Patents

Literature

36results about How to "Wither evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automated Congou black tea production process

InactiveCN102422910APlay the role of dynamic fermentationUniform fermentationPre-extraction tea treatmentAutomatic controlManufacturing line

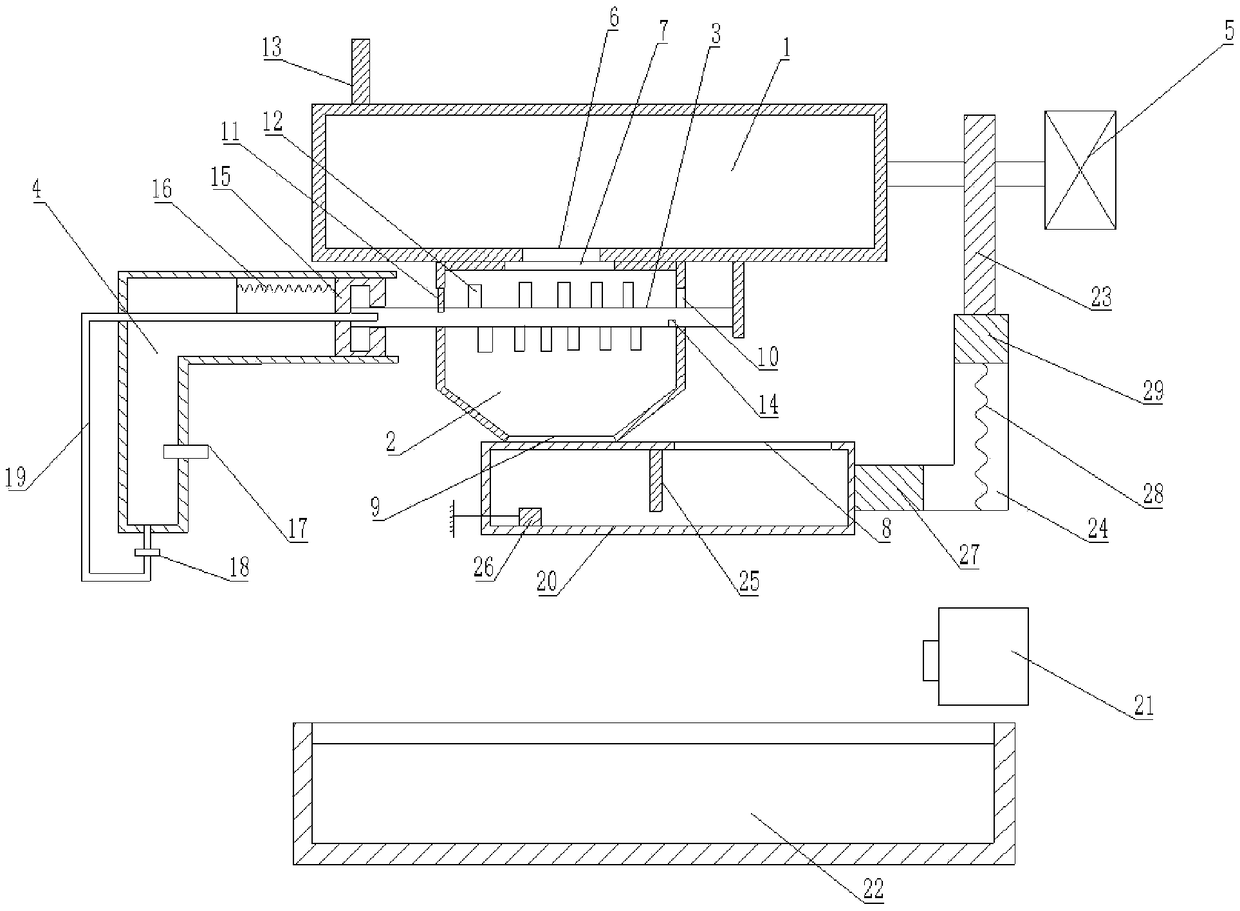

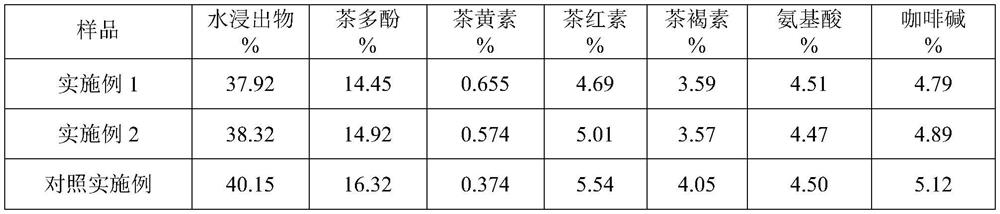

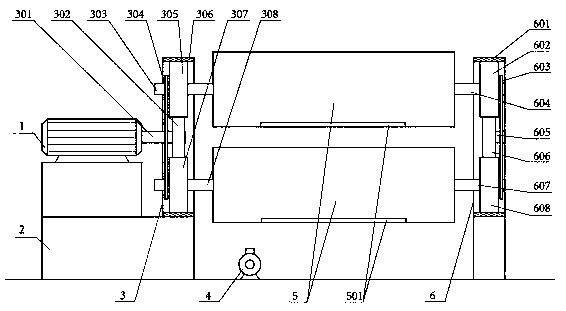

The invention discloses an automated Congou black tea production process, which includes a staged dynamic withering technique, a continuous and progressive pressure rolling technique, a high-speed rotational deblocking technique, a variable-temperature dynamic fermentation technique, a microwave tempering and dehydration technique and the like; the staged dynamic withering technique is carried out by four automatic vertical withering machines, the continuous and progressive pressure rolling technique is carried out by six 65 model automatic rolling machines, the high-speed rotational deblocking technique is carried out by a high-speed rotating roller type deblocking machine, the fermentation temperatures of different stages are controlled by an automatic fermentation machine in the variable-temperature dynamic fermentation technique, and on-line tempering is carried out by a microwave tempering machine in the microwave tempering and dehydration technique. The automatic vertical withering machines, the automatic rolling machines, the high-speed rotating roller type deblocking machine, the automatic fermentation machine, the microwave tempering machine, two automatic driers and other equipment are connected through a production line and adopt an automatic control system, consequently, Congou black tea processing realizes automated, continuous and clean production, the quality and sanitary quality of the tea are increased, and the working efficiency is remarkably increased.

Owner:TEA RES INST ANHUI ACAD OF AGRI SCI +1

Green tea processing process

The invention discloses a green tea processing process, belonging to the technical field of tea processing. The green tea processing process comprises the following steps: putting picked fresh leaves into a room to naturally wither, and then withering the leaves in hot air; repeatedly operating until moisture of the withered leaves is 45-55%; cooling by utilizing cold air until temperature of the withered leaves is 15-20 DEG C; transferring the cooled withered leaves into a roller water-removing machine for primary water-removing; taking out and spreading the leaves in a dustpan, and quickly transferring the leaves into a microwave water-removing machine for secondary water-removing 5-10 minutes latter; taking out and putting the water-removed tea leaves into a pan to stir-fry, and taking out the tea leaves after stir-frying for 3-5 minutes, wherein the temperature of the pan is 60-70 DEG C; rolling; drying; and putting the dried tea leaves into an aroma raising machine, and preparing a finished product 3-5 minutes later, wherein the temperature of the aroma raising machine is 90-100 DEG C. The green tea processing process is uniform and complete in water-removing, and the prepared green tea is strong in aroma.

Owner:务川自治县鑫隆缘茶业有限责任公司

Withering method for black tea

ActiveCN103636825AImprove efficacyAvoid tea withering too quicklyPre-extraction tea treatmentBudLeaf margin

The invention provides a withering method for black tea. The withering method specifically comprises the following steps: placing tea leaves into a withering machine and withering the tea leaves; paving the tea leaves according to the thickness of 40-60 centimeters; firstly, withering by cold air for 2-3 hours and withering by hot air for 1-2 hours, wherein the temperature of the hot air is 35-40 DEG C; stopping the machine for 1 hour; withering by the hot air for 1-2 hours, wherein the temperature of the hot air is 35-40 DEG C; and in the whole withering process, overturning the tea leaves for one time every 15 minutes. According to the withering method for the black tea, an existing withering machine is used for withering and is mechanically operated and the effect is improved; the specific withering time of the cold air and the hot air is set; firstly, the withering is carried out by the cold air and the tea leaves are prevented from being withered too fast, the withering time is short and the physicochemical changes are intense; bud tips and leaf margins are prevented from being withered, and are prevented from even becoming red; then the tea leaves are sufficiently withered by using hot air, and the hot air withering can effectively guarantee that the tea leaves are uniformly and sufficiently withered; meanwhile, the withering time is greatly shortened.

Owner:湖北龙王垭茶业有限公司

Black tea manufacturing method

The invention provides a black tea manufacturing method which comprises the following special steps: (1) wilting: tea leaves are put in a wilting machine for wilting, the spreading thickness of the tea leaves is 40-60 cm, the tea leaves are first wilted for 2-3 h by cold air and then wilted for 1-2 h by hot air, the hot air temperature is 35-40 DEG C, the wilting machine is stopped for 1 h, the tea leaves are wilted for 1-2 h by hot air again, the hot air temperature is 35-40 DEG C, and during the wilting process, the tea leaves are turned every 15 minutes; (2) twisting: a twisting machine is adopted for twisting the tea leaves; (3) fermenting: a full-automatic fermenting machine is adopted for fermenting; (4) drying: the tea leaves are put in a drying machine, the spreading thickness is 8-10 cm, the tea leaves are dried for 10-15 min for the first time at the control temperature of 130 DEG C, then are dried for 10-15 min for the second time at the control temperature of 80 DEG C, next, the tea leaves are taken out from the drying machine, and are cooled for 30-40 min after being spread, and the tea leaves are put in the drying machine again and then dried for 6-10 min for the third time at the control temperature of 80 DEG C. The black tea manufacturing method can reduce the manufacturing time of black tea considerably, and improves the black tea quality.

Owner:湖北龙王垭茶业有限公司

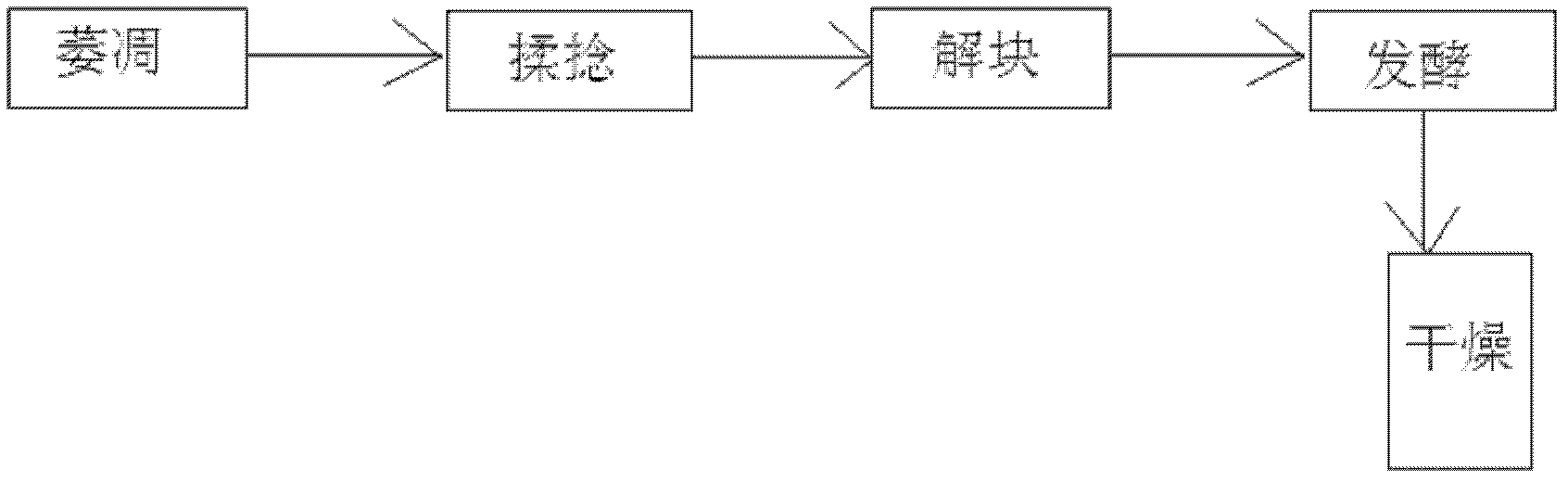

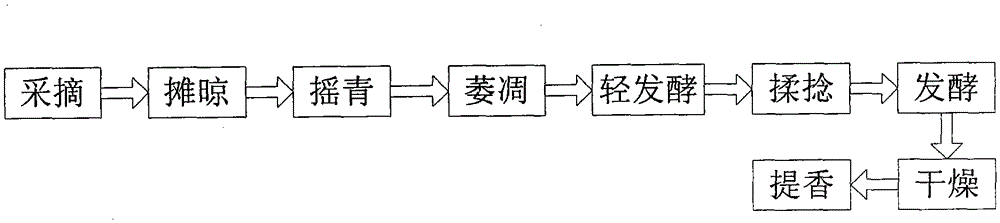

Production process of Congou black tea

InactiveCN105285191AWither evenlyPrevent dryingPre-extraction tea treatmentResource utilizationBlack tea

The invention provides a production process of congou black tea. The production process comprises the process of selecting tea leaves, withering, rocking green, rolling, fermenting and drying. In summer and autumn, tea contains high tea polyphenol so as to be not suitable for preparing green tea, but through the production process of the Congou black tea, fresh tea leaves are sufficiently fermented within short time, and the bitterness of the tea leaves is changed, so that the prepared black tea has intensive tea aroma, thick taste, bright color, and sweet aftertaste. According to the production process of congou black tea, the traditional production mode that the tea leaves in summer and autumn only can be used for preparing green tea can be broken through, and the utilization ratio of the fresh leaf resources can be increased, so that the purpose of increasing income of tea farmers can be achieved.

Owner:李红权

Preparation method for black tea

The invention relates to a preparation method for black tea. The preparation method is characterized in that the method comprises the following steps: firstly, one-bud-two-leaf fresh leaves are selected as a raw material, the fresh leaves are picked from summer tea; secondly, the picked fresh leaves are placed in a withering trough, the spreading thickness is 5-10cm, the temperature is controlled at 25-30 DEG C, the withering time is 2-3h, then cold air withering is carried out, the fresh leaves are turned over and spread, the spreading thickness is 3-5cm, the temperature is controlled at 0-5 DEG C, the withering time is 1-2h, and finally daylight withering is carried out for 6-8h. The black tea has a red and bright soup color, tastes mellow, and has high quality.

Owner:GUANGXI ZHAOPING NINGXIANGCUI TEA FACTORY

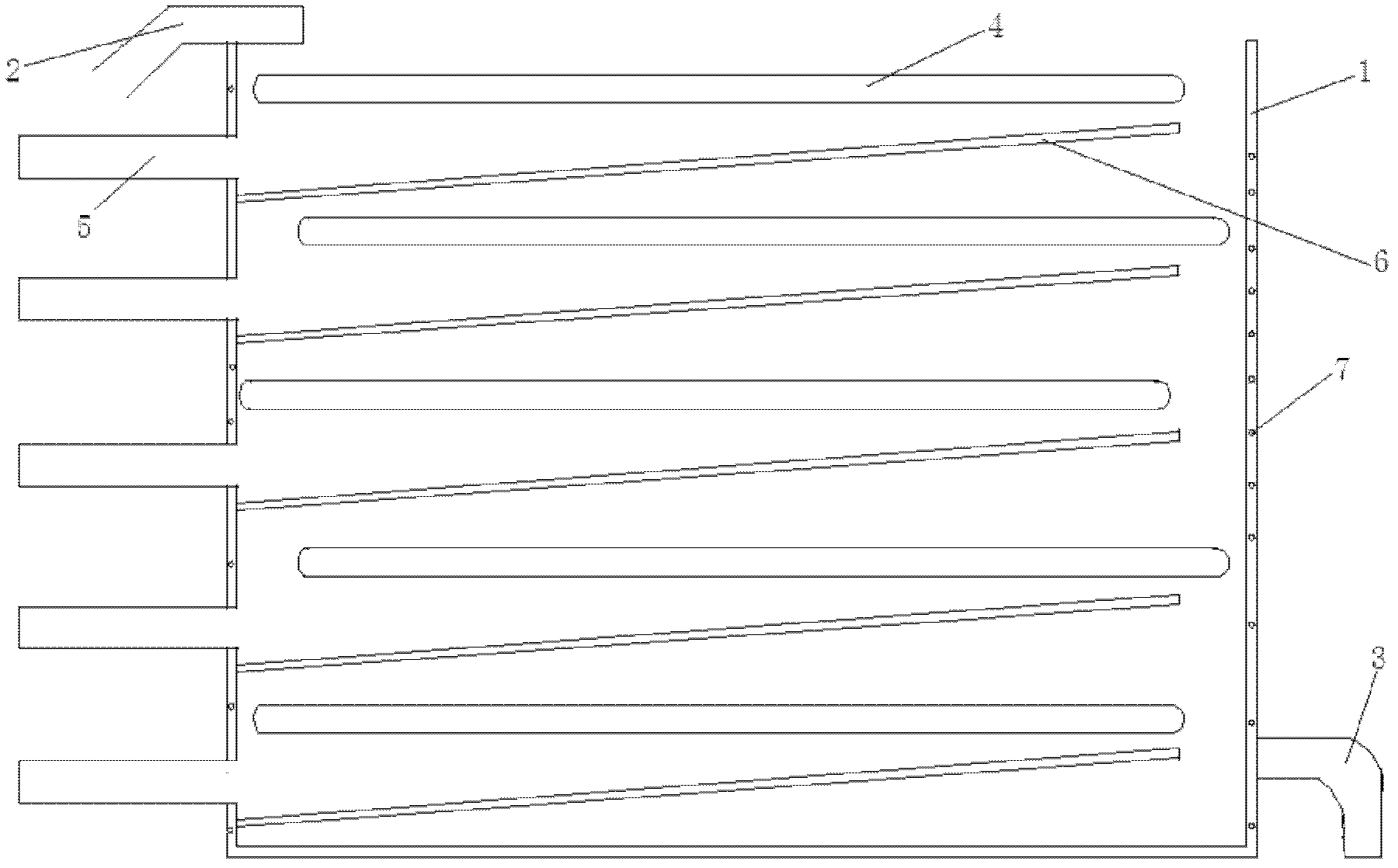

Tea withering machine

PendingCN105851294AAvoid wastingImprove collection efficiencyPre-extraction tea treatmentEngineeringAir blower

The invention discloses a tea withering device in the field of tea production equipment. The tea withering device comprises a withering groove, and the bottom face of the withering groove is connected with a cavity used for conveying hot air; the upper end face of the cavity is seamlessly attached to the bottom face of the withering groove, the bottom face of the withering groove and the upper end face of the cavity are each densely provided with ventilation holes, and the ventilation holes enable the withering groove to be communicated with the cavity; the outer wall of the cavity is provided with connecting holes penetrating through the outer wall, and the ventilation holes are connected with a hot-air blower; a netted tea spreading net is laid on the inner wall of the withering groove. According to the tea withering device, the cavity is arranged, so that hot air generated by the hot air blower has to wither tea leaves through the cavity, heat waste is avoided, and meanwhile tea withering quality is improved; the tea spreading net is arranged, so that after the tea leaves are withered, the tea spreading net can be tightened, the tea leaves are collected in the tea spreading net at a time, and tea collection efficiency is improved.

Owner:务川自治县雾青茶业有限公司

Withering method of Gongfu black tea

InactiveCN106343048AAccelerate dehydrationWither evenlyPre-extraction tea treatmentBlack teaTea leaf

The invention provides a withering method of Gongfu black tea. The method comprises the following steps: 1) picking tea tree fresh leaves, putting on a withering rack, and withering for 1.0-1.5 hours, wherein the withering thickness is 0.5-2.5cm, and the leaves are stirred 3-4 times in the withering process; 2) withering the tea leaves in a withering machine with cold air for 50-70 minutes, wherein the tea leaf spreading thickness is 30-40cm; 3) withering with hot air for 30-40 minutes, wherein the hot air temperature is 35-40 DEG C; 4) withering with cold air for 30-50 minutes; 5) withering with hot air for 70-90 minutes, wherein the hot air temperature is 35-40 DEG C; 6) shutting down for 50 minutes; and 7) withering with hot air for 110-130 minutes, wherein the hot air temperature is 35-40 DEG C, and the tea leaves are stirred every 15 minutes in the whole withering process. The method can accelerate the water loss of the fresh leaves and accelerate the conversion of substances in the fresh leaves, and the tea leaves can be withered uniformly and sufficiently. Meanwhile, the method greatly shortens the withering time.

Owner:柳城县国营伏虎华侨农场茶厂

Processing technology of white tea

The invention discloses a processing technology of white tea in the field of processing of tea leaves. The processing technology comprises the steps of performing picking, performing withering, performing shaping and performing drying, in the step of withering, placing picked leaves in outdoor environment of 25-30 DEG C, performing natural withering, after natural withering, enabling a plurality of infrared lamp tubes to be fixed to the inside wall of a withering box, enabling an air inlet to the formed in the bottom of the withering box, enabling an air outlet to be formed in the top of the withering box, enabling the air outlet to be connected with an exhaust fan, performing rotary withering on the naturally-withered leaves in the withering box, controlling and maintaining the temperature of the withering box to be 32-45 DEG C, controlling the rotating speed of a screen mesh to be 6r / min, and controlling the rotary withering time to be 1-2h. Compared with a conventional technology, the adopted technology provided by the invention has the advantages that the withering is more uniform, the withering efficiency is higher, and the preserved white fine long hair is more complete. After the processed white tea is brewed, tea soup is delicately fragrant, slightly sweet and slightly fragrant, the soup color is light, the white fine long hair is rich in fragrance, the taste is fresh, mellow and delicious, and the quality is better than that of traditional products.

Owner:正安县吐香茶业有限责任公司

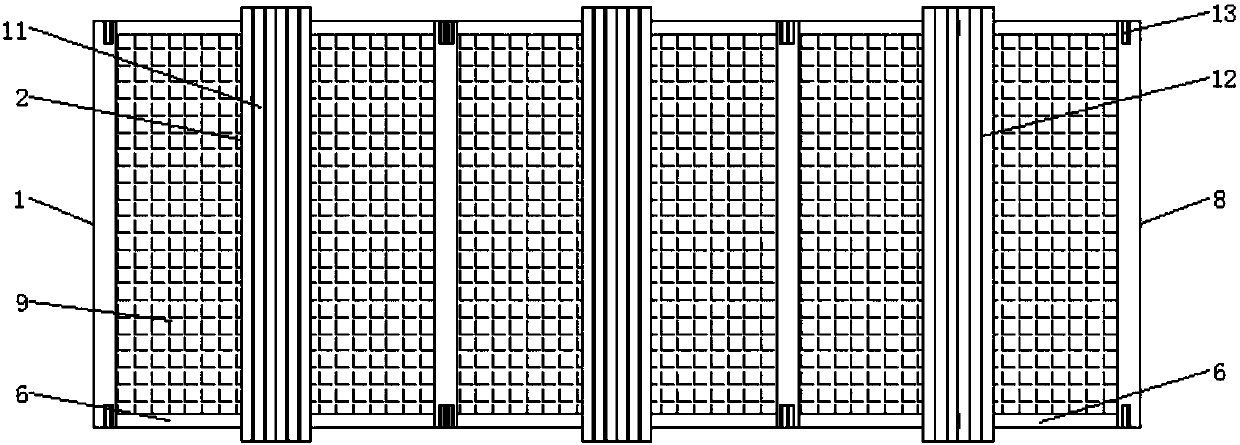

Tea withering trough

ActiveCN107801798AEvenly distributedAchieve flippingPre-extraction tea treatmentDrive wheelEngineering

The invention discloses a tea withering trough. The withering trough comprises a trough body; the bottom wall of the trough body is fixedly connected to a plurality of air blowers; a penetrating conveying device is erected on the side wall of the trough body; the conveying device comprises a driving wheel and a conveying belt; the driving wheel is in transmission connection with the conveying belt; the surface of the conveying belt is provided with a plurality of bulges; a heating device is arranged in the middle space of the conveying belt; a feeding device is arranged on one side of the trough body; a beam is fixedly connected to the inner wall of the top end of the trough body; a plurality of baffles and a plurality of stirring rods are sequentially connected to the beam; one end, far away from the beam, of each stirring rod is rotationally connected to a stirring roller; and the side wall of each stirring roller is provided with a plurality of uniformly distributed stirring tips. The withering trough uniformly spreads out tea layers and stirs the tea layers during a withering process so as to realize uniform and high-efficiency withering on tea.

Owner:恩施西特优生态农业开发有限公司

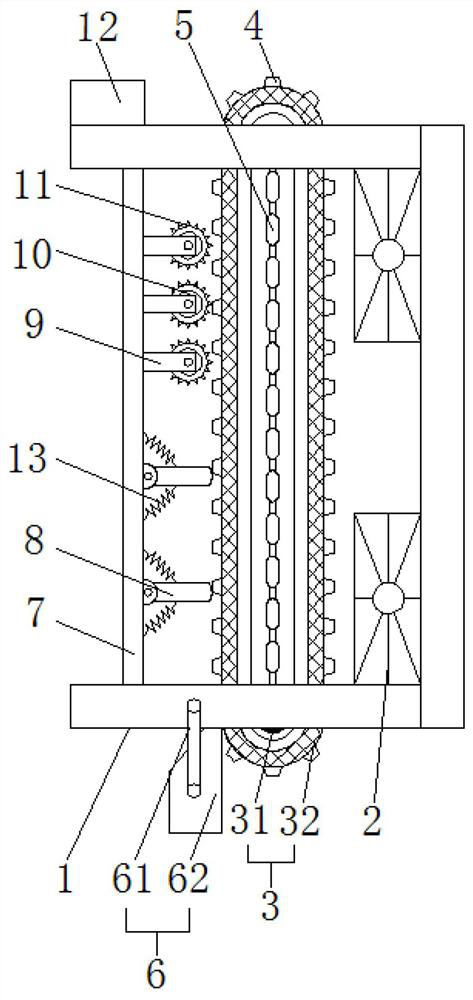

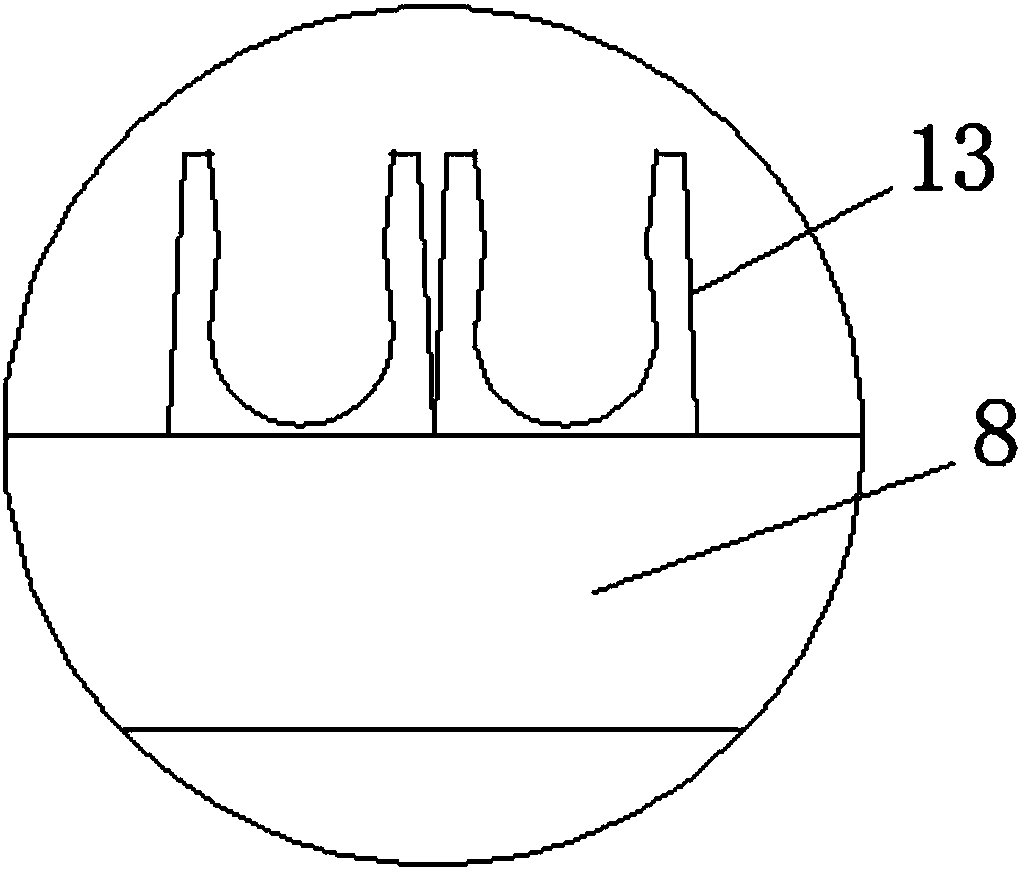

Uniform and fast tea withering machine

ActiveCN106417713AWither evenlyEvaporate evenlyPre-extraction tea treatmentClimate change adaptationAgricultural engineeringAir blower

The invention discloses a uniform and fast tea withering machine. A barrel body comprises a top cover, a bottom cover and a barrel wall, wherein the top cover and the bottom cover are buckled at the two ends of the barrel wall. The uniform and fast tea withering machine comprises a plurality of withering devices, each of the withering devices comprises shaft rods and withering troughs, each of the withering troughs is connected with the corresponding shaft rod through a buckle, the adjacent shaft rods are in detachable connection with each other, and a baffle with the same size as a bottom plate of the withering trough is connected to each of the withering troughs; slide rails are arranged on the barrel wall, a pulley in sliding fit with the corresponding slide rail is arranged on each of the withering troughs, resistance sheets are arranged on each of the slide rails and are connected through a resistance plate, air cylinders are connected to the resistance plate, and a hot air blower is connected to the barrel wall. The uniform and fast tea withering machine disclosed by the invention has the benefits that tea leaves are put in the withering troughs of each of the withering devices, each of the withering troughs is connected with the corresponding shaft rod, and hot air is used for withering the tea leaves to accelerate the tea leaf withering speed; withering is performed in the barrel body, so that the floor area is reduced; the resistance plate is connected with the extension air cylinder and the contraction air cylinder, and the two air cylinders alternately run; each of the withering devices gradually moves downwards, so that the temperature is higher and higher, and the tea leaves are gradually withered.

Owner:汉中云峰茶业发展有限公司

Processing method of flower-aroma black tea

InactiveCN109042988AIncrease physical strengthProtective bowel cleansingPre-extraction tea treatmentTea extractionHazardous substanceBlack tea

The invention provides a processing method of flower-aroma black tea and relates to the technical field of tea leaf processing. The processing method of the flower-aroma black tea, provided by the invention, comprises the following steps: (1) screening tea leaves; (2) spreading and airing; (3) rolling; (4) spraying a nutrient solution; (5) fermenting; (6) spraying tea soup; (7) frying until aromais increased. According to the processing method of the flower-aroma black tea, any harmful substance is not added into raw materials or is not generated in a processing process; the scientific processing method is adopted so that the flower-aroma black tea has the health-care effects of helping to digest, enhancing the physical strength, protecting the liver, clearing intestines and disinfectingand the like; flower extract is added, so that the tea black has a pleasant flower aroma, a continuous mouthfeel and a fragrant taste, and has a long sweet aftertaste after being drunk.

Owner:GUANGXI XIUMEI ZHUANGXIANG ENERGY ENVIRONMENTAL PROTECTION CO LTD

Processing method of moringa tea

InactiveCN109007166AIncrease physical strengthProtect the liverTea substituesMoringaHazardous substance

The invention provides a processing method of a moringa tea, and relates to the technical field of tea processing. The processing method of the moringa tea of the present invention comprises the following steps: (1) picking, (2) washing, (3) fixation, (4) withering, (5) nutrient solution spraying, (6) rolling, (7) fermentation, and (8) drying and sterilization. The processing method of the moringatea of the present invention does not add or produce any harmful substance from the raw material preparation to the processing process. With a scientific processing method and the functional nutrientsolution, the moringa tea of the invention has the health-care effects of helping digestion, strengthening physical strength, protecting the liver, strengthening the stomach and conditioning intestines, and the tea is soft and fragrant in mouth feel, and is lasting in sweet aftertaste and refreshing after being drunk.

Owner:GUANGXI XIUMEI ZHUANGXIANG ENERGY ENVIRONMENTAL PROTECTION CO LTD

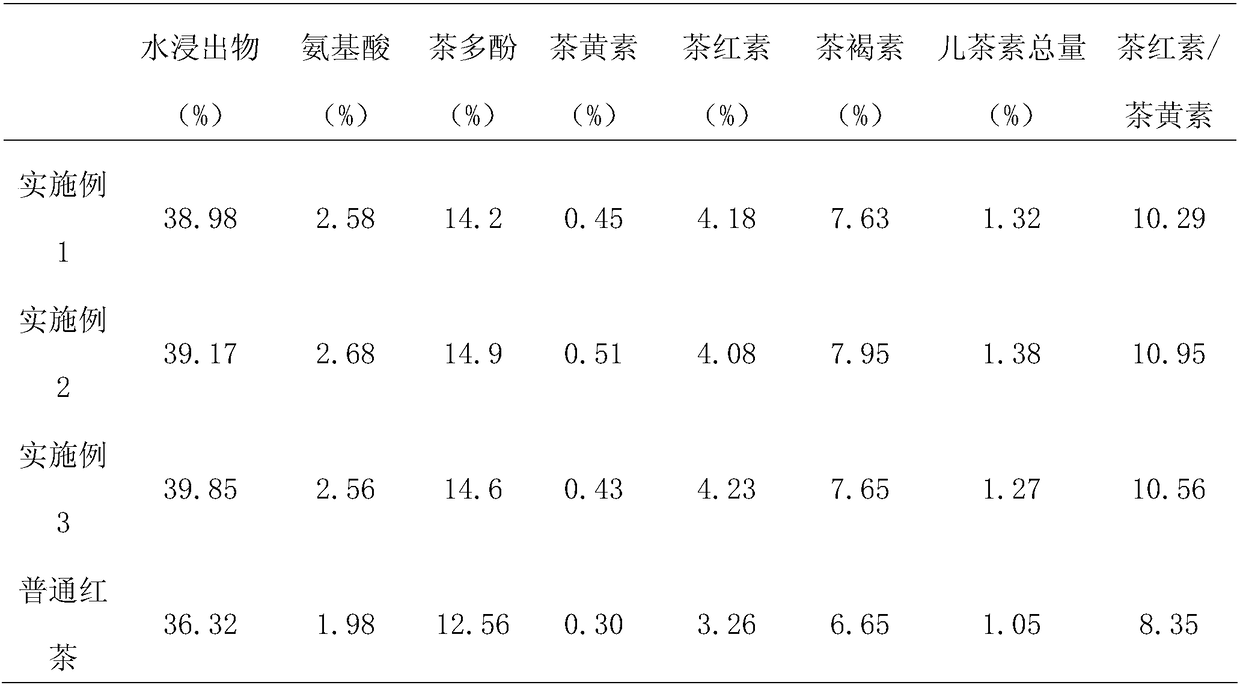

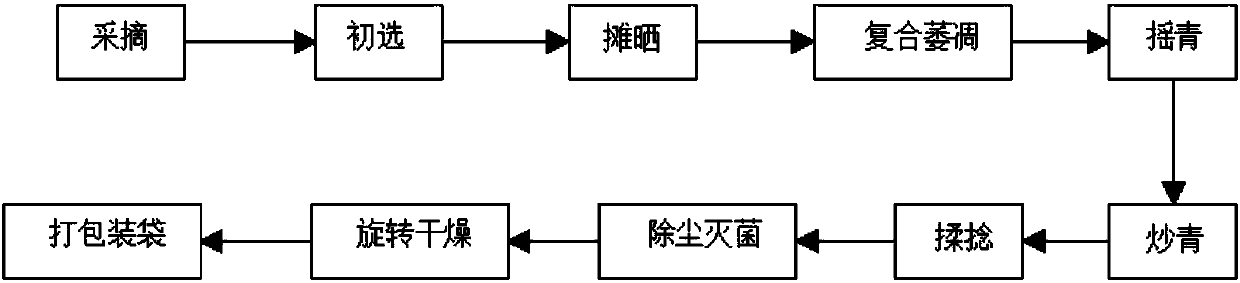

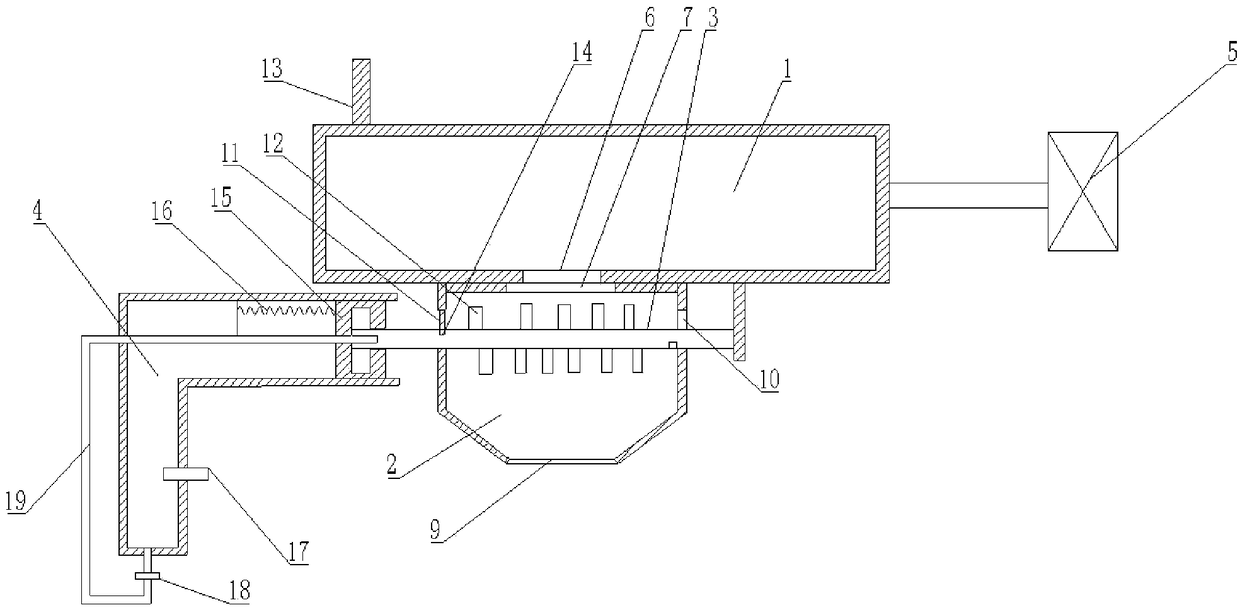

Production technology of tea leaves

InactiveCN110150400AImprove appearance and qualityIncrease profitPre-extraction tea treatmentEpigallo-catechin gallateTea leaf

The invention discloses a production technology of tea leaves. The production technology comprises the steps of picking, primary selection, spreading and drying in the sun, composite withering, rocking of the green tea leaves, stir fixation, rolling, dedusting and sterilization, rotary drying and packaging and bagging; through the modes of composite withering and rotary drying, the tea leaves makecontact with air comprehensively in the tea leaf withering process, the phenomena of accumulation and pile fermentation do not occur, after more uniform withering, the tea leaves are processed to form the finished product, and therefore the produced product meets the flat, even and straight requirements of the appearance of the tea leaves; the color, fragrance and taste of the produced tea leavesare balanced, the appearance and quality of the tea leaves are improved, the utilization rate of the tea leaves is increased, and the produced finished product tea is good in quality, attractive in appearance, mellow in fragrance, even in appearance and high in content of amino acid and an aqueous extract; after brewing of the tea leaves, the tea liquid color is light, the tea liquid has a rich fragrance, is sweet, has a moisturizing effect and promotes the secretion of saliva, and compared with a traditional product, the quality of the tea leaves is better.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Tea withering device

InactiveCN108812969AThere will be no deteriorationEvenly heatedPre-extraction tea treatmentEngineeringTea leaf

Belonging to the technical field of tea processing, the invention specifically discloses a tea withering device, which comprises a feeding barrel, a withering barrel under the feeding barrel, a horizontal rotating shaft, a heating component arranged in the withering barrel and a motor connected to the feeding barrel. The feeding barrel is equipped with a first discharge port, the upper end of thewithering barrel is equipped with a first feed inlet, which is used for transporting tea into the withering barrel, and two ends of the horizontal rotating shaft are a driving end and a driven end respectively. The surface of the horizontal rotating shaft is provided with first through-holes and is in fixed connection with stirring blades. Opening are disposed on two sides of the withering barrelsymmetrically, the horizontal rotating shaft runs through the withering barrel through the opening, and the opening at one side of the withering barrel is equipped with a support rod. The surface of the feeding barrel is provided with a curve bulge, the surface of the horizontal rotating shaft is equipped with a closed curve type first groove, and the free end of the support rod is in sliding connection with the first groove. The tea withering device with the above structure can solve the tea deterioration problem caused by a long-time heating state in the tea withering process.

Owner:ZUNYI ZHENGAN LIXIA TEA IND CO LTD

Preparation method of black tea cake

The invention relates to a preparation method of a black tea cake. The method comprises the following steps of leaf selection, primary withering, secondary withering, fine manipulation of tea leaves,stem cutting, rolling, fermenting, screening, pressing, baking, reheating for fragrance enhancement and packaging. According to the method, the tea leaves can be uniformly withered by combining primary withering with secondary withering, old tea leaves and tender leaf stems can be withered equally in the same way, and rolling and fermentation of black tea are facilitated. Meanwhile, the fragranceof the black tea can be increased by 4-6% in comparison with conventional black tea in a mode of performing reheating for fragrance enhancement, people can directly smell the difference of the black tea through the human sense organs, and the quality and mouthfeel of the black tea are obviously improved. In addition, through pressing, the tea leaves are pressed into tea balls or tea cakes, so thatthe tea leaves are conveniently transported by carrying machines of the tea leaves, the storage time of the tea leaves is prolonged, and retrograde mildewing is avoided. The tea cake has the advantages of being pure in taste, strong in fragrance and convenient to store, carry and transport.

Owner:徐银龙

A kind of tea withering tank

ActiveCN107801798BEvenly distributedAchieve flippingPre-extraction tea treatmentDrive wheelEngineering

Owner:恩施西特优生态农业开发有限公司

Black tea processing method

The invention discloses black tea processing method which comprises the following steps: (1) selecting fresh leaves; (2) withering; (3) rolling; (4) fermenting; (5) sterilizing; (6) drying; (7) packaging; (8) curing; and (9) increasing aroma. The withering is performed at a constant temperature, the defect that the method is influenced by weather and diurnal temperature variation is overcome, and the fresh leaves can be uniformly withered; an ultraviolet sterilization step is increased after fermentation, so that some microbial bacteria produced during fermentation can be killed; the tea is refrigerated and cured after packaging, so that the beneficial components of the tea are further developed; and static high-temperature aroma improving is performed after packaging and curing, so that the conditions that the tea leaves are collided to damage the tea shape and the tea aroma is volatilized can be avoided. The tea made by the method disclosed by the invention is high in quality, stable in quality, strong in aroma, red and transparent in soup after making and mellow in taste.

Owner:广西昭平县将军红商贸有限公司

Preparation technology of Danxia black tea

PendingCN109362902AEnsure consistencyImprove qualityPre-extraction tea treatmentBlack teaTemperature difference

The invention discloses a preparation technology of Danxia black tea. The preparation technology comprises the following steps of selecting fresh leaves, performing withering, performing rolling, performing fermentation, performing baking, performing refining and performing packaging inspection. According to the preparation technology of Danxia black tea disclosed by the invention, the consistencyof Danxia black tea products can be guaranteed, the quality of the products can be improved, besides, withering is uniform, the Danxia black tea cannot be influenced by temperature differences of climate, and the technology is simple.

Owner:仁化县红丹舒茶业有限公司

Black tea withering method

InactiveCN106387103AAccelerate dehydrationWither evenlyPre-extraction tea treatmentCold airBlack tea

The invention provides a black tea withering method. The black tea withering method comprises the following steps: 1), picking fresh tea leaves from tea trees, placing the picked tea leaves on a withering shelf, wherein the withering thickness is 0.5-3.5 centimeters and the withering time is 1.5-2.5 hours, and turning the tea leaves for 4-5 times during withering; 2) placing the tea leaves in a withering machine, wherein the spreading thickness of the tea leaves is 40-60 centimeters, and withering the tea leaves by using cold air for 30-45 minutes; 3), carrying out withering by using hot air for 60-80 minutes, wherein the temperature of the hot air is 35-40 DEG C; 4), carrying out withering by using cold air for 50-70 minutes; 5), carrying out withering by using hot air for 30-50 minutes, wherein the temperature of the hot air is 35-40 DEG C; 6) stopping the withering machine for 1 hour; and 7), carrying out withering by using hot air for 130-150 minutes, wherein the temperature of the hot air is 35-40 DEG C. The tea leaves are turned once every 15 minutes during the whole withering processes. The black tea withering method has the advantages of accelerating water loss of the fresh leaves, speeding up internal substance transformation in the fresh tea leaves and so on. By adopting the black tea withering method disclosed by the invention, the tea leaves are uniformly and fully withered; moreover, the withering time is greatly reduced.

Owner:柳城县国营伏虎华侨农场茶厂

Processing method of fructus cinnamomi black tea

The invention relates to a fructus cinnamomi black tea processing method. The method comprises the following steps of 1) withering, spreading picked fresh fructus cinnamomi tea leaves in a withering tank, and controlling the environment temperature to be 20-35 DEG C, the air humidity to be 65-75% and the withering time to be 9-16 hours during withering; 2) rolling, putting the withered leaves treated in the step 1) into a rolling machine, and rolling until the cell damage rate of the withered leaves is more than 80% and the leaves are more than 90% into strips; (3) fermentation, uniformly spreading the rolled leaves treated in the step (2), then putting the rolled leaves into a fermentation box for fermentation, and stopping fermentation until the leaves have obvious flower and fruit fragrance or sweet fragrance and are orange red or purple bronze; 4) drying, drying the fermented tea leaves with gross fire until the water content of the tea leaves is 30-40%, and then drying with sufficient fire until the water content of the tea leaves is 6-7%; and 5) aroma enhancement, carrying out low-temperature baking aroma enhancement on the dried tea leaves. The method is advantaged in that the obtained fructus cinnamomi black tea is high in the aflavin content, obvious in flower fragrance, high in quality and suitable for batch popularization and production.

Owner:湖南兴盛茶业科技有限责任公司

High quality production method of summer black tea

The invention relates to a high quality production method of summer black tea. The method comprises the operational steps of: 1) picking; 2) withering; 3) rolling; 4) fermenting; 5) drying with gross fire; and 6) drying with complete fire. The method is improved in that a rocking operational step is added between the step 2) and the step 3). The rocking operational step comprises the steps of rocking for three times by using a tea speed regulation rocking machine, and accelerating fresh leaves to wither uniformly and cinch tea stripes compactly during rolling, and meanwhile to develop aroma of product tea, wherein the rocking rotating speed and standing time are in a trend of increase progressively. The method further comprises the steps of: after step 6), paving and wetting for 1 hour and roasting and extracting aroma; through the roasting process, green taste of rough tea is eliminated, the liquor color is red and strong, and the tea is sweet and has a scent with aroma of mature fruit, and sweet degree of taste is increased. By using summer fresh leaves as raw materials, the content of thearubigins is improved by 36.0-44.8% compared with summer black tea prepared by conventional processes, and types and content of high boiling point scent components are further remarkably improved.

Owner:青岛崂矿尊圃茶业有限公司

A kind of withering method of black tea

The invention provides a withering method for black tea. The withering method specifically comprises the following steps: placing tea leaves into a withering machine and withering the tea leaves; paving the tea leaves according to the thickness of 40-60 centimeters; firstly, withering by cold air for 2-3 hours and withering by hot air for 1-2 hours, wherein the temperature of the hot air is 35-40 DEG C; stopping the machine for 1 hour; withering by the hot air for 1-2 hours, wherein the temperature of the hot air is 35-40 DEG C; and in the whole withering process, overturning the tea leaves for one time every 15 minutes. According to the withering method for the black tea, an existing withering machine is used for withering and is mechanically operated and the effect is improved; the specific withering time of the cold air and the hot air is set; firstly, the withering is carried out by the cold air and the tea leaves are prevented from being withered too fast, the withering time is short and the physicochemical changes are intense; bud tips and leaf margins are prevented from being withered, and are prevented from even becoming red; then the tea leaves are sufficiently withered by using hot air, and the hot air withering can effectively guarantee that the tea leaves are uniformly and sufficiently withered; meanwhile, the withering time is greatly shortened.

Owner:湖北龙王垭茶业有限公司

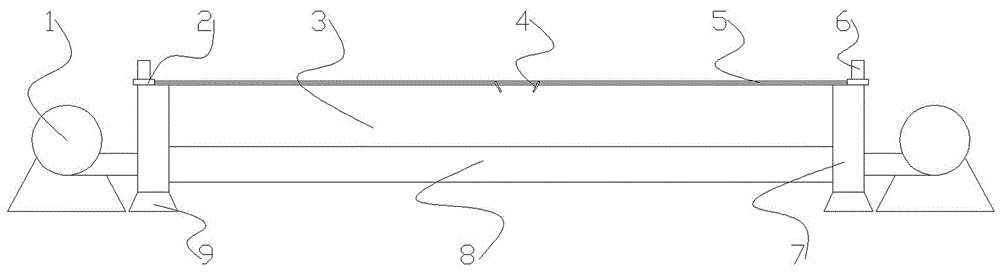

Tea leaf withering and rocking device

InactiveCN108935780AWither evenlyEvenly heatedPre-extraction tea treatmentAgricultural engineeringMaterial resources

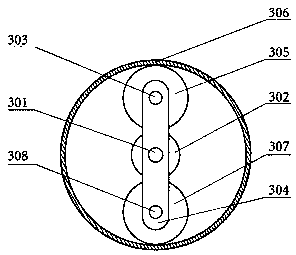

The invention discloses a tea leaf withering and rocking device, comprising a base (2); a main planetary gear (3) and a sub-planetary wheel (6) are arranged on the base; the main planetary gear (3) isconnected to a motor (1); the motor (1) is connected to the base (2); more than two mesh sieve cylinders (5) are connected between the main planetary gear (3) and the sub-planetary wheel (6); sieve holes are arranged on the mesh sieve cylinders (5); a heat blower (4) is arranged below the mesh sieve cylinders (5); and a discharge cover (501) is arranged on each mesh sieve cylinder (5). The tea leaf withering and rocking device provided by the invention combines the withering and rocking processes to avoid human adverse factors when the two processes are alternated, reduces the processing time, manpower and material resources, and realizes uniform processing of the tea leaves, high processing efficiency of tea, low energy consumption, low cost, stable tea quality and mellow aroma.

Owner:GUIZHOU PROVINCE ZHENGAN COUNTY YIREN TEA IND CO LTD

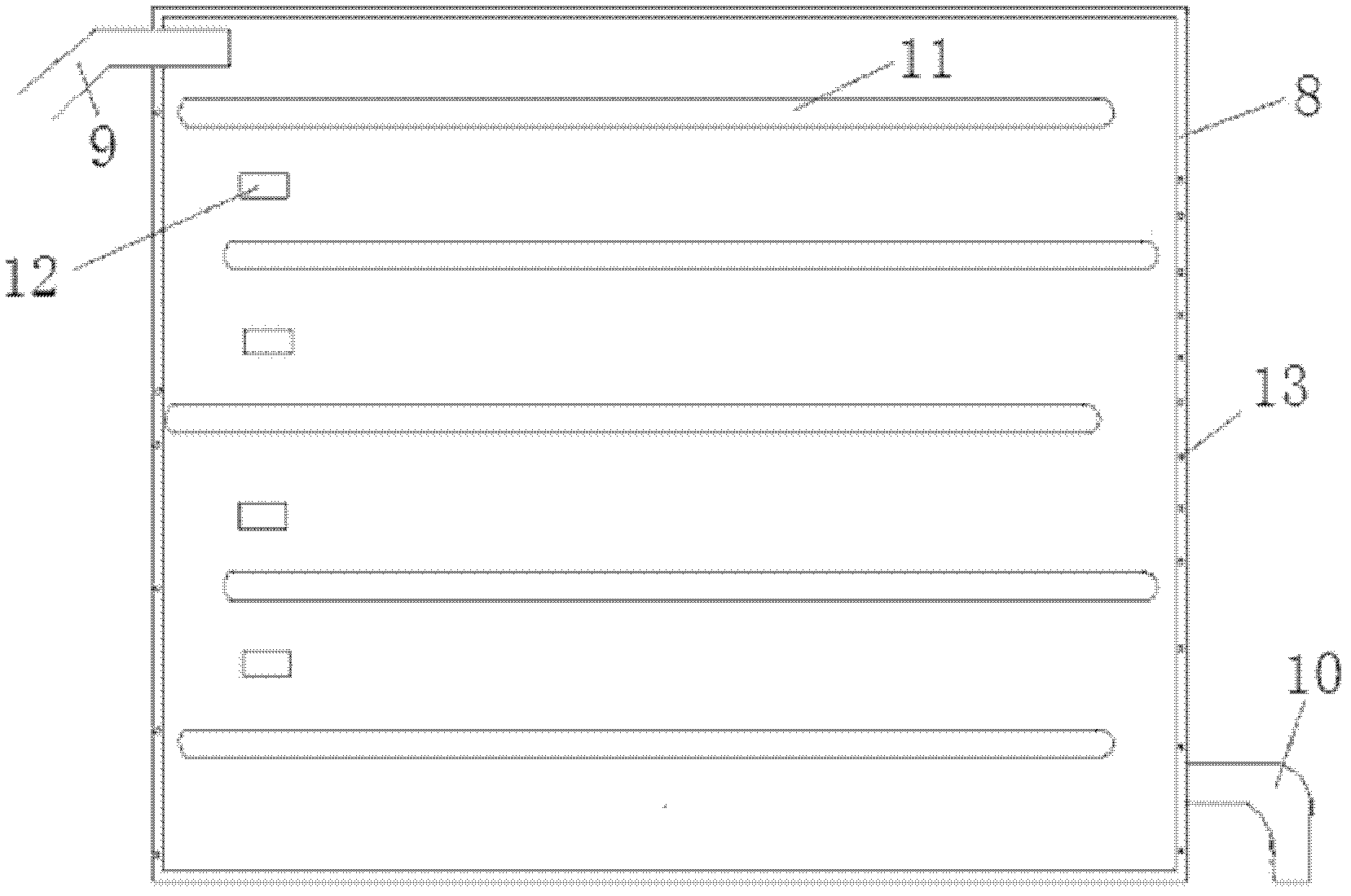

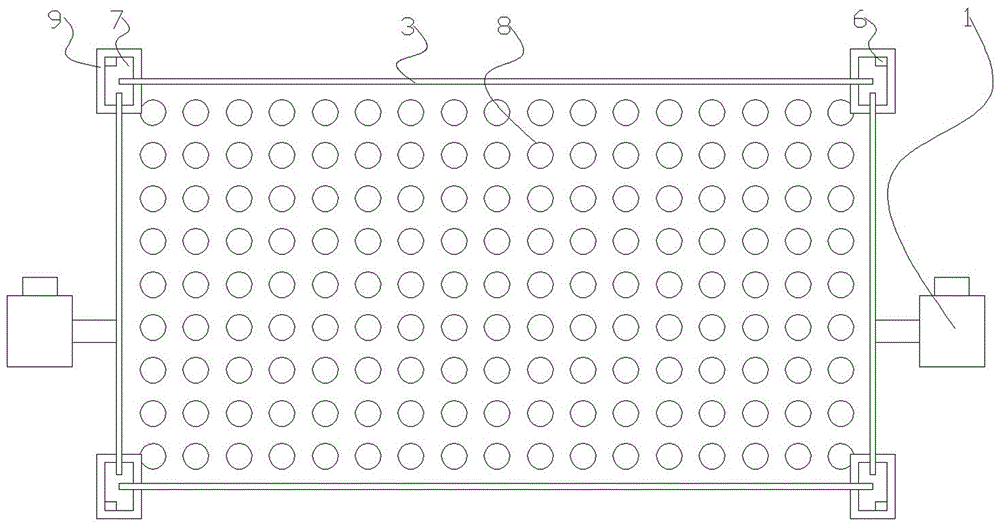

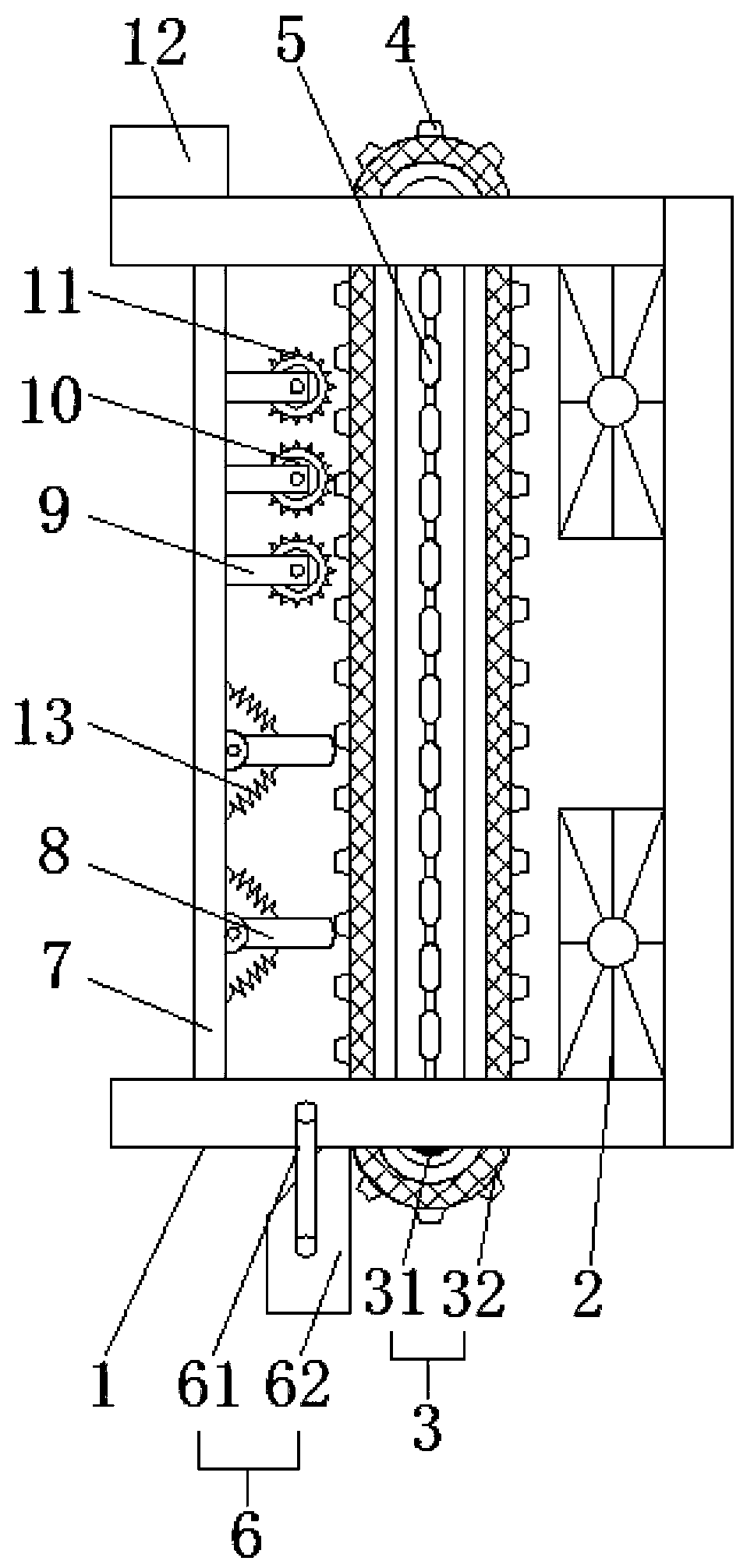

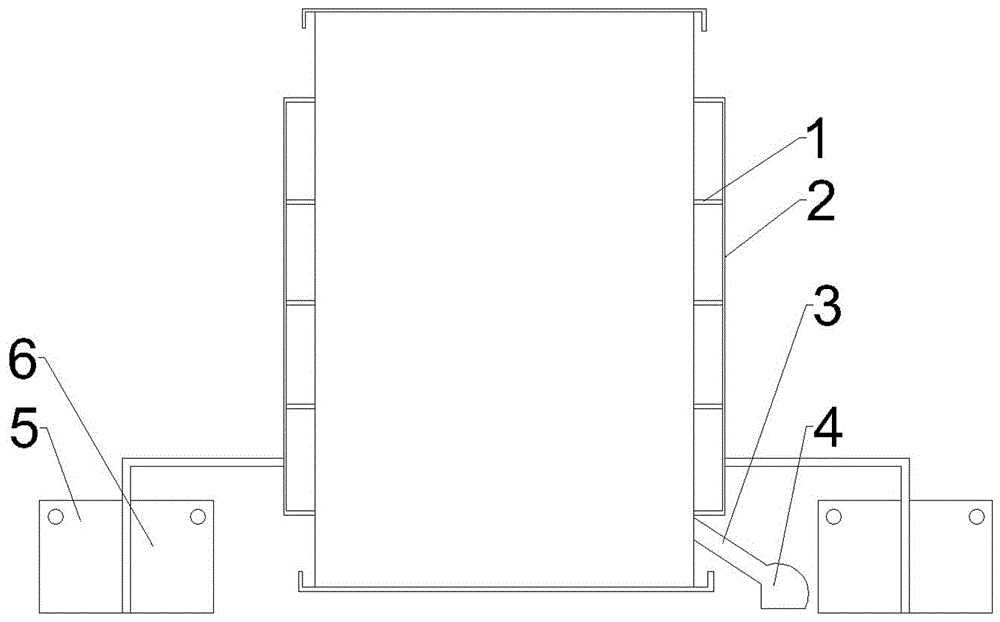

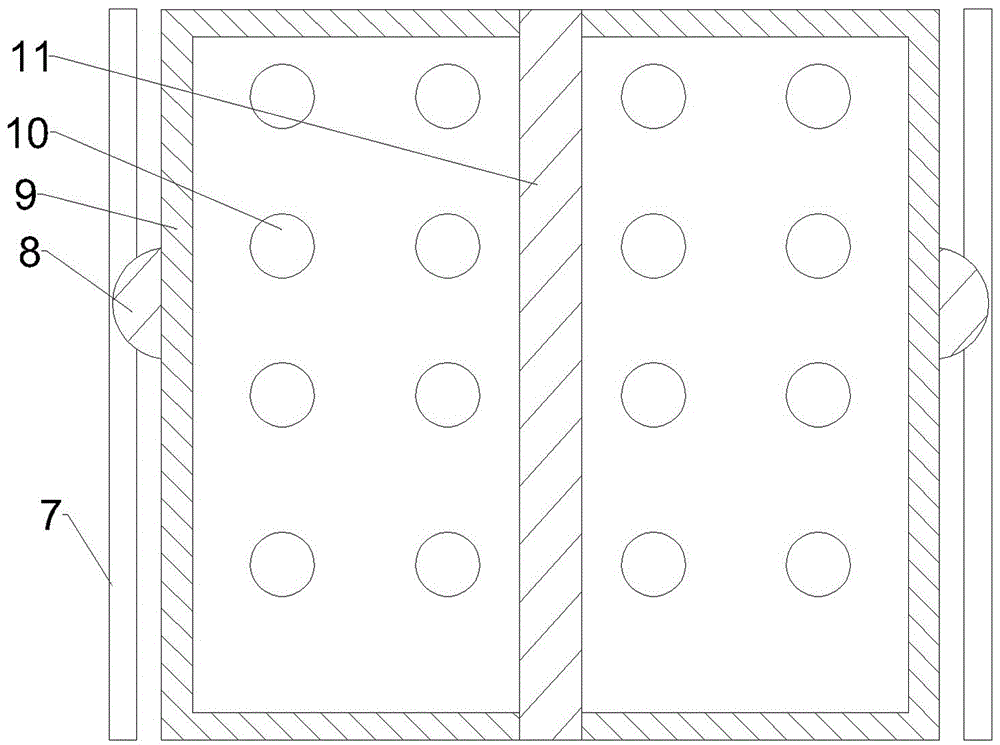

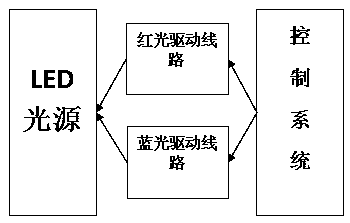

Withering device and withering method of Gongfu black tea with intermittent circulation light

ActiveCN105394206BGet rid of the limitations of light withering processingIncreased withering effectPre-extraction tea treatmentControl systemEngineering

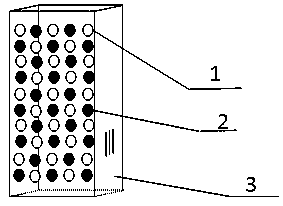

The invention relates to a kungfu black tea intermittent cyclic-lighting withering apparatus and a withering method, and belongs to the technical field of tea processing. The apparatus comprises a withering apparatus body provided with an LED light source. The LED light source includes red lighting units and blue lighting units, which are spaced in an array manner. The red lighting units and blue lighting units are electrically connected to independent driving circuits, which are electrically connected to a control system. Through using the apparatus, withering becomes uniform by performing red lighting, blue lighting, and stirring during intermission. Prepared black tea smells fragrant, has lasting fragrance, and tastes sweet and mellow.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

A kind of processing method of winter tea

ActiveCN105145896BImprove qualityEmerald green colorPre-extraction tea treatmentCooking & bakingFlavor

The present invention relates to a winter tea processing and manufacturing method which belongs to the processing field of tea leaves. The method comprises the following steps 1) picking; 2) spreading and airing; 3) roasting; 4) withering; 5) primary baking; 6) spreading and cooling; 7) water spraying; 8) secondary baking; and 9) stacking. Early sprouted tender leaves of tea trees planted at an altitude of 800-1000 m are picked on winter frosty days and used as raw materials to manufacture tea; the picked and spread and aired tea leaves are subjected to baking, which can speed up fragrance improving; in the withering process, a blower and an exhaust fan are matched in use to conduct air blowing and air drafting at the lower position of the tea leaves, which can reduce the air humidity in the lower position, keep a uniform flow of air above and below, enable the tea leaves to be evenly withered without being turned over, and improve product quality; and in addition, the use of water spraying process can remove the dust absorbed during the production process of the tea leaves, thus ensuring products to be hygeian. In summary, the produced tea leaves are clean and hygeian, thick and infusion-enduring, strong in aroma, fresh and mellow in taste, low in bitter and astringent taste, and mellow in flavor.

Owner:广西乐业县乐碧园茶业有限公司

Processing method of selenium-enriched moringa tea

The invention provides a processing method of selenium-enriched moringa tea and relates to the technical field of tea leaf processing. The processing method of the moringa tea, provided by the invention, comprises the following steps: (1) picking; (2) washing; (3) carrying out fixation; (4) spraying a selenium protein protection solution; (5) withering; (6) spraying a nutrient solution; (7) rolling; (8) fermenting; (9) drying and sterilizing. According to the processing method of the selenium-enriched moringa tea, provided by the invention, any harmful substance is not added in raw materials or is not generated in a processing process; oxidization and degradation of selenium protein in the moringa tea can be prevented in a production process, and the produced selenium-enriched moringa teahas a fresh and mellow, and delicious taste; the tea soup is transparent and has a lasting clean aroma; the selenium-enriched moringa tea has the health-care effects of helping to digest, activating blood circulation to dissipate blood stasis, resolving dampness and appetizing, improving the immunity and the like through the scientific processing method and a functional health-care auxiliary agent.

Owner:GUANGXI XIUMEI ZHUANGXIANG ENERGY ENVIRONMENTAL PROTECTION CO LTD

A method of making black tea

ActiveCN103621697BWither evenlyFully atrophiedPre-extraction tea treatmentTemperature controlAgricultural engineering

The invention proposes a method for making black tea, the specific steps are as follows: (1) wilting, place the tea leaves in a wilting machine, spread the tea leaves to a thickness of 40-60 cm, firstly wilt with cold air for 2-3 hours, Then hot air withering for 1-2 hours, hot air temperature 35-40 ℃, stop for 1 hour, then hot air withering for 1-2 hours, hot air temperature 35-40 ℃; Stir once; (2) Knead, use a kneading machine to knead; (3) Ferment, use a fully automatic fermenter to ferment; (4) Dry, put the tea leaves in the dryer, spreading out the thickness of 8-10 cm; Drying, control the temperature at 130°C, and the time is 10-15 minutes; second drying, control the temperature at 120°C, and the time is 10-15 minutes; then take the tea out of the dryer and let it cool for 30-40 minutes; third drying Dry, put the tea leaves into the drier again to dry, control the temperature at 80°C, and the time is 6-10 minutes. The invention can greatly reduce the production time of black tea and improve the quality of black tea.

Owner:湖北龙王垭茶业有限公司

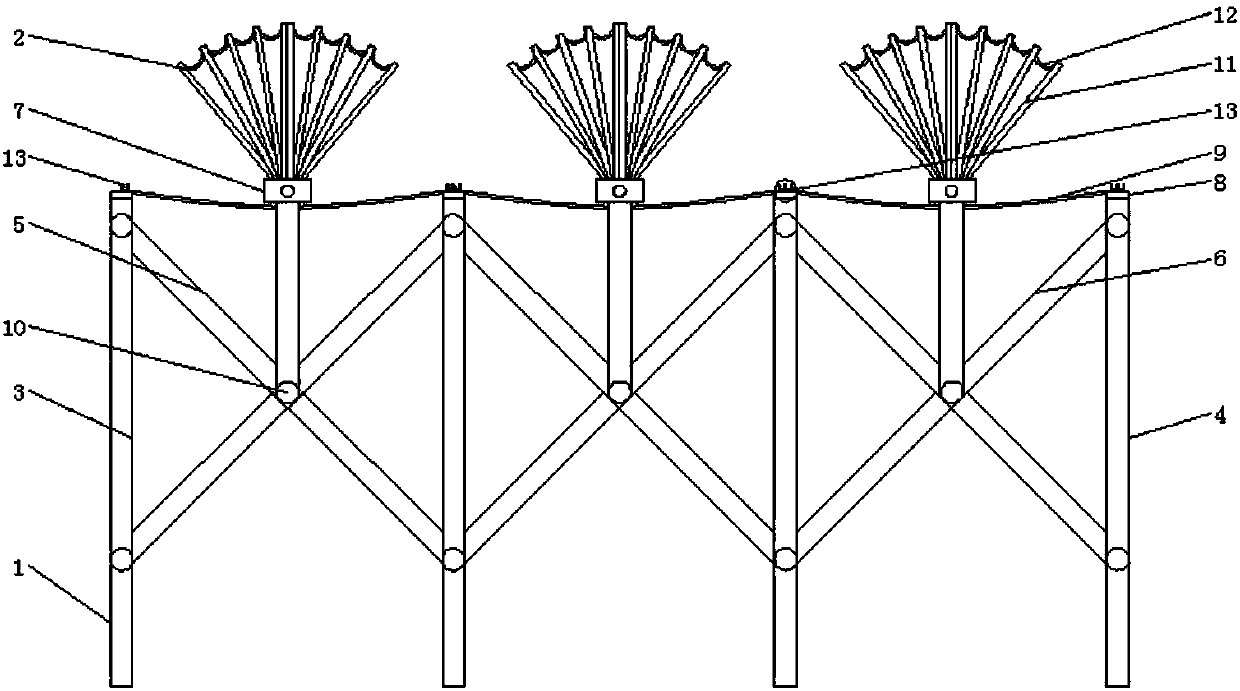

Sun-drying frame for tea leaf withering

InactiveCN107917592AWither evenlyHigh speedPre-extraction tea treatmentClimate change adaptationEngineeringDomestic animal

The invention discloses a sun-drying frame for tea leaf withering. The sun-drying frame comprises connecting frames and ceilings, wherein the ceilings are movably connected to the top ends of the connecting frames; the connecting frames comprise connecting rods I, connecting rods II, connecting rods III, connecting rods IV and supporting rods; two connecting rods I and two connecting rods II are correspondingly arranged on the left and right sides of each connecting frame; and the connecting rods III and the connecting rods IV are movably connected in a crossed manner. The sun-drying frame disclosed by the invention has the beneficial effects of being simple in structure and convenient to use; when in use, the sun-drying frame is clean and sanitary; fresh leaves of a tea tree are preventedfrom falling to the ground, and then domestic animals such as chickens and dogs are prevented from treading on the tea leaves; spreading and sun-drying nets are high in ventilation performance and air permeability, and then the tea leaf withering process is uniform and fast; under the situation of strong light, the ceilings can be lowered to a certain extent and used for blocking the sun; and when the tea leaves cannot be timely taken into a room in the weather of sudden rain, the ceilings can be lowered so as to keep out the rain, and then the fresh leaves of the tea tree can be effectivelyprevented from being withered excessively or getting wet in the rain.

Owner:天方茶业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com