Dry-wet mixing type edger

A hybrid and edging machine technology, which is applied to machine tools, grinding machines, grinding/polishing equipment, etc., which are suitable for grinding the edge of workpieces. It can solve the problems of low edging efficiency and poor edging quality, and achieve slow wear of grinding wheels. , high edging efficiency, and the effect of exempting subsequent drying work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

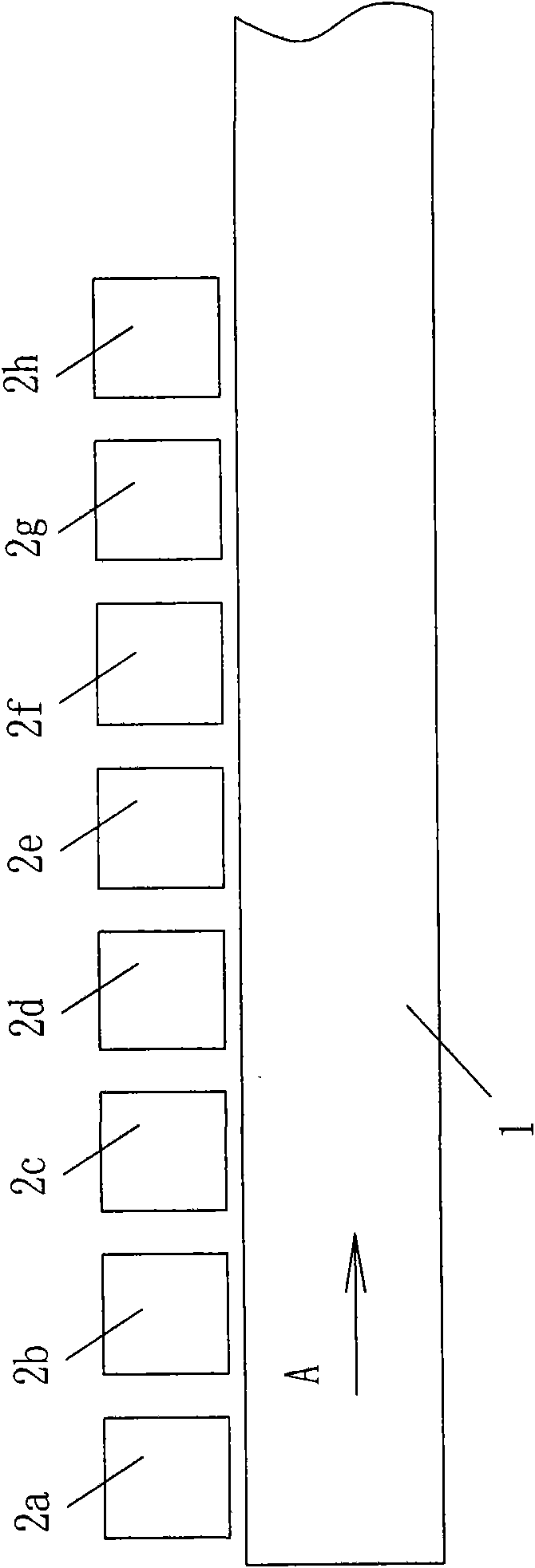

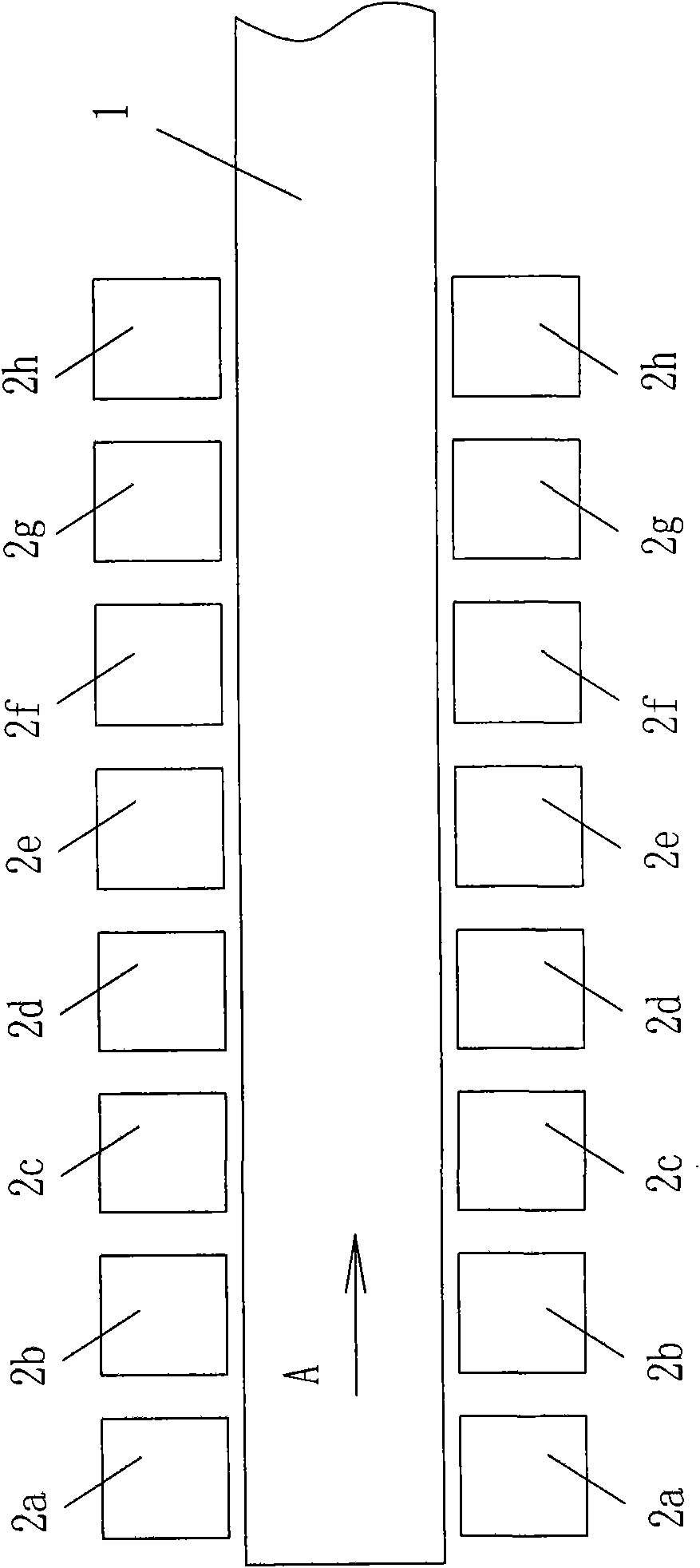

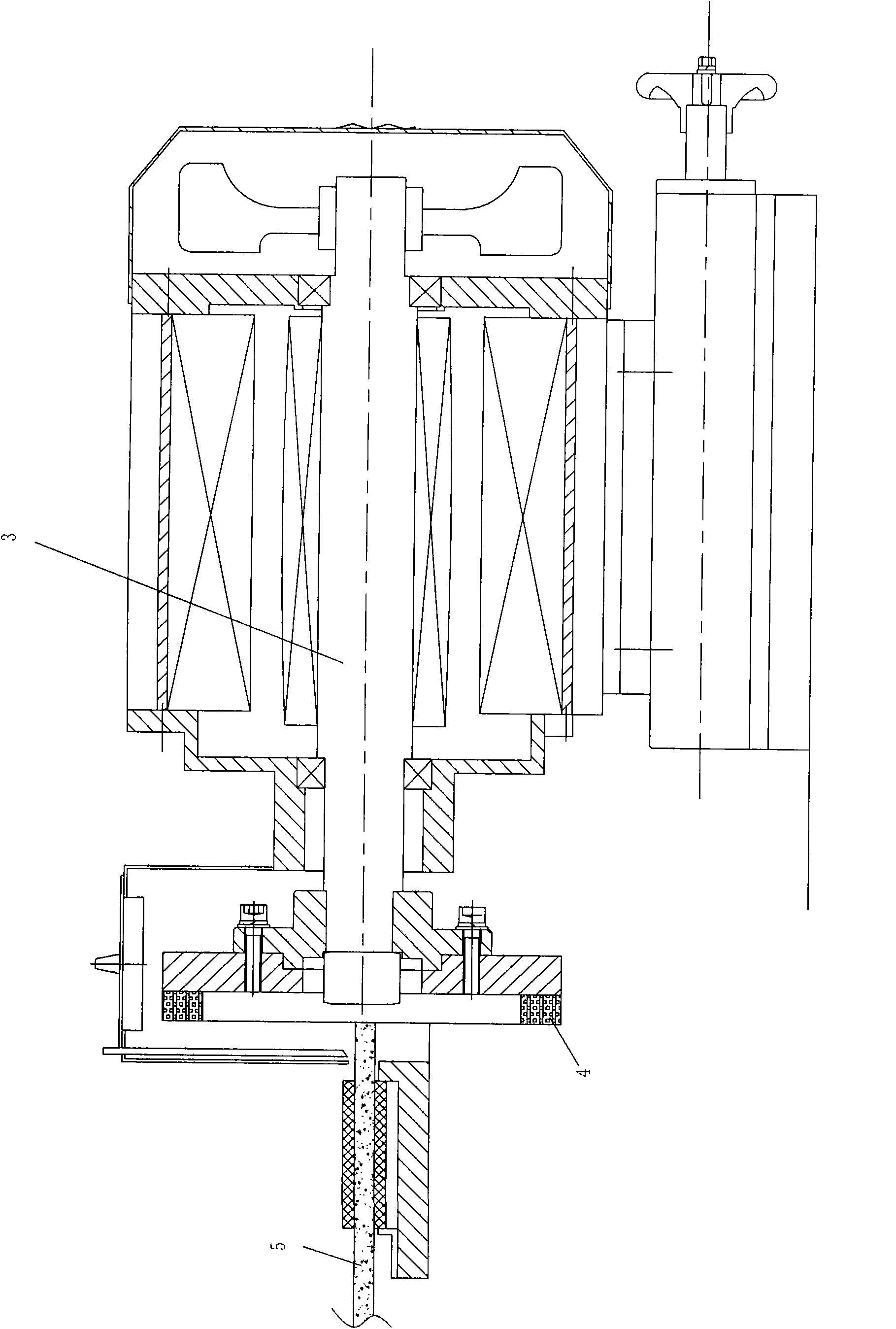

[0012] see figure 1 , viewed from a top view, the dry-wet hybrid edging machine includes a conveyor belt 1 for conveying the workpiece to be processed. Arrow A indicates the direction of travel of the conveyor belt to transport the workpiece. A plurality of edging heads 2 a to 2 h are arranged along the traveling route of the conveyor belt 1 , that is, along the traveling route of the workpiece. figure 1 The edging head is represented abstractly with a box only. The specific structure of the edging head is in Figure 3 to Figure 5 in more detail. The feature of the present invention is that a part of edging heads 2a-2d are micro-water edging heads, and the other part of edging heads 2e-2h are dry-type edging heads, and the dry-type edging heads 2e-2h are located at micro-water edging heads 2a-2h. 2d downstream. The structure of the combination of dry and wet edging heads enables the workpiece to be edged by micro-water edging heads 2a-2d first, and then by dry-type edging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com