Patents

Literature

56results about How to "Slow loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

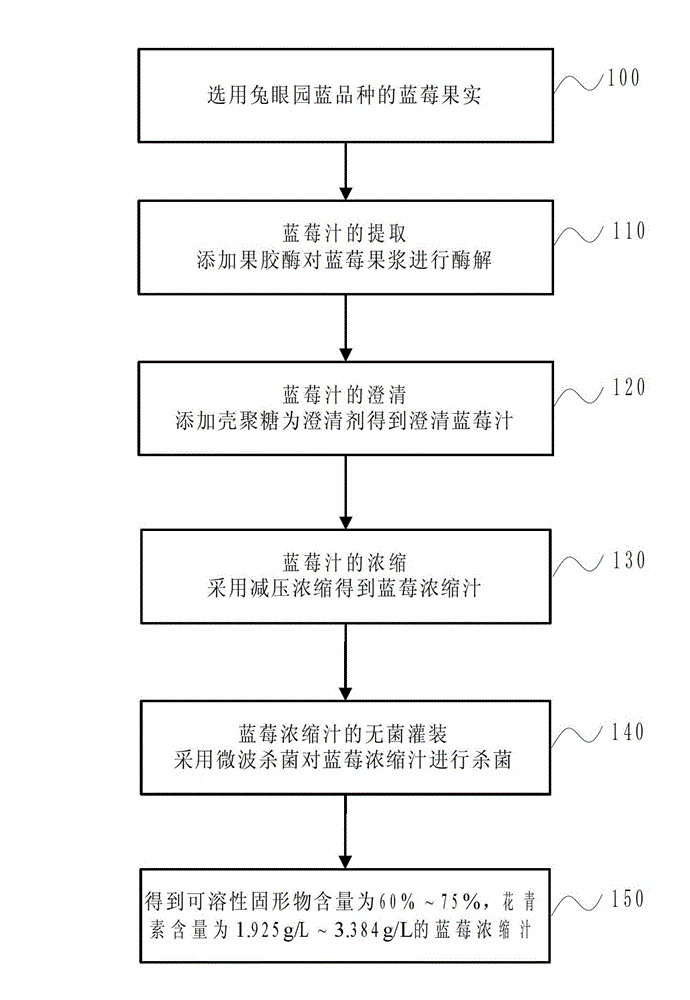

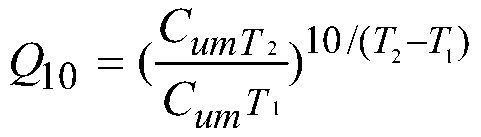

Preparation process of blueberry concentrated juice with high content of anthocyanin

The invention provides a preparation process of blueberry concentrated juice with high content of anthocyanin. According to the preparation process provided by the invention, pectase is adopted for performing enzymolysis on blueberry pulp, chitosan is adopted as a clarifying agent for obtaining clear blueberry juice, a decompression concentration process is adopted for preparing the blueberry concentrated juice, and microwave sterilization is adopted for sterilizing the blueberry concentrated juice. The preparation process comprises the following steps of: selecting blueberry fruits in vaccinium ashei gardenblue species; extracting the blueberry juice, and adding the pectase to perform the enzymolysis on the blueberry pulp; clarifying the blueberry juice, and adding the chitosan as the clarifying agent for obtaining the clear blueberry juice; concentrating the blueberry juice, and adopting the decompression concentration to obtain the blueberry concentrated juice; and performing sterile filling on the blueberry juice, and adopting the microwave sterilization to sterilize the blueberry concentrated juice, wherein the content of soluble solids in the blueberry concentrated juice is 60%-75%, and the content of the anthocyanin is 1.925g / L-3.384g / L. The preparation process provided by the invention can not only effectively prevent the loss of the anthocyanin in the blueberry concentrated juice, but also shorten the concentration time, control the production cost of the preparation process and effectively protect color, luster, fragrance and other sensory qualities of the blueberry juice.

Owner:ANHUI AGRICULTURAL UNIVERSITY

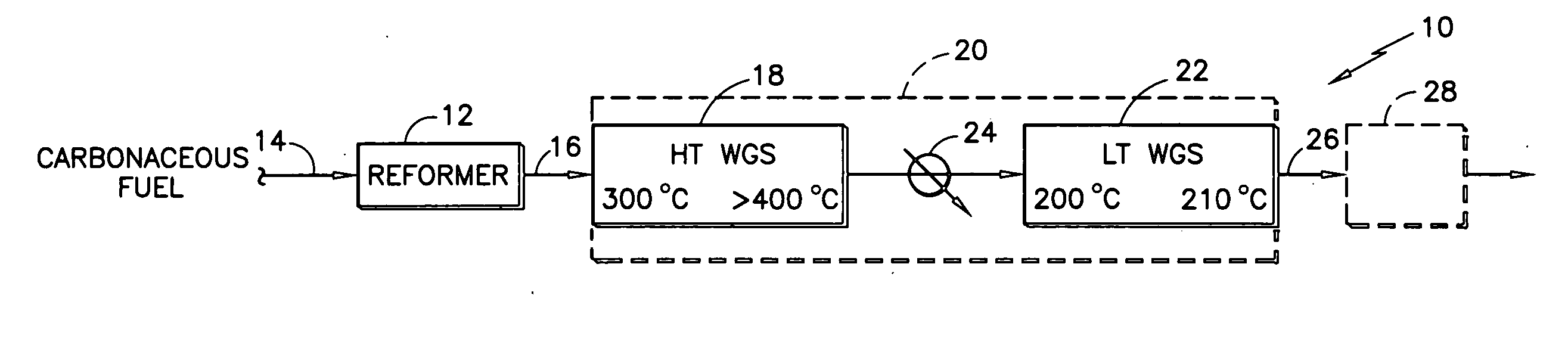

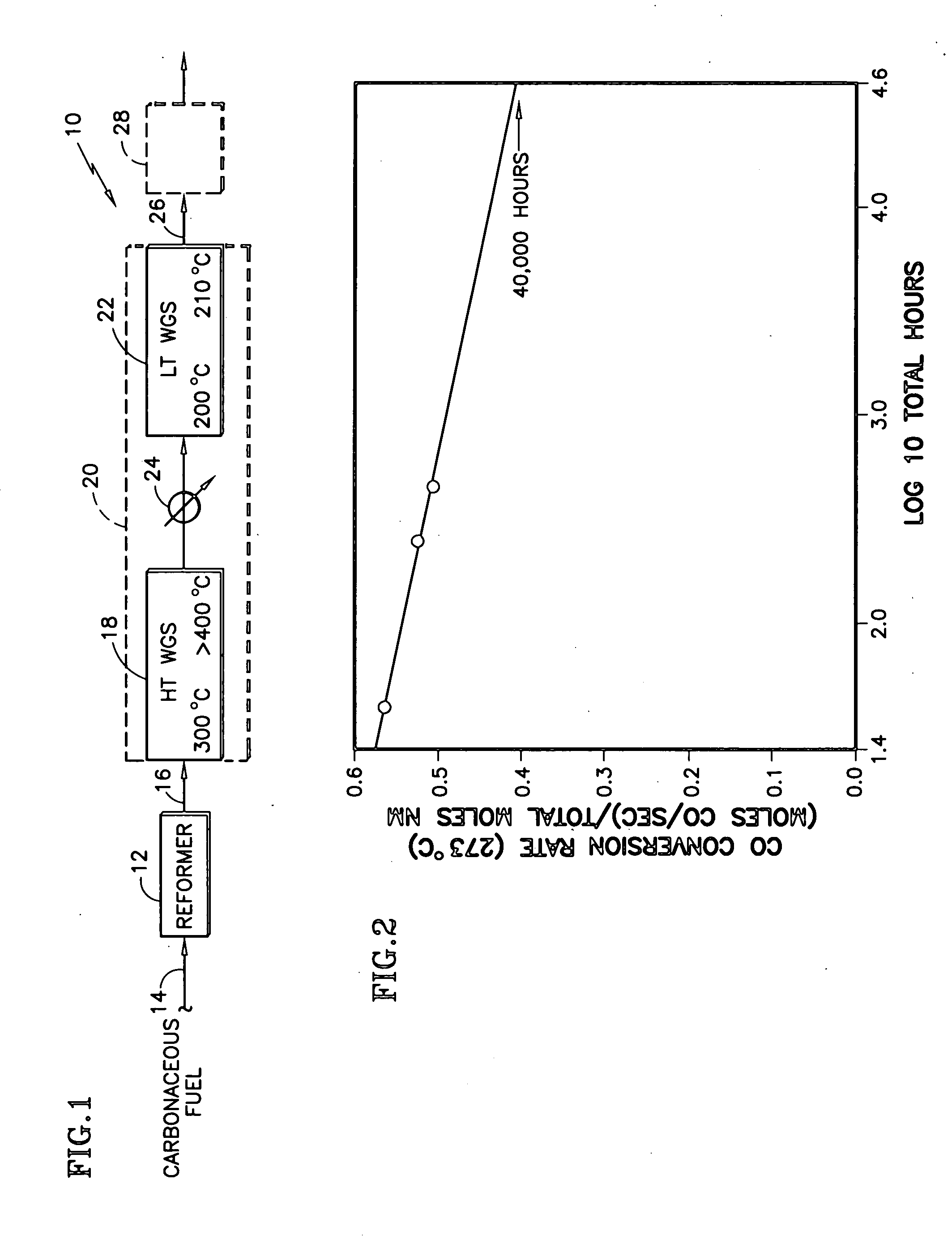

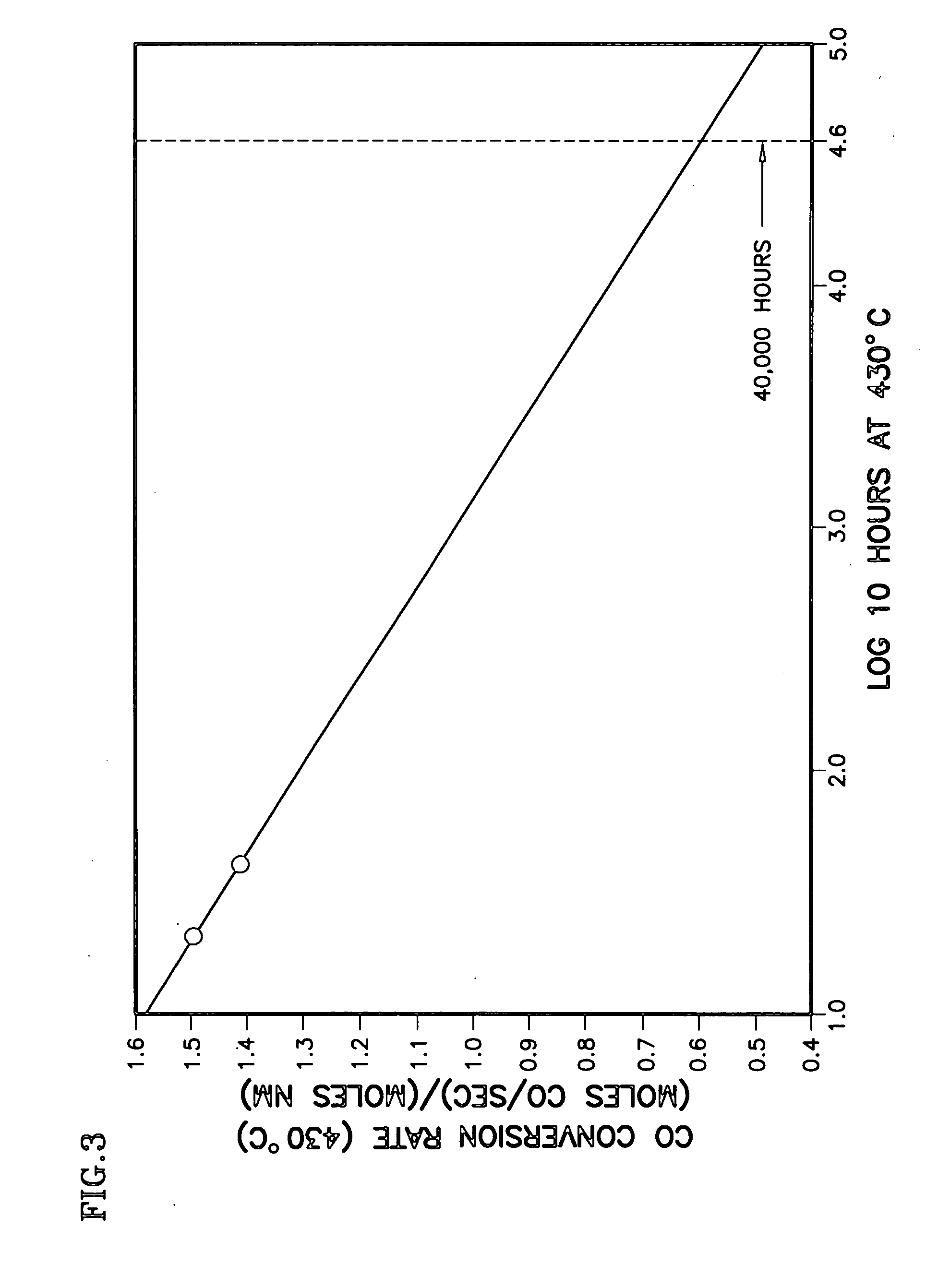

Durable catalyst for processing carbonaceous fuel, and the method of making

InactiveUS20060233691A1Simple structureAvoid turbidityTantalum compoundsHydrogen/synthetic gas productionBoiling pointWater-gas shift reaction

A doped, nanocrystalline, ceria-containing, mixed metal oxide supports a noble metal to provide a thermally-durable catalyst for processing carbonaceous fuels, particularly for the water gas shift reactions. The mixed metal oxide includes Zr and / or Hf and is normally susceptible to oxide ion vacancy ordering at elevated temperature reducing conditions. A dopant is selected to inhibit such oxide ion vacancy ordering. The dopant is preferably selected from the group consisting of W, Mo, Ta, and Nb, most preferably W, for providing a thermally-durable catalyst at operating temperatures exceeding 400° C. The noble metal is preferably Pt and / or Re. The doped ceria-containing mixed metal oxide is prepared from 2 or 3 aqueous solutions variously containing ceria, Zr and / or Hf, the dopant, and urea. The solutions are heated to below boiling, combined in a particular sequence and manner, and brought to boiling to crystallize and precipitate the doped ceria-containing mixed metal oxide.

Owner:INT FUEL CELLS

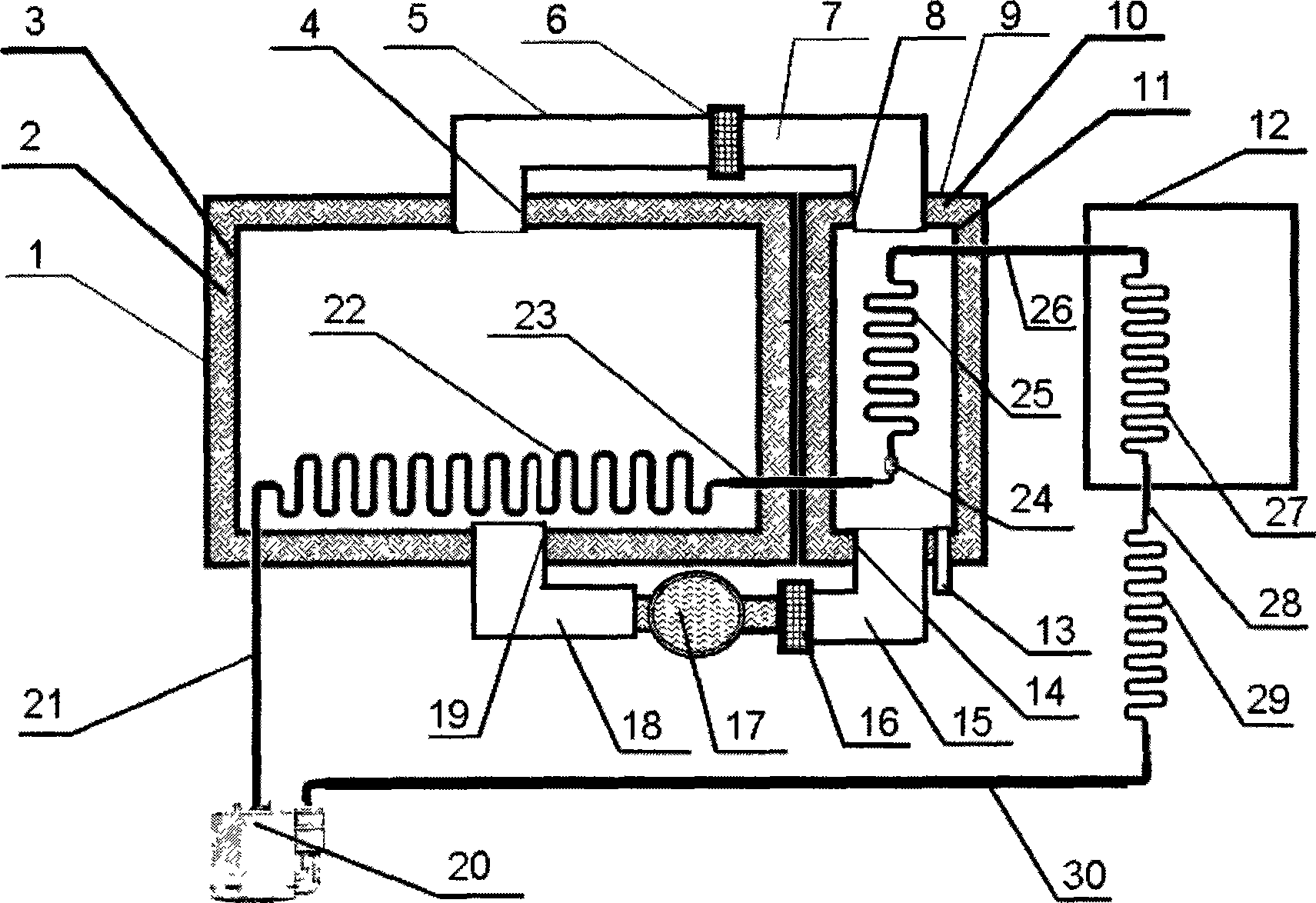

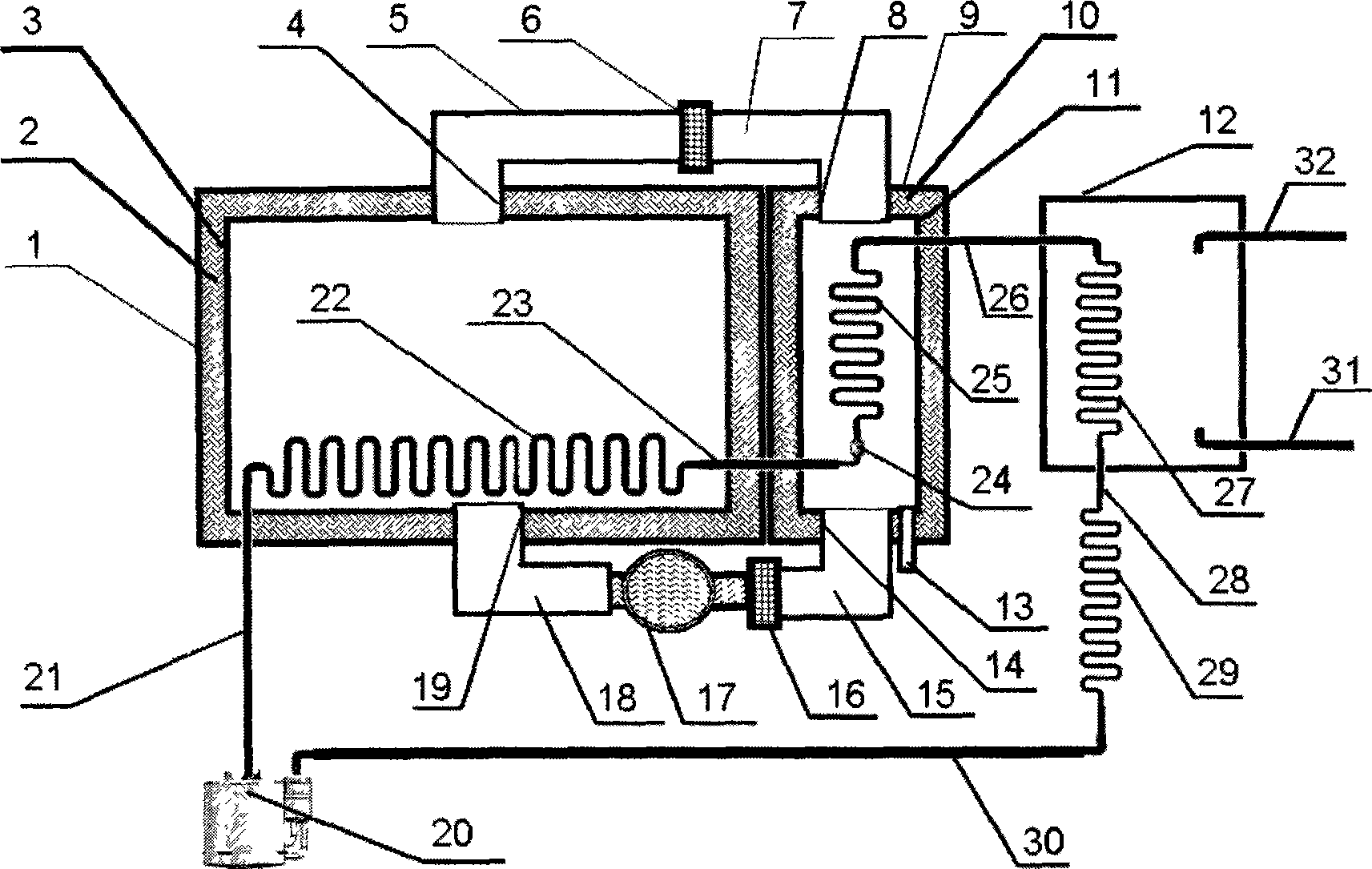

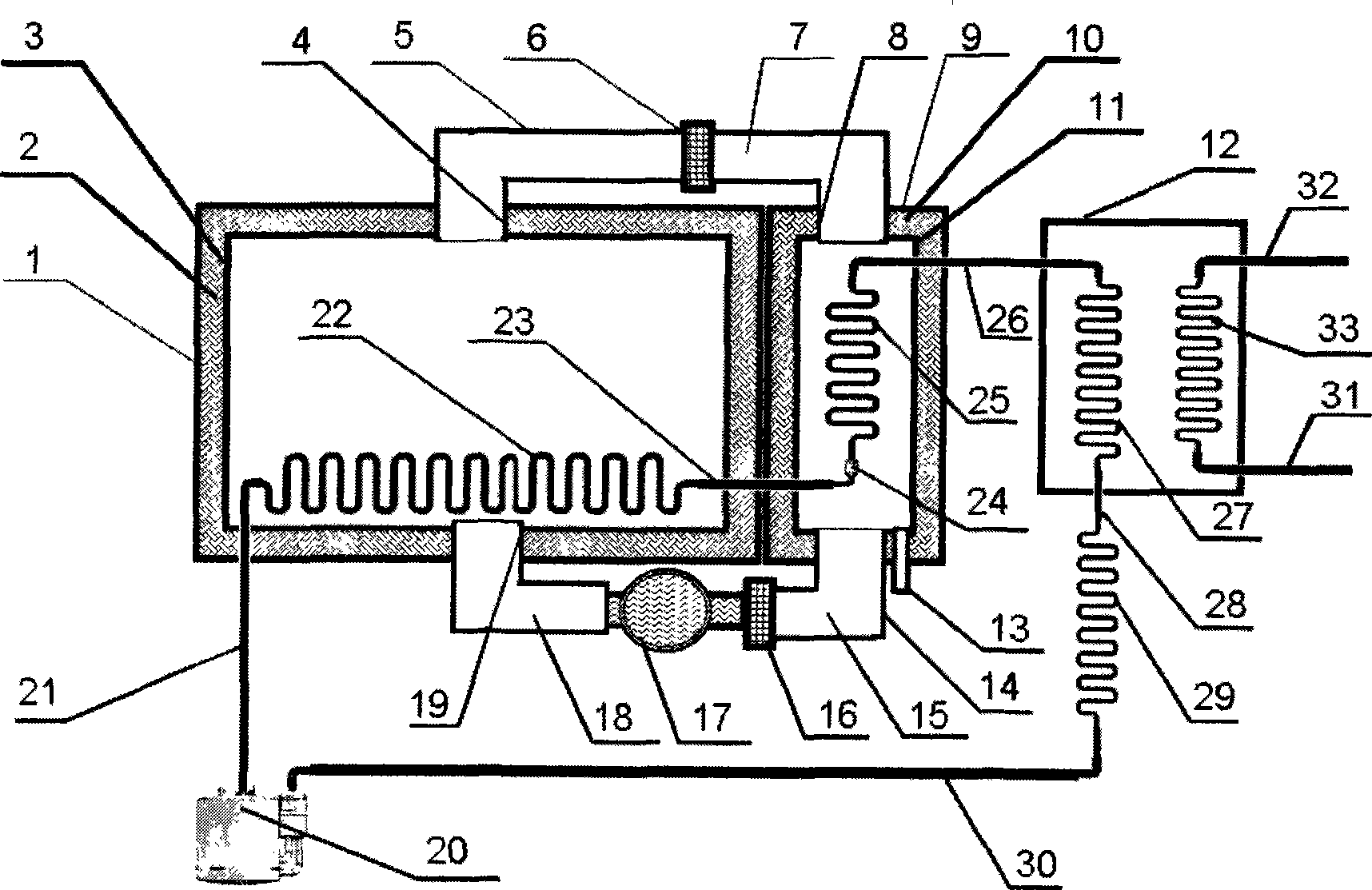

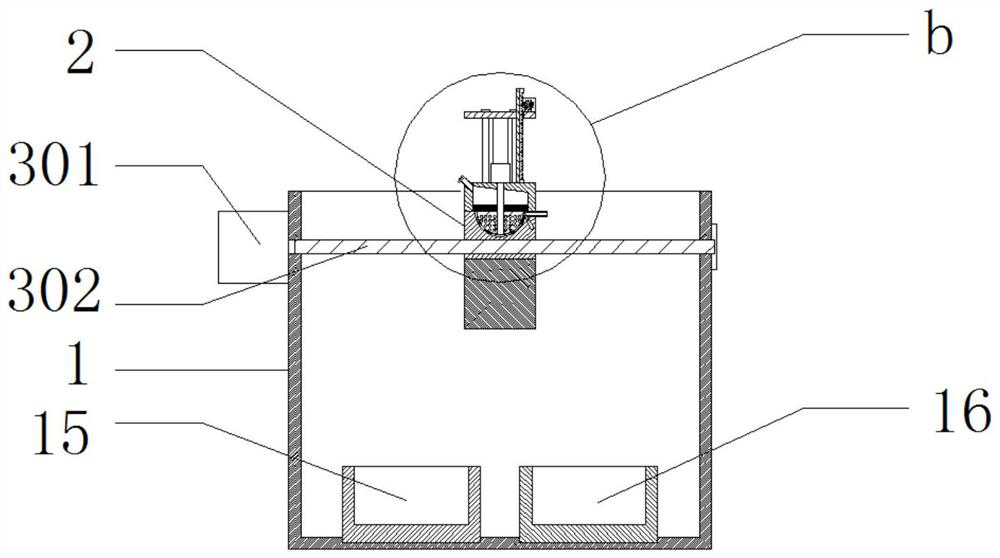

Waste heat cyclic utilization type high-efficiency energy-saving drying machine

The invention discloses an efficient energy-saving drying machine which is of a waste heat recycling model, comprising a high temperature heat-preservation cylinder assembly, a low temperature heat-preservation cylinder assembly and a multi-source heatpump assembly. The machine not only uses the multi-source heatpump technology to improve the heating efficiency, but also takes the original useless hot air as heat power supply to absorb heat from hot air by utilizing a heat absorbing coil, meanwhile, the moisture of the temperature-lowed hot air is condensed into water, the air becomes drier and drier and the temperature becomes higher and higher, after the temperature reaches a seted dgree, a program controller adjusts the working frequency of a compressor by a frequency converter so as to ensure the temperature to keep an optimum temperature. In this way, all drying machines can save more than 80% electricity and the invention is certainly one of the most important energy-saving and emission-reduction measures, which is a thorough revolution of the drying machines. According to that drying all materials in the world needs 3000 billion degrees per year currently, if 80% electricity can be saved, 2400 billion degrees of electricity can be saved, 0.864 billion tons of coal can be saved and 1.4688 billion tons of carbon dioxide emission can be reduced per year.

Owner:凌建军

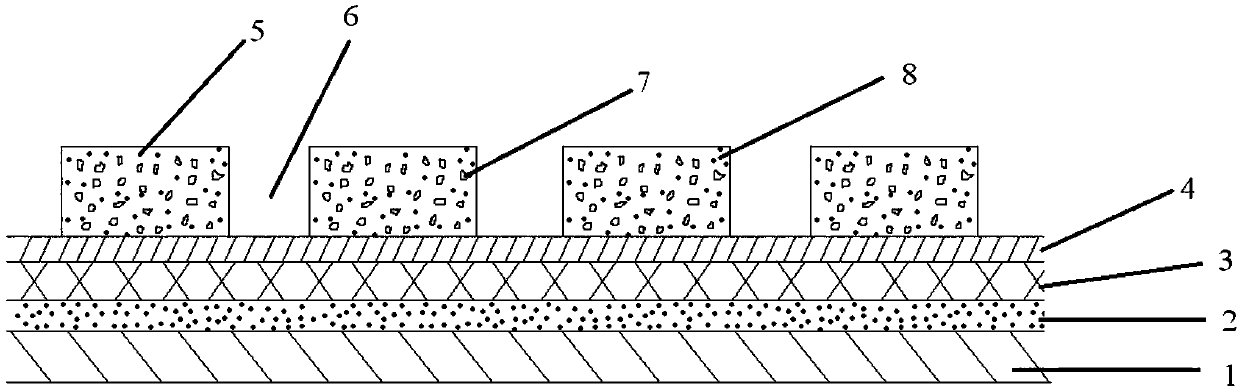

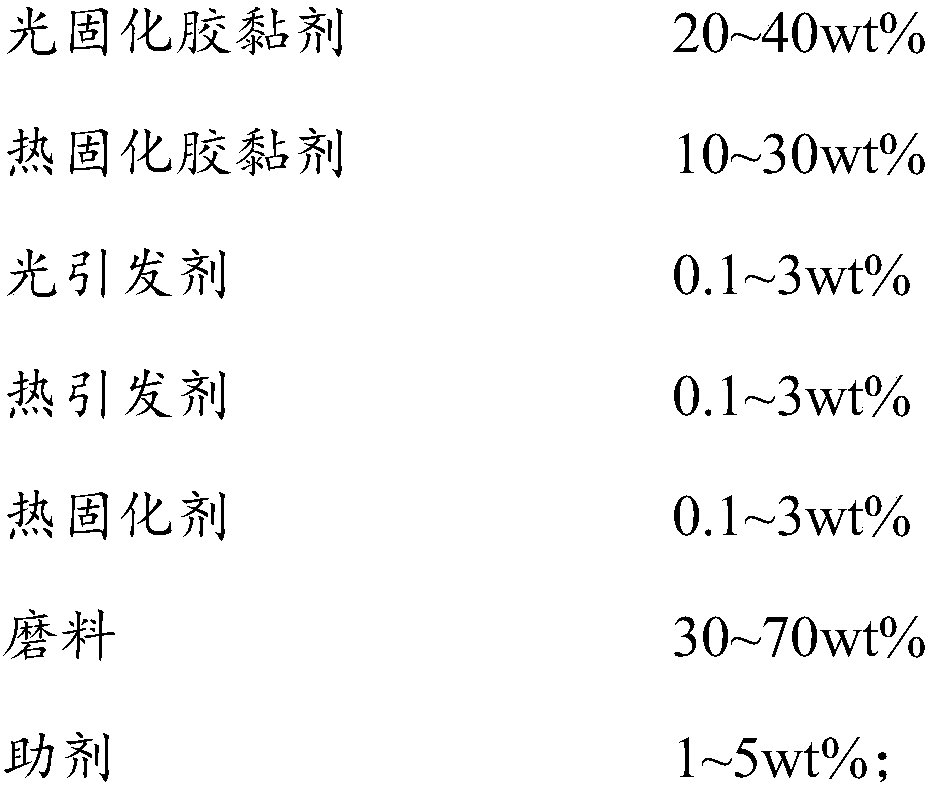

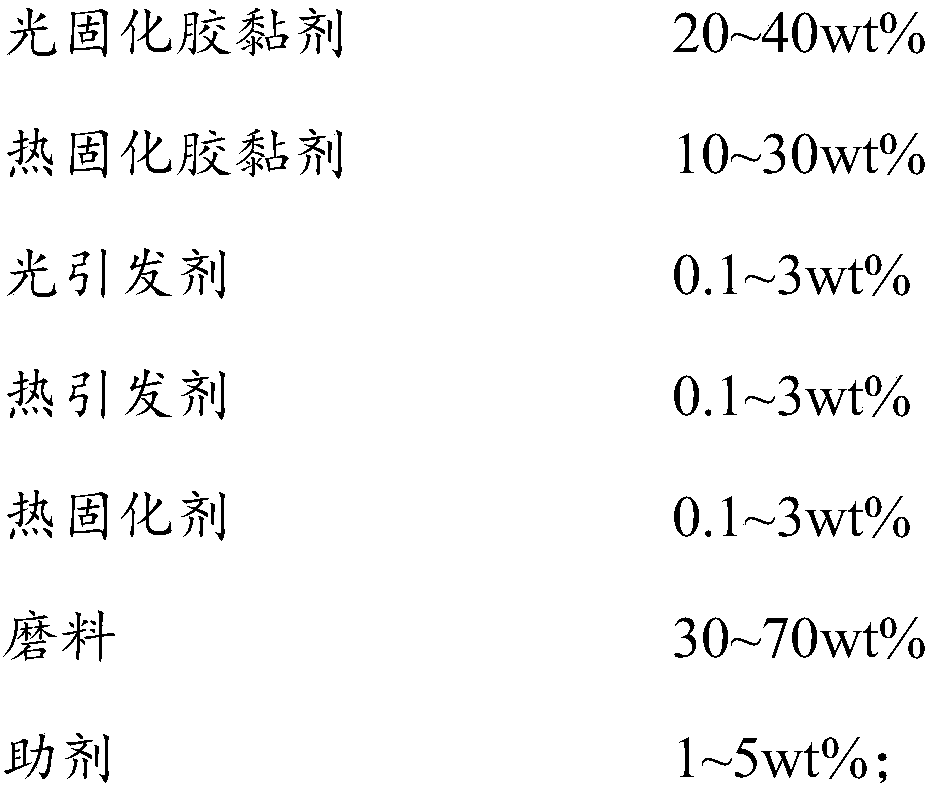

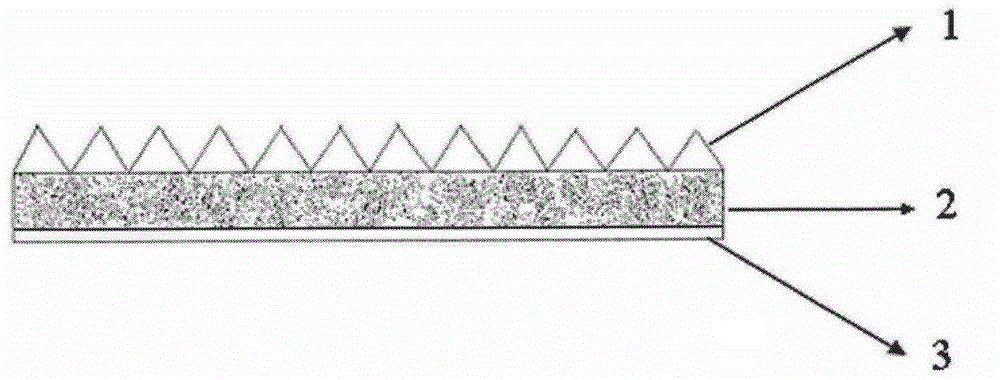

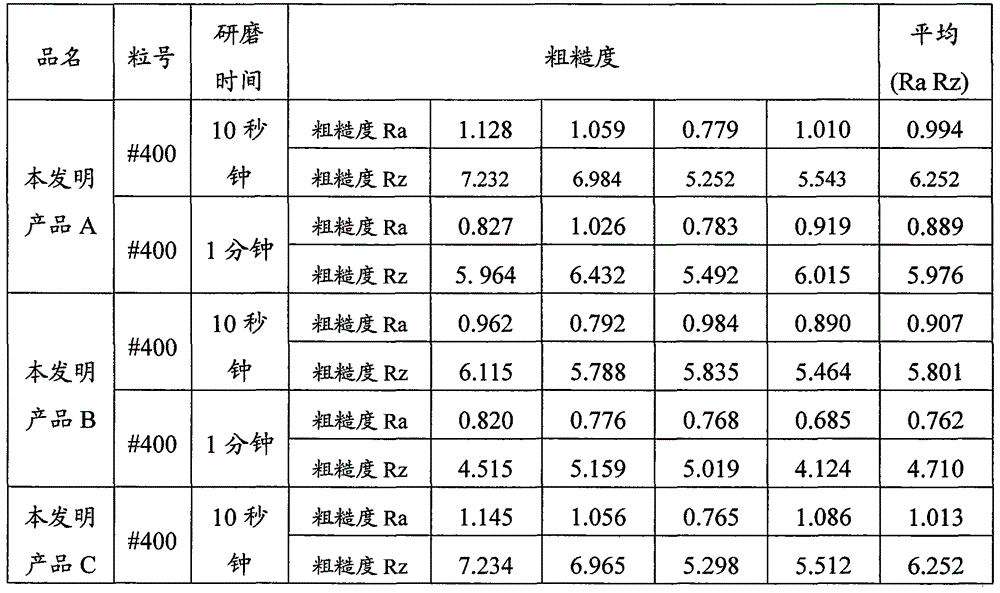

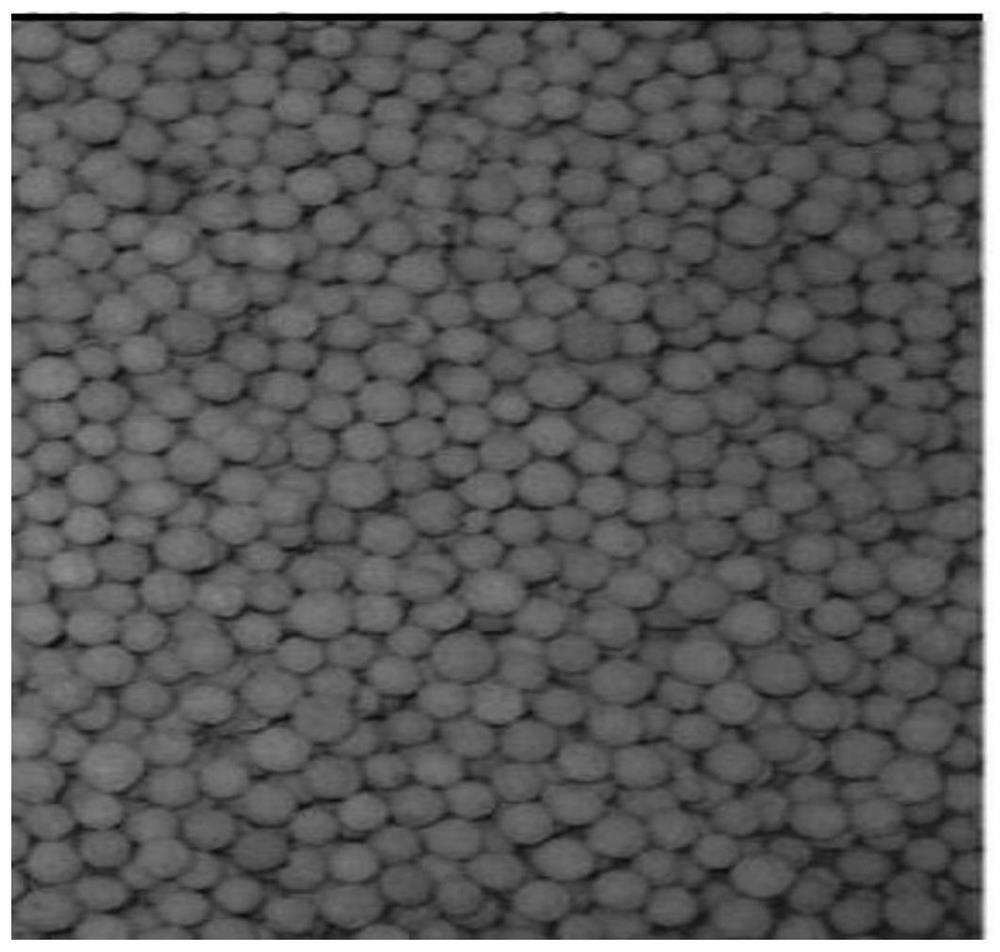

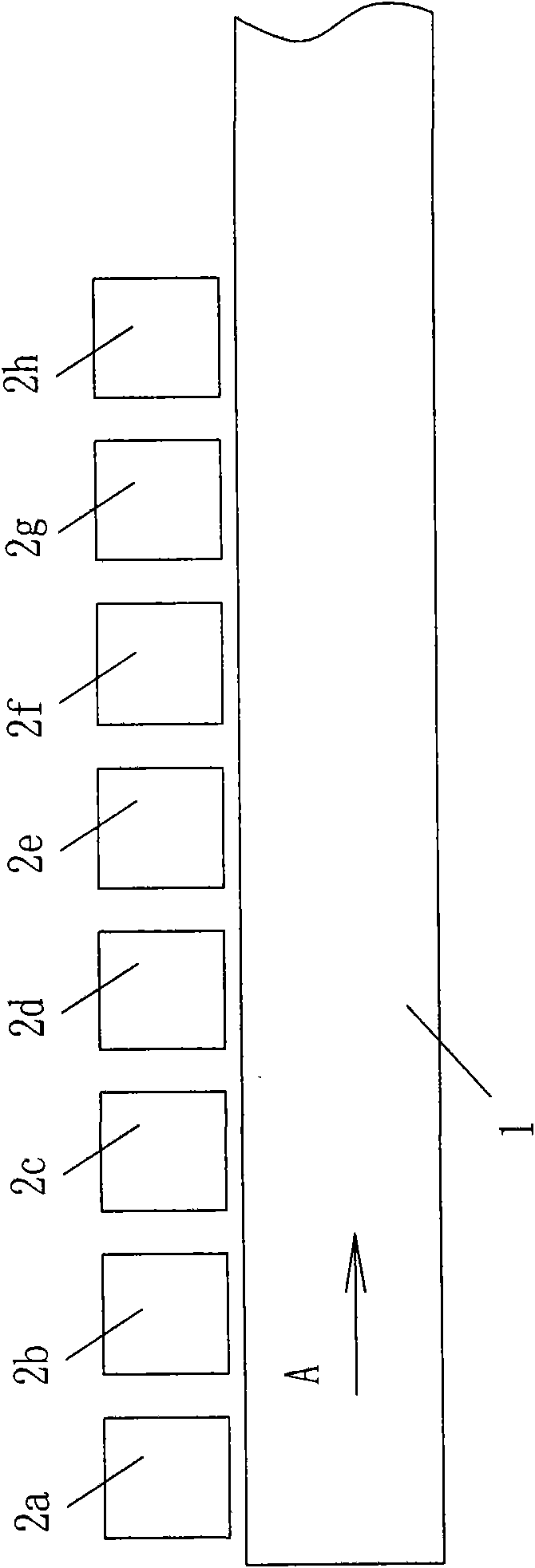

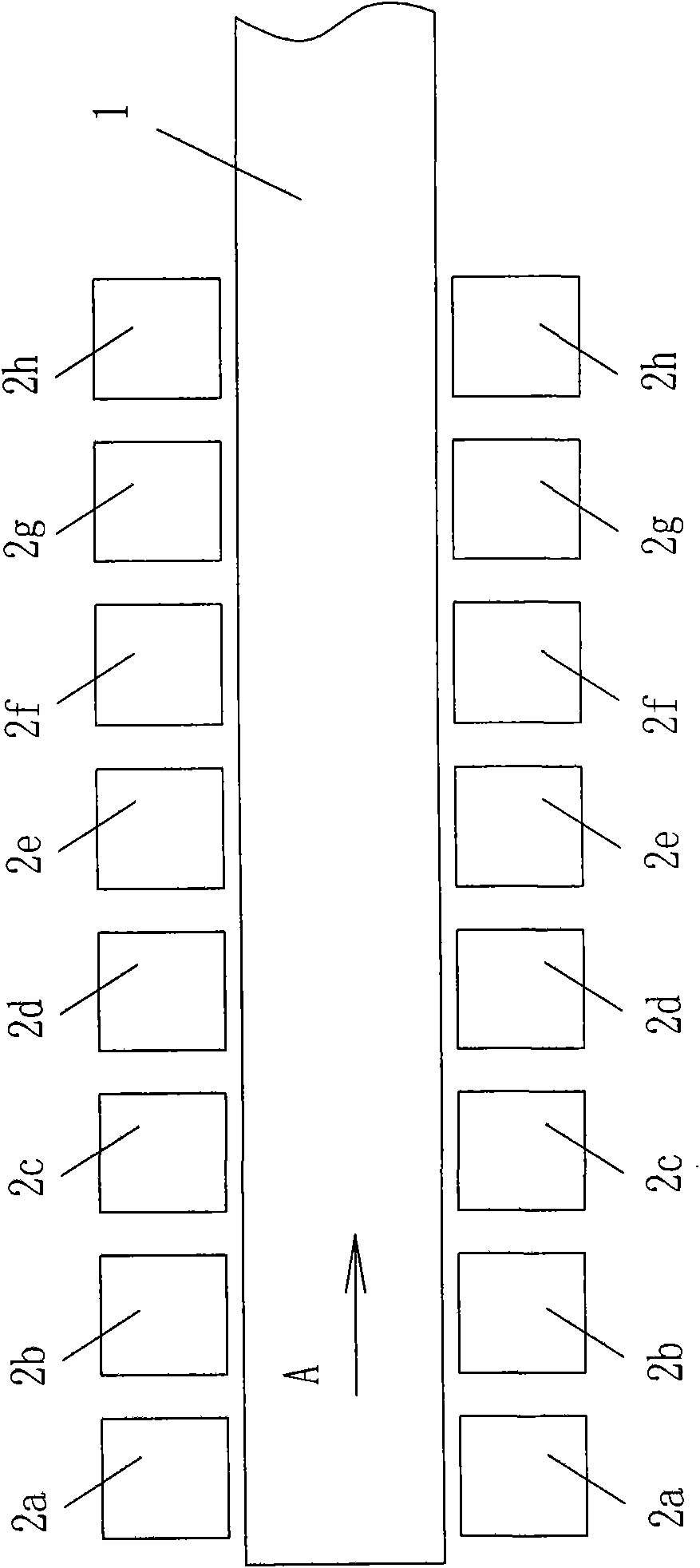

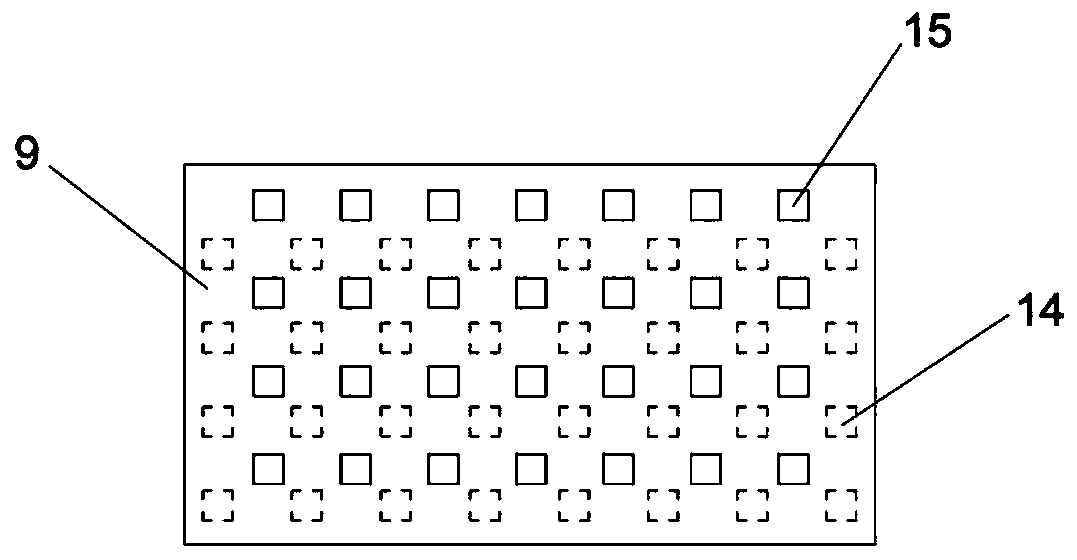

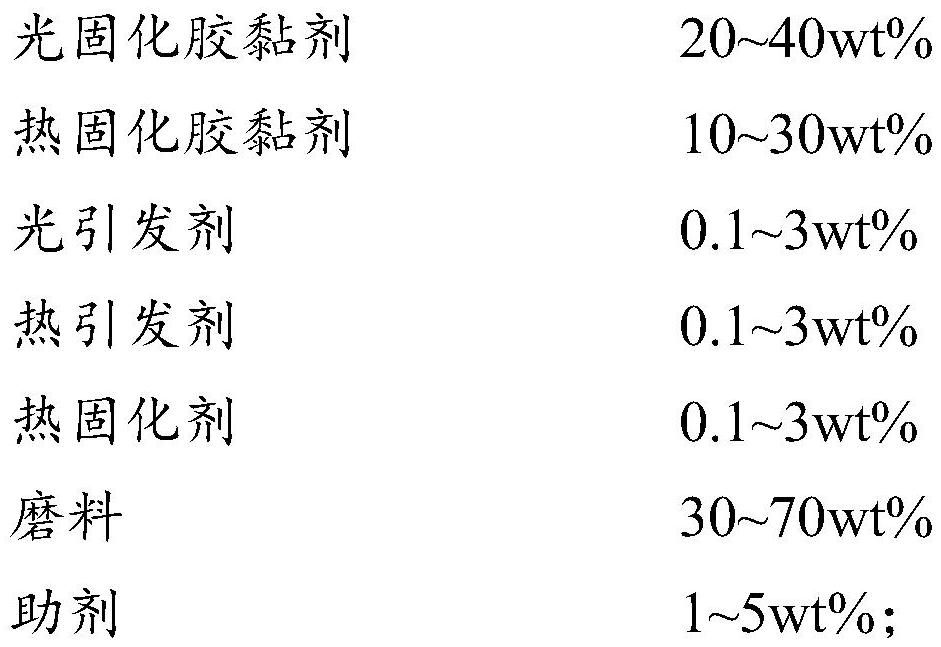

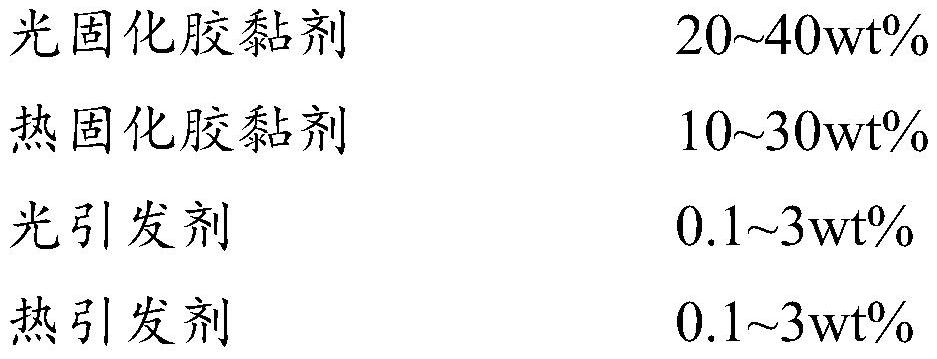

Three-dimensional grinding material and preparation method thereof

ActiveCN107553312AReduce lossGuaranteed bonding strengthOther chemical processesAbrasion apparatusEpoxyAdhesive

The invention provides a three-dimensional grinding material. The three-dimensional grinding material comprises a substrate, an adhesive layer which is compounded on the substrate, a base material which is compounded on the adhesive layer, a bottom adhesive layer which is compounded on the base material, and a plurality of grinding blocks which are arranged on the bottom adhesive layer; a gap is reserved between every two adjacent grinding blocks; the grinding blocks are formed by curing a mixture, wherein the mixture is comprises 20 to 40 weight percent of a photo-curing adhesive, 10 to 30 weight percent of a thermo-curing adhesive, 0.1 to 3 weight percent of a photoinitiator, 0.1 to 3 weight percent of a thermal initiator, 0.1 to 3 weight percent of a thermo-curing agent, 30 to 70 weightpercent of a grinding material, and 1 to 5 weight percent of an auxiliary agent, wherein the photo-curing adhesive is selected from polyurethane acrylate resin; and the thermo-curing adhesive is selected from epoxy resin. The invention also provides a preparation method of the there-dimensional grinding material. The three-dimensional grinding material which is prepared from the polyurethane acrylate resin and the epoxy resin serving as adhesives provided by the invention is slow in loss and long in service life.

Owner:河北思瑞恩新材料科技有限公司

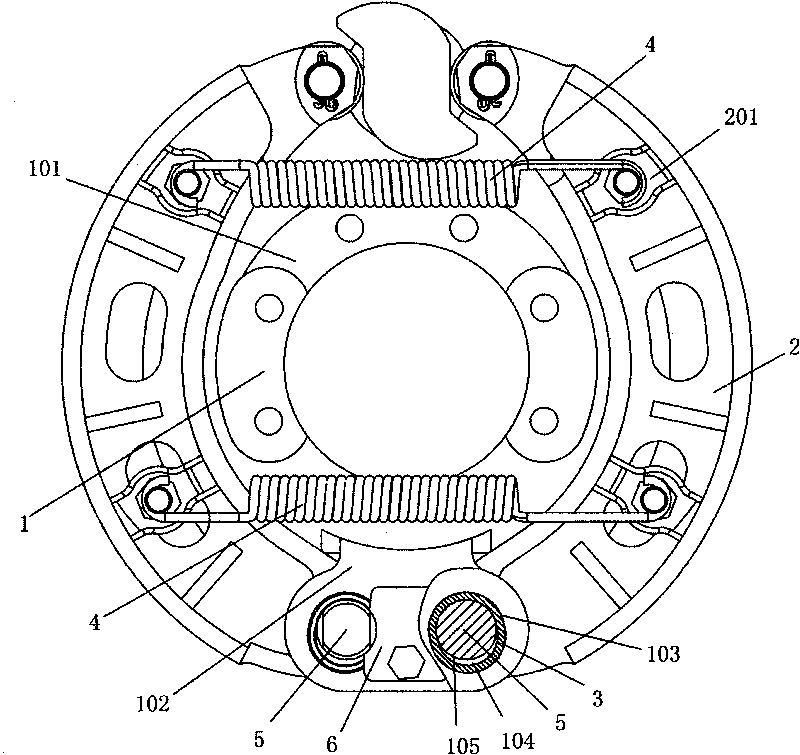

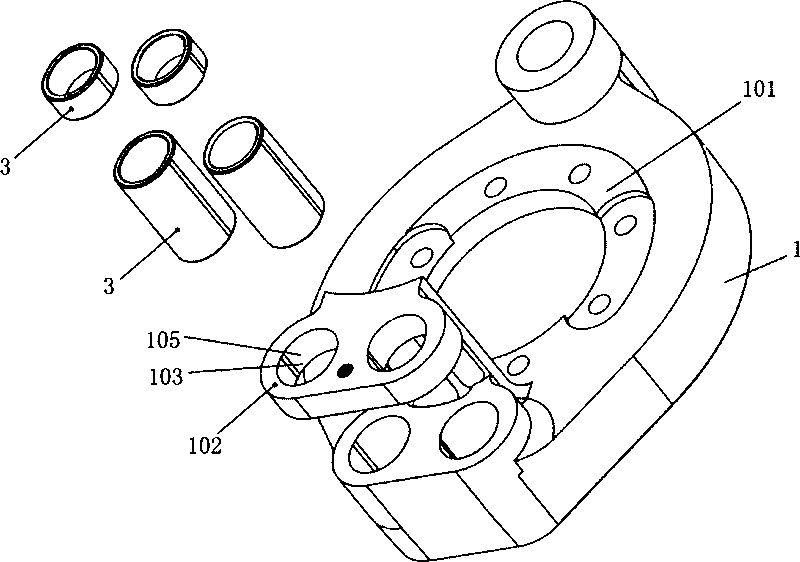

Improved brake bottom plate of drum brake

The invention discloses an improved brake bottom plate of a drum brake, which comprises a brake bottom plate, wherein a connecting disk is arranged on the brake bottom plate; a plurality of installing holes are arranged on the connecting disk; the brake bottom plate is convexly provided with a clamping part; connecting through holes are formed on the clamping part; the end parts of a left brake shoe and a right brake shoe are inserted into the clamping part of the brake bottom plate and are connected with the clamping part; the clamping part of the brake bottom plate is provided with the connecting through holes positioned at the upper layer and the lower layer, and a notch is formed at the middle part; the connecting through holes are cut for certain gaps; and the gaps and the connecting through holes form an integrated guide groove. The improved brake bottom plate of the invention has a uniform friction surface, prolongs the service life of friction plates, the brake and the brake bottom plate, has more reliable brake and higher brake efficiency, and improves the driving safety and the driving and riding comfort.

Owner:杨群英

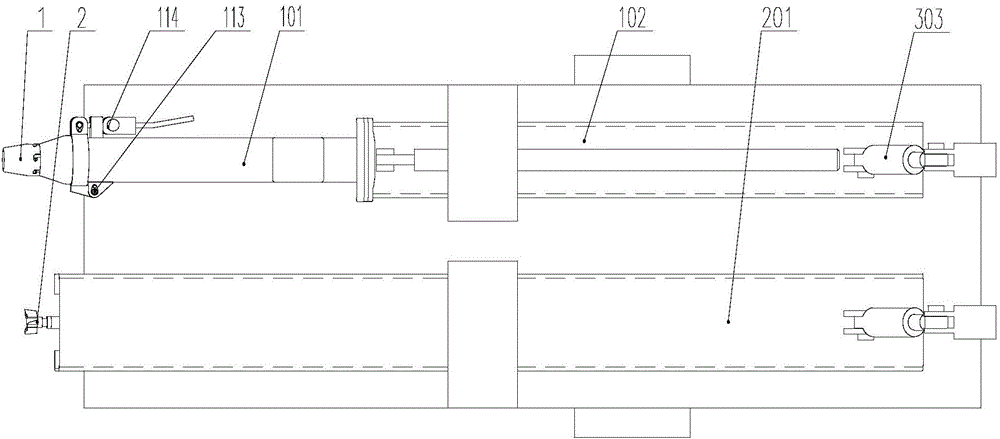

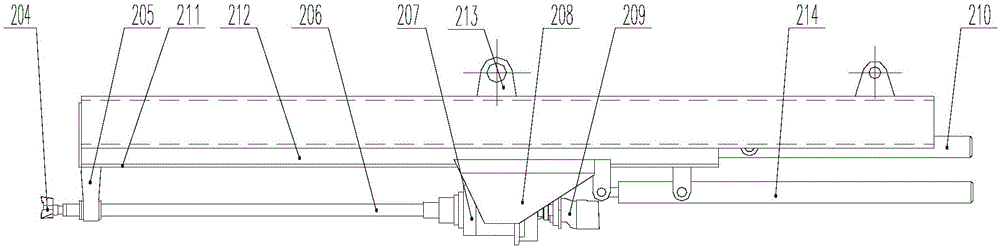

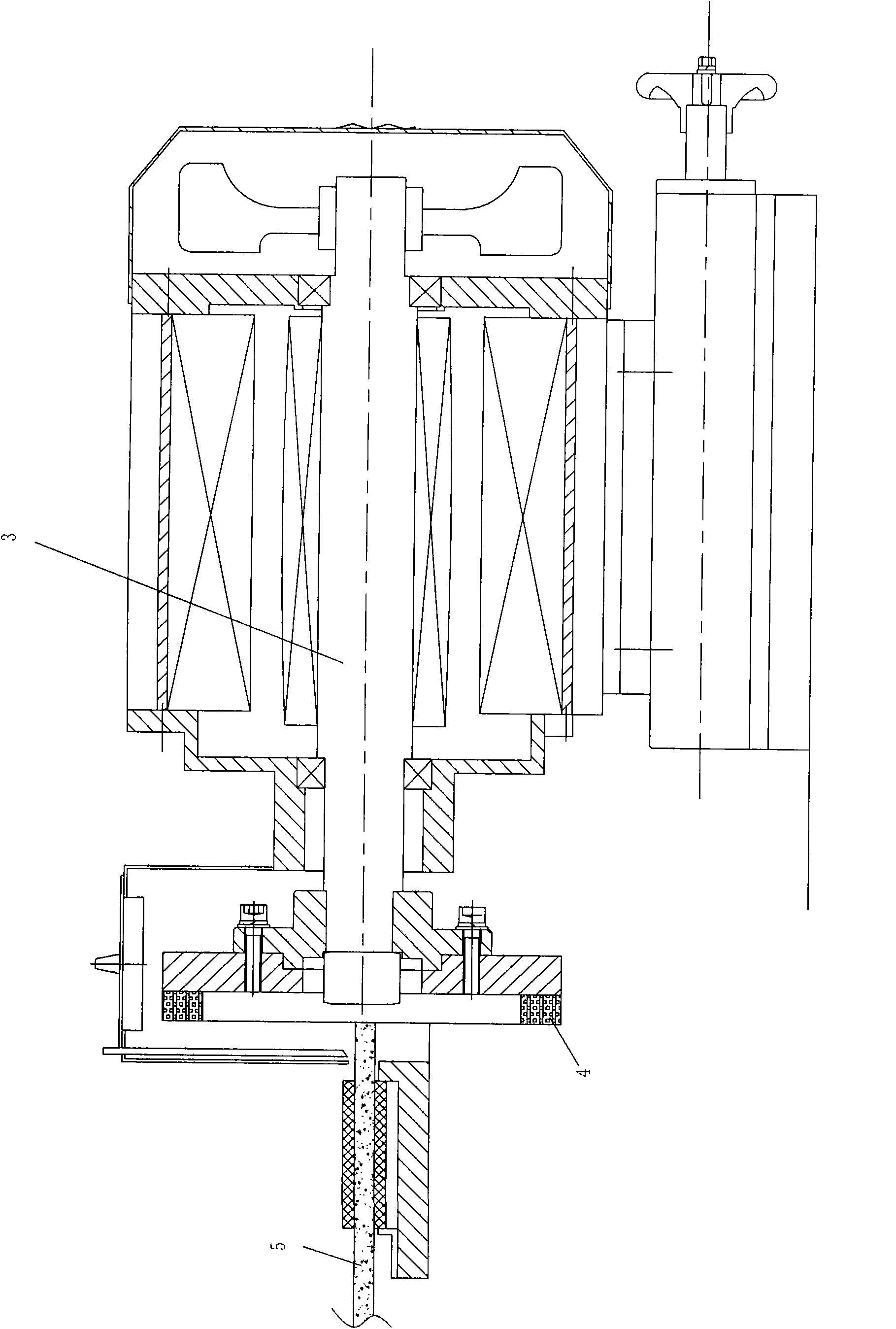

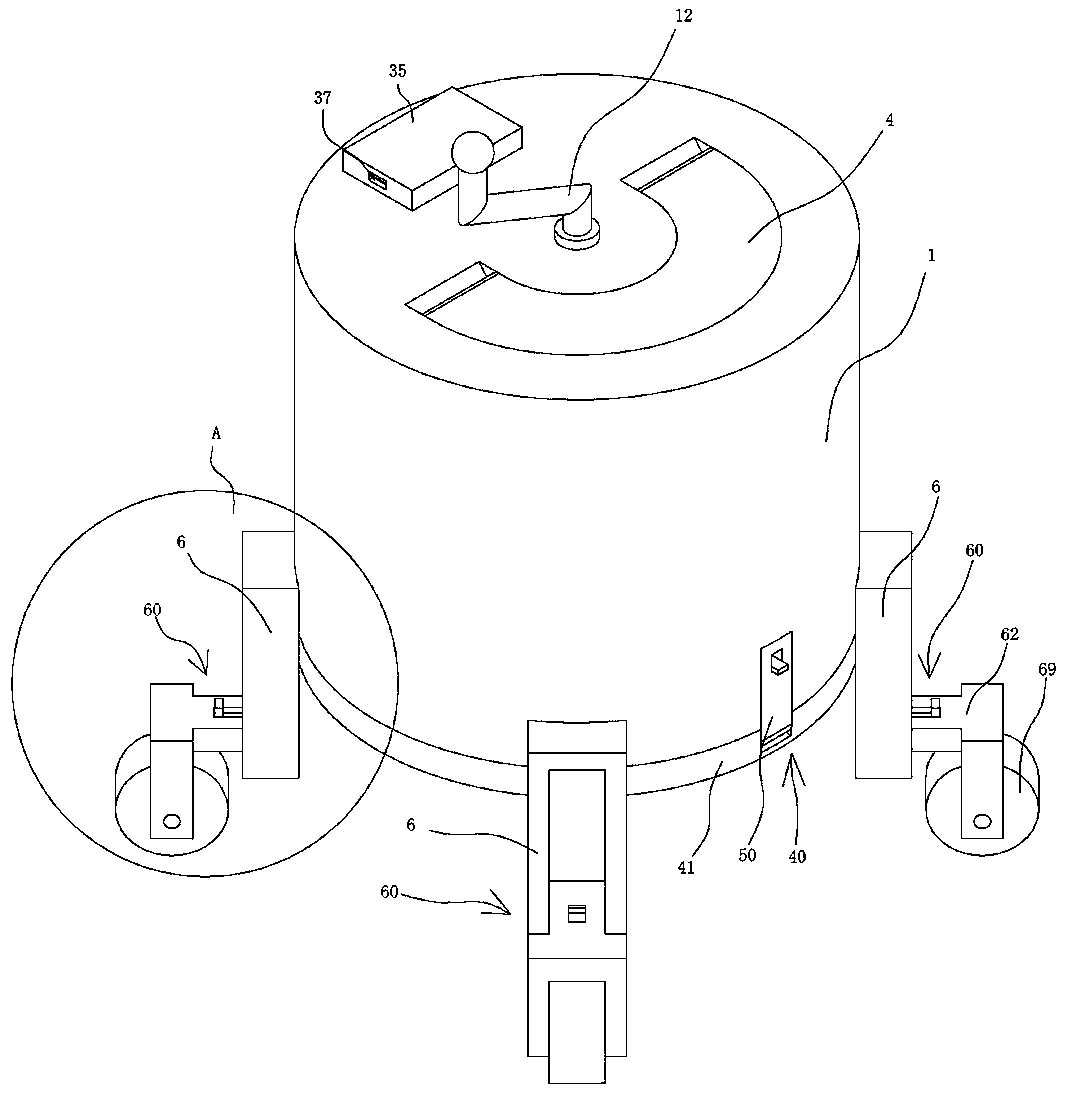

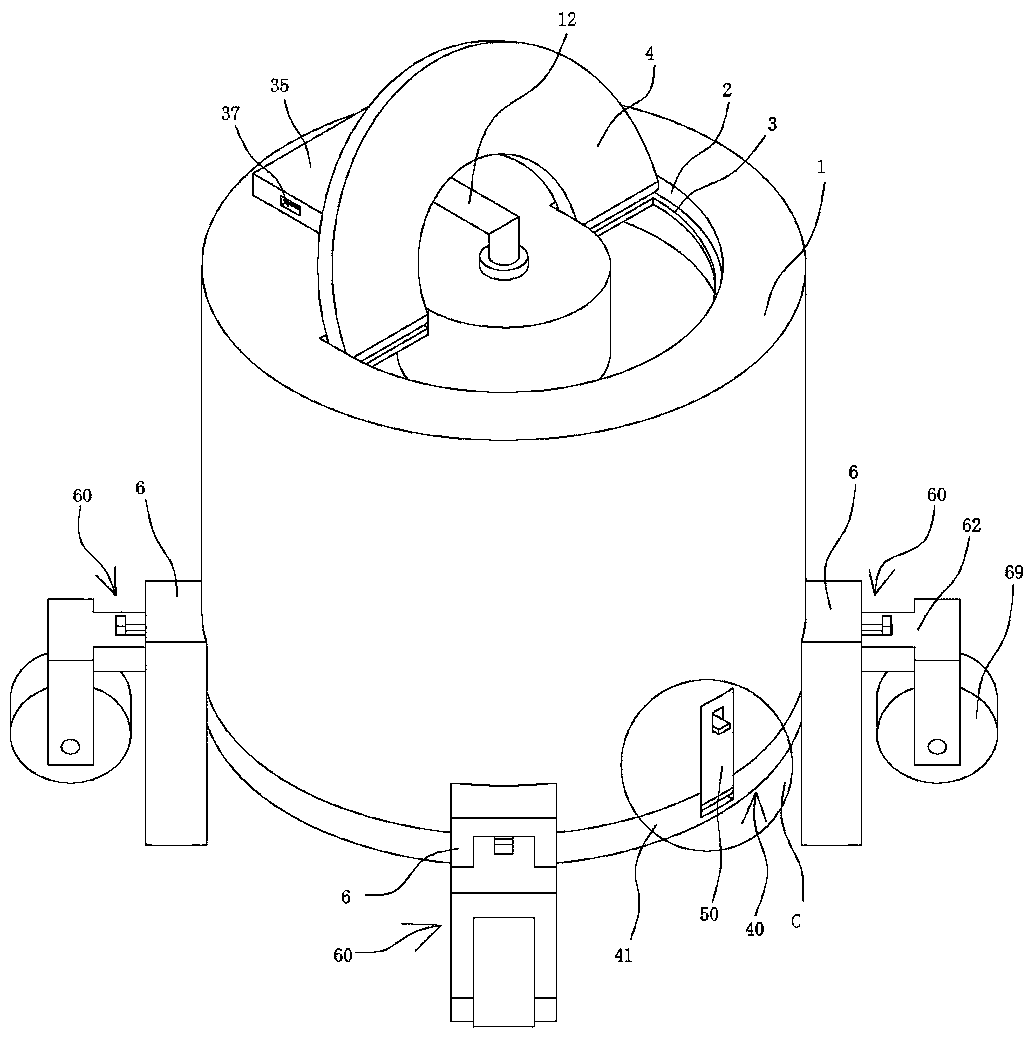

Tremolo device for stringed instrument and stringed instrument

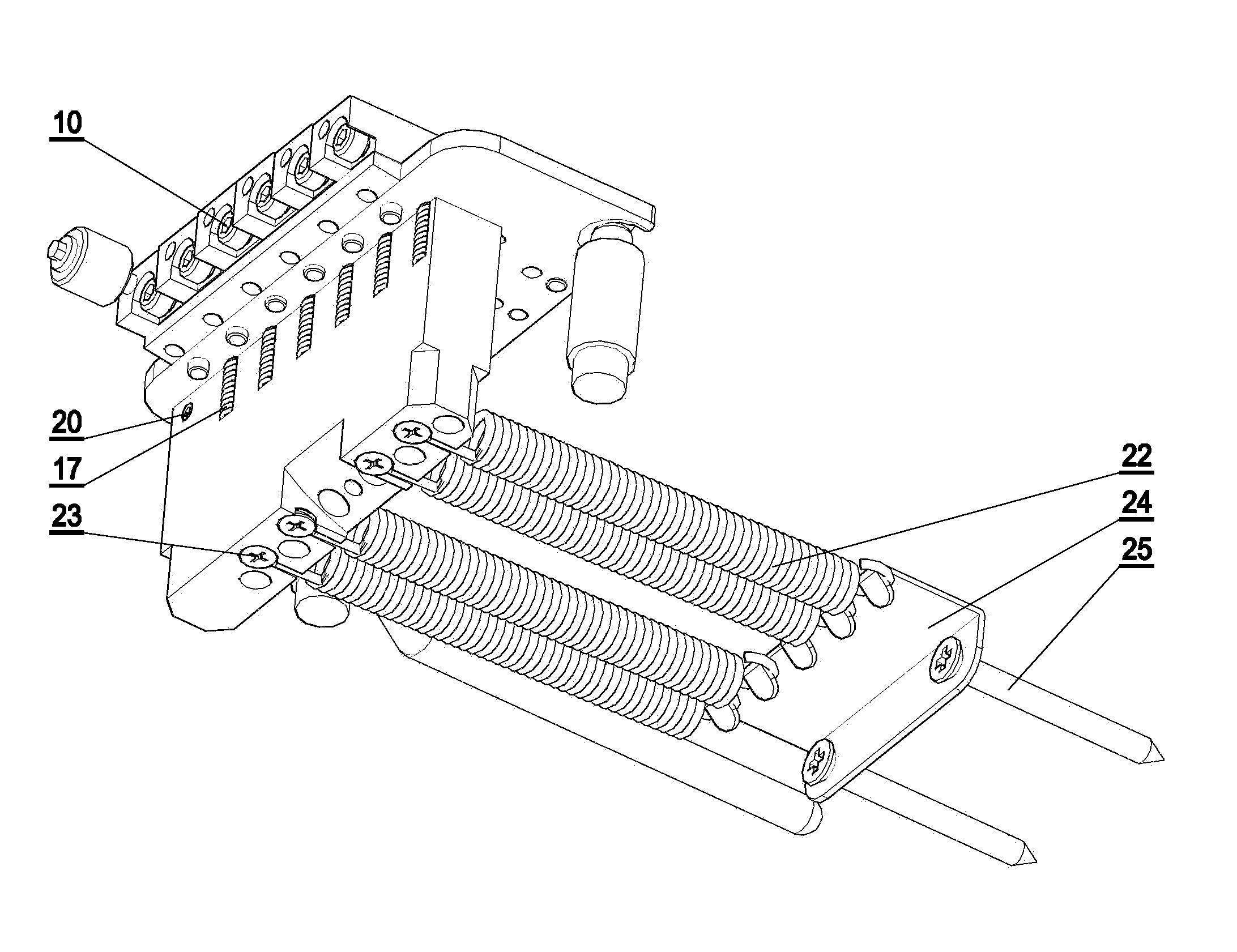

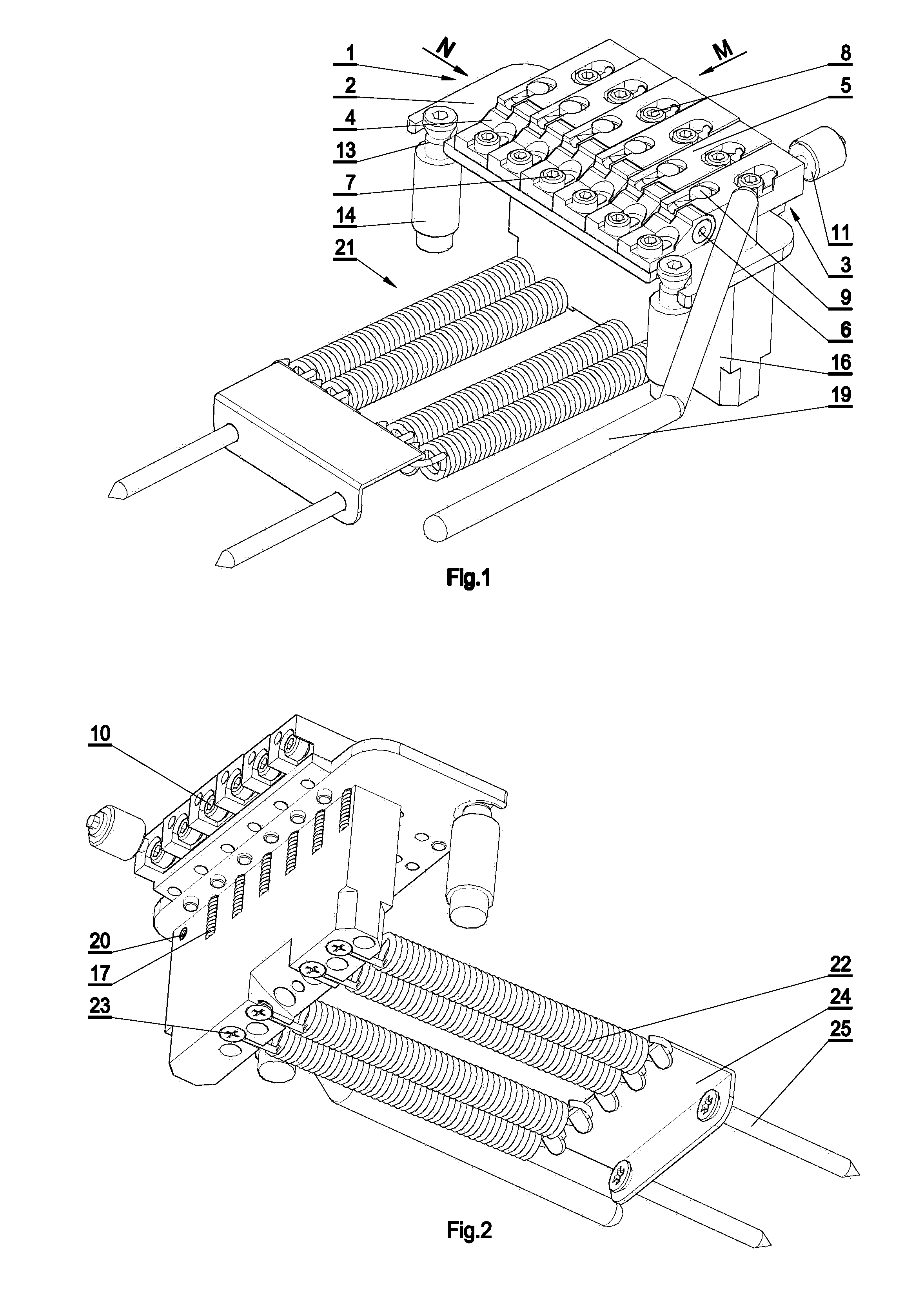

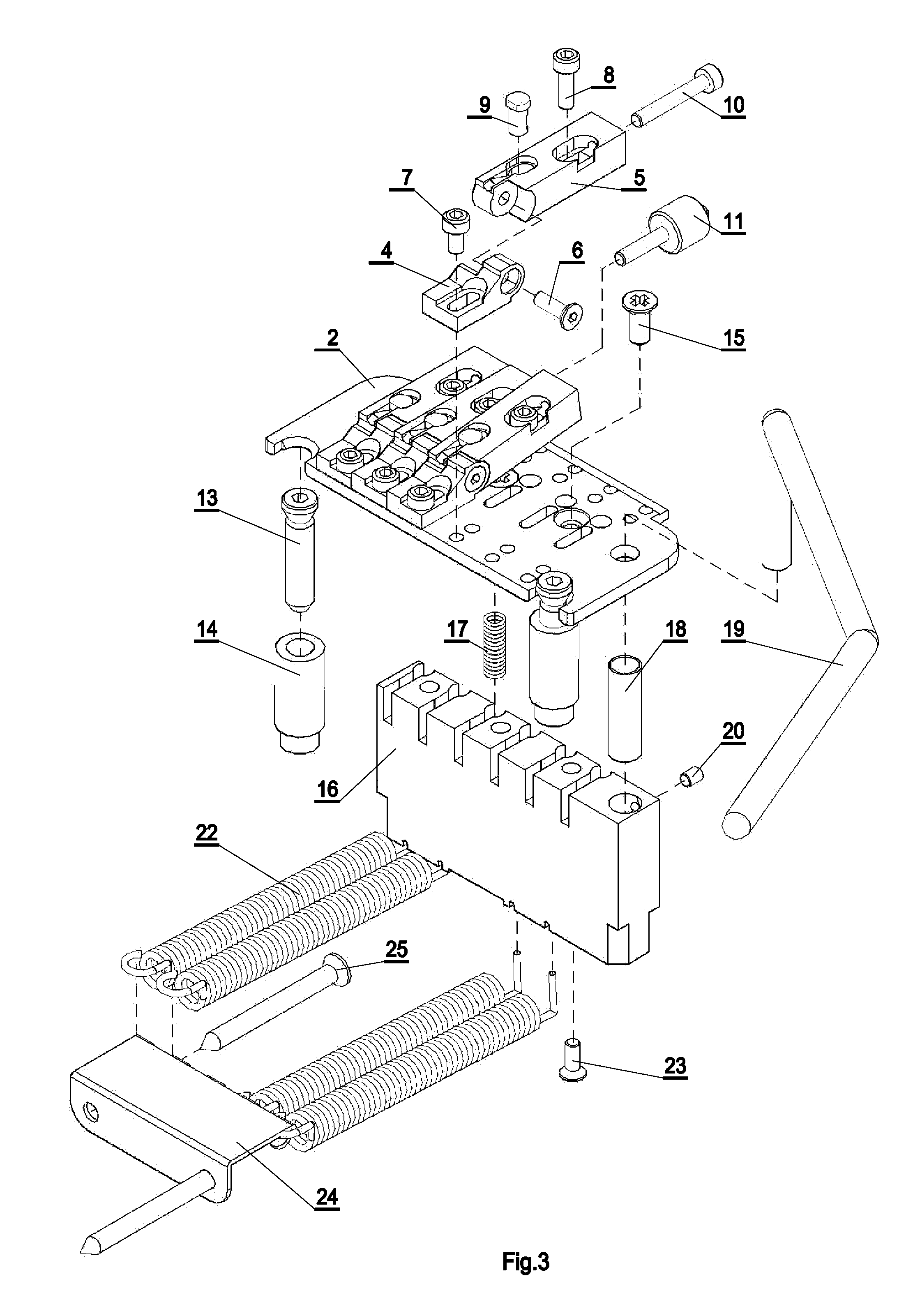

A tremolo device for stringed instrument and a stringed instrument. The tremolo device (1) includes base plate (2) with saddle assemblies (3) mounted independently and corresponding to strings. Each saddle assembly includes front (4) and rear (5) string saddle, located on the base plate upper surface and connected movably with asymmetric arms and connecting element (6). At each saddle assembly there is saddle mounting screw (7) for positioning to the base plate, string lock insert (9), string lock screw (10) for locking string (32) and fine tuning screw (8). To the base plate sustain block (16) is mounted with recesses (16a) and openings (16b), also housings (16c) with fine tuning springs (17), contacting with the respective rear (5) string saddle. To the sustain block (16) balancing mechanism (21) and tremolo arm (19) are settled. The stringed instrument is equipped with tremolo unit (1) and top lock unit (37).

Owner:MASLAROV TEODOR DIMITROV

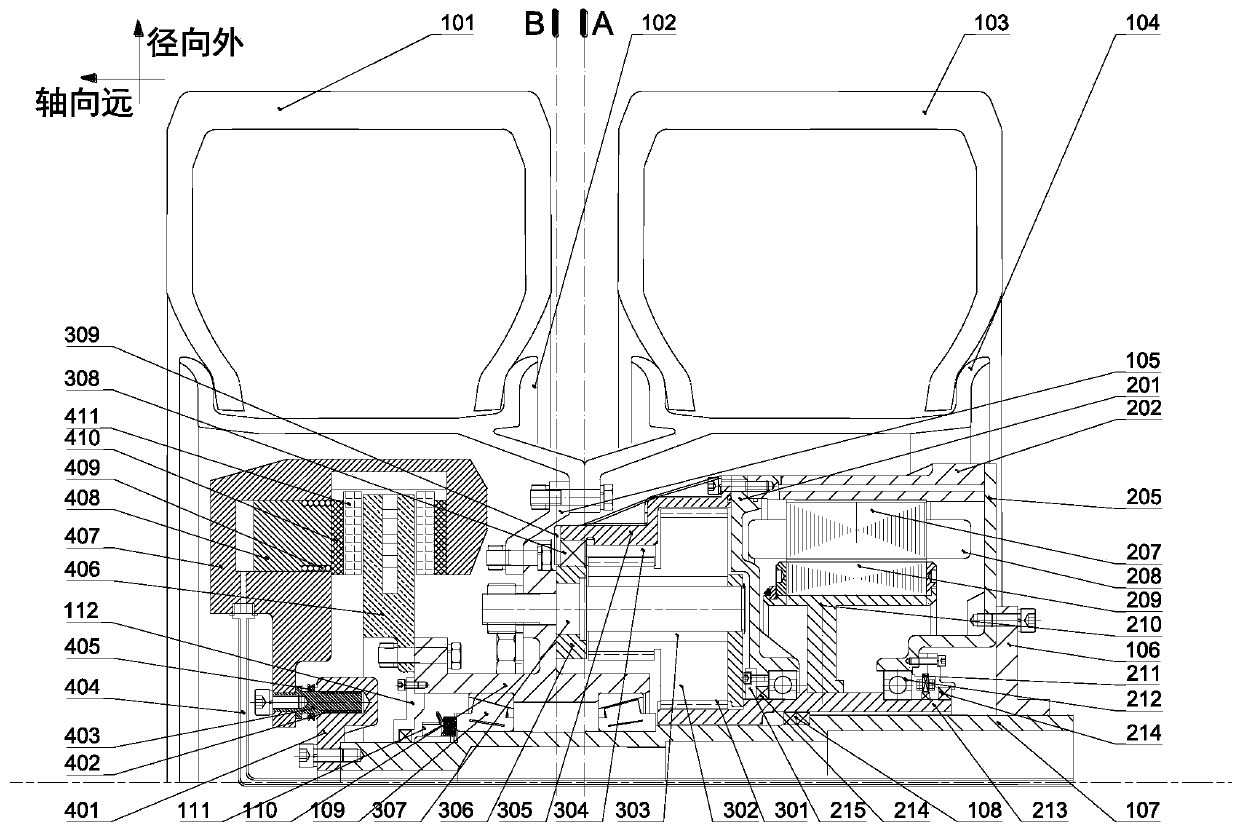

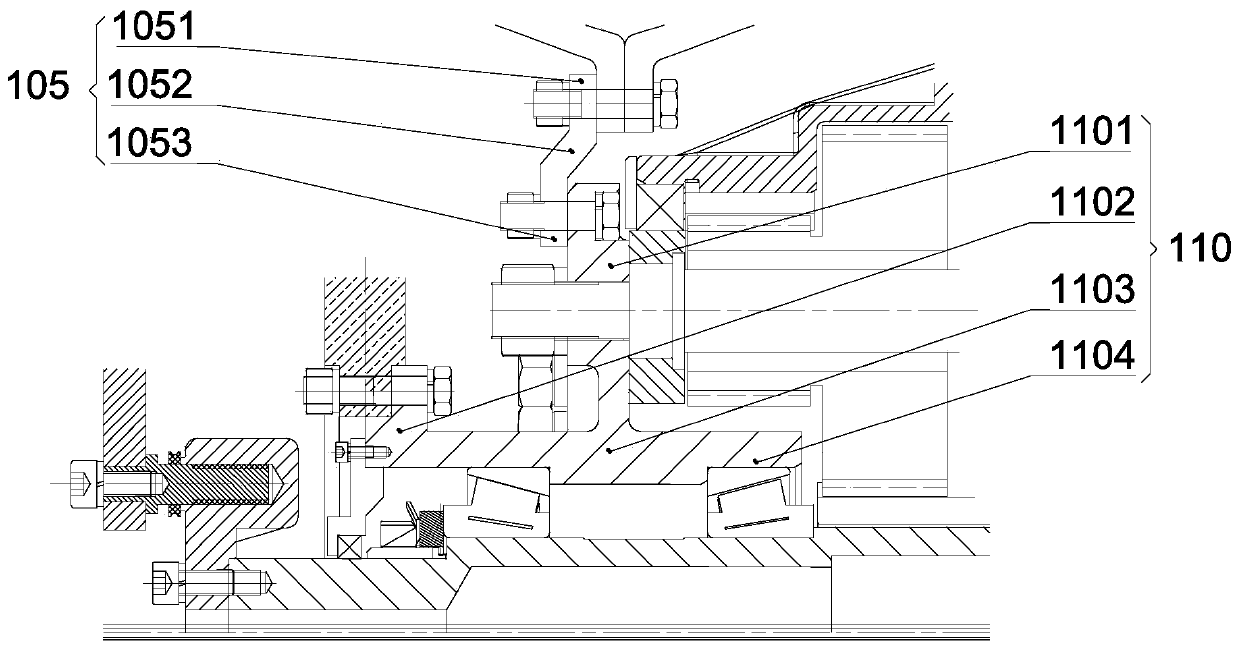

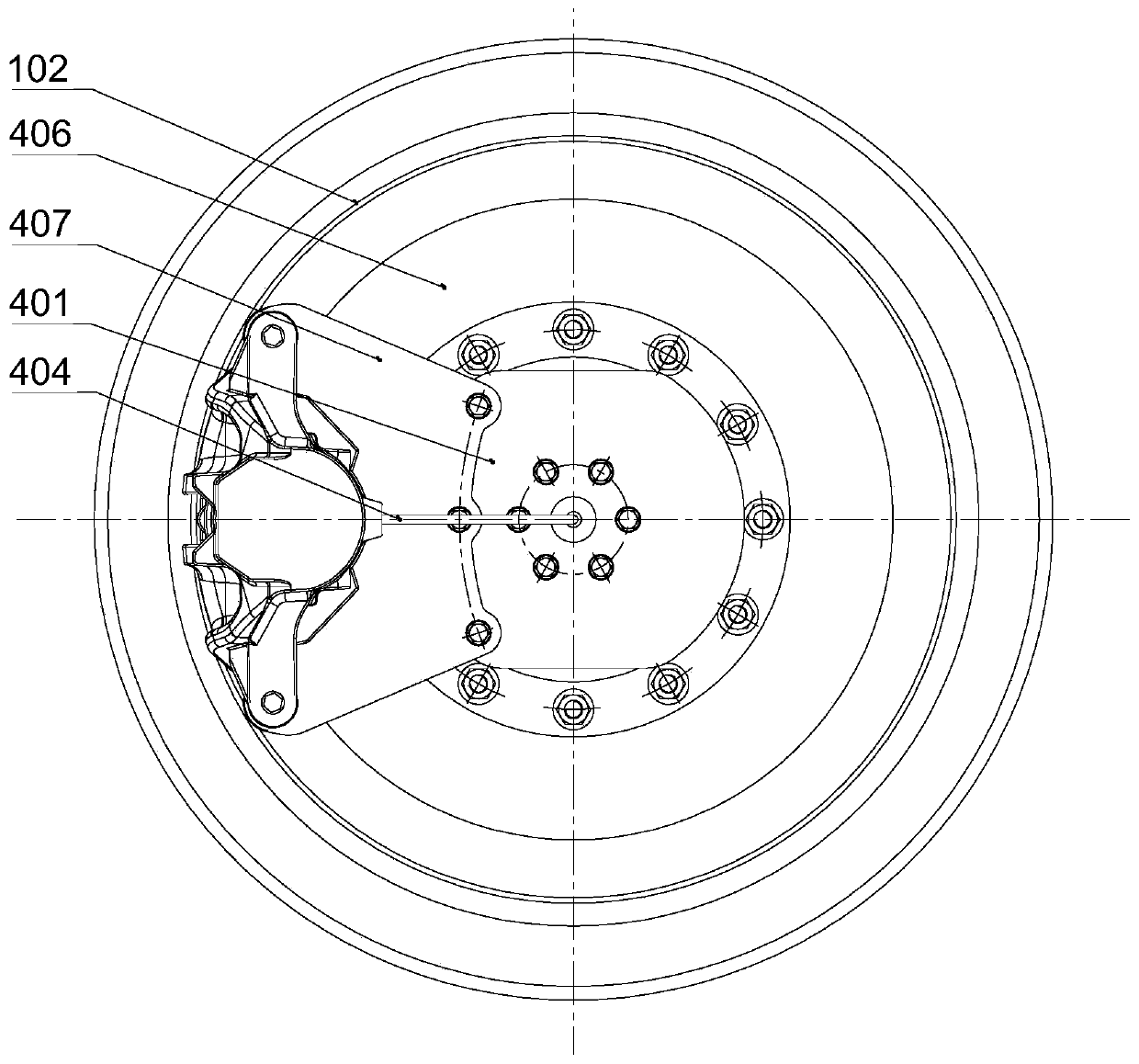

Heavy-load electric wheel

PendingCN111361358AAxial dimension shortCost controlBraking element arrangementsMagnetic circuit rotating partsReduction driveGear wheel

The invention discloses a heavy-load electric wheel, and belongs to the field of electric vehicle power devices. A brake, a planetary gear reducer and a hub motor are sequentially arranged on the outer side of a supporting shaft from the distant to the near; the outer side of a hub is connected with a spoke mounting plane of a rim through a spoke, and the hub is mounted on the outer side of the supporting shaft through a pair of hub bearings; a brake caliper support in the brake is installed outside the distal facet of the wheel supporting shaft through a bolt, and a brake disc is installed ona brake disc installation flange of the hub; a hub part of the hub motor rotor support is sleeved on the rotor shaft; and a sun gear in the planetary gear reducer is disposed outside the distal end side of the rotor shaft. The axial size of the whole electric wheel assembly is short, and the hub motor, the planetary gear reducer and the brake are all arranged in the space defined by the rim on the inner side and the outer side of the electric wheel assembly, so that the electric wheel assembly can be suitable for common commercial vehicle double-tire parallel loading wheels.

Owner:南京清研易为新能源动力有限责任公司

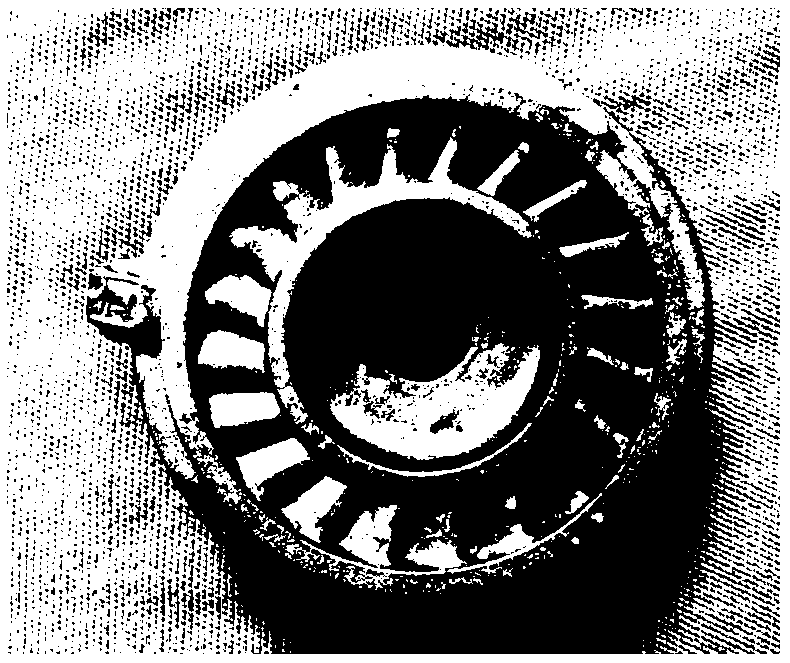

Coated abrasive tool and production method thereof

ActiveCN104889896ASlow lossExtended service lifeAbrasion apparatusGrinding devicesPhase splittingN dimethylformamide

The invention provides a coated abrasive tool comprising a base material layer, binding agent and an abrasive material. The coated abrasive tool is characterized in that the base material layer is a porous film; the porous film is obtained by applying a mixed solution of polyurethane resin, wood powder, defoaming agent, flatting agent and N, N-dimethylformamide to the surface of a fluffy cloth base and subjecting the cloth base to phase splitting and film forming in coagulating bath. The coated abrasive tool has the advantages that the coated abrasive tool wears slowly during use, service life is long, flex resistance, flexibility, elasticity and tensile strength are high and precision production requirements can be met.

Owner:清远市百优研磨材料有限公司

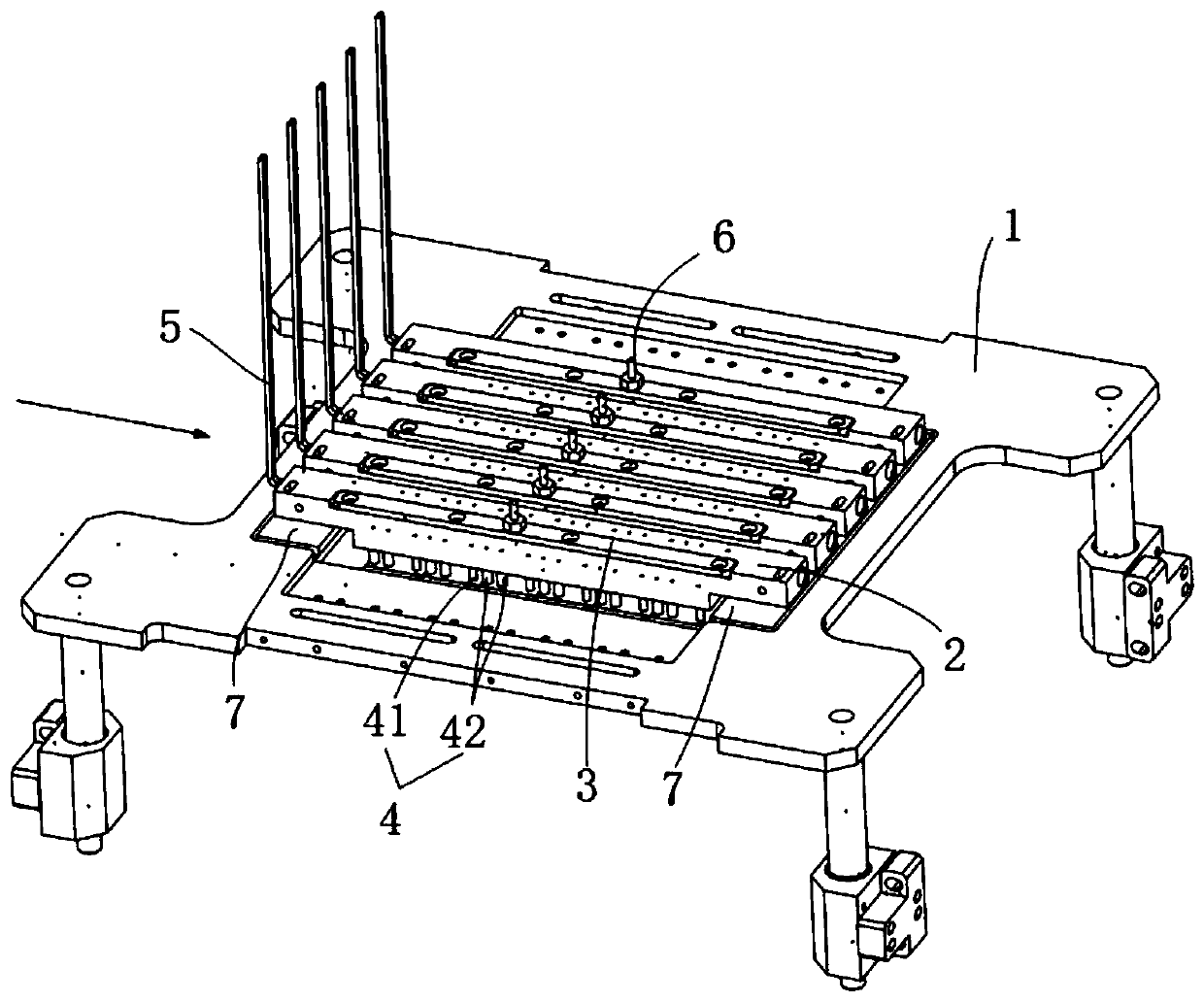

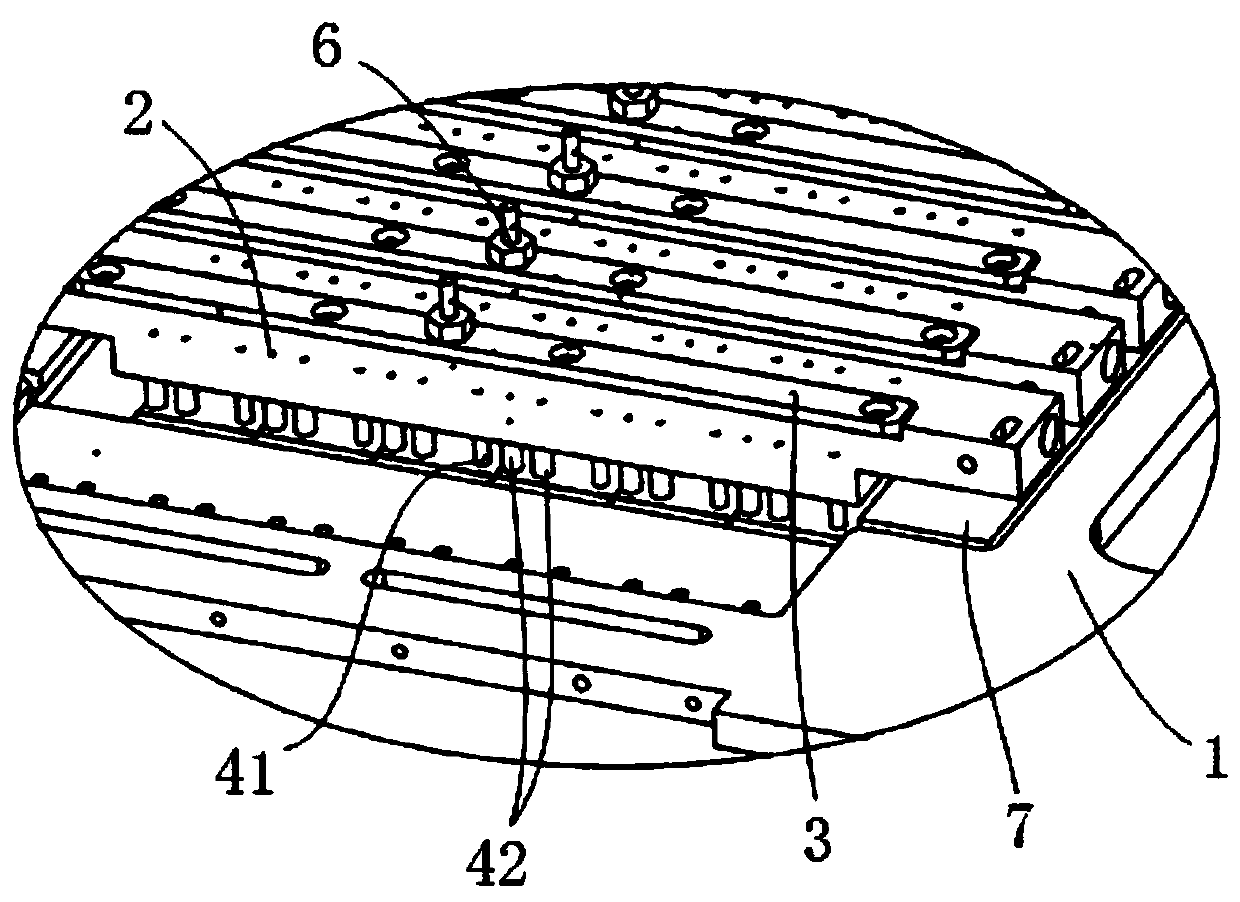

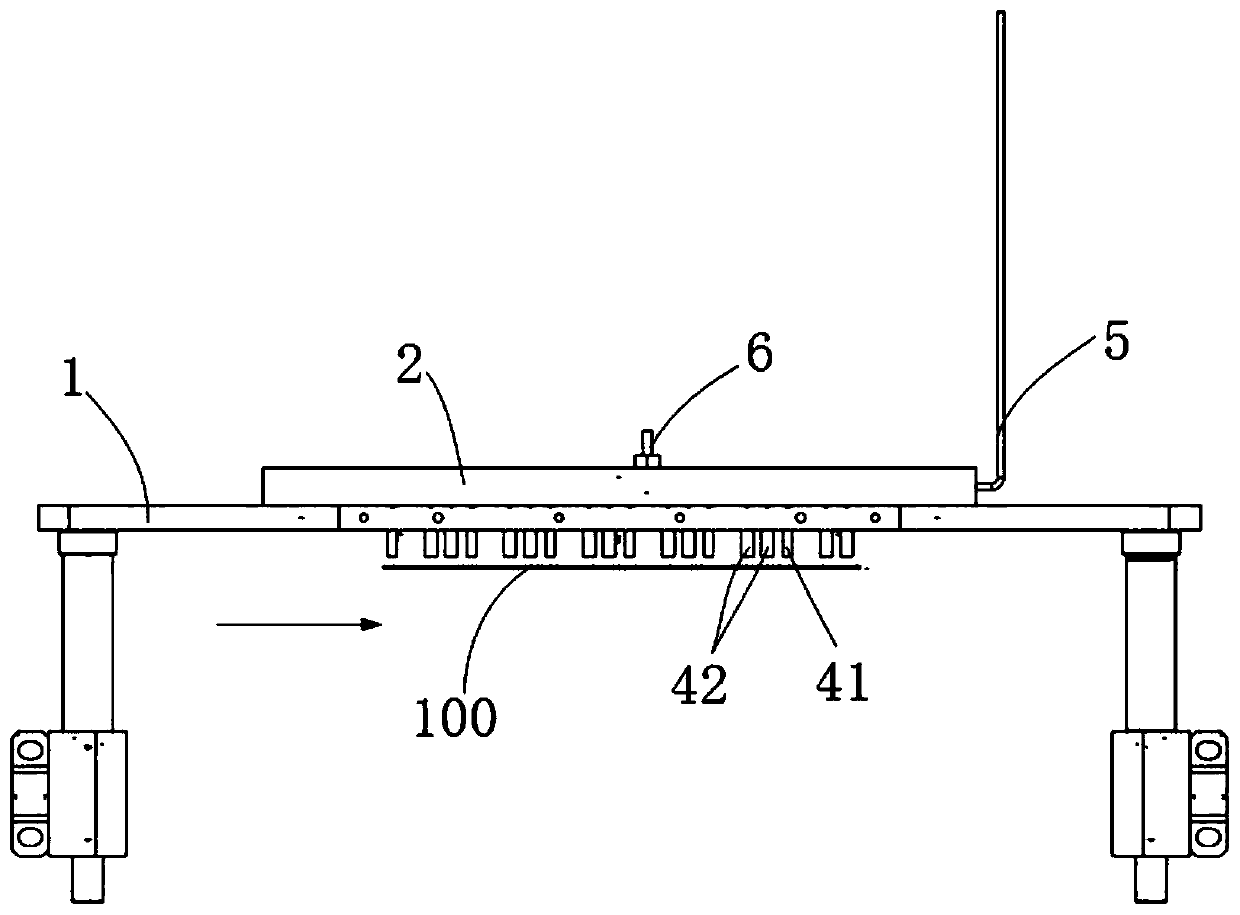

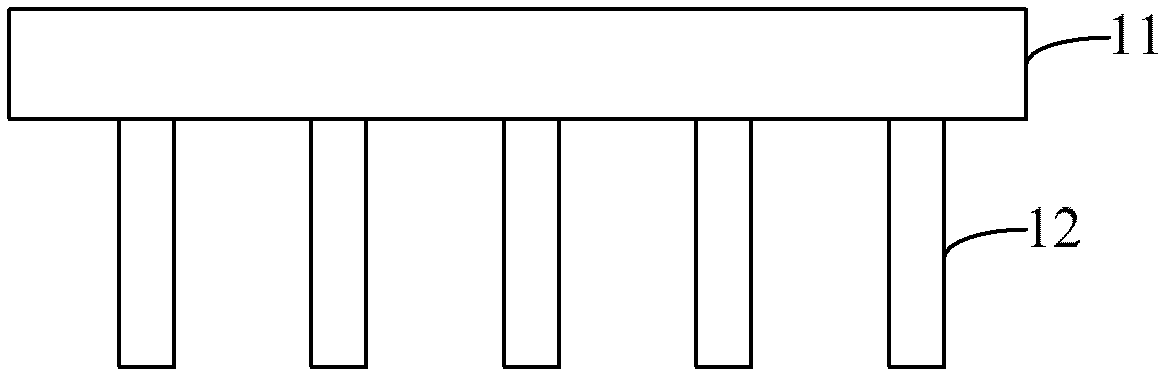

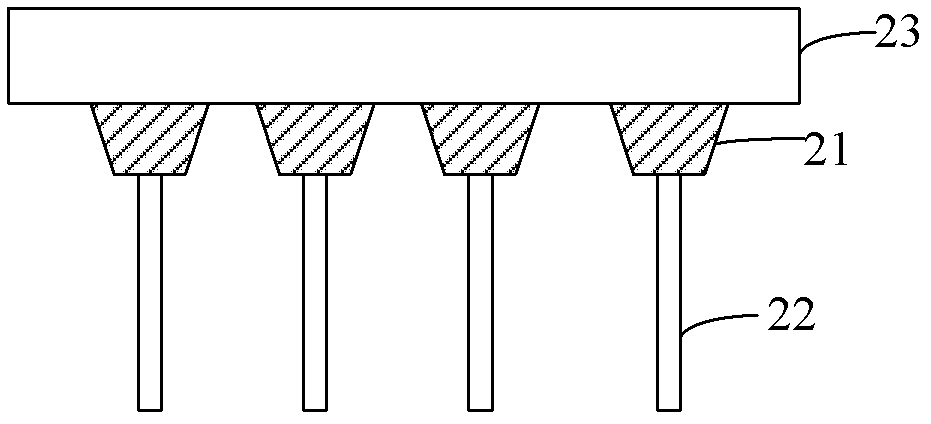

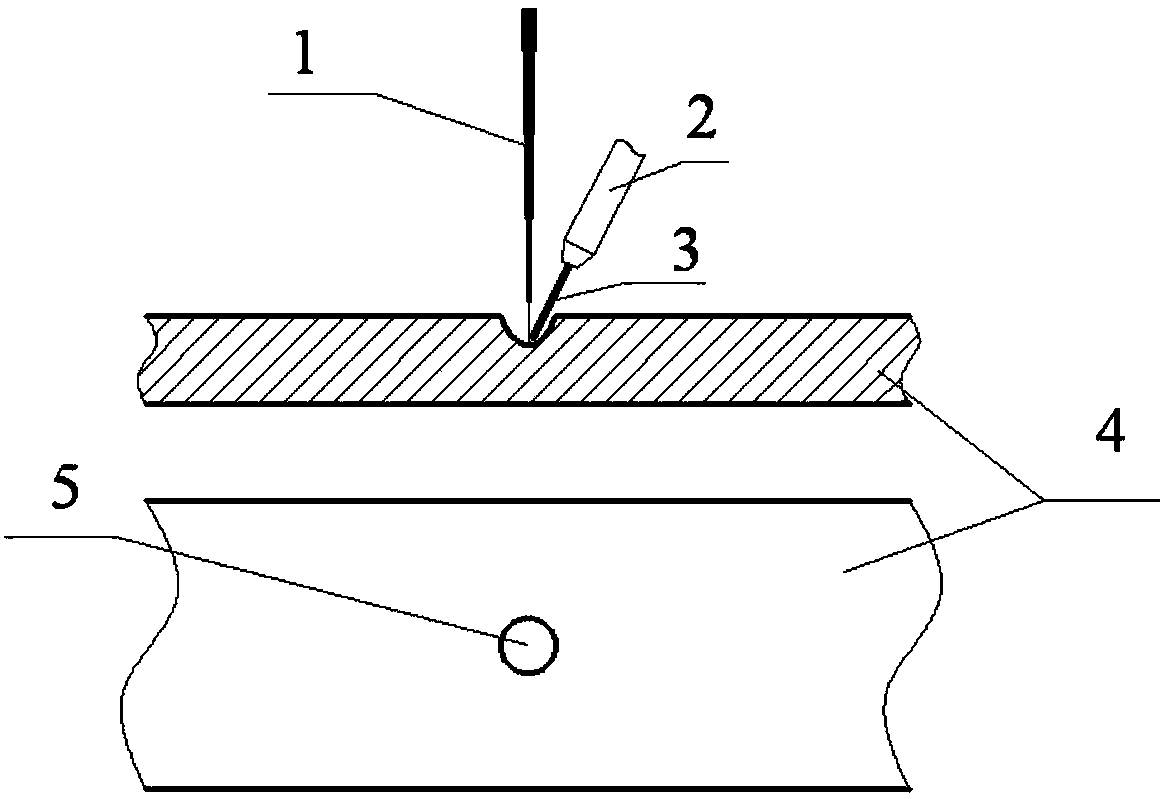

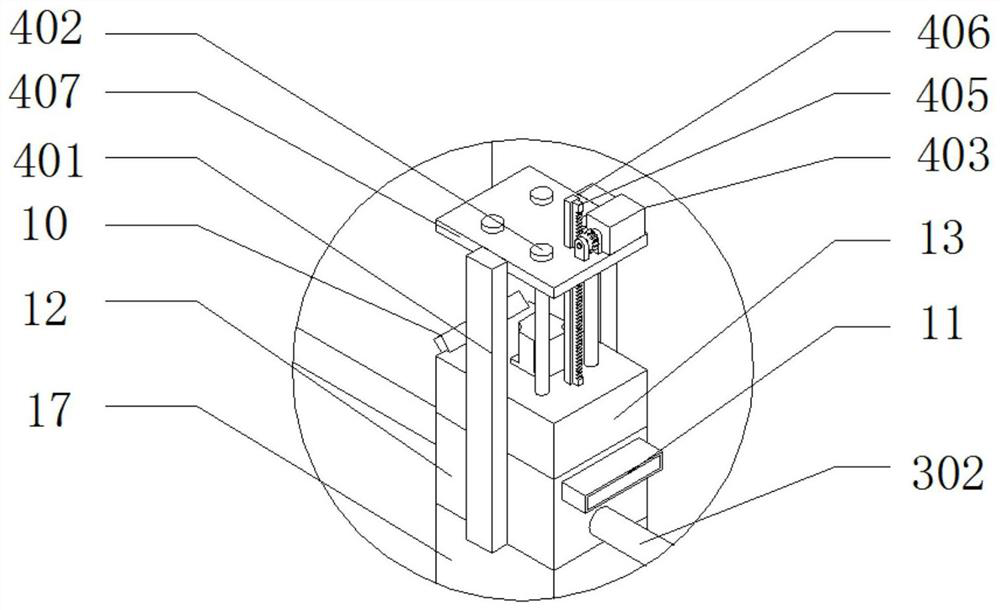

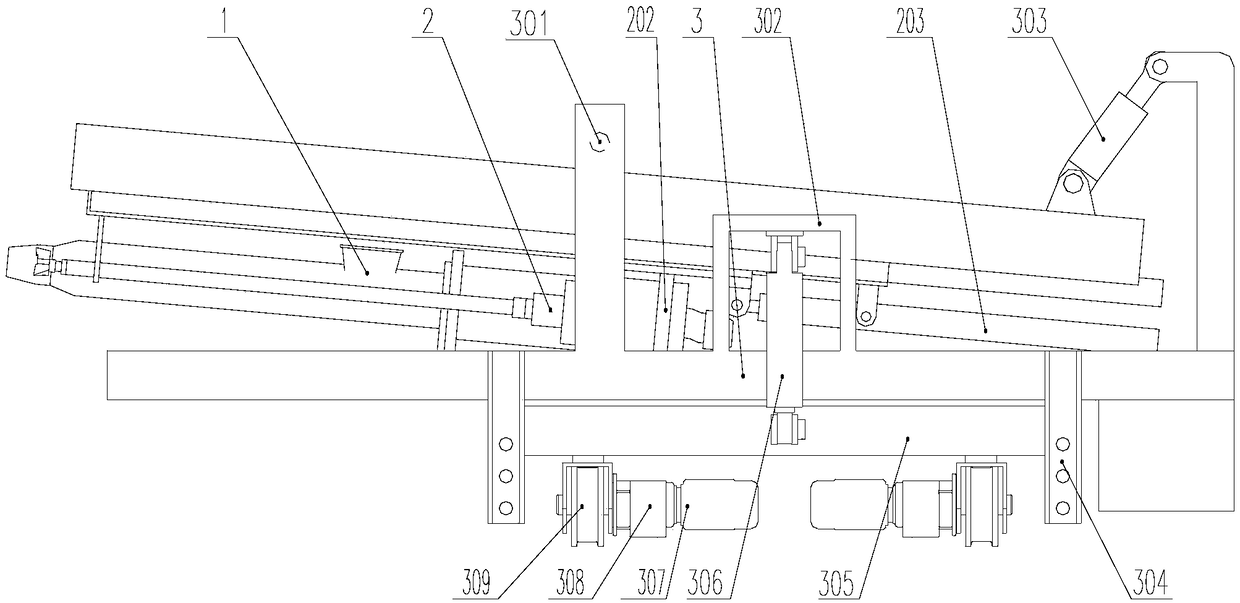

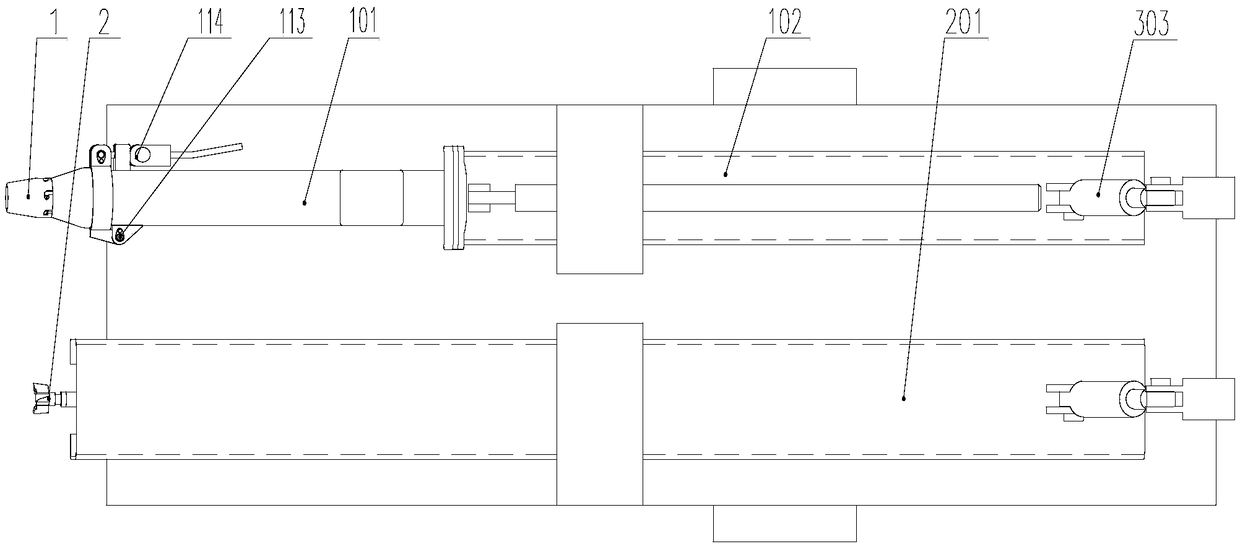

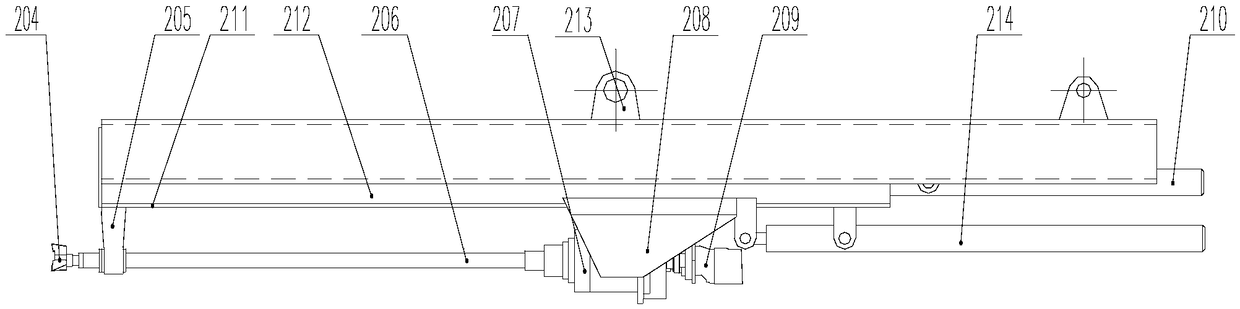

Welding device and series welding equipment

PendingCN110625217ASlow lossControl welding effectFinal product manufactureThermometers using electric/magnetic elementsEngineeringWelding

The invention discloses a welding device and series welding equipment. The welding device comprises a rack, a mounting plate mounted on the rack, and a heating component for heating the mounting plate. The welding device further comprises a pressing needle for pressing a portion to be welded, and the pressing needle is mounted on the mounting plate and can acquire heat from the mounting plate. Thepressing needle carries out heating welding on stacked battery pieces and welding strips through the acquired heat. According to the technical scheme, the welding temperature can be accurately controlled through pressing needle welding, and therefore the welding effect of the front faces and the back faces of the battery pieces can be effectively controlled, and the welding quality of a battery string can be improved.

Owner:WUXI AUTOWELL TECH

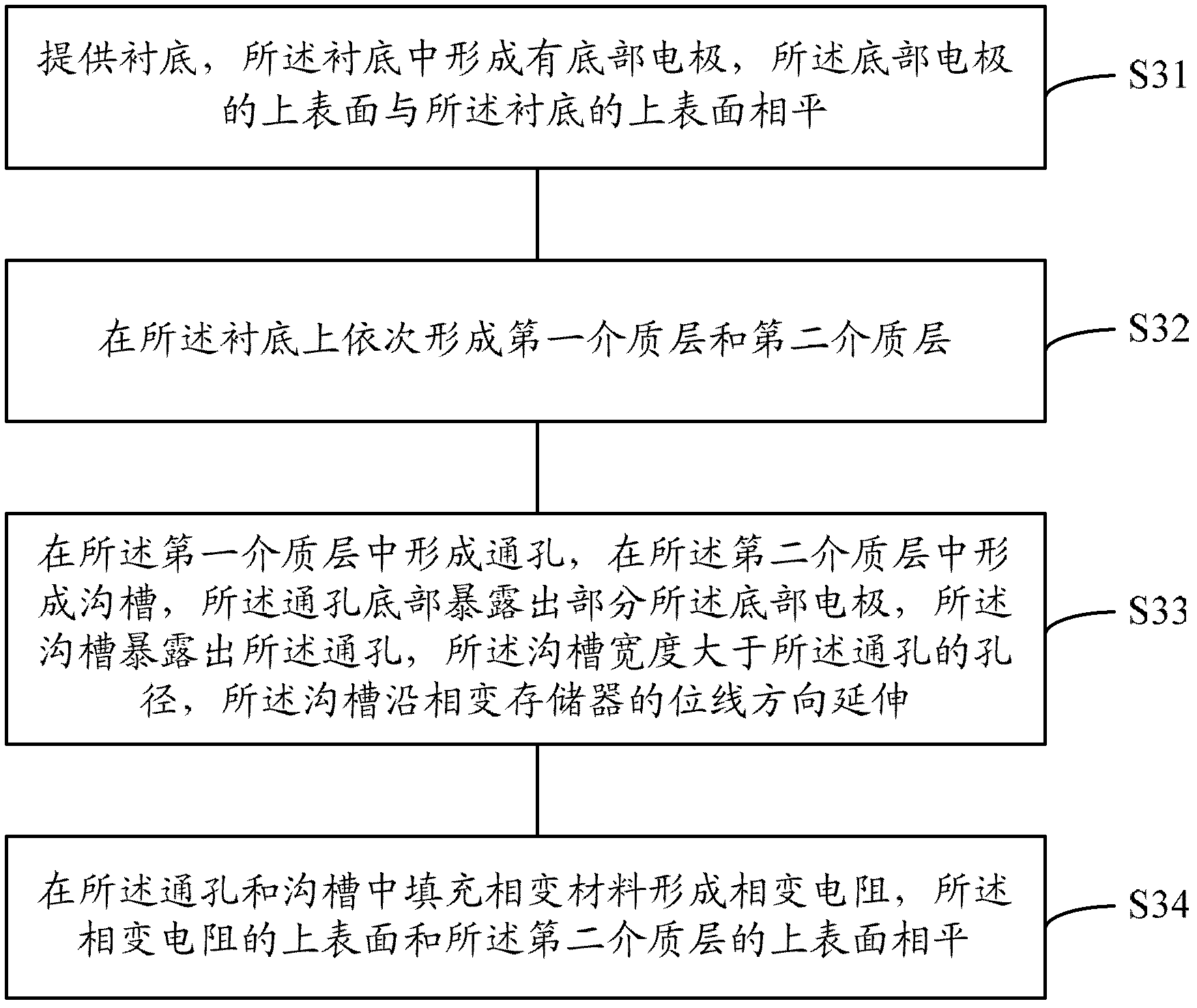

Phase change resistor in phase change memory and forming method thereof

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for repairing flaws of titanium-aluminum intermetallic compound castings

The invention belongs to the technical field of additive repairing, and relates to a method for repairing flaws of titanium-aluminum intermetallic compound castings. A vacuum environment condition isadopted in the whole process of electron beam fuse repairing, vacuum pressure intensity is 10<-2>Pa to 10<-3>Pa, and thus pollution caused by harmful elements such as N, O and H in the repairing process can be effectively avoided. Laser cladding repairing and arc welding repairing methods can hardly avoid pollution caused by harmful elements such as N, O and H, especially in a high-temperature state, the harmful elements can strongly cause embrittlement and cracking of titanium-aluminum intermetallic compounds, and then repairing fails. The material metallurgical quality after repairing in thevacuum environment is superior to that of other repairing methods, and repairing flaws can be effectively avoided; in addition, the heat loss speed is low under the vacuum environment, and after repairing, the cooling speed is low and heat stress is low, so that the risk of cracks is greatly lowered. Through vacuum annealing treatment in a furnace after repairing, repairing stress can be removedin time, the structure of a repaired area can be regulated, and delayed cracks of the repaired castings can be effectively avoided.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Graphene lithium ion battery electrolyte

InactiveCN107799815ASolve the problem of poor high and low temperature performanceImprove thermal stabilitySecondary cellsOrganic solventPhysical chemistry

The invention relates to technical fields of graphene preparation and graphene application, and specifically to a graphene lithium ion battery electrolyte. The graphene lithium ion battery electrolytecomprises the components in parts by mass: 120-220 parts of organic solvent, 14-33 parts of lithium salt, 5-10 parts of additives and 10-15 parts of graphene, wherein the additives comprise a flame-retardant additive, a film-forming additive and a low-temperature additive; and the flame-retardant additive adopts a graphene-molybdenum oxide nanometer flame-retardant composite material. The graphene lithium ion battery electrolyte is high in safety and high-low-temperature performance.

Owner:NANJING XUYURUI MATERIAL TECH CO LTD

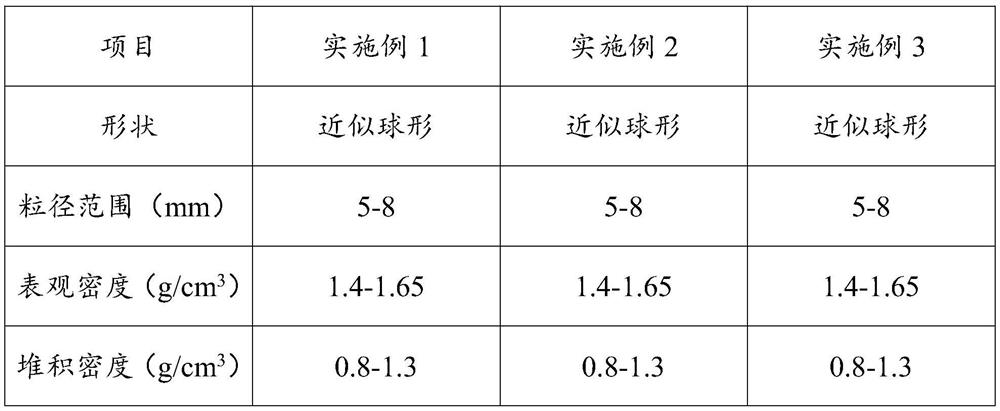

Novel lightweight high-porosity ceramic filter material and preparation method thereof

ActiveCN112608130AAlleviates acidic deficienciesReduce miningTreatment using aerobic processesWater contaminantsCellulosePorosity

The invention relates to the technical field of sewage treatment, and discloses a novel lightweight high-porosity ceramic filter material and a preparation method thereof. Fly ash floating beads, coal gangue and diatomite are used as aggregates, hydroxymethyl cellulose is used as a binder, dolomite powder, a pore-forming agent and limestone are used as auxiliary materials to prepare the ceramic filter material, and carbon nanofibers are attached to the surface of the ceramic filter material. The filter material is strong in pollutant holding capacity, high in filter material utilization rate and slow in water head loss increase, the filter speed can reach 16m / h, the working period is more than 24h, and the periodic water yield reaches 800-1000m < 3 > / m3 and is 1.5-2 times of that of a quartz sand filter material under the same condition.

Owner:TIANJIN UNIV +1

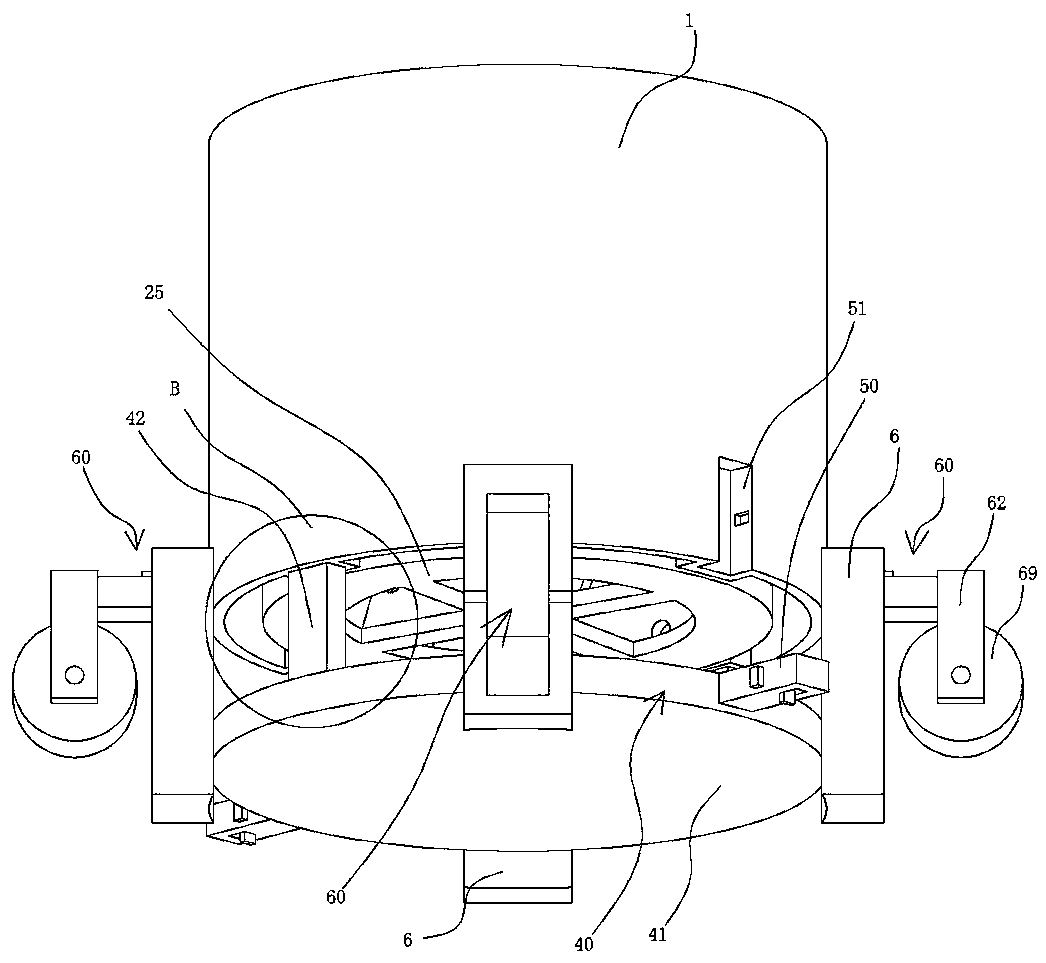

Efficient processing technology of coix seed decoction pieces

InactiveCN111991523AEvenly heatedRapid reusePharmaceutical product form changePlant ingredientsHorticultureFood science

The invention discloses an efficient processing technology of coix seed decoction pieces. The processing technology comprises the following steps: clean coix seeds are soaked in water, steamed and dried; a certain quantity of dried coix seeds are added into a stir-frying device for being stir-fried with sand and screened; the stir-fried coix seeds are discharged from the stir-frying device, the discharged coix seeds are finely screened to remove the stir-fried coix seeds stir-fried to brown, the coix seeds which are not stir-fried to be qualified are put into the stir-frying device to be stir-fried again until the stir-frying requirement is met, the stir-fried coix seeds which are stir-fried to be qualified are cooled at the normal temperature, and the cooled coix seeds are sub-packaged. The stir-frying device comprises a bracket, a stir-frying mechanism, a stir-frying box body and a stir-frying box cover for covering the stir-frying box body, the stir-frying box cover is provided witha containing cavity with a downward opening, and a filter screen plate of a filter screen is fixedly installed at the opening of the containing cavity. The coix seed decoction pieces can be stir-fried and screened in the same device, and sand after screening can be rapidly reutilized.

Owner:安徽鑫泰药业有限公司

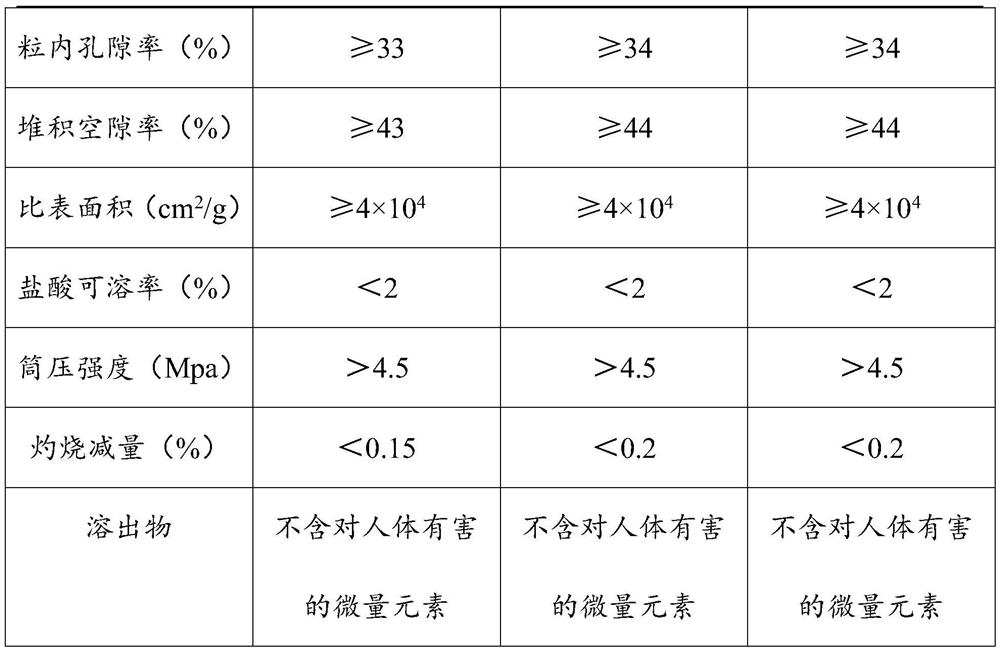

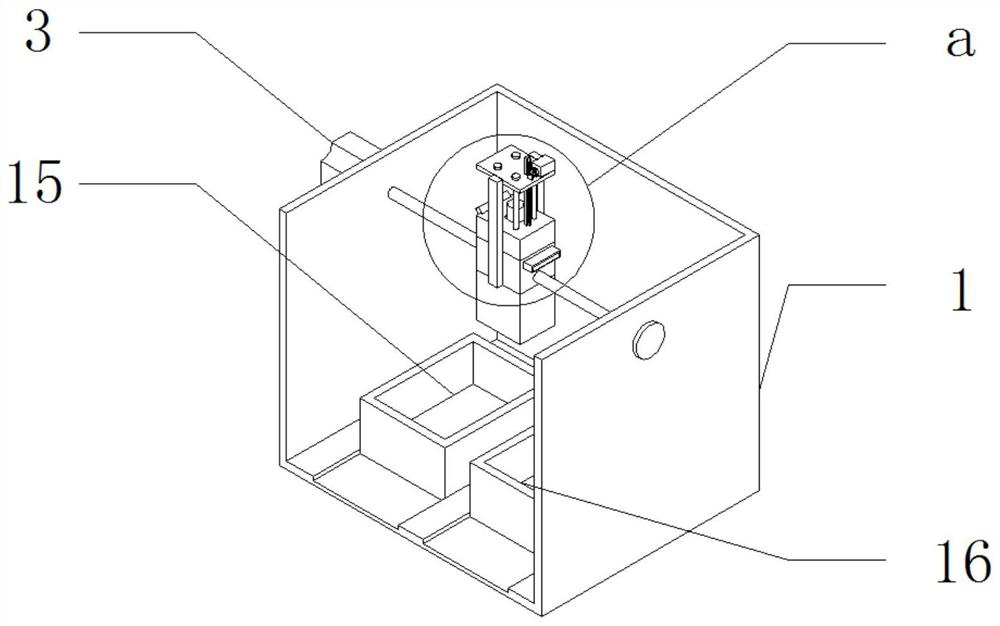

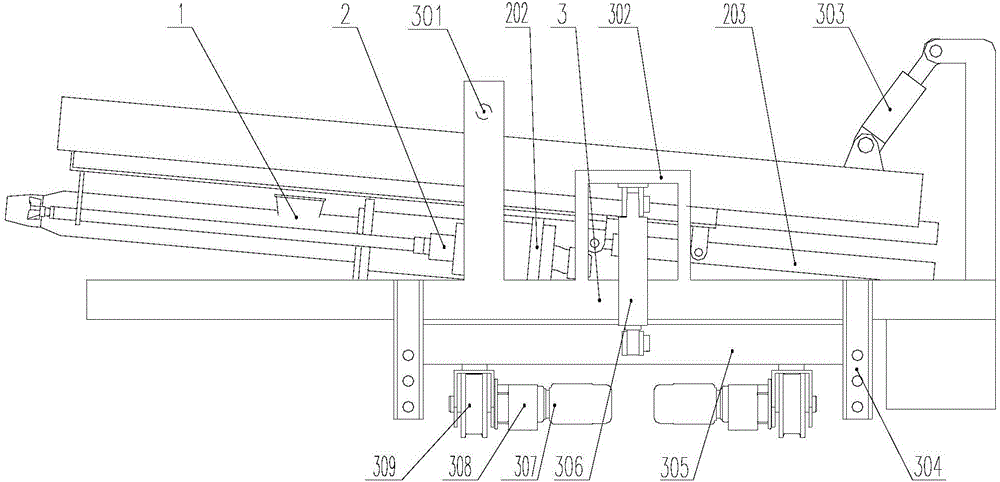

Multi-degree-of-freedom submerged-arc furnace opening and plugging machine based on cutting type opening

ActiveCN106247803AAvoid impact damageReduce the impact of mobilityCharge manipulationMulti degree of freedomEngineering

The invention discloses a multi-degree-of-freedom submerged-arc furnace opening and plugging machine based on cutting type opening, which comprises a rotary cutting type opening machine, a plugging machine and a multi-degree-of-freedom adjustable type platform shared by the rotary cutting type opening machine and the plugging machine. The opening machine is of a rotary cutting type structure; a rotary cutting device, a propelling device and a telescopic arm are arranged on the opening machine; the propelling device propels the rotary cutting device to carry out feeding operation on the telescopic arm; and the multi-degree-of-freedom adjustable type platform is equipped with an amplitude varying device, a lifting device and a travelling device. According to a real-time position of a furnace hole, multi-degree-of-freedom position adjustment of each station is realized by virtue of lifting of the lifting device, angle increase and decrease of the amplitude varying device, extension and retraction of the telescopic arm and ring-shaped displacement of the travelling device; and the rotary cutting type opening is used to replace drilling of a conventional pneumatic or hydraulic rock drill, so that cost is reduced, and opening and hole-forming quality is improved.

Owner:山河智能特种装备有限公司

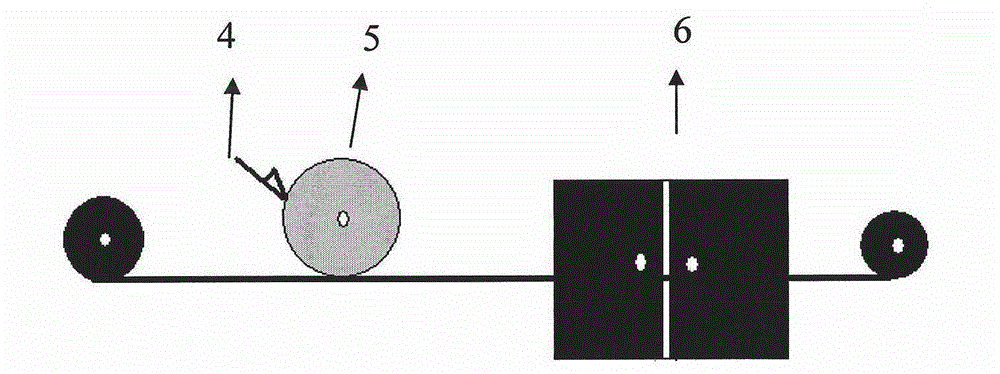

Dry-wet mixing type edger

ActiveCN101623840AAvoid subsequent dryingImprove edging efficiencyEdge grinding machinesEngineeringMoisture

The invention relates to a dry-wet mixing type edger, which comprises a plurality of edging heads arranged along a processing line of workpieces to be processed. The edger has the main characteristics that: one part edging head of a plurality of edging heads are moisture edging heads, while the other part edging heads are dry type edging heads; and the dry type edging heads are positioned on the down stream of the moisture edging heads on the processing line of the workpieces to be processed. The edger has the advantages of a wet type edger and a dry type edger, not only can keep higher edging efficiency, but also can reduce the wastage rate of edging wheels, and can avoid the subsequent drying processing operation.

Owner:FOSHAN DINGSHUN TECH CO LTD

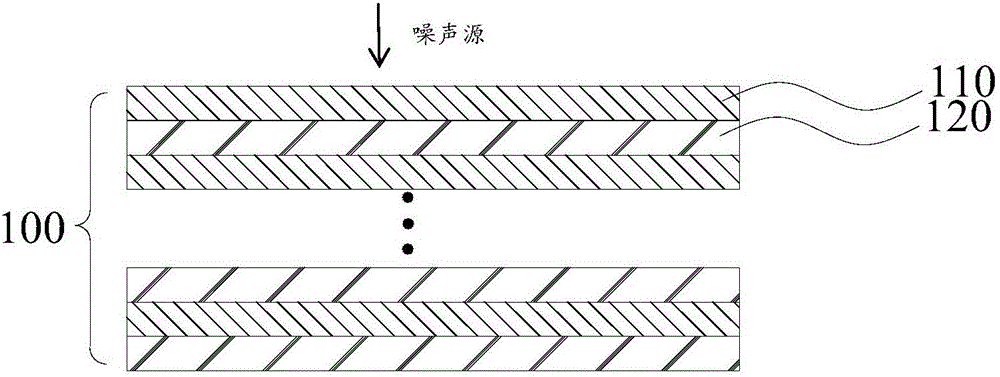

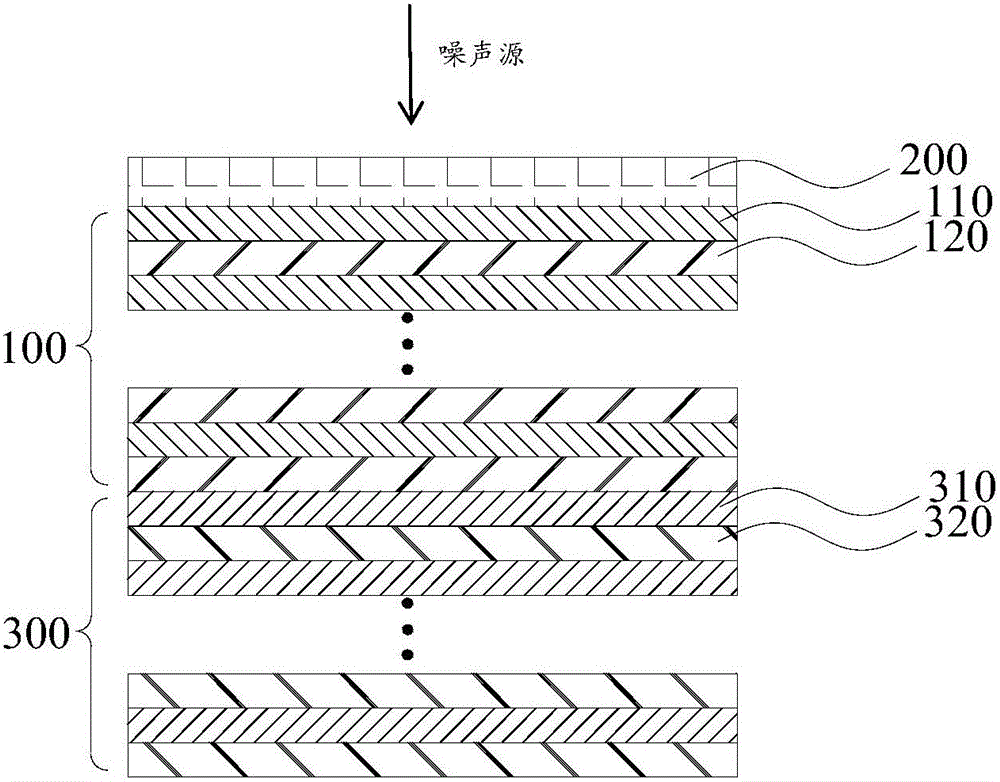

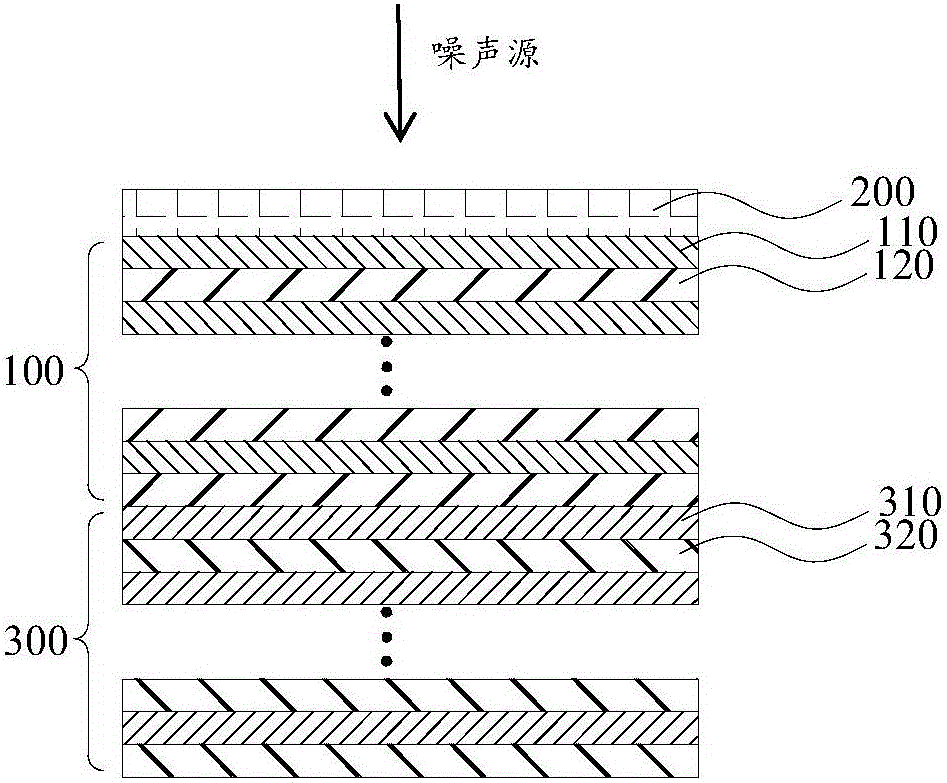

Sound insulating material and application thereof

ActiveCN106827694AReduce noiseImprove insulation effectTableware washing/rinsing machine detailsSynthetic resin layered productsEngineeringAcoustic impedance

The invention provides a sound insulating material and an application thereof. The sound insulating material comprises a first stacked structure, wherein the first stacked structure comprises a plurality of first foaming layers and a plurality of first non-foaming layers, which are arranged at intervals. The sound insulating material has a good sound insulating effect, relatively low density and relatively light quality; noise is reflected from multiple layers by using acoustic impedance mismatching of the plurality of first foaming layers and the plurality of first non-foaming layers; and the contradiction between high sound insulation and low density and the problem of high noise penetrating power are solved.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

Outdoor manual laundry device

ActiveCN110924034AReduce labor intensityImprove work efficiencyHand implementsTextiles and paperProcess engineeringLaundry

The invention discloses an outdoor manual laundry device comprising a machine body; a feeding port is formed in one end of the machine body, a flip cover is arranged at the feeding port, a platform isarranged at one end of the feeding port, one side of the machine body is provided with a transmission mechanism capable of amplifying input rotating speed, the other end of the transmission mechanismextends into the machine body and is provided with a stirring mechanism, one side of the transmission mechanism is provided with a power generation mechanism, the other side of the machine body is provided with a discharging mechanism capable of moving up and down, and the bottom end of the machine body is provided with a plurality of uniformly distributed moving mechanisms. The outdoor manual laundry device in the invention has the beneficial effects that the portability of the outdoor manual laundry device during moving can be improved through the moving mechanisms, which is more remarkablein long-distance carrying moving process, and the labor intensity of operators can be effectively reduced.

Owner:泰安晟智智能科技有限公司

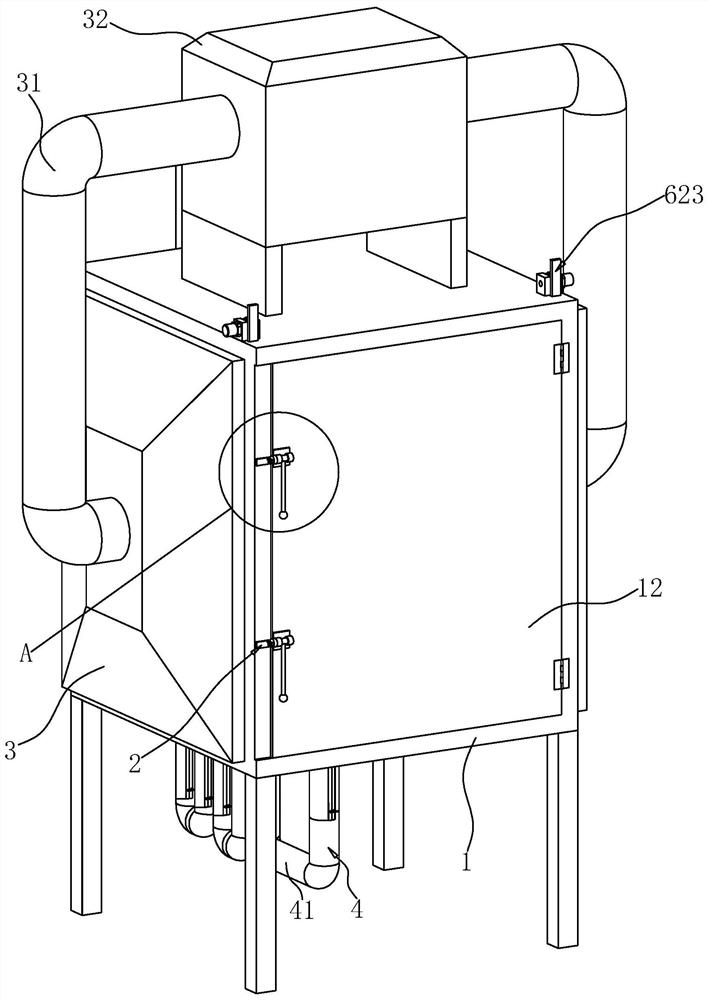

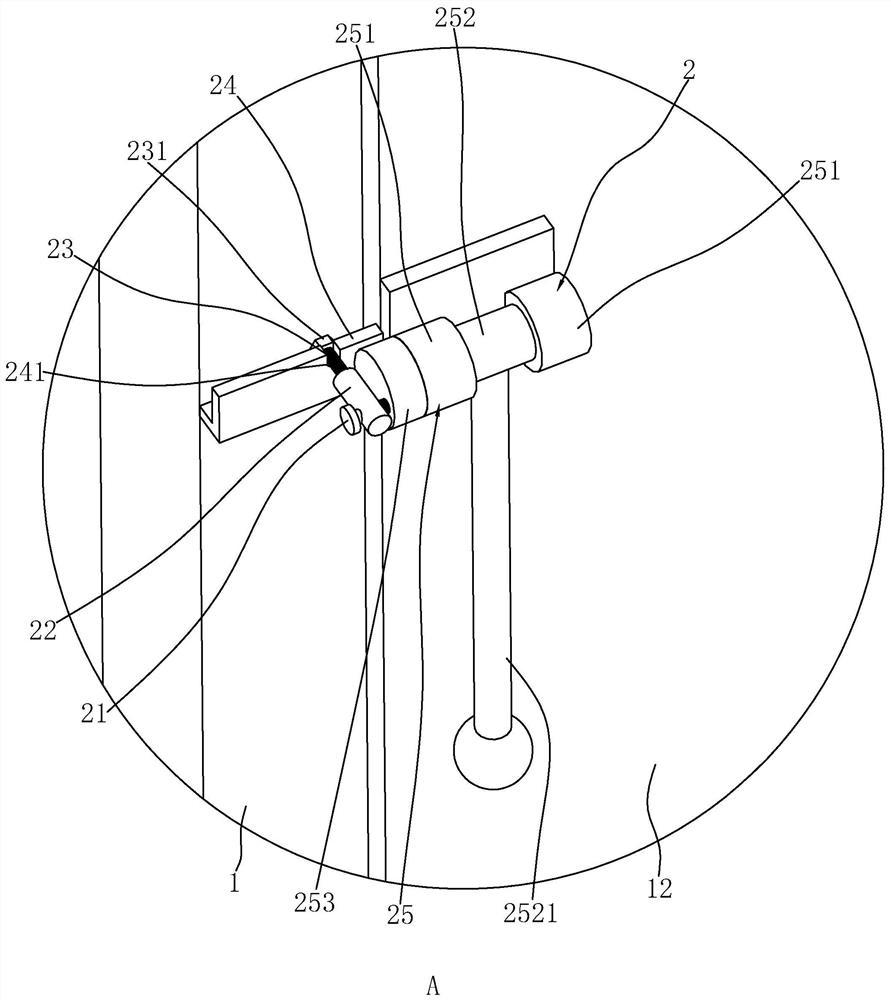

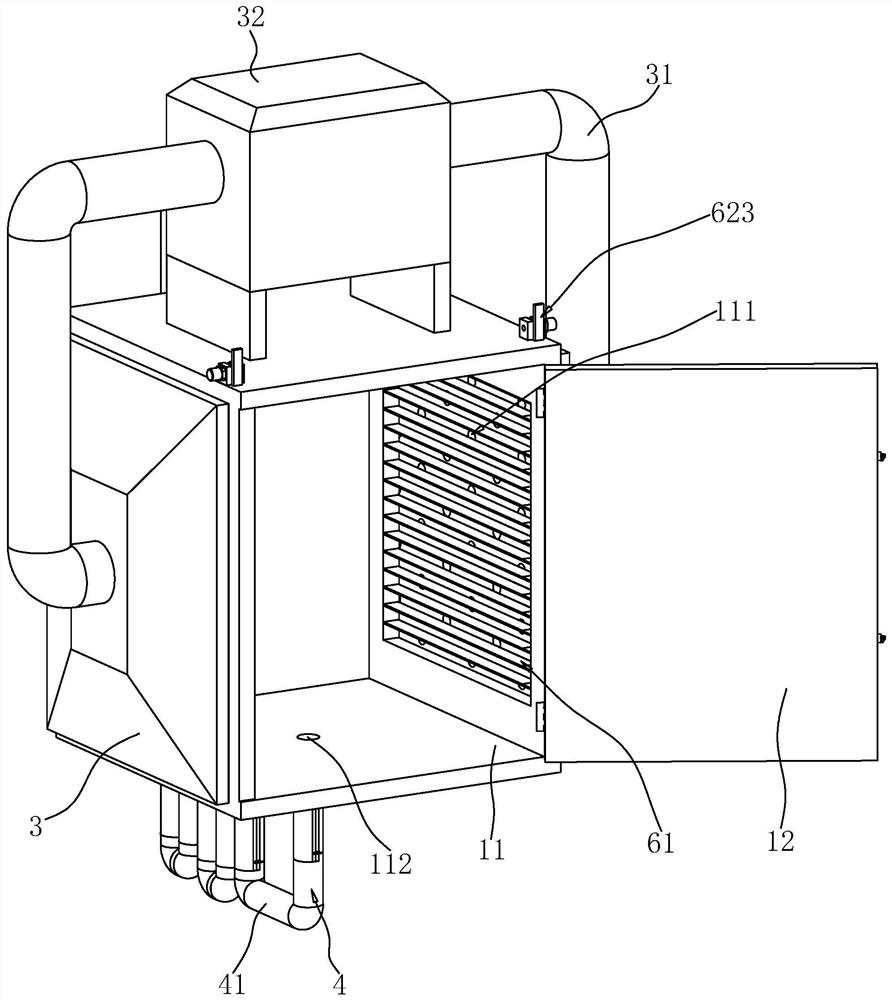

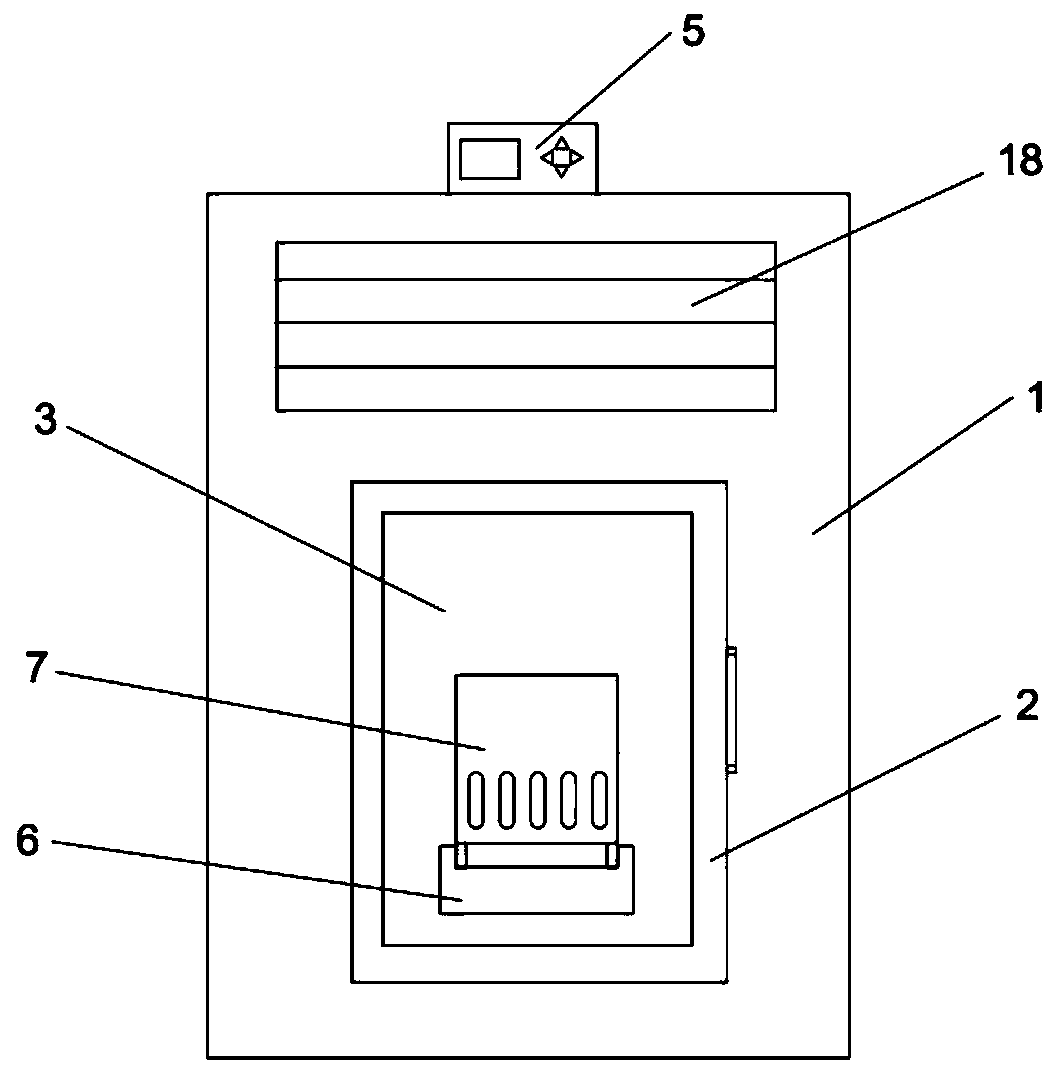

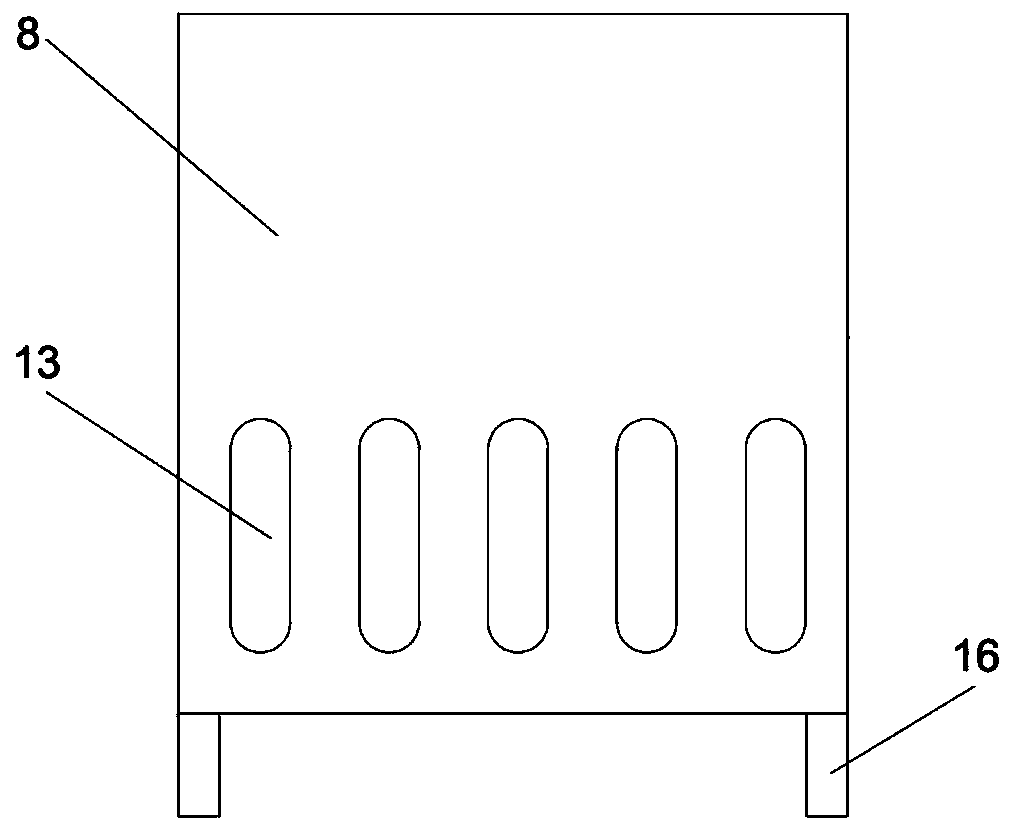

Hot air circulating oven

InactiveCN112146373ASlow lossAchieve high efficiency and energy savingDrying gas arrangementsDrying solid materialsEngineeringLaboratory oven

The invention relates to a hot air circulation oven which comprises an oven body, a drying chamber is formed in the oven body, an opening mechanism is arranged on one side of the drying chamber, a sealing door plate is arranged at the opening of the drying chamber, air inlets allowing hot air to enter are formed in the two opposite sides of the drying chamber, a moisture discharging opening is formed in the lower side of the drying chamber and communicates with dehumidifying pipes through an exhaust fan, the dehumidifying pipes are perpendicular to the horizontal plane, every two adjacent dehumidifying pipes communicate with each other through a communicating pipe, the two communicating pipes located on the same dehumidifying pipe are located on the upper side and the lower side of the dehumidifying pipe respectively, the multiple dehumidifying pipes and the communicating pipes are arranged in an arch shape, the dehumidifying pipe located at the tail end is connected with an air heater, the other end of the air heater is connected with a hot air blower, the other side of the hot air blower communicates with a hot air cover, and the hot air cover is attached to the side wall of thebox body and communicates with the air inlets. The hot air circulation oven has the effect of reducing the energy consumption.

Owner:北京春风药业有限公司

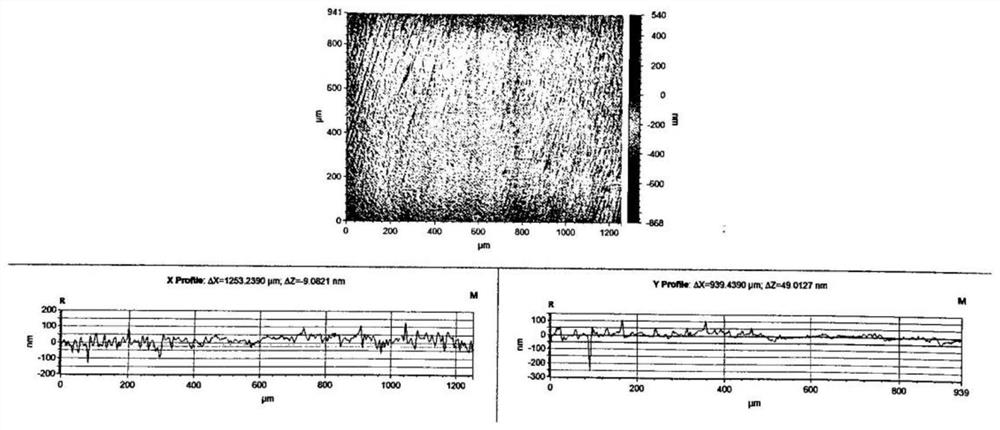

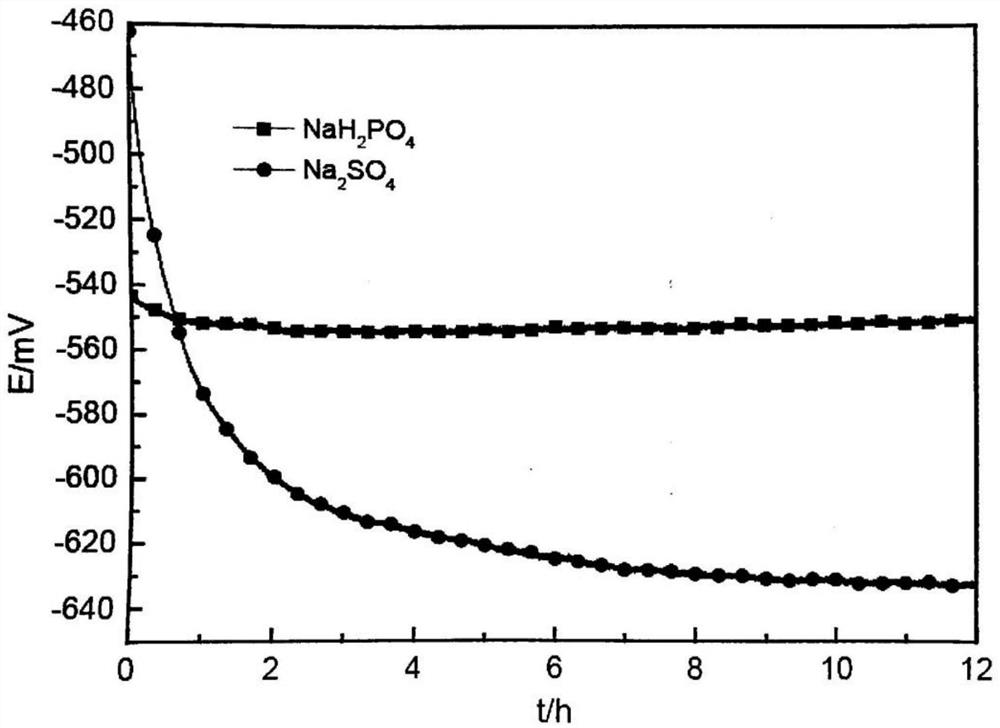

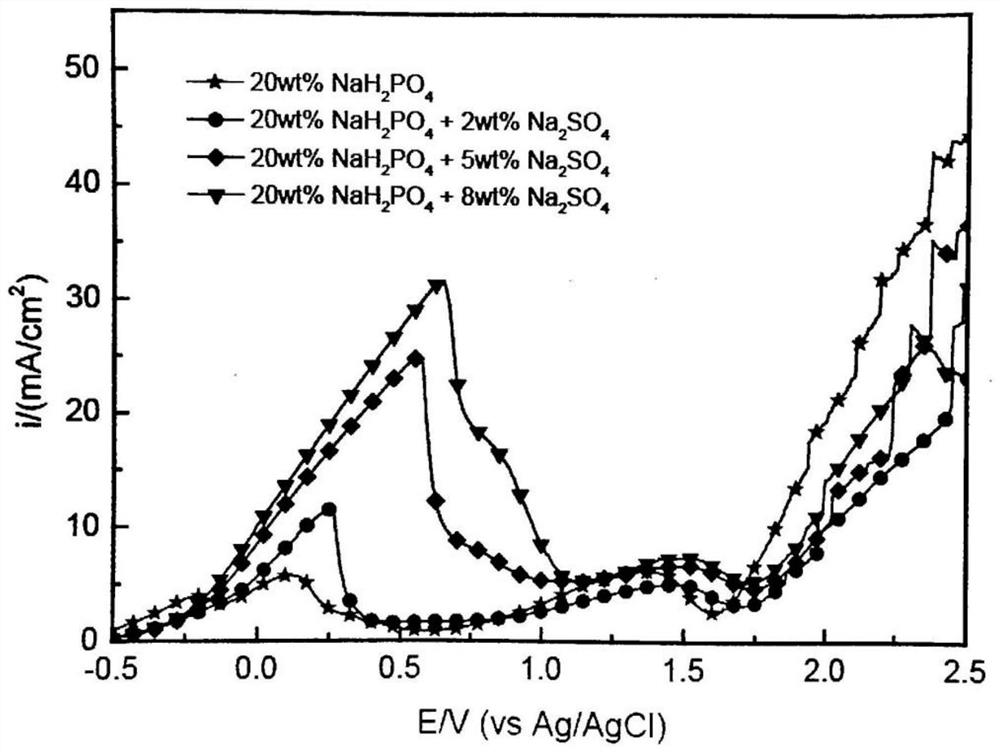

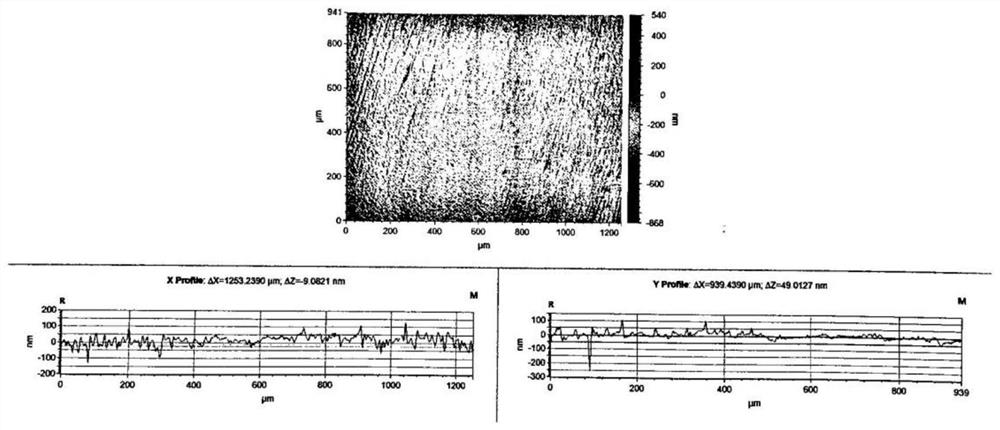

High-speed steel roller material electrolytic grinding electrolyte and electrolyte supply system

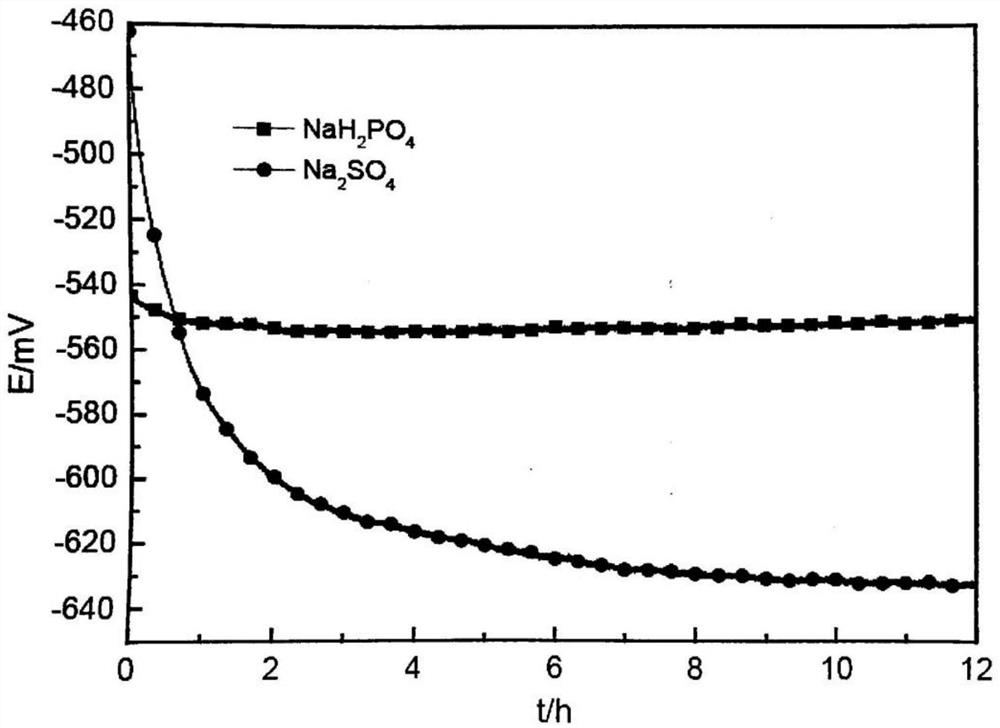

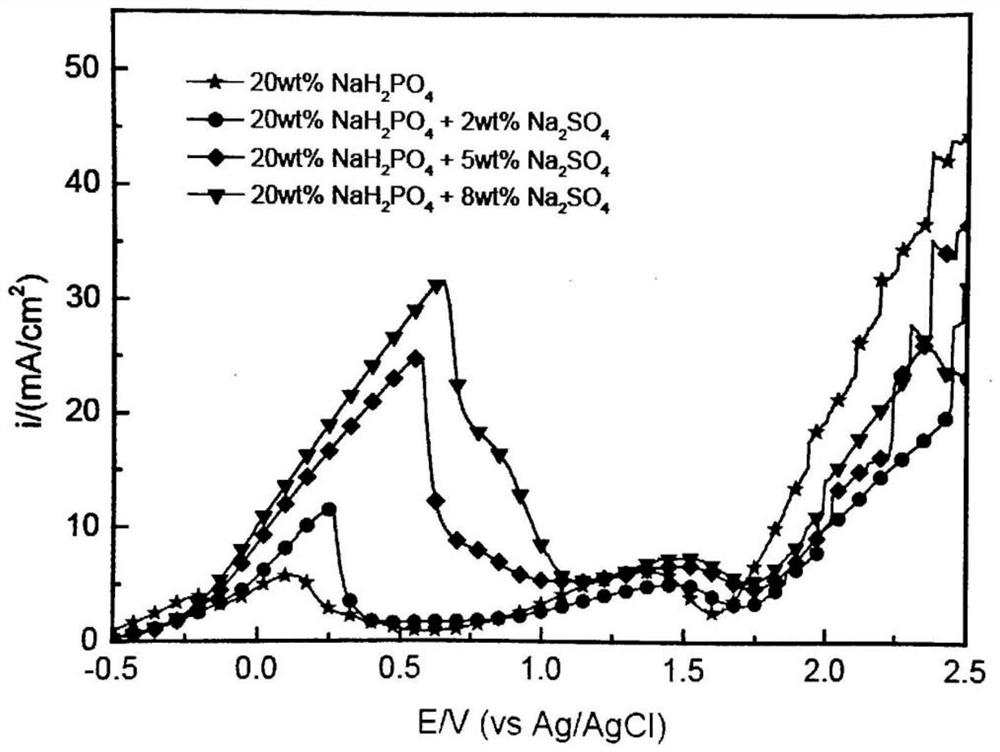

The invention belongs to the technical field of electrochemical machining of metal materials, and discloses a high-speed steel roller material electrolytic grinding electrolyte which comprises sodium dihydrogen phosphate, sodium sulfate and deionized water. An electrolyte supply system for electrolytic grinding of high-speed steel roller materials comprises a machining power source, a grinding wheel, a cathode tool, a water containing tank, a motor, a hydraulic pump, an electrolytic reaction tank, a filter, a three-way pipe, a two-position two-way normally-open electromagnetic valve, a safety valve, a pressure reducing valve, a pressure gauge, a throttling valve, an electromagnetic flowmeter, a gate valve, a one-way valve, a modification device and a cooling-water machine, and the water tank is filled with electrolyte and is connected with a liquid level switch, a coarse filter screen, a PH detector, a heater, a fine filter screen, a temperature sensor, a liquid level meter, a liquid discharge valve and a water tank sealing cover. The problems of low machining efficiency, high machining cost and poor surface quality of mechanical grinding machining and repairing of a high-speed steel roller in the prior art are solved, and the electrolyte and the electrolyte supply system are suitable for electrolytic grinding of high-speed steel roller materials.

Owner:GUIZHOU UNIV

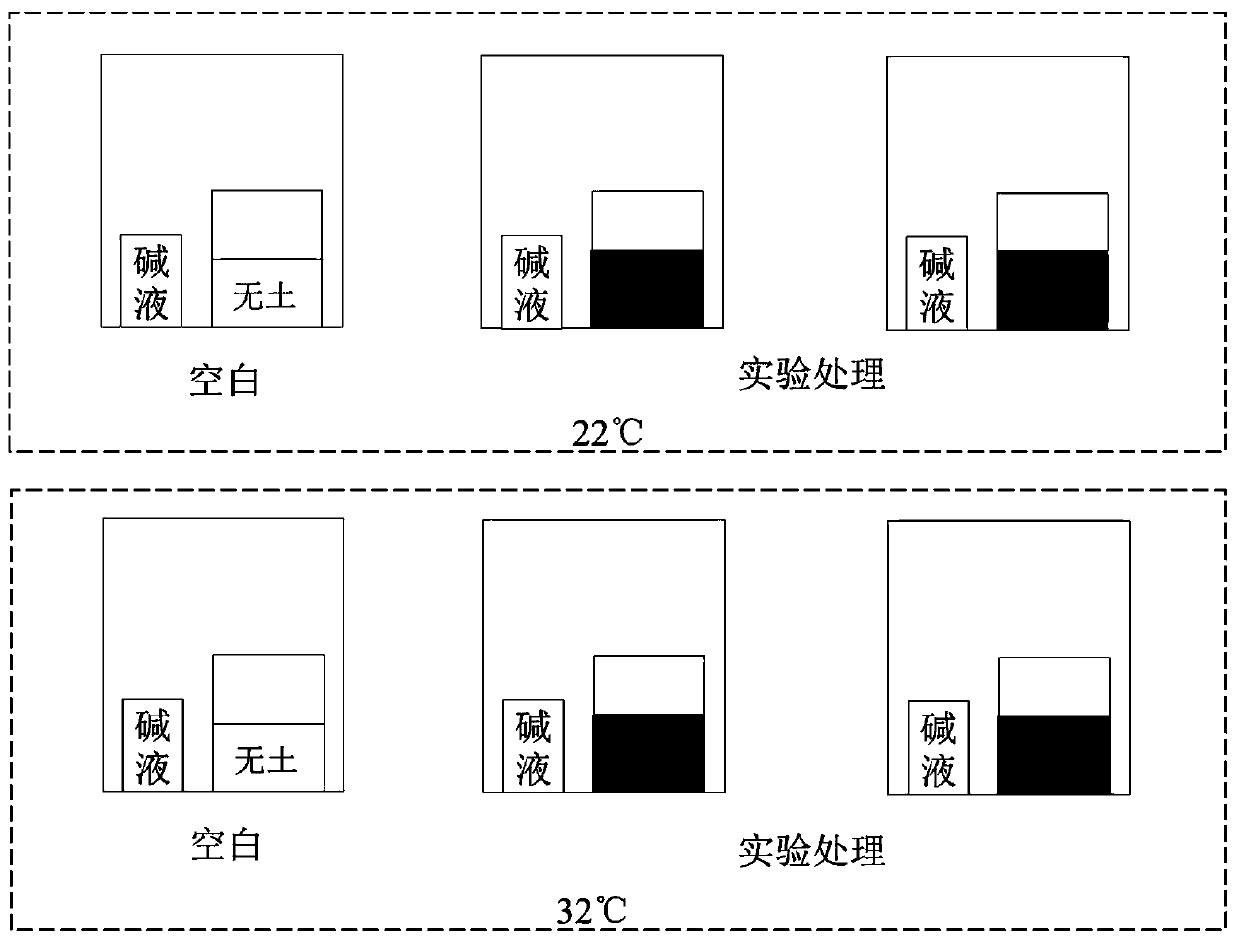

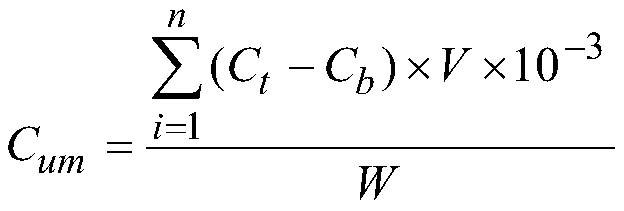

Method for evaluating decomposition temperature sensitivity of soil carbon bank

The invention discloses a method for evaluating the decomposition temperature sensitivity of a soil carbon bank. The method comprises the steps of (1) uniformly mixing different types of soil with biochar respectively, and putting the mixture into a culture bottle; 2) keeping the water content of the sample constant in the whole culture process by using a weighing method; (3) putting the sample and the opening of a small bottle containing alkali liquor into a non-transparent screw sealing bottle, and (4) putting the sealing bottle into two thermostats with different temperatures to be culturedin a dark place, and finally calculating the soil respiration CO2-C content. By adopting the method, the influence of the addition of the charcoal on the decomposition of the active and inert carbonbanks can be known.

Owner:CHONGQING THREE GORGES UNIV

Preparation process of scented tea

PendingCN112314741AStrong fragrance of flower budsStrong fragrancePre-extraction tea treatmentTea flavoringGreen teasEngineering

The invention discloses a preparation process of scented tea. The preparation method comprises the following steps: selecting fresh flower buds which are picked in the morning of sunny days and do notbloom completely, and removing stalks; selecting a special tea base or full / half parched green tea; selecting a totally-enclosed fermentation vessel with good air permeability; cleaning the fermentation vessel to ensure that the inside of the base is clean and dry; paving the flower buds at the bottom, then covering the next layer of tea leaves with the next layer of flower buds completely everytime, and finally capping and sealing the base with the tea leaves; after the base is sealed, opening the base at any time to check the temperature in the base, when the temperature in the base reaches 50-60 DEG C, starting to turn over the flower buds and the leaves for cooling, fully mixing the flower buds with the tea leaves, and cooling the temperature in the base to room temperature; and sealing the base for 24-48 hours, starting to screen the flowers when the flower buds are completely withered and become dark yellow, and spreading and cooling the tea leaves of which the flowers are screened out to room temperature, wherein the finished product needs at least three times of scenting; and after scenting for multiple times, drying the tea leaves without the flower buds, improving fragrance, and naturally cooling the tea leaves to obtain a finished product. According to the preparation process, an existing scented tea scenting process is changed, so that the scented tea has strongerfragrance.

Owner:四川马边荞坝贡茶有限公司

Preparation process of blueberry concentrated juice with high content of anthocyanin

The invention provides a preparation process of blueberry concentrated juice with high content of anthocyanin. According to the preparation process provided by the invention, pectase is adopted for performing enzymolysis on blueberry pulp, chitosan is adopted as a clarifying agent for obtaining clear blueberry juice, a decompression concentration process is adopted for preparing the blueberry concentrated juice, and microwave sterilization is adopted for sterilizing the blueberry concentrated juice. The preparation process comprises the following steps of: selecting blueberry fruits in vaccinium ashei gardenblue species; extracting the blueberry juice, and adding the pectase to perform the enzymolysis on the blueberry pulp; clarifying the blueberry juice, and adding the chitosan as the clarifying agent for obtaining the clear blueberry juice; concentrating the blueberry juice, and adopting the decompression concentration to obtain the blueberry concentrated juice; and performing sterile filling on the blueberry juice, and adopting the microwave sterilization to sterilize the blueberry concentrated juice, wherein the content of soluble solids in the blueberry concentrated juice is 60%-75%, and the content of the anthocyanin is 1.925g / L-3.384g / L. The preparation process provided by the invention can not only effectively prevent the loss of the anthocyanin in the blueberry concentrated juice, but also shorten the concentration time, control the production cost of the preparation process and effectively protect color, luster, fragrance and other sensory qualities of the blueberry juice.

Owner:ANHUI AGRICULTURAL UNIVERSITY

A test method for electrolyte used in electrolytic grinding of high-speed steel roll material

The invention belongs to the technical field of electrochemical processing of metal materials, and discloses a test method for the electrolyte used in the electrolytic grinding of high-speed steel roll materials. The electrolyte obtained by using the method is calculated by mass percentage: sodium sulfate 2%~8%, phosphoric acid Sodium dihydrogen is 20%, and the balance is deionized water; the method also uses an electrolyte liquid supply system for electrolytic grinding of high-speed steel roll materials, which includes processing power supply, grinding wheel, cathode tool, water tank, motor, Hydraulic pumps, electrolytic reaction tanks, filters, tee pipes, solenoid valves, safety valves, pressure reducing valves, pressure gauges, throttle valves, electromagnetic flowmeters, modification devices and chillers. The water tank is connected with liquid level switches, filter screen, PH detector, heater, temperature sensor, liquid level gauge, liquid unloading valve and water tank cover; the present invention solves the problem of low processing efficiency, high processing cost and surface quality of the prior art mechanical grinding processing and repairing high-speed steel rolls Poor problem, used for electrolytic grinding of high-speed steel roll material.

Owner:GUIZHOU UNIV

Adhesive used for waterproof roll and preparation method of adhesive

InactiveCN105038617AImprove surface activityGood temperature and shear resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveFiberAdhesive

The invention discloses an adhesive used for a waterproof roll. The adhesive used for the waterproof roll takes lactic acid / glycerol organic zirconium as a crosslinking agent and an ethylene-ethyl acrylate copolymer fiber-based solution as a thickening agent, so that the adhesive used for the waterproof roll has obvious temperature-sensitive crosslinking property, and gel with good temperature and shearing sustainability can be formed under the crosslinking action; meanwhile, the copolymer base solution treated by fibers is adopted, so that surface activity of the copolymer can be improved, the crosslinking effect can be promoted, and viscoelasticity and thixotropy can be improved.

Owner:合肥启华环保科技有限公司

Biomass fuel heating furnace capable of improving heat absorption efficiency and heating equipment for biomass fuel heating furnace

PendingCN109990311AImprove absorption efficiencyIncrease collisionStoves/ranges with convection heatingLighting and heating apparatusCombustionWater storage tank

The invention relates to the technical field of heating equipment, in particular to a biomass fuel heating furnace capable of improving the heat absorption efficiency and heating equipment for the biomass fuel heating furnace. The biomass fuel heating furnace comprises a furnace body, a furnace door, a hearth, a combustion device, a smoke exhausting device, an air supply device, an air inducing device and an intelligent control board; the combustion device comprises a furnace core and a flame resistance cover; the flame resistance cover is collectively formed by a side wall, a top plate and apartition plate in an enclosing manner; the partition plate divides the flame resistance cover into a lower flame resistance chamber and an upper flame resistance chamber and is provided with a plurality of lower flame outlets penetrating through the partition plate; the top plate is provided with a plurality of upper flame outlets penetrating through the top plate; and the lower flame outlets andthe upper flame outlets are arranged in a staggered manner. The biomass fuel heating furnace further comprises the heating equipment connected with the heating furnace; and the heating equipment comprises a heat dissipation device, a water storage tank and a connecting device. For the biomass fuel heating furnace, by adding the flame resistance cover above the furnace core, rapid loss of heat caused by excessively large flame during burning combustion of a fuel is avoided, and thus the effect of delaying soaking is achieved.

Owner:青岛汇鑫德工贸有限公司

A multi-degree-of-freedom submerged arc furnace plugging eye opening machine based on cutting eye opening

ActiveCN106247803BAvoid impact damageReduce the impact of mobilityCharge manipulationMulti degree of freedomEngineering

The invention discloses a multi-degree-of-freedom submerged-arc furnace opening and plugging machine based on cutting type opening, which comprises a rotary cutting type opening machine, a plugging machine and a multi-degree-of-freedom adjustable type platform shared by the rotary cutting type opening machine and the plugging machine. The opening machine is of a rotary cutting type structure; a rotary cutting device, a propelling device and a telescopic arm are arranged on the opening machine; the propelling device propels the rotary cutting device to carry out feeding operation on the telescopic arm; and the multi-degree-of-freedom adjustable type platform is equipped with an amplitude varying device, a lifting device and a travelling device. According to a real-time position of a furnace hole, multi-degree-of-freedom position adjustment of each station is realized by virtue of lifting of the lifting device, angle increase and decrease of the amplitude varying device, extension and retraction of the telescopic arm and ring-shaped displacement of the travelling device; and the rotary cutting type opening is used to replace drilling of a conventional pneumatic or hydraulic rock drill, so that cost is reduced, and opening and hole-forming quality is improved.

Owner:山河智能特种装备有限公司

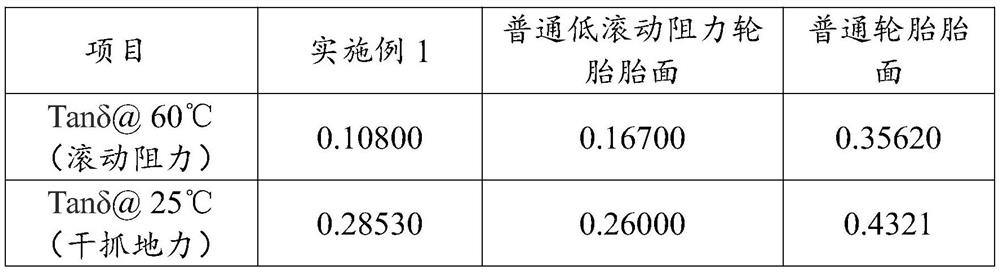

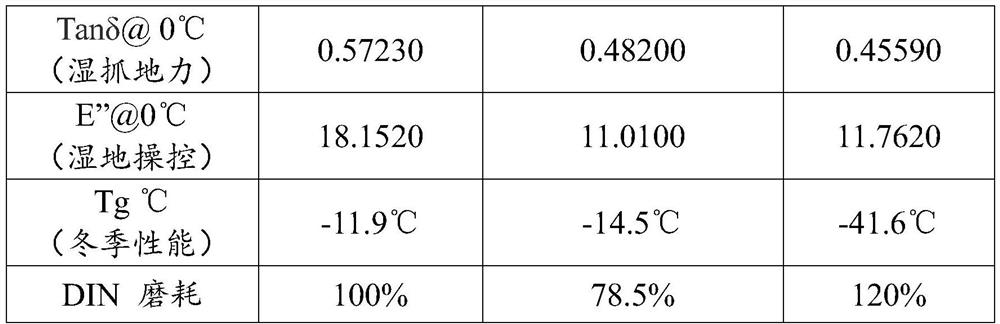

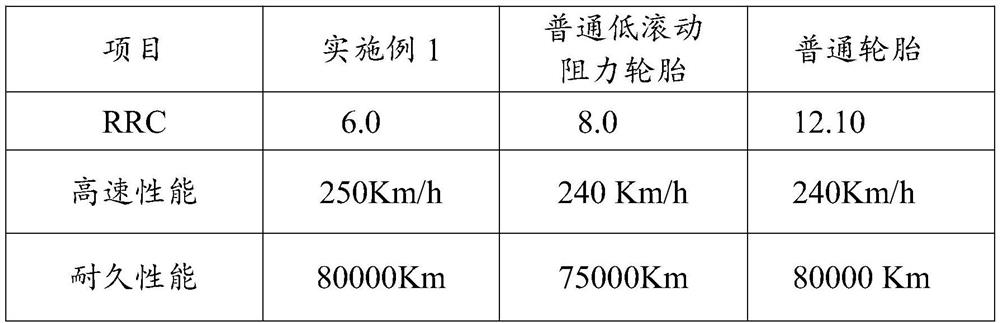

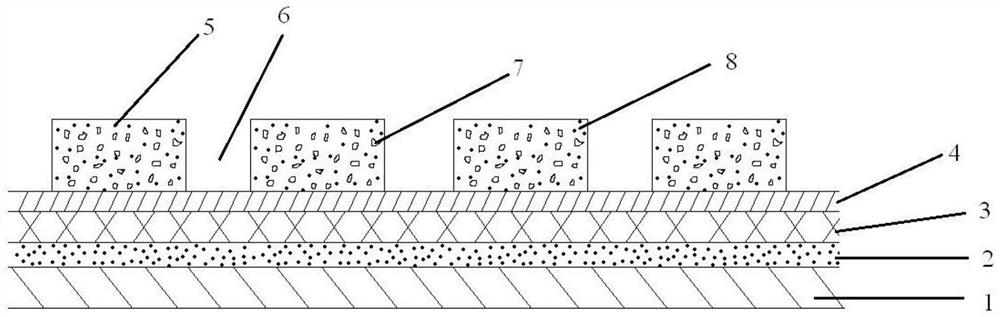

A kind of high-grip performance and low rolling resistance tire tread compound and its synthesis method

ActiveCN109796647BLow ride rolling resistanceLow heat generationSpecial tyresRolling resistance optimizationPolymer scienceRolling resistance

The invention discloses a tire tread rubber material with high grip performance and low rolling resistance. The tire tread rubber material with high grip performance and low rolling resistance comprises: SSBR6270 40-44% by weight percentage , natural rubber SIR20 12-15%, highly dispersed silica 26-30%, antioxidant 2.0-3.0%, coupling agent X-50S 3-5%, active agent 1-3%, plasticizer 2-4 %, 0.6-0.9% vulcanizing agent, 1.2-1.6% accelerator and 0.07-0.1% anti-scorch agent, the combined styrene content of the solution-polymerized styrene-butadiene rubber SSBR6270 is 23.5-26.5%, and the oil content is 25.8-28.8%, The specific surface area of the highly dispersed white carbon black is 200-230m 2 / g, the sum of the contents of each component is 100%. Through the above-mentioned method, the technology provided by the present invention has strong grip performance on dry ground, strong cornering control ability, and small driving rolling resistance. Wetland driving safety factor, durability up to standard.

Owner:KENDA RUBBER CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com