Chemical raw material reaction device capable of realizing gas-liquid separation

A technology for chemical raw materials and reaction devices, which is applied in the field of chemical raw material reaction devices, can solve problems such as affecting product quality, can no longer be used, and reactant deterioration, and achieves the effects of increasing economic benefits, ensuring product quality, and improving conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

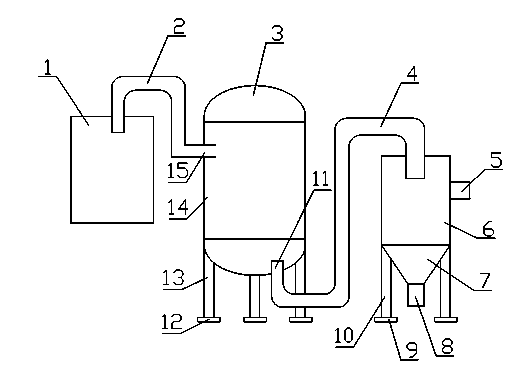

[0009] The specific embodiments of the present invention are given below with reference to the accompanying drawings, which are used to further describe the composition of the present invention in detail.

[0010] This embodiment is a chemical raw material reaction device capable of realizing gas-liquid separation, including a housing 14, the two ends of the housing 14 are welded with a head 3, the bottom of the lower end of the head 3 is provided with a leg 13, and a pressure plate is installed at the bottom of the leg 13 12. The shell 14 is provided with a feed port 15, one end of the pipe 2 is connected to the feed port 15, the other end of the pipe 2 extends into the vacuum system 1, and the lower end head 3 is provided with a discharge port 11, and the discharge port 11 is provided. The port 11 is connected with a connecting pipe 4, and the connecting pipe 4 extends into the gas-liquid separator. The gas-liquid separator is composed of a straight cylinder 6 and a cone cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com