Patents

Literature

201results about How to "Prevent drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

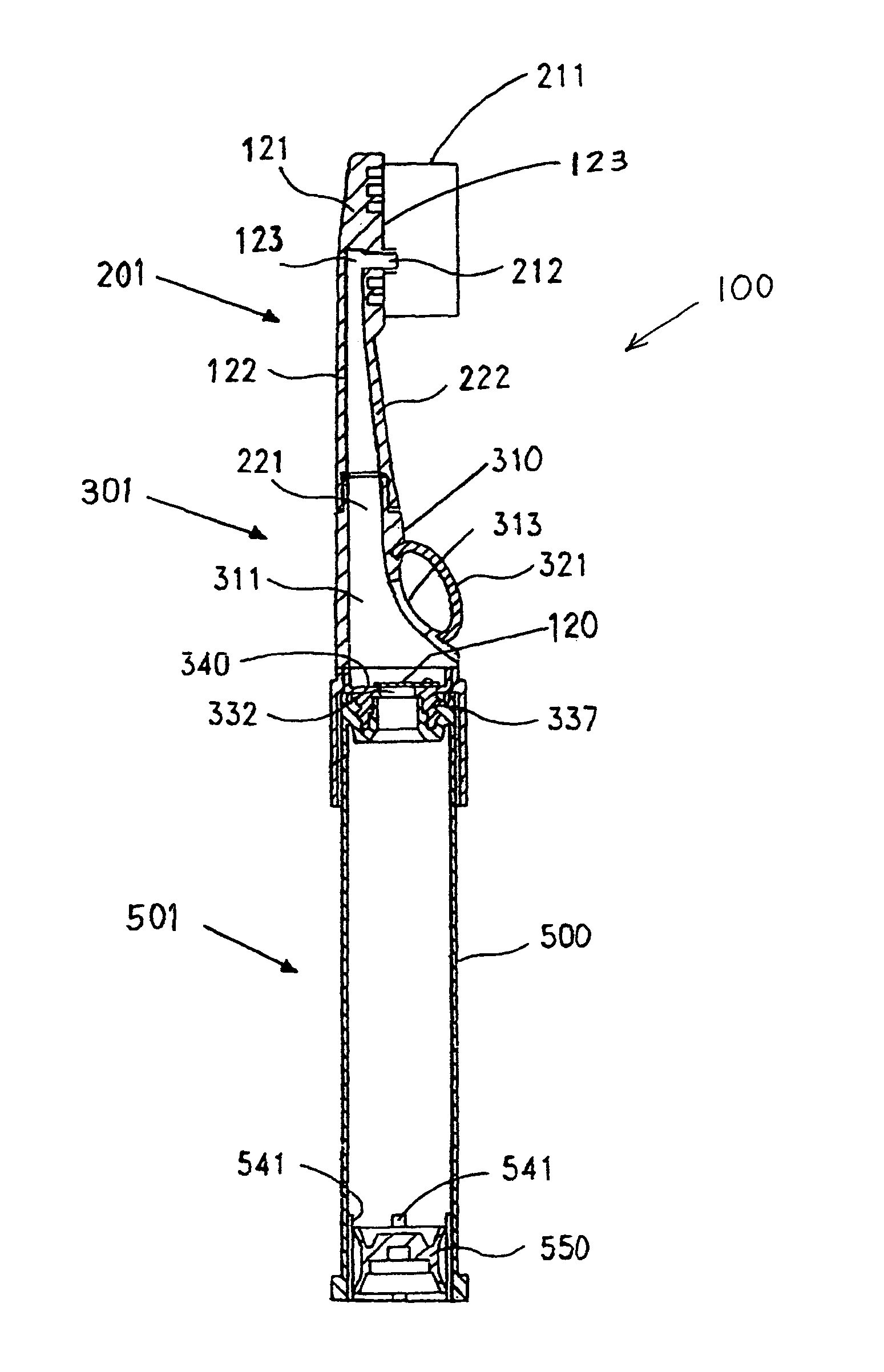

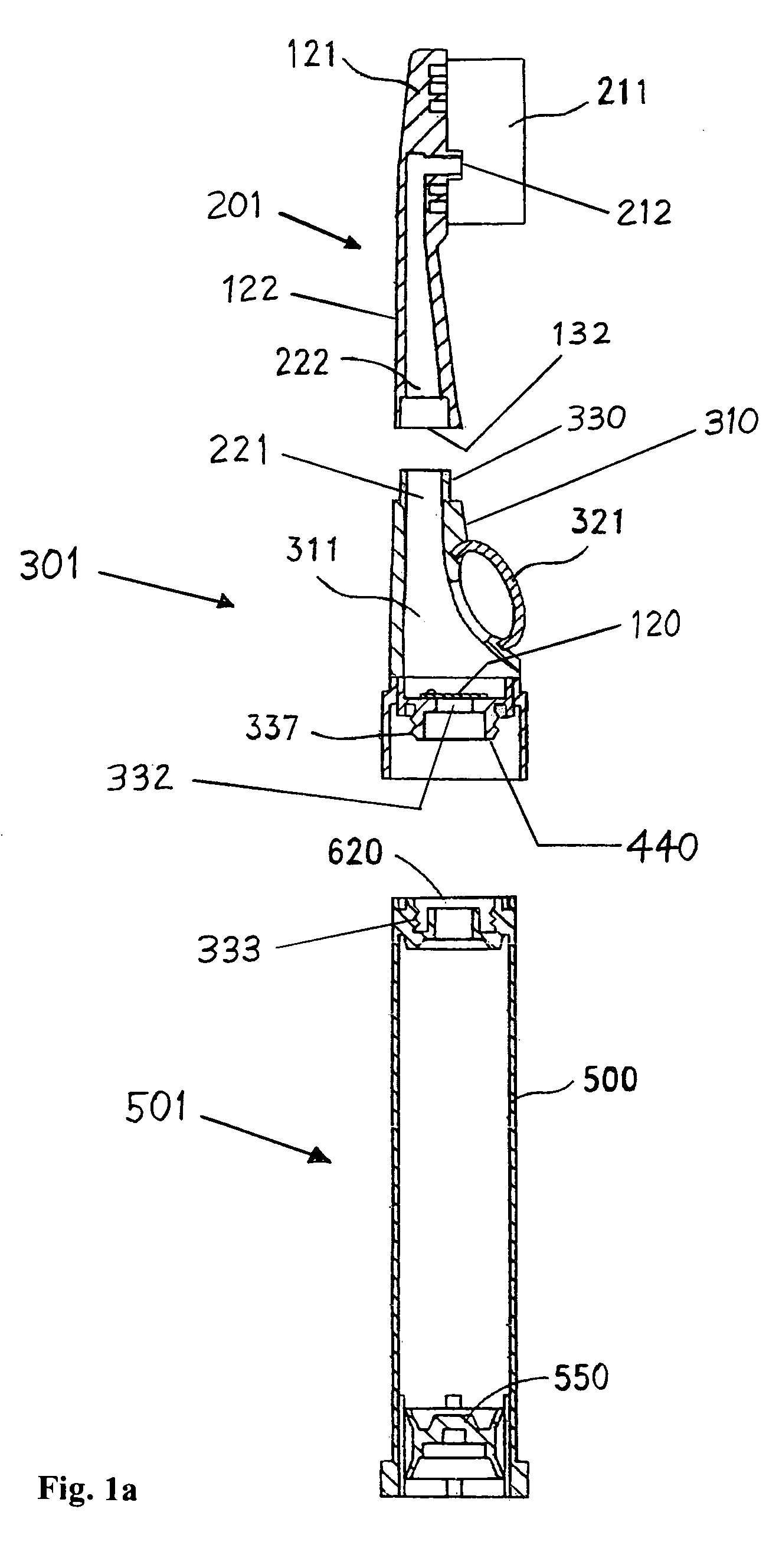

Manual and electrical pump toothbrushes for dispensing liquid and paste dentifrices

InactiveUS20070041779A1Prevent backflowPrevent dryingCarpet cleanersFloor cleanersToothpasteEngineering

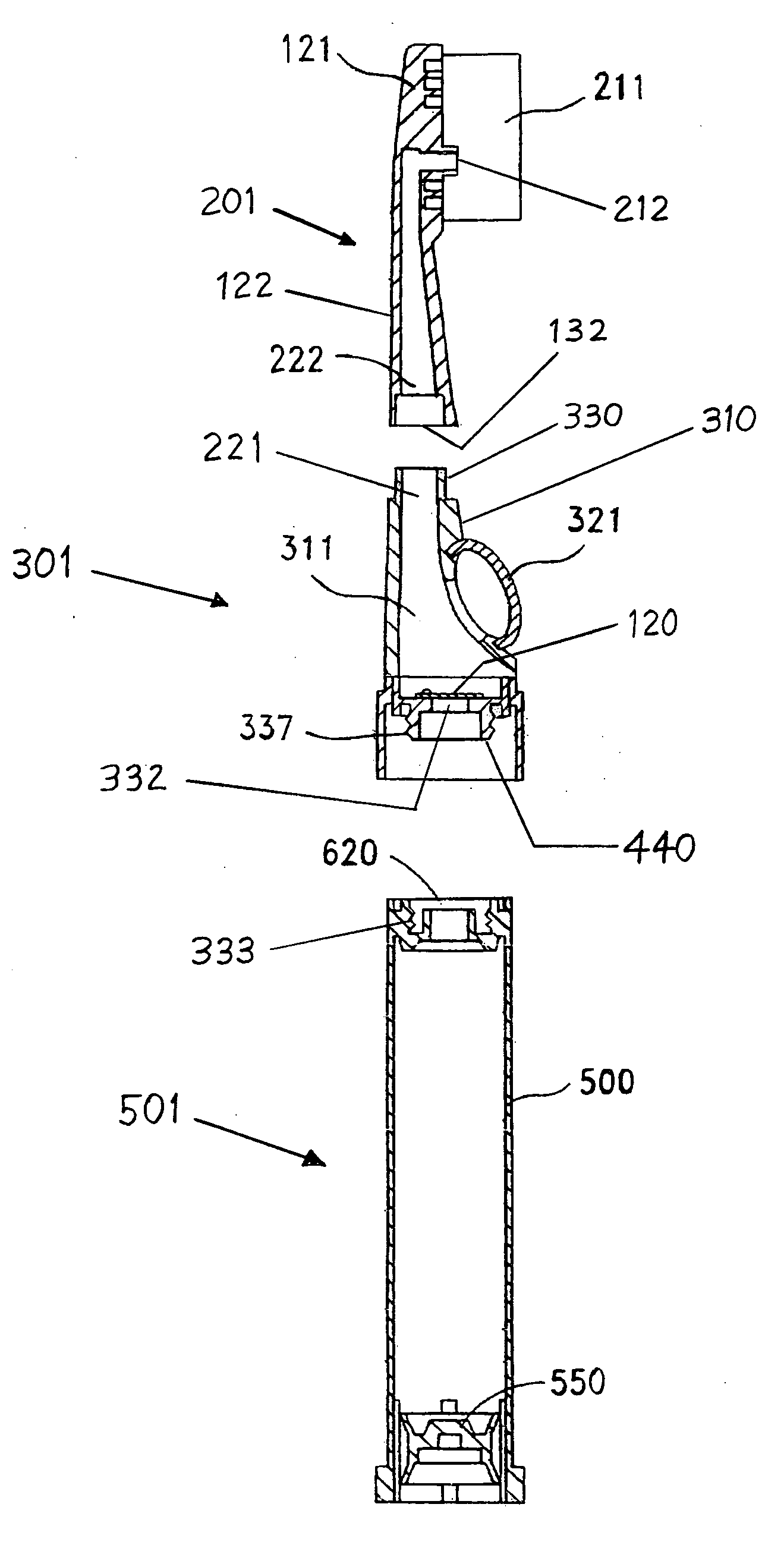

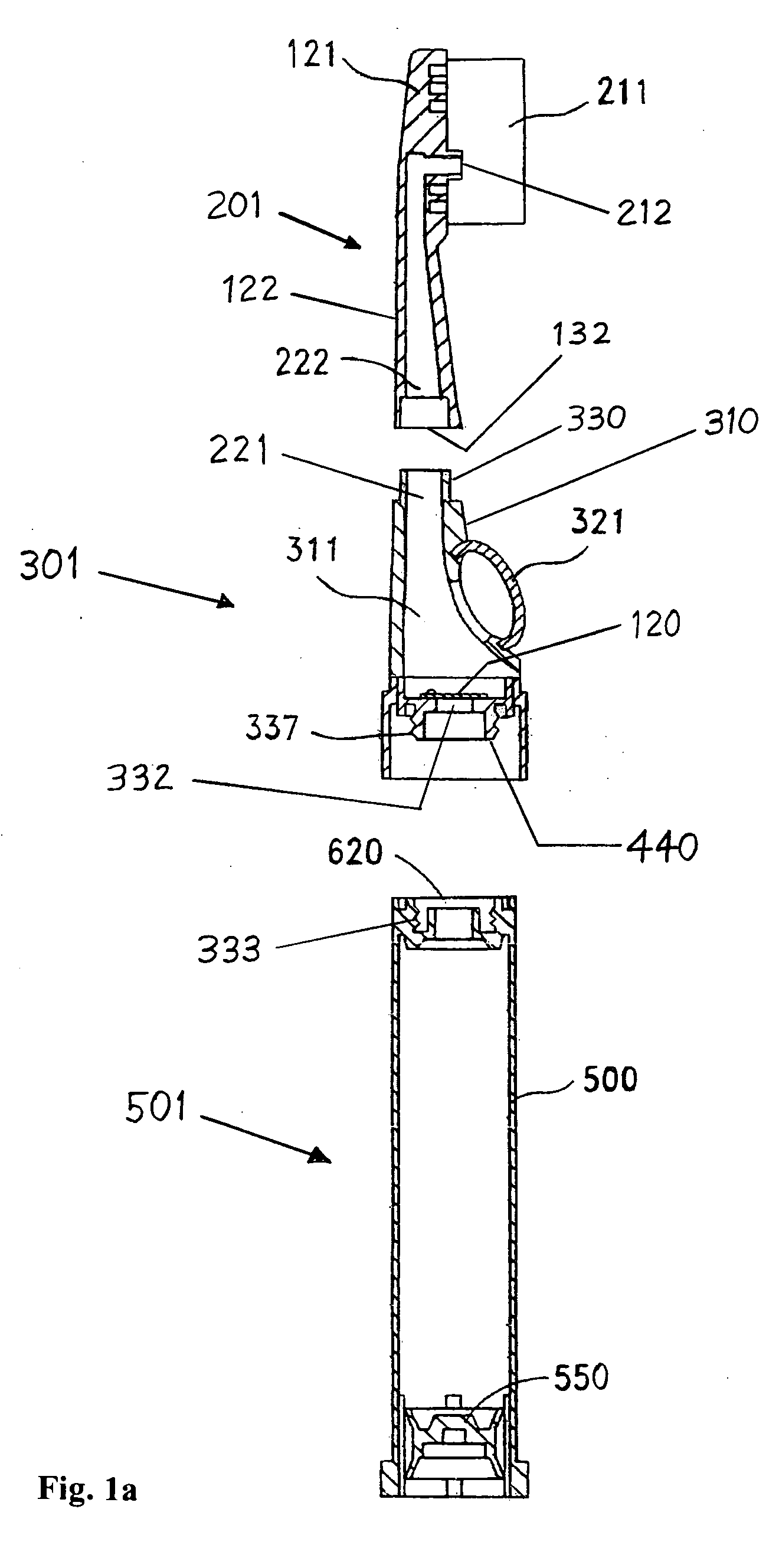

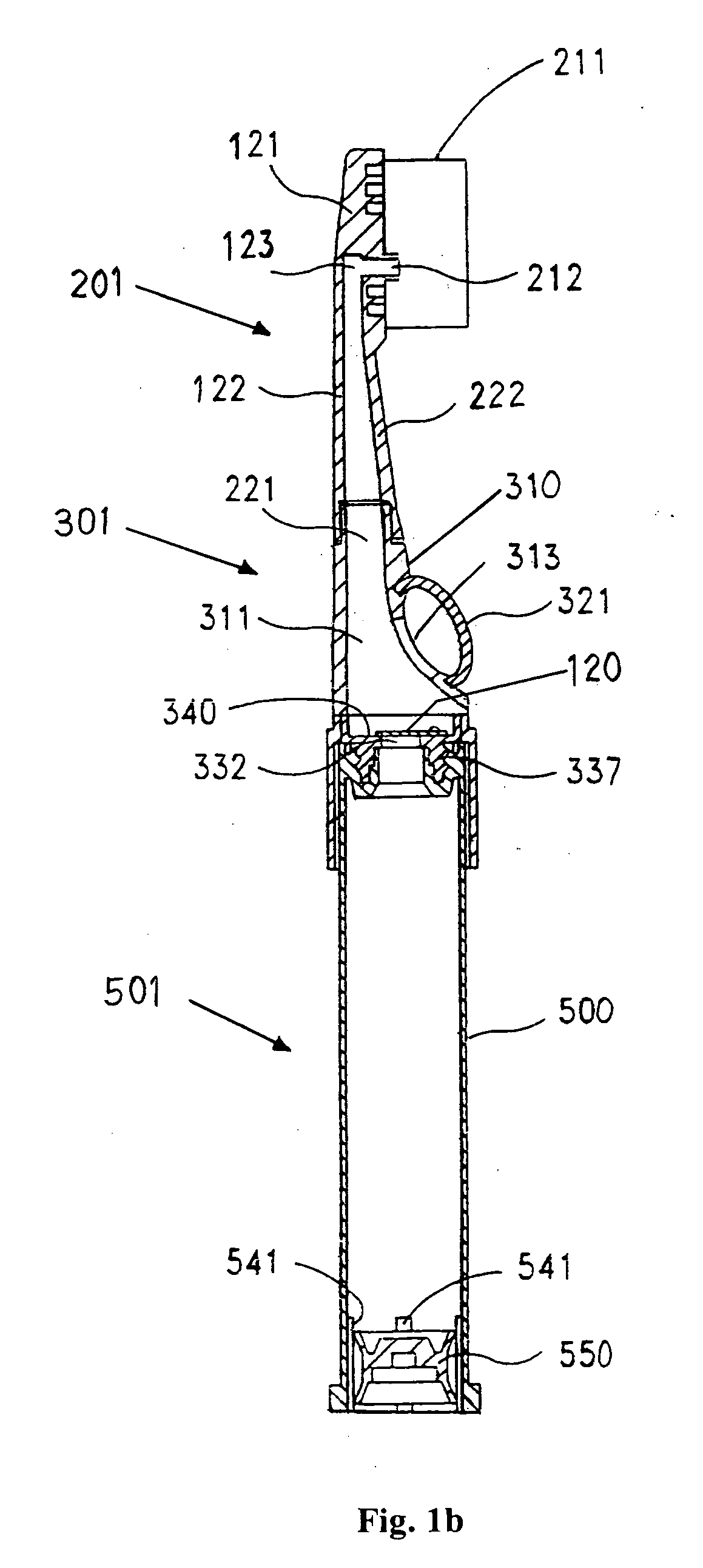

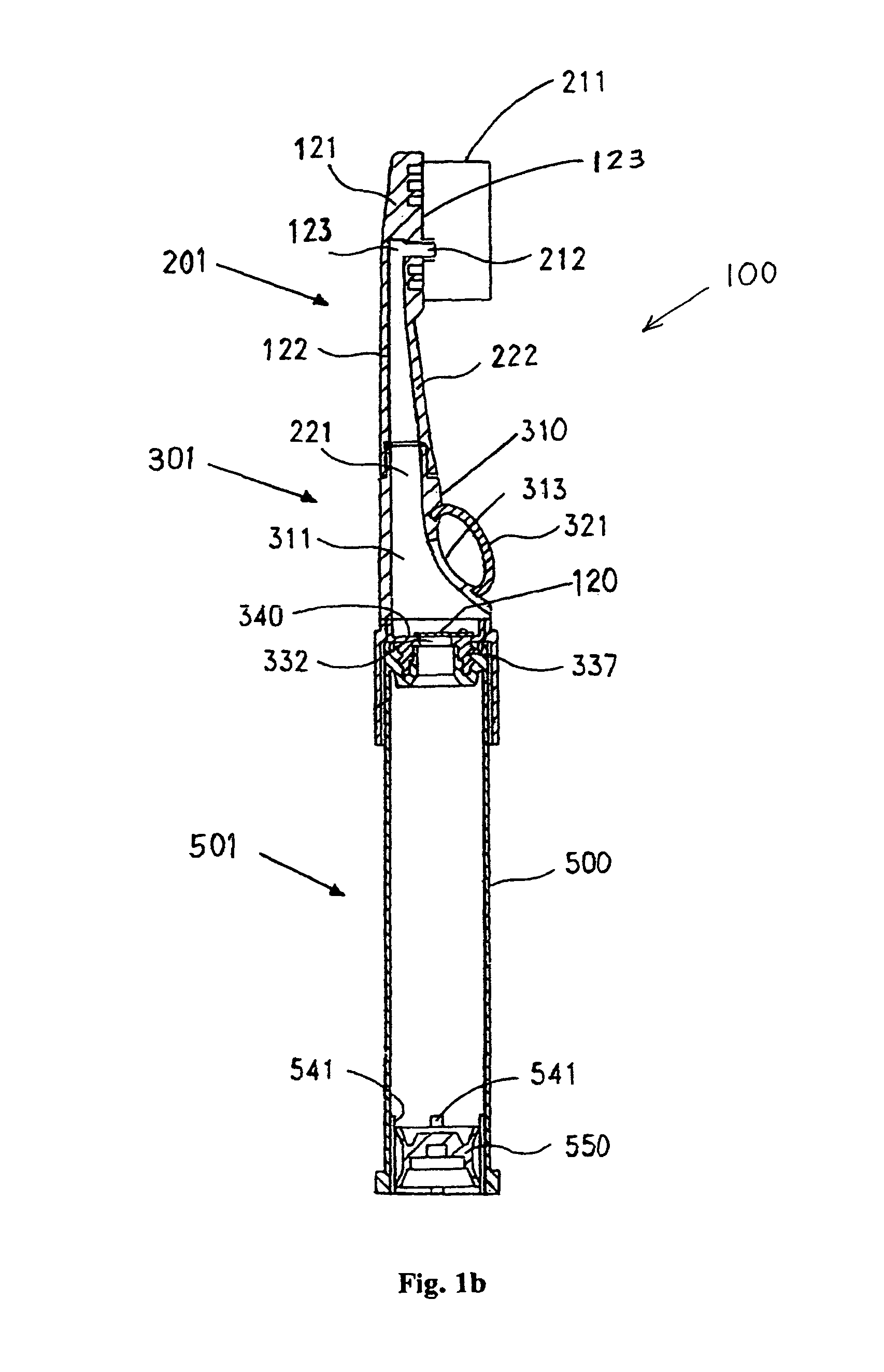

Pump toothbrush being provided for maximizing the benefit of brushing with liquid dentifrice by conveniently dispensing the dentifrice incrementally with one-hand to teeth surfaces and spaces between teeth without interrupting the continuous brushing motion. Common pump head and cartridge structure enable dispensing any kind of liquid and paste dentifrices. The pump head is equipped with an elastic compressible button for pumping with thumb and an inlet connector for mounting a refillable piston cartridge. A built-in self-closing slit valve in the brush head prevents backflow and drying of dentifrice material at the spout opening. The slit valve opens and closes automatically with the pumping action. The dispensing mechanism and cartridge structure are applicable to manual and electrical pump toothbrushes which use common cartridges. A toothbrush container having vent-tube and vent-caps is also provided for selective venting and sealing a pump toothbrush.

Owner:KUO YOUTI

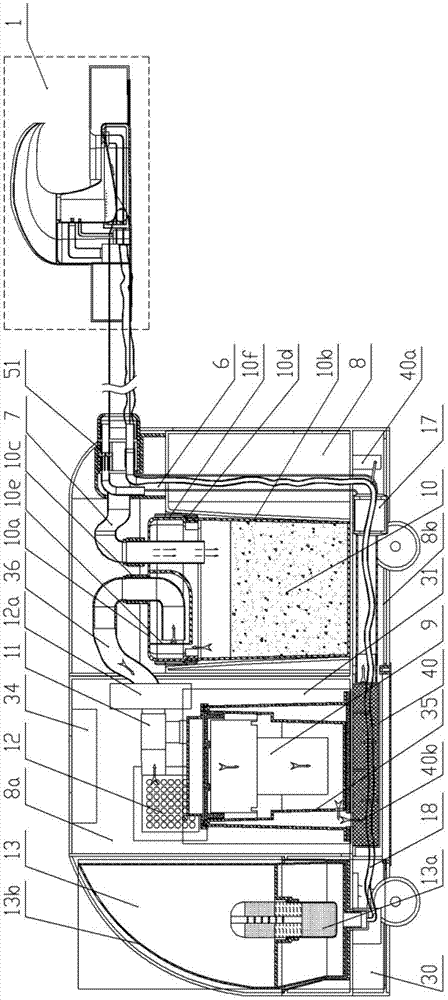

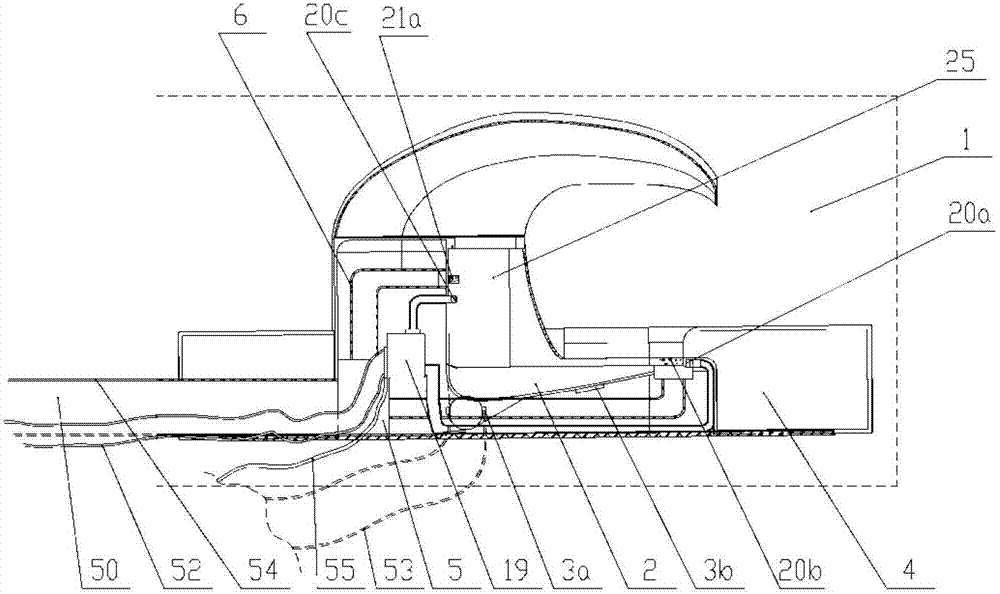

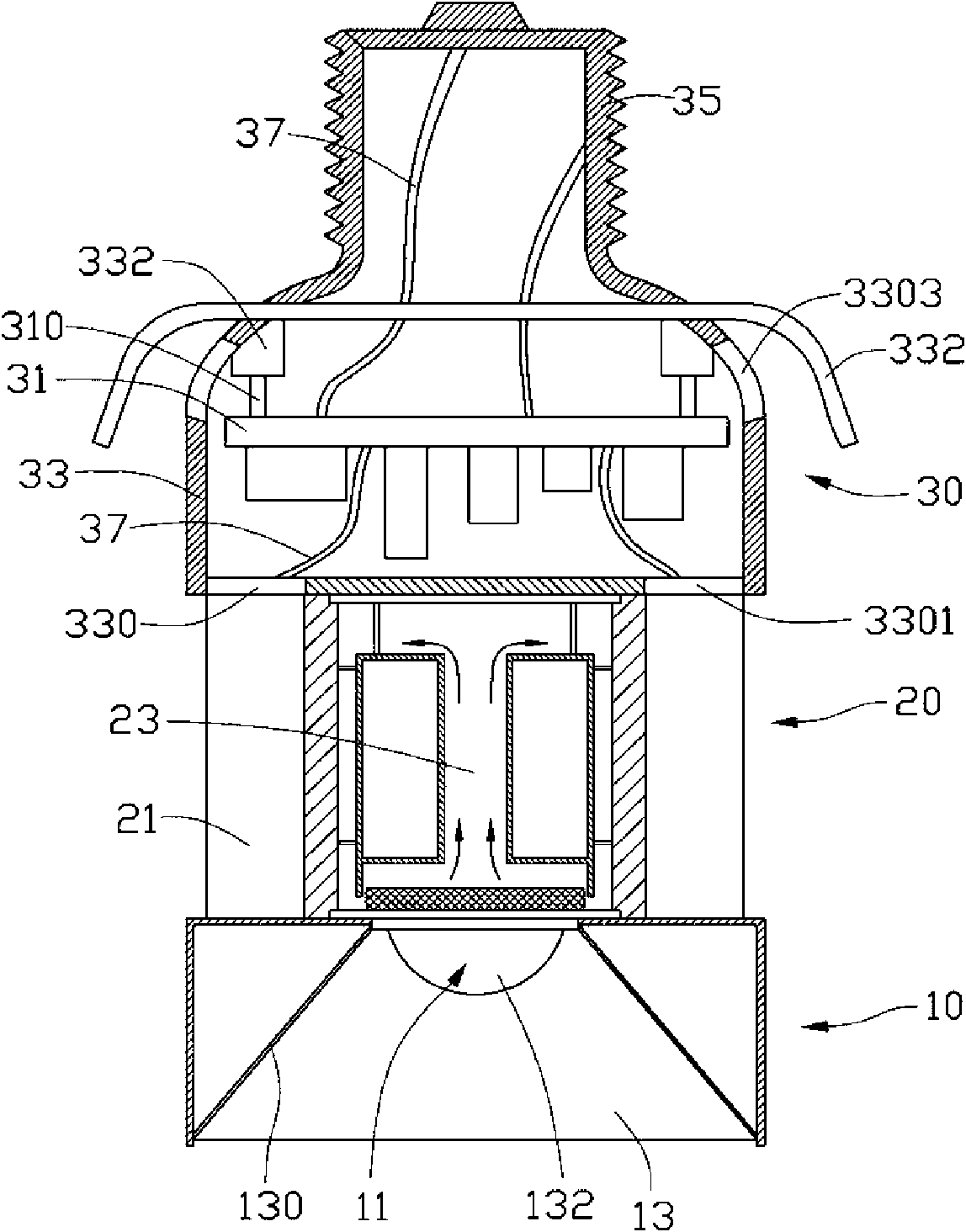

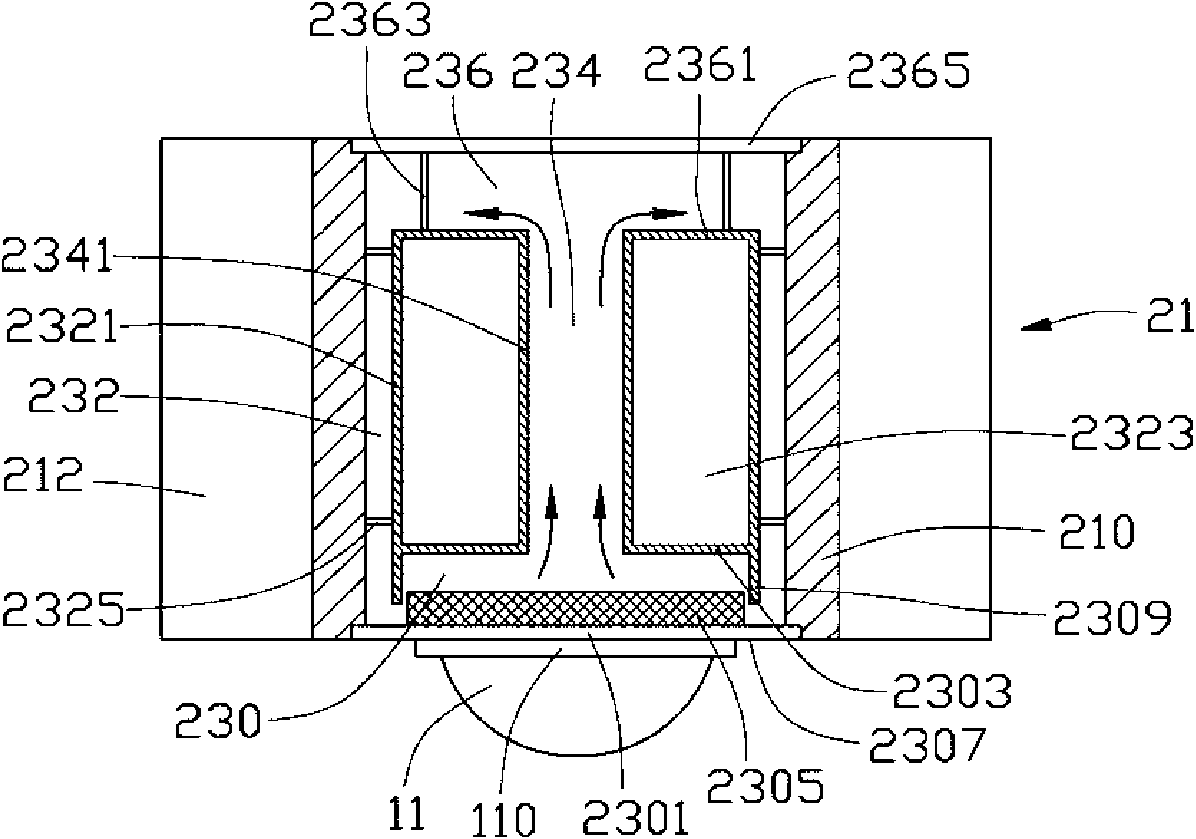

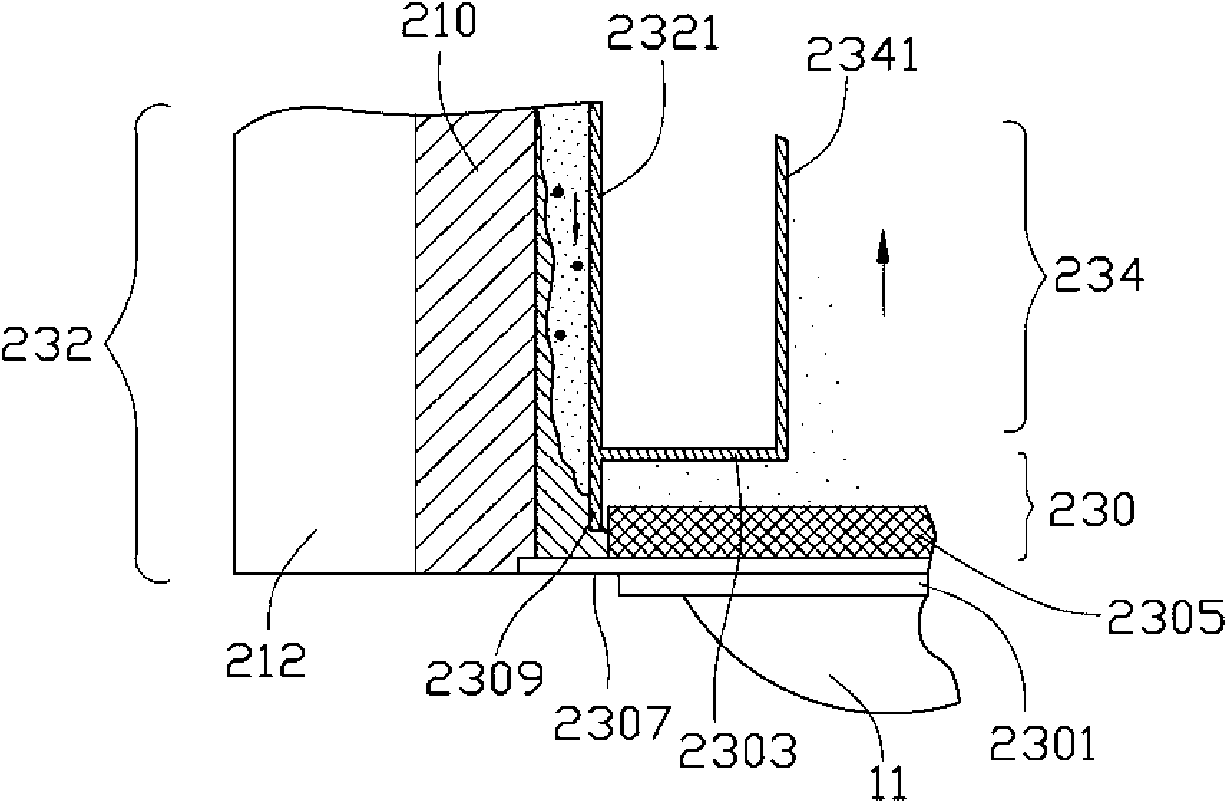

Intelligent nursing toilet system

ActiveCN102920565AGood dirt absorption effectGuaranteed cleaning comfortMedical transportElectrical and Electronics engineeringToilet

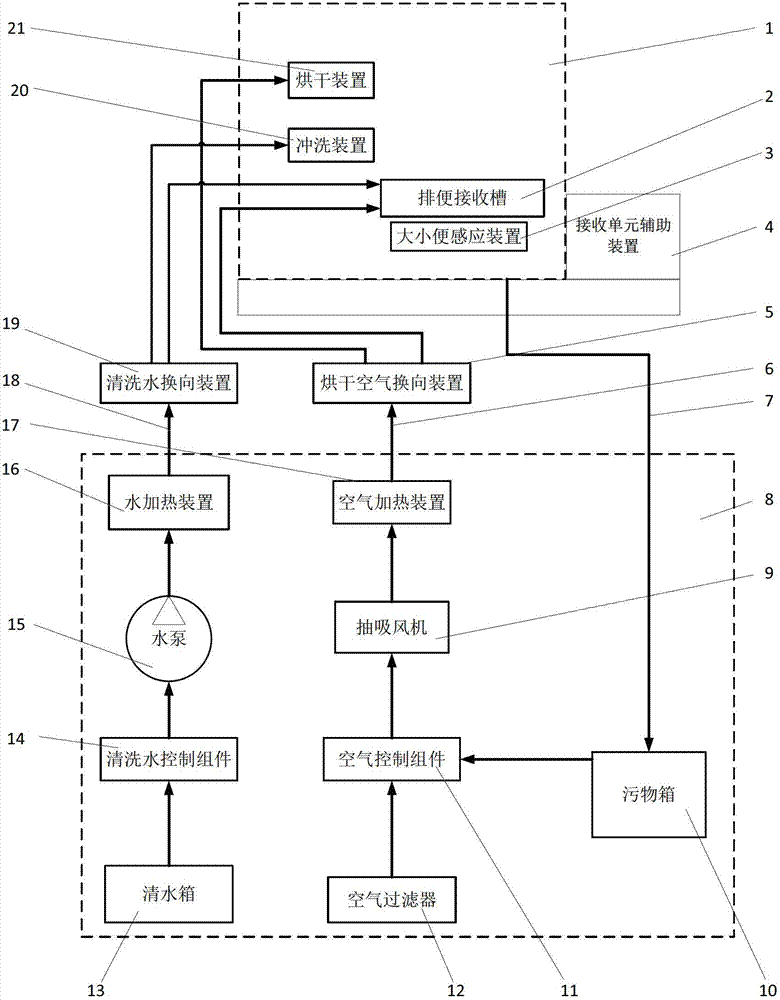

The invention particularly discloses an intelligent nursing toilet system. The system comprises a defecation receiving assembly, a toilet host assembly and a connecting pipeline assembly, wherein the connecting pipeline assembly comprises a washing pipeline, a blow-off pipeline, a vacuum pipeline and an electrical pipeline; the defecation receiving assembly comprises a drying unit, a flushing unit, a defecation receiving unit and a detection unit, the drying unit and the flushing unit are arranged over the defecation receiving assembly, and the detection unit is arranged in the defecation receiving assembly; the defecation host assembly comprises a dirt box, a washing water unit, a vacuum control unit and a control unit; the detection unit, the washing water unit and the vacuum control unit are connected with the control unit respectively through the electrical pipeline; the defecation receiving assembly is connected with the dirt box through the blow-off pipeline on one hand and connected with the vacuum control unit and the washing water unit respectively on the other hand; and the flushing unit is connected with the washing unit through the washing pipeline, the drying unit is connected with the vacuum control unit through the vacuum pipeline, and the dirt box is connected with the vacuum control unit.

Owner:CRRC SHANDONG CO LTD

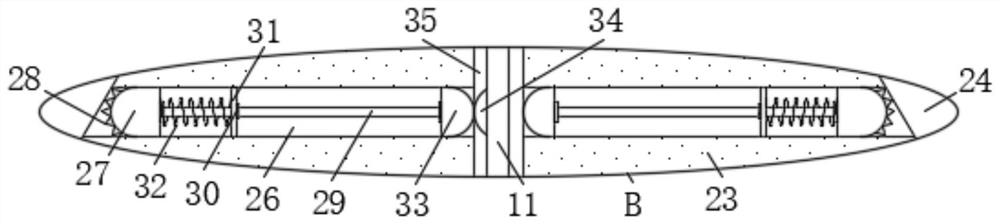

Manual and electrical pump toothbrushes for dispensing liquid and paste dentifrices

Pump toothbrush comprising a refillable cartridge containing dentifrice material, a pump head having an elastic compressible button, and a brush head having a spout opening attached with a slit valve. The slit valve prevents backflow and drying of the dentifrice material at the spout opening. The slit valve opens and closes automatically with the pumping action. The dispensing mechanism and cartridge structure are applicable to manual and electrical pump toothbrushes.

Owner:KUO YOUTI

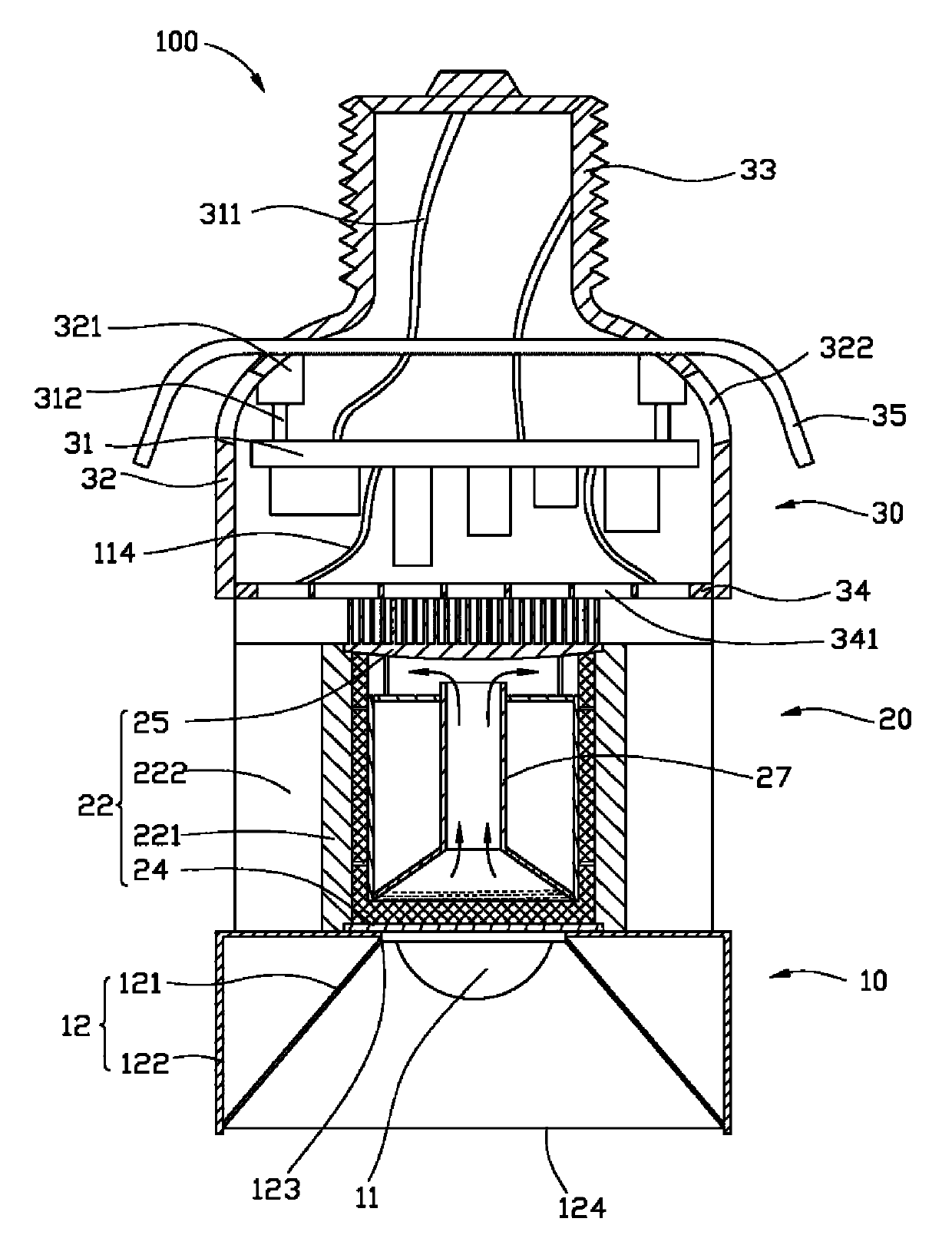

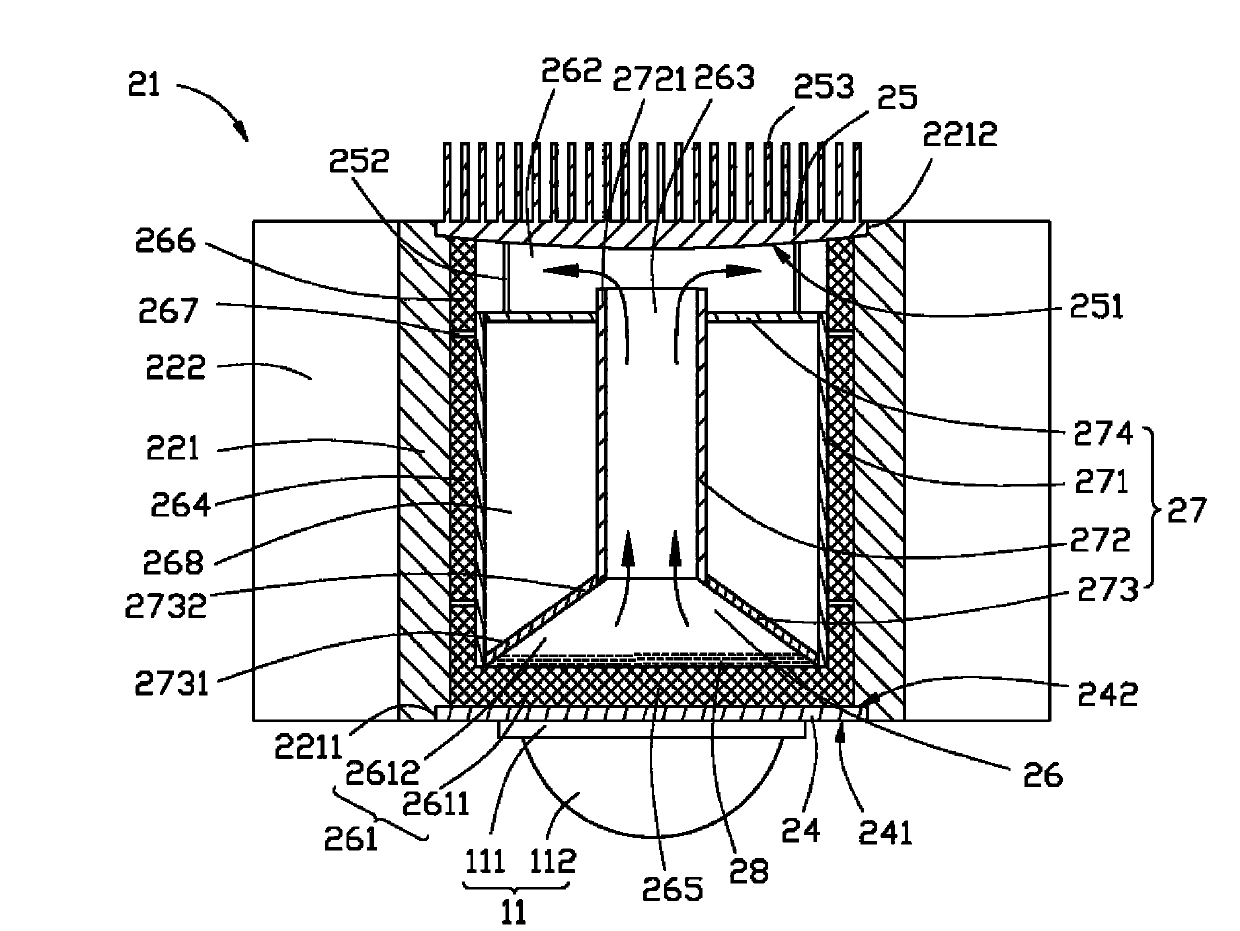

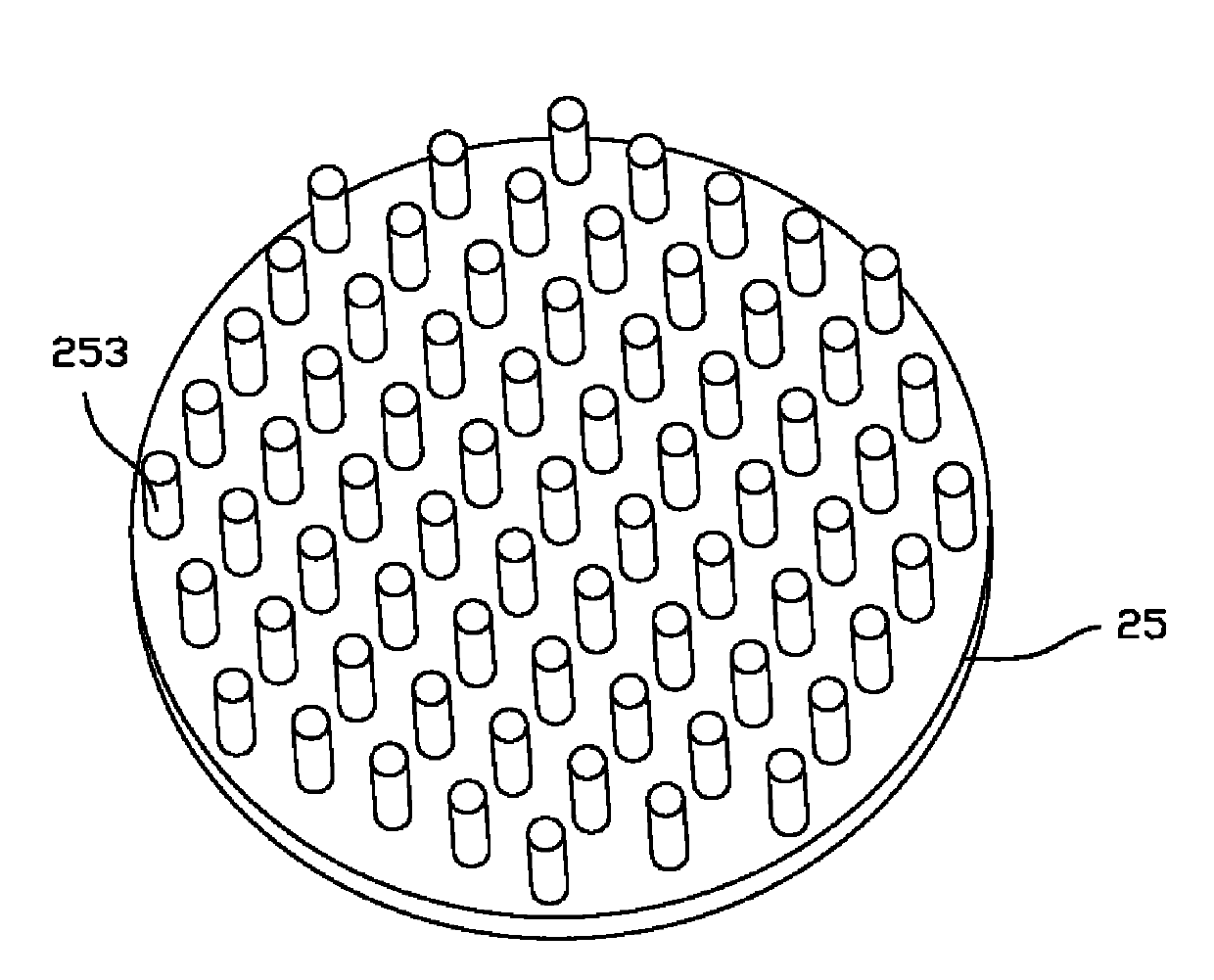

Light-emitting diode lamp

InactiveCN101943335AHigh secondary coldnessImprove cooling efficiencyPoint-like light sourceSemiconductor/solid-state device detailsWorking fluidHeat resistance

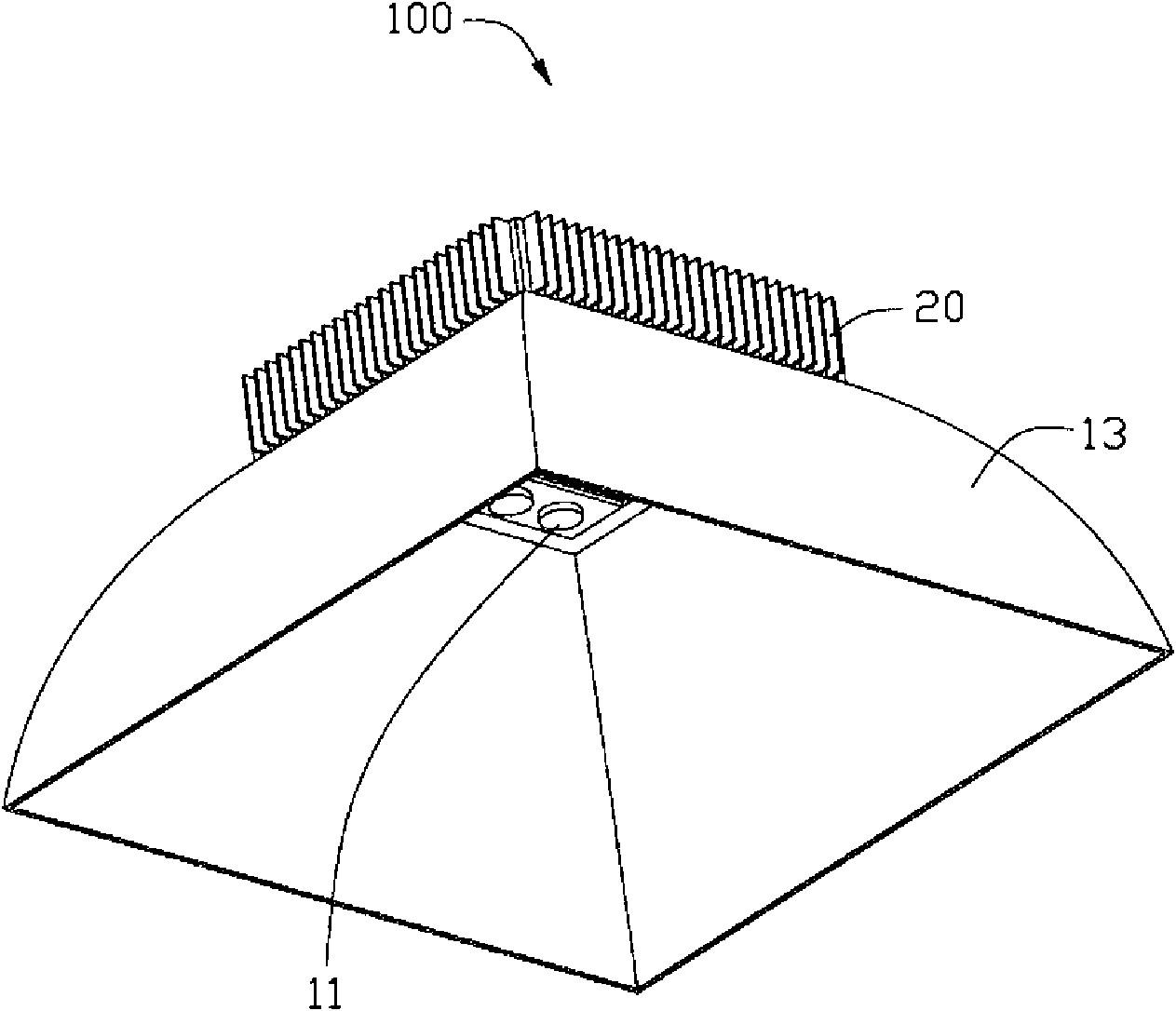

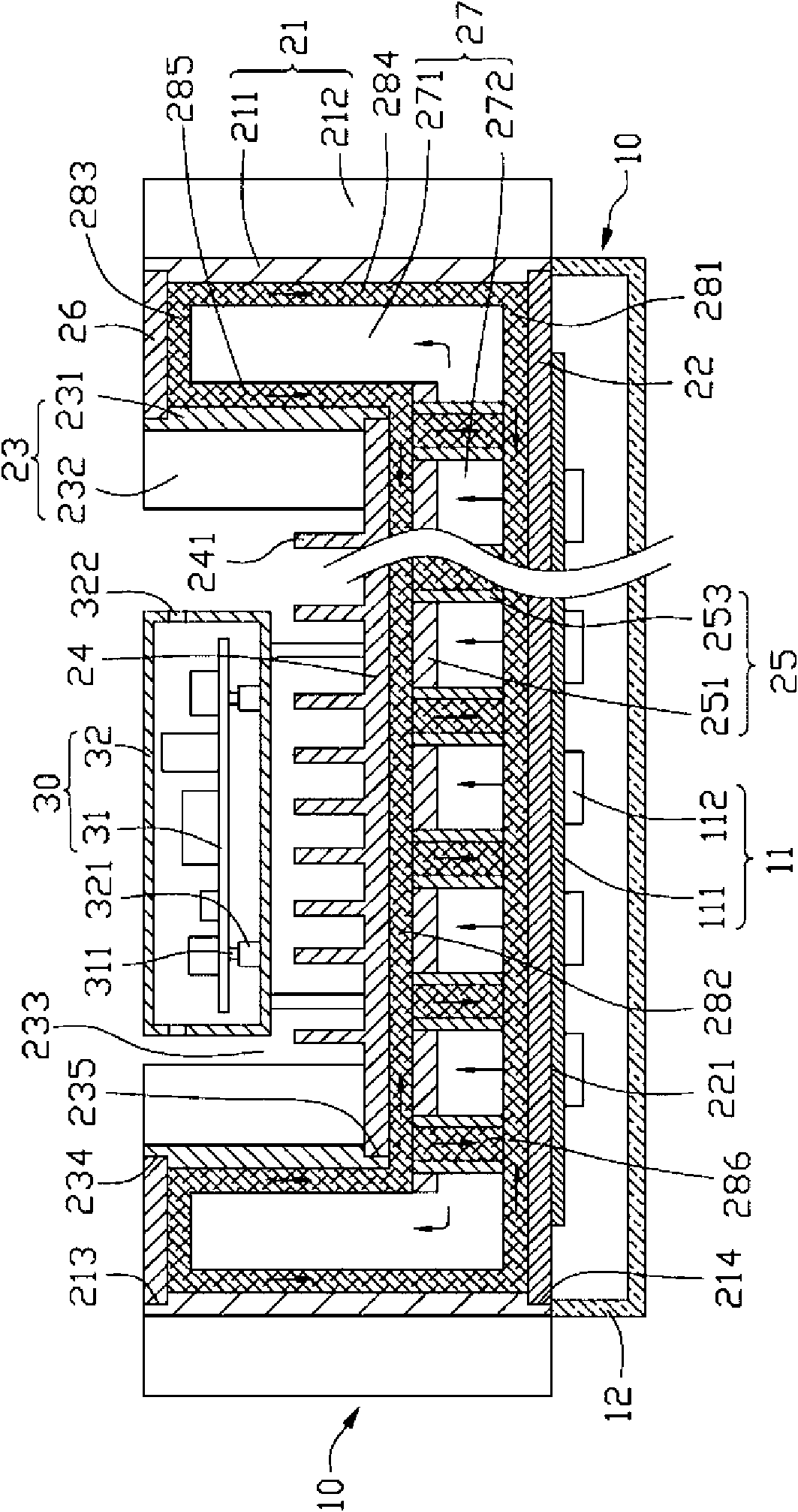

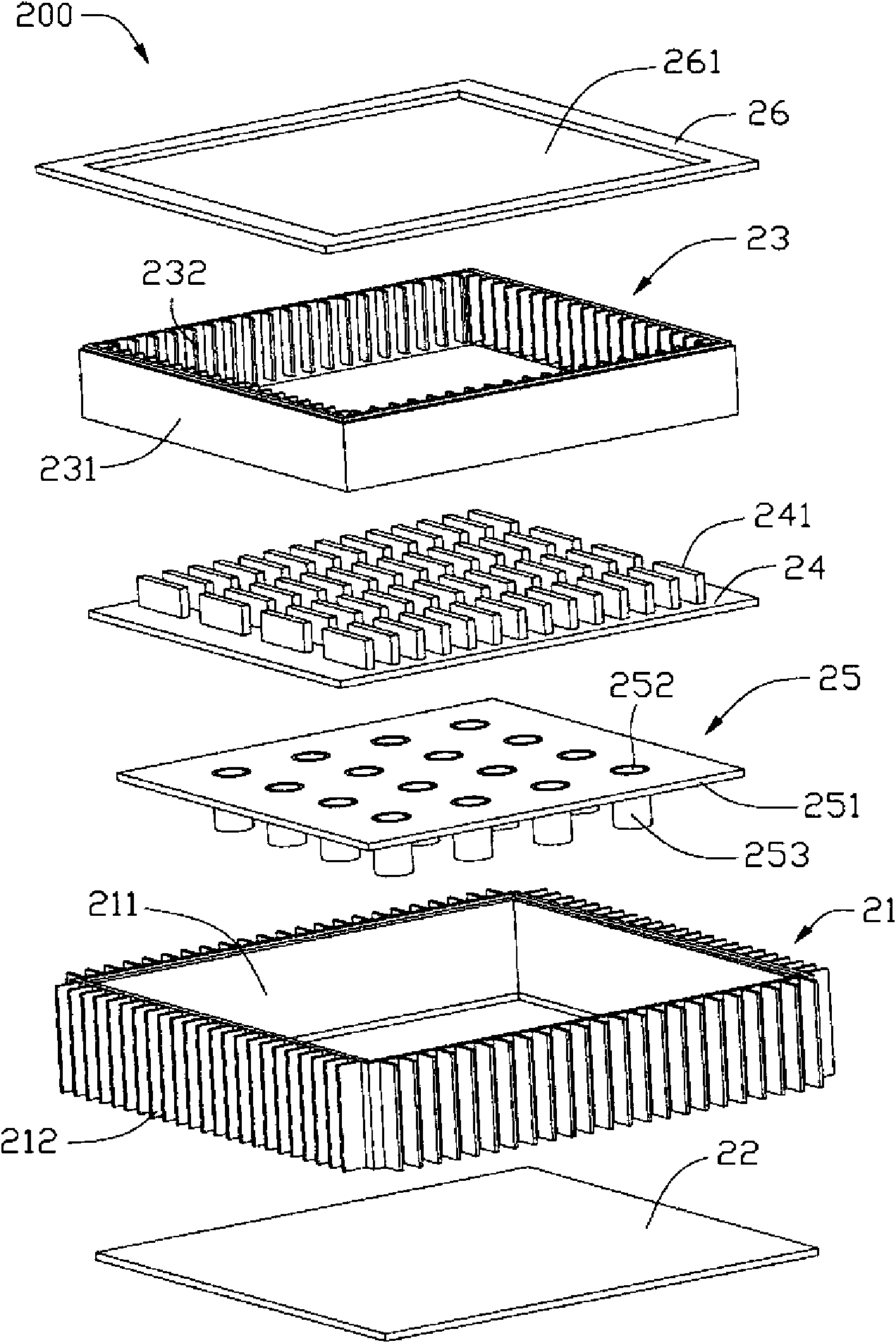

The invention discloses a light-emitting diode lamp which comprises a heat radiating part, an optical part and an electric part. The heat radiating part comprises a heat exchange loop device. The heat exchange loop device comprises a first heat radiator, a heat absorber plate, a second heat radiator, a first cover plate, a heat-insulating element and an annular second cover plate. The first heat radiator, the heat absorber plate, the second heat radiator, the first cover plate and the second cover plate form a closed first cavity body; and a second cavity body opened toward a top end is formed in the second heat radiator. A capillary structure is arranged on the surface of a side wall inside the first cavity body. A working fluid is filled in the capillary structure. The heat-insulating element is arranged in the first cavity body and between the first cover plate and the heat absorber plate. The heat-insulating element comprises a heat-insulating plate which is arranged near the first cover plate and provided with a plurality of through holes. The heat-insulating plate of the heat-insulating element can effectively prevent a reflowing low-temperature condensate from being in contact with reverse high-temperature saturated steam directly for heat transfer to increase the flow resistance and the heat resistance of the condensate reflowing to an evaporation part.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

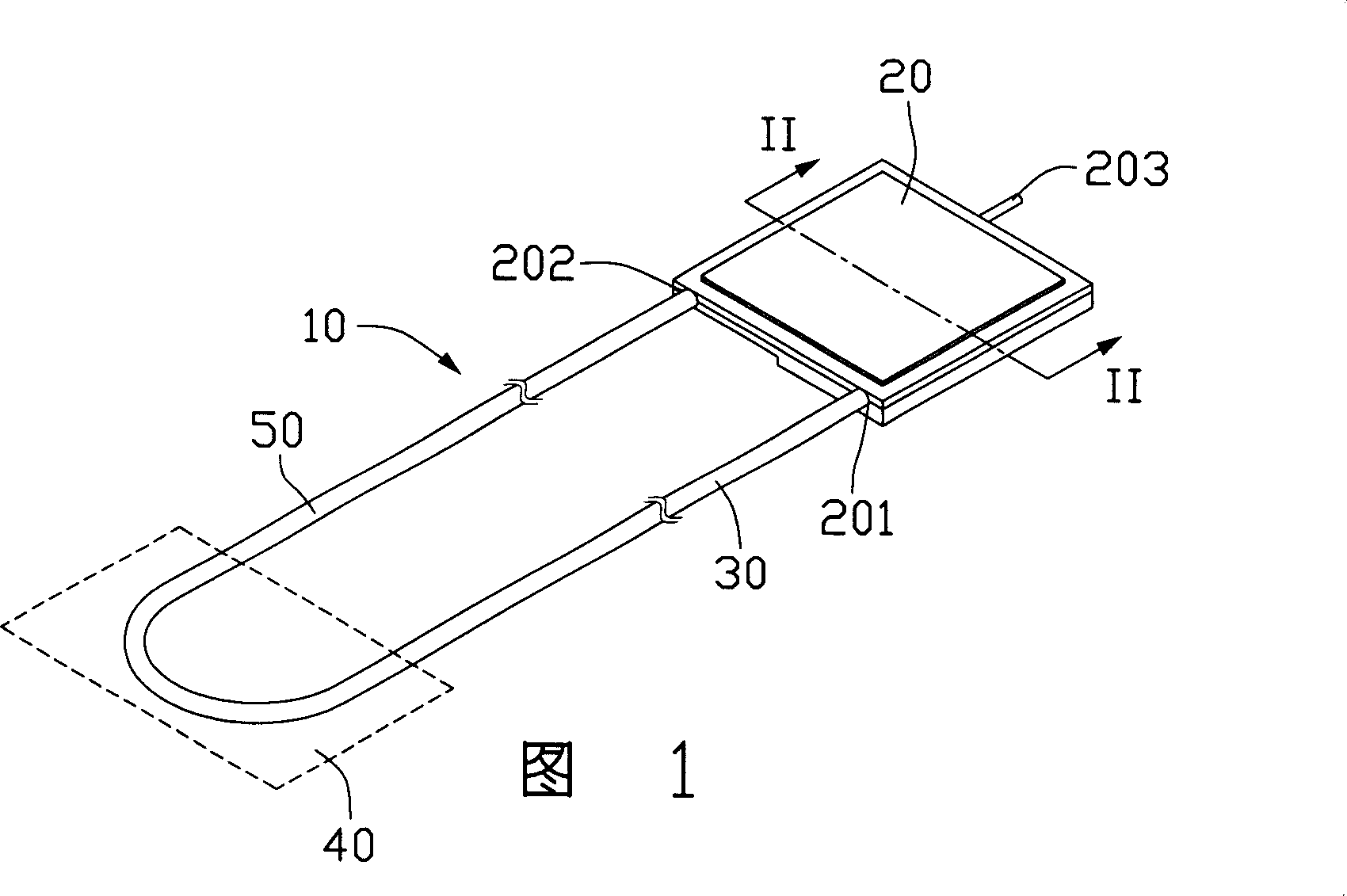

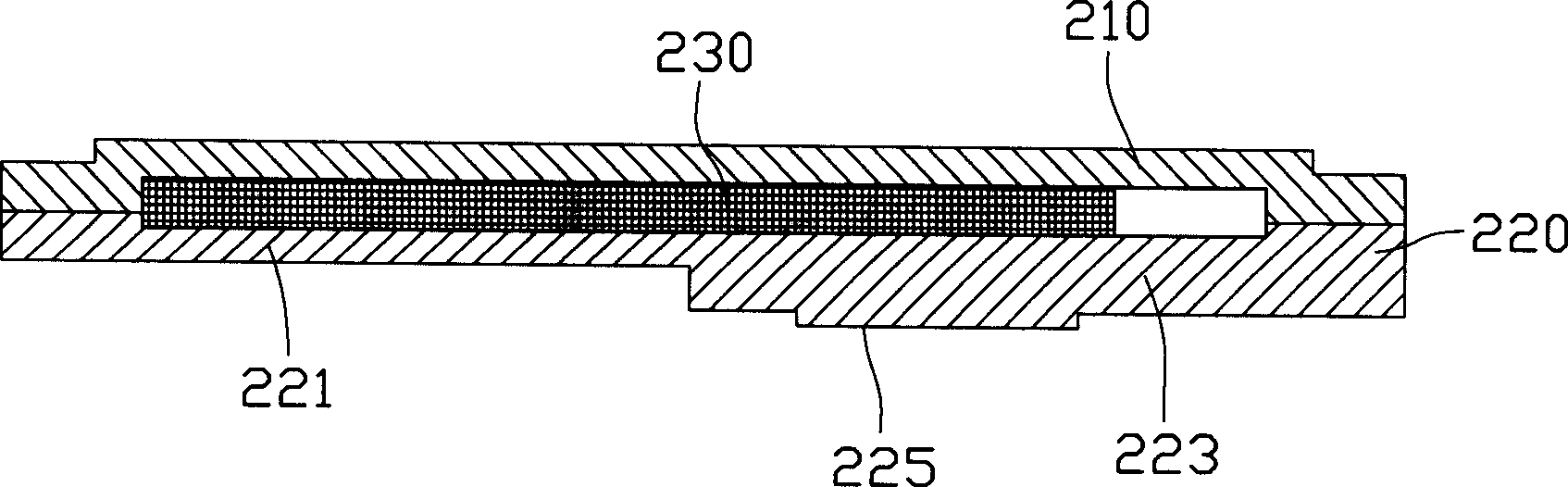

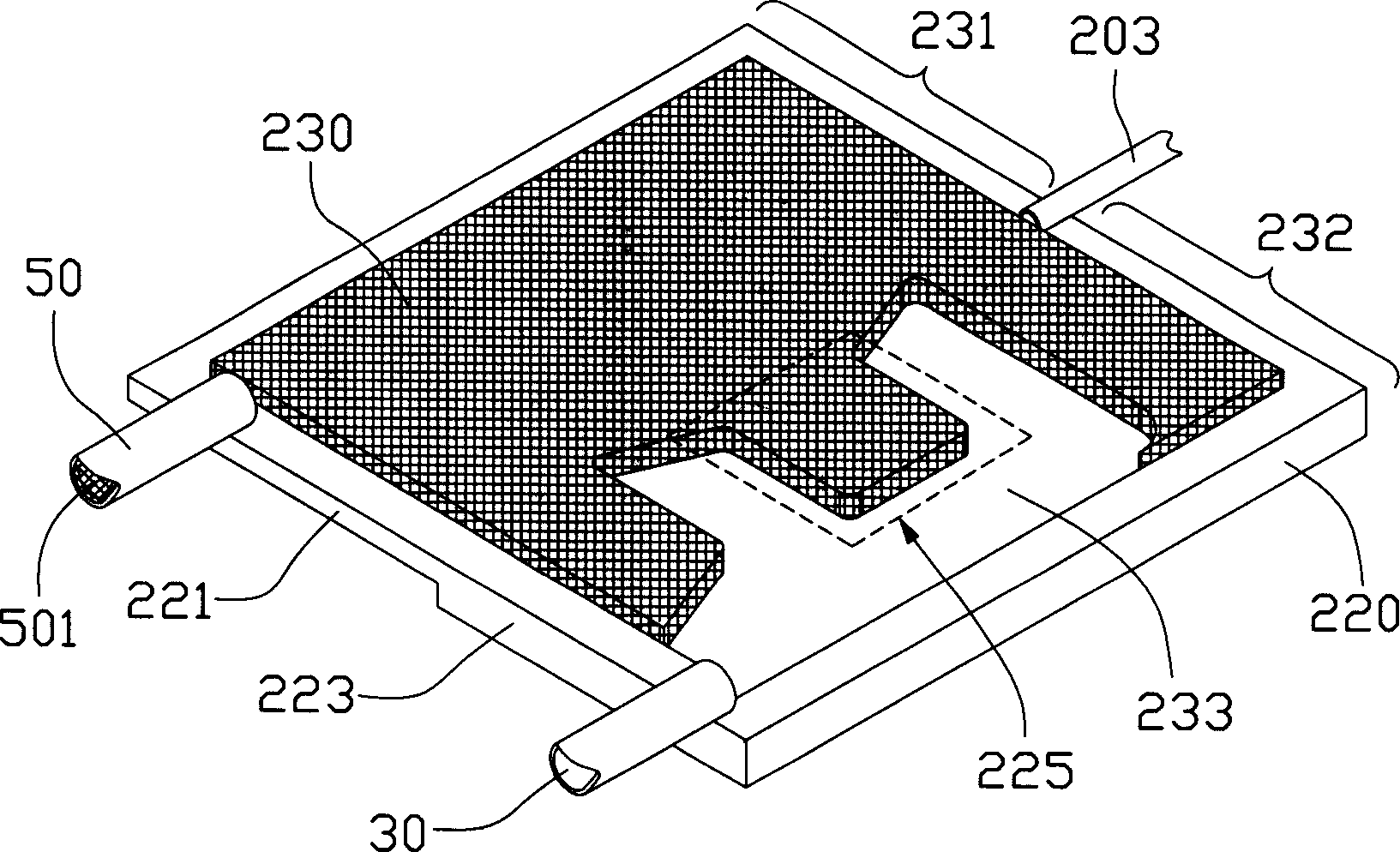

Thin loop type radiating apparatus

InactiveCN1893041AReduce savingsReduce generationDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidLiquid state

The heat sink includes an evaporator, a condenser, a steam conduit, and a backflow conduit. A cavity is formed in the evaporator, and working fluid is filled to the cavity. The cavity is divided into evaporation section and channel section of micro flow in liquid phase. After absorbing quantity of heat in the evaporation section, the working fluid generates steam, which through the steam conduit reaches to the condenser, where steam is cooled to liquid state. Through the backflow conduit, the cooled liquid is returned back to the condenser so as to constitute an airtight heat exchange loop. Structure for reducing steam cumulated on channel section is setup on the evaporator in order to reduce resistance for working fluid to flow back to the evaporation section. Thus, the invention guarantees circulation in one direction, and high efficiency for transferring heat.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

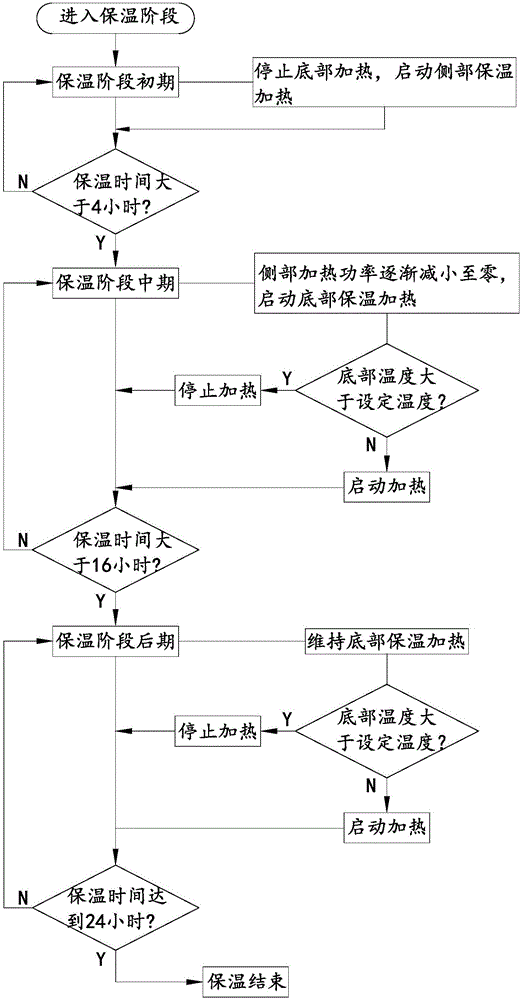

Heat preservation control method for electric rice cooker

ActiveCN106510481AAvoid hardening and yellowingConsistent tasteTemperature control using electric meansWarming devicesEngineeringCooker

The invention discloses a heat preservation control method for an electric rice cooker, belongs to the technical field of kitchen cooking, and solves the problem of food hardening and yellowing caused by long-time heat preservation of an existing electric rice cooker. The electric rice cooker comprises a control unit, a heating apparatus and an inner pot, wherein the heating apparatus comprises a bottom heater for heating the bottom of the inner pot and a side heater for heating the side part of the inner pot. According to the heat preservation control method, the control unit controls the bottom heater and the side heater to alternately perform heat-preservation heating according to a set heat preservation temperature after the electric rice cooker enters a heat preservation stage. The heat preservation control method is used for the electric rice cooker to perform food cooking such as rice cooking, congee cooking and the like.

Owner:JOYOUNG CO LTD

Light-emitting diode lamp and light engine thereof

InactiveCN101769458AStable light outputHigh light efficiencyPoint-like light sourceElectric circuit arrangementsWorking fluidEngineering

The invention relates to a light-emitting diode lamp and a light engine adopted by the light-emitting diode lamp. The light-emitting diode lamp comprises an optical chamber, an electrical chamber and a heat radiating chamber, wherein the heat radiating chamber is arranged between the optical chamber and the electrical chamber; the optical chamber comprise at least one light-emitting diode light source and a light emergent passage; the electrical chamber comprises a shield and a circuit board; the heat radiating chamber comprises a heat radiator and a loop device; the heat radiator comprises an annular heat radiating base, a plurality of fins which are distributed at the peripheral surface of the heat radiating base, as well as a heat absorbing plate and a heating radiating cover plate which are respectively arranged at both ends of the heat radiating base; the heating radiating base, the heat absorbing plate and the heat radiating cover plate form a sealed cavity; the working fluid is filled into the cavity; the light-emitting diode light source is arranged on the outer surface of the heat absorbing plate; the loop device is arranged in the cavity and divides the cavity into an evaporating part, a condensing part, a steam passage and a reflux passage, and a capillary structure is filled into the reflux passage.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

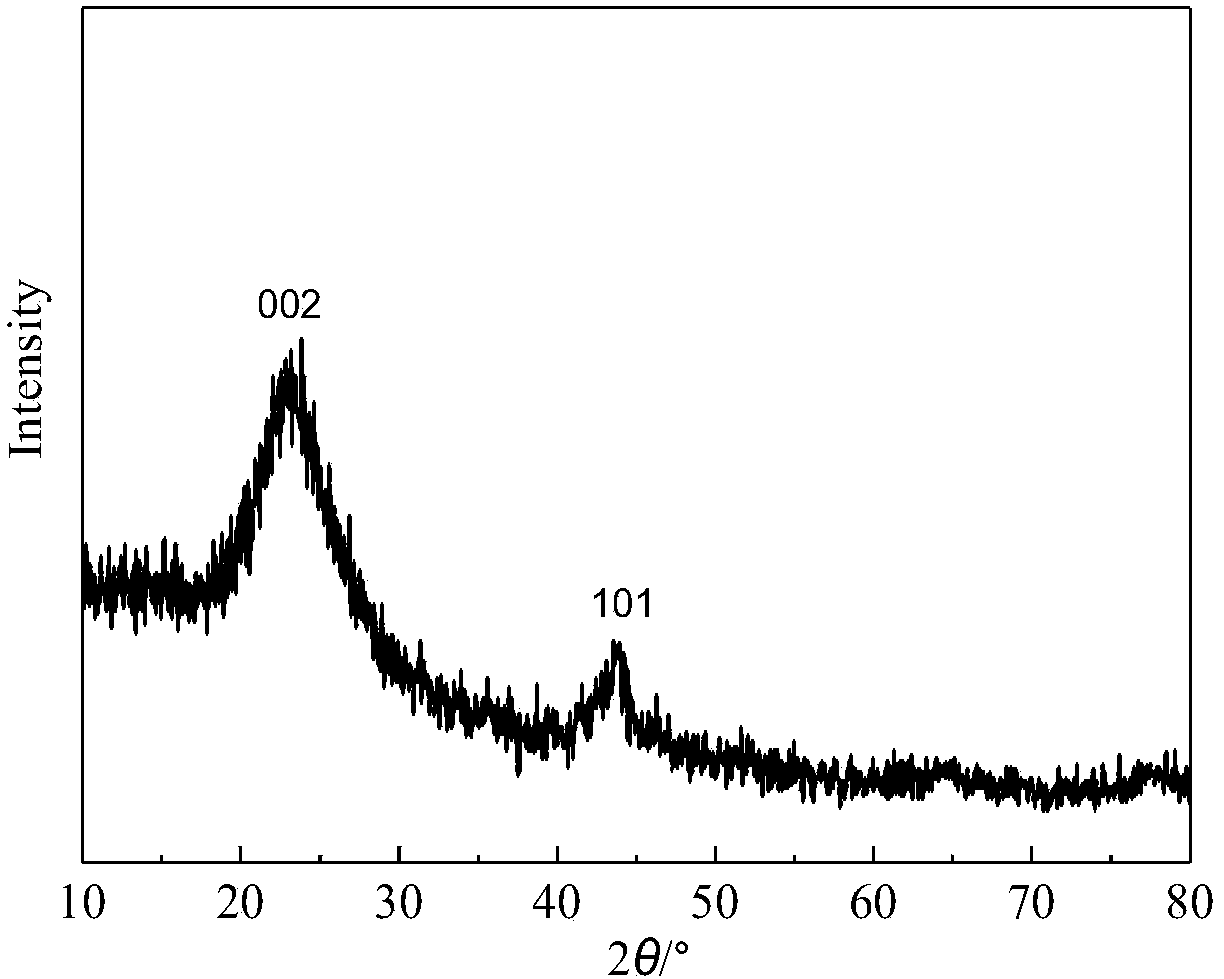

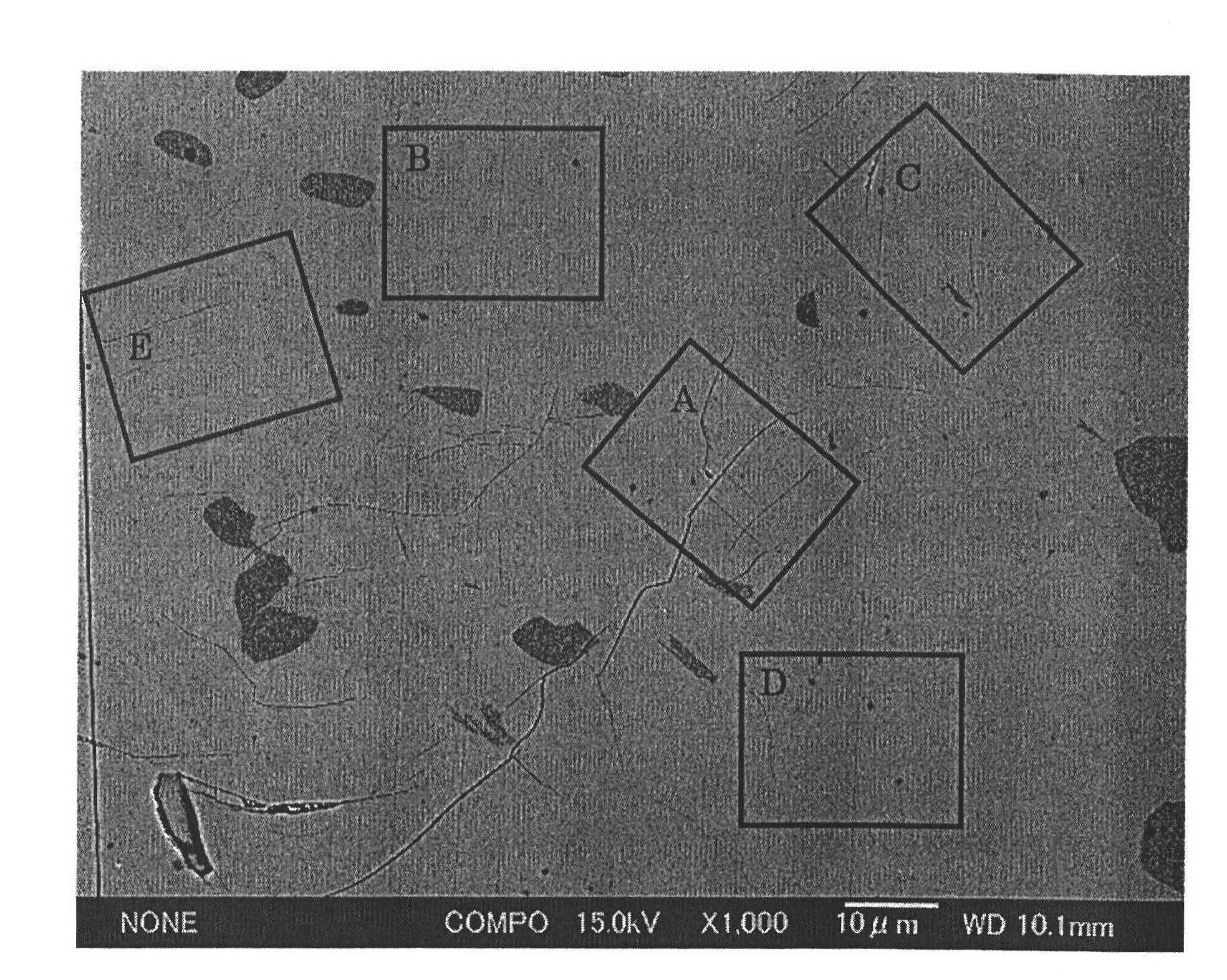

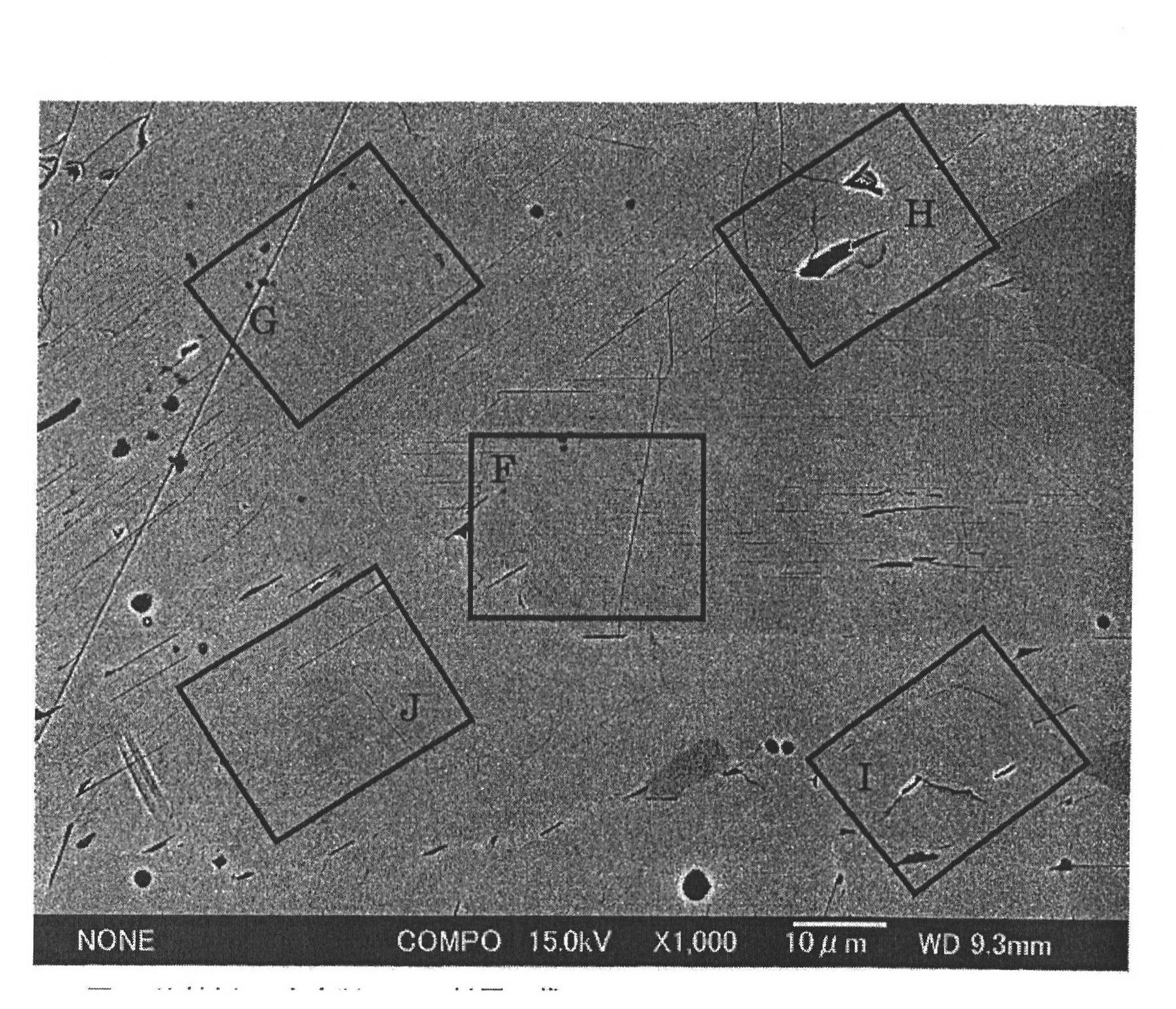

Method for preparing modified graphite negative electrode material of sodium ion battery

ActiveCN104377346AIncrease sodium storage capacityImprove structural stabilityCell electrodesCarbon layerCarbonization

The invention provides a method for preparing a modified graphite negative electrode material of a sodium ion battery and aims at solving the problem of lacking of a suitable negative electrode material of the sodium ion battery at present. The method comprises the steps of preparing paste graphite oxide by using a Hummer method, cladding the graphite oxide with asphalt, phenolic resin or glucose as carbon precursors, and carrying out carbonization heat treating on the graphite oxide clad with the carbon precursors under an inert gas atmosphere. The method has the advantages of being simple, wide in raw material sources, suitable for large-scale industrial production, and the like. According to the obtained modified graphite negative electrode material, the carbon layer spacing is not less than 0.35nm, and the thickness of the carbon clad layer is 0.01-1 micron.

Owner:LIAONING TECHNICAL UNIVERSITY

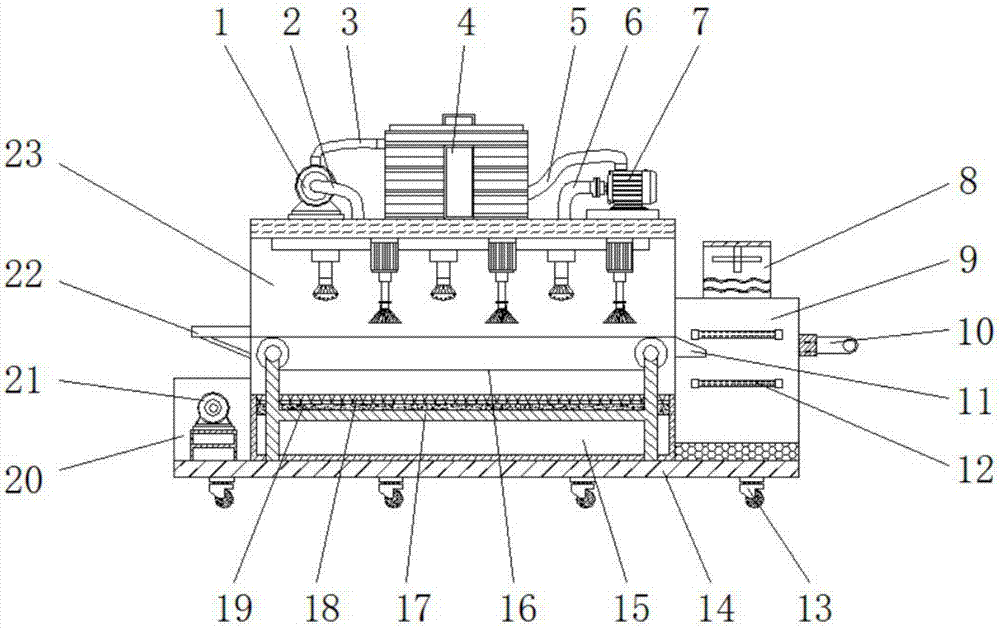

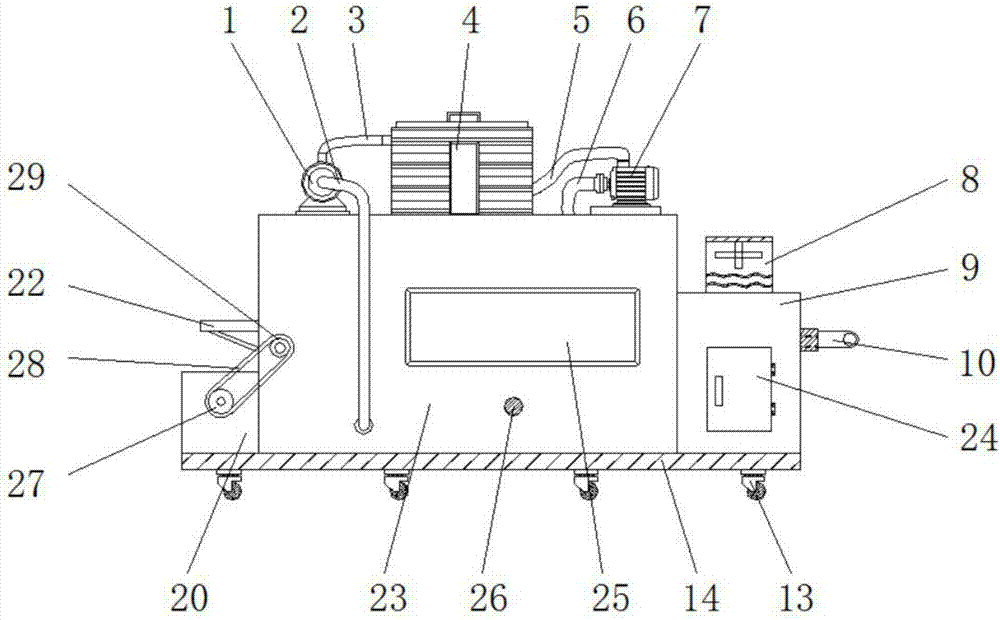

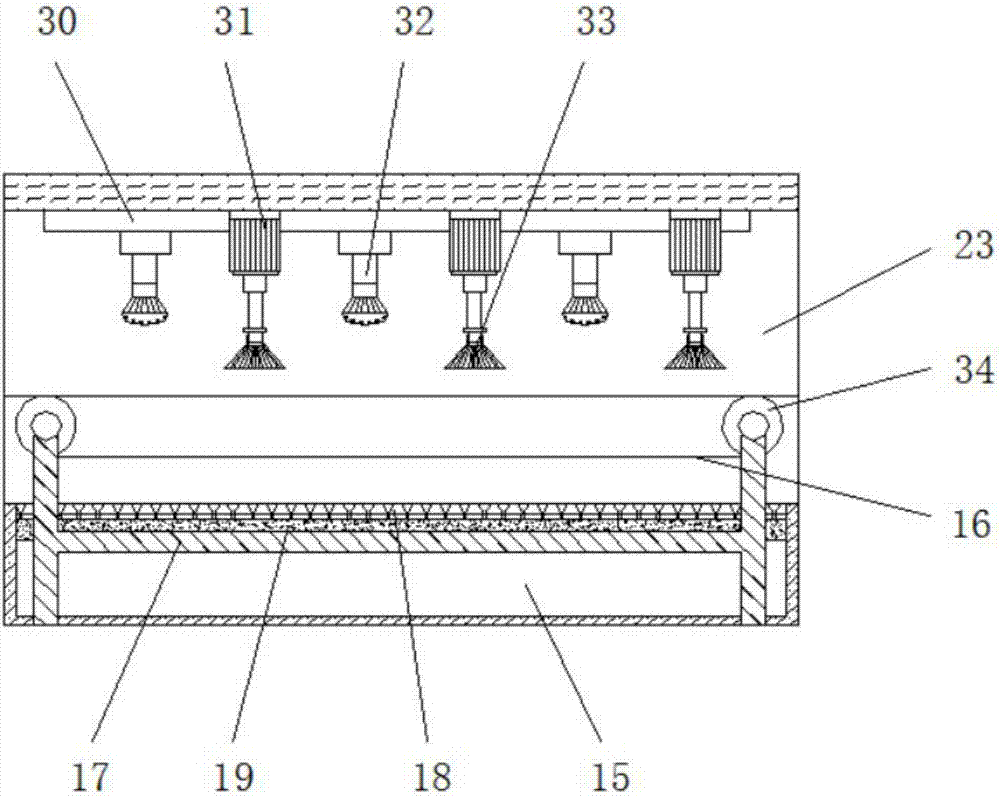

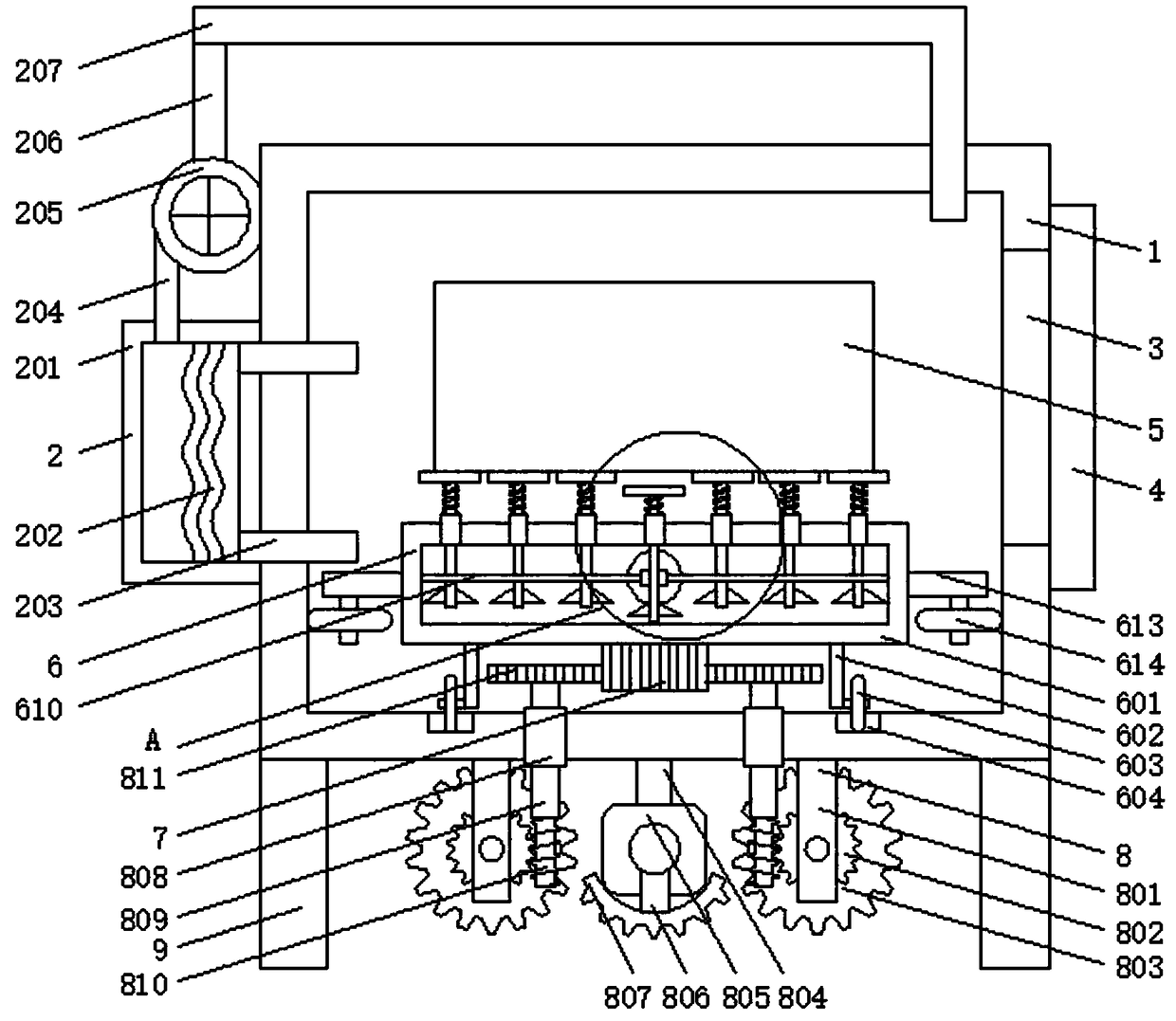

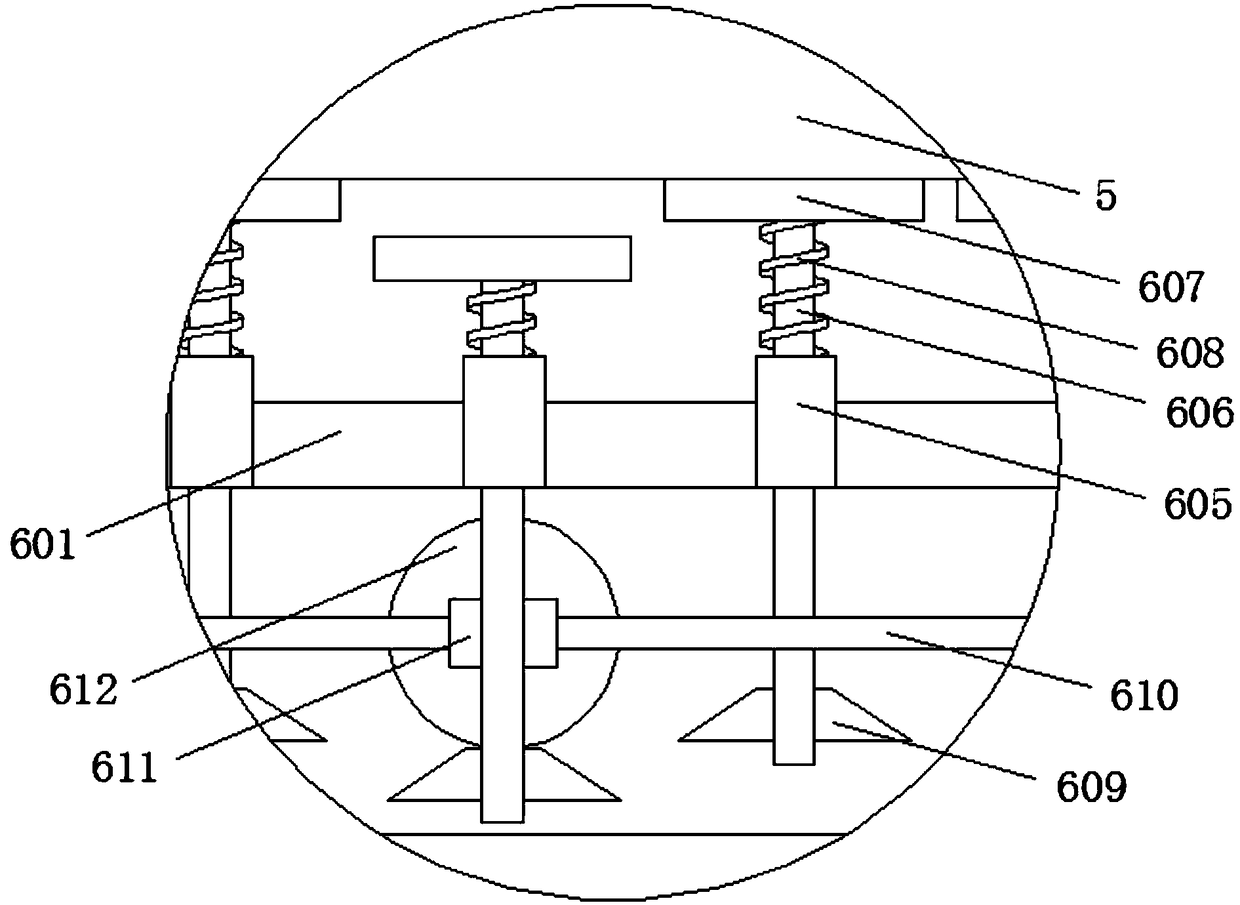

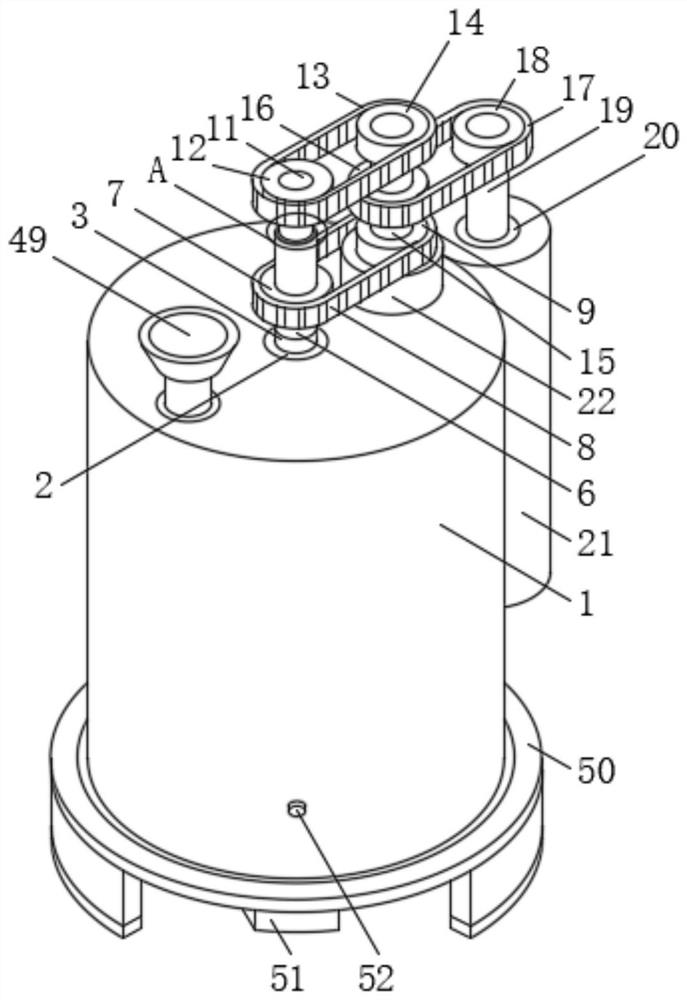

Modified transparent plastic silkworm net cleaning device for agricultural silkworm breeding

InactiveCN107321685AEasy to cleanSpeed up dryingDrying gas arrangementsCleaning using toolsRinse waterEngineering

The invention relates to a modified transparent plastic silkworm net cleaning device for agricultural silkworm breeding. The device comprises a water tank, an air supply pipe, a drying oven, a base and a cleaning box, wherein wheels are evenly arranged on two sides of the bottom end of the base, the cleaning box is arranged at the top end of the base, and the water tank is arranged at the top end of the cleaning box; a suction pump is arranged at the top end of the cleaning box on one side of the water tank, a water outlet of the suction pump is connected to the top end of the water tank through a second aqueduct, and a water inlet of the suction pump is connected to the bottom end of one side of the cleaning box through a first aqueduct. According to the modified transparent plastic silkworm net cleaning device, a conveyor belt is arranged, so that the device is high in automation degree, and people can clean a silkworm net in a large-scale mode conveniently and rapidly; spray-heads and cleaning brushes are arranged on the device, so that the silkworm net can be washed through high pressure water, the surface of the silkworm net can be washed at the same time, and meanwhile the process is repeated multiple times, so that the cleaning effect is greatly improved.

Owner:李小燕

Making method of poultry meat products

The invention relates to a making method of poultry meat products. The specific steps of the making method comprise the operation procedures of treating living chickens within a definite time and at definite temperature, cleaning the treated chickens, draining the cleaned chickens, applying condiments, pickling the chickens applied with the condiments, trimming the pickled chickens, air-drying the trimmed chickens, and vacuum-packing the air-dried chickens. According to the making method of the poultry meat products disclosed by the invention, the making time is short, industrialized production can be completely realized, natural sunshine can be fully utilized for drying the chickens, a drying link in a conventional technology is effectively avoided, and further the production cost is reduced; besides, the made air-dried chickens are tender in meat quality, low in fat, unique in taste and delicious in taste.

Owner:NANTONG YUTU GROUP

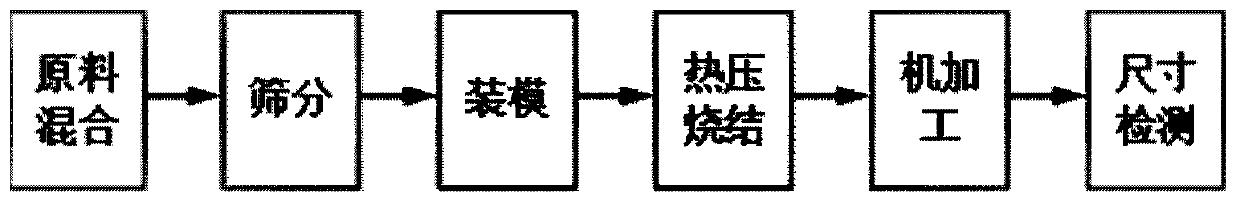

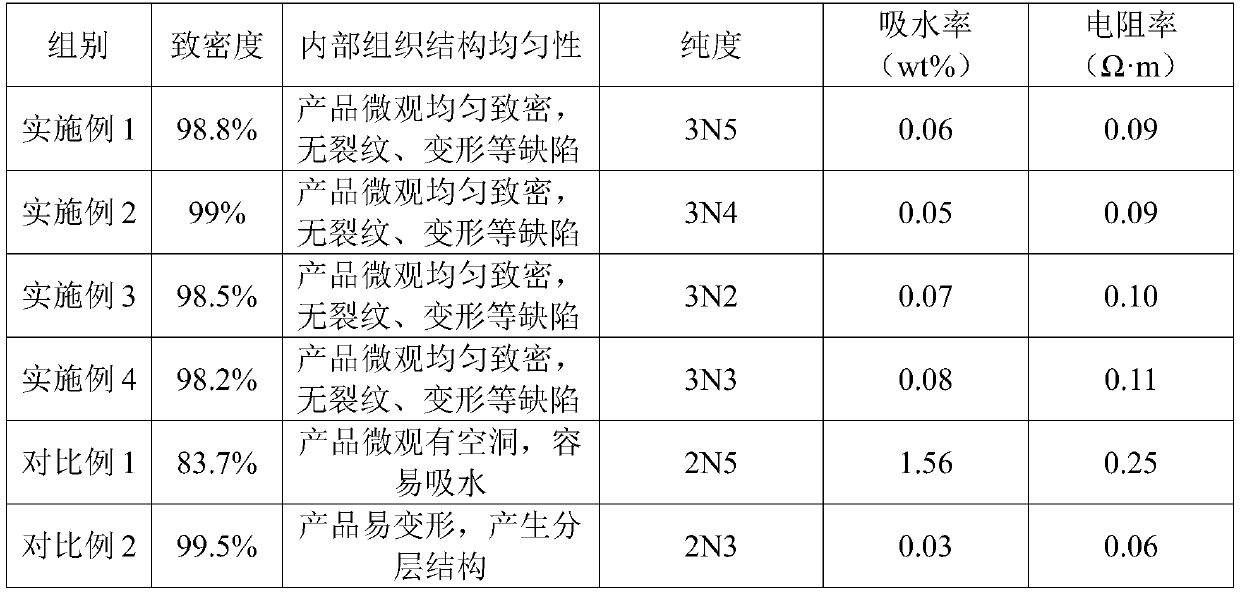

Carbon-silicon carbide ceramic sputtering target and preparation method thereof

ActiveCN111233480APrevent dryingAvoid breakingVacuum evaporation coatingSputtering coatingSilicon carbideHot press

The invention relates to a carbon-silicon carbide ceramic sputtering target and a preparation method thereof. The preparation method comprises the following steps: (1) mixing carbon powder, silicon carbide powder and a binder according to a ratio, and carrying out screening treatment; (2) filling a mold with the mixed powder screened in the step (1) and tamping by using a tool; (3) carrying out hot pressed sintering treatment on the mold tamped in the step (2) at 1850-2200 DEG C to obtain a carbon-silicon carbide ceramic sputtering target blank; and (4) machining the carbon-silicon carbide ceramic sputtering target blank obtained in the step (3) to obtain the carbon-silicon carbide ceramic sputtering target. The preparation method is simple in technological process and short in productionperiod; and the prepared carbon-silicon carbide ceramic sputtering target has the density of more than or equal to 98%, the purity of more than or equal to 3N, the water absorption rate of less than 0.1% and the resistivity of less than 0.15 ohm.m, meets the requirements of the carbon-silicon carbide ceramic sputtering target on the density and the formability, and provides more excellent performance guarantee for subsequent sputtering use.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

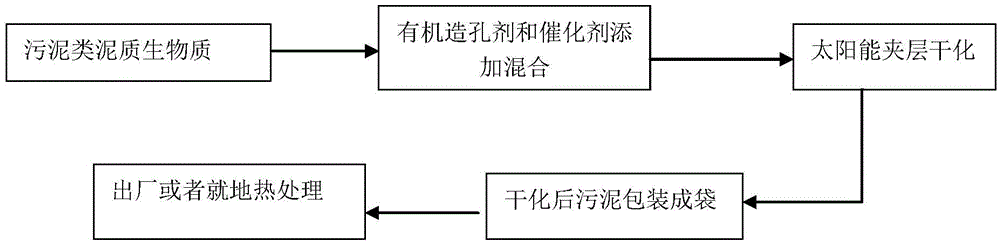

Method for realizing anti-shrinkage recarburization sludge drying

ActiveCN105481221AHigh carbon contentGood yieldSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentSludgePolyvinyl alcohol

A method for realizing anti-shrinkage recarburization sludge drying is characterized in that an organic pore-forming agent and a catalyst are added into a sludge dry basis subjected to centrifugal dewatering to be uniformly mixed, distributing is carried out in a solar power interlayer drying system, and through the organic combination of the synergistic effect of framework construction and the pore-forming agent and solar power drying, a low-shrinkage recarburization function on the basis of realizing quick sludge drying is realized, wherein the organic pore-forming agent comprises 50-80% of a pore-forming agent and 20-50% of an aggregate according to the mass ratio; the pore-forming agent is prepared by mixing one or more of natural fibers such as starch, saw dust, sawdust and crop stalks according to an arbitrary ratio; the aggregate is prepared by mixing one or more of high-molecular polymers such as polyvinyl chloride, polystyrene, polyvinyl alcohol and resin according to an arbitrary ratio; the catalyst is the KOH solution with the concentration of greater than or equal to 0.4 mol / L, and the mass ratio of the catalyst to the organic pore-forming agent is 1:1, and the adding amount of the organic pore-forming agent is 5-30% of that of the sludge dry basis. According to the method, the dried sludge size is reduced, and when the sludge moisture content is less than 20%, the dried sludge size is reduced to 16.4-52.2% of the original size of sludge; after pyrolysis, the carbon recovery rate is increased by 20-30%, and BET is increased by 40-120%.

Owner:SHANGHAI JIAO TONG UNIV

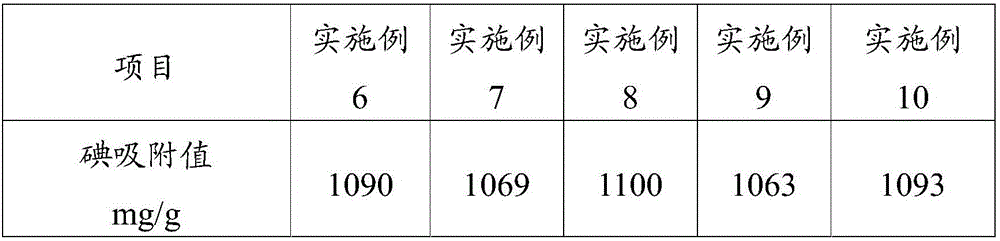

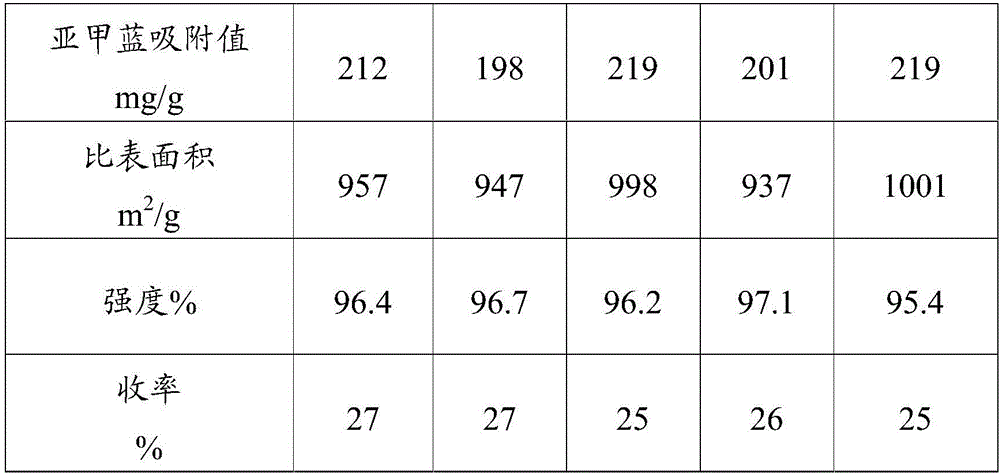

Method for preparing active carbon with developed mesopores by using coal

InactiveCN108439399ASolve the problem of low mesoporosityHigh porosityCarbon compoundsActivated carbonNitrate

The invention discloses a method for preparing active carbon with developed mesopores by using coal. The method comprises: preparing coal by using weakly caking coal and gas coal as raw materials, andcrushing to obtain raw material coal; carrying out briquetting molding on the raw material coal, and granulating to obtain coal particles; carrying out oxidization treatment and carbonization treatment on the coal particles to obtain a carbonized material; and immersing the carbonized material by using a nitrate solution, drying the immersed carbonized material, and carrying out activation treatment to obtain active carbon. According to the present invention, the active carbon is prepared by using a certain amount of the weakly caking coal and the gas coal, such that the properties and the matching effect of the raw materials are well combined; compared to the traditional coal-based briquetting active carbon, the active carbon product of the present invention has the effectively-improvedmesoporosity under the action of the immersing with the nitrate; and with the method, the problem that the mesoporosity is low due to the complete application of coal as the raw material in the production of the traditional coal-based briquetting active carbon is solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

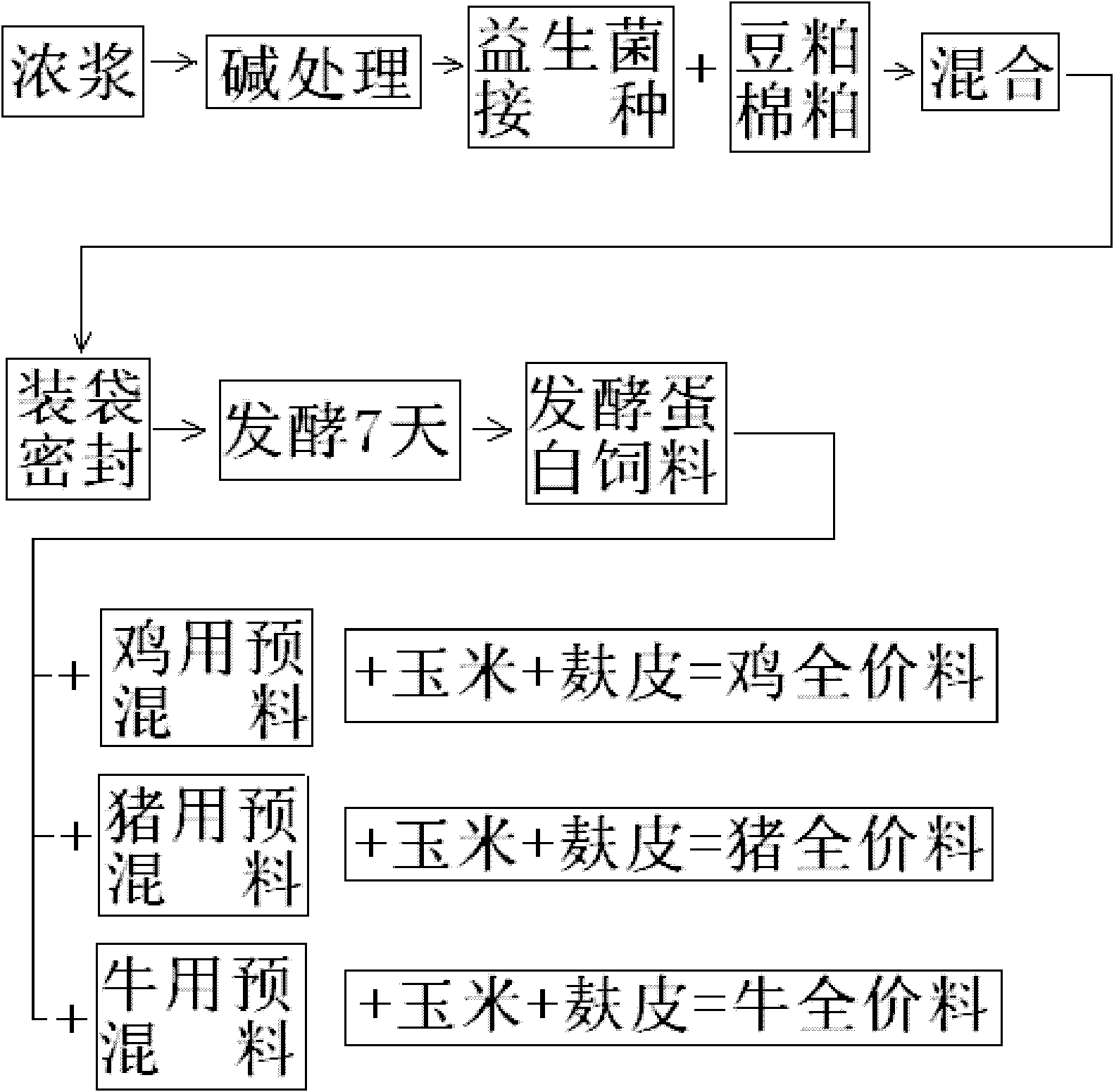

Technology for preparing fermented protein concentrated feed from dense slurry

InactiveCN102726598APrevent dryingSave on drying costsFood processingAnimal feeding stuffCalcium hydroxideSlurry

The invention discloses a technology for preparing fermented protein concentrated feed from dense slurry and relates to a technology for producing feed. The technology comprises the following steps of 1), a dense slurry alkali-treatment process comprising adding an alkali and calcium hydrate into dense slurry so that a pH value is in a range of 6.8 to 7.2, 2), a probiotic addition process comprising controlling a temperature of dense slurry in a range of 37 to 41 DEG C, adding probiotics into the dense slurry obtained by the step 1 with stirring and with determining a pH value of the dense slurry, and when the pH value is in a range of 5.8 to 6.2, stopping probiotic addition, 3) a dense slurry-dry material mixing process comprising adding a mixed fry material of soybean meal and cottonseed meal into the dense slurry obtained by the step 2, and stirring, wherein a weight ratio of the dense slurry to the mixed fry material is 1: (1-1.5), and 4) a bagging and fermentation process comprising putting a mixed wet material obtained by the step 3 into plastic bags, carrying out heat-sealing packaging and carrying out fermentation at a normal temperature for 7 to 10 days. The technology solves the problems that the existing technology for producing dense slurry feed by a drying method has a high cost and can damage nutrients of feed.

Owner:LUOYANG MUYUAN AUTOMATIC CONTROL EQUIP

Production process of Congou black tea

InactiveCN105285191AWither evenlyPrevent dryingPre-extraction tea treatmentResource utilizationBlack tea

The invention provides a production process of congou black tea. The production process comprises the process of selecting tea leaves, withering, rocking green, rolling, fermenting and drying. In summer and autumn, tea contains high tea polyphenol so as to be not suitable for preparing green tea, but through the production process of the Congou black tea, fresh tea leaves are sufficiently fermented within short time, and the bitterness of the tea leaves is changed, so that the prepared black tea has intensive tea aroma, thick taste, bright color, and sweet aftertaste. According to the production process of congou black tea, the traditional production mode that the tea leaves in summer and autumn only can be used for preparing green tea can be broken through, and the utilization ratio of the fresh leaf resources can be increased, so that the purpose of increasing income of tea farmers can be achieved.

Owner:李红权

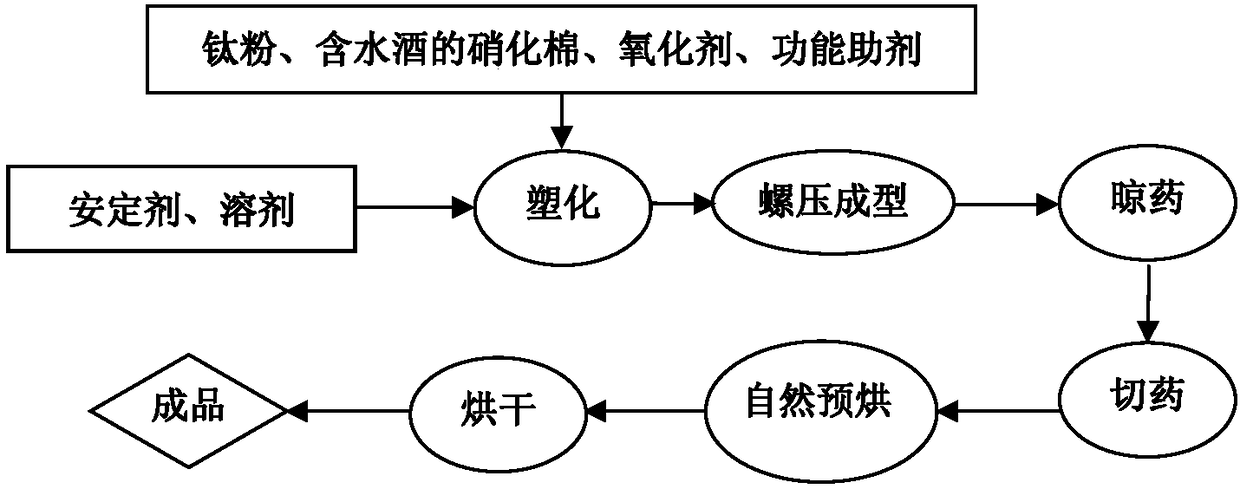

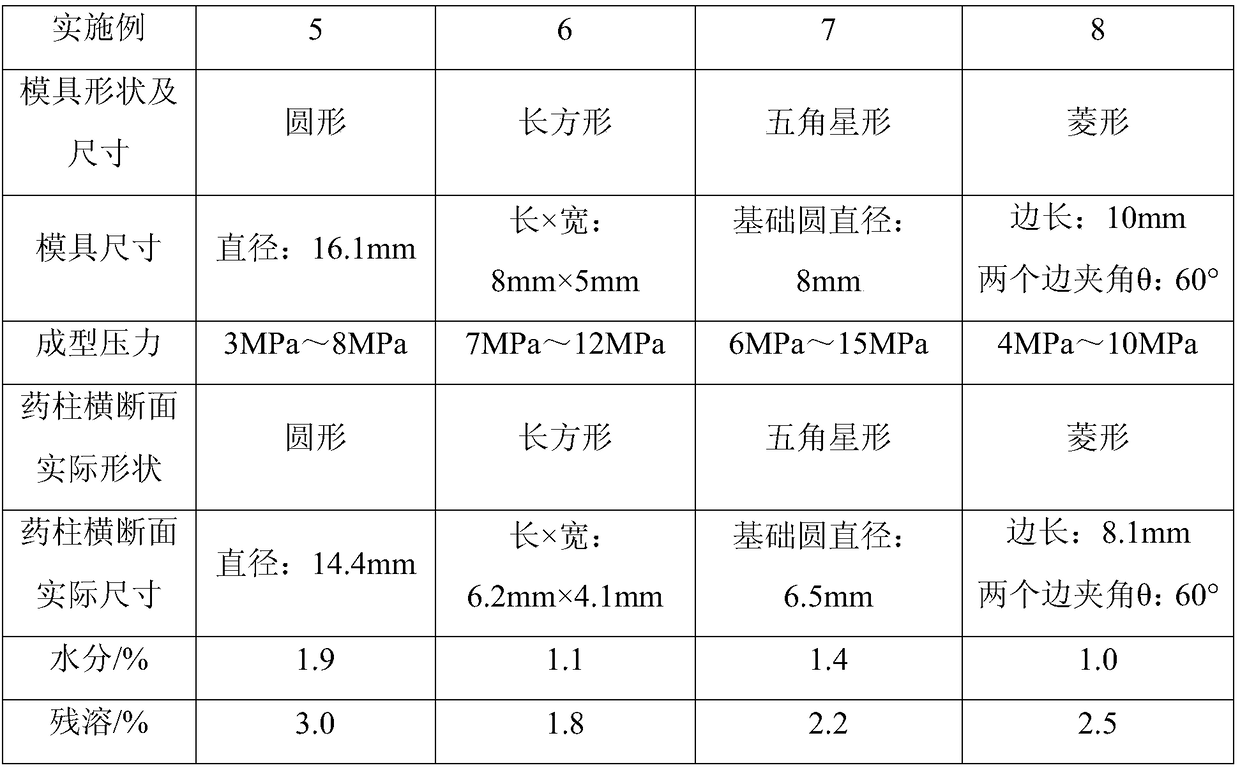

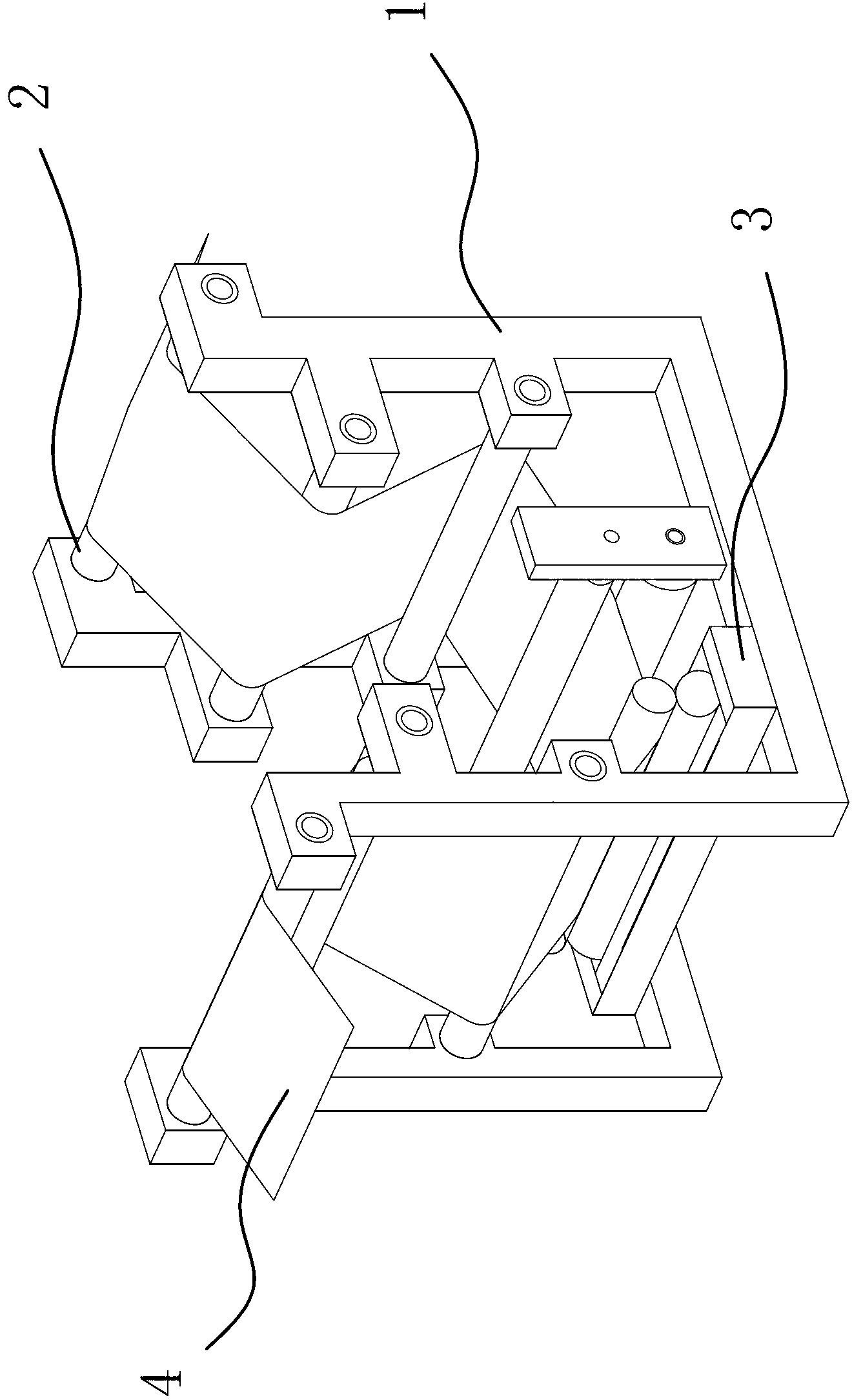

Cold light firework powder column and screw compression forming process thereof

InactiveCN108117468APrevent dryingAvoid dry mixExplosive working-up apparatusFireworksCompression moldingCombustion

The invention discloses a cold light firework powder column and a screw compression forming process thereof, belonging to the field of fireworks and crackers. The screw compression forming process ofthe cold light firework powder column has the beneficial effects that the raw materials are easily available, and the production is relatively safe. The process comprises the following steps: plastifying nitrocotton containing water wine, an oxidant, titanium powder and a functional aid by virtue of a solvent dissolved with a stabilizing agent, so as to obtain a plastified material; compacting theplastified material by virtue of a screw compressor, carrying out compression molding by virtue of a mold, and carrying out airing, cutting and drying, so as to obtain the finished cold light firework powder column. The nitrocotton containing water wine is directly utilized as the raw material, and the proportion of the materials in the plastifying process is adjusted, so that the nitrocotton containing water wine and the other raw materials can be relatively uniformly mixed, the plastified material is relatively compact, and the production process is safe and reliable; and the combustion speed of the prepared powder column is controllable, and the product quality is stable.

Owner:LUZHOU NORTH CHEM IND

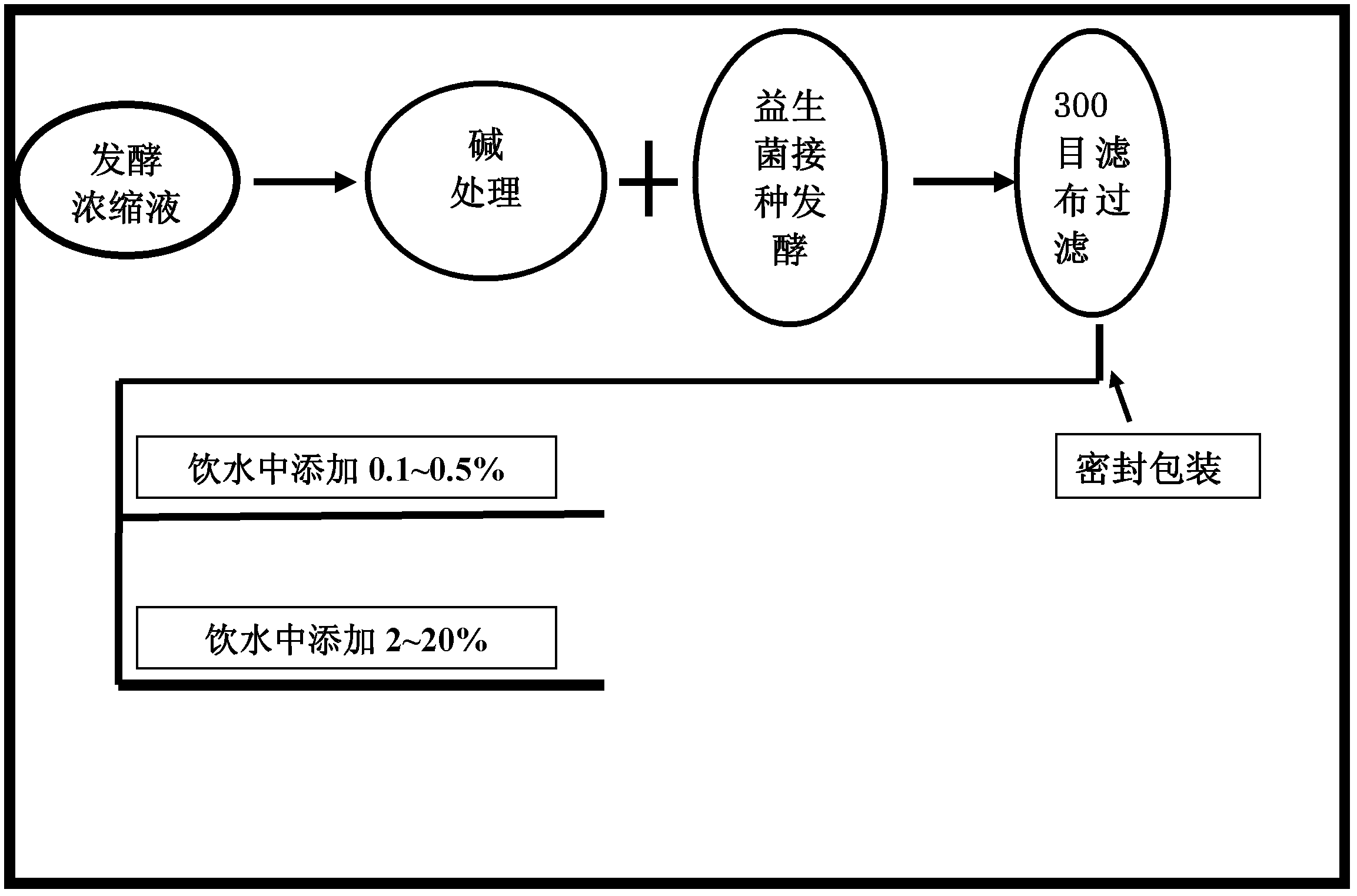

Preparation process and application method of liquid drinking-water agent prepared from concentrated fermentation waste liquid

InactiveCN103156062ASave on drying costsImprove feeding effectAnimal feeding stuffChemistryCalcium hydroxide

The invention relates to a preparation process and an application method of a liquid drinking-water agent prepared from concentrated fermentation waste liquid. The method comprises the steps that: (1) the concentrated fermentation waste liquid is subjected to alkali treatment, wherein the concentrated fermentation waste liquid purchased from a bio-fermentation plant is placed in a vessel; alkali and calcium hydroxide are added; and the pH value of the liquid is regulated to 5.5-7.2; (2) composite probiotics are added, wherein the temperature in the liquid is controlled at 37-41 DEG C, a composite probiotic strain is added into the liquid, and fermentation is carried out; liquid pH value changes are determined; when the pH value is approximately 5, the fermentation is stopped; (3) filtration is carried out by using a 300-mesh filtering cloth; and (4) the liquid is packaged into a vessel. 0.1-0.5% or 2-20% of the liquid drinking-water agent is added into drinking-water. With the invention, problems such as high cost and reduced feedstuff nutritive value of concentrated fermentation waste liquid feedstuff bake-drying treatment of prior arts are solved.

Owner:LUOYANG MUYUAN AUTOMATIC CONTROL EQUIP

Binder-free high-strength fine coal briquetting method

The invention discloses a high-strength fine coal briquetting method. The briquetting method comprises the following steps: a. pulverizing feed coal to obtain pulverized coal, wherein the average grain size of the pulverized coal is not less than 20mu m, the content of the pulverized coal with the grain size not more than 80mu m is not less than 90wt%, and the content of the pulverized coal with the grain size of 40-80mu m is not less than 10wt%; b. feeding the pulverized coal obtained in the step a into a feeding bin of briquetting equipment, and degassing the material in the feeding bin; c. adjusting the temperature of the material in the feeding bin to be 50-100 DEG C, and adjusting the moisture content of the material to be 2-8wt%; and d. feeding the material in the feeding bin into the briquetting equipment to be briquetted to obtain briquette. The briquetting method has the advantages that the briquetting method has wide adaptability to coal types; the feed coal is unnecessary to be pulverized into undersize grains; and the briquette product with strength more than 89% can be also prepared without adopting any binder even if the non-binding coal with the greatest briquetting difficulty is used as the feed coal.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

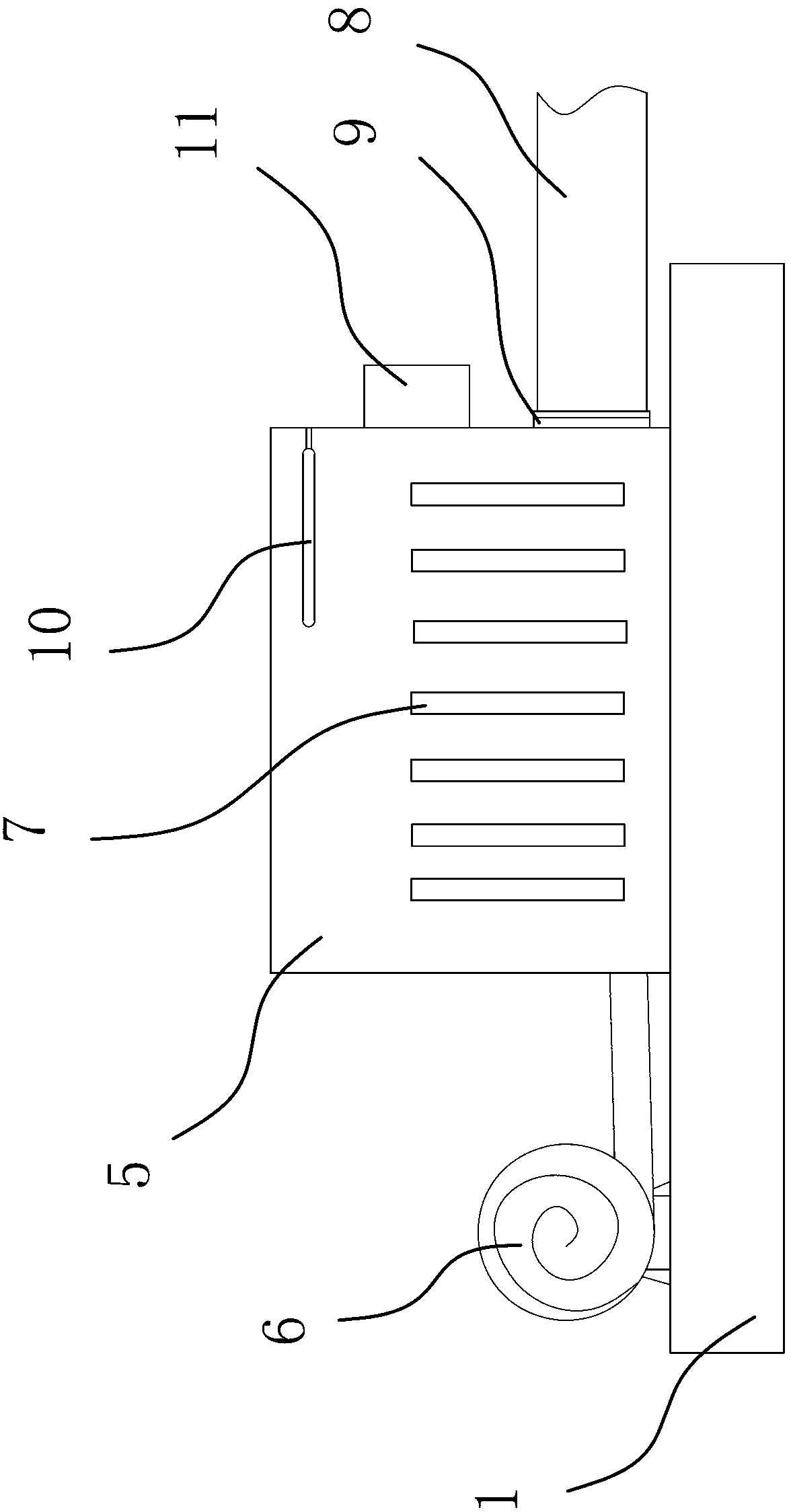

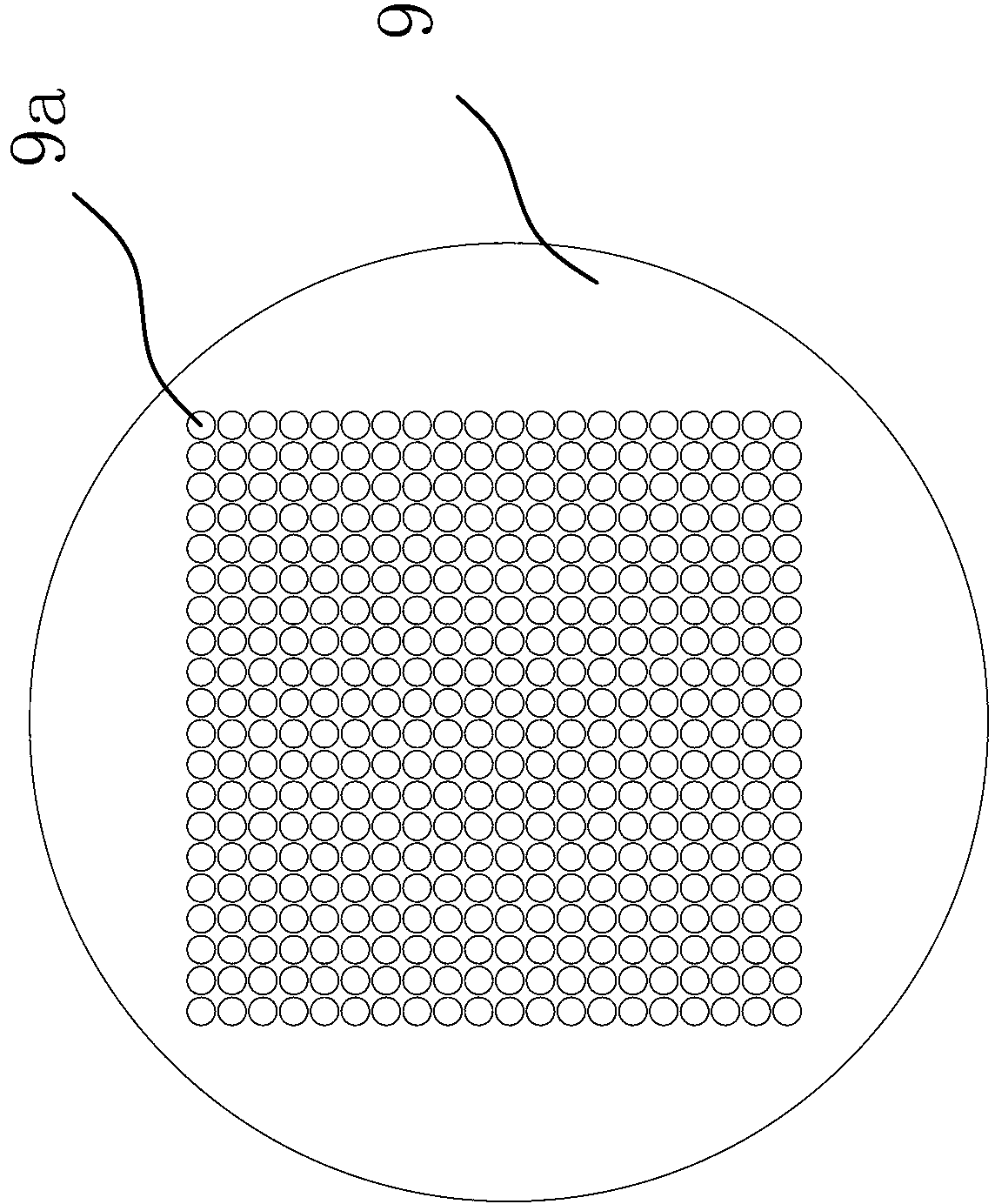

Drying device of packaging bag printing machine

InactiveCN103223769APrevent dryingImprove drying effectPrinting press partsEngineeringPrinting press

The invention provides a drying device of a packaging bag printing machine, and belongs to the technical field of printing. The technical problems such as instable drying and poor drying effect of the existing drying device of the printing machine are solved. According to the drying device of the packaging bag printing machine, the printing machine comprises a rack, as well as a plurality of guide rollers and a printing box which are arranged on the rack; the drying device comprises a heating box in which a cavity is formed, as well as a fan which is arranged at one side of the heating box; both the heating box and the fan are fixed to the rack; the heating box is internally provided with a plurality of electrical heating fins; an air outlet pipe of the fan is communicated with the cavity; an air outlet is formed in the other side of the heating box; the air outlet leads to a printed surface of the packaging bag through an air delivery pipe; and a clapboard in which a plurality of through holes are formed is arranged on the air outlet. The drying device is capable of effectively preventing hot air and greatly drying the printed patterns on the packaging bag, and is simple in structure and good in drying effect.

Owner:HAINING JINYUE PRINTING

Efficient and quality-improved spinning process with recovered fiber of polyester waste cloth

PendingCN111334887APrevent dryingImprove qualitySpinning solution de-aeratingFilament forming substance formingPolyesterFiber

The invention relates to an efficient and quality-improved spinning process with recovered fiber of polyester waste cloth. The process comprises the following steps of 1, picking or sorting polyesterwaste cloth; 2, tearing up; 3, dispensing; 4, buffering materials; 5, dense processing; 6, melting; 7, carrying out primary filtration; 8, homogenized thickening; 9, carrying out fine filtration; 10,spinning; 11, cooling forming; 12, oiling pumping; 13, multichannel drafting; 14, crimping; 15, forming; 16, cutting; and 17, packing. The process provided by the invention has higher process efficiency. By using the process provided by the invention, not only the waste polyester fabric before spinning can be prevented from granule making and drying, but also the final quality can be improved. Thewhole process has controllable product viscosity and can save costs.

Owner:江苏志成新材料科技有限公司

Preparing method for coal-based briquette active carbon without binding agent

ActiveCN105800610AWide adaptabilityHigh strengthCarbon compoundsShaping pressActivated carbonBriquette

The invention discloses a preparing method for coal-based briquette active carbon without a binding agent.The forming process comprises the steps that raw material coal is prepared into shaped coal with a shaping process; the obtained shaped coal is broken and granulated, and then carbonization treatment and activation treatment are carried out to prepare active carbon.In the preparing method, the raw material coat shaping process is high in coal variety adaptability, a shaped coal product with the strength higher than 90% can also be prepared even with non-caking coal with the maximum shaping difficulty as the raw material coal under the situation that no binding agent needs to be adopted, and thus the quality such as the strength of the active carbon can be easily improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

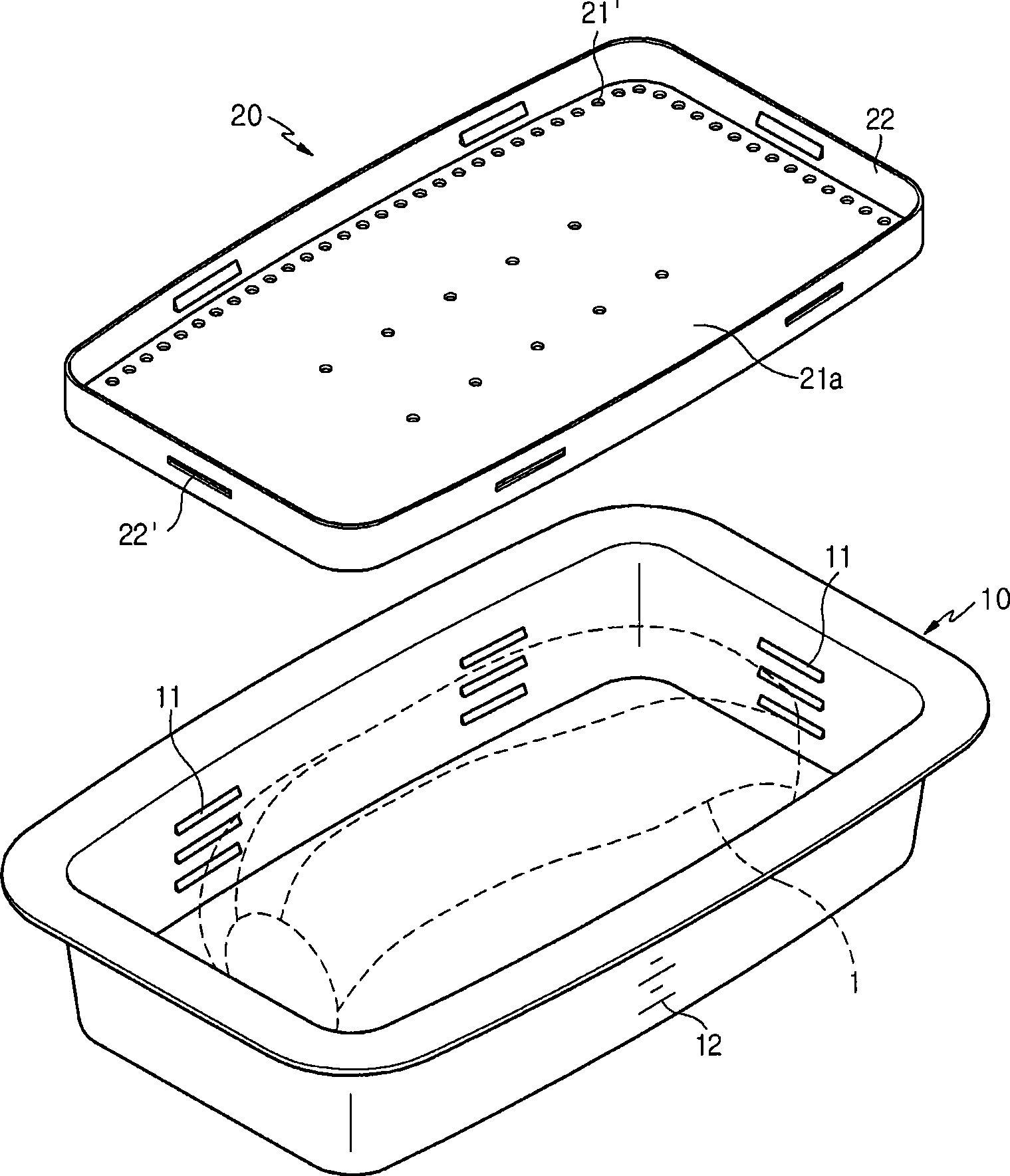

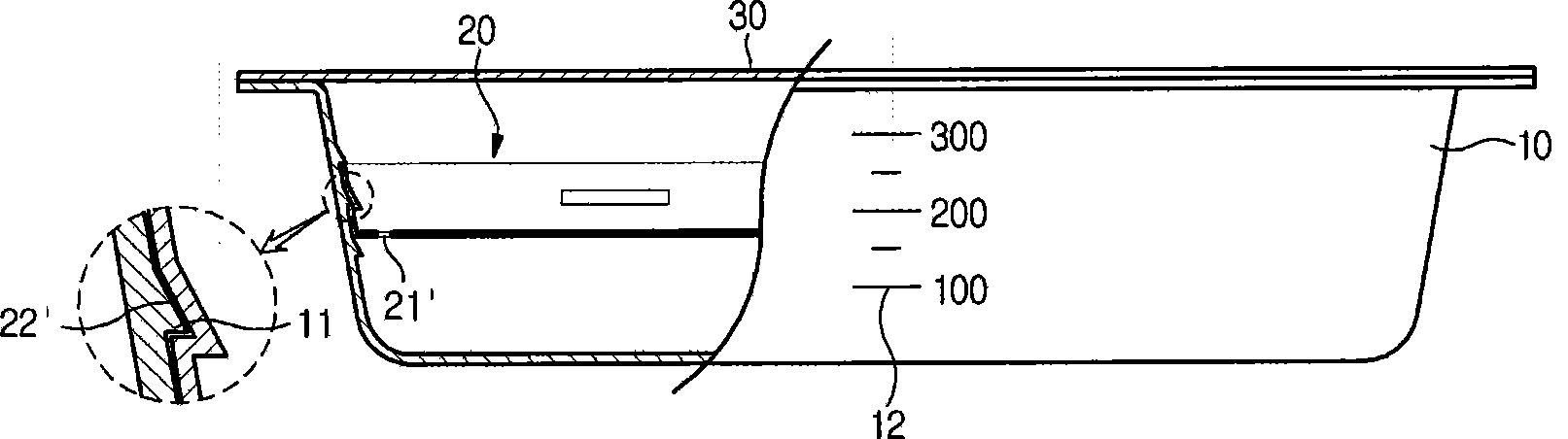

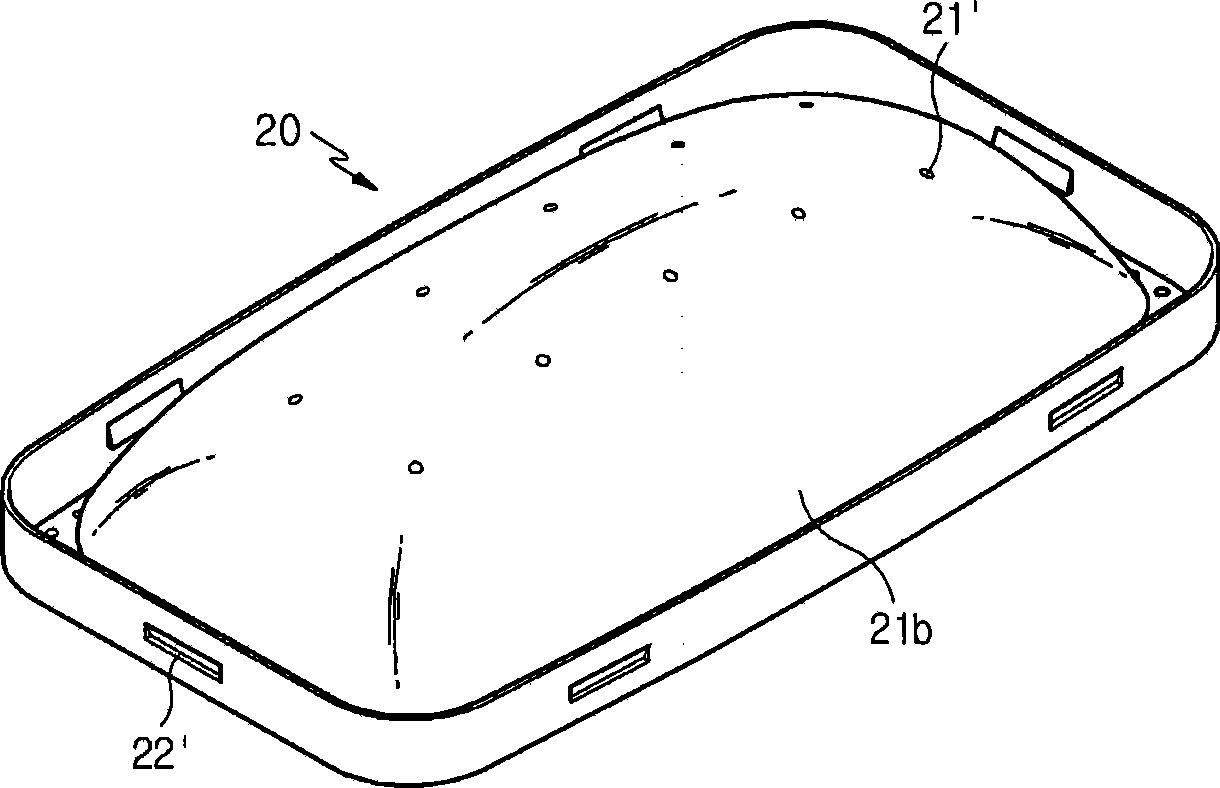

Kimchi container having improved fermentation and ripening function, and kimchi ripening method using the same

InactiveCN101502312AShipping fresh and deliciousReduce oxidationKitchen equipmentFruits/vegetable preservation using acidsRipeningEngineering

Disclosed are a kimchi container with an improved fermentation and ripening function and a kimchi ripening method. The container includes a body and holding unit. The body accommodates kimchi, and includes locking protrusions normally projected from four sides of an inner wall and an opened side to be vacuum-sealed after accommodation of the kimchi. The holding unit includes a contact part having a cross-sectional area corresponding to that of the inner bottom of the body, and through-holes formed in the circumference and at a central region of the upper side. The holding unit further includes locking grooves, to be fitted onto corresponding locking protrusions of the body, formed at an outer wall upwardly extended from and integrally formed with the rim of the contact part. Thereby, tilting of the kimchi container causes the kimchi juice to circulate freely through the holding unit and to return to the kimchi.

Owner:チャンチュンドンワンチョクバルカンパニーリミテッド

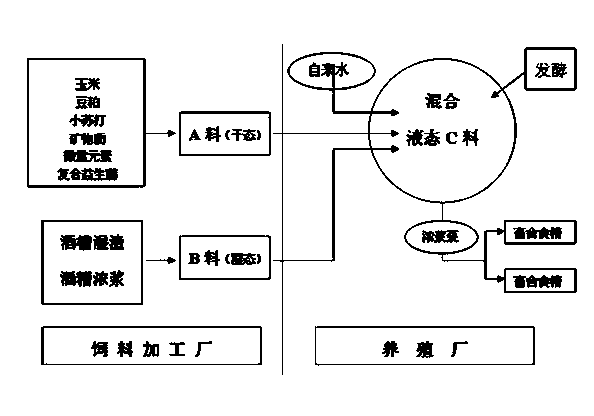

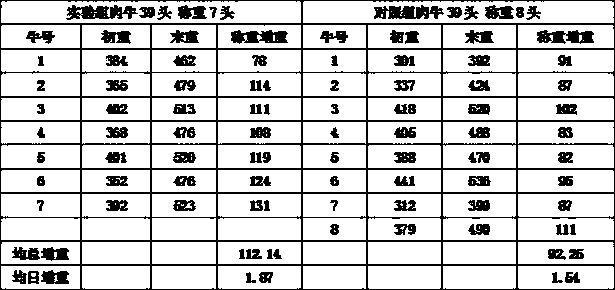

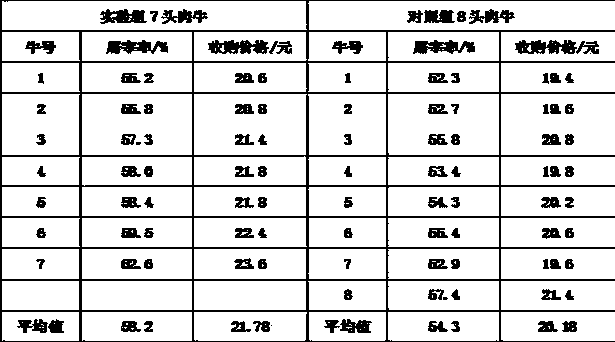

Wet fermentation protein feed for efficient fattening process of beef cattle

InactiveCN103766618ANutritional value well preservedImprove feeding effectFood processingAnimal feeding stuffGrass mixtureMixed feed

The invention relates to a wet fermentation protein feed for an efficient fattening process of beef cattle, and includes a production process of the wet fermentation protein feed and a usage method of the feed in efficient fattening of beef cattle. The production process of the wet fermentation protein feed is as below: crushing and mixing corn, soybean meal, baking soda, minerals, trace elements and compound probiotics according to a certain proportion, and filling the materials into bags; mixing wet slag of distillers' grains and dense slurry of distillers' grains according to a certain proportion and sealing for preservation, wherein the preservation period reaches more than 6 months; mixing the above two materials according to the mass ratio of 1:3-5, adding water, adjusting the pH value of the mixed feed to 6-7, placing for fermentation for 4-8 h to obtain the wet fermentation protein feed. Each beef cattle is fed with 8-12 Kg of the wet fermentation protein feed per day in 2 or 3 times; for each feeding, grass is added first, and then the mixed wet fermentation protein feed is poured on the grass; and by eating the feed and grass mixture, the beef cattle can gain weight by 1.81-1.87 Kg / D.

Owner:LUOYANG MUYUAN AUTOMATIC CONTROL EQUIP

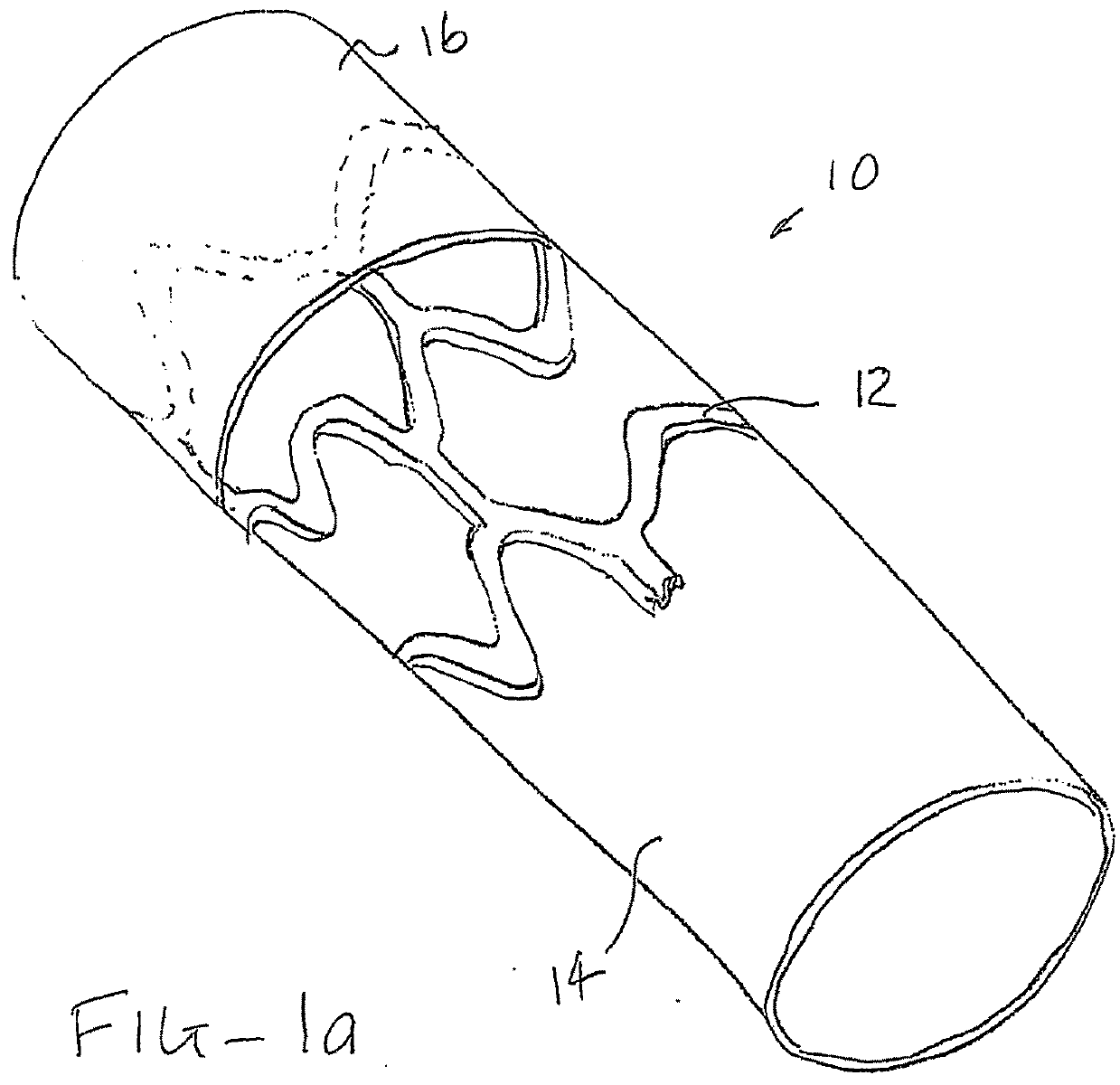

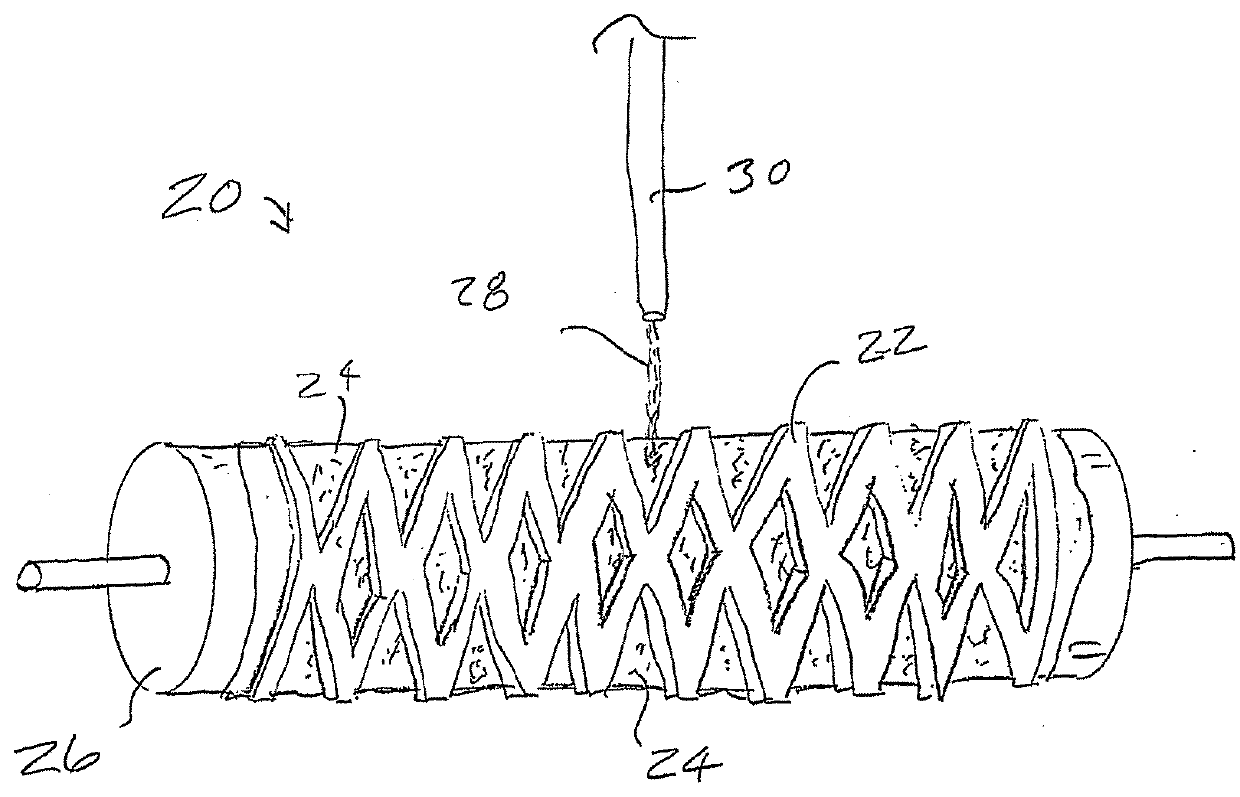

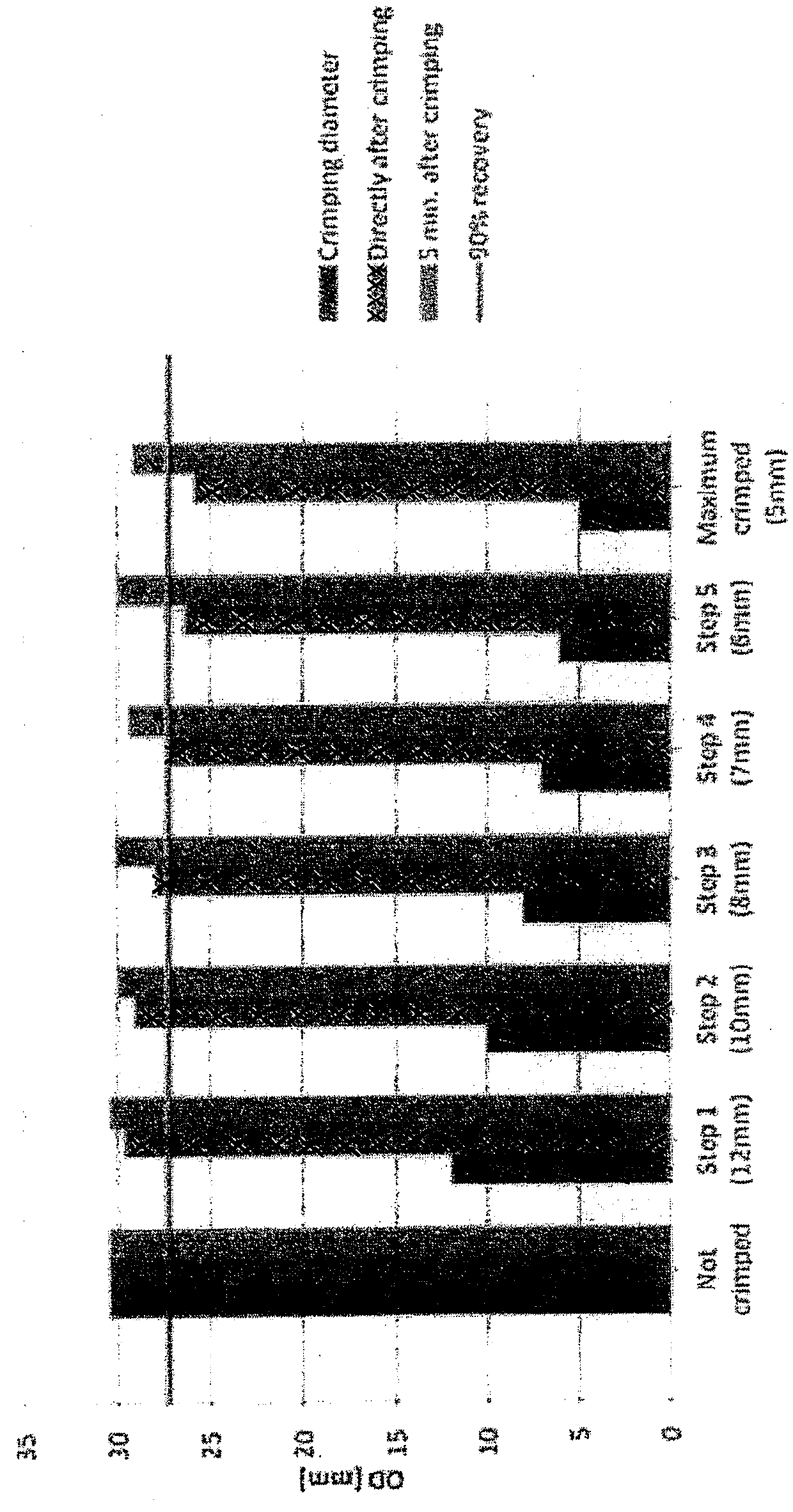

Methods for electrospin coating and laminating of endoluminal prostheses

ActiveUS20180274131A1Inhibit further dilationAvoid breakingStentsFilament/thread formingFiberAdhesive

Endoluminal and other as implantable prostheses are fabricated in electrospinning apparatus including a target and an applicator. A solution comprising a polymer and a solvent is directed to the target with a first electrical potential between the target and the applicator to produce a first set of fibers. The same or another solution is continued to be delivered through the applicator onto the target while applying a second electrical potential to produce a second set of fibers having a second solvent fraction, and the same or different solution may be delivered while applying a third potential difference to produce a laminated structure having at least three layers. By properly controlling the electrical potentials and solvent fractions, an adhesive layer can be formed to serve a glue or adhesive between the inner and outer layers, and a stent or other scaffold may be positioned between the inner and outer layers to form a covered stent or graft.

Owner:XELTIS AG

Illumination device

InactiveCN101865371AGuaranteed antipyretic functionAutomatically adjust the degree of phase changePoint-like light sourceSemiconductor/solid-state device detailsPhase changeLoop device

The invention discloses an illumination device, which comprises an optical part, an electric part, and a radiating part which is arranged between the optical part and the electric part. The radiating part comprises a radiator and a loop device, wherein the radiator comprises a hollow radiating base and a plurality of fins which are thermally connected with an outer surface of the radiating base; and the loop device is arranged inside the radiating base, so that the radiating base forms an outer wall of the loop device. The loop device also comprises a cylindrical part, a lower cover, and an upper cover, wherein the cylindrical part is arranged inside the radiating base and is provided with at least one axial through hole; the lower cover is made of a material with good thermal conductivity, and the outer surface of the lower cover is thermally connected with a light source; the lower cover and the upper cover seal two ends of the radiating base respectively, so that an evaporating part is formed between the lower end of the cylindrical part and the lower cover; a condensation part is formed between an outer surface of the cylindrical part and an inner surface of the radiating base; and the through hole of the cylindrical part forms at least one steam channel which is communicated with the evaporating part and the condensation part. By means of the phase change of working fluidin the loop device, the released heat of the light source is continuously removed at high radiating efficiency when the light source illuminates.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Ceramic blank drying device for ceramic processing

ActiveCN108870927AEasy to dryFully dryDrying gas arrangementsDrying chambers/containersMetallurgyElectric heating

The invention provides a ceramic blank drying device for ceramic processing, and relates to the field of ceramic processing. The ceramic blank drying device for ceramic processing comprises a drying bucket and a ceramic blank body, and a drying device body is connected to the middle of the left side of the drying bucket and comprises a hot air box; the right side of the hot air box is welded to the left side of the drying bucket, electric heating wires are connected to the inner wall of the hot air box, the top and the bottom of the right side of the hot air box are both communicated with a hot air guide pipe, and the right sides of the hot air guide pipes penetrate through the left side of the drying bucket and extends into an inner cavity of the drying bucket. When the ceramic blank drying device is in use, through a balance weight wheel, trapezoidal blocks are pressed downwards in sequence to pull a lifting rod to move downwards, and thus a bearing plate moves downwards, so that thebearing plate is separated from the ceramic blank body, and the bottom of the ceramic blank body can be conveniently dried; then the ceramic blank drying device can sufficiently dry a ceramic blank conveniently and quickly, and the finished product rate of ceramic processing is greatly increased.

Owner:梅州市溪山陶瓷有限公司

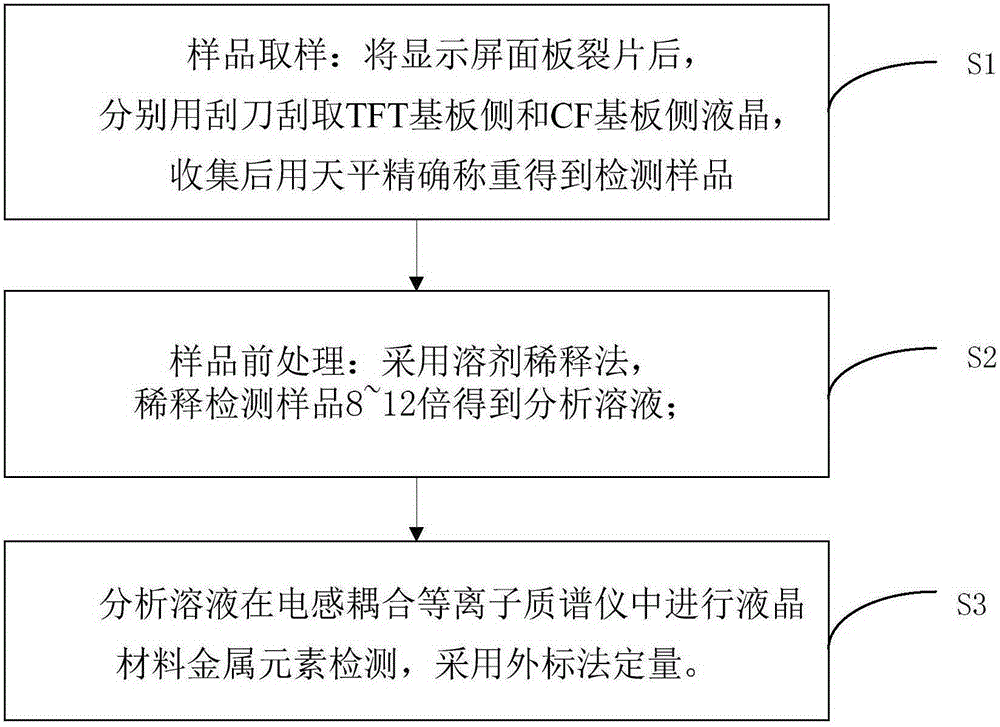

Detection method for metallic element in liquid crystal material

ActiveCN105158323AGood repeatabilityImprove sampling efficiencyWithdrawing sample devicesPreparing sample for investigationSolventThin-film-transistor liquid-crystal display

The invention discloses a detection method for a metallic element in a liquid crystal material. The method comprises the following steps: sampling: a step of cracking a thin film transistor liquid crystal display screen panel into pieces, scraping liquid crystal located at a TFT substrate side and liquid crystal located at a CF substrate side with a scraper, collecting the liquid crystal and accurately weighing the liquid crystal with a balance so as to obtain a detection sample; pretreatment of the sample: a step of diluting the detection sample to 8 to 12 times by using a solvent dilution method so as to obtain an analysis solution; and detection: a step of sending the analysis solution into an inductive coupling plasma mass spectrometer to detect the metallic element in the liquid crystal material and carrying out quantification by using an external standard method. The detection method for the metallic element in the liquid crystal material can rapidly and accurately analyze the concentration of the metallic element in the liquid crystal material.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

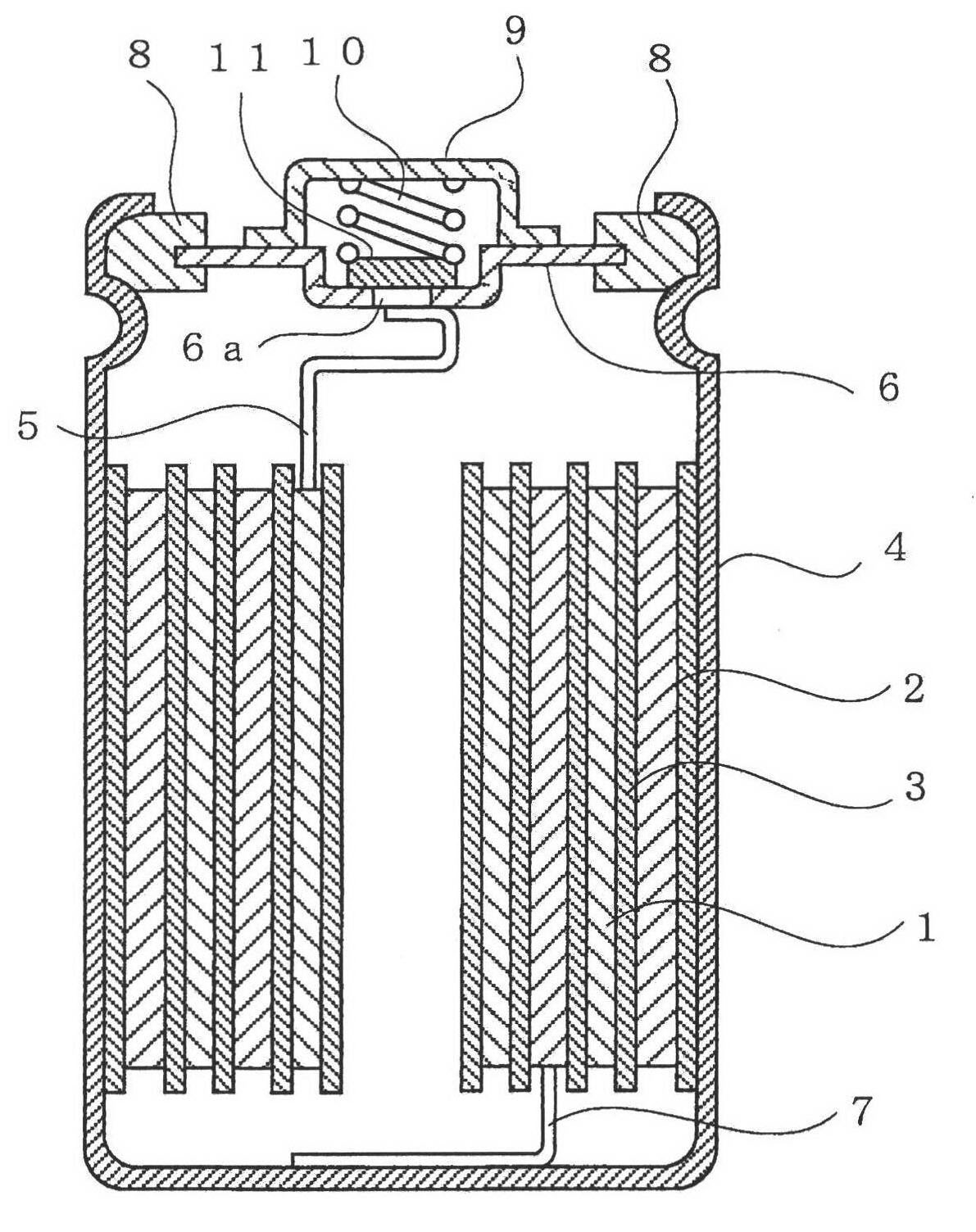

Hydrogen-absorbing alloy, fabrication method thereof and alkaline storage battery

InactiveCN102104145AIncrease capacityHigh hydrogen storage capacityAlkaline accumulator electrodesNickel accumulatorsRare-earth elementCrystal structure

An alkaline storage battery has a negative electrode using a hydrogen-absorbing alloy represented by a general formula Ln1-xMgxNiyAz wherein Ln is at least one element selected from rare-earth elements including Y, Ca, Zr, and Ti, A is at least one element selected from Co, Fe, Mn, V, Cr, Nb, Al, Ga, Zn, Sn, Cu, Si, P and B, and 0.15<=x<=0.30, 0<z<=1.5, and 2.8<=y+z<=4.0 are satisfied. The hydrogen-absorbing alloy has a hexagonal system crystal structure or a rhombohedral system crystal structure as its main phase and has a subphase of line which average number of not less than 50 nm in thickness existing in the range of 10 [mu]m10 [mu]m in the cross section of the main phase is 3 or less.

Owner:SANYO ELECTRIC CO LTD

Abalone processing method

InactiveCN105533494AAvoid deformationKeep the original tasteFood scienceCore temperatureWater temperature

The present invention provides a processing method of abalones with completely retained nutrient and chewiness during mouth entrance. The processing method comprises the following steps: the impurities of fresh abalones are removed, the treated abalones are put into water at a temperature of 40-50 DEG C to be heated for 7-8 min, and the heated abalones are taken out until the water temperature reaches 88-92 DEG C; the heated abalones are put into water at a temperature of 0-5 DEG C to be cooled for 10-15 min until the core temperature of the abalones drops into below 12 DEG C; the cooled abalones are gutted and during the gutting process the shells and the meat of the abalones always maintain unseparated; and the gutted abalones are marinated with spices for 35-45 h at a pickling ambient temperature maintained at 0-5 DEG C to obtain the finished products of the abalones. The beneficial effects of the abalone processing method are as follows: the impurities of the fresh abalones are removed, the treated abalones are put into water at a temperature of 40-50 DEG C to be heated for 7-8 min until the water temperature reaches 88-92 DEG C, then the heated abalones are taken out and cooled, and the spices are added into the cooled abalones at a temperature of 0-5 DEG C to conduct pickling for 35-45 h, which can fully retain the nutrients of the fresh abalones. The obtained abalones are fresh and tender in meat quality and have chewiness once entering mouth.

Owner:福州日兴水产食品有限公司

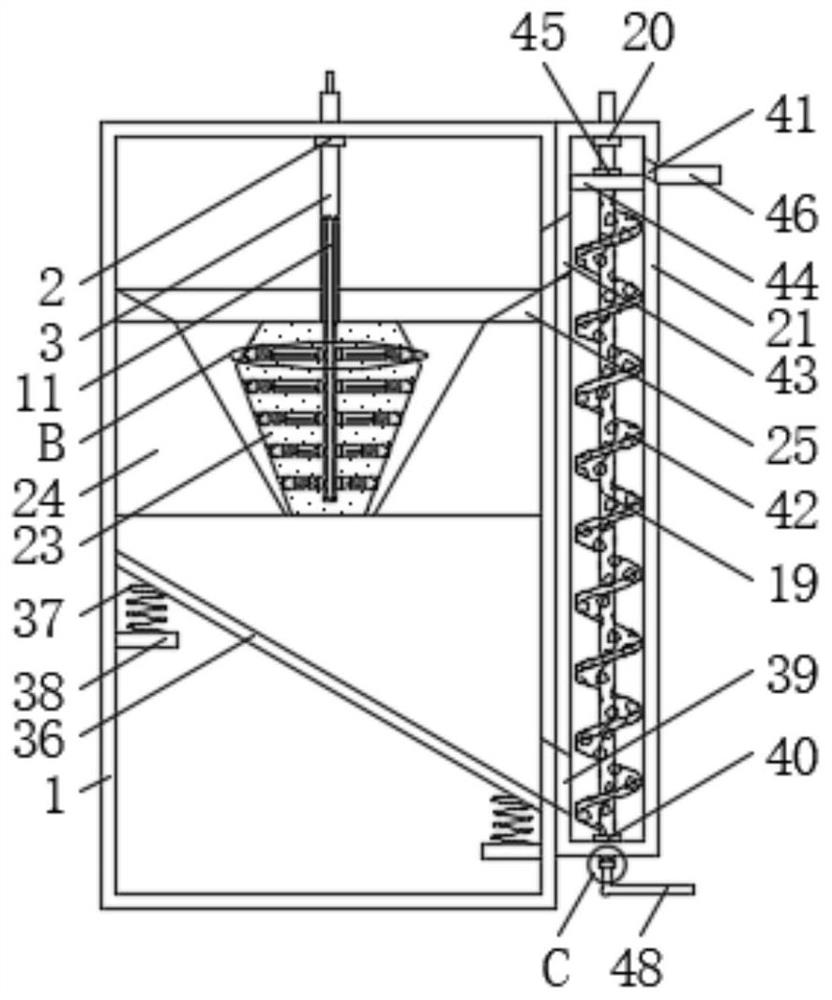

Cake smashing device with drying function for fertilizer processing and drying process

InactiveCN112473874AAvoid stickingReduce adhesionManure dryingDrying gas arrangementsAgricultural scienceSpiral blade

The invention discloses a cake smashing device with a drying function for fertilizer processing and a drying process, and relates to the field of fertilizer production. The cake smashing device comprises a smashing tank, a first bearing is clamped to the top of the smashing tank, a first connecting cylinder is sleeved with the first bearing, and an inserting cylinder is arranged in the first connecting cylinder in an inserted and sleeved mode. Through mutual cooperation of a torsion spring, the inserting cylinder, a first supporting spring, a second supporting spring, spiral blades, a filtering plate, an air pipe, a feeding hopper, a crushing base, a crushing roller, a knocking hammer, crushing teeth, a cam and an arc-shaped handle, the situation that the interior of caked fertilizer cannot be completely dried can be avoided, high-temperature airflow makes full contact with the fertilizer, a convenient, effective and comprehensive drying effect is achieved, fertilizer flows upwards andis stirred to be dried quickly and thoroughly, the fertilizer can be prevented from adhering to the inner wall of a lifting tank by enabling the fertilizer to flow upwards in the lifting tank, and the possibility of adhering is reduced.

Owner:嘉施利(荆州)化肥有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com