Electric pump

An electric pump and pump body technology, applied in the direction of pump, pump device, non-variable-capacity pump, etc., can solve the problems of low efficiency, complex structure, long axial dimension of the motor, etc., and achieve short axial dimension and low processing cost. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

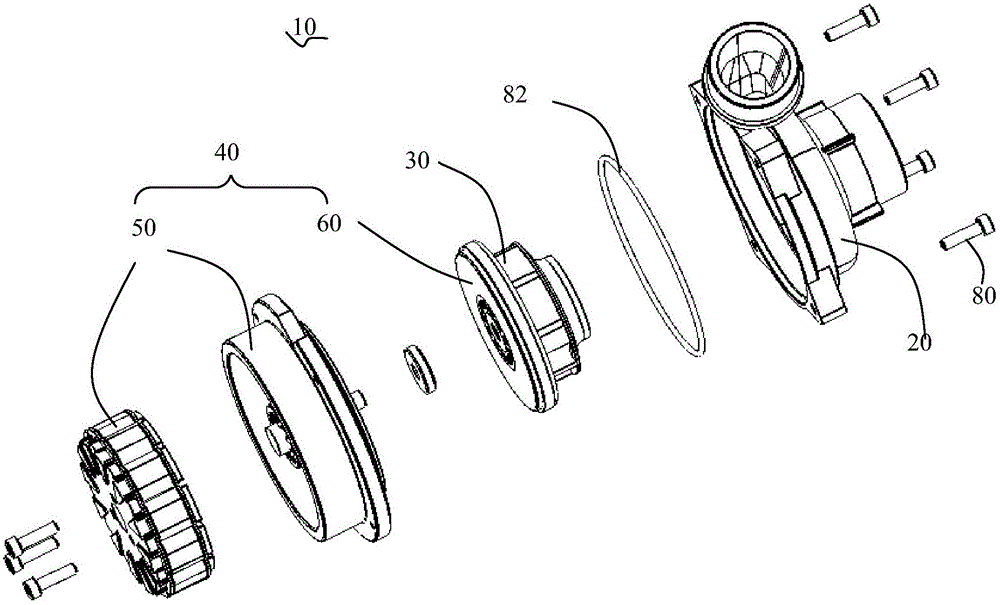

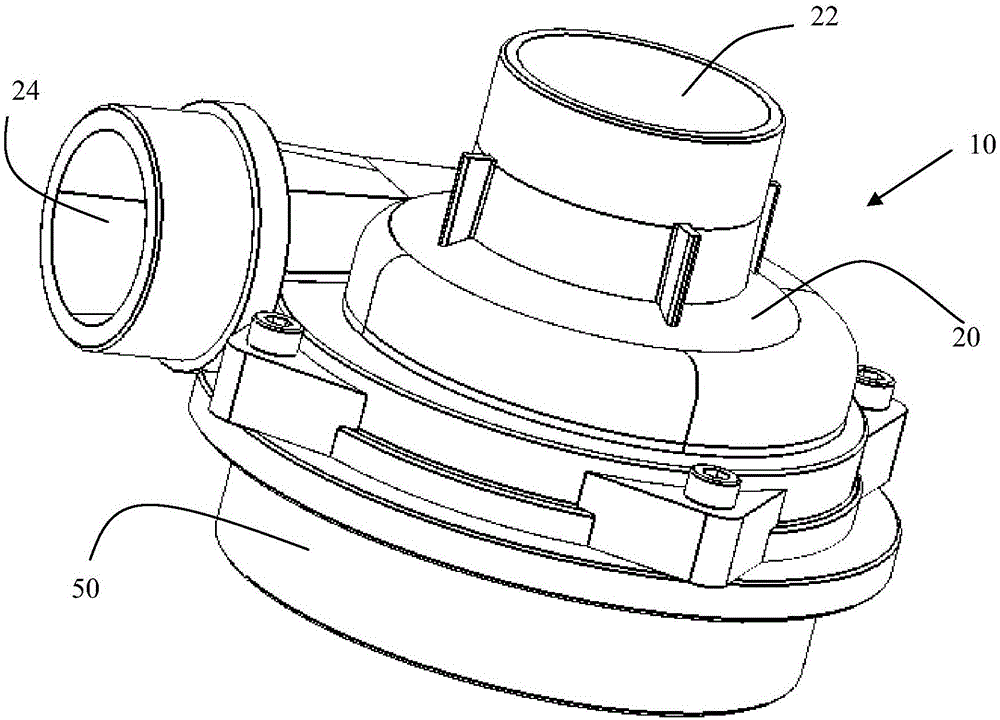

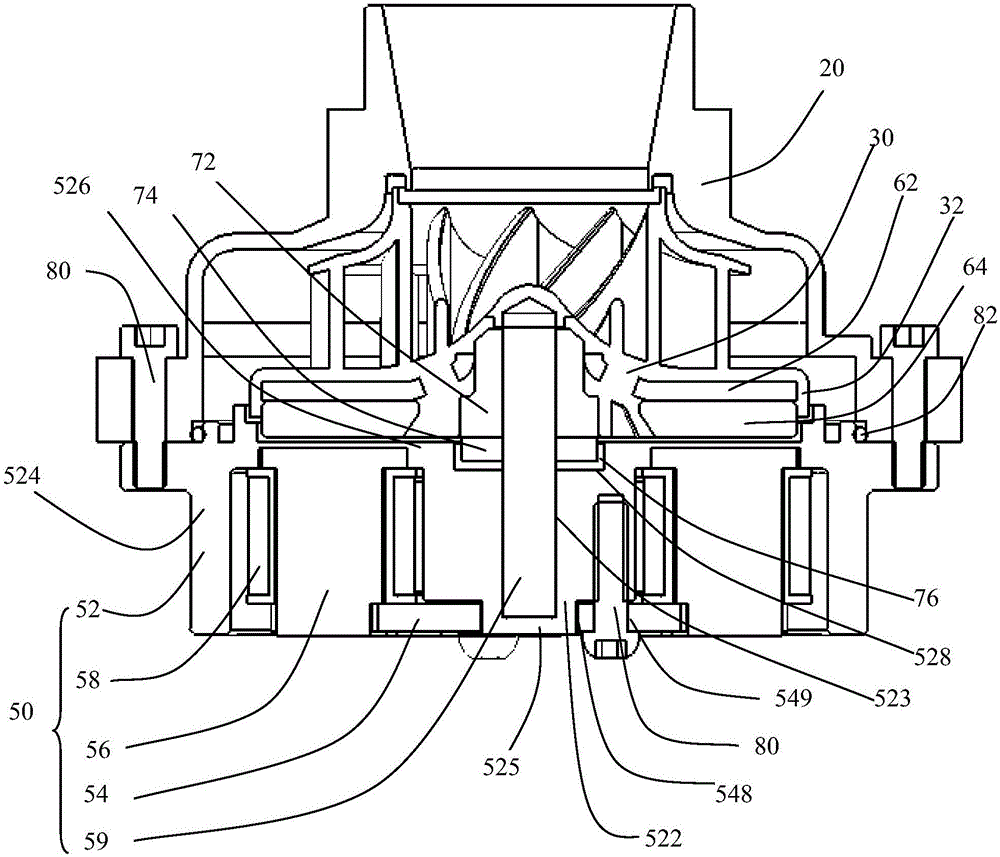

[0020] refer to Figure 1 to Figure 3 An electric pump 10 provided by an embodiment of the present invention includes a pump body 20 , an impeller 30 accommodated in the pump body 20 , and a motor 40 that drives the impeller 30 to rotate.

[0021] The pump body 20 includes an inlet 22 and an outlet 24 . In this embodiment, the inlet 22 is arranged along the axial direction of the impeller 30 , and the outlet 24 is arranged along the circumferential direction of the pump body 20 . As the motor 40 drives the impeller 30 to rotate, fluid will be pumped into the pump body inlet 22 and out of the outlet 24 .

[0022] The motor 40 includes a stator 50 and a rotor 60 . The stator 50 includes a housing 52, a stator yoke 54 fixed to the housing 52, a plurality of stator teeth 56 arranged at intervals along the circumferential direction of the stator yoke 54, and a coil 58 wound on the stator teeth 56 and fixed to the center of the housing 52. Axis 59. The housing 52 includes a suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com