagnetic/electric field screeningElectricityElectromagnetic interference

A permanent magnet DC motor 10 having electromagnetic interference (EMI) suppression includes a metal motor housing 12 and a brush card assembly 34. The brush card assembly includes brushes 20 and leads 24 constructed and arranged to be coupled with a source of power to power the motor. A brush card housing 14 has a first portion 18 housing the brushes and a second portion 22, integral with the first portion, and housing the leads. A printed circuit board 26 is mounted with respect to the second portion of the housing and carries at least one electromagnetic interference (EMI) suppression component 30 constructed and arranged to suppress EMI generated by the motor. The leads are electrically connected to the printed circuit board so that current can be provided through the printed circuit board to the brushes. A contact member 40 is electrically connected between the printed circuit board and the metal motor housing so that the at least one EMI suppression component couples the brushes to the metal motor housing thereby causing the metal motor housing to become an AC ground and EMI shield.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

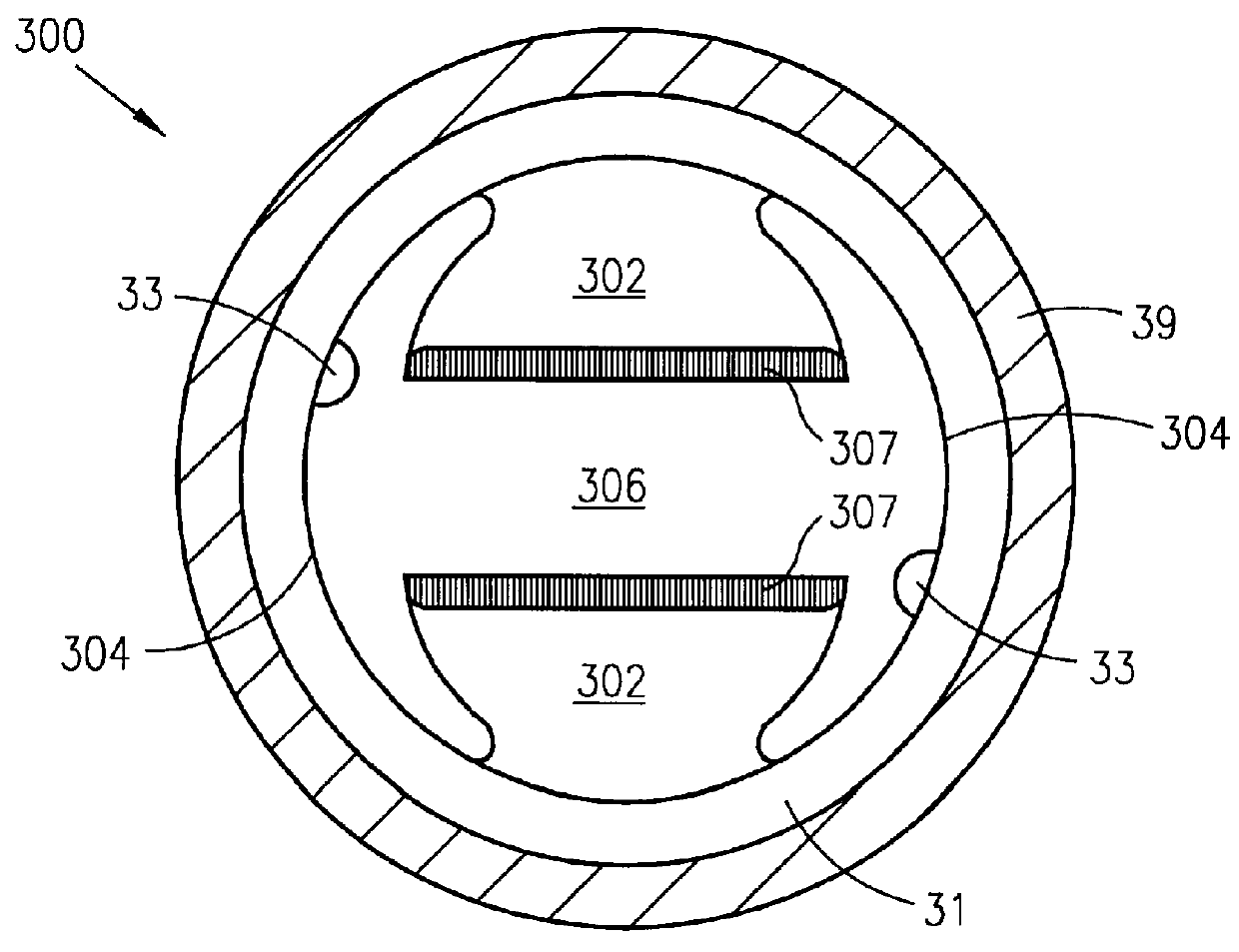

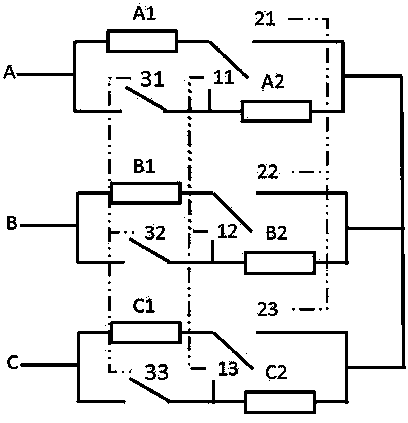

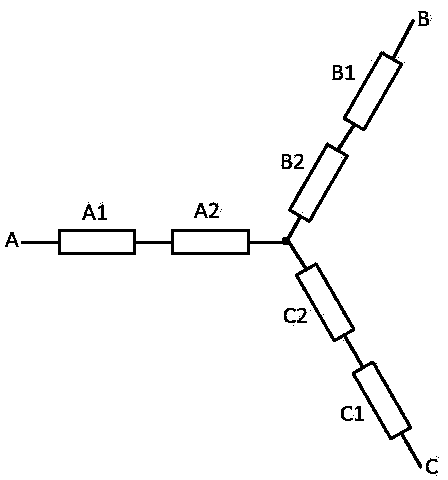

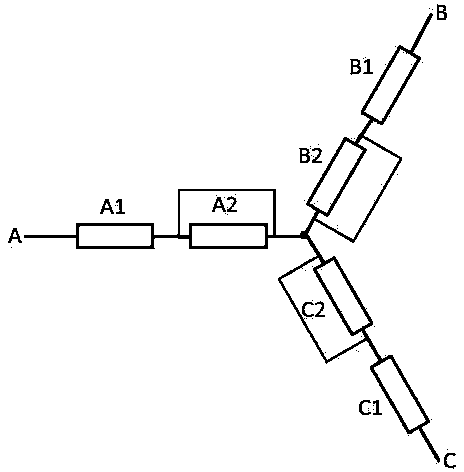

Multi-winding motor

InactiveCN103701288AImprove efficiencyTo achieve the purpose of optimizationAC motor controlElectric machinesAlternating currentElectric vehicle

The invention discloses a multi-winding motor for an electric vehicle / electric automobile, and belongs to permanent magnet direct current motors. The multi-winding motor comprises a rotor and a stator, wherein the rotor rotates around the shaft of the rotor; the stator encircles the rotor; the stator is provided with more than one coil winding which is divide into first coil windings (A1, B1 and C1) and second coil windings (A2, B2 and C2); the first and second coil windings are mutually independent and can be connected in series and in parallel through a relay selector switch according to a requirement. The motor can serve as an alternating current motor to generate power.

Owner:洛阳市睿仕行智能科技发展有限公司

Core-free permanent magnet direct current motor with axial magnetic field for electric vehicle

InactiveCN102355101AImprove battery lifeImprove climbing abilityMagnetic circuit rotating partsElectric machinesElectric machineMetallic materials

The invention discloses a core-free permanent magnet direct current motor with an axial magnetic field for an electric vehicle. The motor comprises permanent magnets, magnetic conduction yokes, a bearing, a shaft core and a hub. A core-free inner stator is arranged coaxially on the shaft core. The two sides of the inner stator are coaxially provided with a rotor on which an even number of permanent magnets are uniformly distributed respectively. The inner edges of the rotors are connected with the magnetic conduction yokes on the two sides of the motor respectively, and are arranged together with the shaft core of the motor by the bearing. The outer edges of the rotors are connected together with the hub of the motor by the magnetic conduction yokes. The two sides of the stator are provided with the rotor respectively, a core and a toothed groove are not required, the dual rotors and the single stator form dual air gaps, and the magnetic field is axial. The efficiency of the motor is improved, effective metal materials are saved, the life mileage of the motor is increased, the climbing capability of the motor is improved and the battery replacement cycle of the electric vehicle is prolonged; and the motor is particularly suitable for use as a driving motor for the electric vehicle.

Owner:王春煜

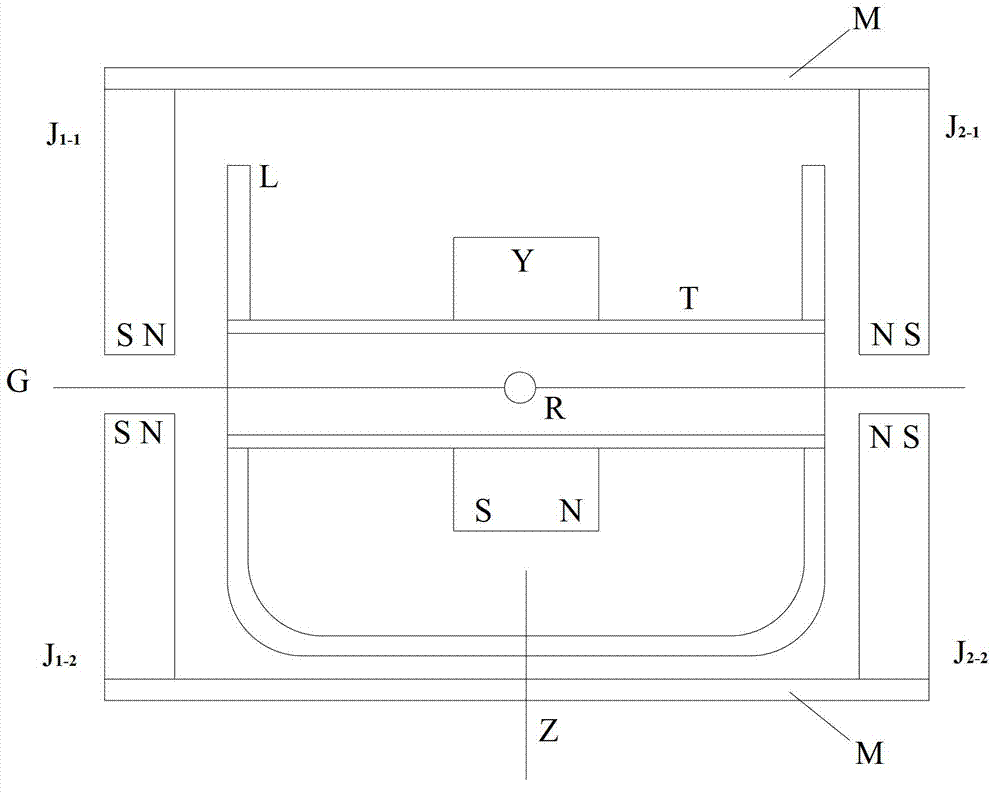

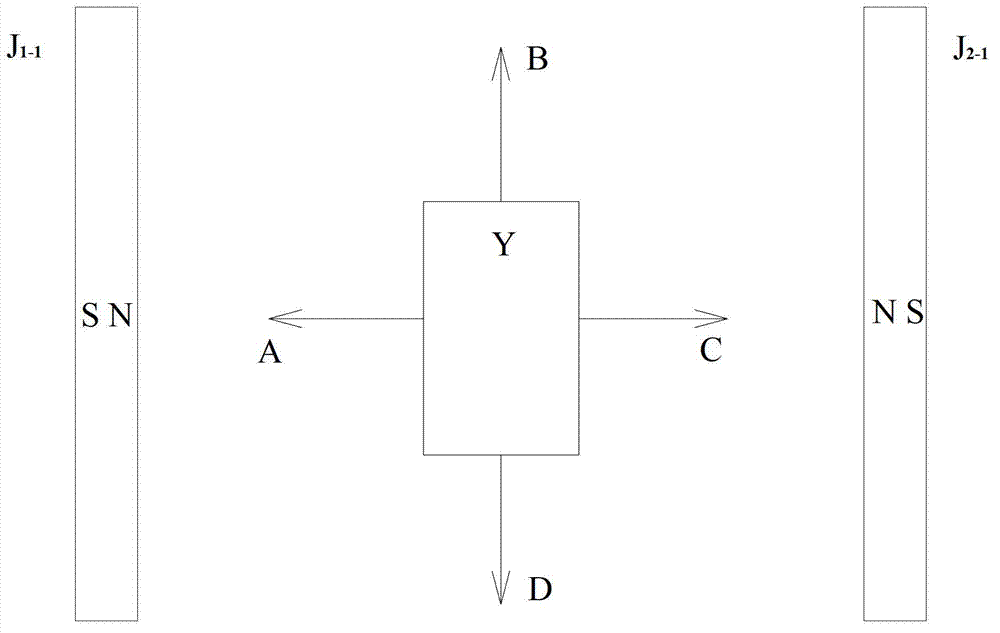

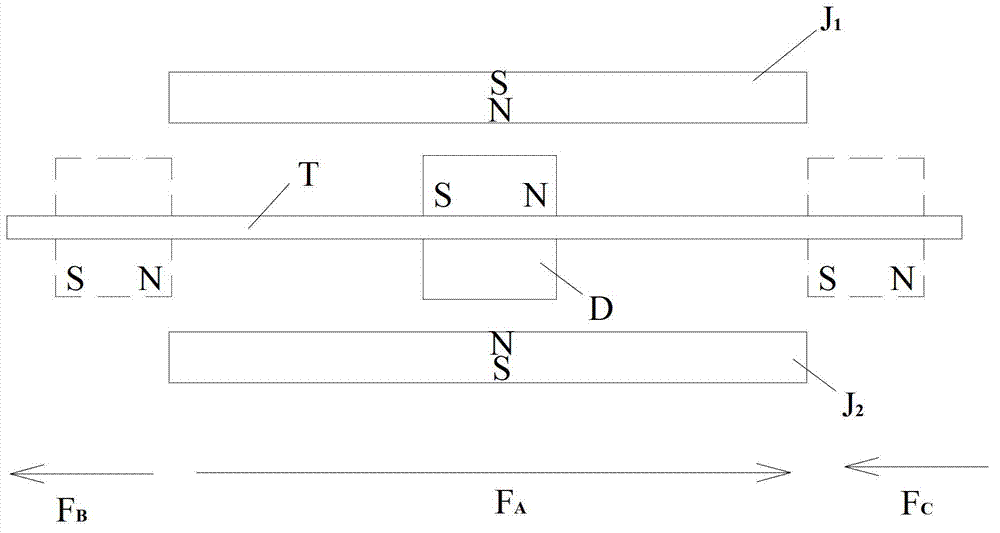

Magnet force device

The invention discloses a magnet force device and relates to an application of magnets in electromechanical devices. The magnet force device solves the problem of taking out energy from magnetic fields of the magnets and saves energy by means of the magnets. A force except for the attractive force and the repulsive force is further found out between two magnets, a movable magnet is arranged in the magnetic field of a static magnet, the included angle formed between the pole axis direction of the movable magnet and the pole axis direction of the static magnet is 90 degrees, the static magnet does not move, and the movable magnet moves due to the force which is called the magnet force. The attractive force and the repulsive force are respectively arranged on the outer side of the magnetic field of the static magnet. The attractive force, the repulsive force and the magnet force can serve as the pushing force, so that energy can be saved. The attractive force and the repulsive force can also be avoided, and only the magnet force of the magnets serves as the main power for motion to form a power device of linear motion or rotation motion, so that a large amount of energy can be saved. The magnetic field of the static magnet can be replaced by the magnetic field of an electromagnetic coil, and the movable magnet can move due to the magnet force, so that a power device the same as a permanent magnet direct current motor can be formed.

Owner:矫祥田

Upper air slow descending device based on magnetorheological fluid damper

InactiveCN105251144AQuick Brake ResponseSmooth and slow down effectBuilding rescueGear wheelControl theory

The invention relates to an upper air slow descending device based on a magnetorheological fluid damper. A winch is connected with permanent magnet direct-current generators through a gear transmission set. The permanent magnet direct-current generators are installed on the rotary magnetorheological fluid damper through a generator support. The matched braking torque is provided through the rotary magnetorheological fluid damper according to the descending speed of a person or a heavy object, so that the person or the heavy object descends at a constant speed, and upper air slow descent of the person or the heavy object is achieved. By the adoption of the upper air slow descending device, kinetic energy generated in the descending process of the person or the heavy object descending from the upper air is used and converted into electric energy through the permanent magnet direct-current generators, and the electric current is then supplied to the rotary magnetorheological fluid damper; and the different degrees of magnetic field intensity are generated by excitation coils according to the electric current, the braking torque is generated by magnetorheological fluid shearing stress in gaps between a fixed disc and rotary discs, the braking torque is correspondingly changed along with the descending speed of the person or the heavy object, and the self-adaptive control over the person or the heavy object is achieved. The upper air slow descending device is suitable for personnel self-rescue, upper air fire protection operation and the like and the self-rescue and other-people-rescue efficiency can be improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

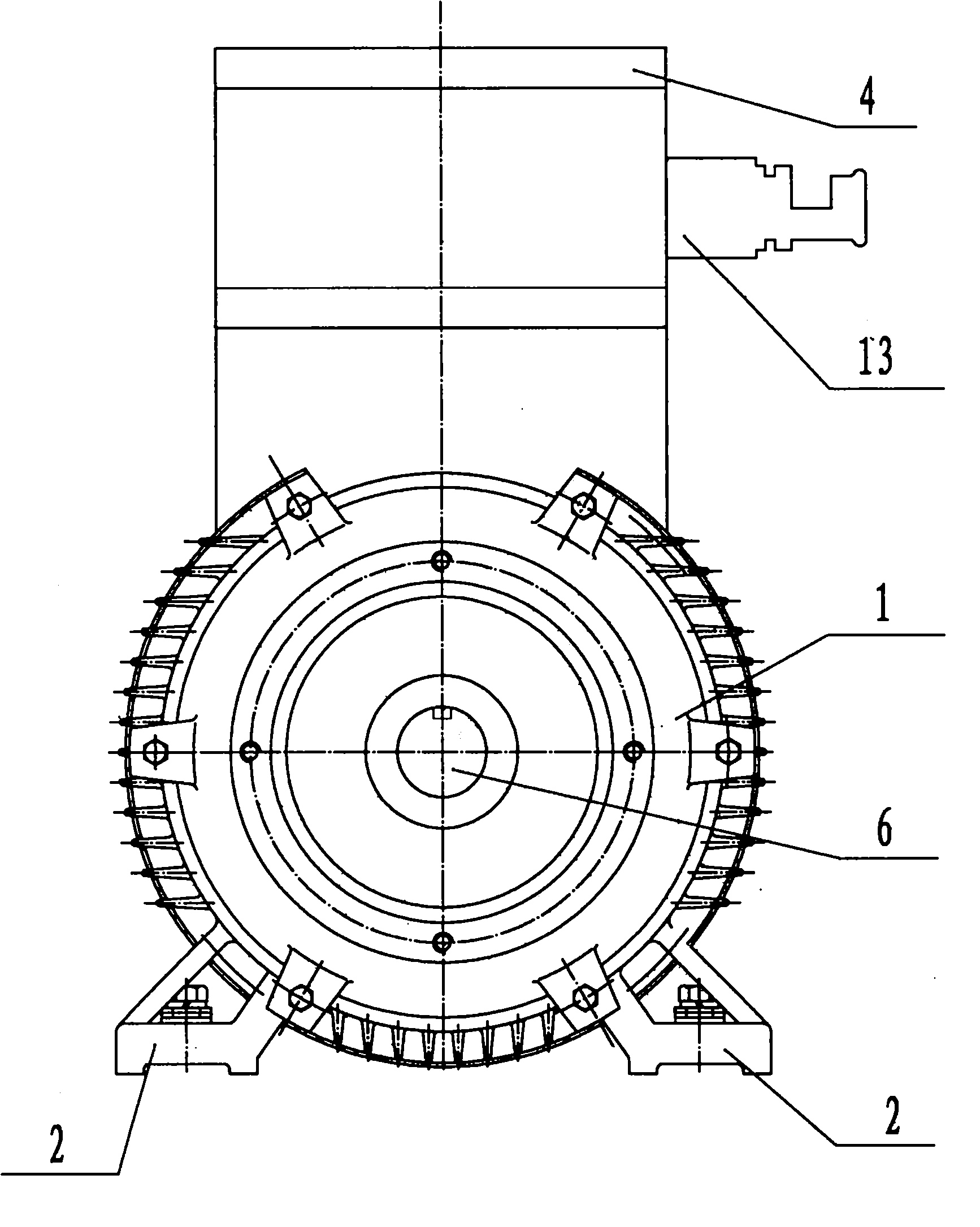

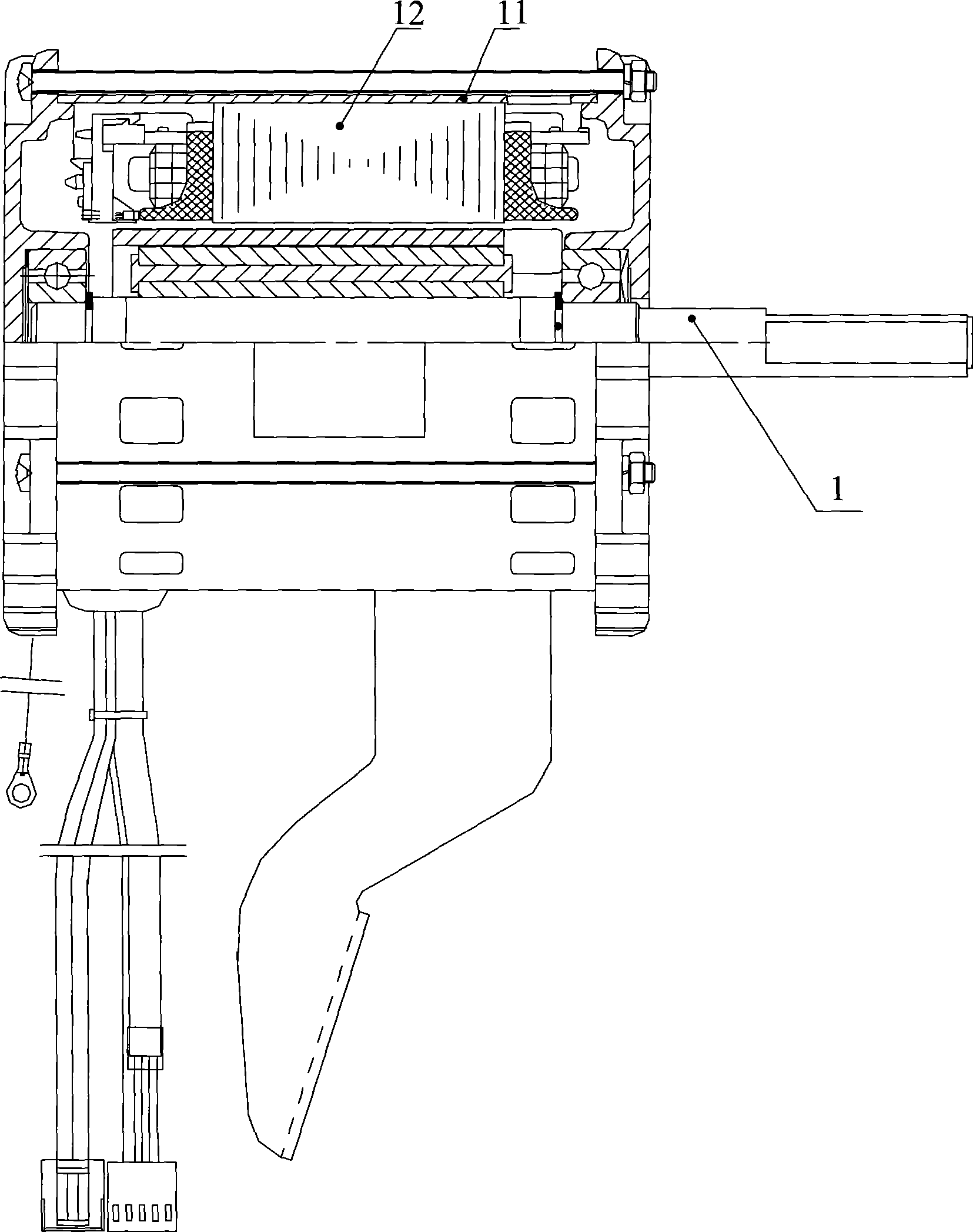

Anti-explosion permanent magnet direct-current brushless motor with controller

ActiveCN101860162ALarge overload torqueCompact structureAssociation with control/drive circuitsMagnetic circuit rotating partsBrushless motorsStator coil

The invention relates to an anti-explosion permanent magnet direct-current brushless motor with a controller, mainly comprising a motor, a stator, a rotor, a controller, a connecting box, a strong current connector post, a weak current patching panel, a protective cover, a fan, a motor shaft, a sealing bearing, a stator coil, a stator silicon steel sheet, a rotor neodymium iron boron magnet strip, a position sensor, a magnetic disc and a cable, wherein a structure for connecting the stator coil, the silicon steel sheet, the rotor neodymium iron boron magnet strip, the position sensor, the magnetic disc and the fan is adopted in the motor; the sealing bearing is used as the bearing of the motor, and the controller adopts microcomputer program control; and strong current control and weak current control are combined. The motor and the controller have advanced design, compact structure, safety, stability, reliability, high efficiency, energy saving, large overload torque, dust and water proofing, no brush and stepless speed change and is an ideal anti-explosion, permanent magnet, direct current and brushless motor with a brake.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

Vented end cap with integrated splash shield for permanent magnet DC motor

ActiveUS20050168080A1Cooling/ventillation arrangementSupports/enclosures/casingsForeign matterEngineering

A permanent magnet D.C. electric motor 36 includes a motor housing 29 having first and second ends. The second end 42 is substantially closed and has an end of a shaft 35 extending there from. The second end includes vent holes 20 therein. The first end 27 is substantially open. An end cap 31 closes the first end of the housing. The end cap 31 has venting holes 34 therein for permitting air to pass there-through to cool the motor. A splash shield 32 is integral with the end cap 31 and covers the venting holes 34 in such a manner to limit foreign matter from entering the venting holes while permitting air to flow through the venting holes.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

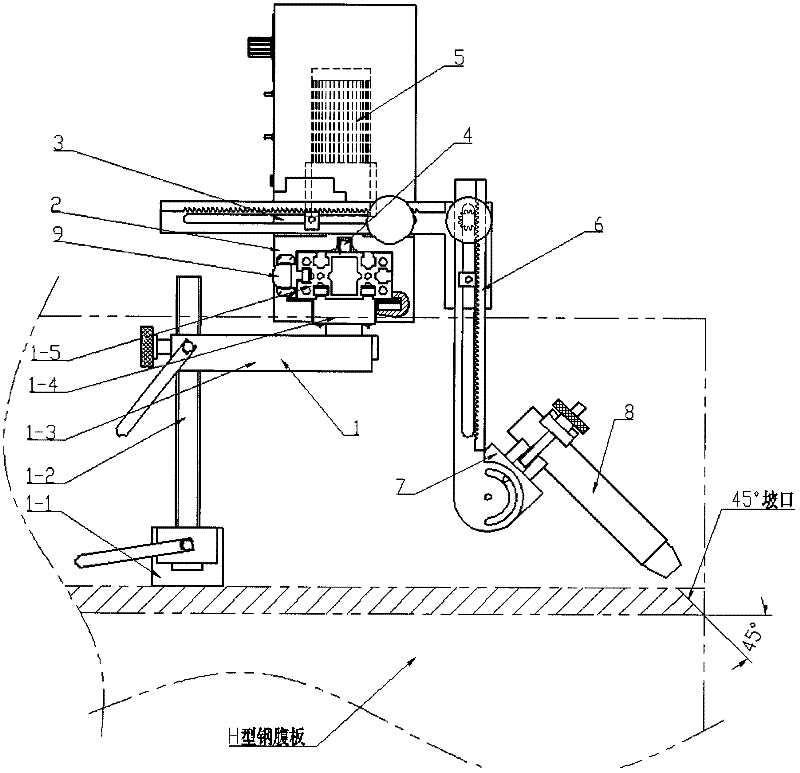

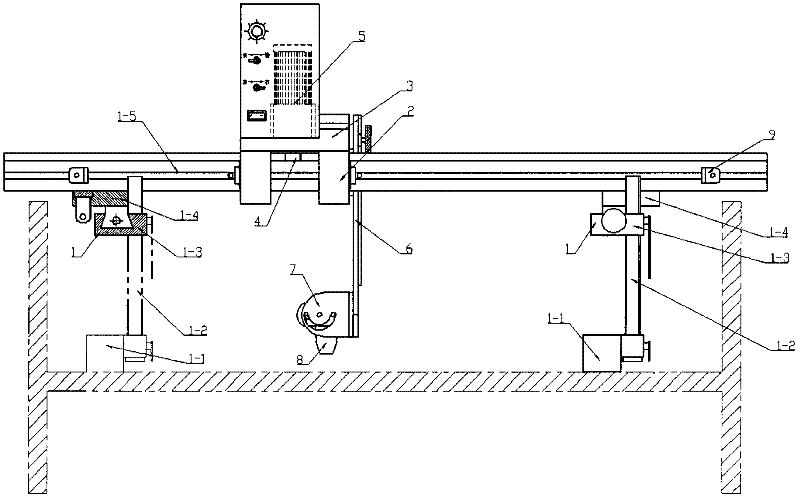

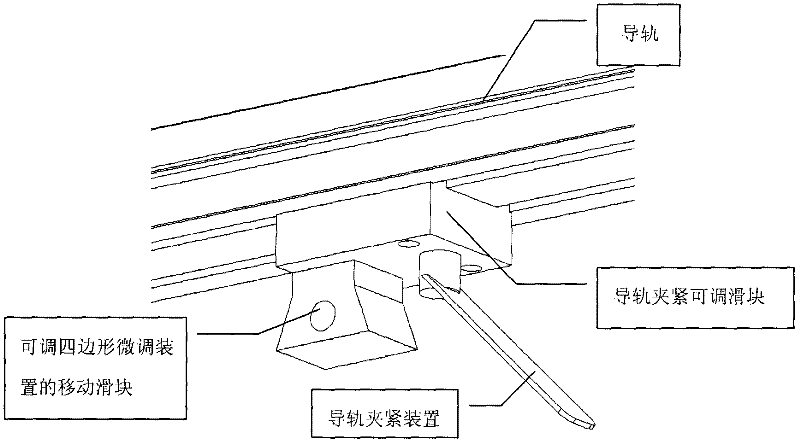

Semi-automatic short distance cutting machine and its cutting method

The invention provides a semi-automatic short-range cutting machine and a cutting method thereof and relates to a small-sized machine used for cutting a profile steel docking groove. The semi-automatic short-range cutting machine comprises a cutting torch (8), on which a manual micromatic setting device (6) is arranged; the manual micromatic setting device (6) is installed on a machine base (3); the machine base (3) is installed on a rail (1-5) in an adjustable quadrilateral mechanism (1) through a rail slider (2); an angle adjustment device (7) is installed at the bottom of the manual micromatic setting device (6); the machine base (3) is provided with a permanent magnet direct current deceleration motor (5); a gear rack (4) is used for realizing the transmission between the permanent magnet direct current deceleration motor (5) and the rail (1-5) so as to drive the cutting torch (8) to run to finish cutting task; a strong-force magnetic base (1-1) consists of two adjacent rotary fixing points and two rotary or clamped fixing points in the adjustable quadrilateral mechanism (1) so that the whole machine is firmly fixed on a processed workpiece. The invention fills the blank in the prior art; the semi-automatic short-range cutting machine has advantages of simple structure, portability and capability of site operation; and the provided cutting method can effectively guarantee cutting quality.

Owner:ZHEJIANG XIZI HEAVY IND MACHINERY

Ultra-small coreless brushless high-efficiency hub motor

ActiveCN105932823AReduce volumeReduce lossElectric machinesMechanical energy handlingReduction driveAlloy

The invention discloses an ultra-small coreless brushless high-efficiency hub motor, and the motor consists of an axle motor and a hub speed reducer. The axle motor is a coreless brushless bipolar permanent magnet DC motor, and is high in efficiency, is small in size, is light in weight and has no magnetic resistance. The axle motor also serves as a left half shaft of a hub. The hub speed reducer is a high-efficiency two-stage planetary gear speed reduction mechanism which is disposed on a right half shaft in a hub housing, and is an independent speed reducer which is fully sealed by an aluminum alloy hub housing. The motor has the excellent conditions for using liquid lubricating oil, and enables the oil not to be leaked easily. The remarkable advantages of the motor used on an electric bicycle also can be reflected by the motor used on an electric motorcycle and an electro-tricycle. Because the motor is high in efficiency, small in size and light in weight, the motor meets the most basic demands of various types of electric vehicles. According to the different requirements of power and mechanical strength of the motors, different types of hub motors can be developed.

Owner:深圳市精锐昌科技有限公司

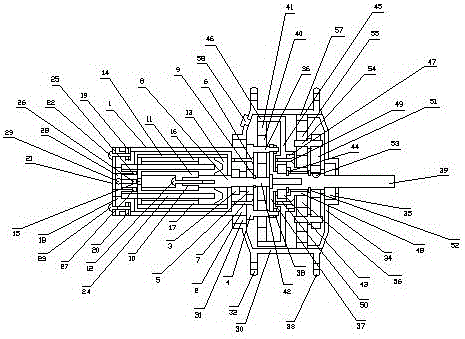

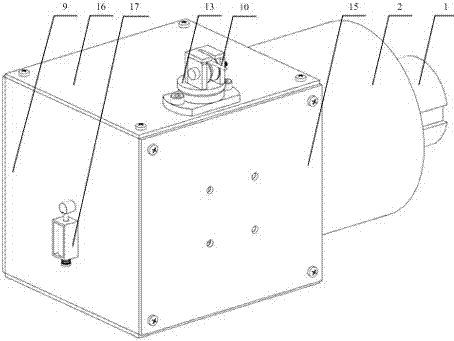

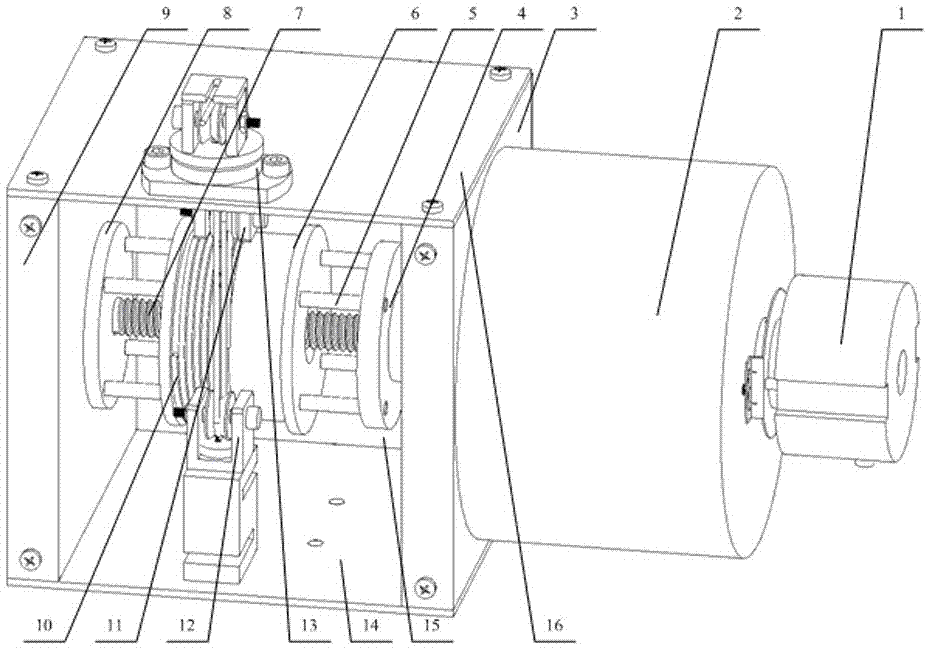

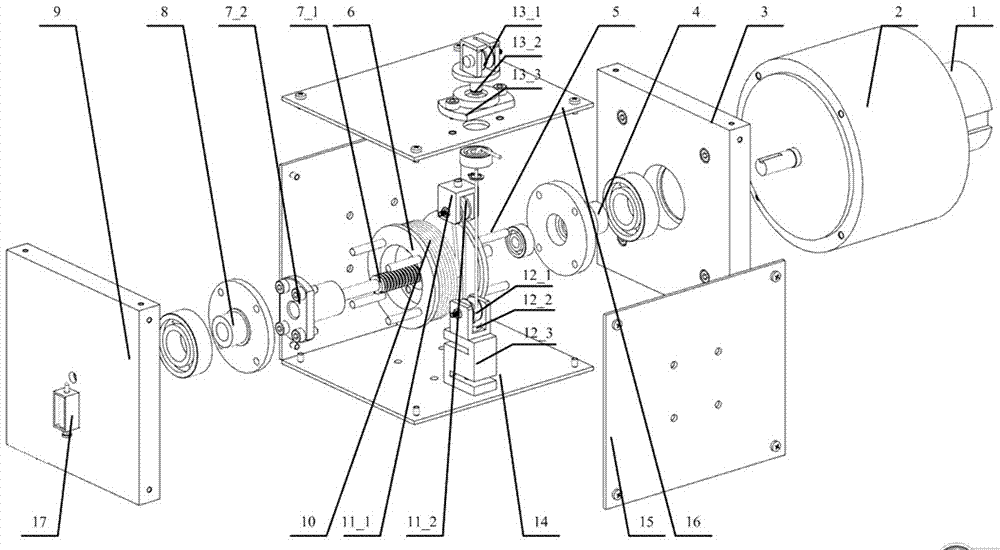

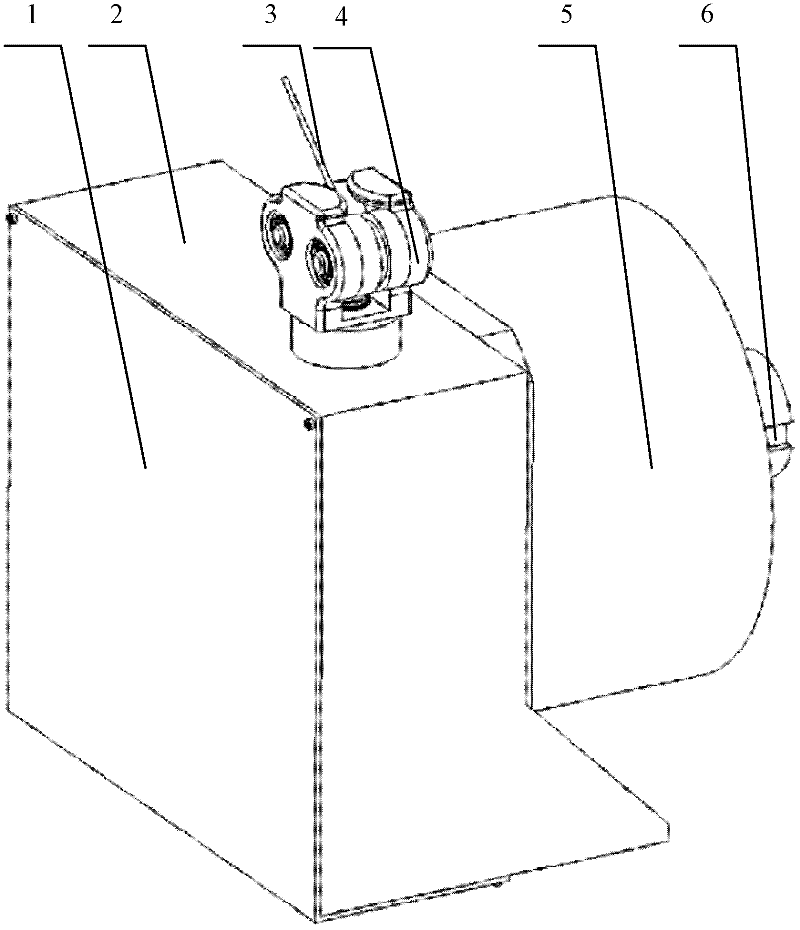

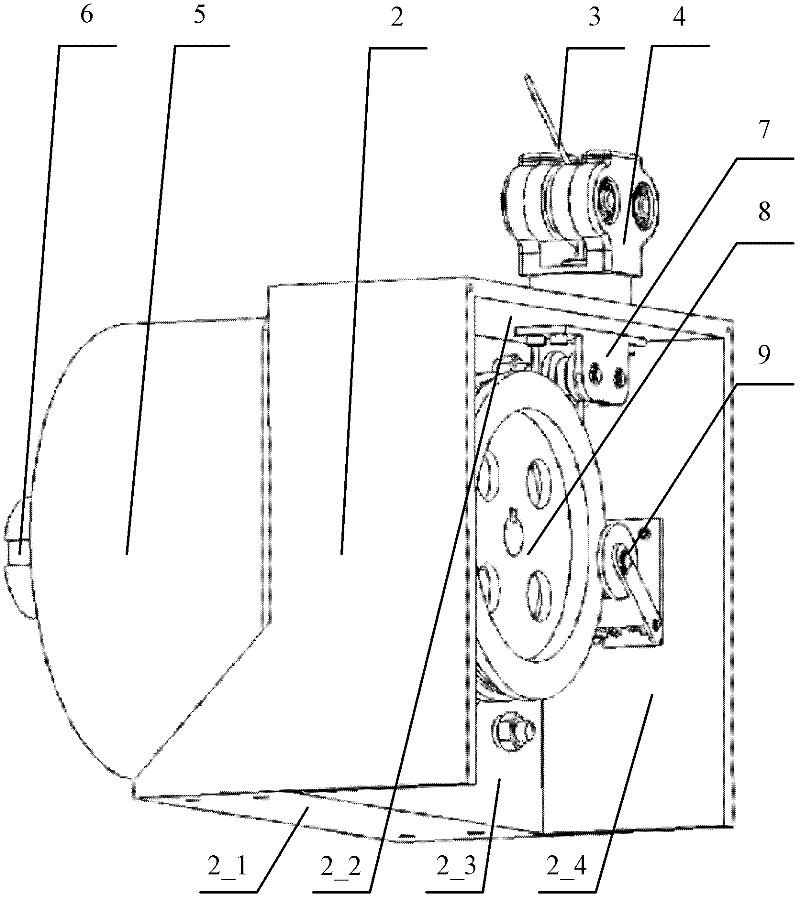

Flexible rope driving device having automatic rope arranging and force measuring functions as well as method

The invention relates to a flexible rope driving device having automatic rope arranging and force measuring functions as well as a method. The device mainly comprises a photoelectric encoder, a permanent-magnet direct-current torque motor, a roller, a ball screw, a back support, a flexible rope, a U-groove guiding mechanism, a force measuring guiding mechanism, a circulation guiding mechanism, a locking device and the like. The roller is driven by the permanent-magnet direct-current torque motor to rotate and moves spirally under the co-constraint of the ball screw and cylindrical guide rails, and the two functions of rope winding and rope arranging can be realized simultaneously. The flexible rope winds around the roller and is output through the U-groove guiding mechanism, the force measuring guiding mechanism and the circulation guiding mechanism sequentially. Two times of the flexible rope tension is measured by a tension sensor, so that the noise of the sensor and the effect of the inertia of the sensor on the measurement result can be reduced; and the locking device controls rotation of the screw, and thus the rope arranging function can be started and stopped. The device has the basic functions of rope winding, rope arranging, guiding, force measuring, jamming prevention and the like, adopts the modular design as a whole, is simple in structure, small in occupation size and high in force measuring accuracy, and the flexible rope winds evenly.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

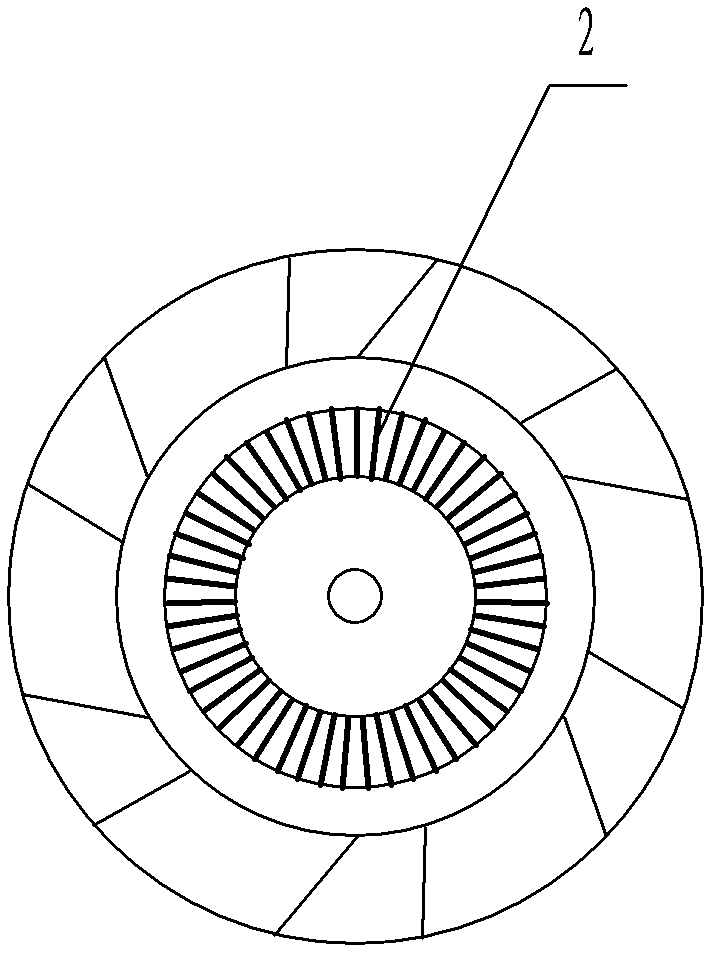

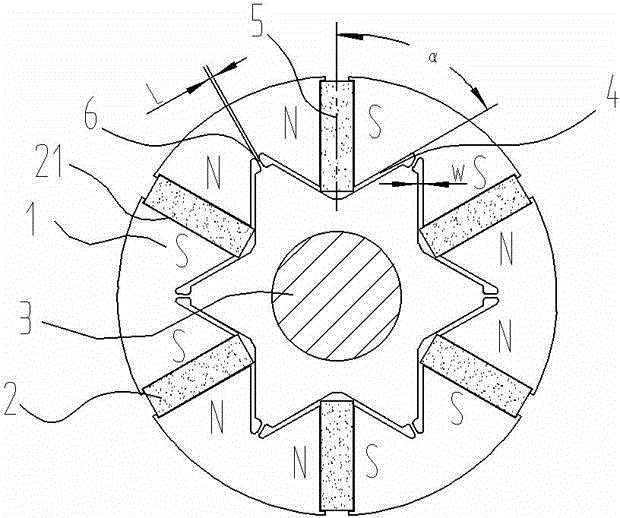

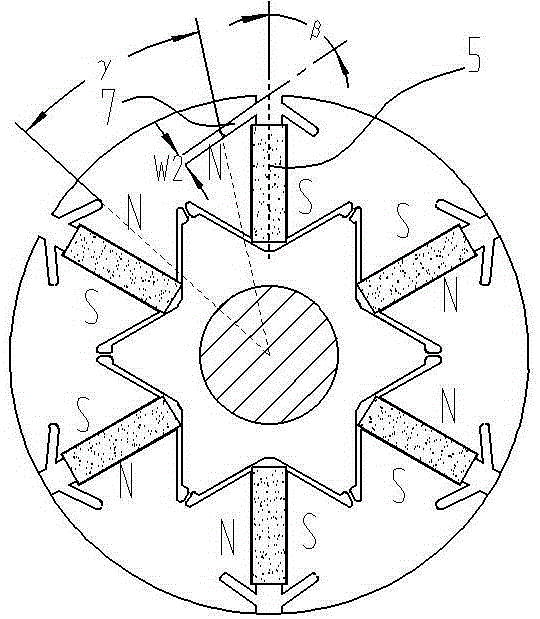

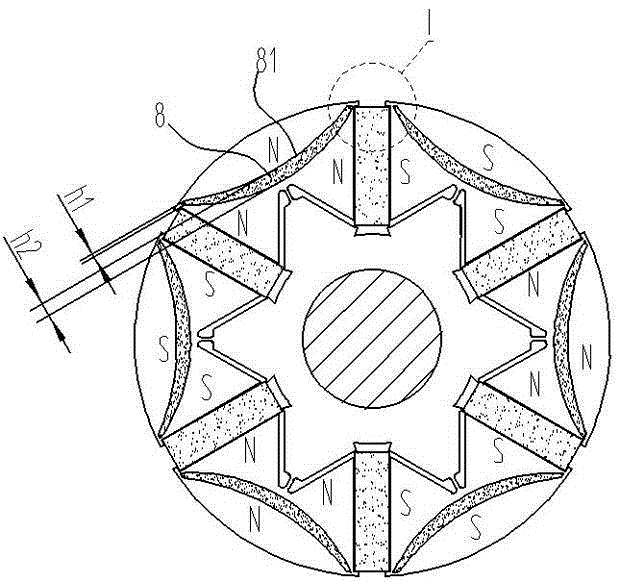

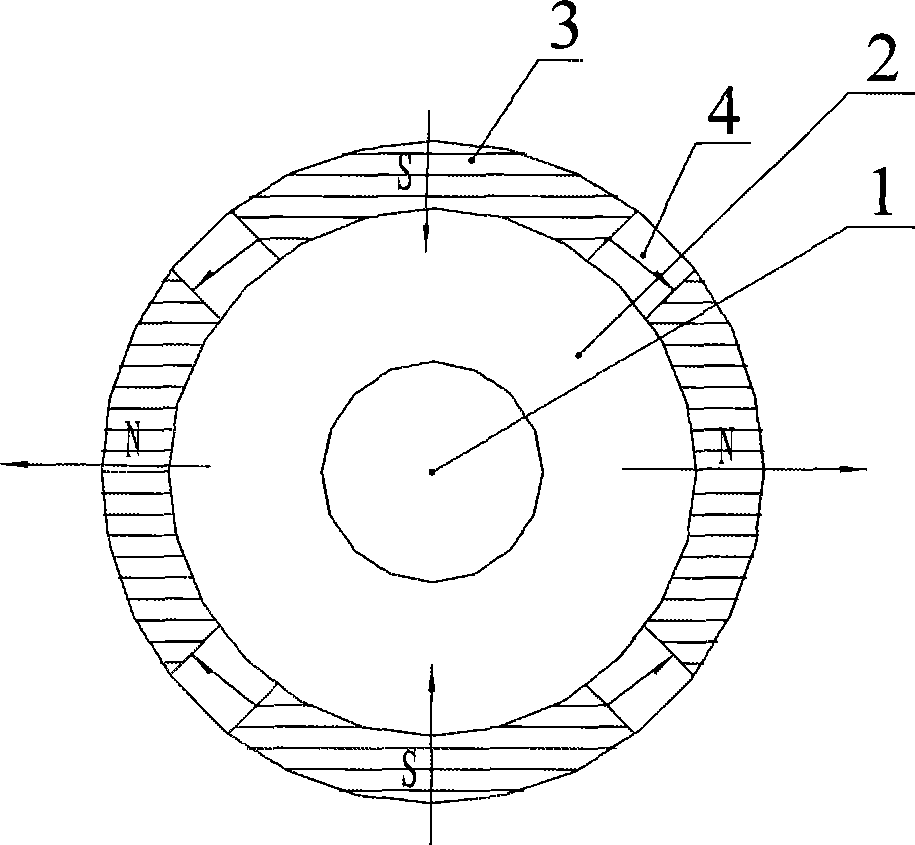

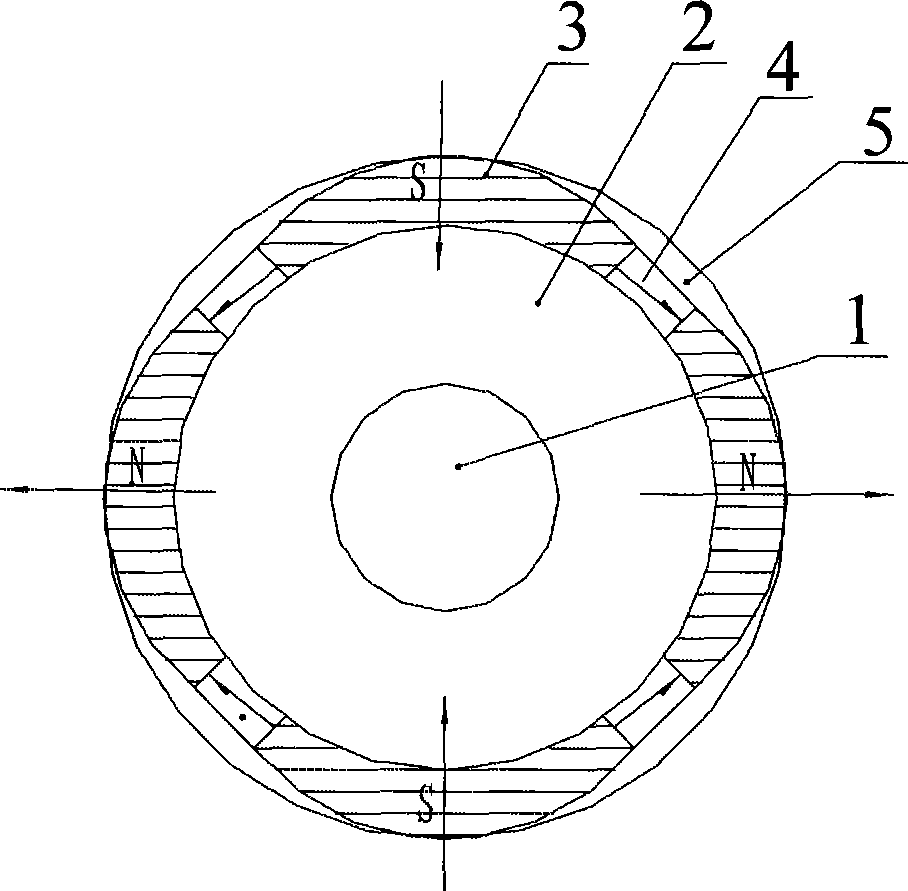

Rotor structure used for tangential permanent magnet direct current brushless motor, and tangential permanent magnet direct current brushless motor

InactiveCN105305760AIncrease working pointHigh torque/current ratioMagnetic circuit rotating partsBrushless motorsElectric machine

The invention discloses a rotor structure used for a tangential permanent magnet direct current brushless motor, and the tangential permanent magnet direct current brushless motor. The rotor structure comprises a rotor iron core, tangential permanent magnets and a rotation shaft; an even number of tangential permanent magnet grooves are formed in the circumference of the rotor iron core radially at the equal intervals; the tangential permanent magnets with the opposite polarities are arranged in the adjacent tangential permanent magnet grooves; the tangential permanent magnets are connected with or disconnected from the near air gap side; the central symmetry of the rotor iron core is maintained; the sides, close to the rotation shaft, of the tangential permanent magnet grooves are communicated with flux-insulation grooves on the two sides of the tangential permanent magnet grooves; the near air gap side of the flux-insulation grooves and the central line of the corresponding tangential permanent magnet grooves extend outwardly at an angle of alpha; and a radially-distributed flux-insulation bridge is formed between the adjacent flux-insulation grooves. The rotor structure used for the tangential permanent magnet direct current brushless motor is simple and compact in structure, small in magnetic leakage factor, high in mechanical strength, convenient to produce, low in manufacturing cost, higher in resistance to demagnetization, and high in overload capacity, so that the tangential permanent magnet direct current brushless motor is higher in torque / current ratio, torque / volume ratio and motor efficiency; and therefore, the rotor structure used for the tangential permanent magnet direct current brushless motor, and the tangential permanent magnet direct current brushless motor are brighter in the application prospects.

Owner:NANJING KANGNI ELECTRONICS TECH

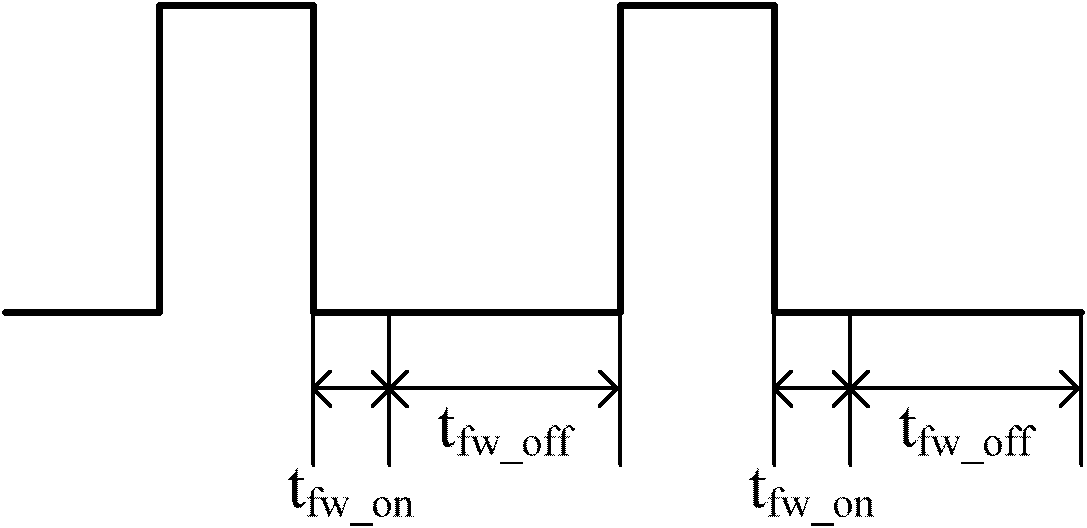

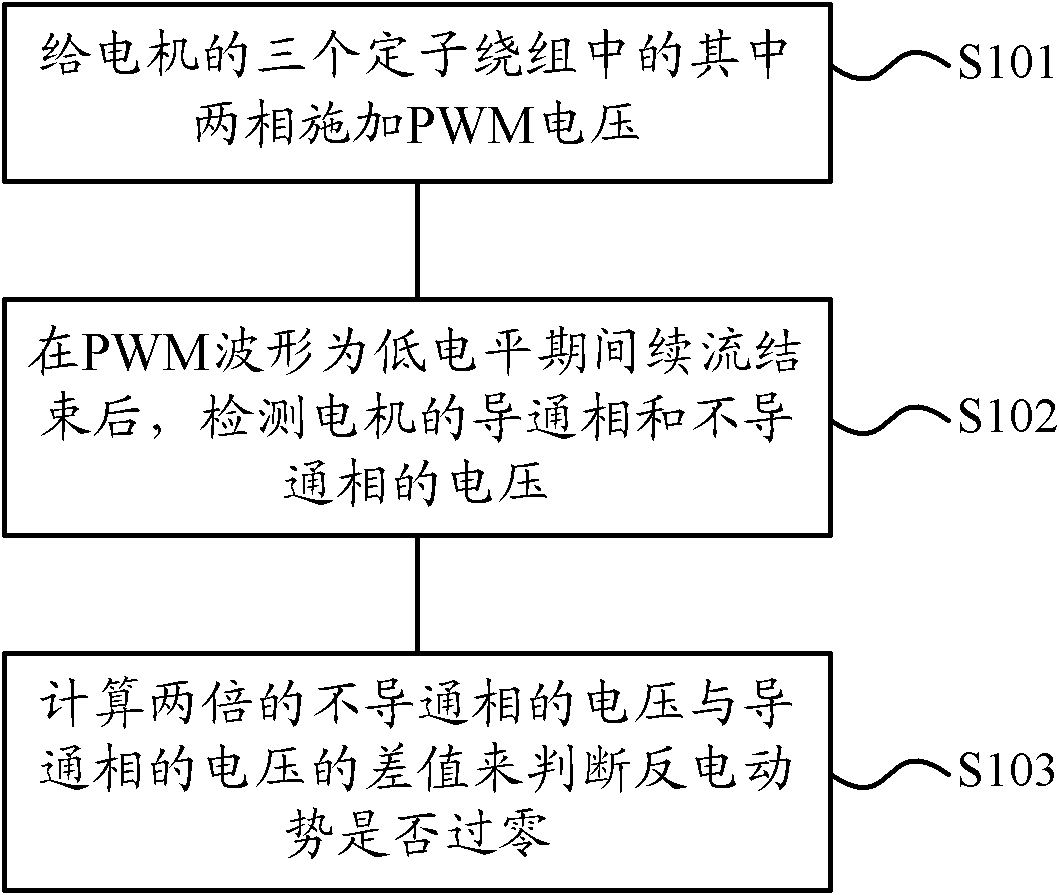

Zero passage detection method and device of counter electromotive force of permanent magnet direct current brushless Hall motor

ActiveCN102012454AEasy to controlEasy to determineCurrent/voltage measurementElectric machineCounter-electromotive force

The invention provides a zero passage detection method of counter electromotive force of a permanent magnet direct current brushless Hall motor, comprising the following steps of: applying PWM (Pulse Wavelength Modulation) voltage on two phases of three stator windings of the motor; detecting the voltage of a conducting phase and a non-conducting phase of the motor after the follow current of the PWM waveform during low level is finished; and judging whether the counter electromotive force passes zero or not by calculating the difference between two times of non-conducting voltage and the voltage of the conducting phase. The invention also provides a zero passage detection device of the counter electromotive force of the permanent magnet direct current brushless Hall motor. Since the detection is not carried out when the PWM waveform is high level, the filter and high-frequency noise can be avoided; and the invention has the advantages of favorable control performance, high precision, wide application range and low cost and is simple for realization in the whole detection process, can conveniently determine the position of a motor rotor in the operation process and realize the control of a brushless direct current motor without a Hall sensor.

Owner:SINO WEALTH ELECTRONICS

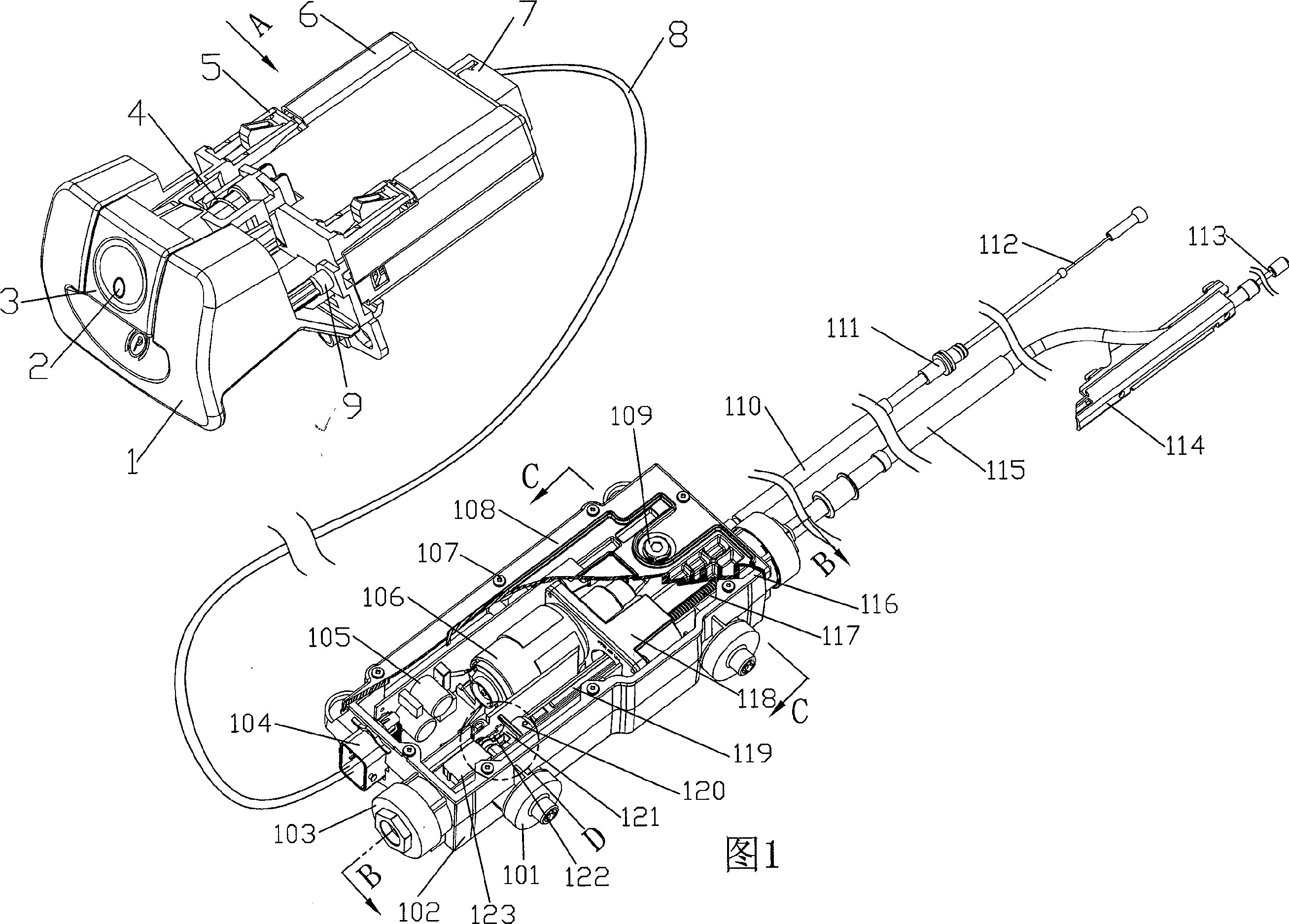

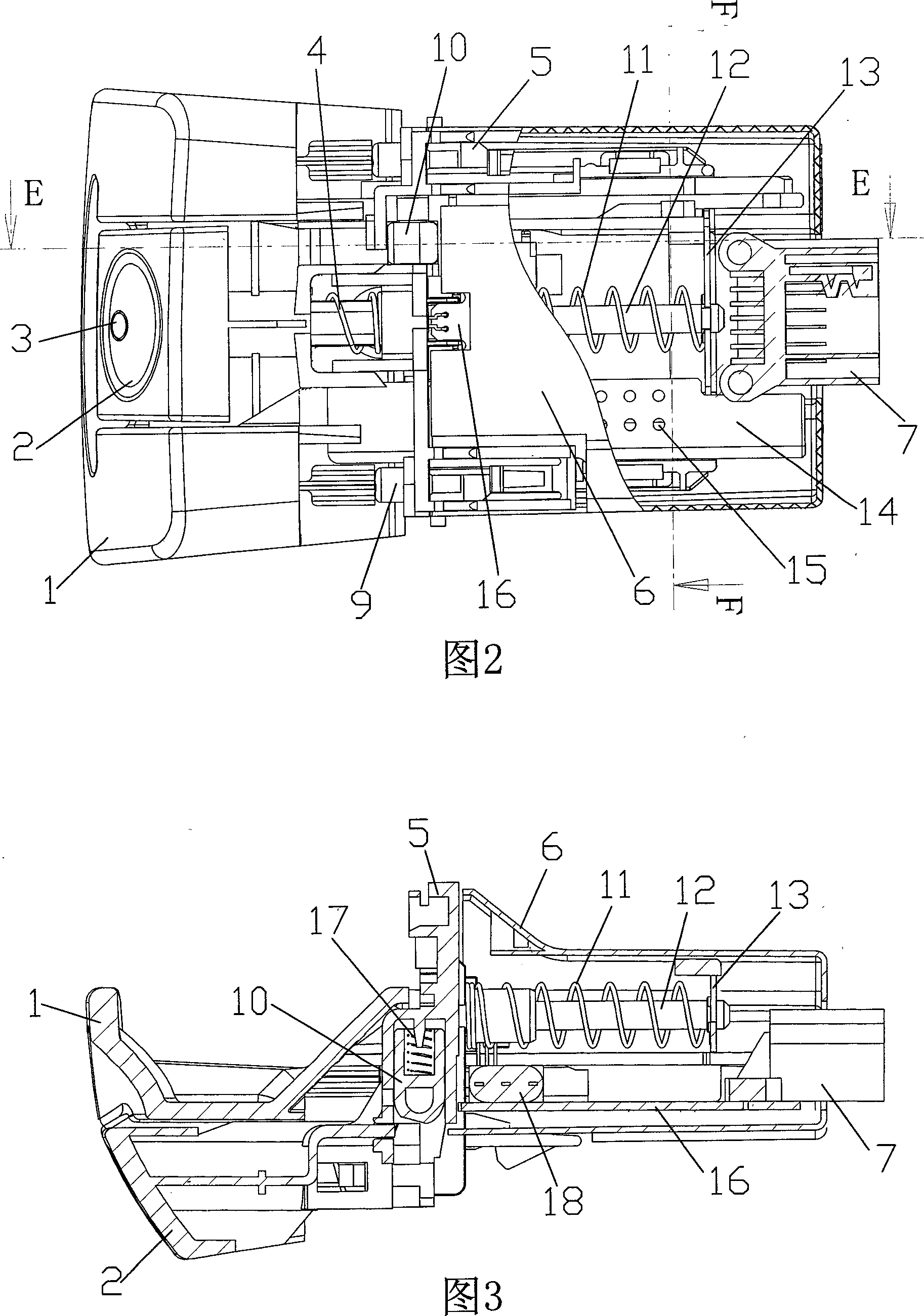

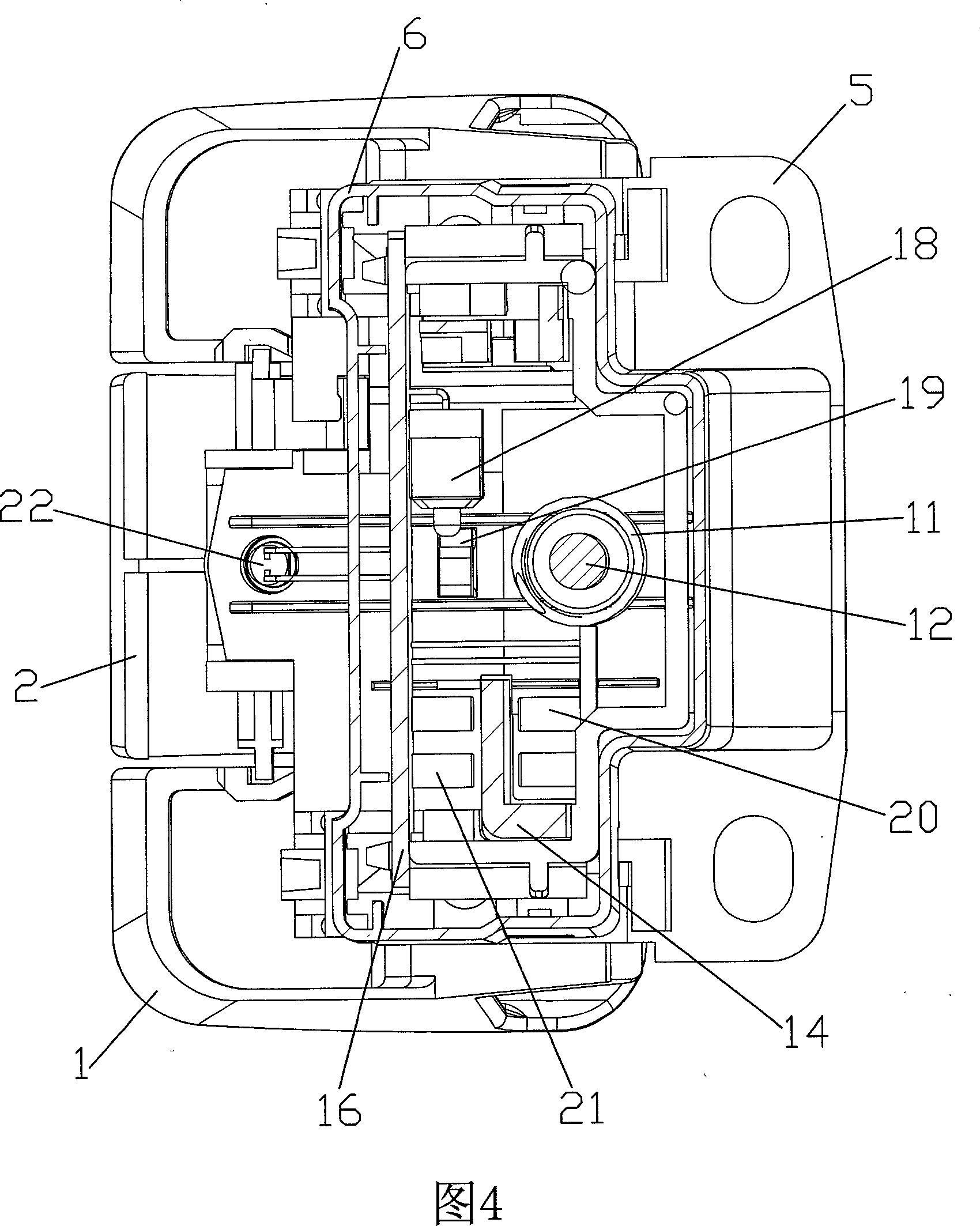

Electric parking device for car

ActiveCN101148168ARealization of electric parkingImprove securityBraking action transmissionInfraredDriver/operator

The electrically driven parking device for automobile includes one parking switch module comprising one casing, one switch rack, one circuit board, one infrared emitting tube and one infrared receiving tube; one parking button with one connected board with one through hole sliding between the infrared emitting tube and the infrared receiving tube; and one executing mechanism comprising one casing, one permanent magnetic DC motor, one speed reducer, one copper sleeve, one screw rod, one braking rope and one rope joint connected to the back wheel braking rope. The present invention is for the driver to control parking electrically while showing the brake state and alarming for fault prompt.

Owner:GUANGXI WANCHAO AUTOMOBILE ELECTRICAL APPLIANCE CO LTD

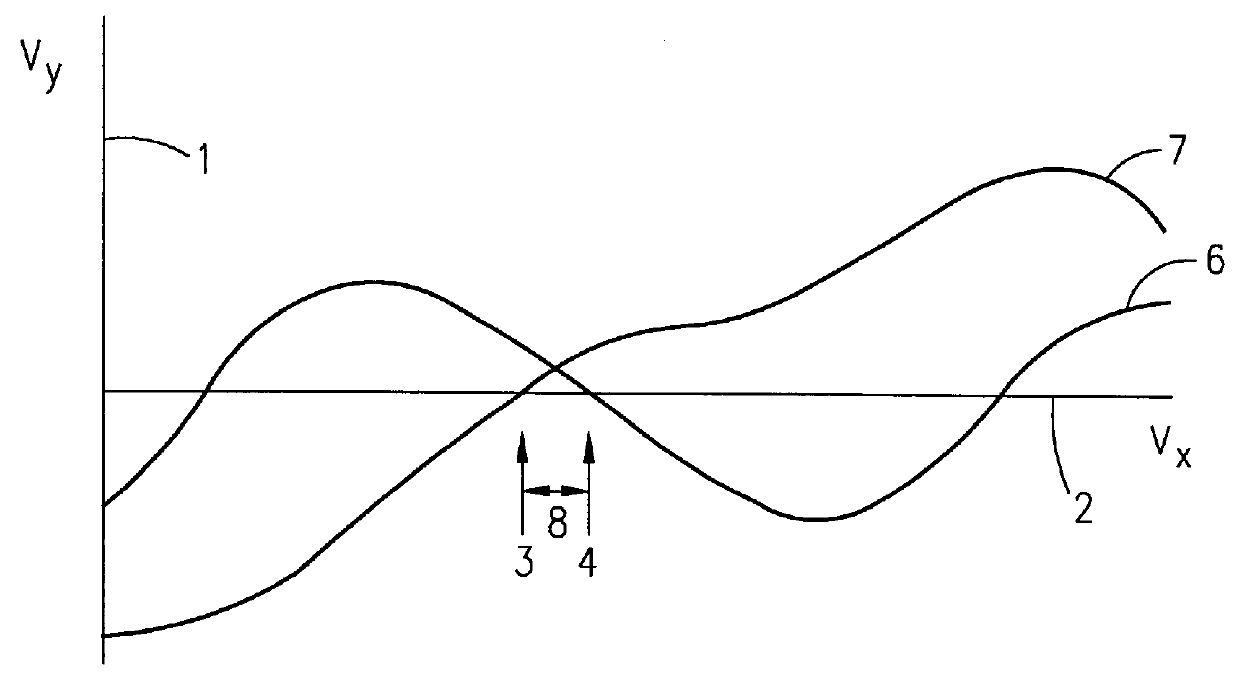

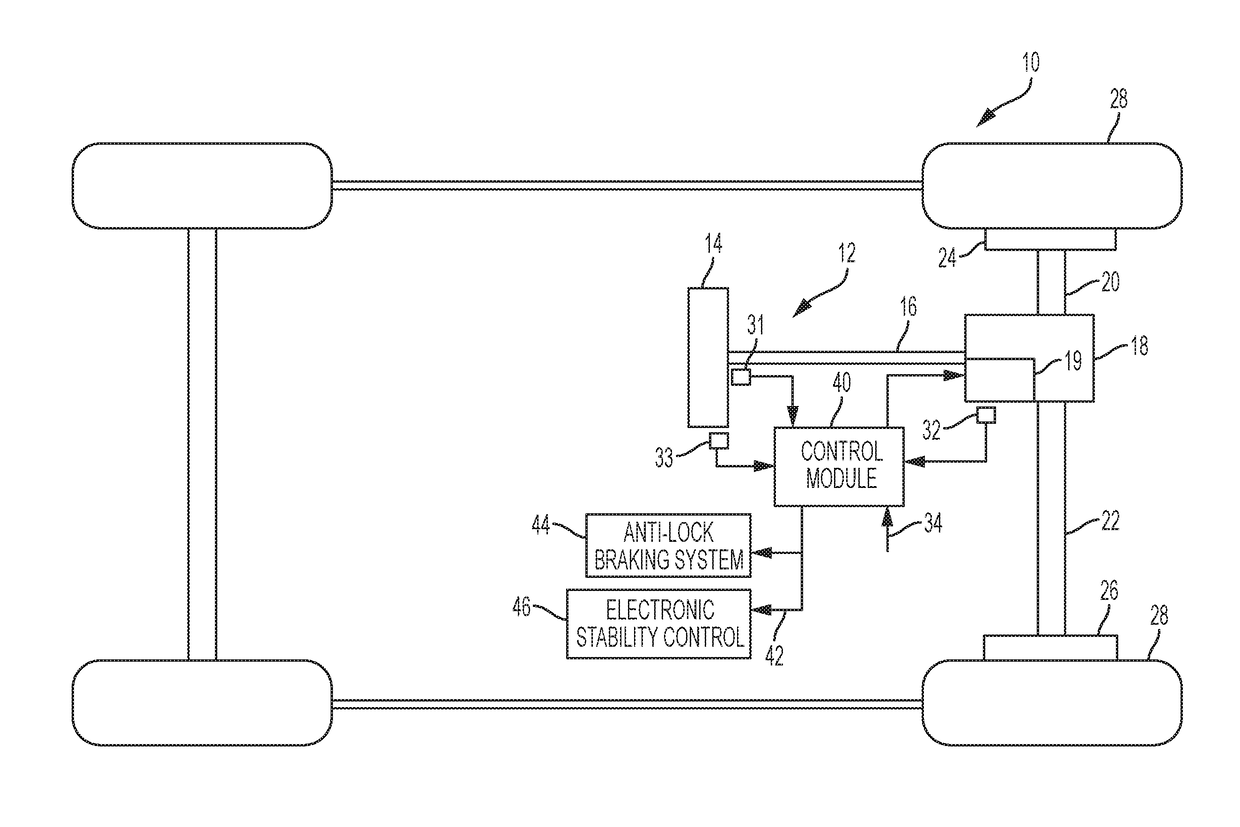

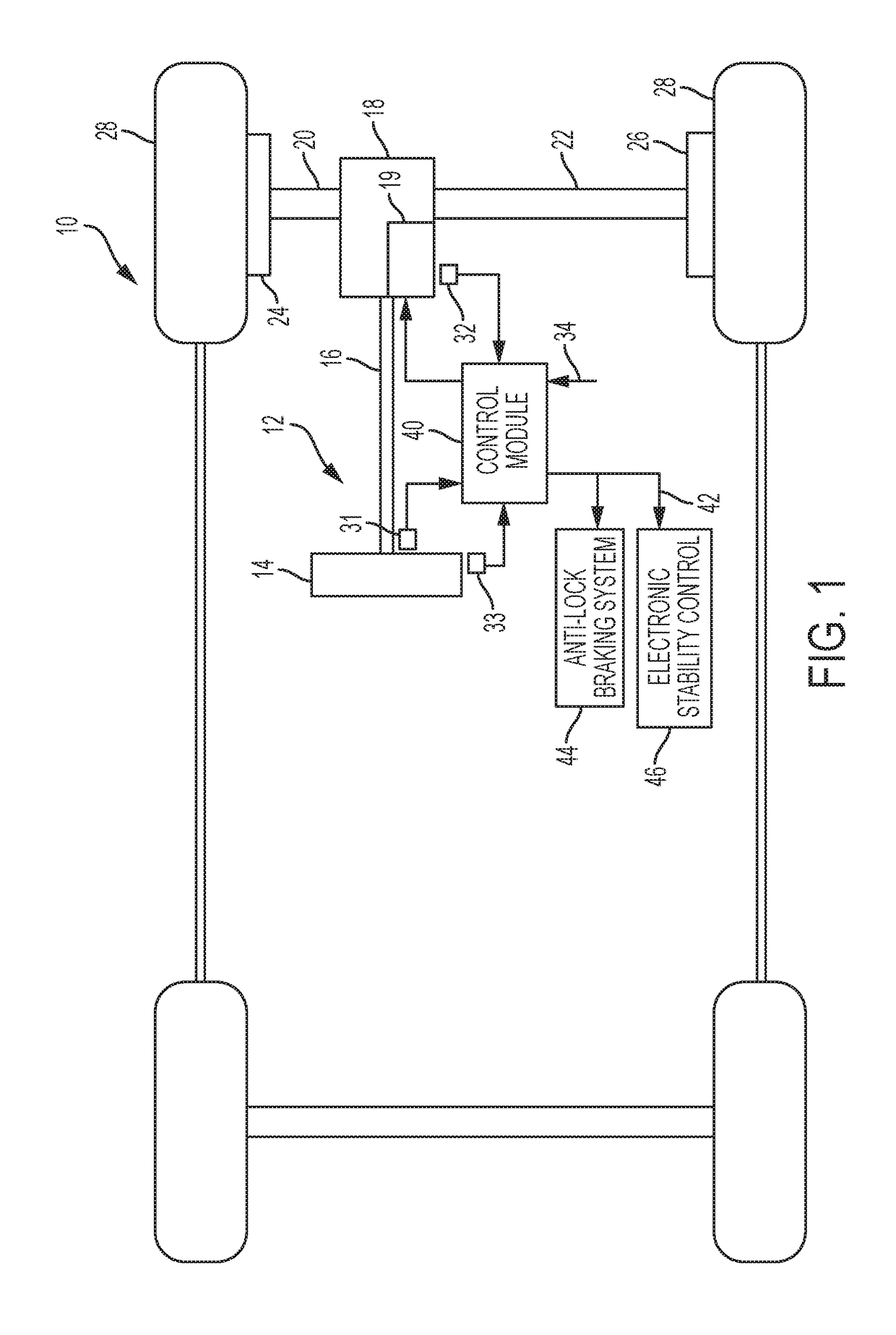

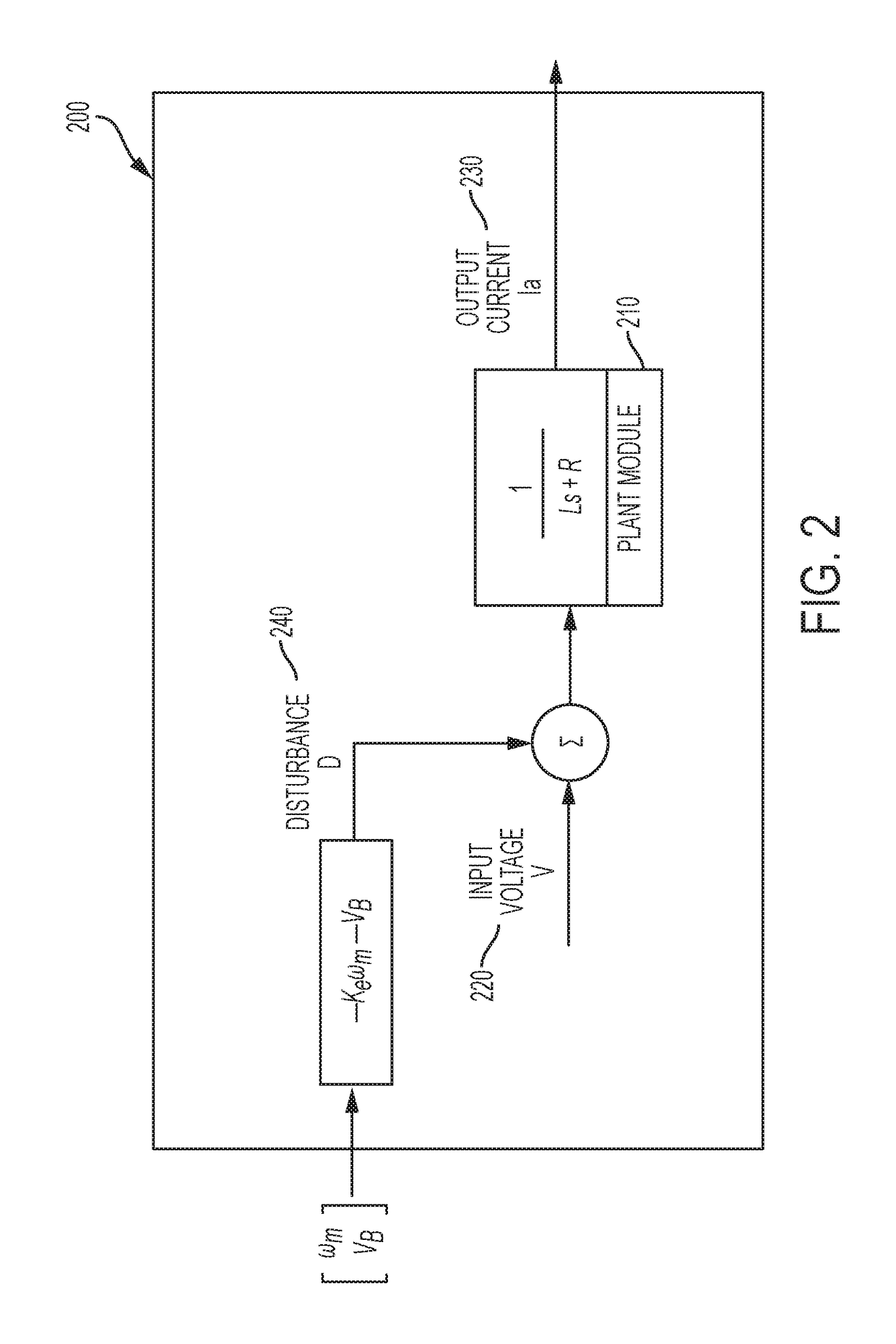

Disturbance observer for permanent magnet direct current machines

ActiveUS20180316291A1Improve motor performanceField or armature current controlElectrical steeringPower flowControl system

Technical solutions are described for a motor control system of a motor to compute a disturbance estimate and use the disturbance estimate to improve the performance of the motor control system. For example, the motor control system includes an observer module that receives an input voltage signal of the motor. The motor control system also receives an output current signal from the motor. The motor control system further computes the disturbance estimate of the motor control system based on a plant model of an electrical subsystem of the motor control system.

Owner:STEERING SOLUTIONS IP HLDG

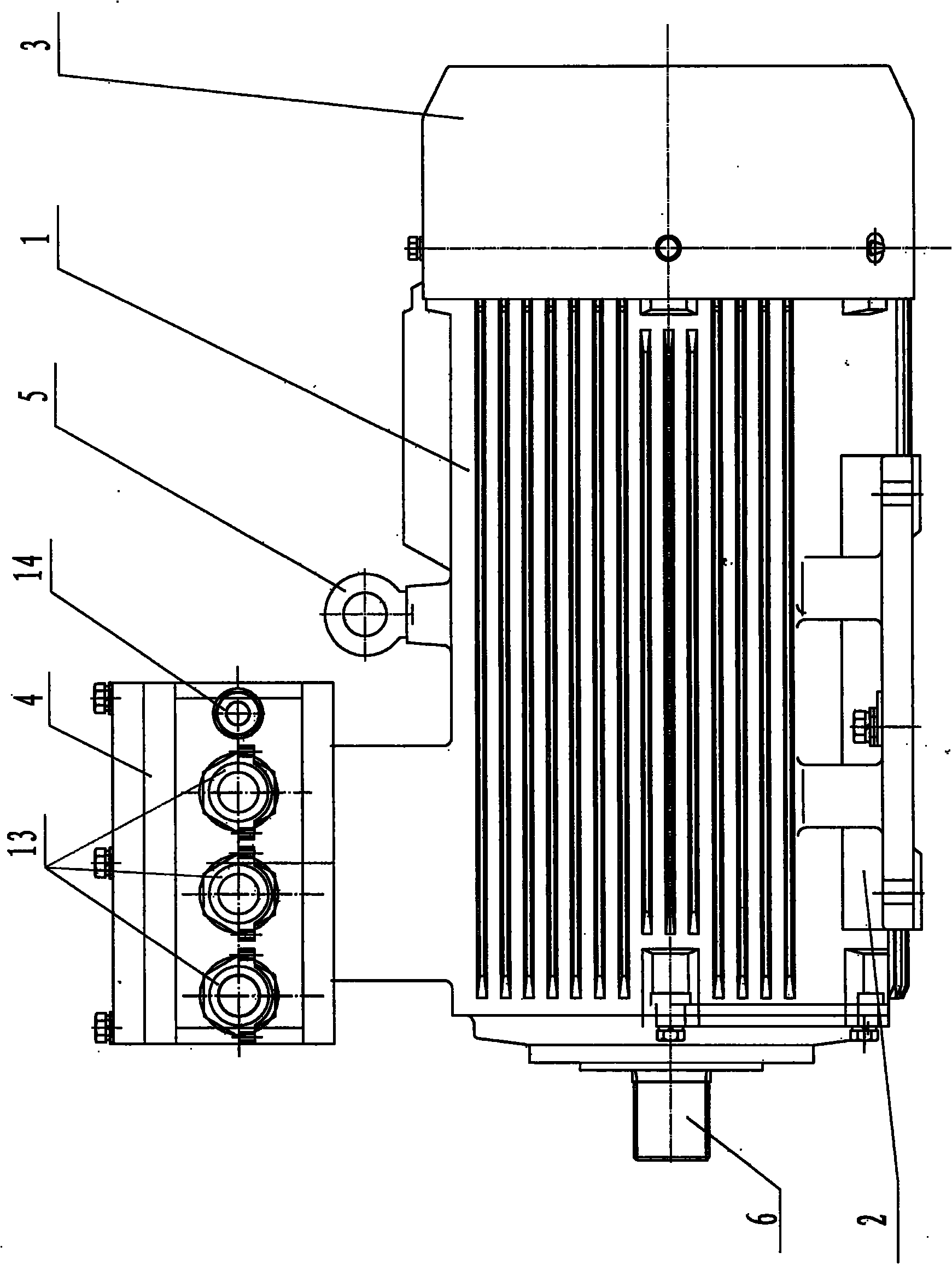

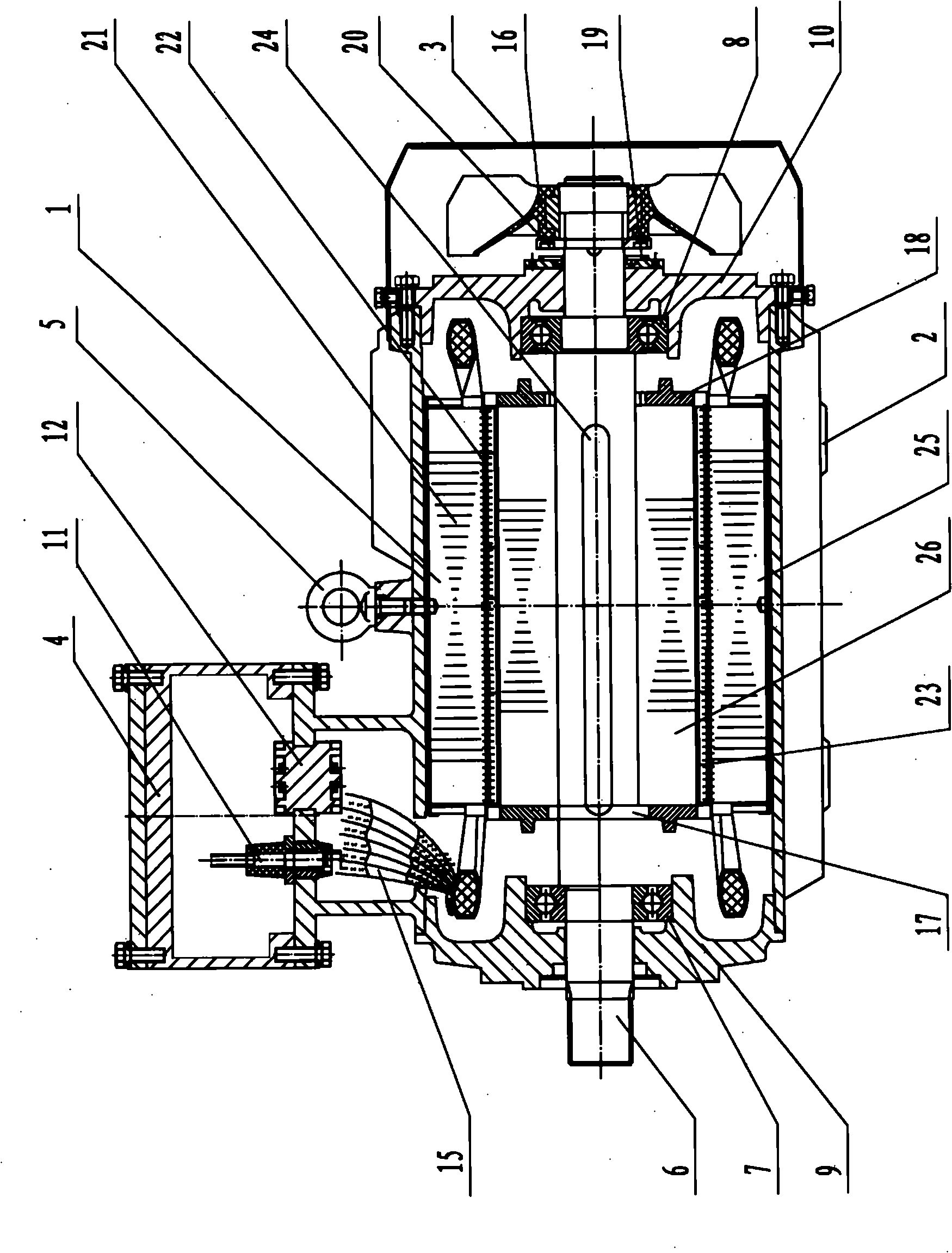

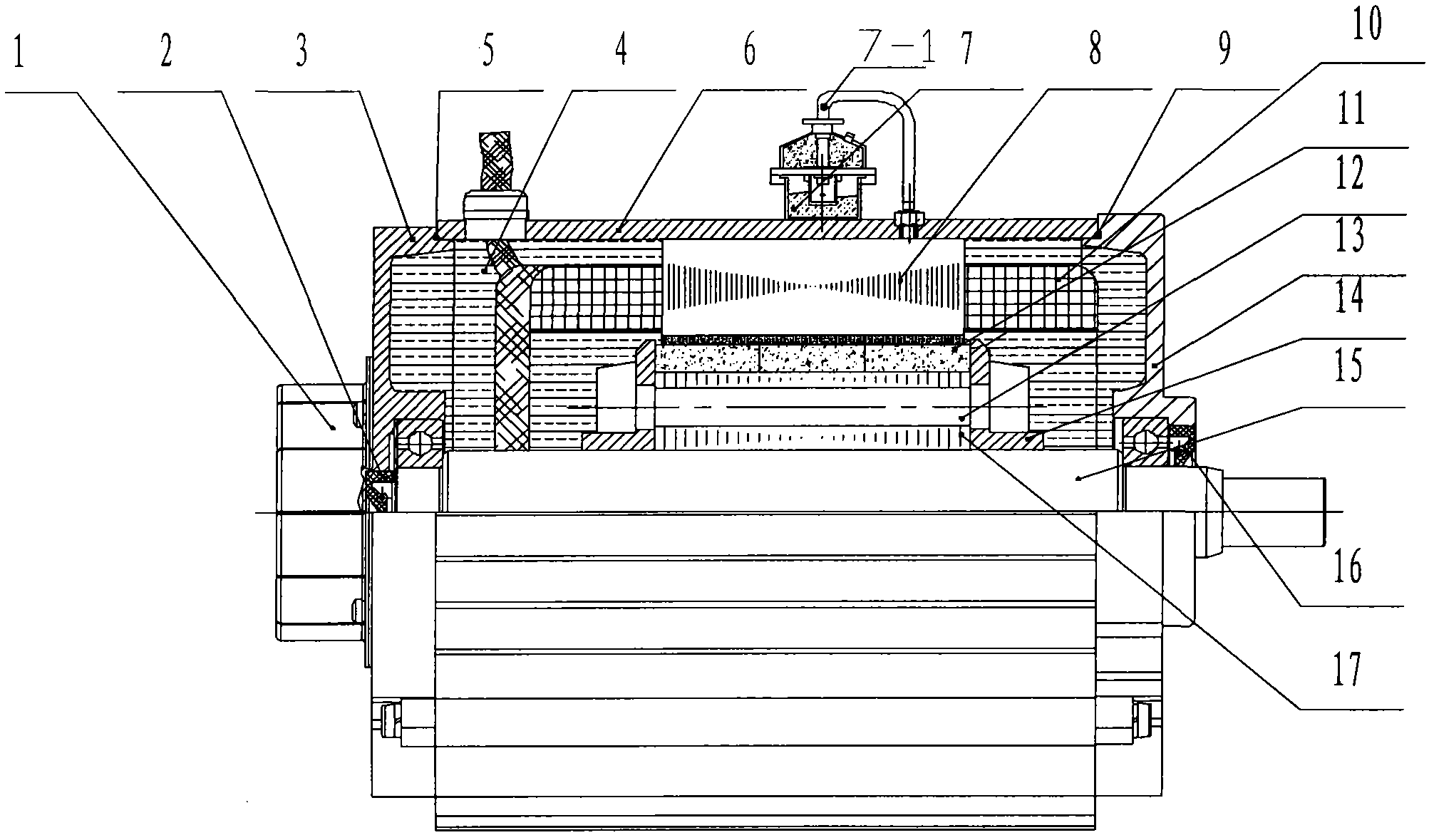

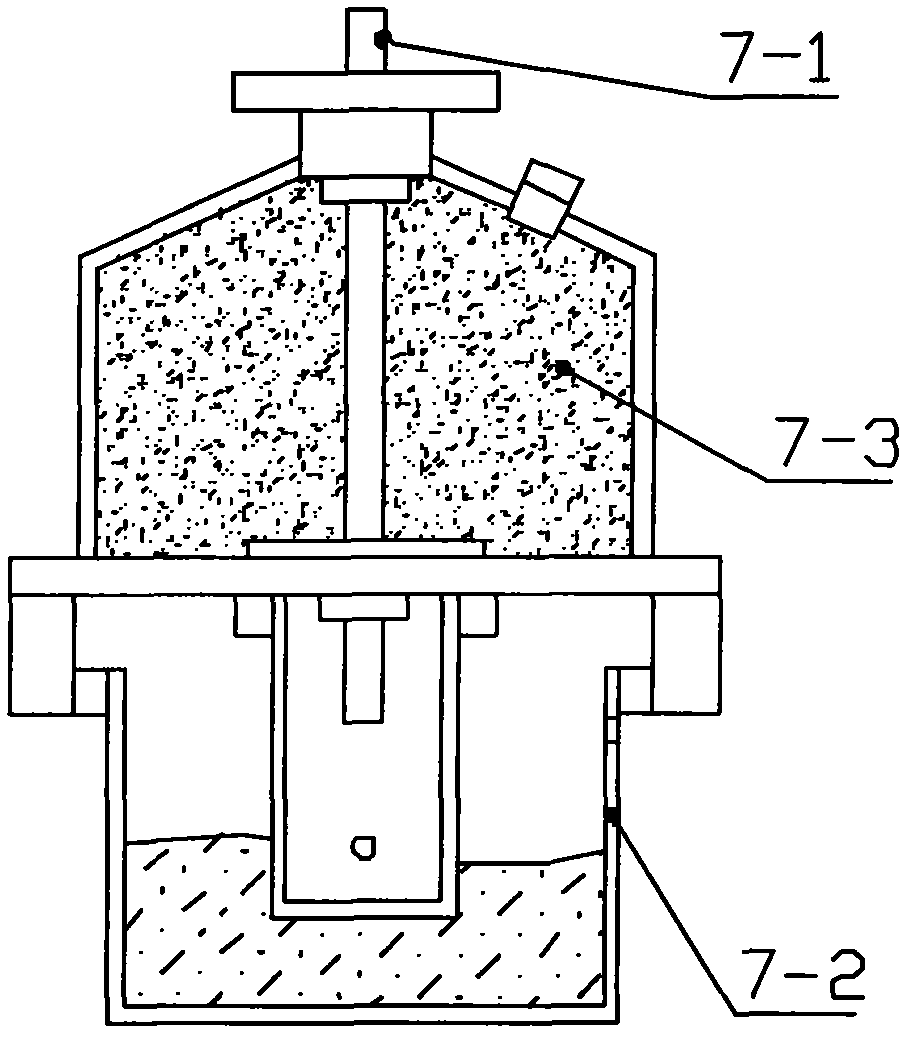

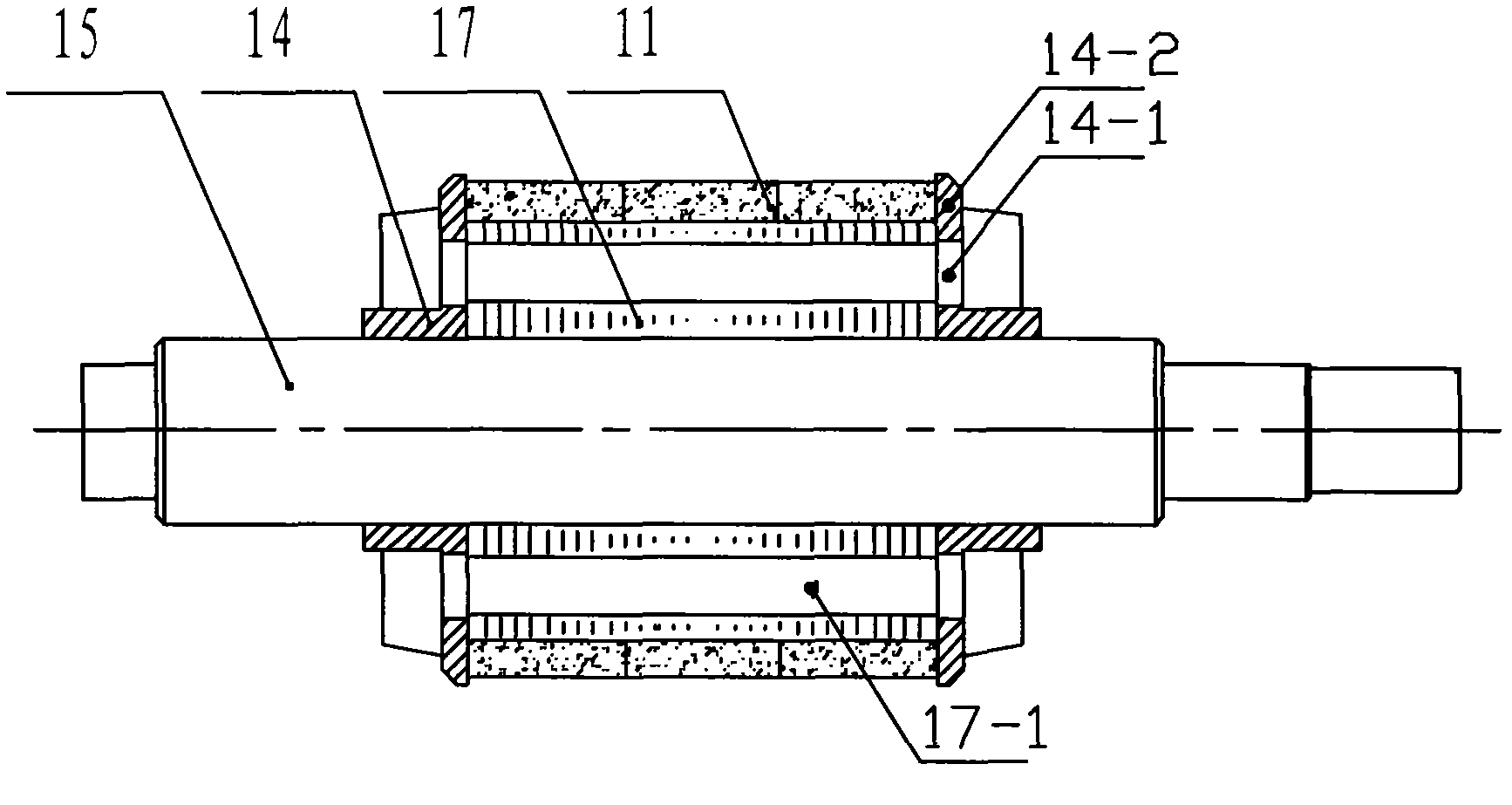

Internal circulation oil-cooled permanent-magnet direct-current motor

ActiveCN102104297ASimple structureStable jobCooling/ventillation arrangementSupports/enclosures/casingsBrushless motorsRespirator

The invention discloses an internal circulation oil-cooled permanent-magnet direct-current motor, and relates to a permanent-magnet direct-current motor, in particular to an oil-cooled permanent-magnet direct-current brushless motor. A motor shaft is horizontally arranged in a shell; a rotor is arranged on the motor shaft; the rotor is arranged on the outer circumference of the rotor; the rotor is folded into a magnetic core by disc-shaped steel plates; a sealing device is arranged on the motor; a cooling oil circulating system is arranged in the motor; in the system, the motor is filled withcooling oil; the disc-shaped steel plates are provided with steel plate through holes; when the disc-shaped steel plates are folded into the magnetic core, cooling oil circulation channels are formedamong the steel plate through holes correspondingly; limit ring blades are arranged inside two limit rings; limit ring circular holes are reserved on the limit ring blades; the positions and the number of the limit ring circular holes are consistent with the positions and the number of the steel plate through holes on the disc-shaped steel plates; a respirator is arranged out of the shell; and the two ends of a conduit of the respirator are respectively connected with the lower cavity of the shell and the inside of the shell. The internal circulation oil-cooled permanent-magnet direct-currentmotor solves the problems that a cooling effect is poor and a permanent-magnet cannot be cooled directly in conventional similar motors.

Owner:ZHEJIANG UNITE MOTOR

Low noise fast response permanent magnet DC brushless motor for constant wind control

InactiveCN101459370AImprove qualityReduce torque fluctuationMagnetic circuit rotating partsMagnetic circuit stationary partsLow noiseBrushless motors

The invention provides a low noise fast response permanent magnet direct current brushless motor for controlling constant air volume, which comprises a shell, a stator and a rotor in the shell, wherein the stator comprises a stator iron core and a stator winding which are fixed on the inner wall of the shell, the rotor comprises a main shaft and a rotor iron core, the external circumferential direction of the rotor iron core is evenly fixed with rotor magnetic poles which comprise radial magnetized magnetic steel and tangential magnetized magnetic steel, the radial magnetized magnetic steel is a main magnetic pole, and the tangential magnetized magnetic steel which is arranged between adjacent main magnetic poles is a side magnetic pole. Or, the inner circumferential direction of the rotor iron core is evenly embedded with built-in radial magnetized rectangular strip magnetic steel which is the main magnetic pole, and the tangential magnetized magnetic steel which is arranged between adjacent main magnetic poles is the side magnetic pole. The low noise fast response permanent magnet direct current brushless motor gathers magnetic through two ways of radial and tangential direction, thereby observably increasing the air gap flux density, greatly reducing the mechanical time constant, increasing fast response, controlling the constant air volume in a high performance, which leads a motor to steadily operate in high efficiency, saving energy, low fluctuation, low noise, frequent starting and rapid response, and the low noise fast response permanent magnet direct current brushless motor can achieve the miniaturization and lightening of the motor.

Owner:苏州和鑫电气股份有限公司

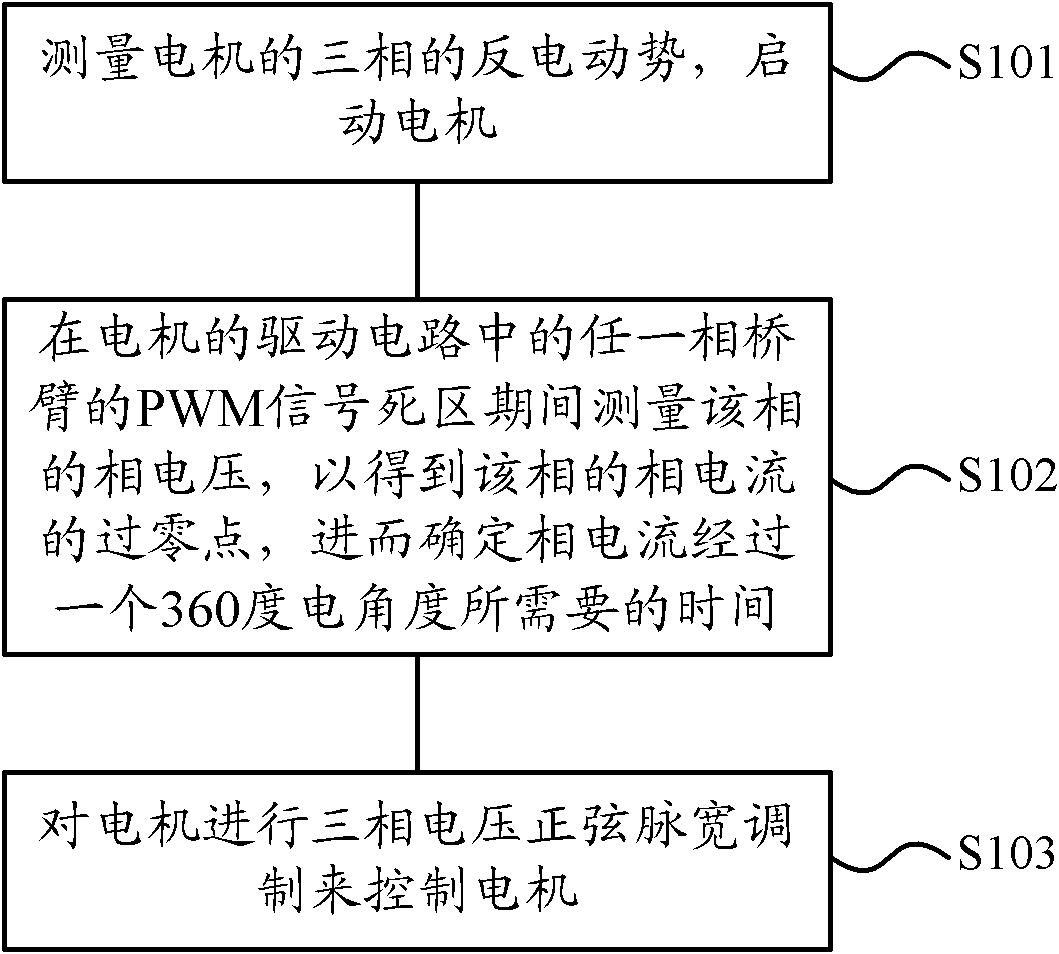

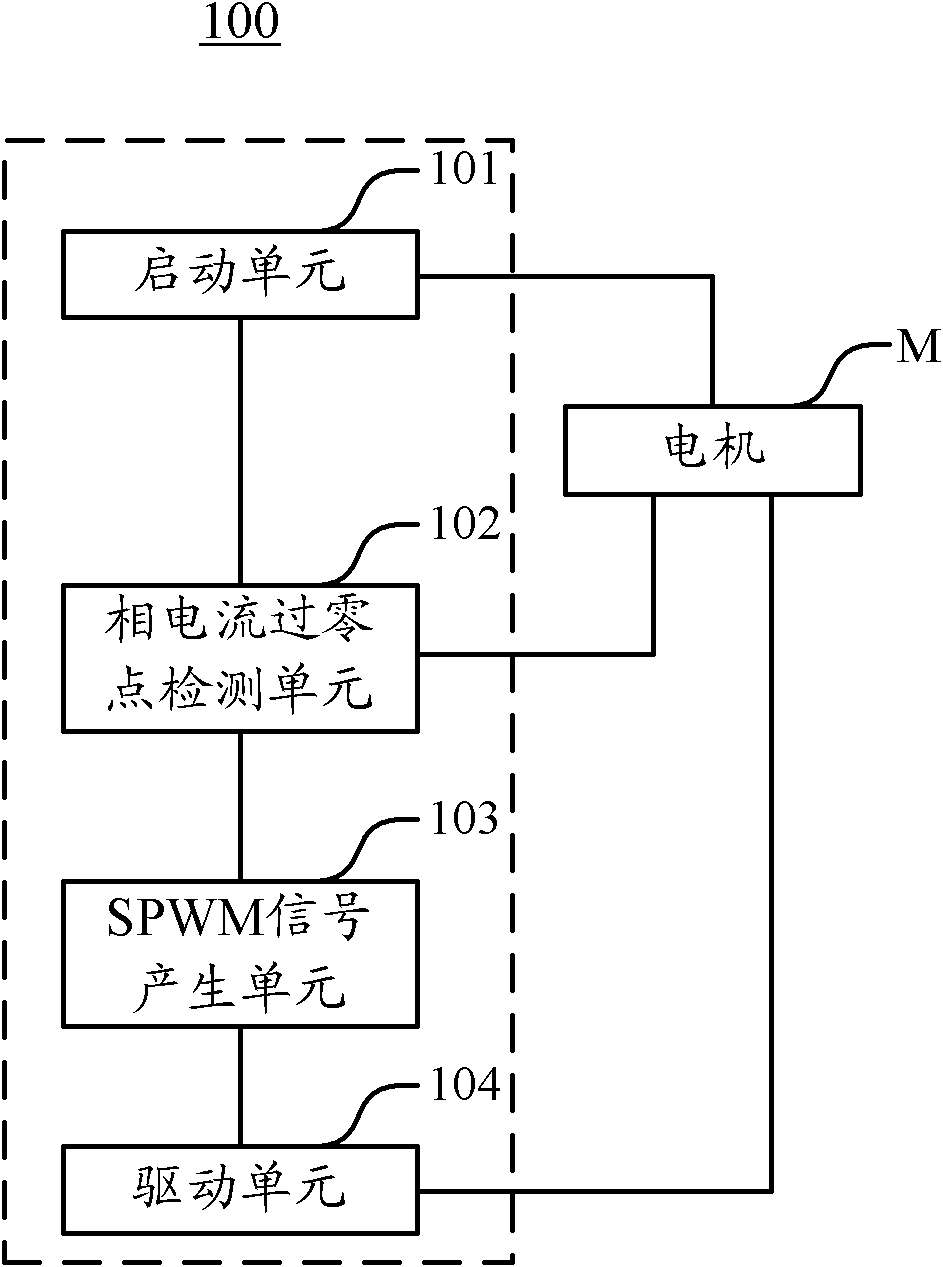

Method and device for controlling permanent magnet direct current brushless without hall motor

ActiveCN102005993AImprove controllabilityLow costSingle motor speed/torque controlElectronic commutatorsPhase currentsElectric machine

The invention provides a method for controlling a permanent magnet direct current brushless without hall motor, comprising the following steps of: measuring a three-phase counter electromotive force of the motor and starting the motor; measuring a phase voltage of any phase in a PWM (Pulse Width Modulation) signal dead zone period of the one phase of bridge arm in a driving circuit of the motor so as to obtain a zero crossing point of phase current of the phase to further determine the time required when the phase current passes through a 360-degree electrical angle; and carrying out three-phase voltage sine pulse width modification (SPWM) on the motor so as to control the motor. Correspondingly, the invention also provides a device for controlling the permanent magnet direct current brushless without hall motor. After the motor is started, the phase voltage of any phase is measured at the PWM signal dead zone period of the one phase of the bridge arm of the driving circuit of the motor to finally obtain the time required when the phase current passes through the 360-degree electrical angle, and then the motor is controlled by using a three-phase SPWM method. In the invention, the motor is controlled on the basis of the existing conditions without extra hardware resources; and the invention is simple and reliable and has good controllability and low cost.

Owner:SINO WEALTH ELECTRONICS

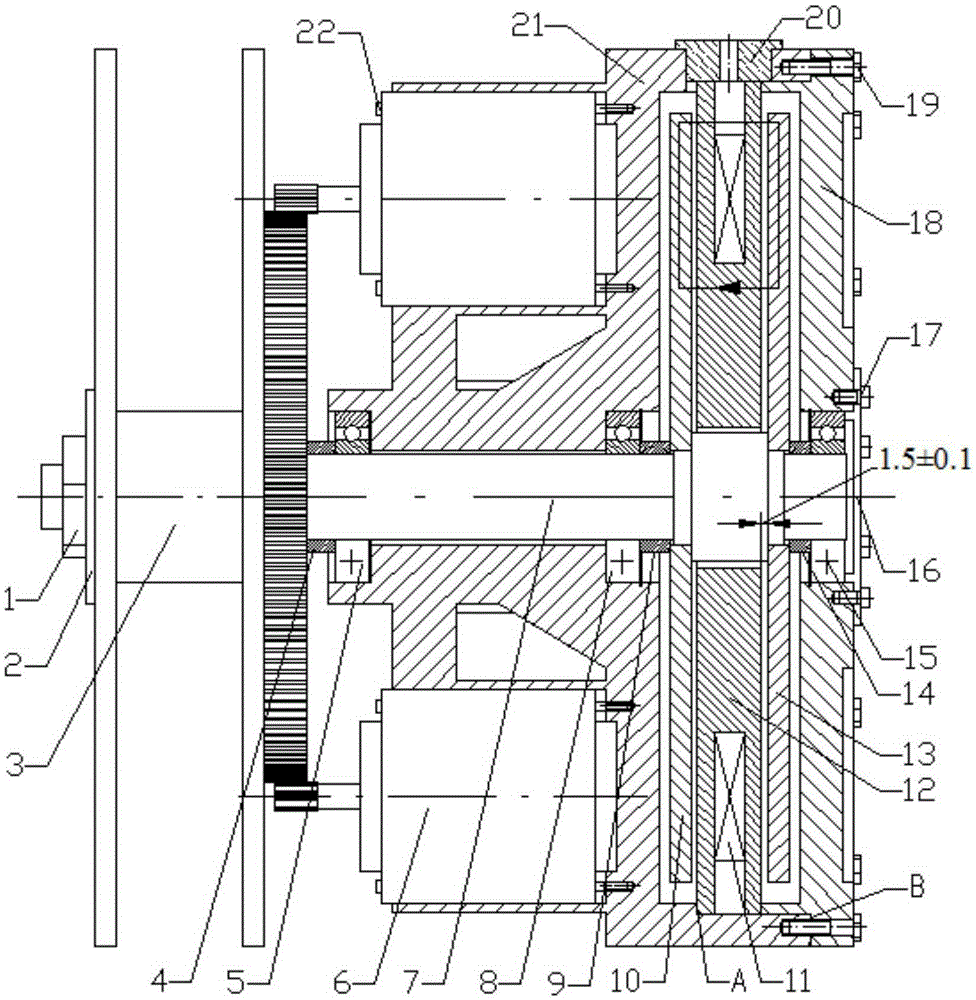

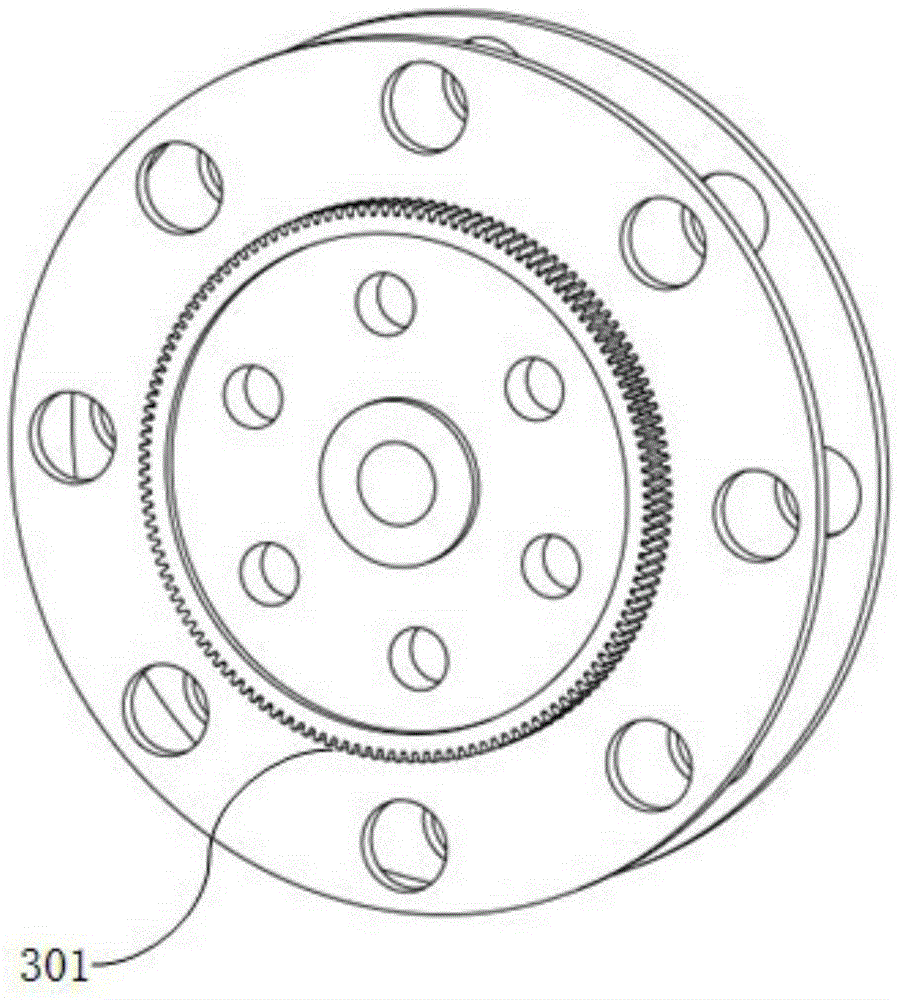

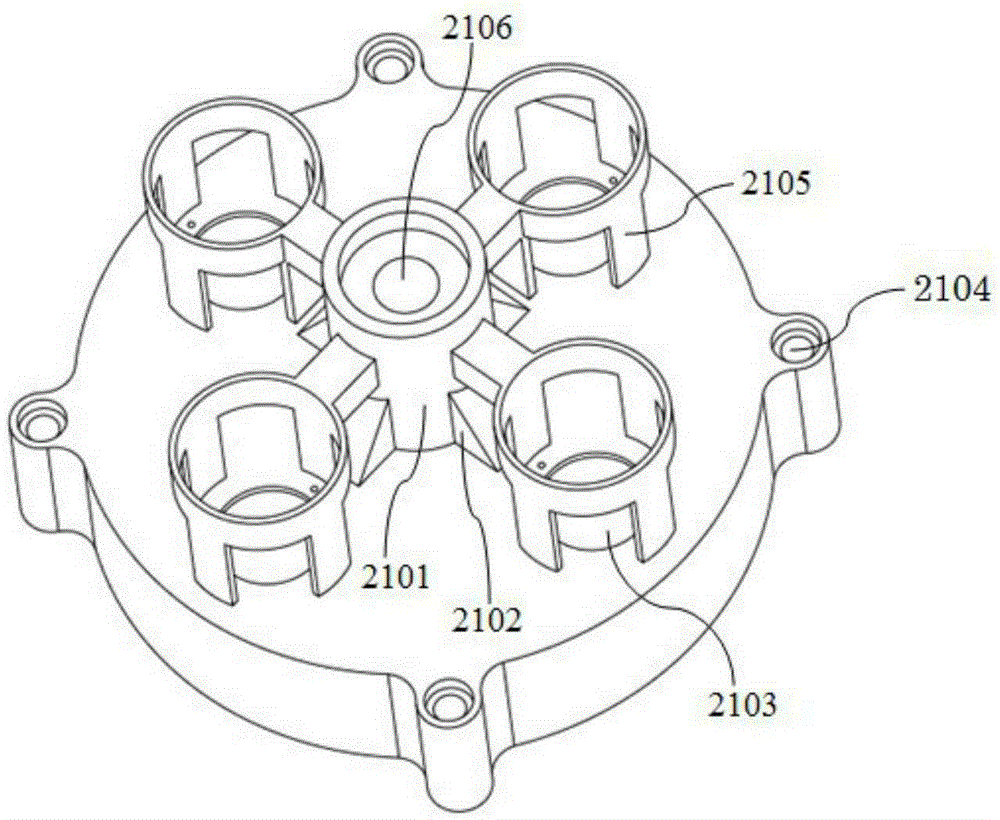

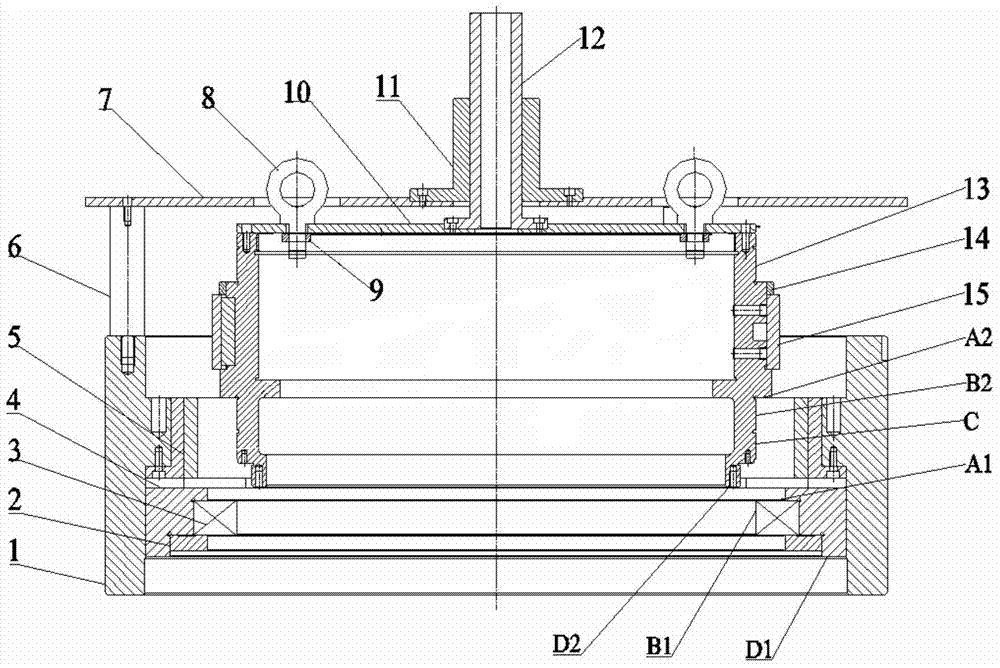

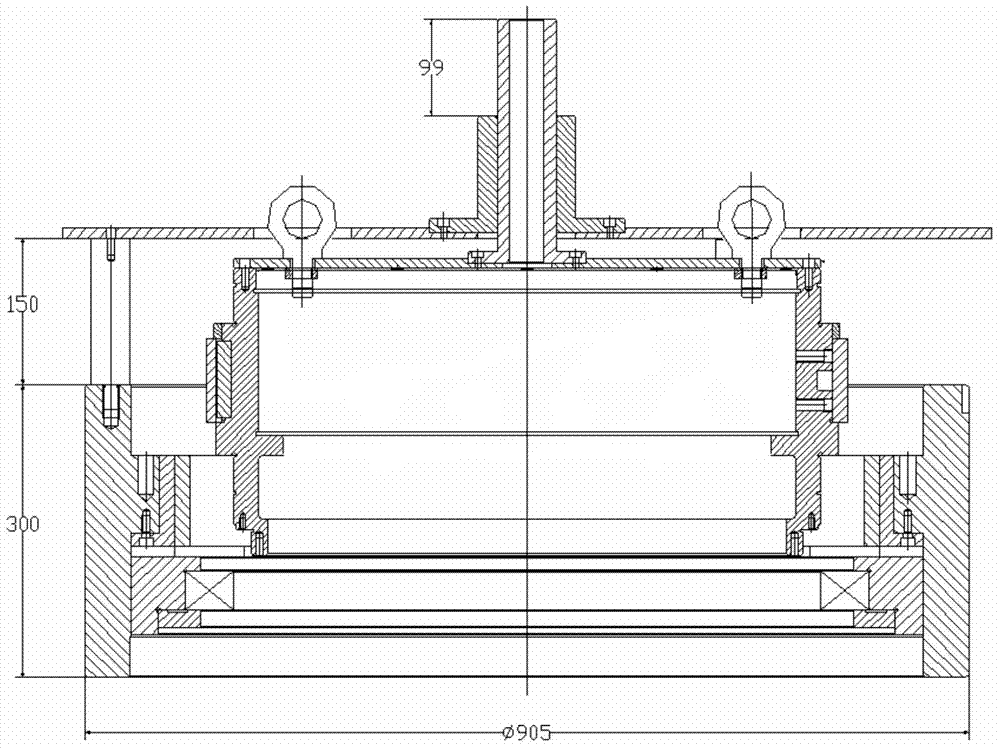

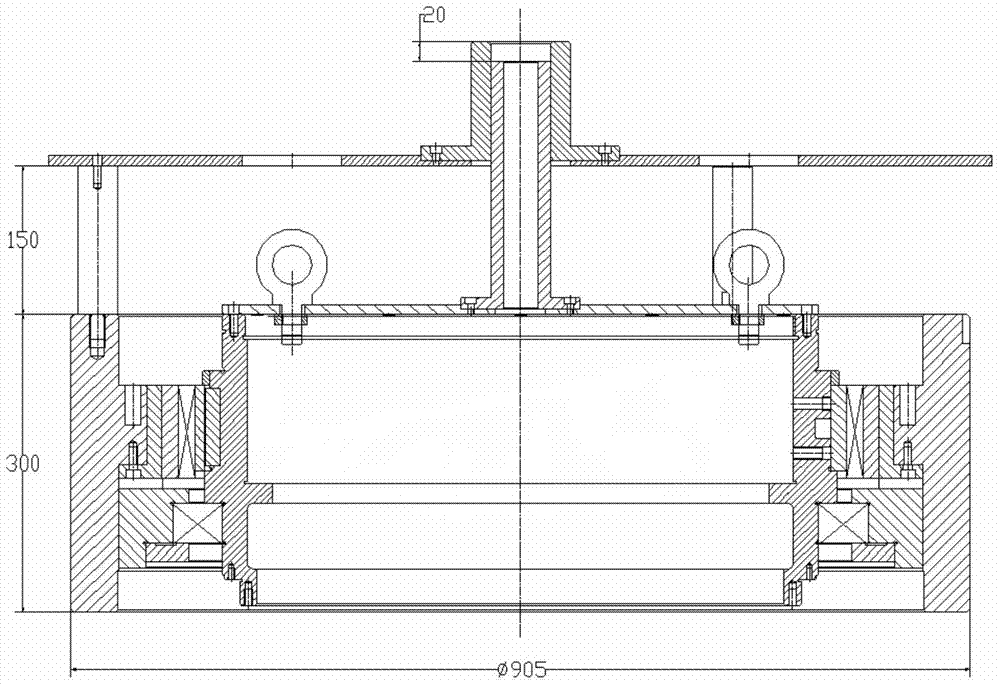

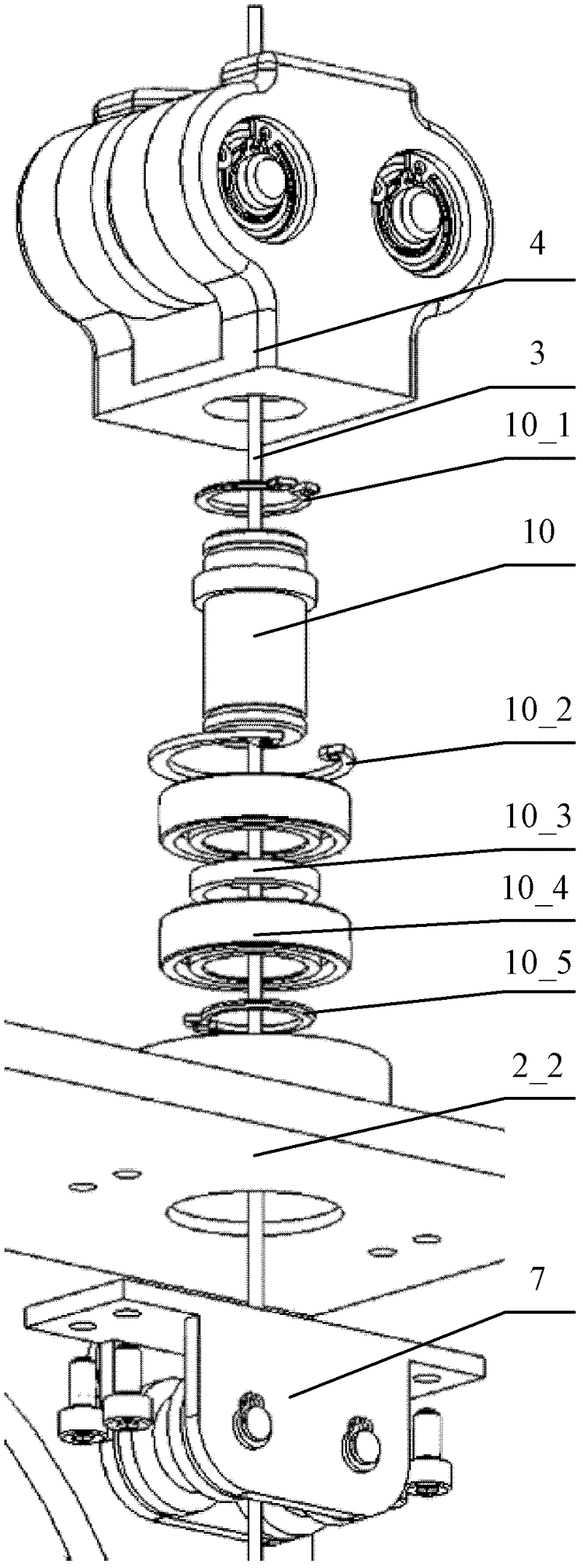

Method for installing large-caliber permanent magnet direct-current torque motor

ActiveCN104269974ASmall form factorCompact structureManufacturing dynamo-electric machinesBall bearingTorque motor

The invention discloses a method for installing a large-caliber permanent magnet direct-current torque motor. The method includes the following steps: (1) a motor stator and a ball bearing are firstly installed in a rotating base; (2) a motor rotor is installed outside a rotating shaft; (3) a guide sleeve fixed to a small disc penetrates through a center through hole in a large disc, and then the large disc is arranged on the outer end faces of three supporting columns; (4) the inner diameter of a guide base is matched with the outer diameter of the guide sleeve, and the guide base is fixed to the large disc; (5) the rotating shaft is downwards slowly moved through a hoisting tool along the guide base under the effect of gravity and slightly rotated around the guide base for enabling the shaft shoulder end face of the rotating shaft to be matched with the inner ring end face of the ball bearing; (6) the distance between the outer end face of a bearing block and the outer end face of the rotating shaft is measured to the required position size, and installation of the torque motor is completed. The method has the advantages of being simple and easy to implement.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

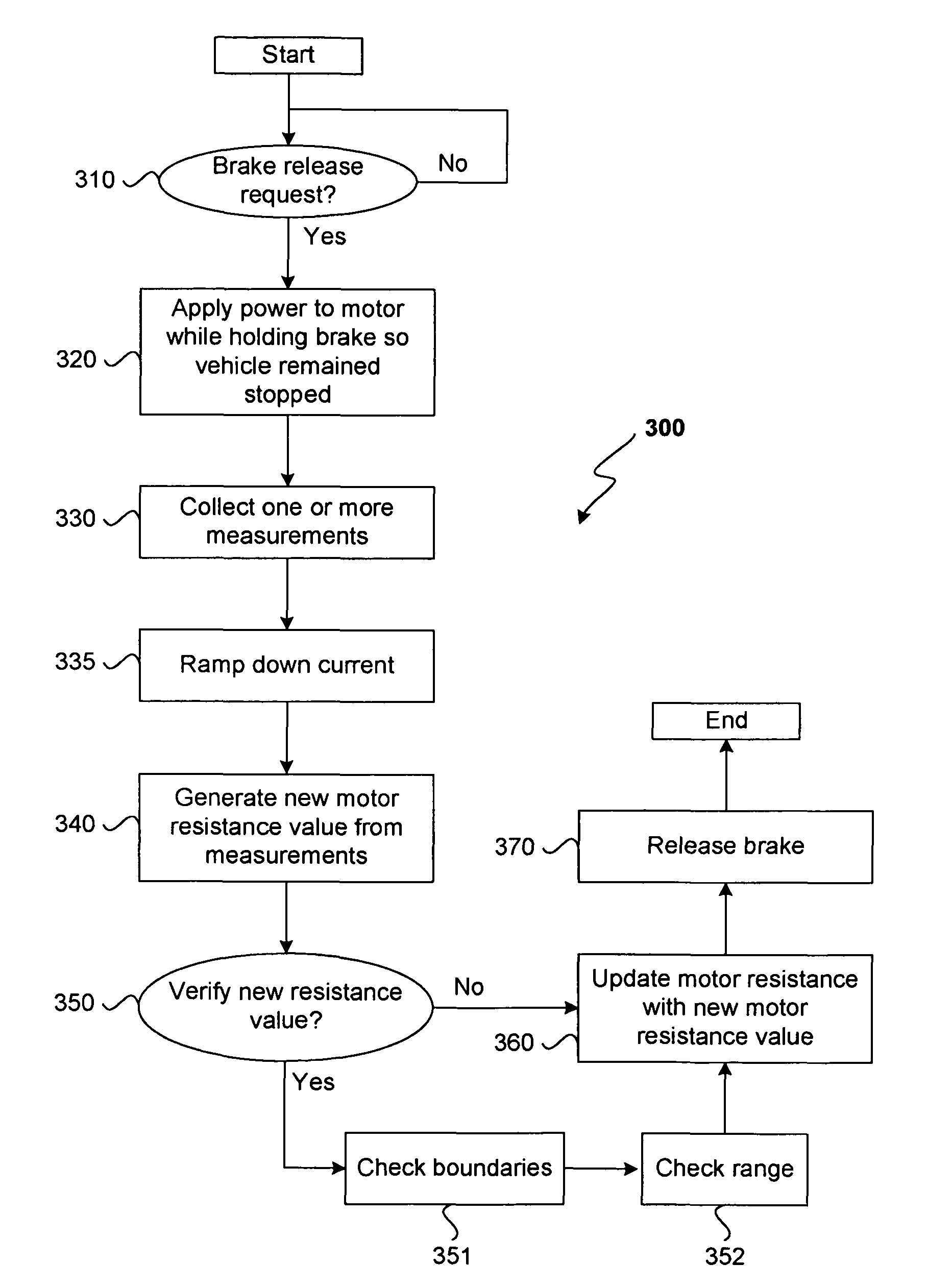

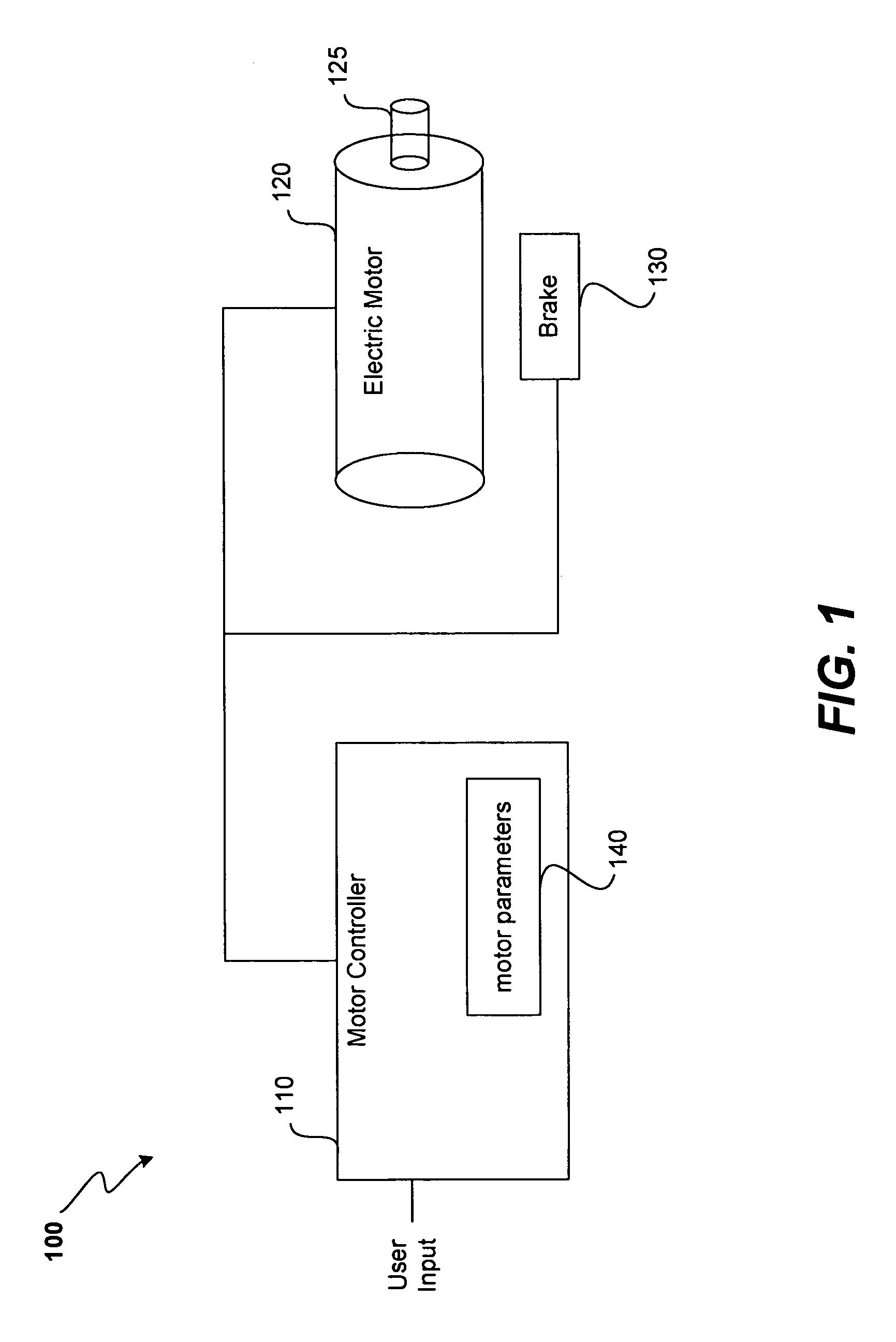

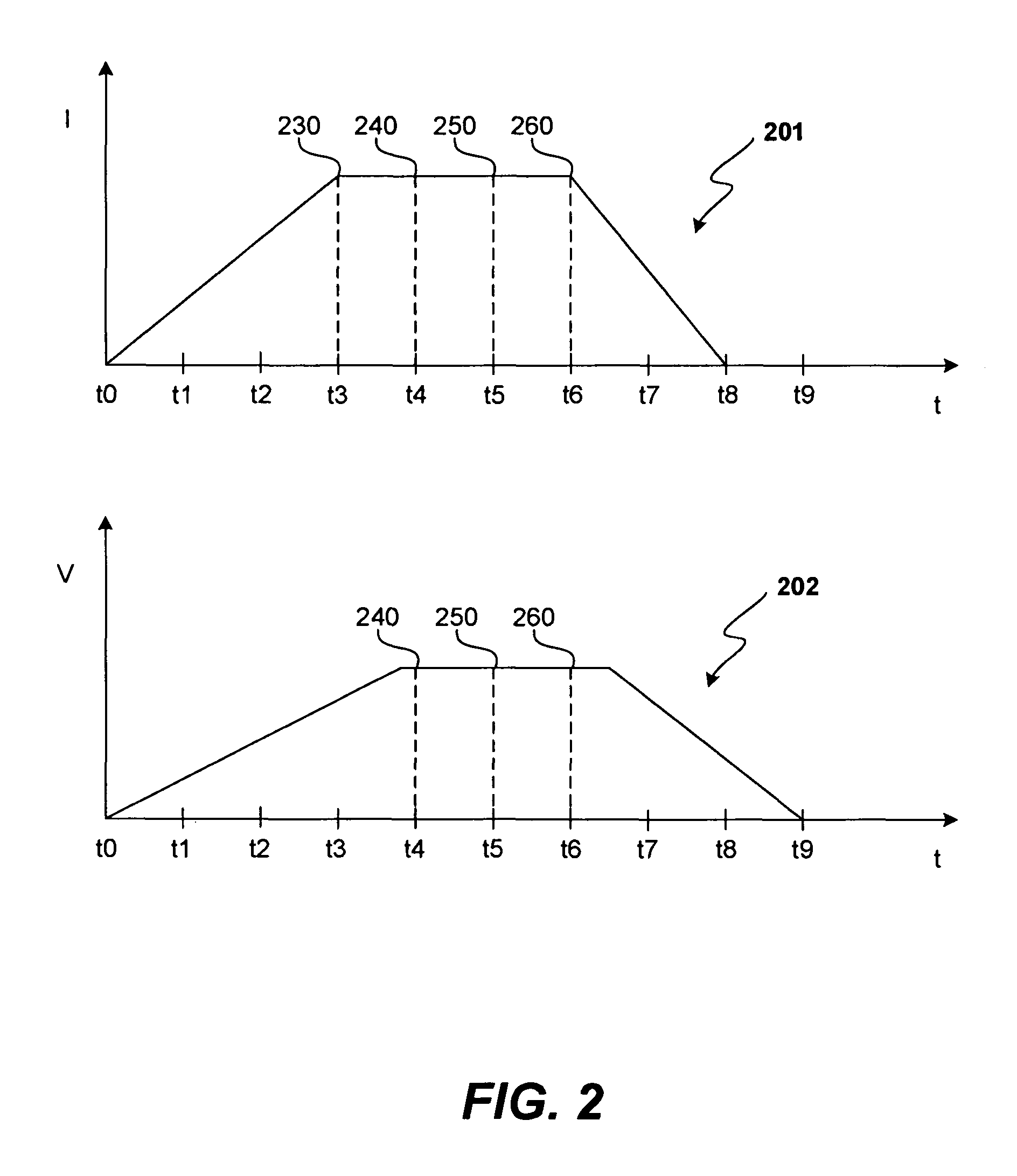

Systems and methods for dynamically compensating motor resistance in electric motors

ActiveUS7898203B2Hybrid vehiclesMotor/generator/converter stoppersElectrical resistance and conductanceMotor controller

Electric motor controllers that dynamically adjust a motor resistance parameter are described. In order to adjust the motor resistance parameter, power is applied the electric motor while the controlled vehicle is stopped and its brake is set so that the vehicle remains stopped while a measurement is taken that can be used to determine motor resistance. A new motor resistance value is then generated based at least in part upon the measurement(s) and the motor resistance parameter is set to the new motor resistance value. The new motor resistance parameter may then be used in the control of the electric motor. In some embodiments, the measurements are taken after the controller receives a brake release request but before actually releasing the brake. The described arrangement can be used in a wide variety of motor controllers and is especially well suited for use in low cost controllers that control motors that are susceptible to wide variations in their resistance such as brushed permanent magnet DC motors.

Owner:CURTIS INSTRUMENTS INC

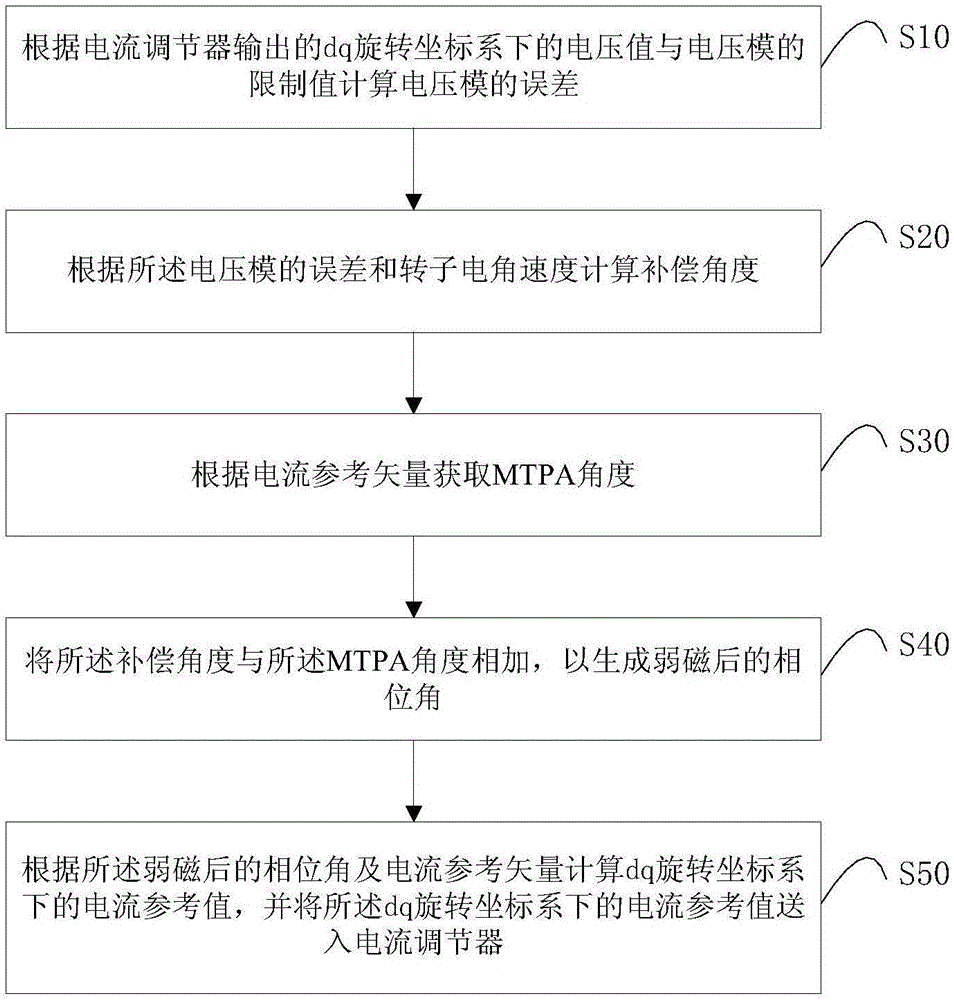

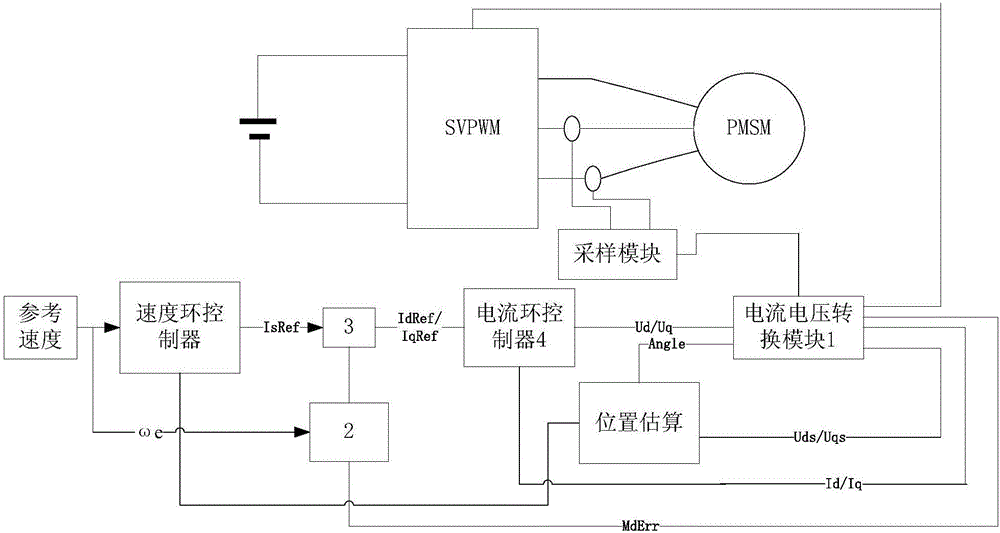

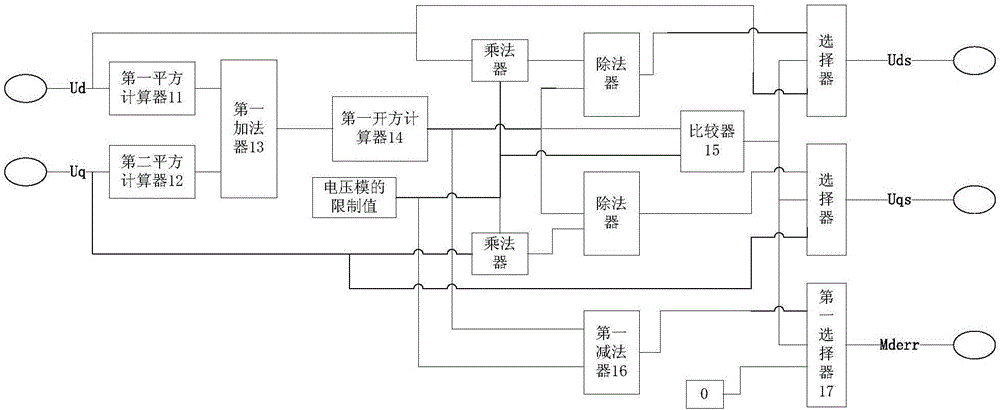

Flux weakening control method and device for permanent magnet direct-current motor

ActiveCN106357182ASimplify the commissioning processLess operationsElectronic commutation motor controlVector control systemsReference vectorAmpere

The invention relates to a flux weakening control method and device for a permanent magnet direct-current motor. The flux weakening control method comprises steps as follows: calculating an error of a voltage mode according to a voltage value output by a current loop controller in a dq rotating coordinate system and a limit value of the voltage mode; calculating a compensation angle according to the error of the voltage mode and an electrical angular velocity of a rotor; obtaining an MTPA (maximum torque per ampere) angle according to a current reference vector; adding the compensation angle to the MTPA angle to generate a flux weakened phase angle; calculating a current reference value in the dq rotating coordinate system according to the flux weakened phase angle and the current reference vector and transmitting the current reference value in the dq rotating coordinate system into the current loop controller. With the implementation of the technical scheme, few algorithm links are needed, the debugging process is simple, and high-frequency noise is reduced.

Owner:深圳市双驰科技有限公司

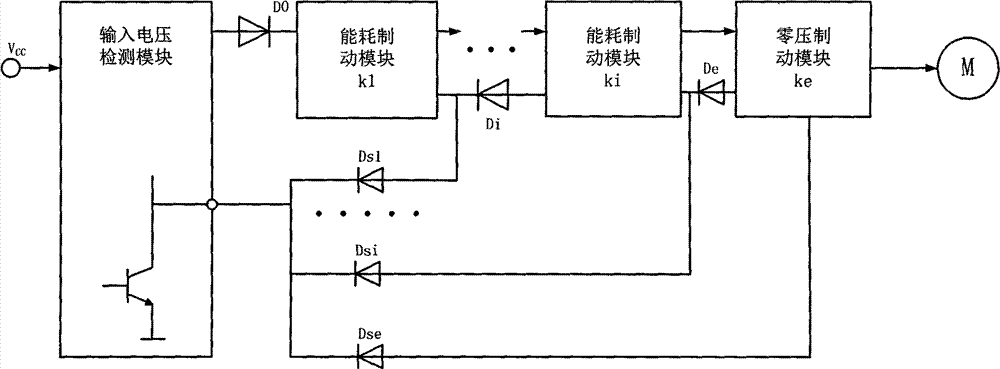

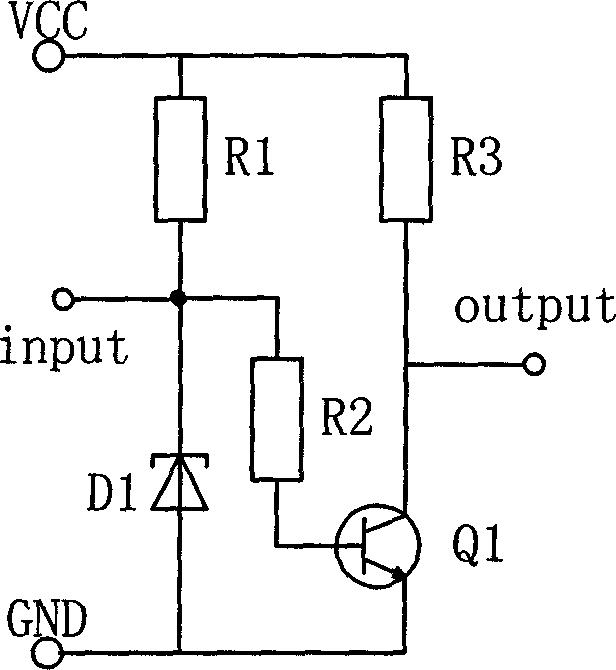

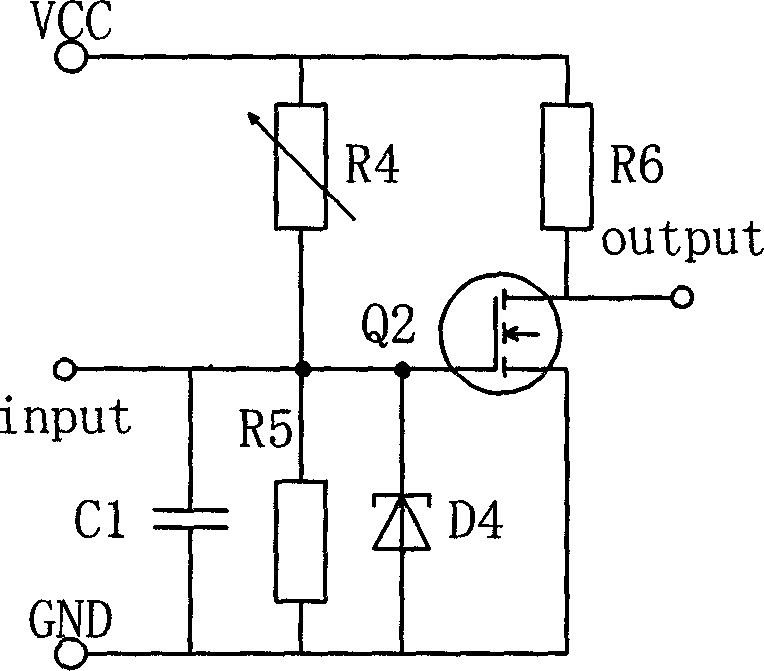

Sectional-type energy consumption brake circuit of permanent-magnet direct current motor

InactiveCN103618483AConstant braking torqueLarge braking torqueDc motor stoppersMechanical energyTransistor

The invention provides a permanent-magnet direct current motor brake device completely achieving brake through electrical actions and having the advantages of being large in braking torque, high in brake speed, good in effect, fast in reaction, good in reliability and high in safety factor. The device is composed of a voltage detection module, i energy consumption braking modules and a zero-voltage braking module. When a zero voltage or under voltage is detected by an input detection module, the first energy consumption braking module works, a power transistor is saturated and switched on, an energy consumption resistor is connected to the two ends of the motor, inertia mechanical energy of a rotor is converted to electric energy, the electric energy is transmitted to the energy consumption resistor to be consumed through heating, and accordingly the motor can operate under braking. Voltage continuously decreases as the braking time of the motor increases. The first module is not in a saturation state any more because the voltage is too low, a high level is output by a control terminal, the next-level energy consumption braking module starts to work, and the first energy consumption braking process is repeated until the last module works.

Owner:LISHUI VOCATIONAL & TECHN COLLEGE

Flexible cable driving unit

InactiveCN102302835AGuaranteed not to fall offSmooth cable transmissionMuscle exercising devicesMulti degree of freedomFlexible cable

The invention aims to provide a flexible cable driving unit. The driving unit comprises a driving unit bracket, a revolving flexible cable guide device, a permanent magnet direct current moment motor, a fixed flexible cable guide device, a flexible cable traction wheel and a guide shaft, wherein the permanent magnet direct current moment motor is arranged outside the driving unit bracket; the flexible cable traction wheel is arranged in the driving unit bracket; an output shaft of the permanent magnet direct current moment motor is connected with the flexible cable traction wheel; the revolving flexible cable guide device is connected with the fixed flexible cable guide device through the guide shaft; the fixed flexible cable guide device is fixed in the driving unit bracket; the revolving flexible cable guide device and the guide shaft are arranged outside the driving unit bracket; and a flexible cable is wound on the flexible cable traction wheel and passes through the fixed flexible cable guide device, the guide shaft and the revolving flexible cable guide device. The flexible cable driving unit can drive the flexible cable in a spatial multi-degree-of-freedom mode, is modular,has a compact integral structure and light weight, and is convenient to transport, assemble and disassemble spatially.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com