Tea withering machine

A technology of withering machine and tea leaves, which is applied in the direction of tea treatment before extraction, etc., which can solve the problems of inconvenient collection of tea leaves and low heat utilization rate, and achieve the effects of expanding area, improving withering efficiency, and improving collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

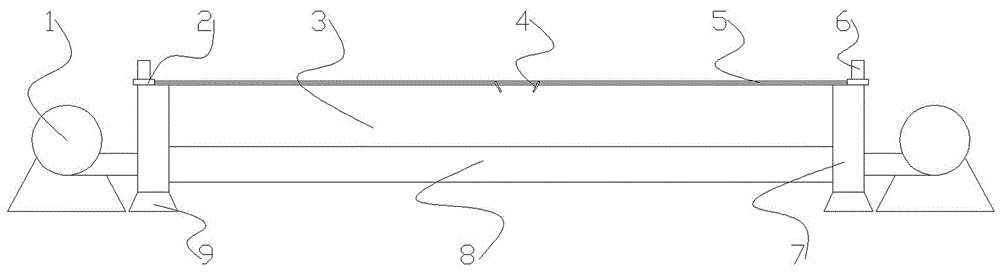

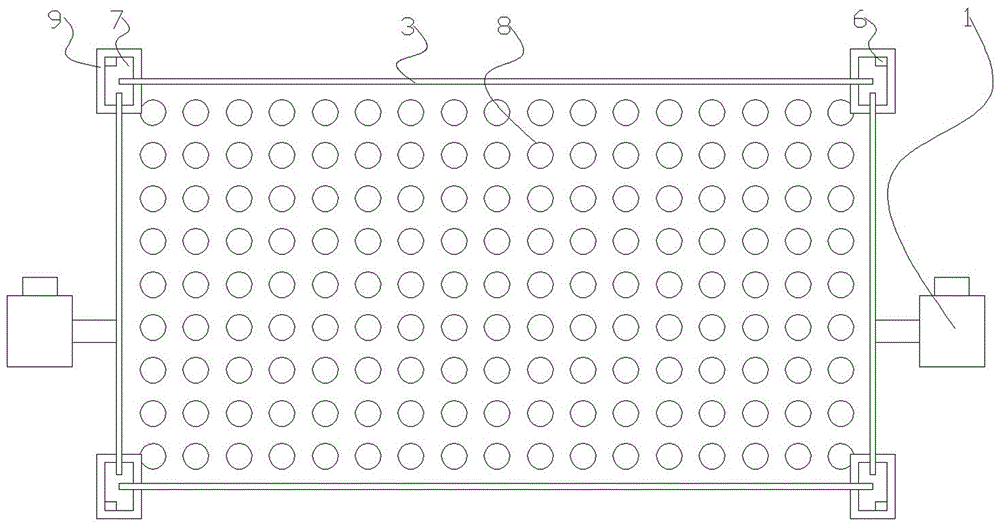

[0016] Such as figure 1 and figure 2 The tea withering machine shown includes a rectangular cavity 8 and a column 7, the bottom surface of the column 7 is provided with an inverted bowl-shaped base 9, the upper end of the column 7 is provided with a vertical rod 6, and two adjacent columns 7 There is a chute on the surface, the cavity 8 is rectangular, and a slider used in conjunction with the chute is provided on the cavity 8; a baffle 3 is slidably connected in the chute, and the baffle 3 is seamless with the upper end surface of the cavity 8 Connect and form a withering tank; the upper end surface of the cavity 8 is evenly distributed with dense air holes, and the outer walls of the corresponding two sides of the cavity 8 are provided with connecting holes, the connecting holes penetrate the outer wall of the cavity 8, and the connecting holes are connected with a hot air blower 1; the inner wall of the withering tank is paved with a tea-spreading net 5, the four corners ...

Embodiment 2

[0020] Embodiment 2 is basically the same as the tea withering machine of embodiment 1, the difference is that the withering tank of embodiment 1 is formed by the upper end surface of baffle plate 3 and cavity 8; and the withering tank in embodiment 2 is a single solid, and provided with a mounting frame, the cavity 8 and the withering tank can be directly placed on the mounting frame in sequence, which avoids the problem that the tea withering machine in embodiment 1 needs to carry out cumbersome installation work before the tea leaves wither.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com