Disc type iron-core-free permanent magnet direct current (PMDC) motor

A permanent magnet direct current, disk-type ironless technology, applied to synchronous motors with stationary armatures and rotating magnets, the shape/style/structure of winding conductors, etc., can solve the problems of industrialization that needs to be improved, complex control systems, Complicated structure and other issues, to achieve excellent fast response performance and dynamic performance, large heat dissipation area, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

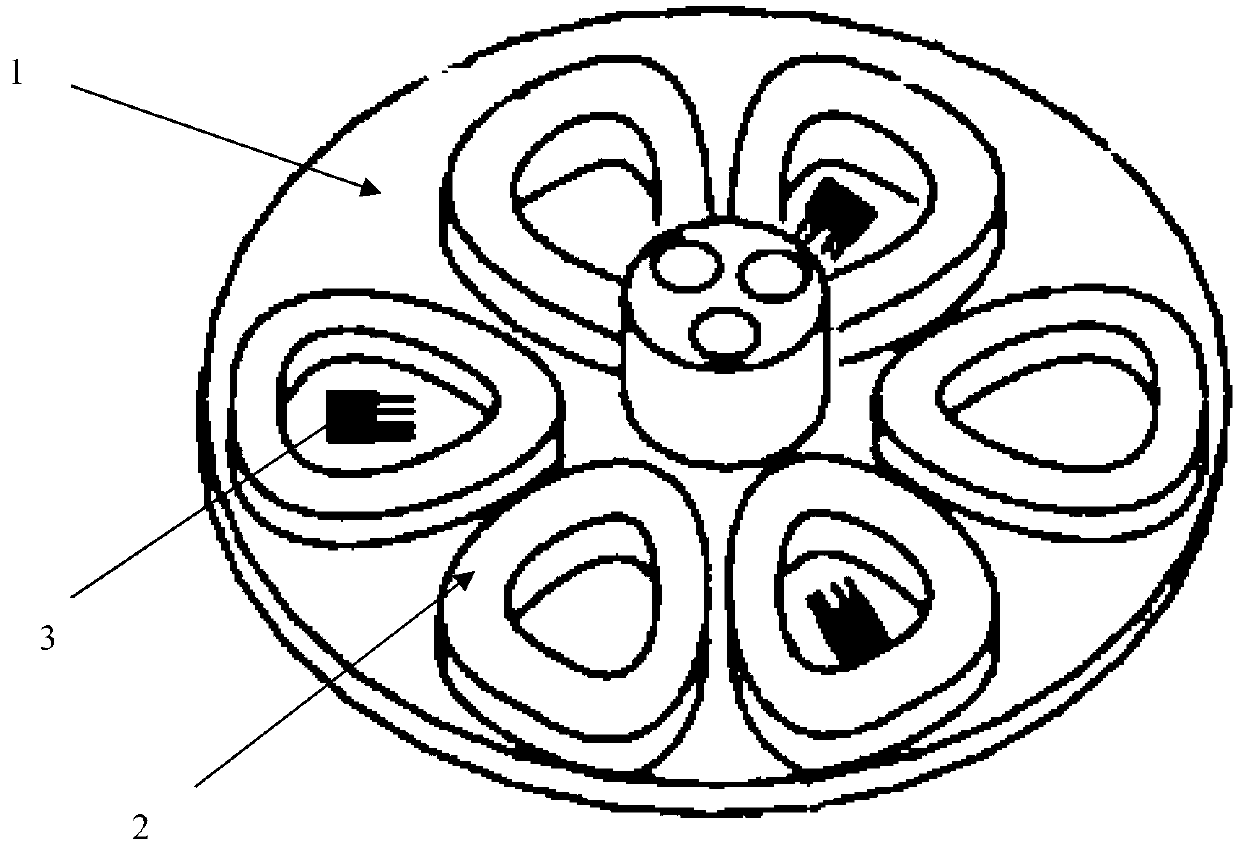

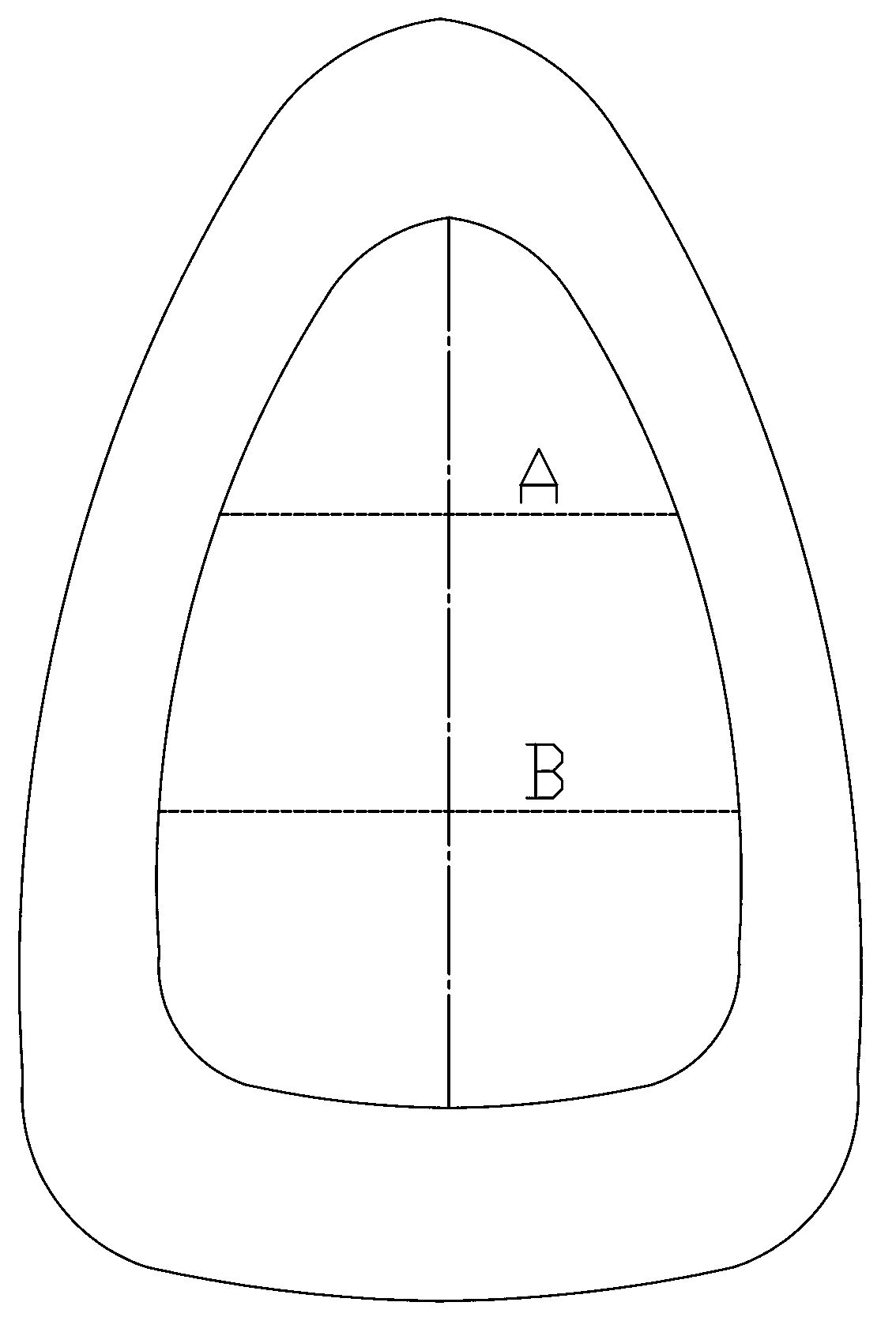

[0025] like Figure 1~Figure 3 As shown, the disc ironless permanent magnet DC motor includes a stator and a rotor, and the structure of the stator is as follows figure 1 As shown, the stator is an axially placed tapered ring winding wound without an iron core, and the magnetic flux passes through the air gap and the winding in the axial direction. The central axis of the axisymmetric tapered ring is divided into three equal parts to form the first inner diameter and the second inner diameter , where the length of the first inner diameter at the tip of the tapered ring is two-thirds of the second inner diameter, as figure 2 shown. The annular winding of this structure has the best magnetoelectric conversion efficiency, which is 15% higher than that of the prior art, and the Hall magnetic sensor is arranged at intervals in the annular winding.

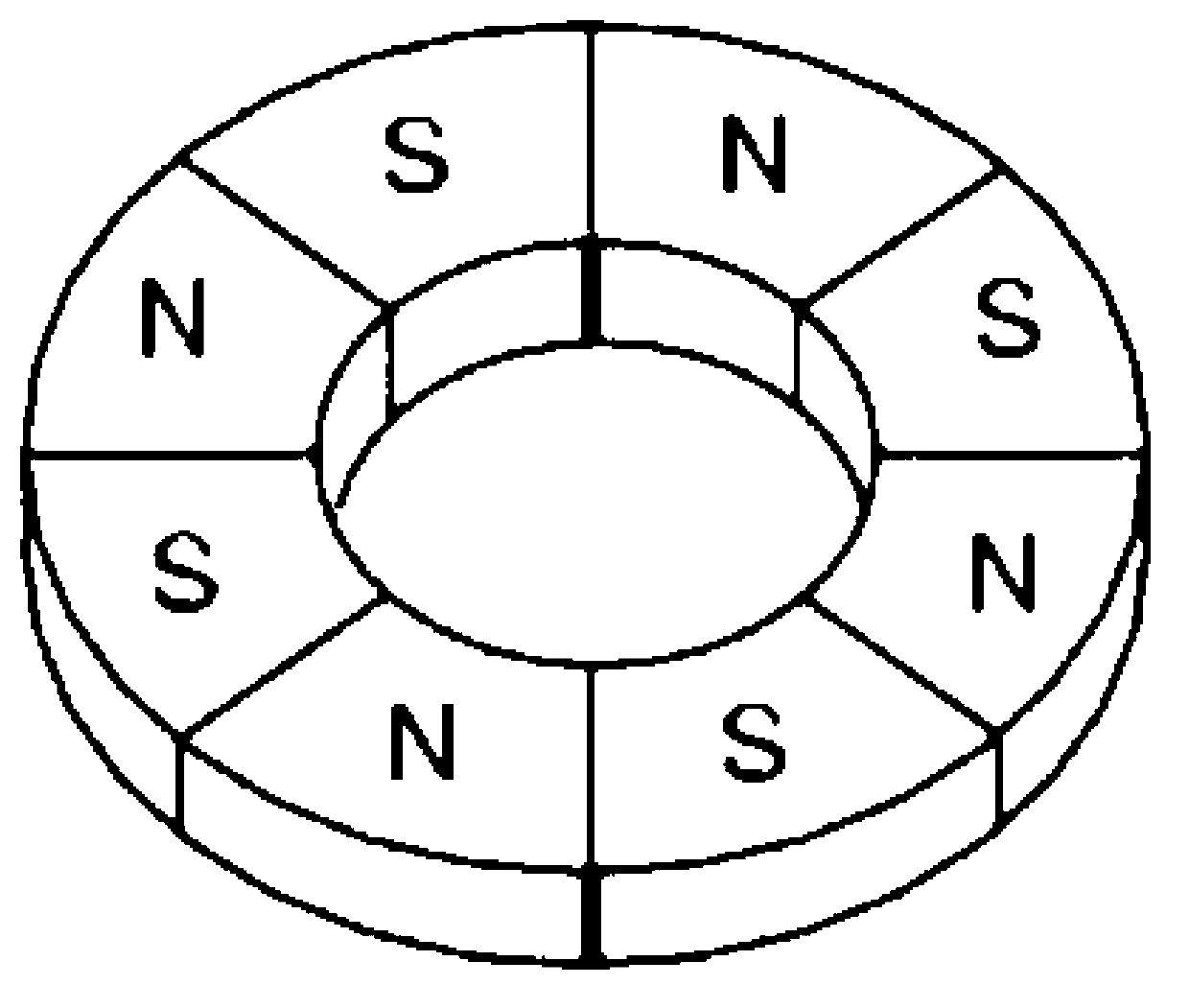

[0026] The rotor is a disc composed of a magnetic steel guide disc and an aluminum shell. The permanent magnets are alternately bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com