Method for installing large-caliber permanent magnet direct-current torque motor

A technology of permanent magnet DC and torque motors, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc. It can solve problems such as difficult to meet installation requirements, and achieve the effects of convenient installation, reduced overall size, and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

[0030] In this embodiment, the motor rotor is fixed on the rotating shaft first, and then the rotating shaft equipped with the motor rotor is installed in the motor stator.

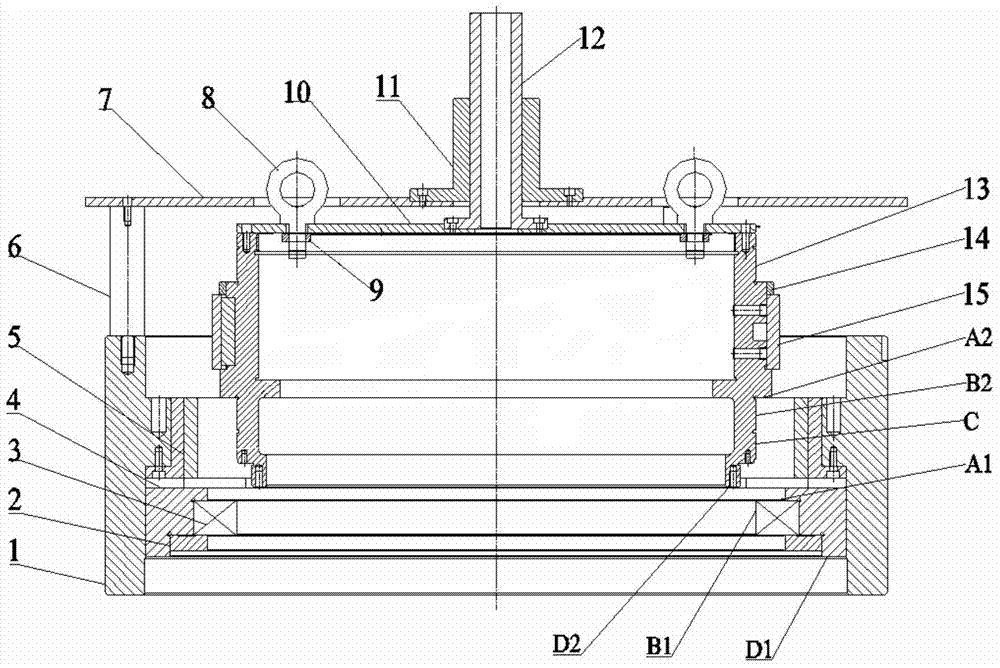

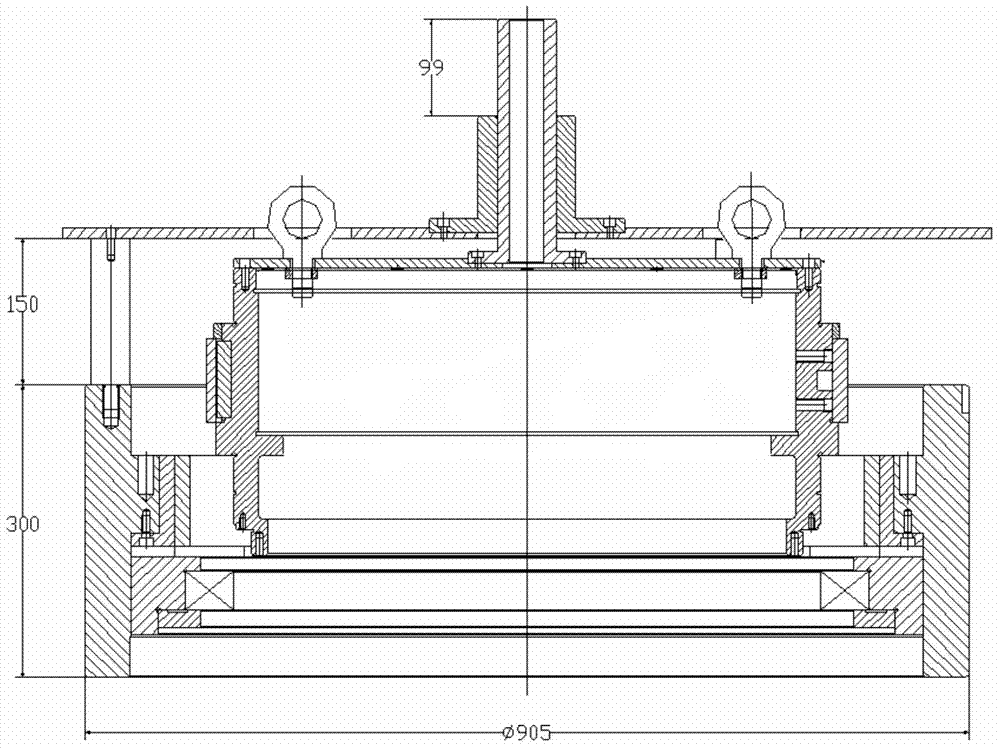

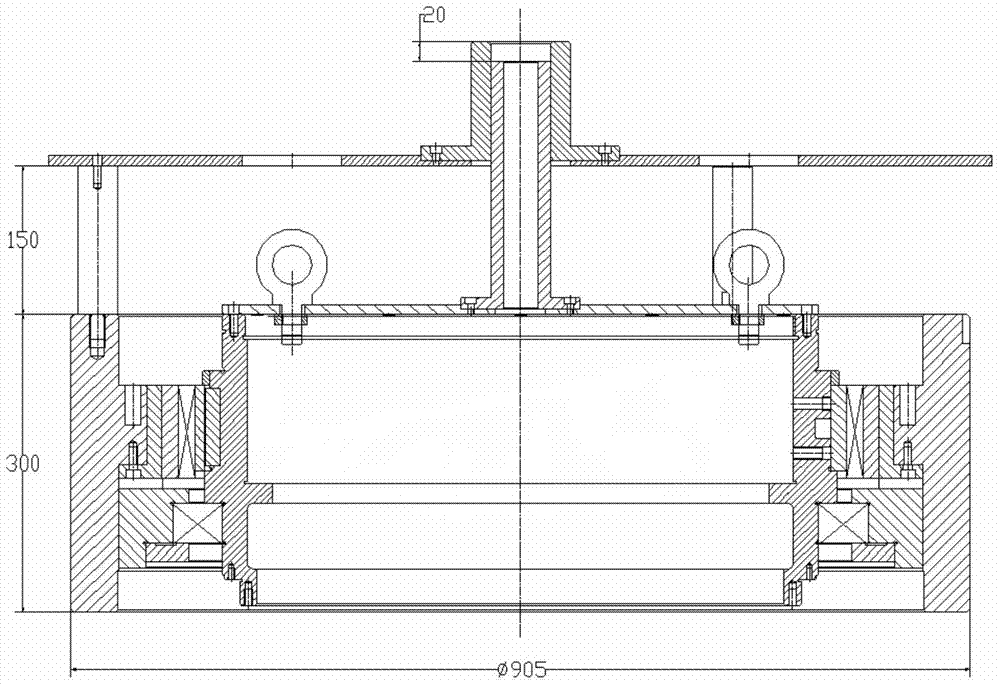

[0031] see first figure 1 , figure 1 It is a structural diagram of the installation method of the split type torque motor in the present invention. Depend on figure 1 It can be seen that the motor stator 5 is fixed in the rotating seat 1, and the bearing seat 4 is installed in the rotating seat 1, and the ball bearing 3 is installed in the bearing seat 4, and is fixed by the bearing cover plate 2. The function of the ball bearing 3 is to support and fix the rotating shaft 13 . The rotating shaft 13 is a hollow shaft, and the motor rotor 15 is installed outside the rotating shaft 13 and fixed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com