Yogurt machine

A yogurt machine and fermentation container technology, applied in milk preparations, dairy products, applications, etc., can solve the problem of spoiled yogurt, which can only be used in the yogurt machine, cannot be ignored, and must be quickly put into the refrigerator for refrigeration. , to avoid the effect of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

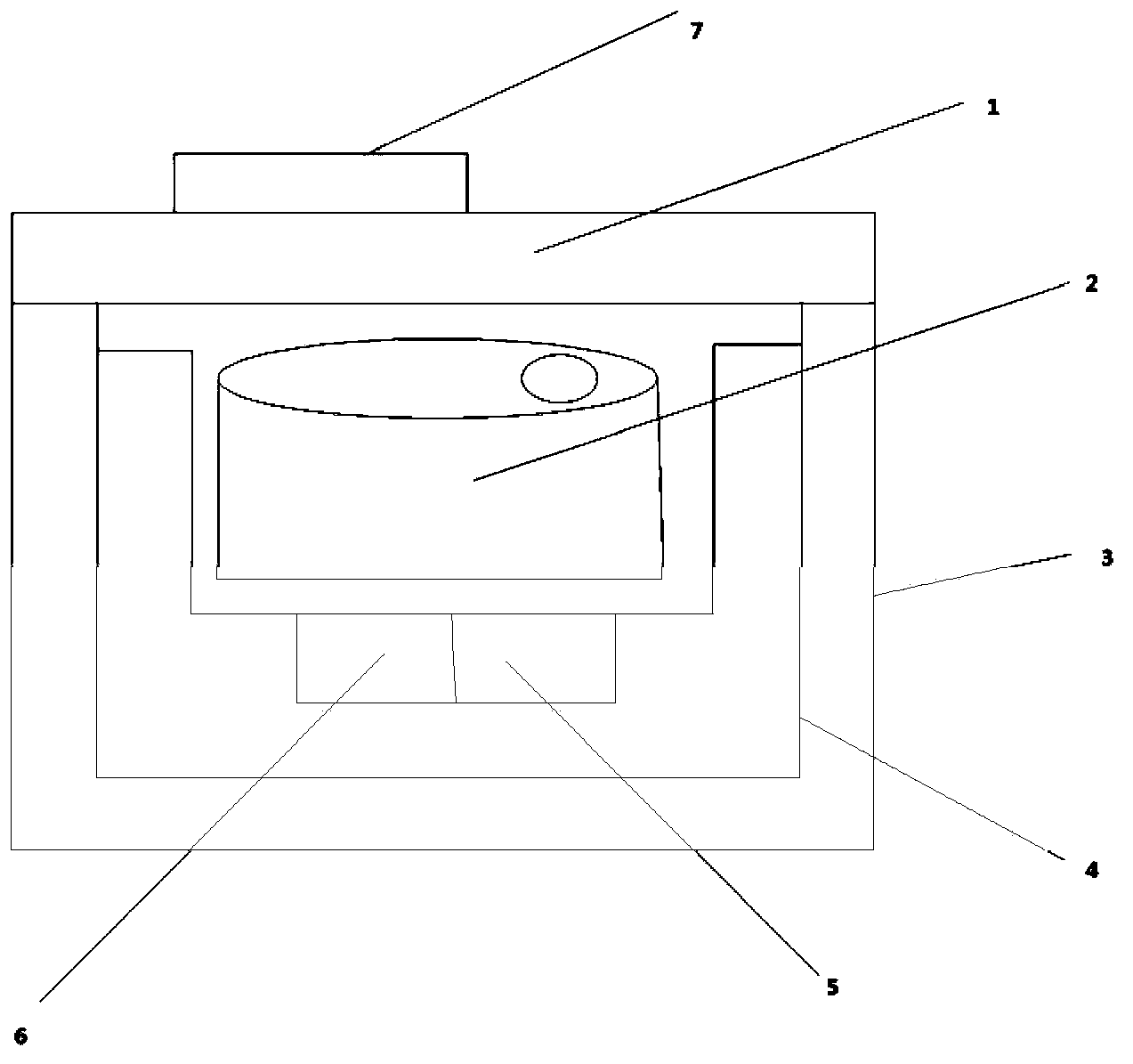

[0011] The specific embodiment of the present invention is as follows: a yogurt machine, comprising a cover 1, a fermentation container 2, an outer shell 3, an inner shell 4, a heating element 5, a control panel 7 and a cooling element 6, the cover 1 is on the outer shell 3; The fermentation container 2 is in the middle of the depression of the inner shell 4; the heating element 5 is in the inner shell 4, at the bottom right of the fermentation container 2; the refrigeration element 6 is on the left side of the heating element 5; the control panel 7 is on the cover 1 superior. When using the yogurt machine, pay attention to controlling the time and temperature. If the finished yogurt cannot be transferred to the refrigerator in time, turn the single valve on the fermentation container 2 before the yogurt machine starts to avoid deterioration of the finished yogurt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com