Heavy-load electric wheel

An electric wheel and spoke technology, applied in electric components, wheels, brakes, etc., can solve problems such as poor reliability of brakes, poor motor stiffness, and failure of rotating seals, and achieve slow friction plate loss, reasonable bearing relationship, and short axial dimensions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

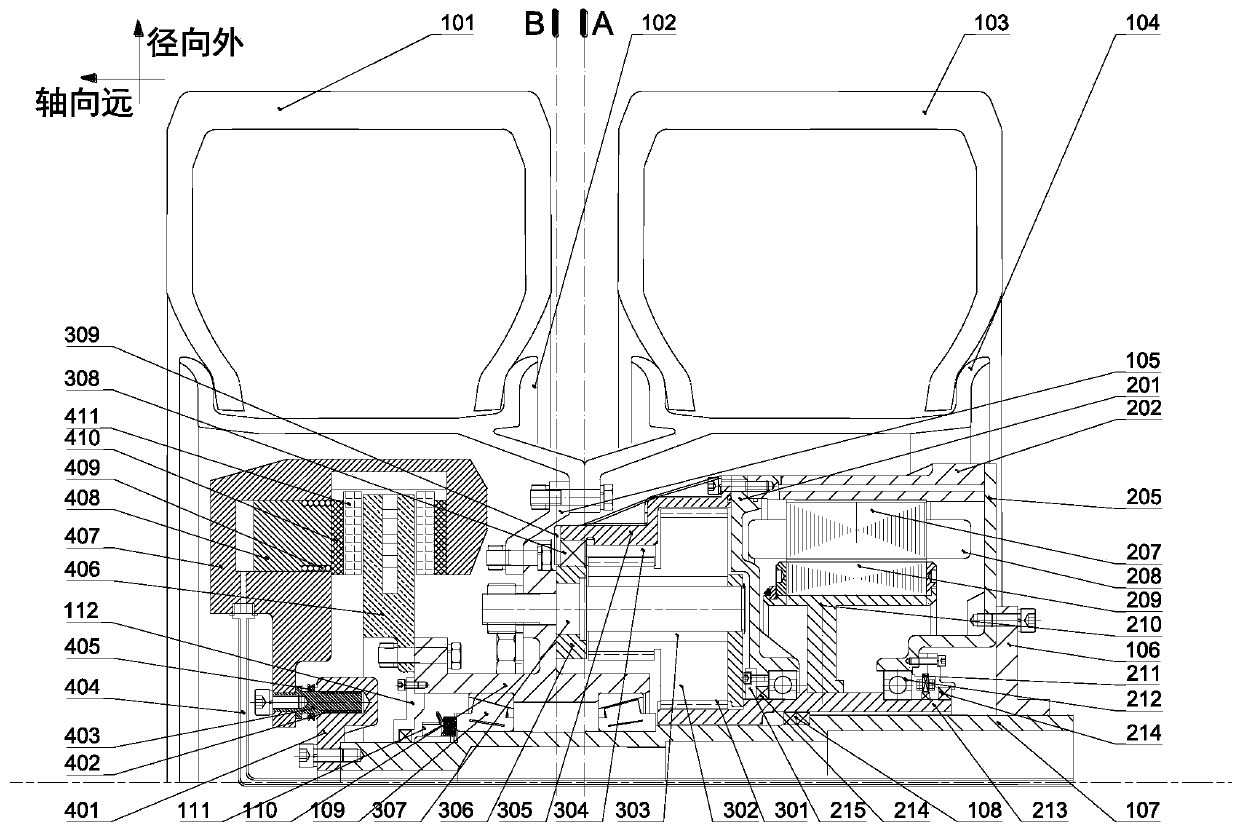

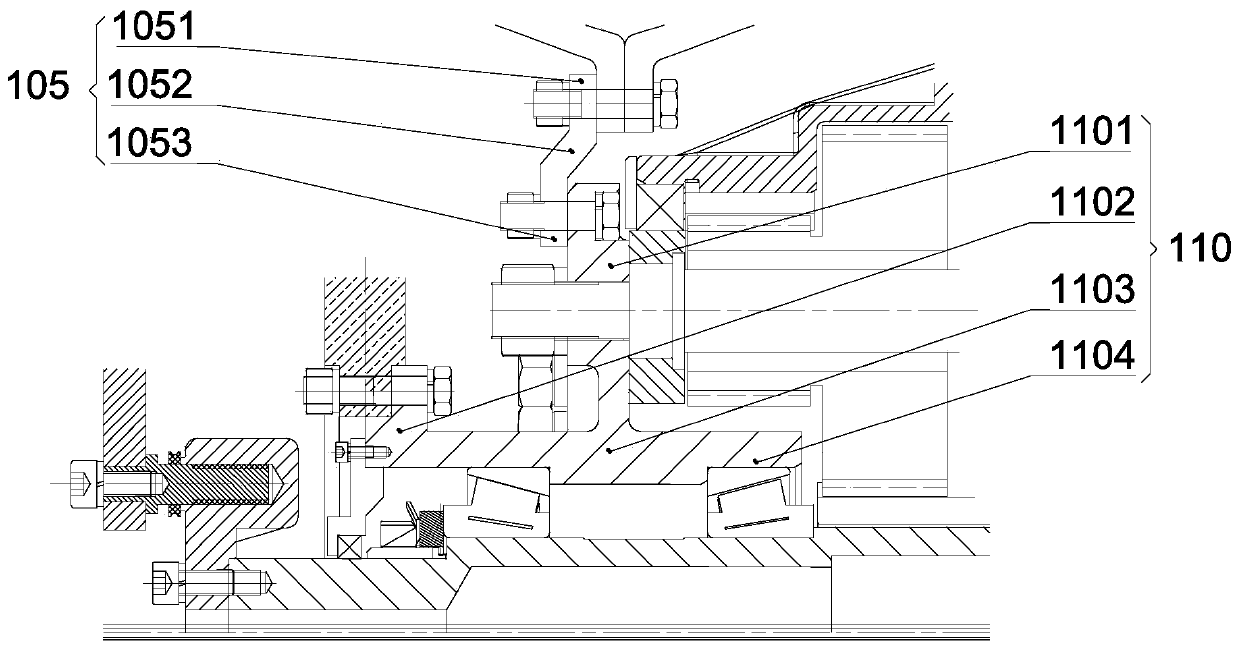

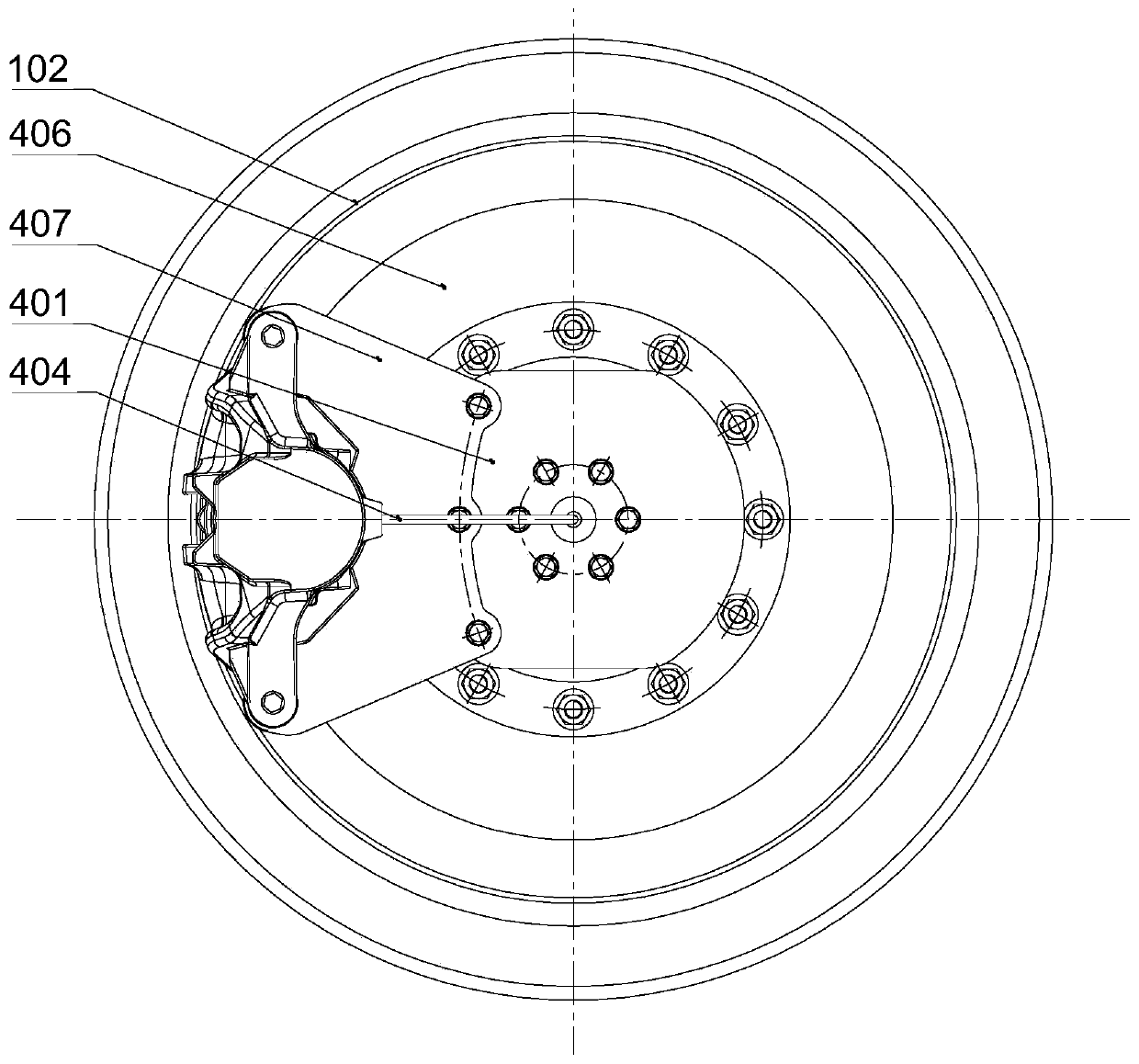

[0046] Such as Figure 1 ~ Figure 5 with Picture 10 The shown embodiment 1 of the present invention includes: wheel support shaft 107, spokes 105, rim 115, hub motor, planetary gear reducer and brake; wherein the brake, planetary gear reducer and hub motor are arranged on the support shaft in order from far to near The outer side of 107, the outer side of the hub 110 is connected with the spoke installation plane of the rim through the spoke 105, the hub 110 is mounted on the outer side of the support shaft 107 through a pair of hub bearings 109; the caliper bracket 401 in the brake is mounted on the wheel support shaft by bolts Outside the distal end of 107, the brake disc 406 is installed on the brake disc mounting flange of the hub 110; the hub part of the hub motor rotor support 210 is sheathed on the rotor shaft 213; the sun gear 301 in the planetary gear reducer is arranged on the rotor Outside the distal end of the shaft 213, the outer end of the planet pin 307 in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com