Tea withering device

A withering device and tea technology, which is applied in the field of tea withering devices, can solve problems such as tea deterioration, and achieve the effect of cost saving and uniform withering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

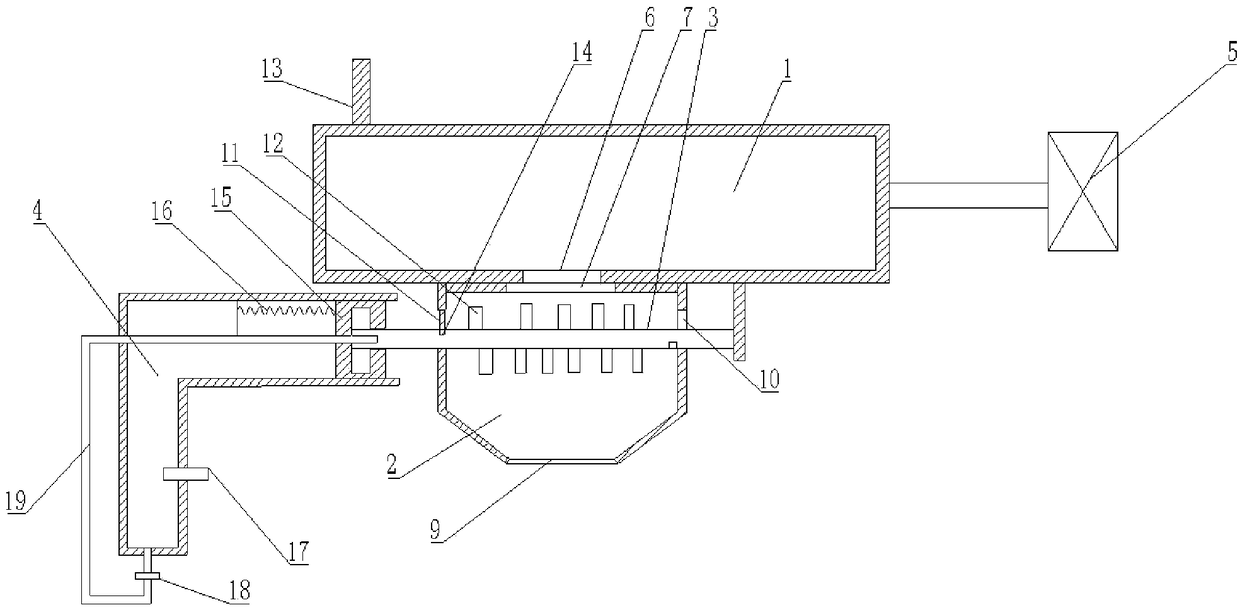

[0024] Such as figure 1 As shown, the tea withering device includes a feeding barrel 1, a conduit, a withering barrel 2 located below the feeding barrel 1, a hollow horizontal rotating shaft 3, a piston barrel 4, a heating component located in the withering barrel 2, and the feeding barrel. 1 motor 5 connected end-face.

[0025] The feeding barrel 1 is provided with a first discharge port 6; the upper end of the withering barrel 2 is provided with a first feed port 7, and the lower end is provided with a second discharge port 9; The tea leaves leaked from the feed port 6 are transported into the withering barrel 2, the first discharge port 6 can face the first feed port 7, and the opening area of the first discharge port 6 is smaller than the opening area of the first feed port 7 .

[0026] Both sides of the withering barrel 2 are symmetrically provided with first openings 10, the horizontal rotating shaft 3 runs through the withering barrel 2 through the first opening 1...

Embodiment 2

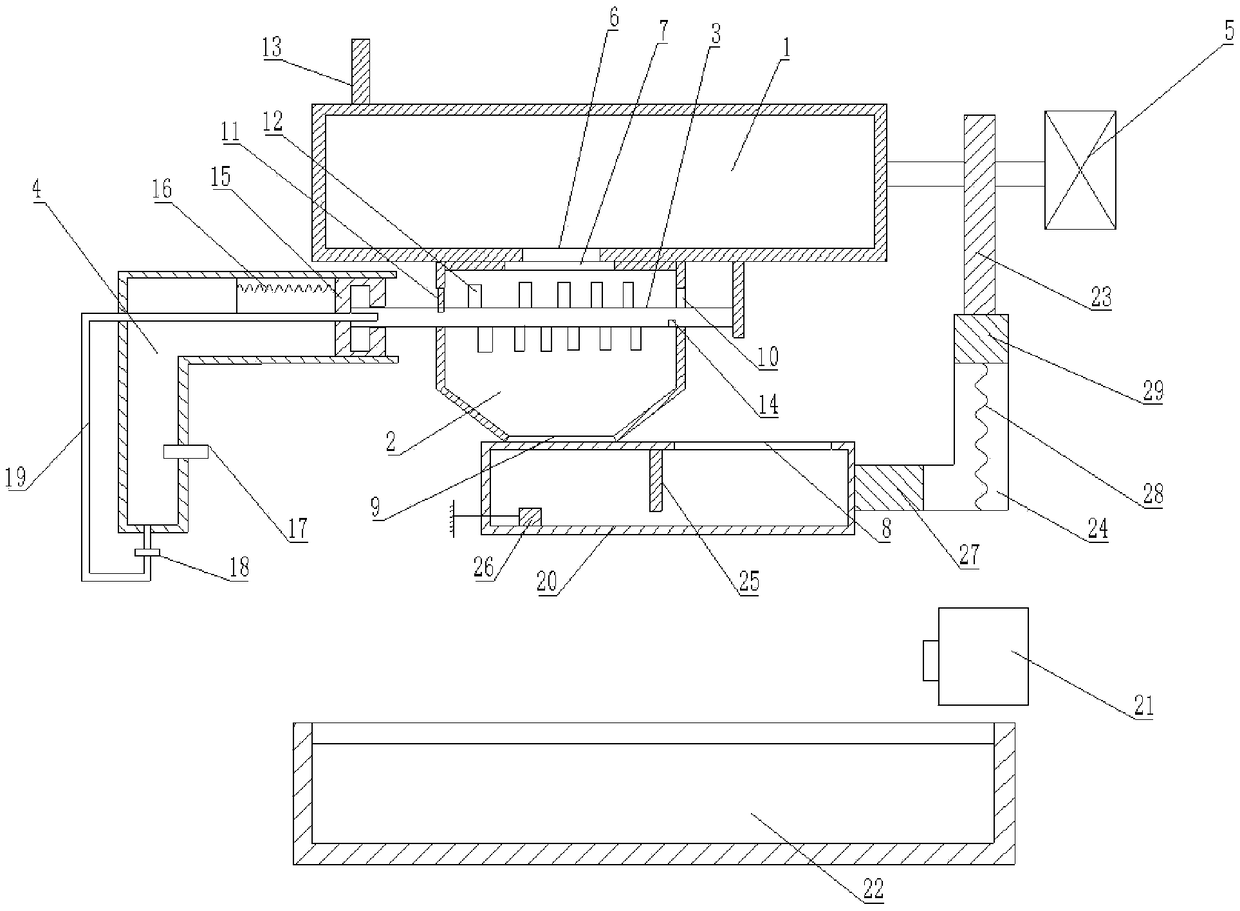

[0035] Tea withering device, such as figure 2 shown. This embodiment is an optimization scheme of Embodiment 1. The difference between this embodiment and Embodiment 1 is that it also includes a vertical spring 28, a connecting rod, and a trash removal bucket 20, a blower fan 21, and aggregates arranged below the withering bucket 2 in sequence. The barrel 22, the impurity removal barrel 20 can block the second discharge port 9, and also includes a cam 23 driven by the output shaft of the motor 5 and a connecting column 24 of "L" shape.

[0036] The trash removal barrel 20 is fixedly connected with a vertical rod 25, and the upper end of the trash removal barrel 20 is provided with a second feed port 8, the second discharge port 9 can be directly opposite to the second feed port 8, and the second feed port 8 The area of the opening 10 of the second feeding port 8 is larger than that of the opening 10 of the second feeding port 9 for transporting the tea leaves falling from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com