Multistage-rake-furnace-based activation method of coal-base activated carbon

A technology of coal-based activated carbon and activation method, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problem of gas diffusion affecting carbonization volatiles escape and activation, coal-based granular activated carbon can not fully meet the requirements, moisture control Difficulty and other problems, to avoid the drying and drying process, low adhesion index, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

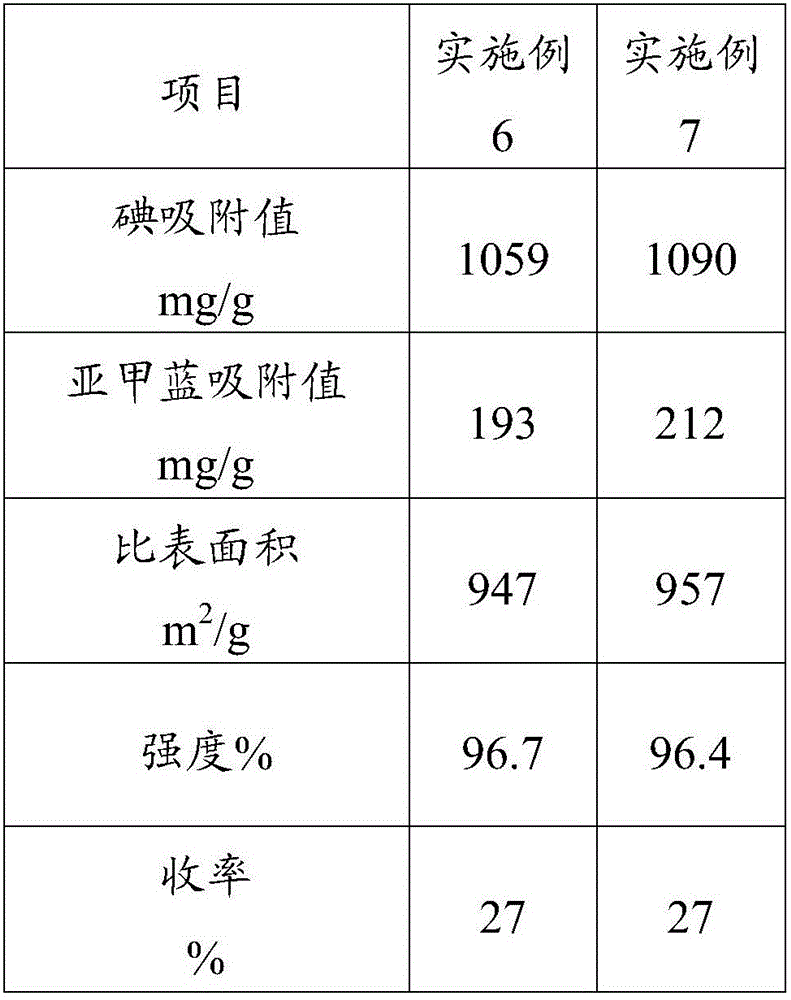

Examples

Embodiment 1

[0047] (1), Xinjiang Hami coal is pulverized to coal powder with an average particle size of 29 μm, and sieved, wherein the content of coal powder with a particle size greater than 80 μm is 2.5 wt %; the content of coal powder with a particle size greater than 40 μm is 28 wt %;

[0048] (2), send the pulverized coal obtained in (1) into the feed bin of the briquette forming equipment, and carry out degassing treatment to the material in the feed bin, keep the negative pressure in the feed bin At 2.5kPa~3kPa;

[0049] (3) Keep the temperature of the material in the feeding bin at 50°C to 55°C, and adjust the moisture content to 7wt to 8wt%;

[0050] (4), the material in the feeding bin is sent into the molding equipment through the screw forced feeder for molding, and the linear pressure between the rollers is about 11-12t / cm during molding, so as to obtain the molding briquette (type coal).

[0051] Detect briquette strength, drum strength (GB / T7702.3-2008) 89.2%.

Embodiment 2

[0053] The difference from Example 1 is that the raw coal is a mixture of Xinjiang Hami coal and Heishan mining area longbituminous coal in a mass ratio of 1:1.

[0054] Detect the strength of the briquette, and the strength of the drum (GB / T7702.3-2008) is 91.4%.

Embodiment 3

[0056] (1) Mix Xinjiang Hami coal and Heishan mining area longbituminous coal uniformly at a mass ratio of 1:1, and crush to coal powder with an average particle size of 35 μm, and then sieve, wherein the content of coal powder with a particle size greater than 80 μm is 8.2 wt%; the content of pulverized coal with a particle size greater than 40 μm is 22wt%;

[0057] (2) Send the pulverized coal obtained in (1) into the mixing chamber for stirring and degassing. The top of the mixing chamber is equipped with an air extraction pipeline to make the density of the pulverized coal after stirring reach 0.60-0.65kg / L, and then pass through the star valve The pulverized coal in the mixing bin is sent to the feeding bin of the briquetting equipment.

[0058] (3) Carry out degassing treatment to the material in the feed bin, keep the negative pressure in the feed bin at 2.5kPa~3kPa;

[0059] (4), keeping the temperature of the material in the feeding bin at 80°C to 85°C, and adjusting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com