Patents

Literature

80results about How to "Achieve flipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

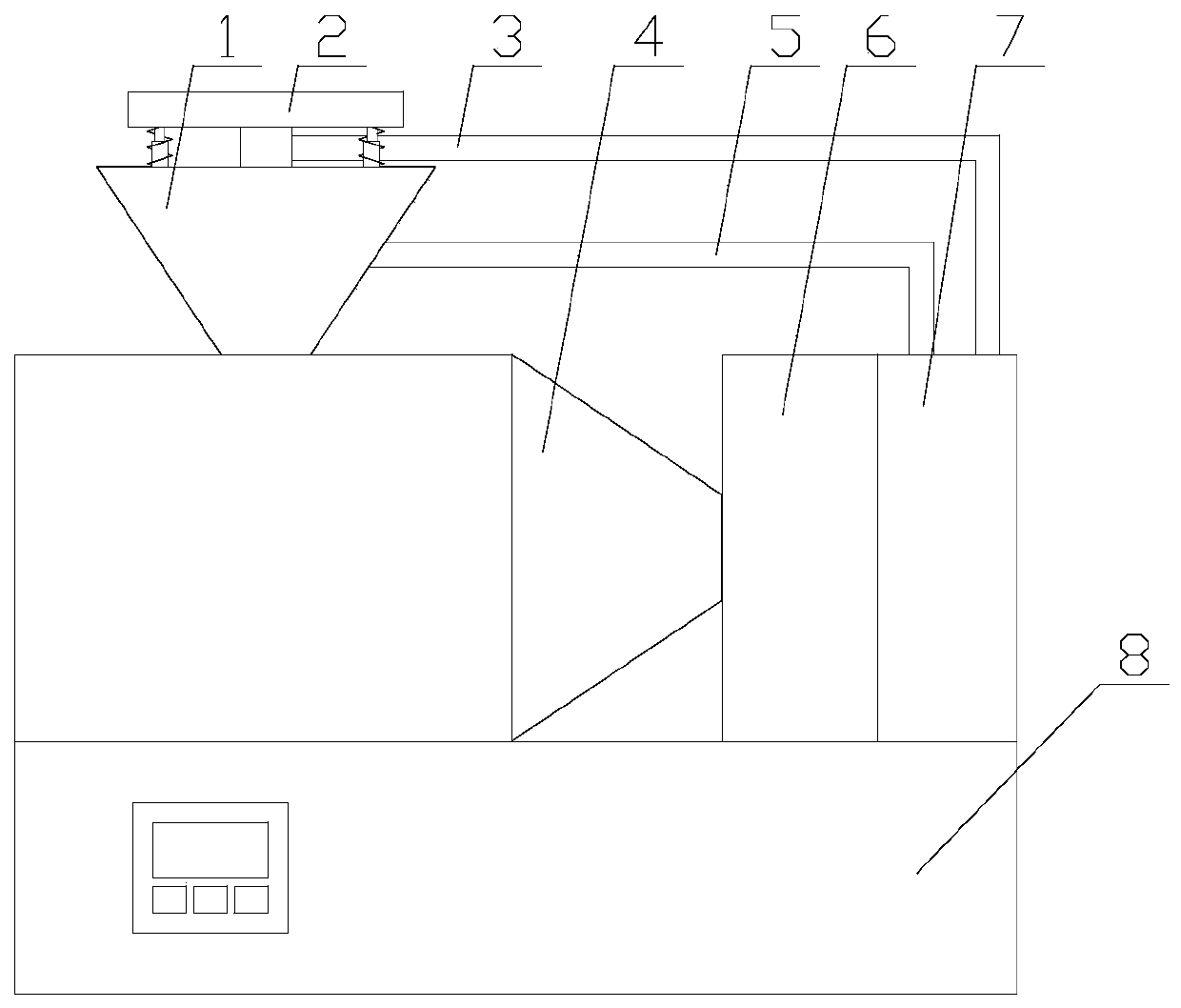

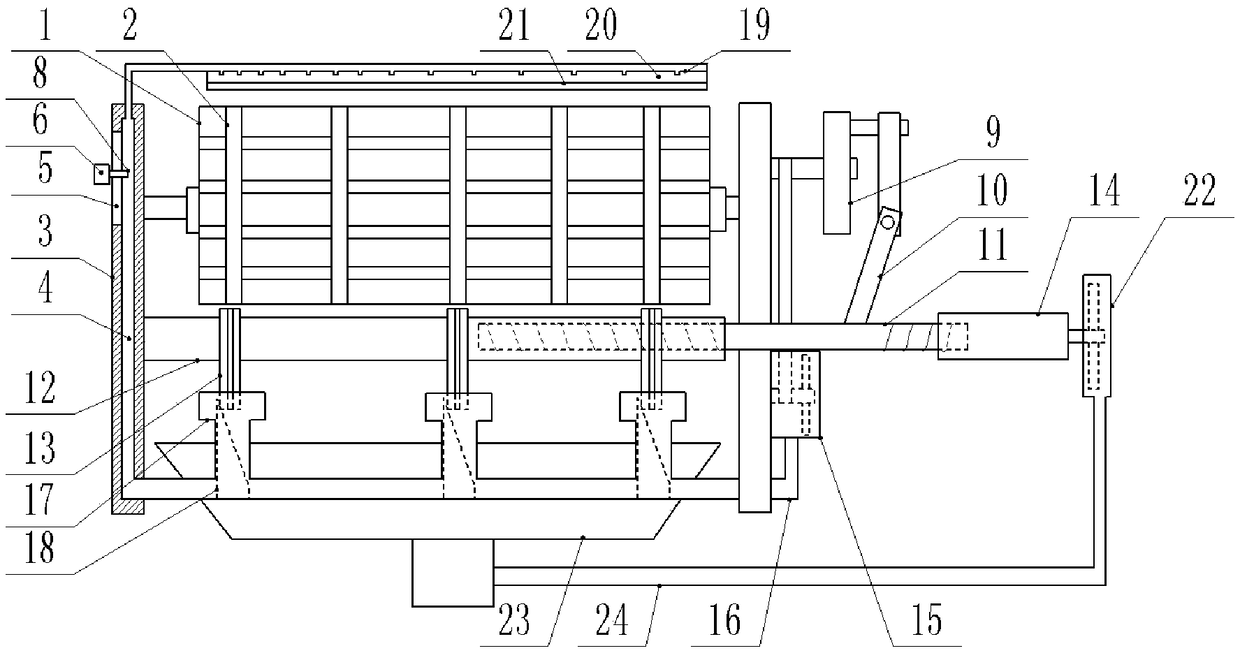

Asphalt stirring device for building construction

InactiveCN105664769AAchieve flippingAchieve hybridRotating receptacle mixersTransportation and packagingArchitectural engineeringAsphalt

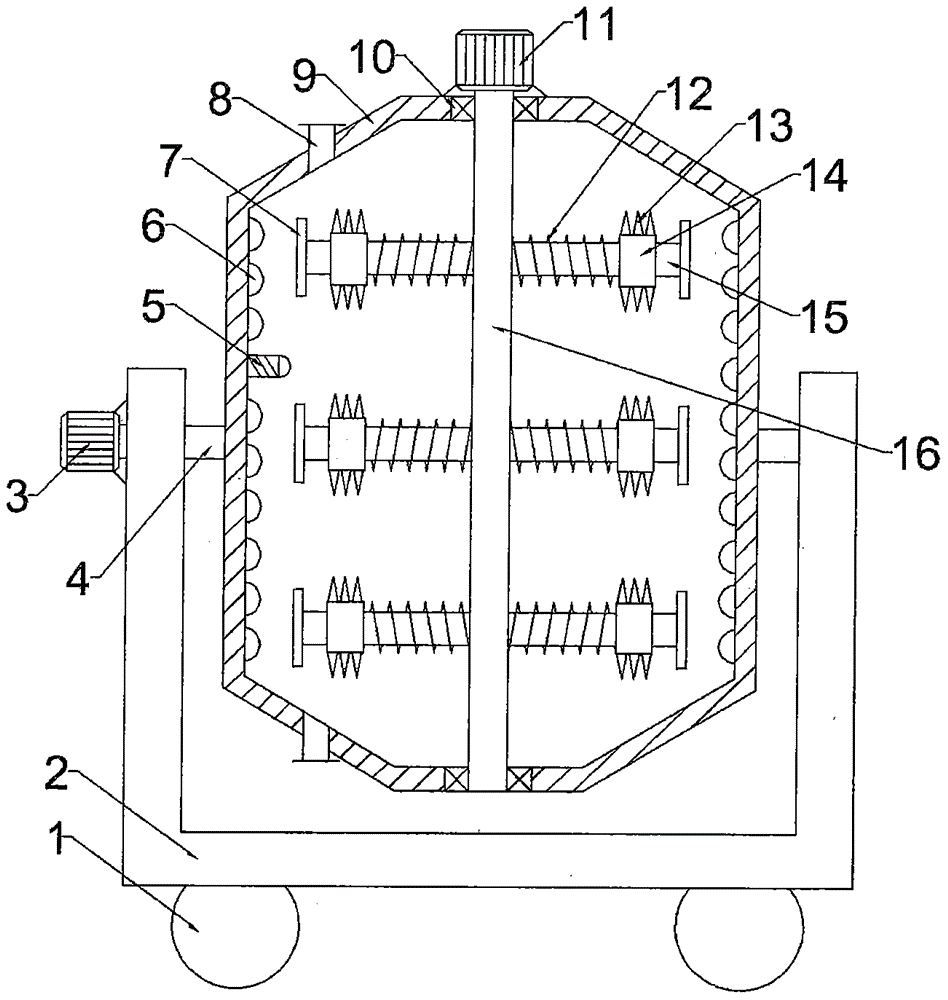

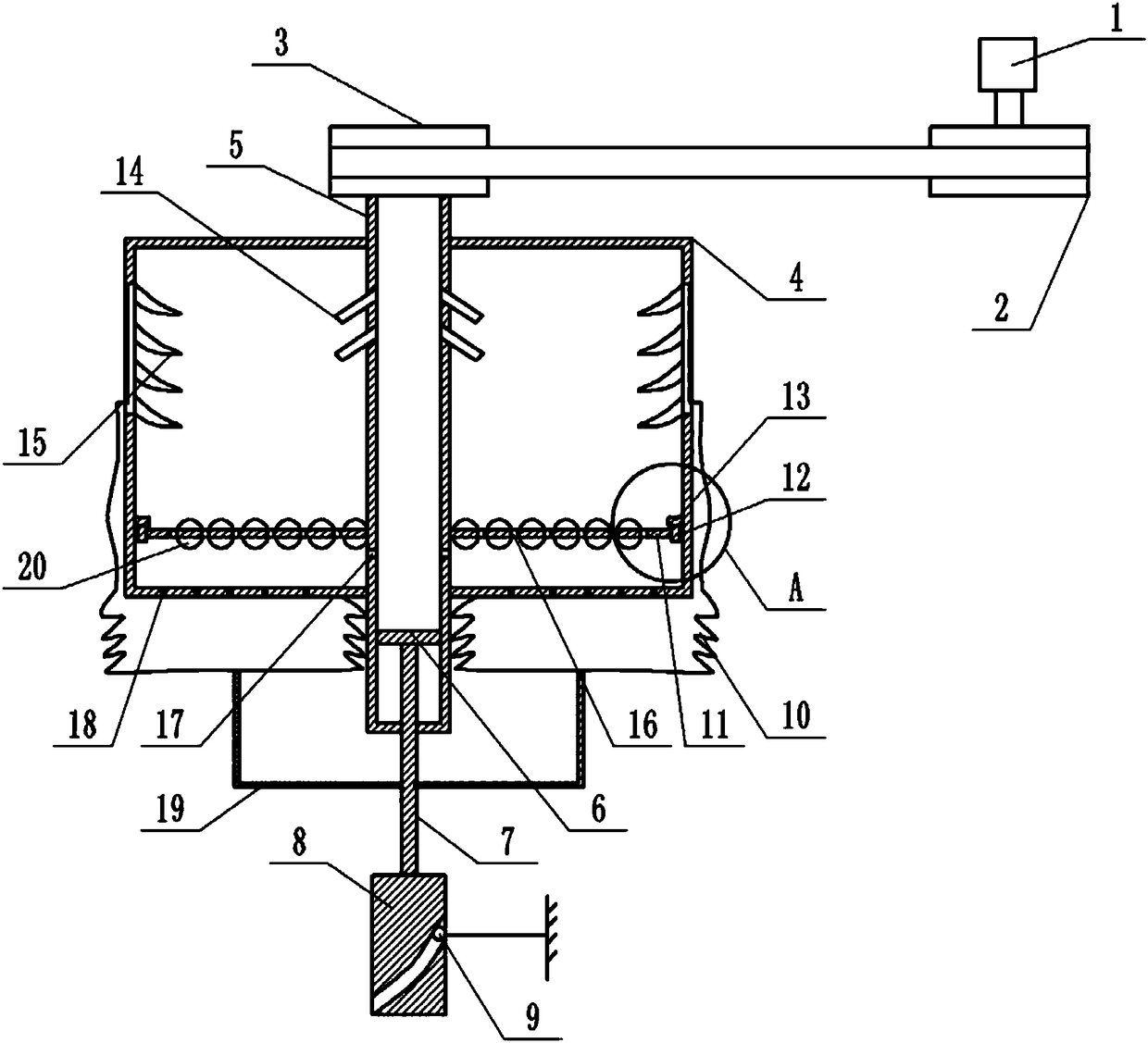

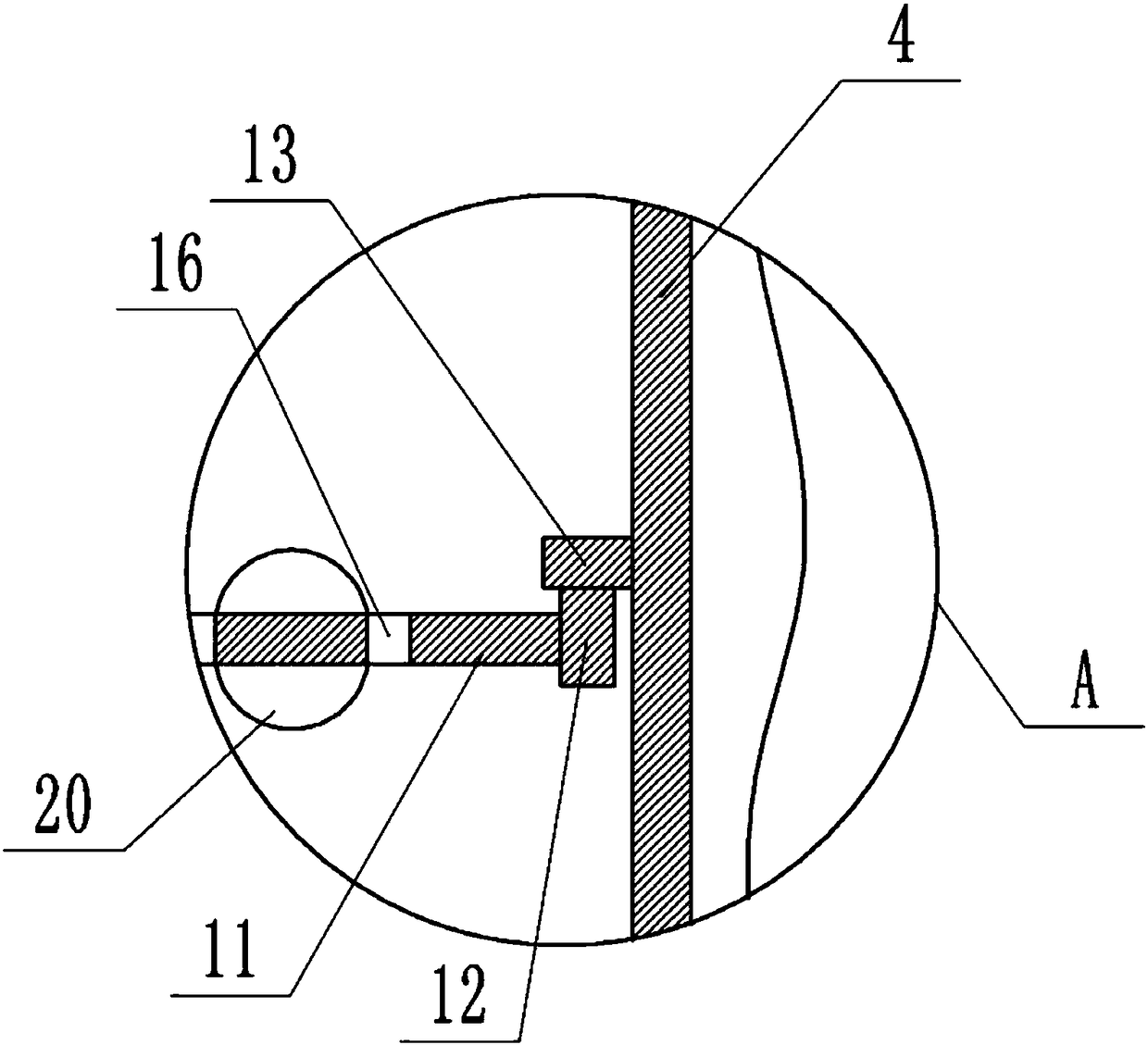

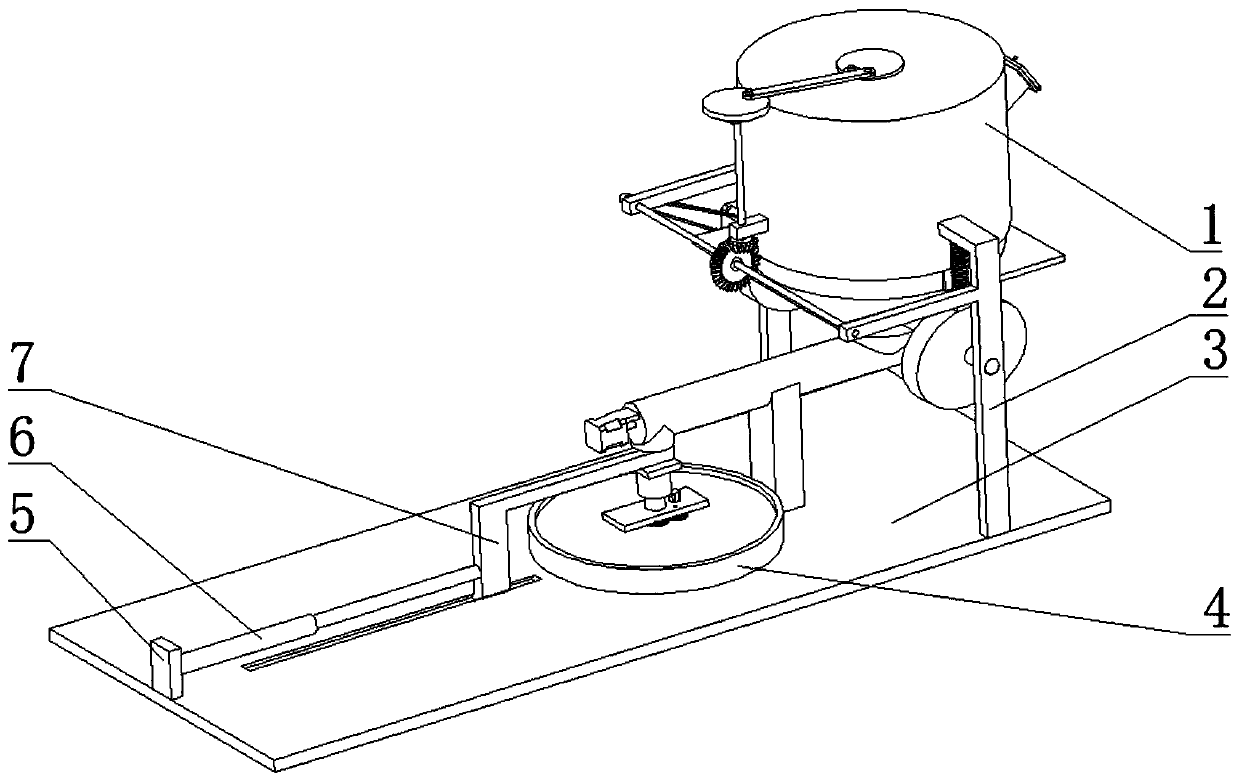

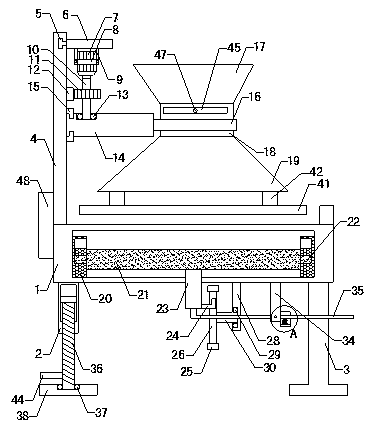

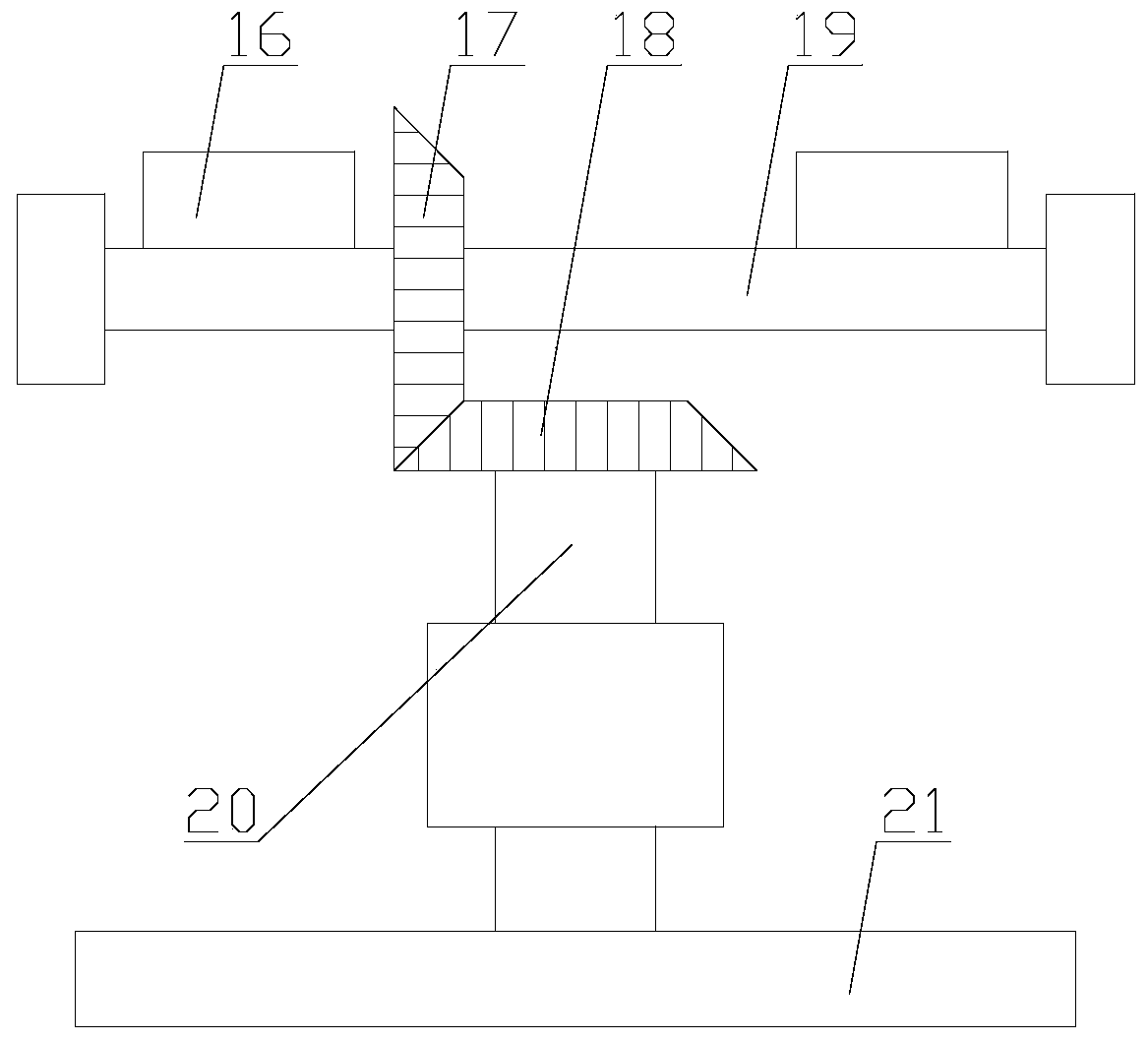

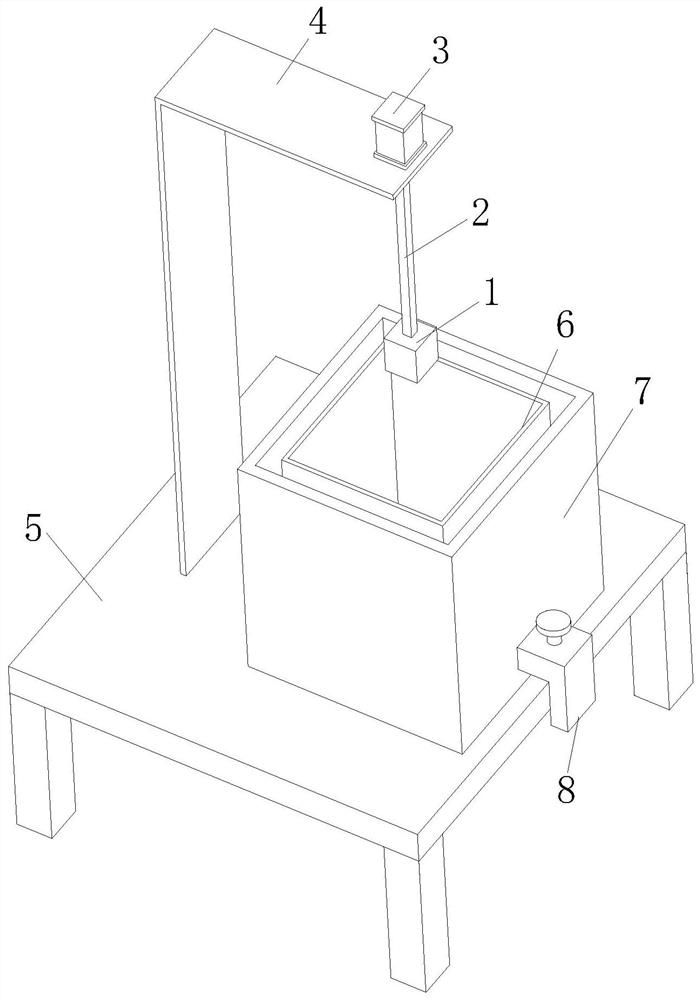

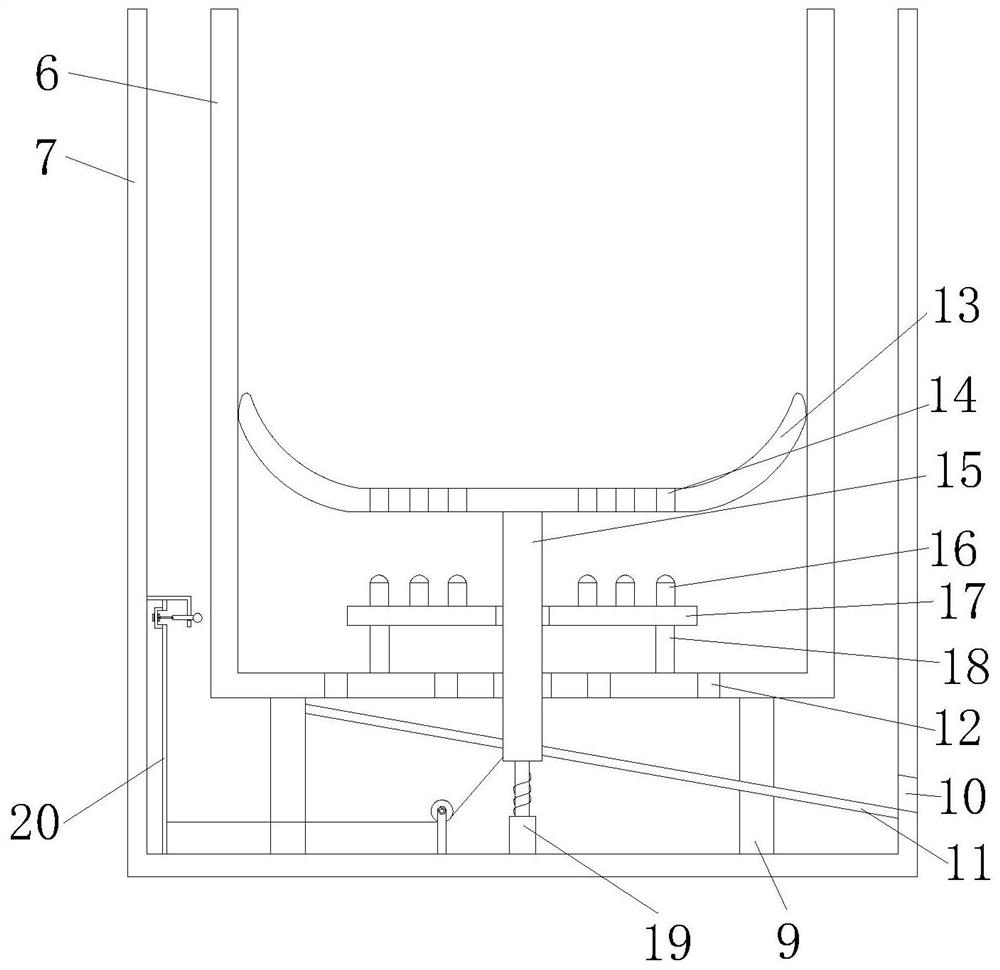

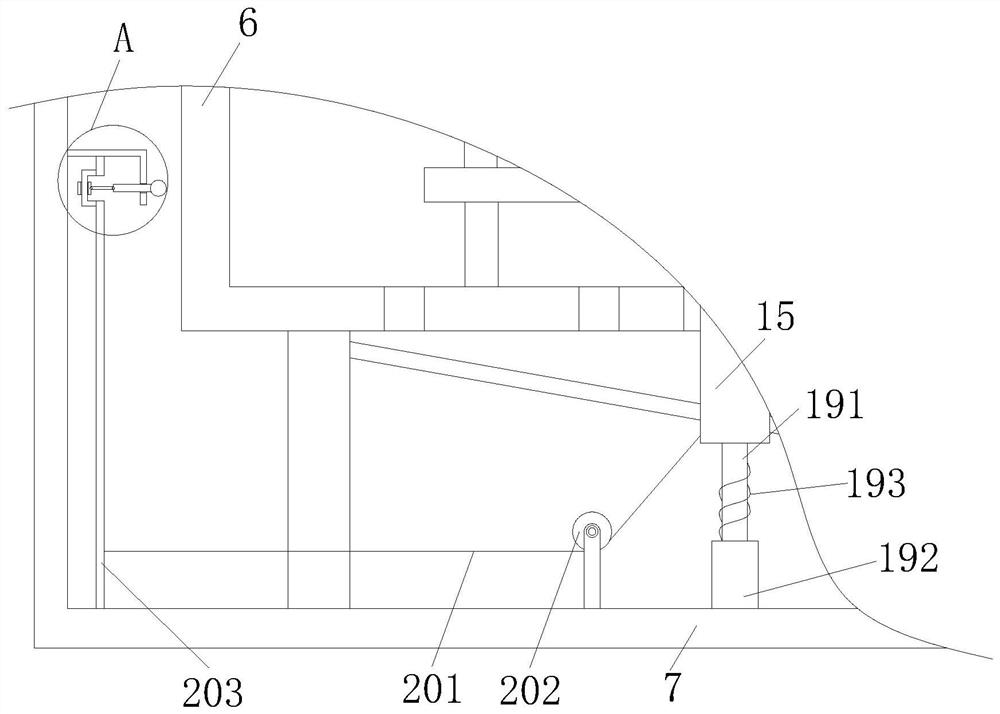

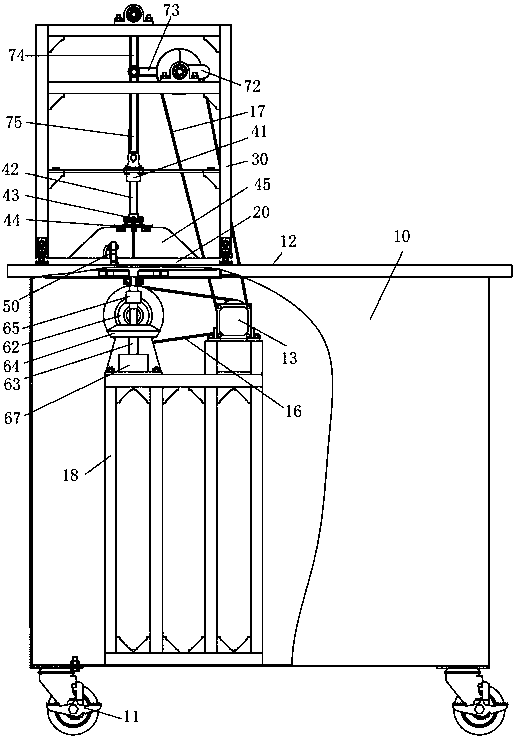

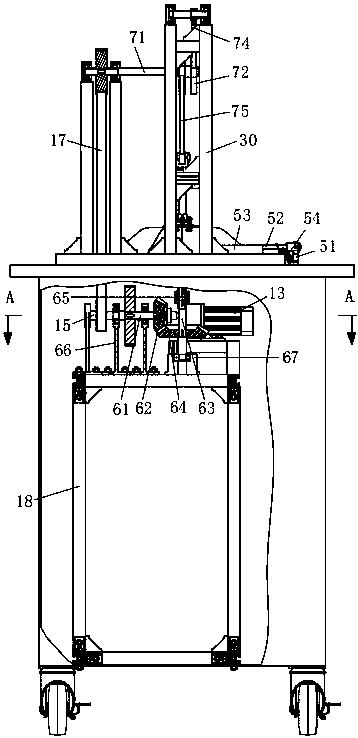

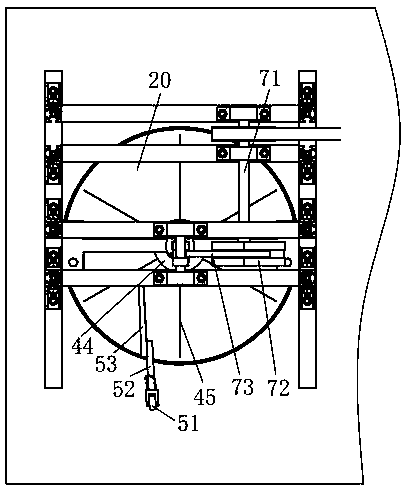

The invention relates to an asphalt stirring device for building construction. The asphalt stirring device comprises a stander and a stirring tank, wherein two support shafts are symmetrically arranged in the middle of the outer surface of the stirring tank and are rotatably connected with support arms on two sides of the stander, and one support shaft is connected with an inverted motor; a stirring shaft is arranged in the stirring tank, the upper end of the stirring shaft is connected with a variable frequency motor located above the stirring tank, a plurality of stirring device are uniformly distributed on the stirring shaft and comprise mounting rods, one ends of the mounting rods are fixedly connected with the stirring shaft, the mounting rods are sleeved by reset springs, one ends of the reset springs are fixedly connected with the stirring shaft, sliding blocks are fixedly connected to the other ends of the reset springs, and the mounting rods are sleeved by the sliding blocks. The asphalt stirring device has the beneficial effects that the inverted motor can drive the stirring tank to rotate by 180 degrees, and then materials at the bottom of the stirring tank are transferred to the top, so that the substantial overturning of the materials is realized, and the effective mixing of the materials is realized.

Owner:杨露萍

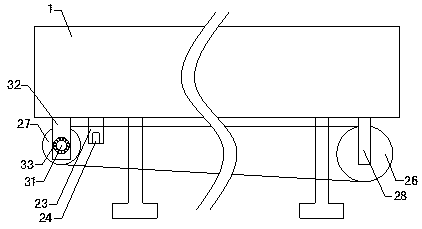

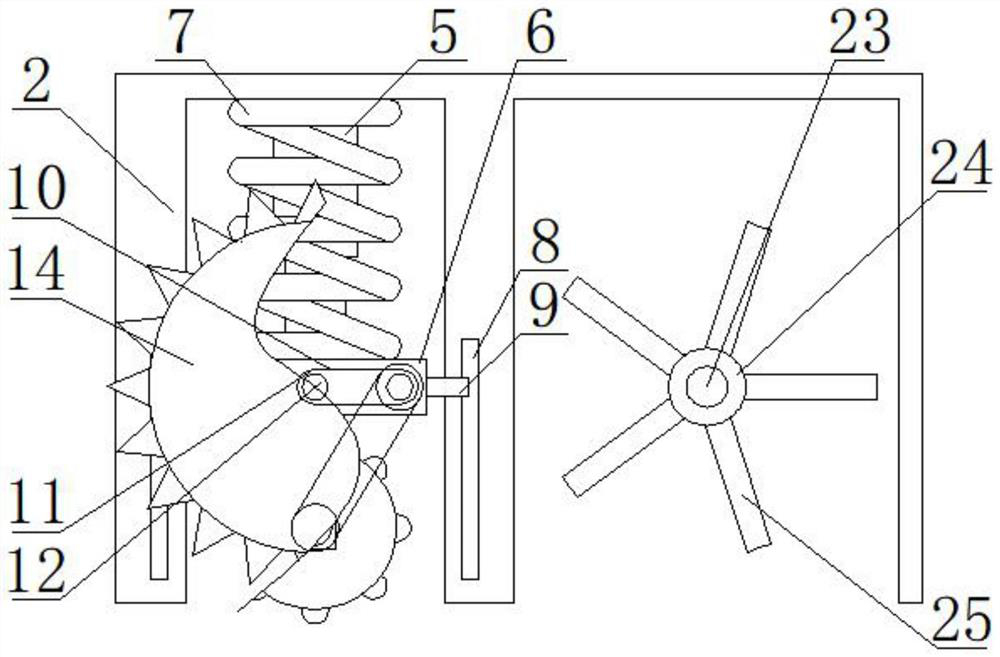

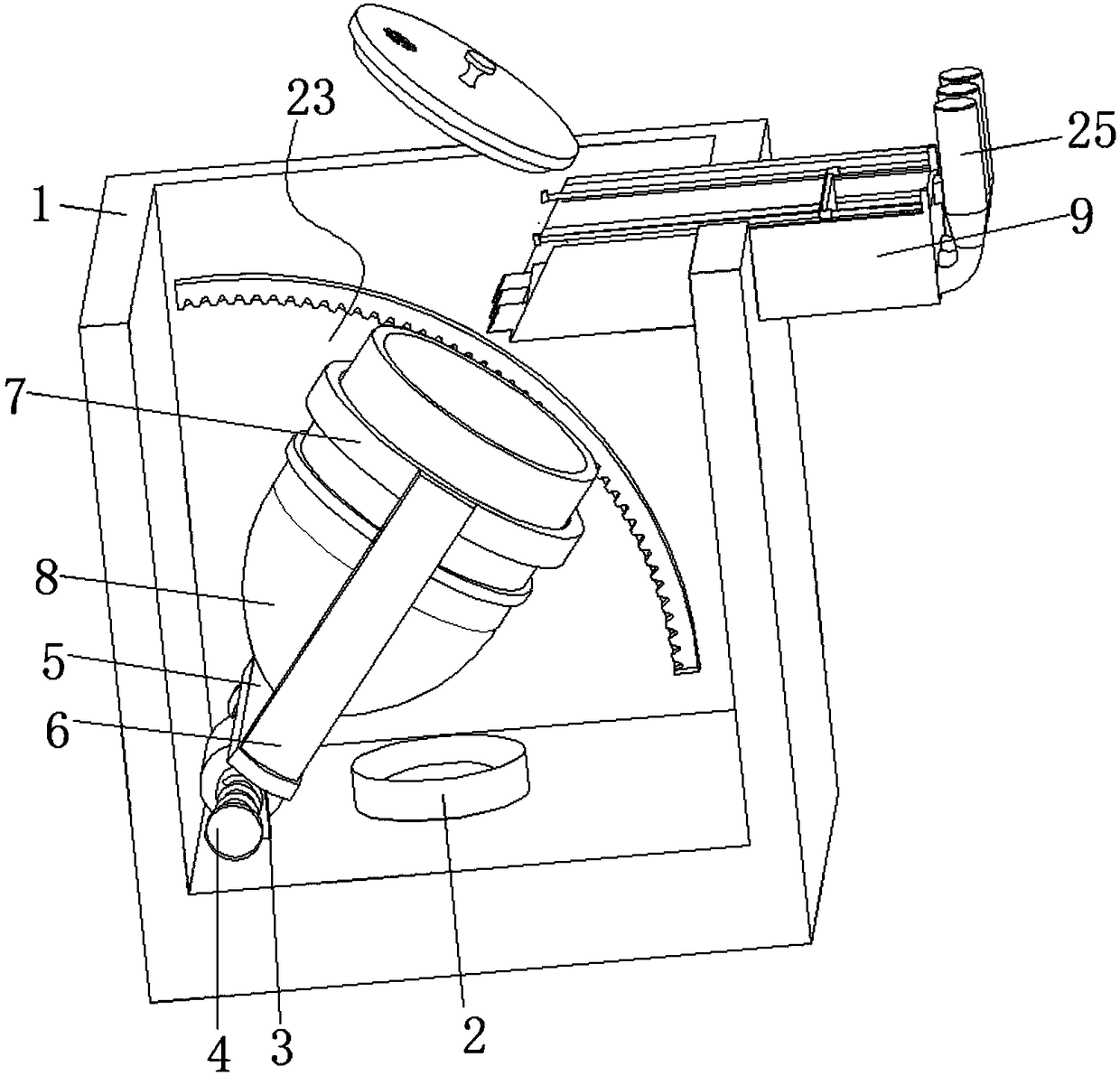

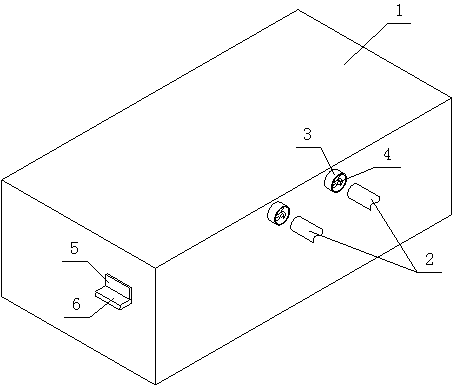

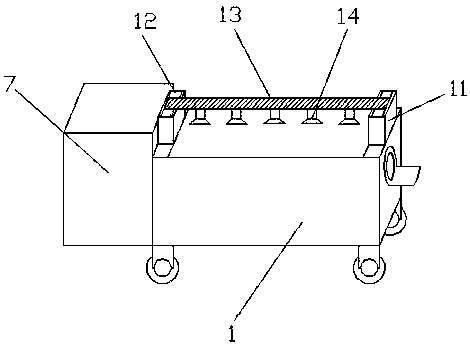

Sand mixing equipment

ActiveCN104815950AAchieve rollingAchieve grindingMould handling/dressing devicesDrive motorEngineering

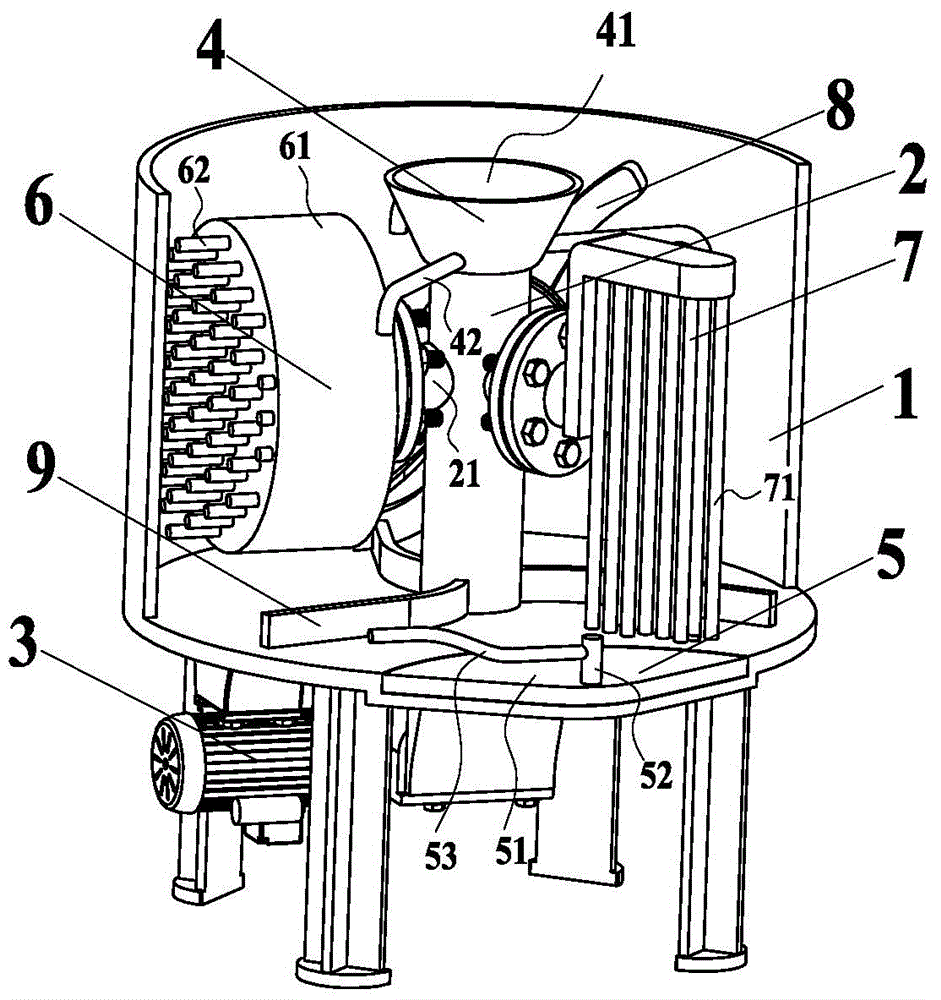

The invention relates to foundry machinery, specifically to sand mixing equipment. The sand mixing equipment comprises a cylinder, a rotation shaft, a driving motor, a watering device, a valve device, a sand rolling device, a sand fluffing device, a sand-casting device and a scraper plate. The cylinder is a hollow cylinder structure. The bottom of the cylinder is provided with a fan-shaped opening. A support plate is arranged at the opening. The opening is used for releasing mixed sand. The support plate is provided with through-holes. The rotation shaft is installed at the middle part of the cylinder. The driving motor is positioned below the cylinder. The watering device is positioned above the rotation shaft. The valve device is installed at the bottom of the cylinder. The sand rolling device, the sand fluffing device, the sand-casting device and the scraper plate are uniformly installed on the periphery of the rotation shaft. The scraper plate is positioned at the bottom of the cylinder. The sand mixing equipment has a simple structure. By effectively integrating a muller, a sand fluffing rod, a plough and the scraper plate, rolling, grinding, stirring and turning-over of a material are realized, and sand-mixing efficiency of the sand mixer is enhanced.

Owner:南通乐士机械有限公司

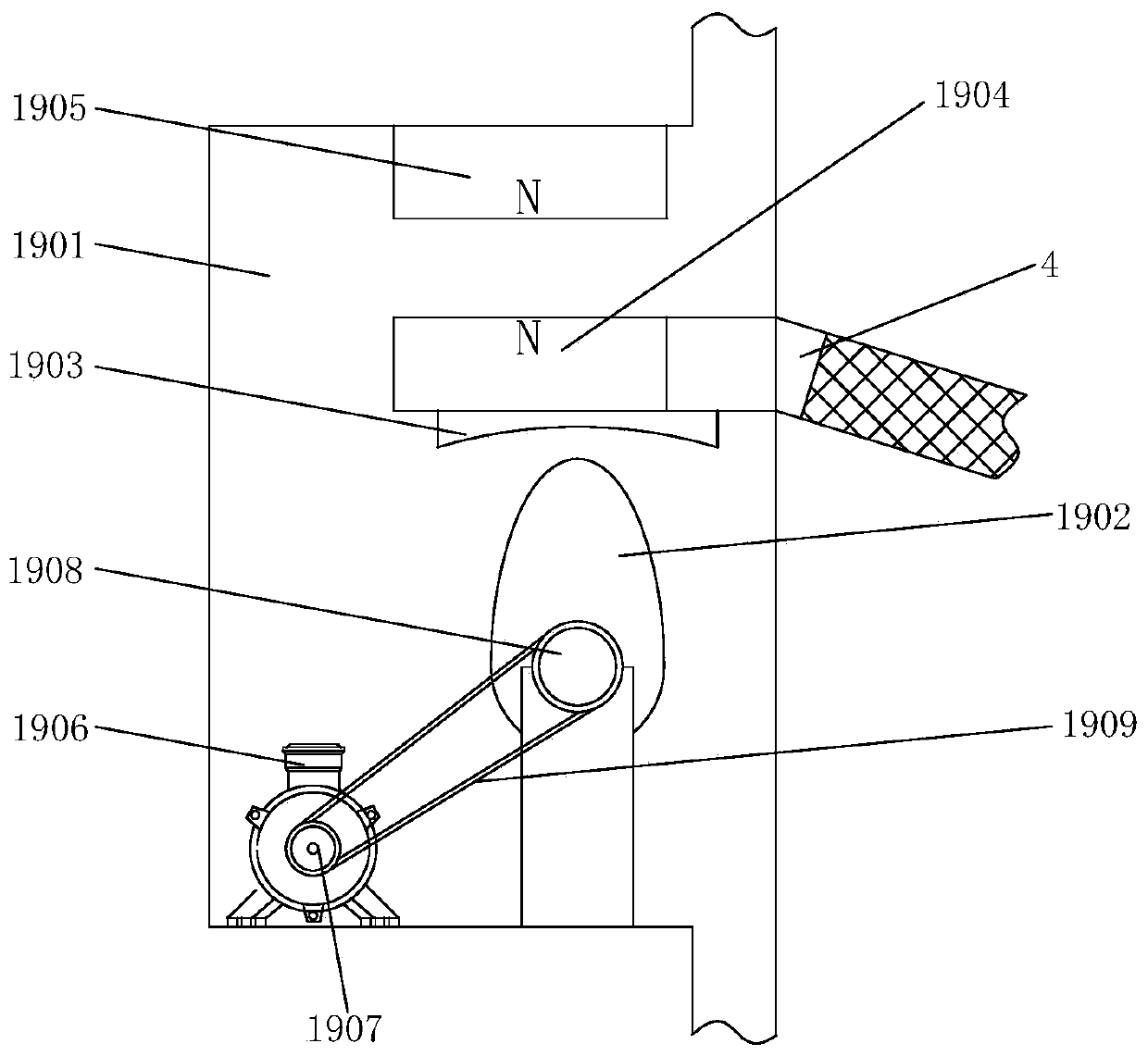

Preliminary cleaning device for textile

ActiveCN108589118AEasy to cleanImprove efficiencyLiquid/gas/vapor fabric treatmentEngineeringWater circulation

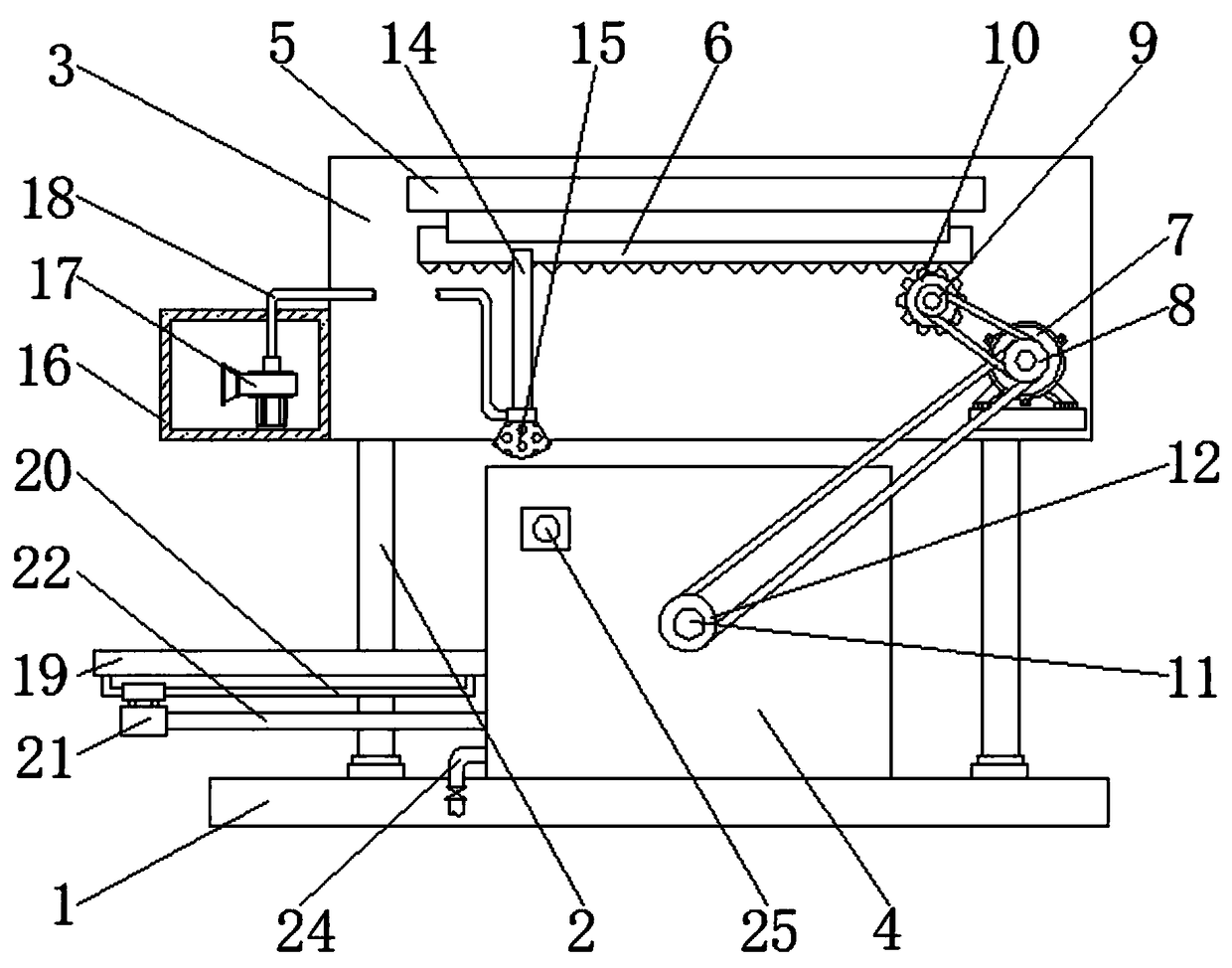

The invention relates to the field of textile processing, in particular to a preliminary cleaning device for textile. The preliminary cleaning device comprises a rack, a motor arranged on the rack, adriving belt pulley driven by the motor, a driven belt pulley driven by the driving belt pulley and a cleaning mechanism connected with the driven belt pulley, wherein the cleaning mechanism comprisesa cleaning box arranged on the rack, a hollow rotating shaft fixedly connected to an axle of the driven belt pulley and vertically penetrating through the cleaning box, a piston glidingly connected to the lower end of the hollow rotating shaft, a cylindrical cam connected to the lower end of the piston rod of the piston, a slider arranged on the rack and sliding in a sliding chute of the cylindrical cam as well as an inflation air bag connected to the bottom of the cleaning box by surrounding the periphery of the hollow rotating shaft. According to the scheme, preliminary cleaning of the textile is completed through water circulation and stirring of the textile in the cleaning box, the cleaning effect is good and the efficiency is high.

Owner:NINGBO WENZE TEXTILE CO LTD

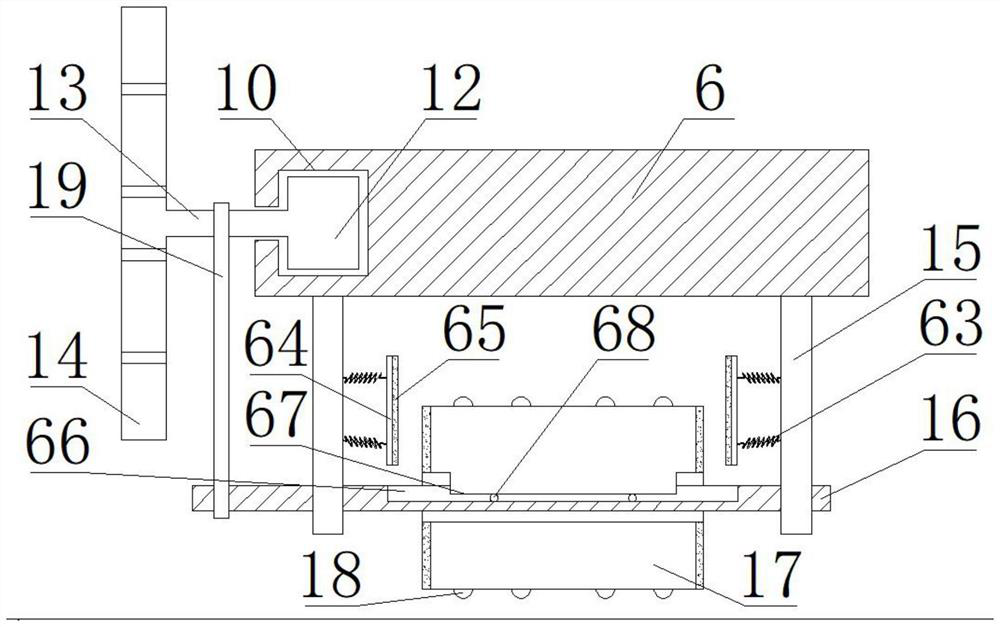

Chemical eluting device for soil repair

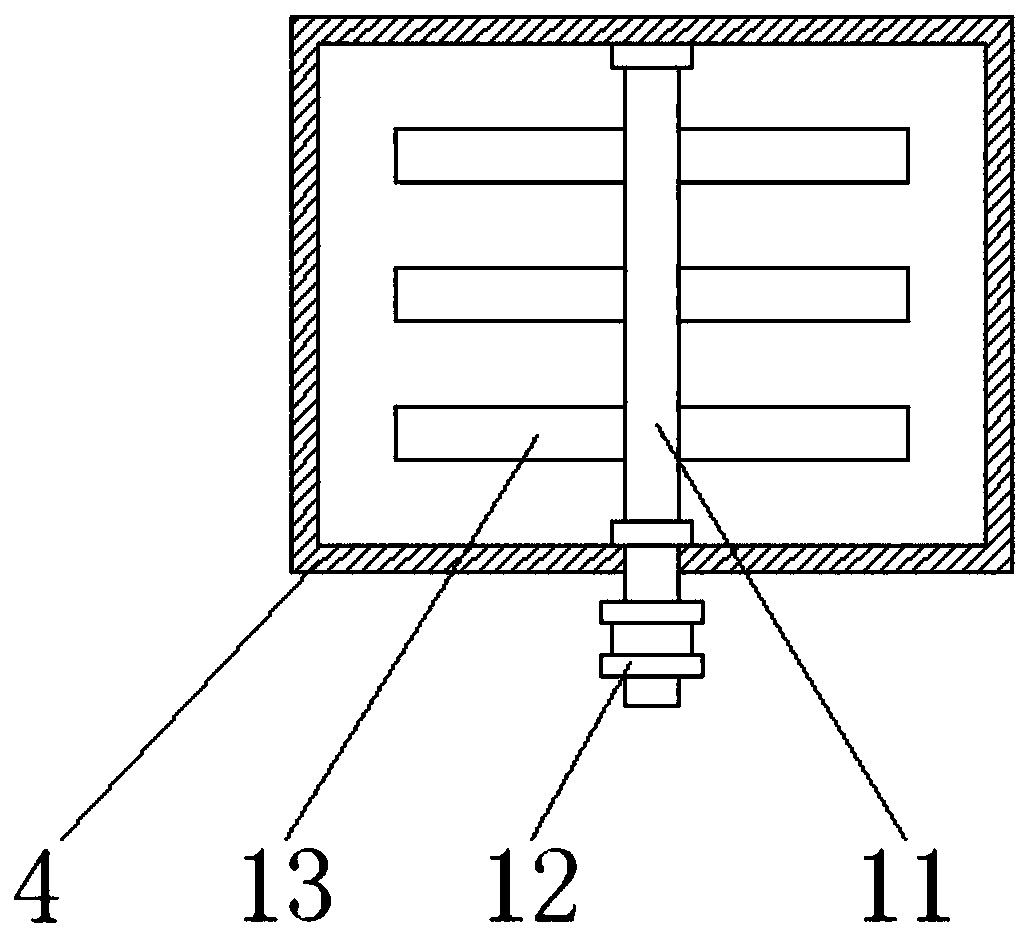

InactiveCN108994060AFully repairedFull repairContaminated soil reclamationElectric machineryPollutant

The invention discloses a chemical eluting device for soil repair. The device comprises a bottom plate. Supporting legs are fixedly connected to two sides of the top of the bottom plate, the top endsof the two supporting legs are fixedly connected to fixed plates, the top of the bottom plate is fixedly connected to a box body, a transverse plate is fixedly connected to the front face of the fixedplate, the bottom of the transverse plate is slidably connected to a rack, a motor is fixedly connected to the bottom of one side of the front face of the fixed plate through a connecting block, a double-groove belt wheel is fixedly connected to one end of the output shaft of the motor, and the outer surface of the double-groove belt wheel is in transmission connection to a first belt wheel through a belt. The invention relates to the technical field of soil repair. According to the chemical eluting device for soil repair, left and right reciprocating motions of a nozzle are achieved, and meanwhile, soil can be overturned through a rotating part, so that an elution and soil are mixed more fully in the chemical eluting process of soil repair, pollutants in the soil can be separated by an eluting liquid to a greater extent, and soil is repaired fully.

Owner:芜湖鑫霖森椽环保科技有限公司

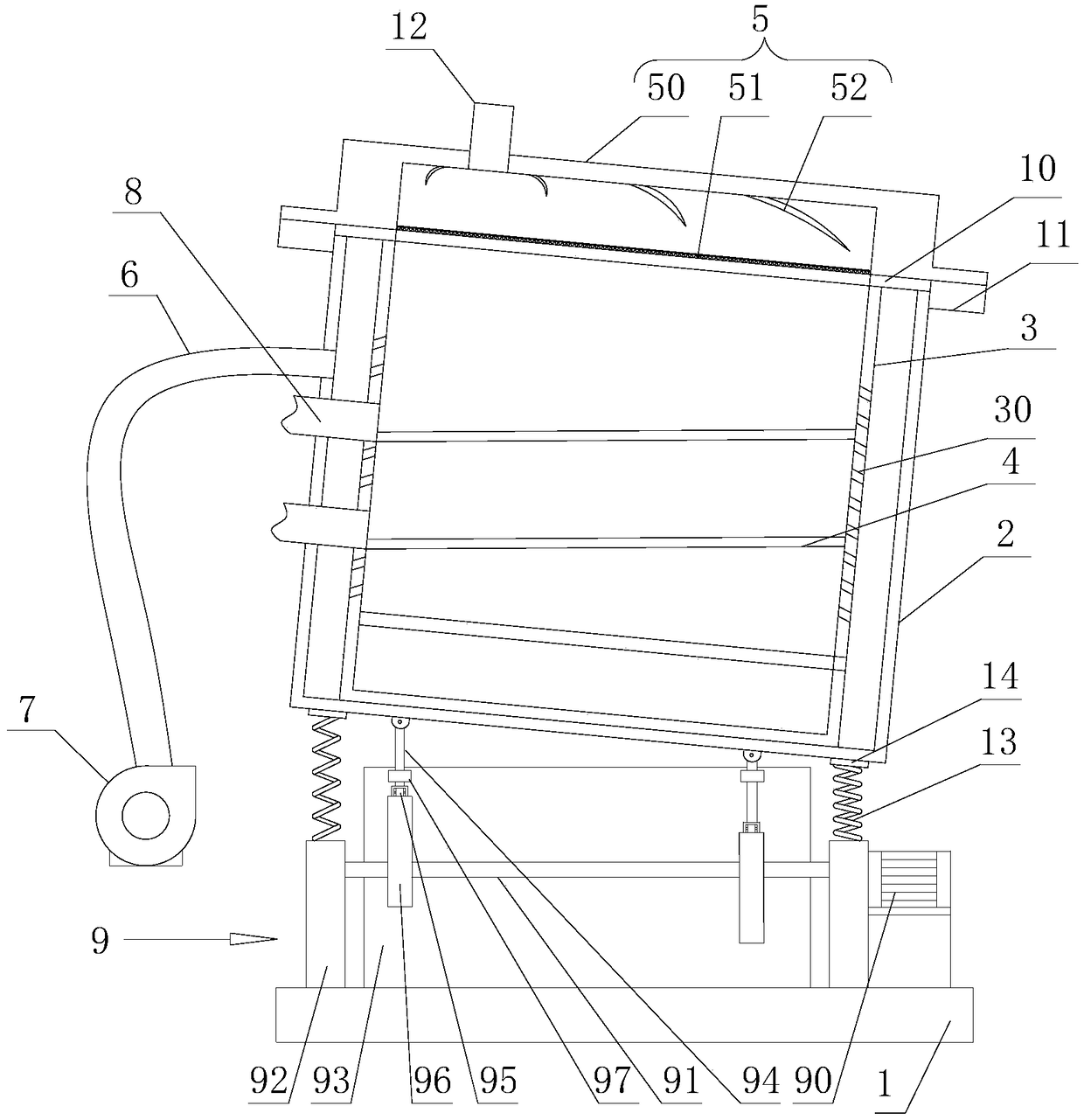

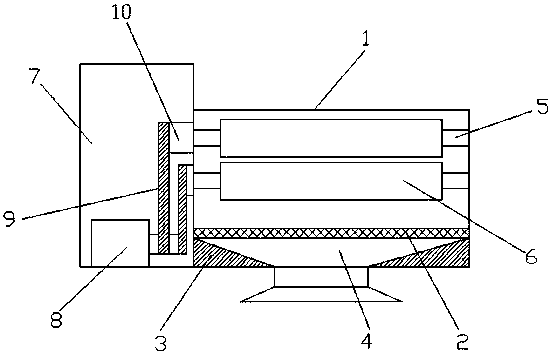

Automatic grain rapid drying device

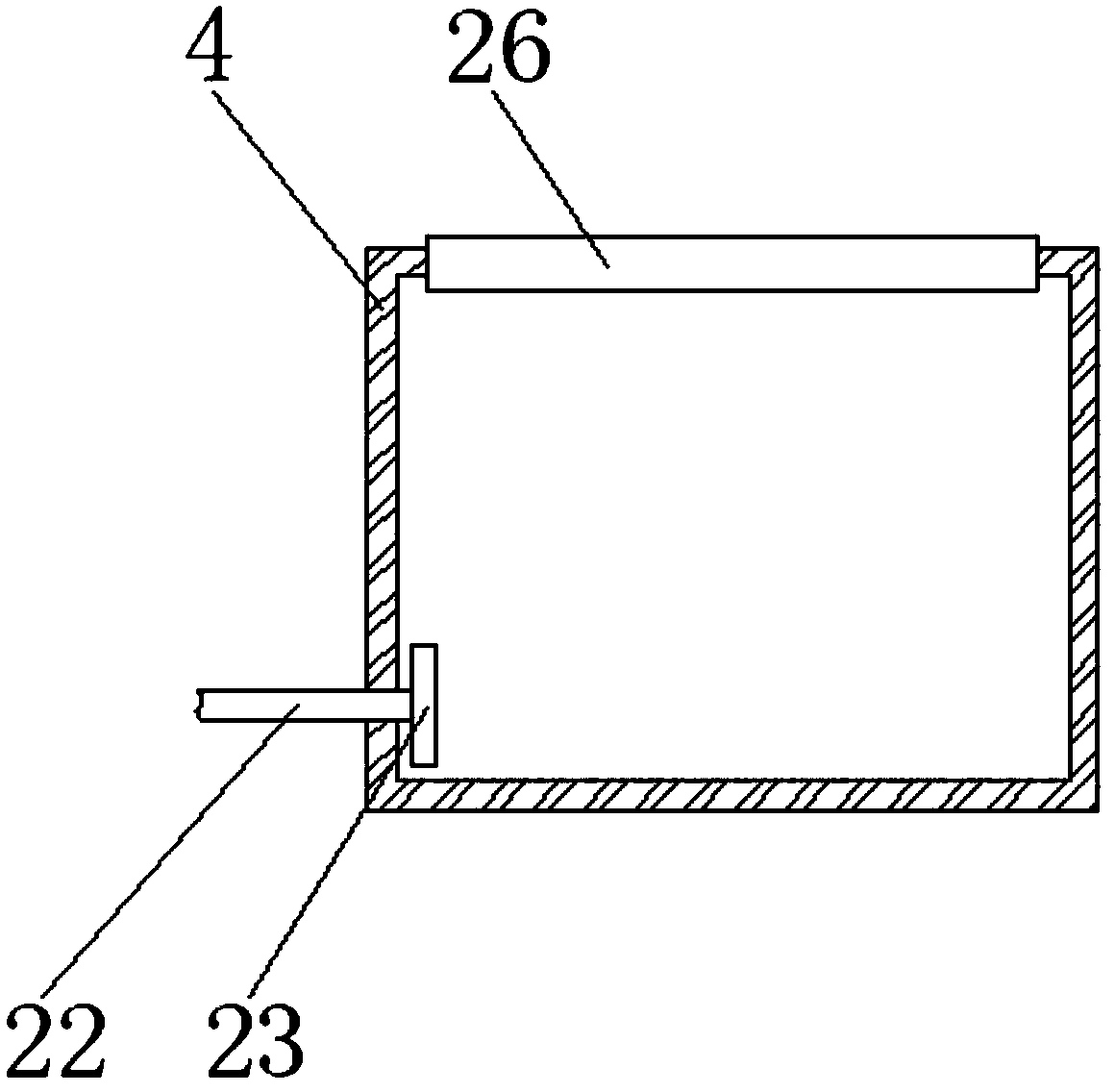

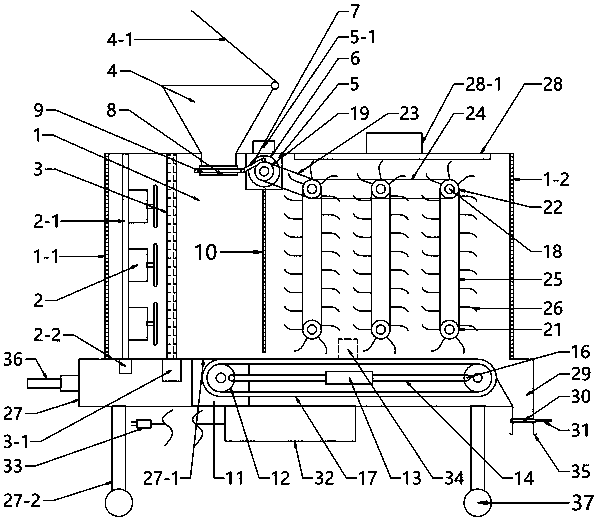

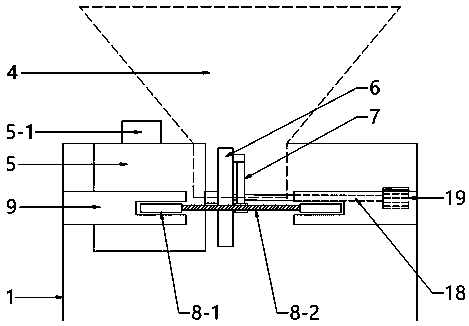

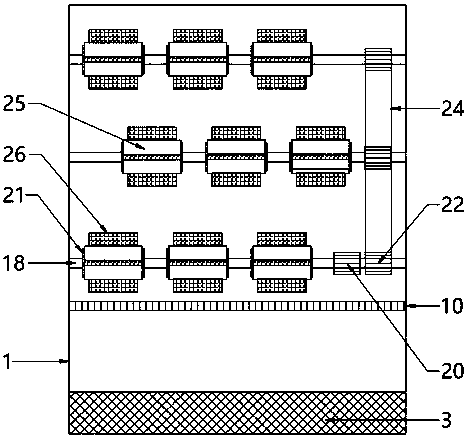

InactiveCN108731455AIncrease temperatureQuick stackDrying gas arrangementsSeed preservation by dryingFiberEvaporation

The invention relates to the technical field of agricultural apparatus, in particular to an automatic grain rapid drying device. The automatic grain rapid drying device comprises a base, a drying box,a conveying device and turning-over devices. A carbon fiber heating net is arranged on the right sides of draught fans; the conveying device is arranged in the base on the lower portion of the dryingbox and comprises a conveying motor, two rotating discs and a conveying track, and an electric heating layer controller is arranged between the two rotating discs; each turning-over device comprisesconnecting shafts, a conveying belt and trays, the connecting shafts are in shaft connection with the front wall and the rear wall of the drying box and are vertically distributed, the multiple sets of turning-over devices are parallelly arranged, and the trays are uniformly distributed on the conveying belts; and a ceramic heating lamp is arranged on the top wall, above the conveying belts, in the drying box. The automatic grain rapid drying device is reasonable in structural design; and the multiple draught fans and the carbon fiber heating net can generate uniform hot air, an electric heating layer in the conveying track can heat the surface of the conveying track continuously in the conveying process, grain is turned over through the trays on the lowermost portion, and evaporation of the hot air blown from a dustproof net is accelerated through the draught fans.

Owner:蔡聿怡

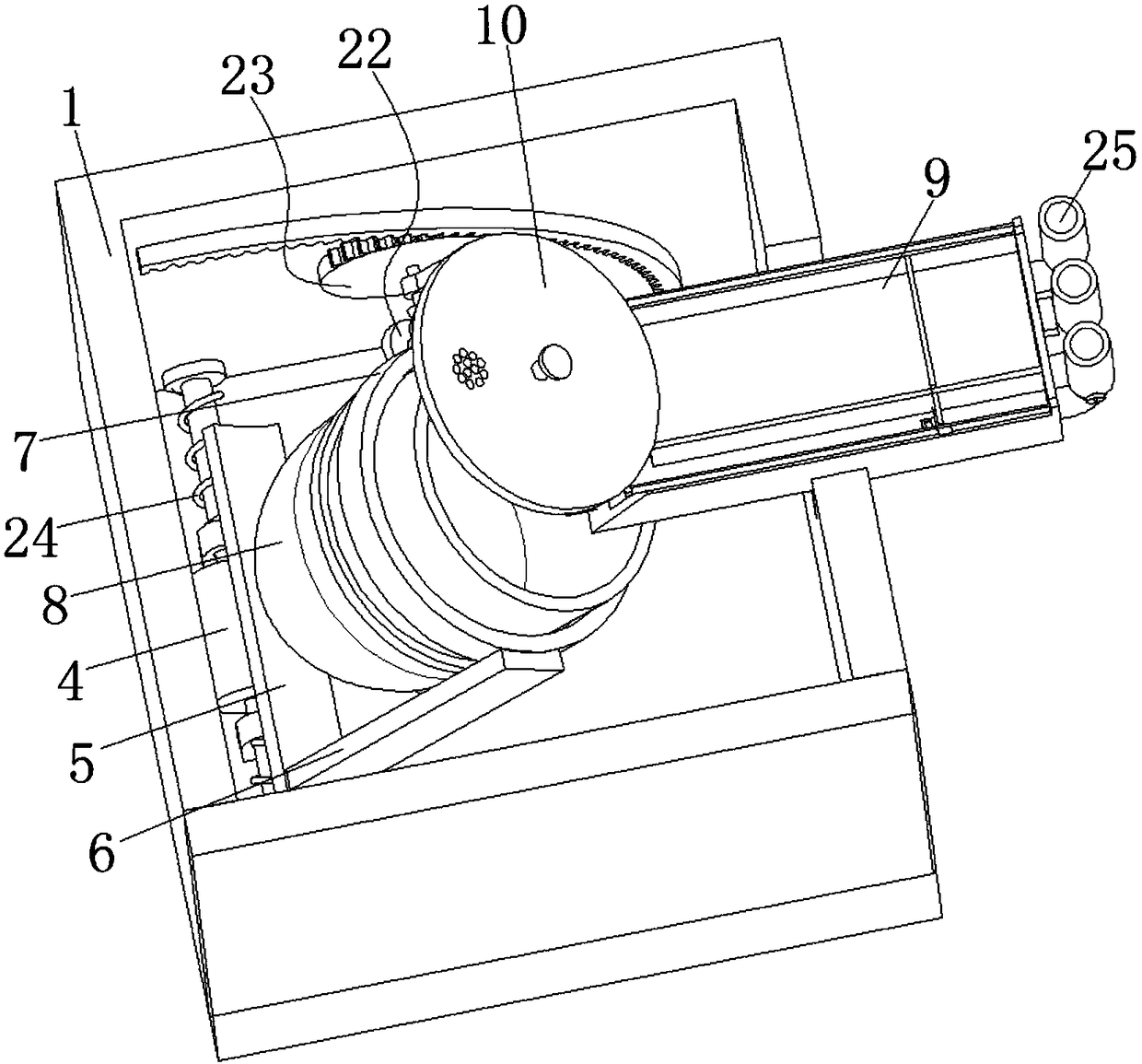

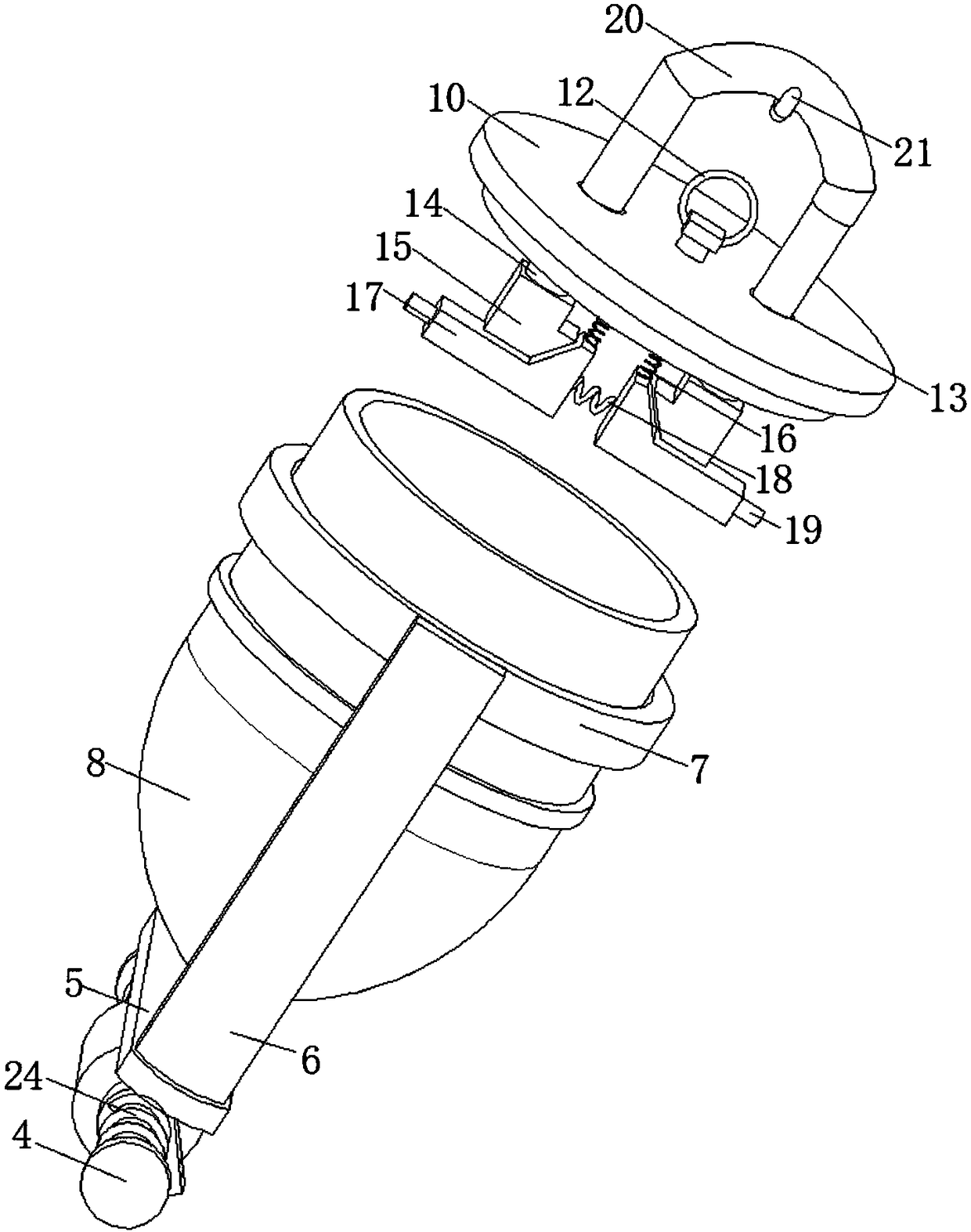

Preparation device and process of puer tea with jujube leaves

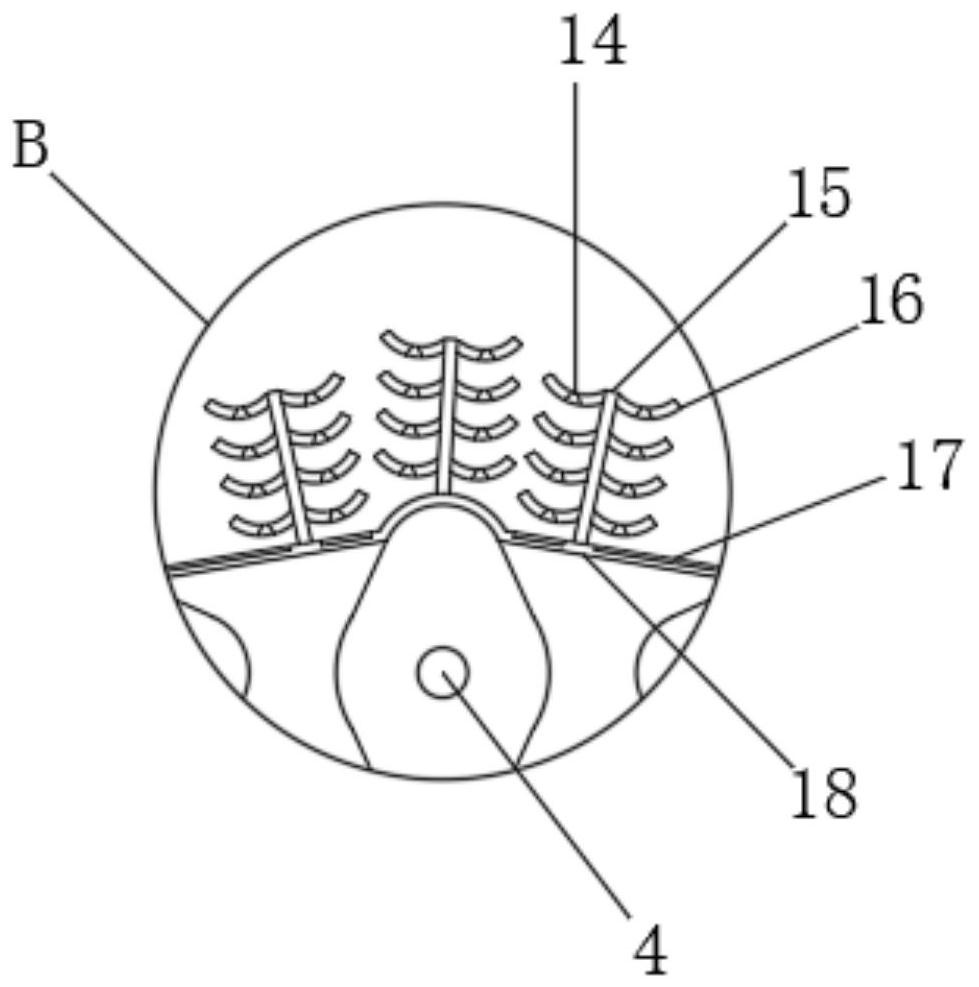

ActiveCN110169477AAchieve flippingRealize the kneading operationTea substituesEngineeringElectric machine

The invention discloses a preparation device and process of puer tea with jujube leaves. The preparation device comprises a base, and is characterized in that the base is fixedly connected to a circular barrel I through symmetrical L-shaped rods I; one side of each L-shaped rod I is fixedly connected to a motor III through a motor bracket II; the output shaft of the motor III is fixedly connectedto one end of a circular shaft I; one end of a belt surrounds a rotating wheel on the output shaft of the motor III; the other end of the belt surrounds one end of a circular shaft III; the circular shaft III is hinged to the end part of a square rod; the middle part of the circular shaft III is fixedly connected to the center of a bevel gear II; the other end of the circular shaft III is hinged to the end part of an another square rod; the other ends of the symmetrical square rods are fixedly connected to the upper parts of one sides of the L-shaped rods I respectively; the bevel gear II is meshed with a bevel gear I.

Owner:LUOYANG NORMAL UNIV

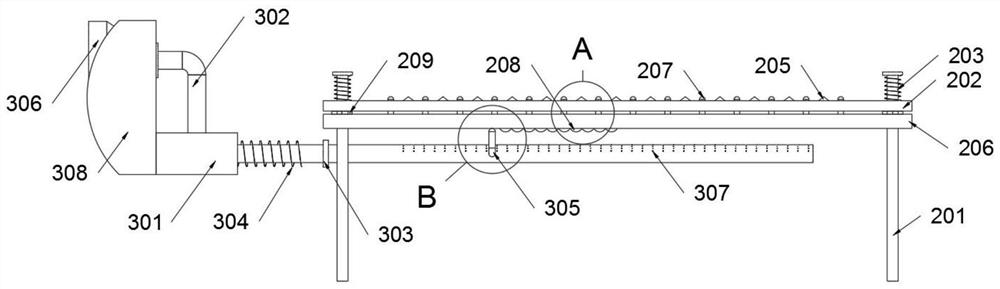

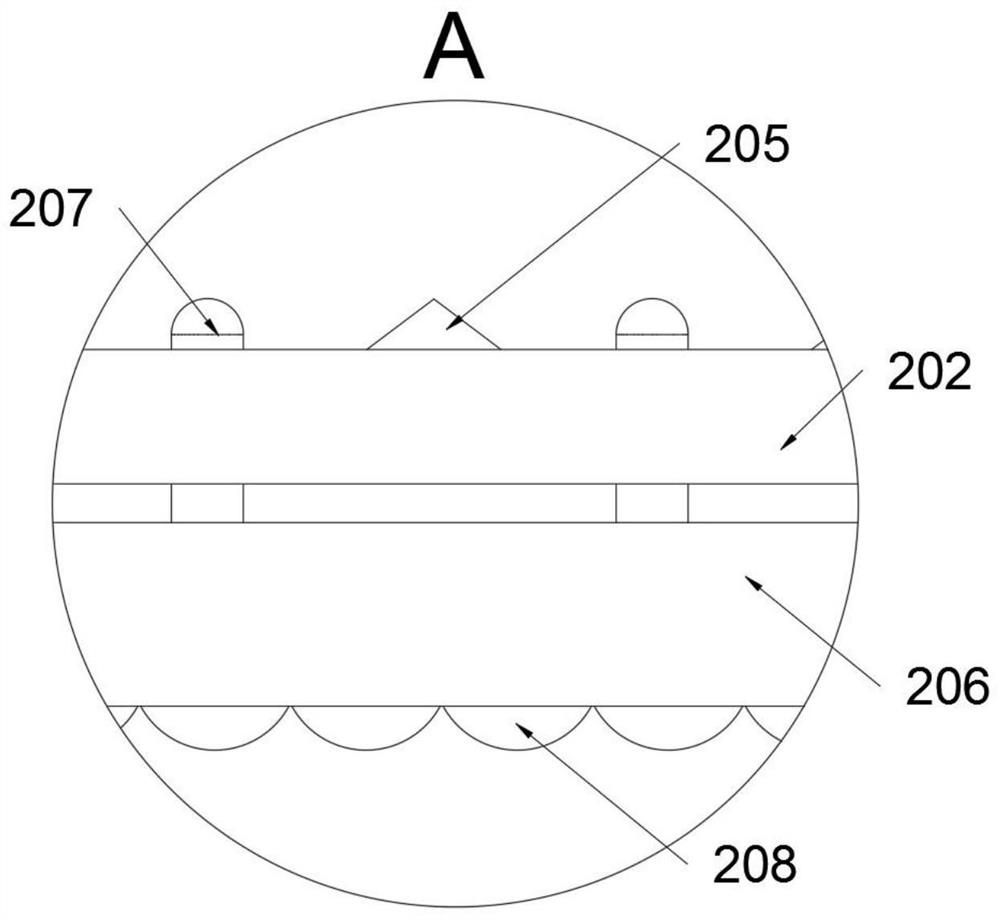

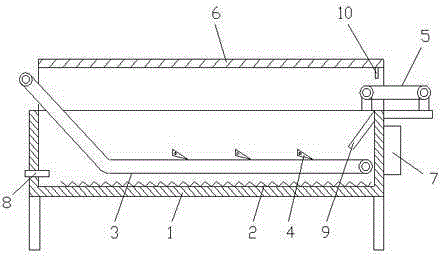

Fritillaria taipaiensis sun-drying device

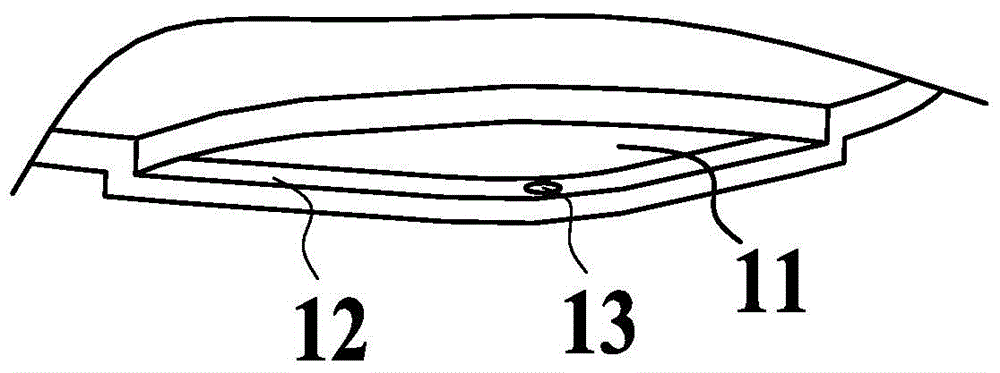

InactiveCN109405462AQuickly flattenImprove ease of useDrying solid materialsDrying machines with local agitationFixed bearingDrive shaft

The invention relates to the technical field of accessory devices for fritillaria taipaiensis processing equipment, particularly to a fritillaria taipaiensis sun-drying device. The fritillaria taipaiensis sun-drying device can improve usage convenience of existing sun-drying devices through arranging an automatic fritillaria taipaiensis flattening device, and can improve fritillaria taipaiensis sun-drying sufficiency of the existing sun-drying devices through arranging a turning device. The fritillaria taipaiensis sun-drying device comprises a sun-drying table, a plurality of sets of left supporting legs and a plurality of sets of right supporting legs; further comprises a location limiting plate, a sliding block, a fixing plate, a motor, a fixing ring, two sets of hanger rods, a transmission shaft, a power gear, a gear strip, a fixed bearing, a driving plate, an upper rail rod, a lower rail rod, a clamping sleeve and a scattering device, wherein the scattering device is provided witha containing box, a transmission pipe and a separating box; and further comprises two sets of limiting plates, a pushing shaft, two sets of clamping shafts, a lifting rod, a power clamping rod, a chain, a driven chain wheel, a driving chain wheel, a driven hanging rod, a driven bearing, a driven rotating shaft, a driving hanging rod, a driving bearing, a driving rotating shaft, a supporting frameand a rotating rod.

Owner:巫溪县瑞雪药材种植有限责任公司

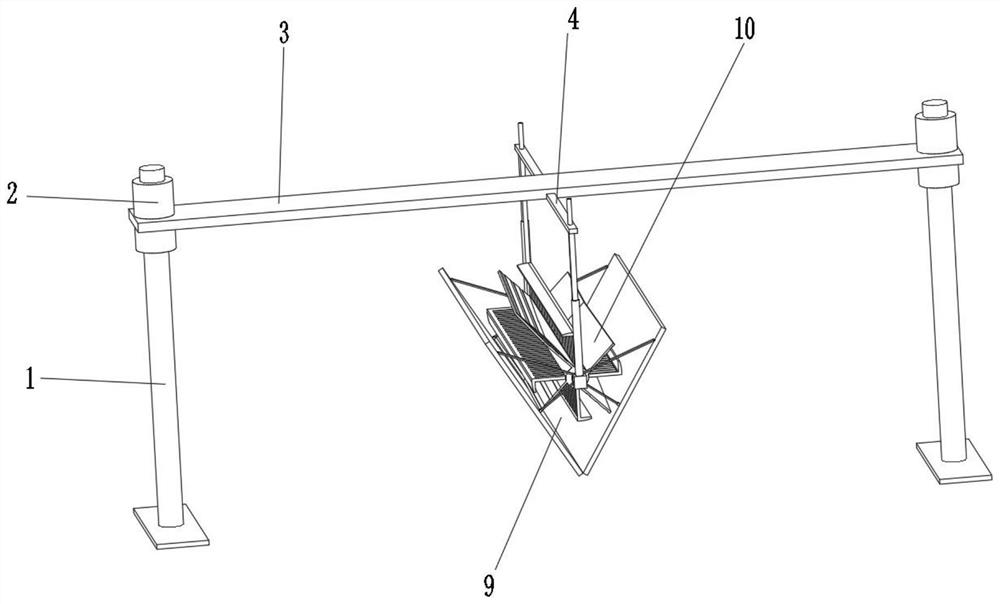

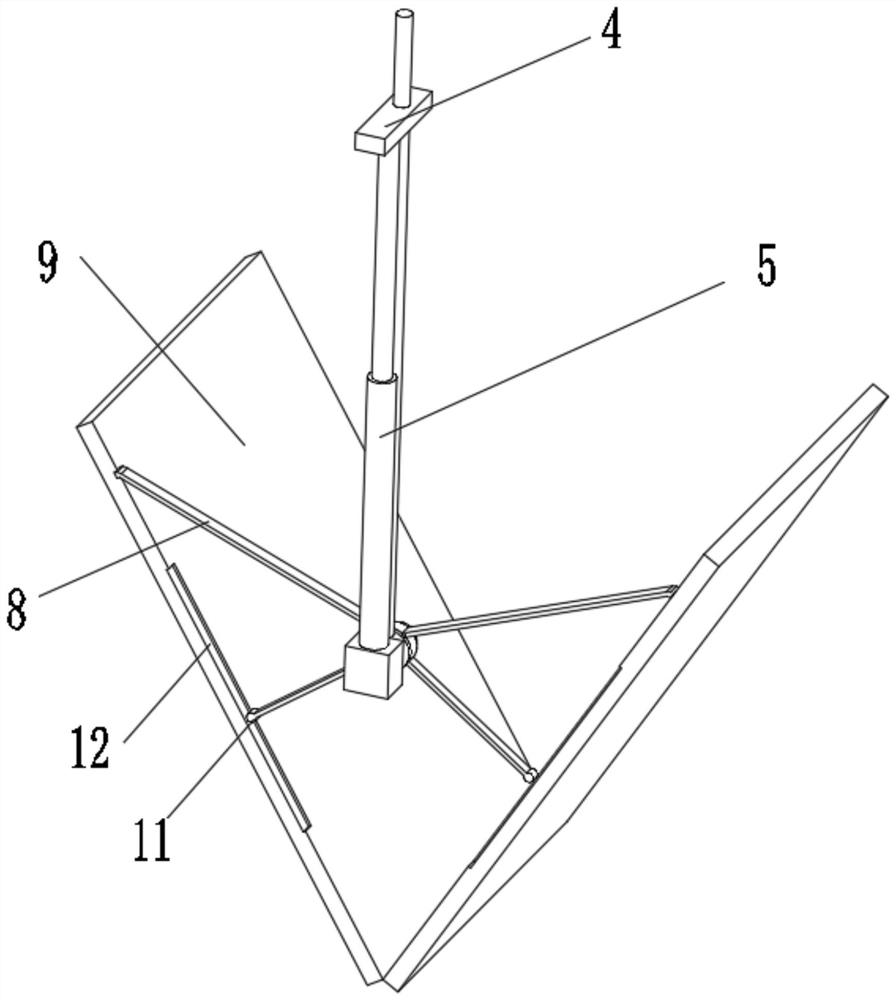

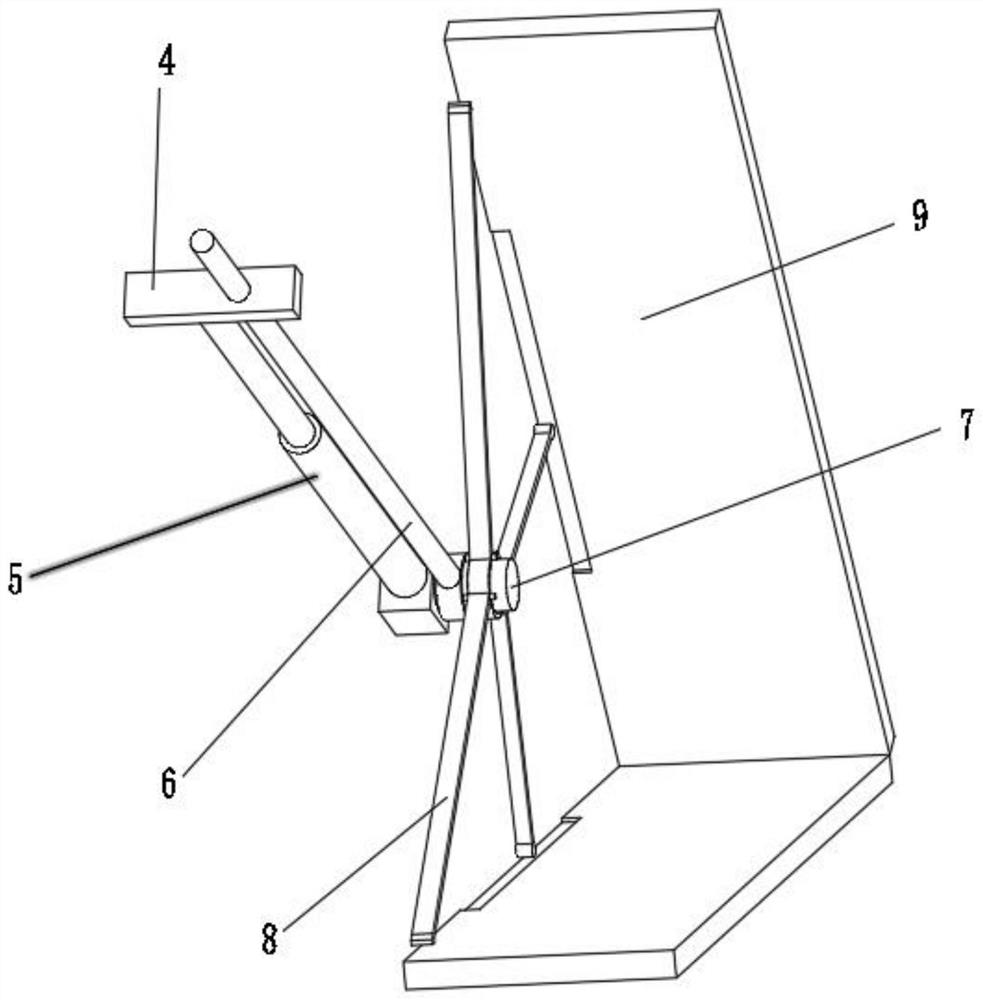

Soybean straw sun-curing device for agricultural production

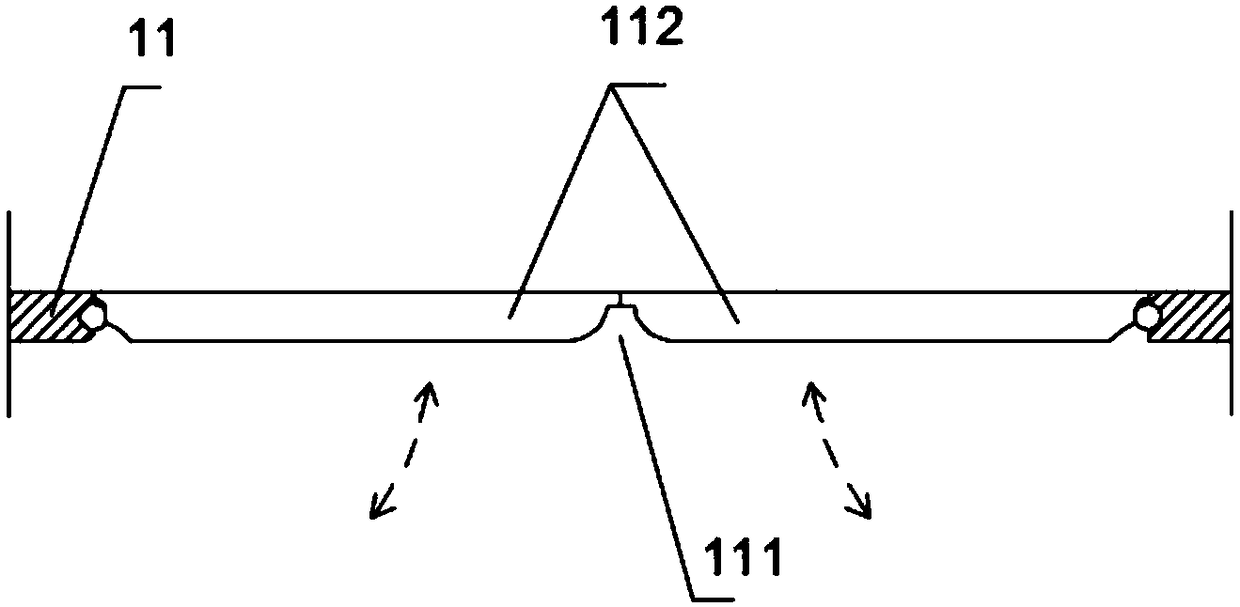

InactiveCN111678305AAchieve flippingKeep dryPhotovoltaic supportsSolar heating energyIsosceles trapezoidAgricultural science

The invention belongs to the technical field of agricultural production and particularly discloses a soybean straw sun-curing device for agricultural production. The soybean straw sun-curing device for agricultural production aims at solving the problem that according to an existing sun-curing device, straw is directly placed and spread on the device, and the straw cannot be overturned in the sun-curing process, so that the straw sun-curing efficiency is low. The soybean straw sun-curing device comprises a sun-curing trough and a base. A same elastic fabric is arranged on the inner walls of the two sides of the sun-curing trough, and bearing rods are arranged on the outer wall of the top of the elastic fabric. Arc-shaped bearing plates are arranged on the outer walls of the two sides of the bearing rods correspondingly. Through holes are formed in the outer walls of the tops of the arc-shaped bearing plates. The cross section of each through hole is of an isosceles trapezoid structure.A mounting groove is formed in the outer wall of the side, close to the bearing rods, of the elastic fabric. By means of the soybean straw sun-curing device, a great amount of sunshine can be provided for the straw for sun-curing; a motor can drive fan blades to rotate in the working process, ascending hot air formed through evaporation in the sun-curing process can be blown away by the fan blades, and drying of air surrounding the sun-curing trough can be effectively guaranteed; and the sun-curing efficiency is further improved.

Owner:烟台浩景农业科技有限公司

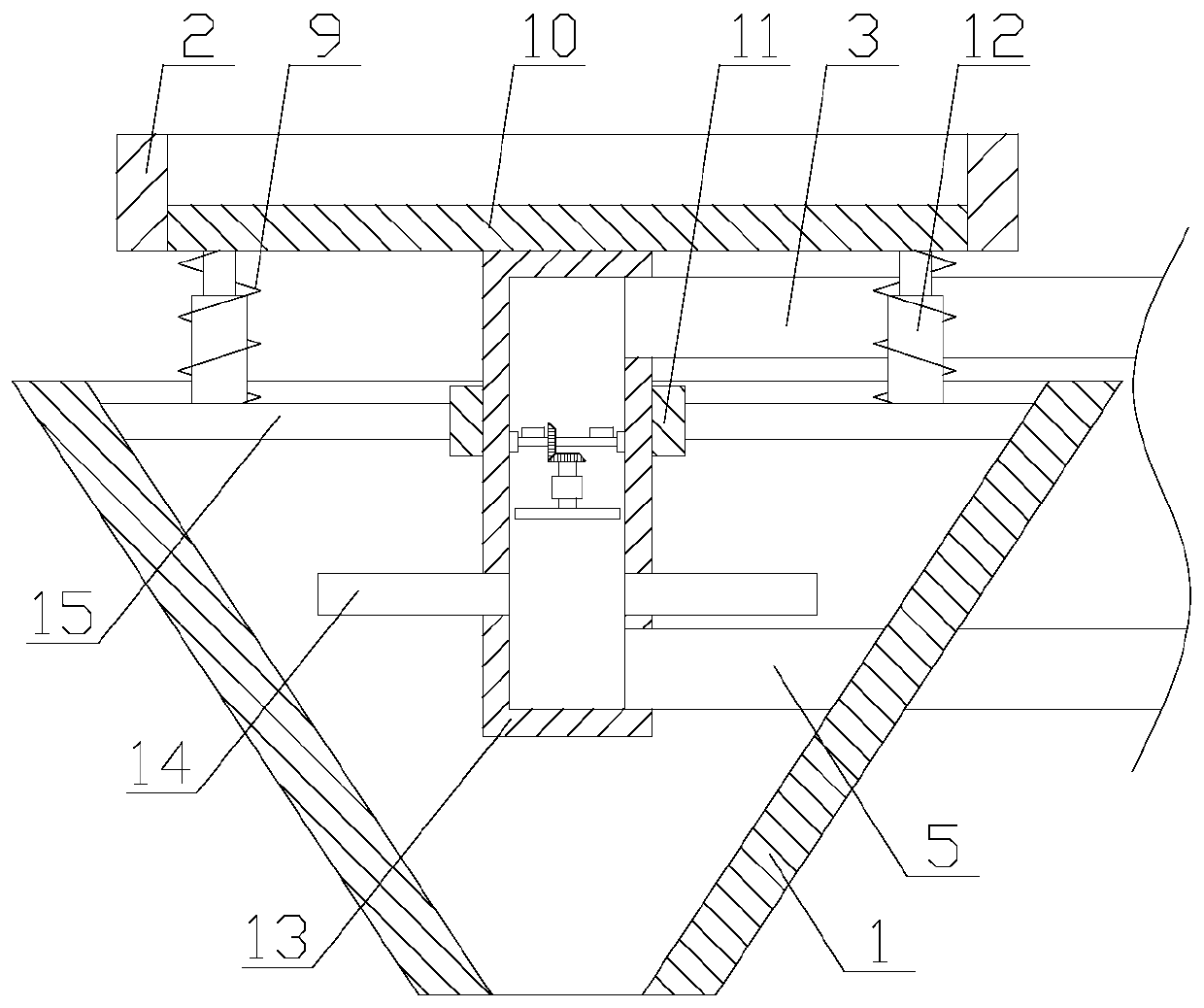

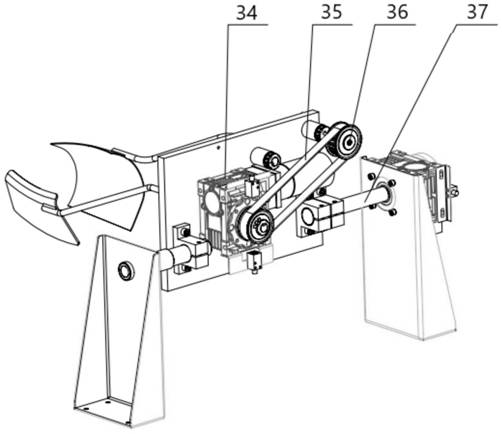

Organic fertilizer fermentation turning device

InactiveCN112279704AGuaranteed sustainable workIncrease air pressureBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringStructural engineering

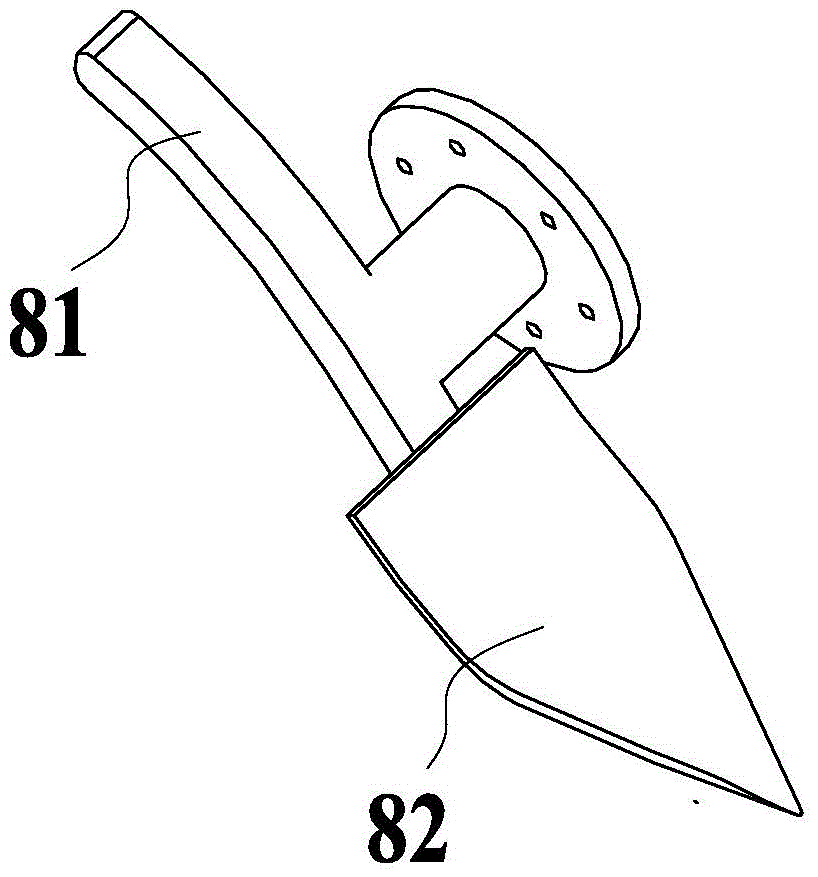

The invention discloses an organic fertilizer fermentation turning device. The device comprises a supporting outer frame; the outer surface of the supporting outer frame is sleeved with a stroke adjusting assembly; an adjusting cross rod is fixedly connected to the transverse position of the stroke adjusting assembly; pressurization driving rod pieces are fixedly connected to the two ends of the bottom of a walking adjusting rod correspondingly; limiting inserting rods penetrate through the interiors of the two ends of the walking adjusting rod and are slidably connected with the interiors ofthe two ends of the walking adjusting rod; adjusting supporting rods are rotatably connected to the positions, located on the back faces of the limiting inserting rods, of the outer axes of transmission connecting shafts; and feeding shovel plates are rotatably connected to the ends, away from the transmission connecting shafts, of the adjusting supporting rods; and a turning and throwing swing mechanism is fixedly connected to the axes of the inner sides of the transmission connecting shafts. The invention belongs to technical fields of organic fertilizers. According to the organic fertilizerfermentation turning device, the resistance of equipment inserted into an organic fertilizer is reduced, the operation of workers is facilitated, meanwhile, the organic fertilizer is extruded towardsthe turning mechanism, turning of the organic fertilizer close to the bottom is achieved, and the turning effect of the organic fertilizer is improved.

Owner:王天庚

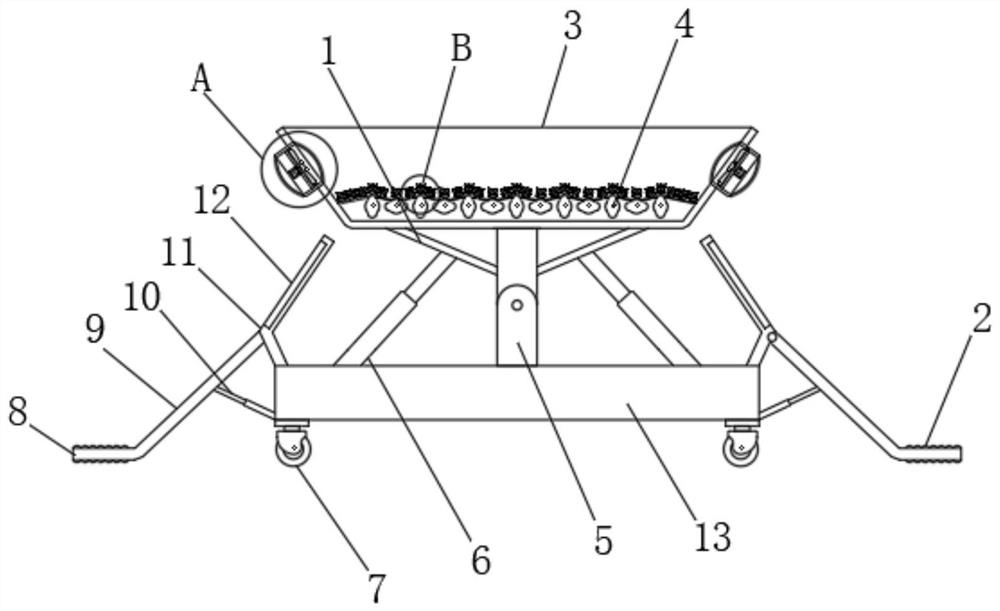

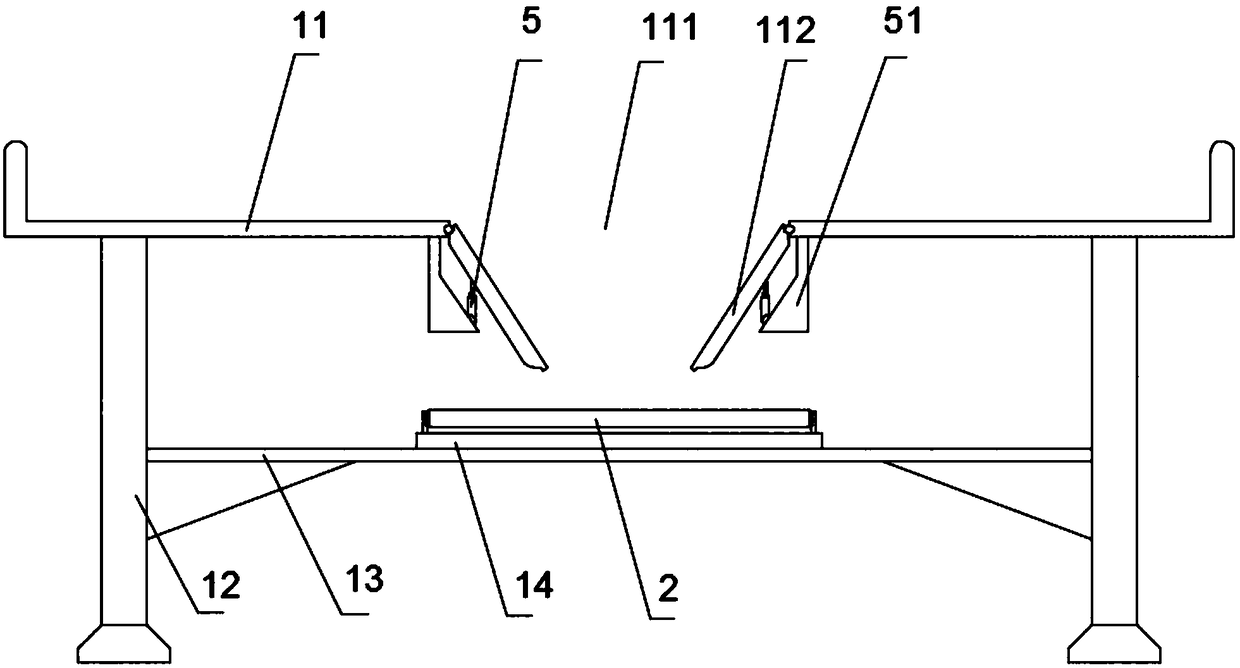

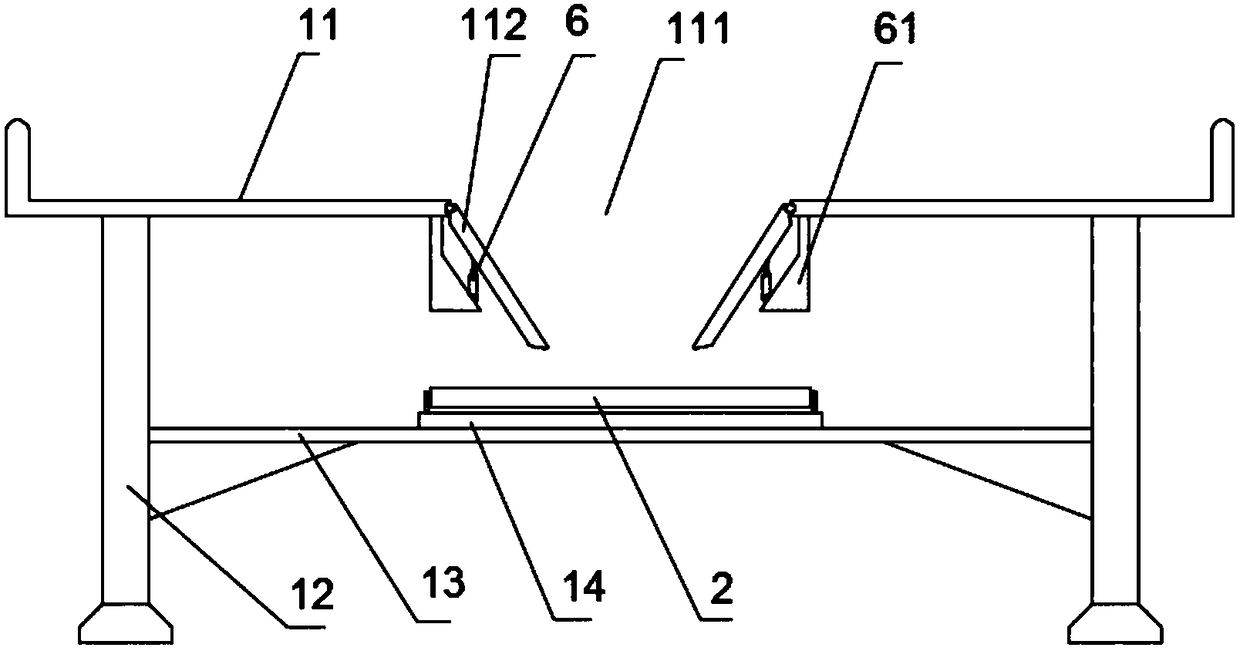

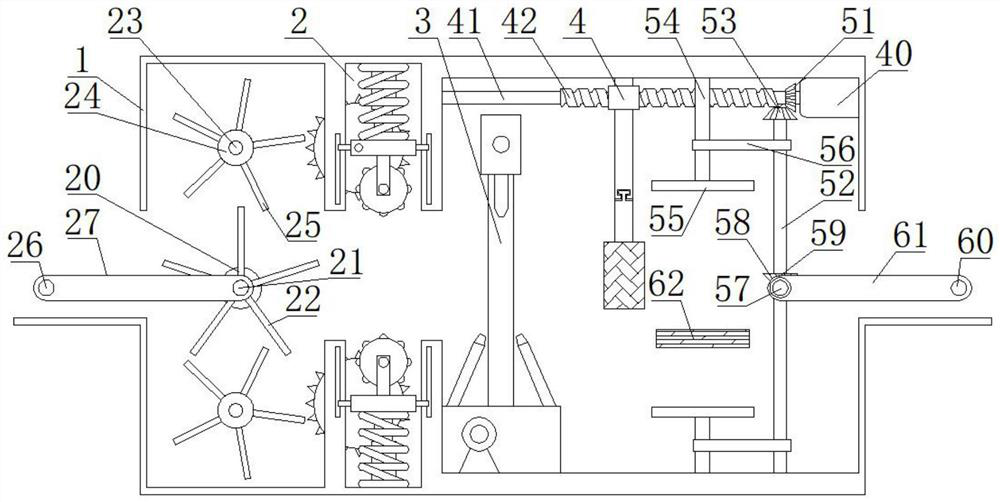

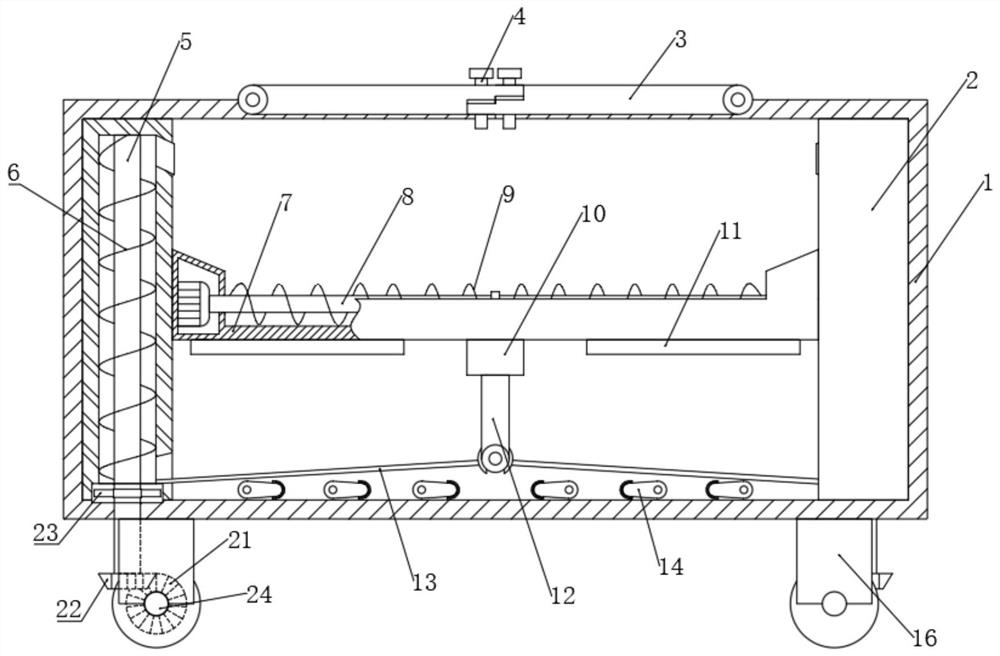

Airing frame for agriculture cereal grain particle airing

InactiveCN108458560ADry evenlyAchieve flippingDrying chambers/containersDrying machines with local agitationEngineeringCereal grain

The invention relates to an airing frame for agriculture cereal grain particle airing. The airing frame comprises an airing frame body, a grain conveying belt, a grain sieving and stacking device anda PLC. The airing frame body comprises an airing plate and supporting legs. A grain unloading groove is formed in the middle portion of the airing plate, and a grain unloading plate capable of overturning up and down is hinged to each of the front side and the rear side of the grain unloading plate. The bottom face of the airing plate is fixedly provided with an overturning drive device for driving the grain unloading plates to do the up-down overturning movement. The grain conveying belt is distributed under the grain unloading groove in the length direction of the airing plate. The grain sieving and stacking device comprises a movable plate, a grain sieving plate, a grain stacking plate and a movement driving device for driving the movable plate to do the reciprocated linear movement inthe width direction of the airing plate. The grain sieving plate comprises a lifting plate, grain sieving teeth distributed in a sawtooth manner, and the movable plate is provided with a penetrating groove. The grain stacking plate is fixed to the lifting plate in an up-down movement manner. The multiple operations including grain spreading, grain sieving, grain stacking and grain filling are integrated, and functions are diverse.

Owner:安徽菲扬新材料有限公司

Environment-friendly energy-saving type oolong tea processing device

ActiveCN110521794AImprove baking efficiencyAvoid OverbakingSievingPre-extraction tea treatmentAgricultural engineeringTea leaf

The present invention discloses an environment-friendly energy-saving type oolong tea processing device. The environment-friendly energy-saving type oolong tea processing device comprises a drying box, a left side of a limiting sleeve block is connected with a tea leaf screening filter screen through a universal joint, a top part of the tea leaf screening filter screen is fixedly connected with anouter spray pipe, a tea residue drying conical plate is fixedly connected in the drying box and at a position close to a lower part, an inner part of the tea residue drying conical plate is fixedly connected with an inner stirring spray pipe, an absorption inner pipe is fixedly connected at a right side in the drying box and located above the tea leaf screening filter screen and the tea residue drying conical plate, and an output end of the absorption inner pipe communicates with a heat preservation pipes. The environment-friendly energy-saving type oolong tea processing device belongs to thetechnical field of oolong tea processing and achieves purposes of accelerating tea leaf baking efficiency, avoiding partial tea leaves to be excessively baked, improving tea leaf baking quality, avoiding a large number of heat losing of baking devices, and improving environmental protection and energy saving.

Owner:安徽省屯溪实验茶场

Plough machine for soil particle refining and sorting

InactiveCN110073746AIncrease porosityGood for crop growthSpadesPloughsAgricultural engineeringPlough

The invention discloses a plough machine for soil particle refining and sorting, comprising a body, wherein support rods are hinged and mounted into an accommodating groove in a sagittal symmetry manner, and a drum motor is fixedly mounted on the rear side surface of the support rod at the rear side; a soil loosening drum shaft is fixedly mounted on the output shaft of the drum motor; when the drum motor is started, the drum motor drives the soil loosening drum to rotate, and the soil loosening drum rotates to loosen the soil; when a first hydraulic rod is started, the first hydraulic rod is extended to push the support rods downwards to loosen the soil; when the first hydraulic rod is retracted, the support rods are pulled upwards, so that the soil loosening drum is stored, and the compacted soil can be ploughed. The graininess of the soil after the plough is refined, and the soil looseness is increased; the plough machine is applicable to large-scale modern agricultural production, and can screen large-grained stones or soil; the soil after screening can be uniformly harrowed to facilitate planting.

Owner:三门器恒机械设备有限公司

Deep frying device capable of relieving adhesion of dried tofu

InactiveCN105248493AReduce adhesionAchieve vibration dispersionOil/fat bakingSmall amplitudeDeep frying

The invention discloses a deep frying device capable of relieving adhesion of dried tofu. The deep frying device comprises an oil tank. An electric heater and a metal belt conveyer are arranged in the oil tank, a material shoveling plate is further arranged in the oil tank and is rotationally installed on the oil tank through a rotating shaft, and the edge of the material shoveling plate abuts against the metal belt conveyer under the self-gravity effect. The deep frying device further comprises a feeding conveyer used for adding materials into the oil tank, a vibrating plate is hinged to the oil tank and located below the discharging end of the feeding conveyer, and a vibrating air cylinder used for driving the vibrating plate to swing around the hinged center is arranged on the outer wall of the oil tank. The deep frying device further comprises a controller for controlling the electric heater, the metal belt conveyer, the feeding conveyer and the vibrating air cylinder. According to the deep frying device capable of relieving adhesion of the dried tofu, the vibrating air cylinder is used for driving the vibrating plate to quickly swing in a small amplitude so that the dried tofu discharged out of the feeding conveyer can be scattered through vibration, and thus the problem of adhesion in the deep frying process of the dried tofu can be well solved.

Owner:CHONGQING YUPAI AGRI PROD DEV

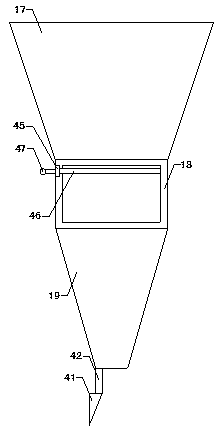

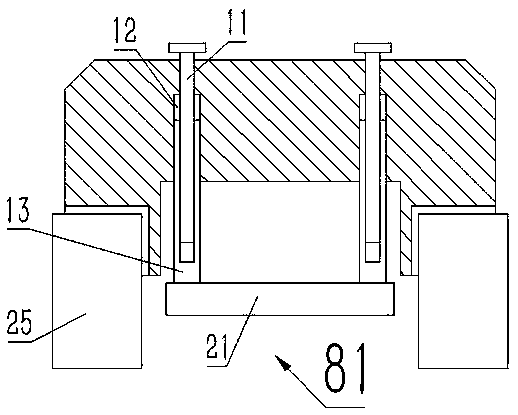

Injection molding machine with raw material preheating function

InactiveCN111216316AAchieve recyclingImprove energy saving performanceMoulding devicePower component

The invention relates to an injection molding machine with the raw material preheating function. The injection molding machine comprises a base, an injection molding device, a forming device and a feeding hopper and further comprises a preheating mechanism and a screening mechanism, wherein the preheating mechanism comprises a lifting pipe, a power component, a water tank, a return pipe, a water duct, a support rod, a support sleeve, a water pump and at least two stirring rods; the screening mechanism comprises a screen mesh, a storing cylinder and two support components; the power component comprises a blade, a driving shaft, a first gear, a second gear, a rotary shaft and a gravity block; and each of the support components comprises a telescopic rod and a spring. According to the injection molding machine with the raw material preheating function, the preheating mechanism can preheat raw material in the hopper, so that recycling of heat on the forming device is realized, and the energy-saving performance and working efficiency of the injection molding machine are improved; and the screening mechanism can screen the raw material, so that quantity of impurities in the raw materialis reduced, and the quality of the finished product produced by the injection molding machine is improved.

Owner:深圳市美邦环保科技有限公司

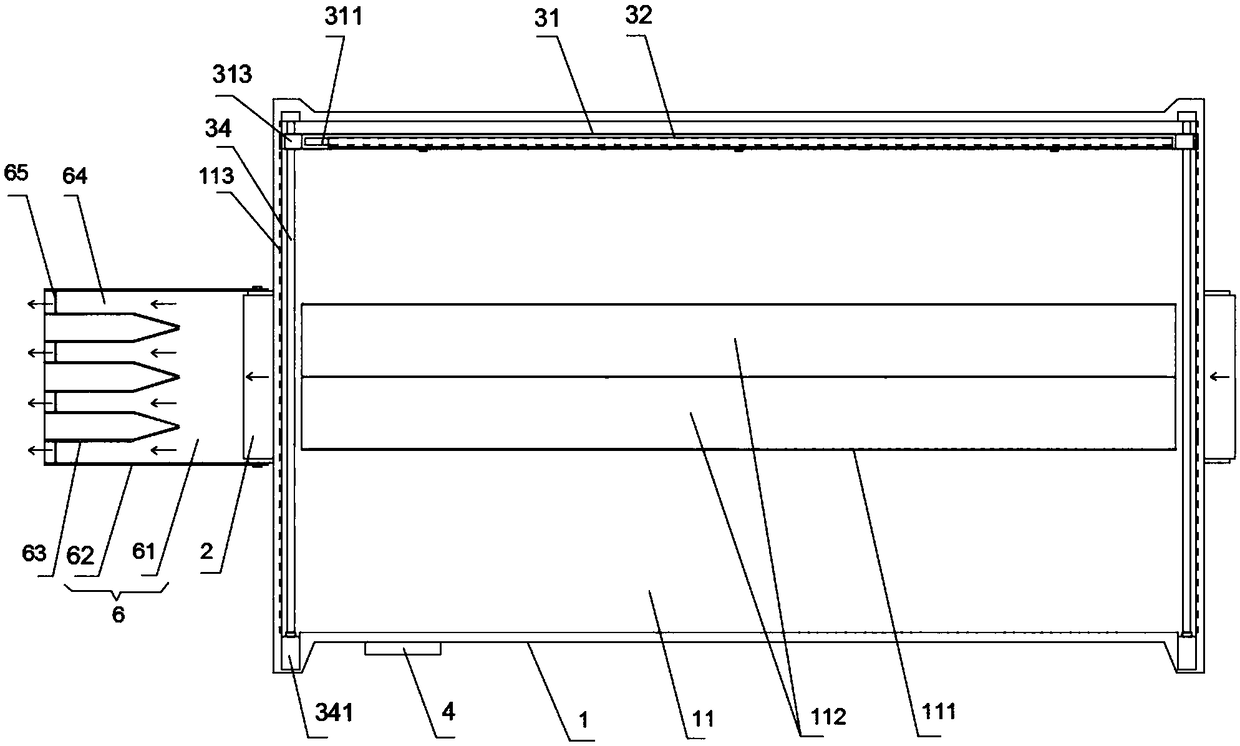

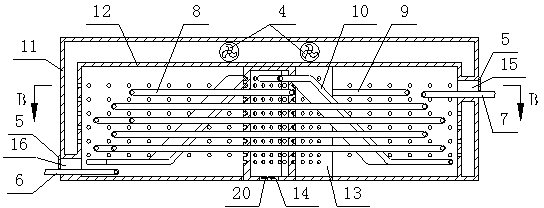

Drying system achieving heating through air source heat pump

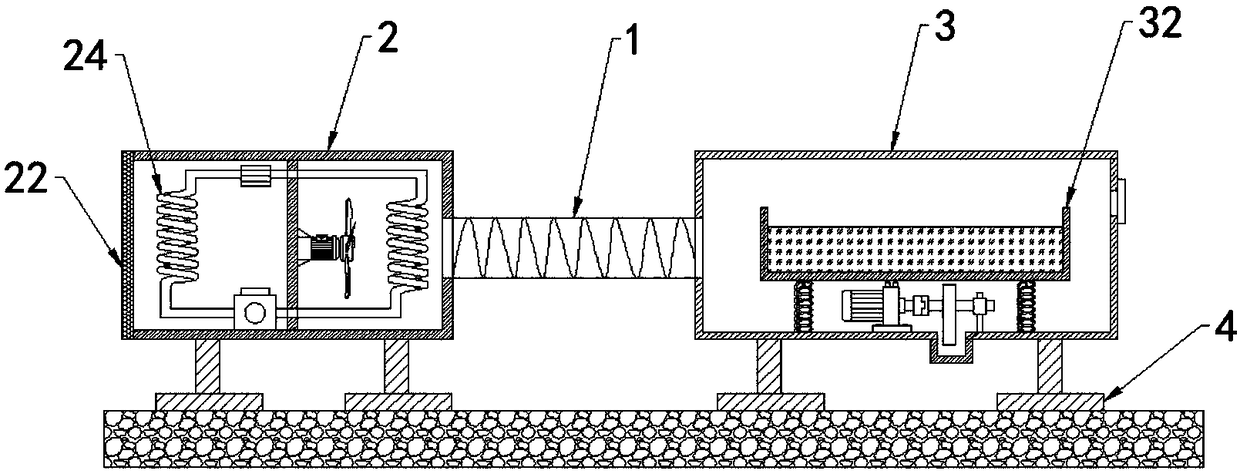

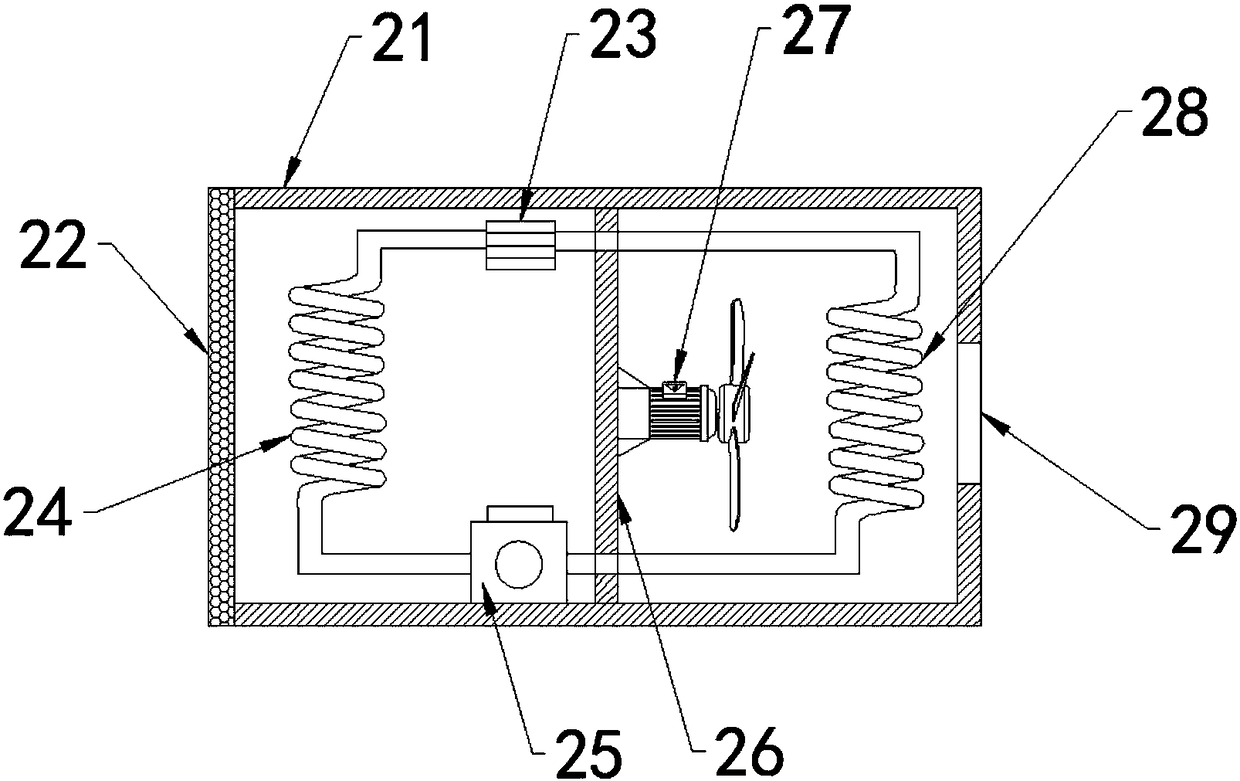

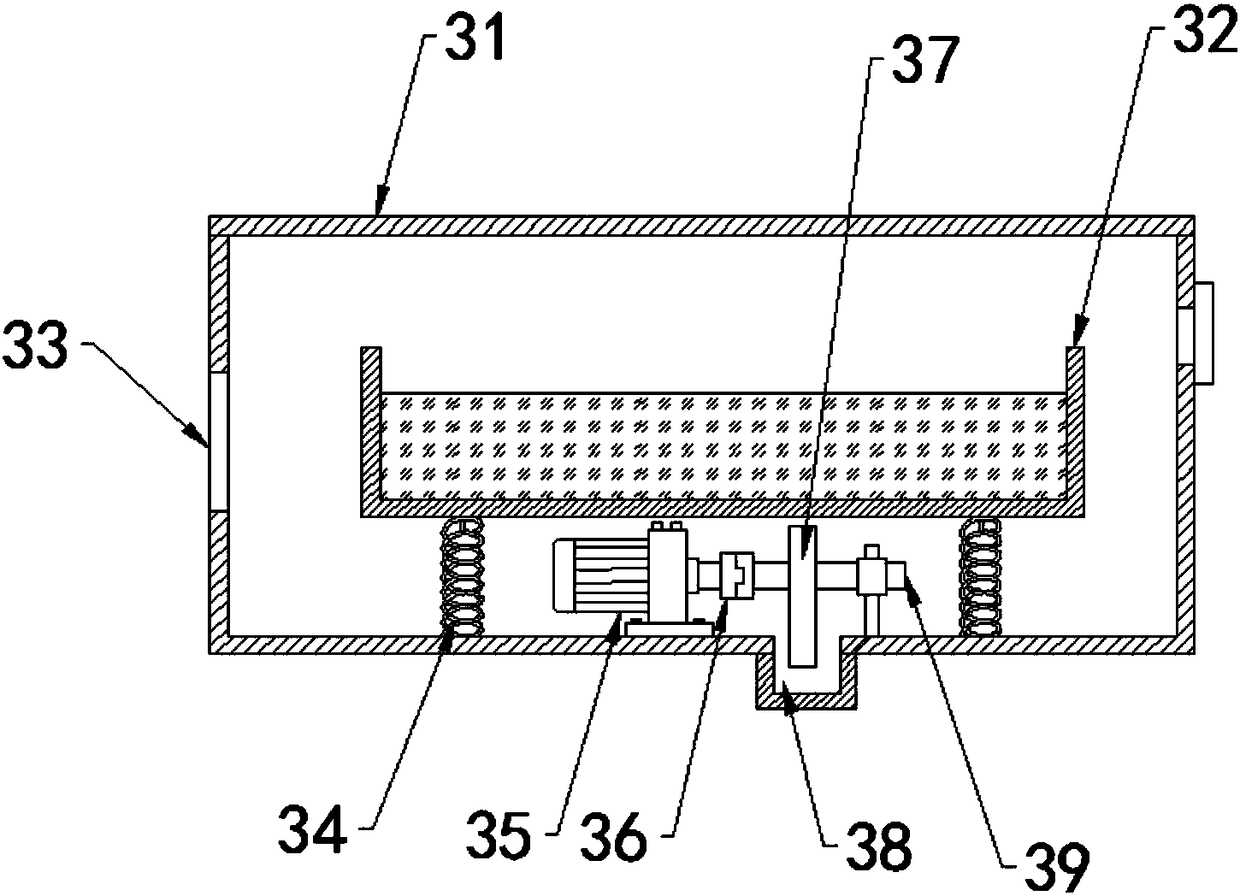

InactiveCN108151493AThe overall structure is simpleReasonable designHeat pumpsDrying gas arrangementsCoalProcess engineering

The invention discloses a drying system achieving heating through an air source heat pump. The drying system comprises the air source heat pump device and a drying device which communicates with the air source heat pump device. The drying device comprises a drying box and a material box which is arranged in the drying box. The bottom of the material box is provided with a plurality of supporting springs. A vibration motor is arranged between the supporting springs. An output shaft of the vibration motor is connected with a rotating shaft through a coupler, and the rotating shaft is connected with a cam. When the drying system is used, a compressor is started to work, an evaporator can absorb a great amount of heat from the outside when carrying out evaporation, then, a condenser works, a great amount of heat is released and is pumped to the drying box through a draught fan, and compared with traditional electrical heating and coal heating, the drying system is more efficient and simpler; and in addition, in the process that materials are dried, the vibration motor can be controlled to work, the material box is enabled to vibrate up and down through a cam, in this way, stirring of the materials can be achieved, the materials on the bottom layer can also be dried, and the product quality is higher.

Owner:广东伊蕾科斯环境科技有限公司

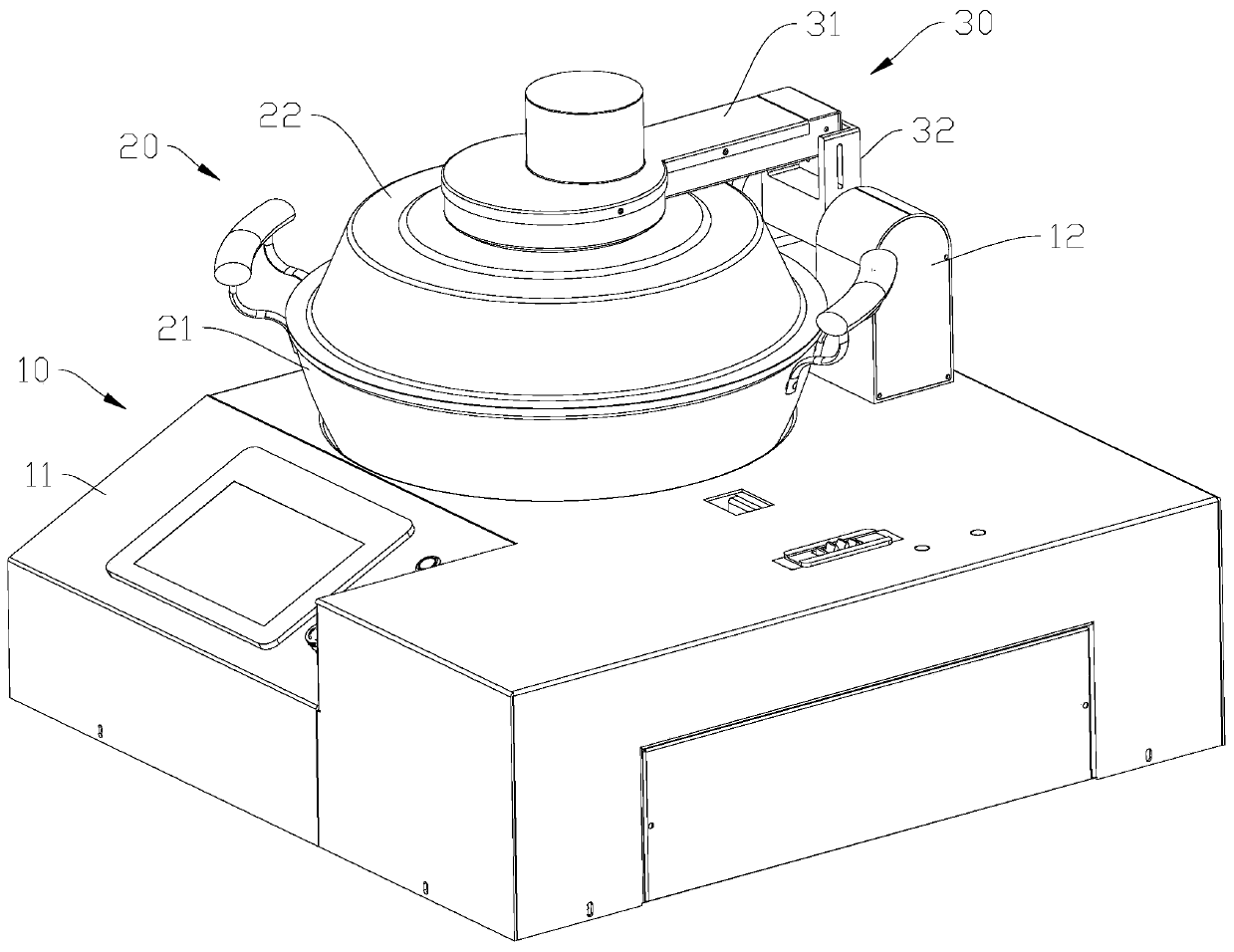

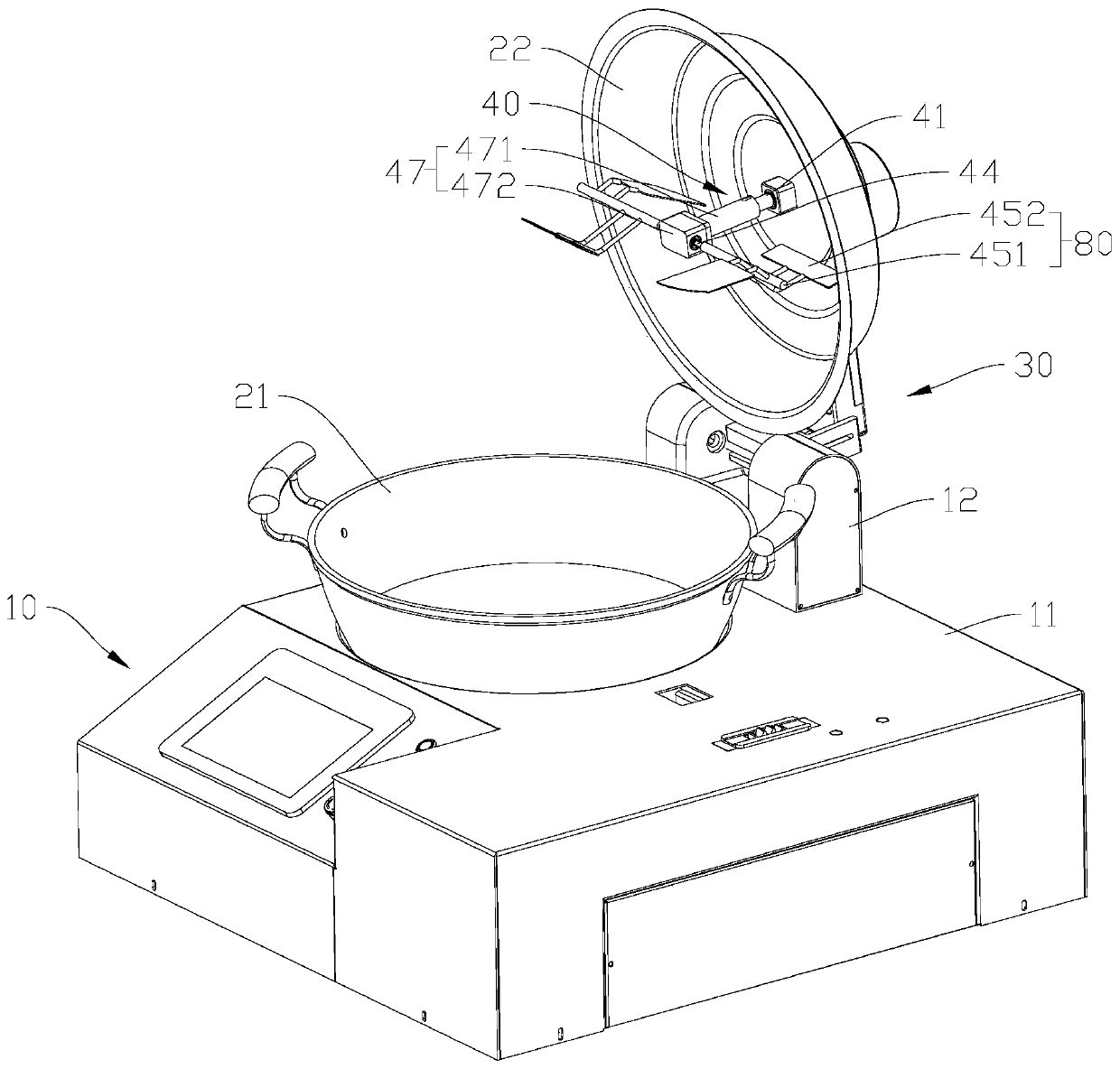

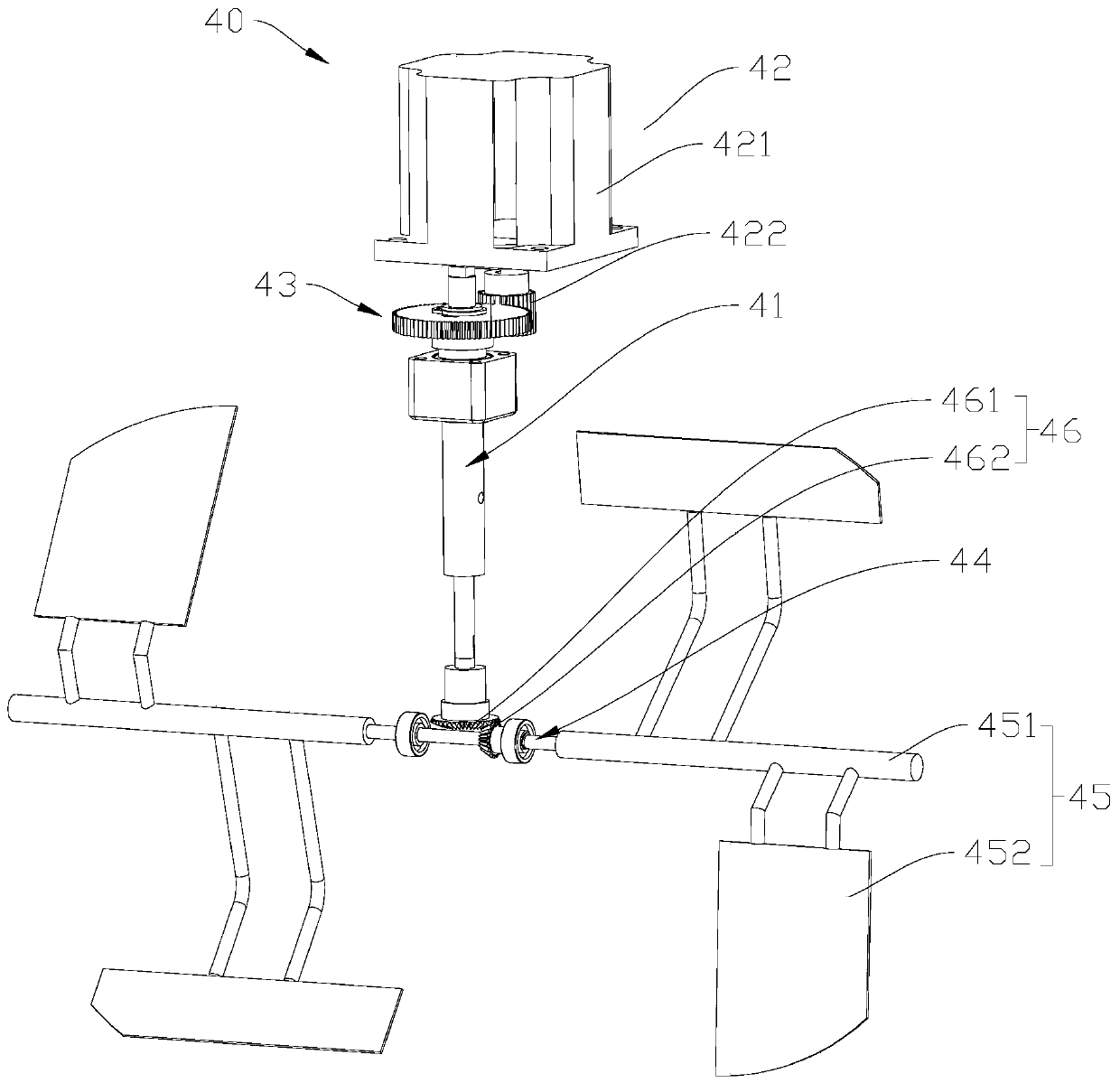

Automatic cooker

PendingCN111568253AAchieve flippingImprove heating uniformityCooking insertsCooking vessel constructionsFood materialCooker

The invention relates to an automatic cooker, which comprises a pot, including a pot body for containing food materials and a pot cover for covering the pot body; and a stir-frying device, which comprises a first rotating shaft arranged on the inner side of the pot cover and extending into the pot body in the vertical direction, a driving mechanism connected with the upper end of the first rotating shaft to drive the first rotating shaft to rotate, and a stirring mechanism arranged at the lower end of the first rotating shaft and driven by the first rotating shaft to do circular motion in thecircumferential direction of the pot body. The stirring mechanism comprises a second rotating shaft connected with the first rotating shaft and perpendicular to the first rotating shaft, and a stirring paddle assembly arranged on the second rotating shaft and driven by the second rotating shaft to rotate in the direction perpendicular to the rotating direction of the first rotating shaft; the first rotating shaft and the second rotating shaft are provided with reversing transmission mechanisms driving the second rotating shaft to rotate in the direction perpendicular to the rotating directionof the first rotating shaft. The stirring mechanism of the automatic cooker can do circular motion in the circumferential direction of the pot body and can rotate in the direction perpendicular to therotating direction of the first rotating shaft, food materials in the pot body can be turned over, and the heating uniformity of the food materials can be improved.

Owner:深圳鸿博智成科技有限公司

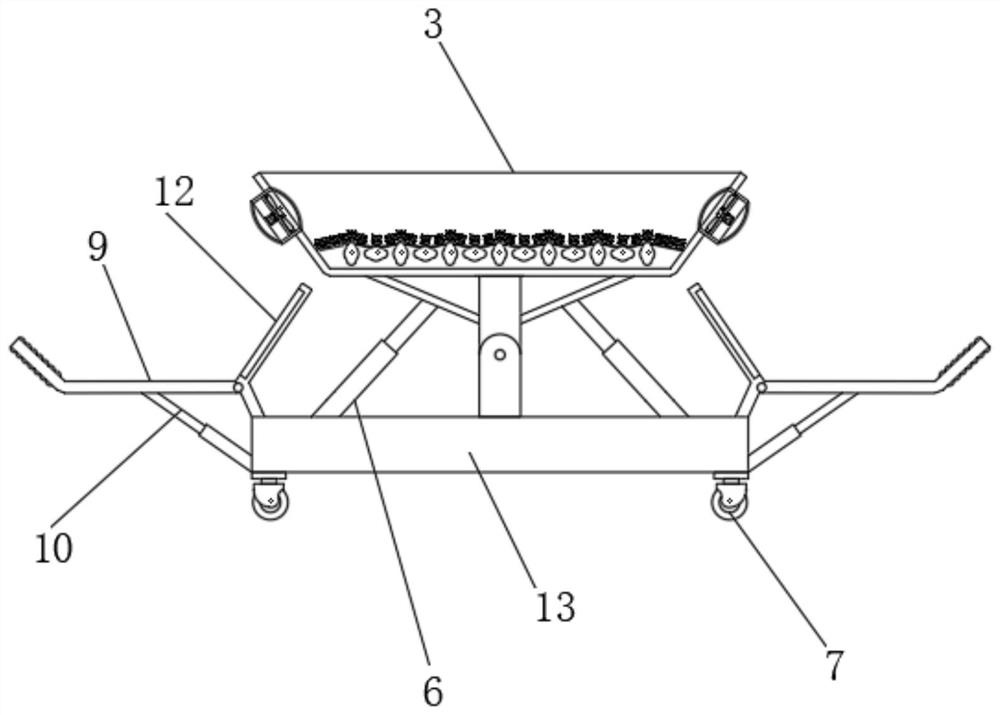

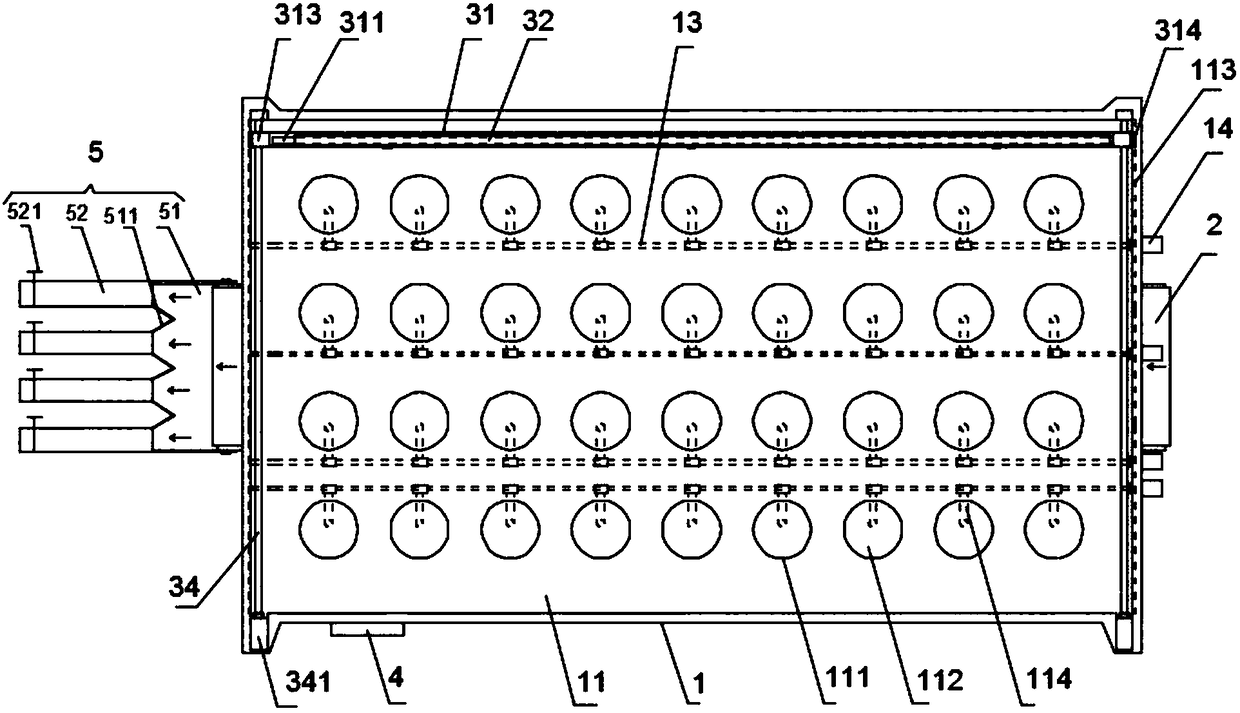

Grain airing device

InactiveCN108375290AAchieve flippingDrying solid materialsDrying machines with local agitationMetallurgyDrive motor

The invention relates to a grain airing device. The grain airing device comprises an airing frame body, a grain conveying belt, a grain-dividing grain-stacking device, and a PLC. According to the provided grain airing device, grain particles are aired on an airing plate, and a grain-stacking plate of the grain-dividing grain-stacking device is adjusted to a certain height, namely the grains can beflattened by using the grain-stacking plate according to a certain thickness; while the grains need to be divided, the grain-stacking plate is adjusted to be ascended and a grain-dividing plate is adjusted to be descended to a suitable height, grain-dividing teeth of the grain-dividing plate are used for ridging and airing the grains, and the transverse position of the grain-dividing plate can bechanged by transversely moving a lifting plate, thereby ridging positions of the grain-dividing teeth are switched; after the grains are aired, an overturn driving motor is used for driving an overturn shaft to rotate to drive a discharge-blocking plate to be downwards overturned so as to open a grain unloading port, the grain particles on the airing plate pass through a grain guide port and fallonto the grain conveying belt, and the grains are conveyed out for packaging; and in the meantime, the grains at other positions on the airing plate can be directly pushed to the unloading port by using the grain-stacking plate and fall onto the grain conveying belt.

Owner:安徽菲扬新材料有限公司

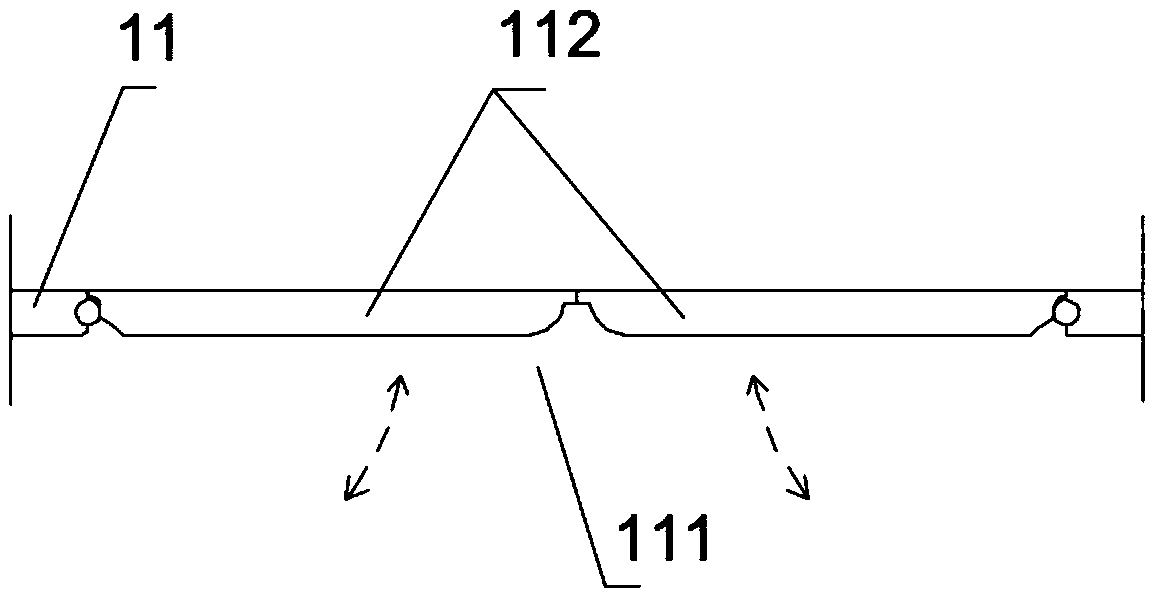

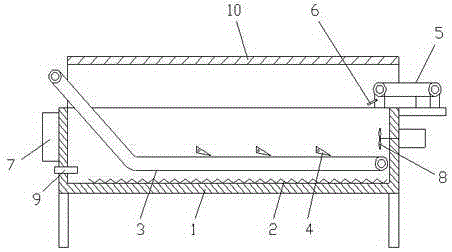

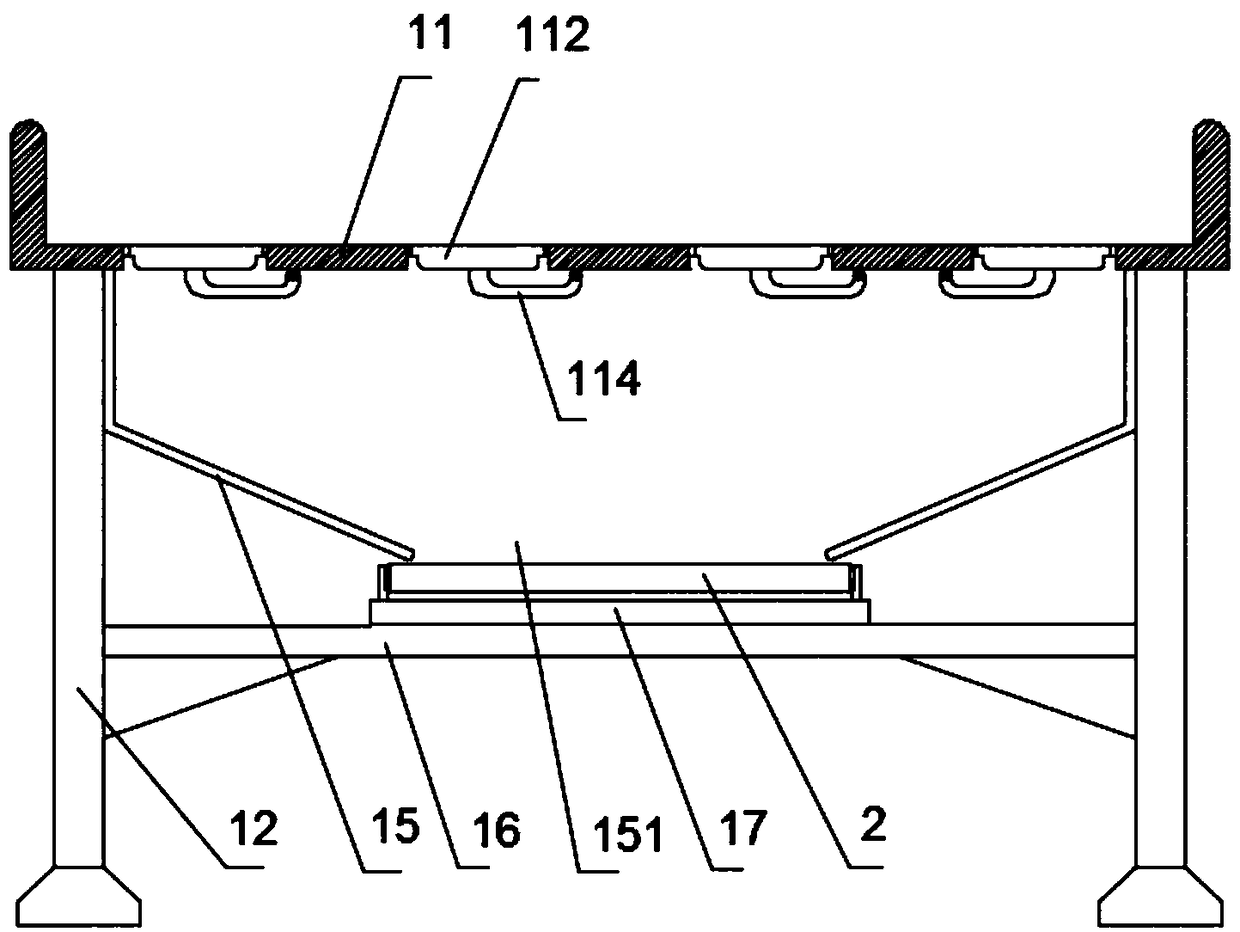

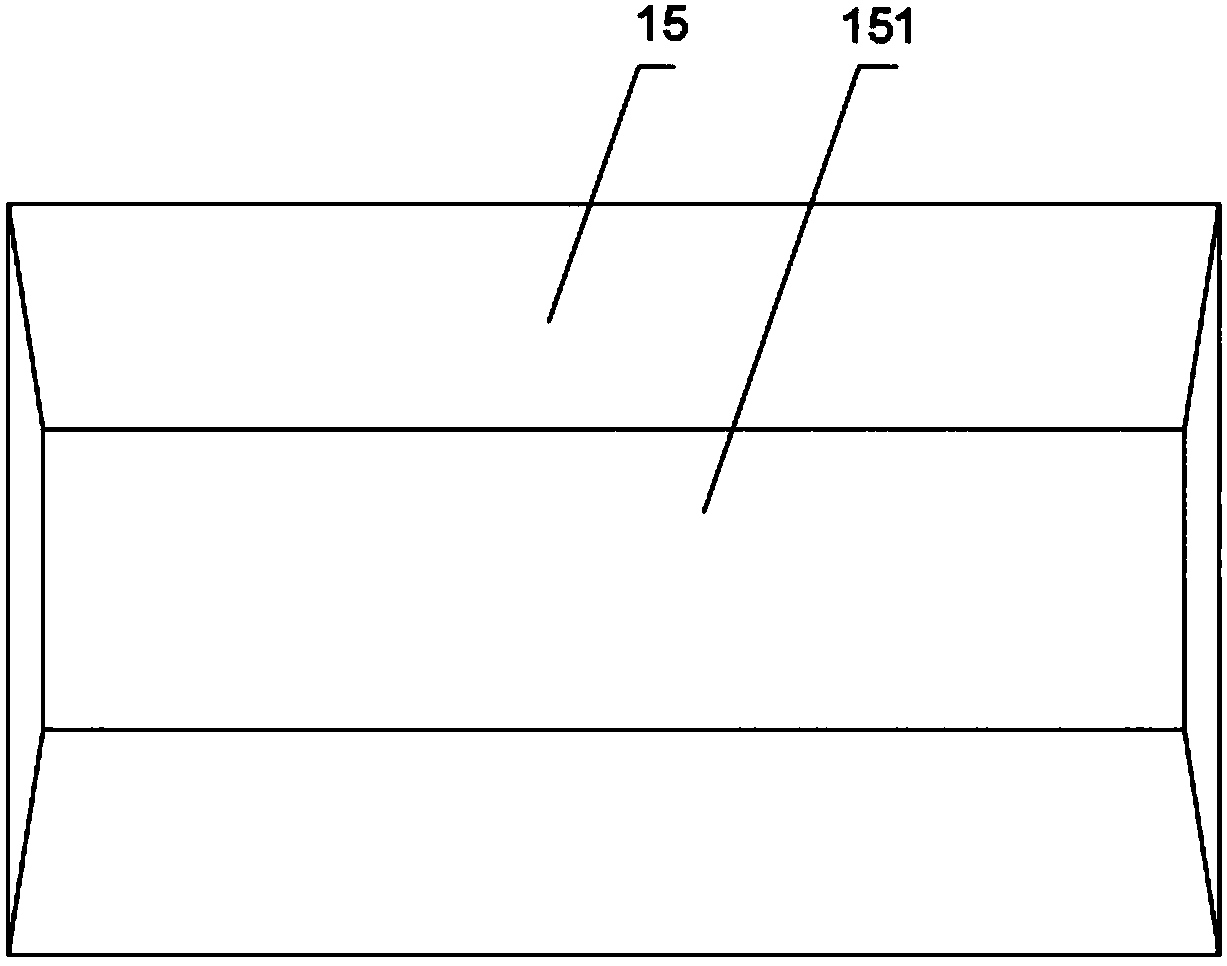

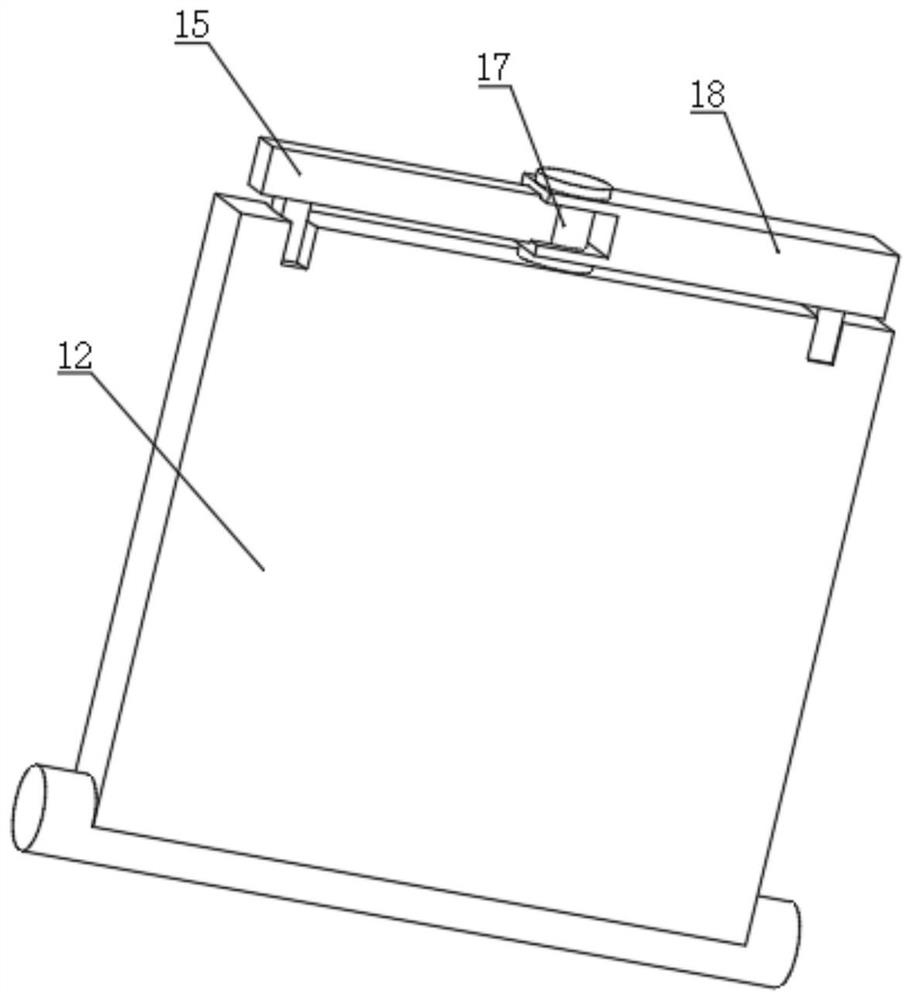

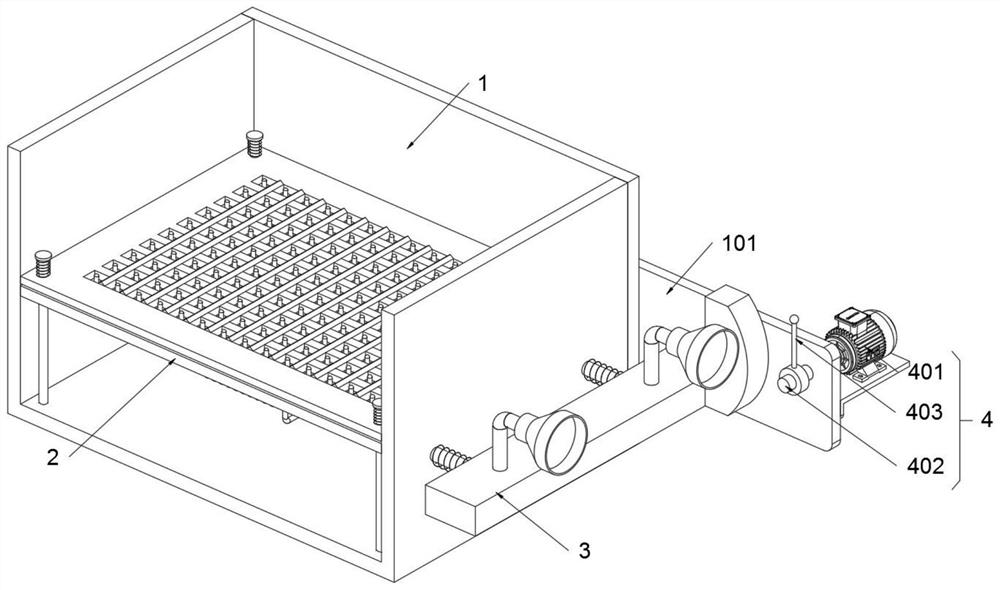

Grain air-curing device

InactiveCN108507304ADry evenlyAchieve flippingDrying solid materials with heatSeed preservation by dryingGrain fillingAgricultural engineering

The invention relates to a grain air-curing device. The device comprises an air-curing rack body, a grain conveyor belt, a grain spreading and piling device and a PLC. According to the grain air-curing device, grains are air-cured on an air-curing plate; a grain piling plate is adjusted to the proper height through a lifting driving device, a grain spreading plate is lifted to be higher than the grain piling plate through the lifting driving device, and thus the grains can be uniformly spread based on a certain thickness through the grain piling plate; when the grains are to be spread, the grain piling plate is lifted and the grain spreading plate is lowered down to the proper height until grain spreading teeth are inserted into a grain layer, the grains can be ridged for air-curing through the grain spreading teeth of the grain spreading plate, and thus the grains can be overturned and uniformly air-cured; after the grains are air-cured, grain unloading plates are driven to downwardsoverturn through electric driving telescoping rods, the grain unloading plates at two sides are downwards overturned to open a grain unloading tank, and thus the grains can directly fall onto the grain conveyor belt through the grain unloading plates; and finally the grains are conveyed to the outer side of the air-curing plate through the grain conveyor belt, and the grains can be directly storedinto a bag to realize grain filling.

Owner:安徽菲扬新材料有限公司

Wood processing paint spraying device

PendingCN113426605AIncrease coefficient of frictionStable transmissionPretreated surfacesCoatingsElectric machineryManufacturing engineering

The invention discloses a wood processing paint spraying device. The wood processing paint spraying device comprises a paint spraying box, wherein a conveying mechanism, a spraying mechanism, a clamping mechanism and a drying mechanism are arranged in the paint spraying box; and the conveying mechanism is characterized in that first electric push rods are fixedly connected to the top and the bottom of the inner wall of the paint spraying box, the bottoms of the first electric push rods are fixedly connected with bearing plates, the outer walls of the first electric push rods are sleeved with first springs, and limiting grooves are formed in the two sides of the conveying mechanism. According to the wood processing paint spraying device, transmission rollers are arranged, a motor is started to drive driving blades to rotate around a first rotating shaft, the driving blades knock driven blades when rotating so that the driven blades can rotate around a transmission rod, then a spur gear meshed with the driven blades can rotate, a first rotating rod can rotate, a first fixing rod enables the transmission rollers to rotate under the action of a first belt, protrusions arranged on the outer walls of the transmission rollers increase the friction coefficient of the device, so that wood plates can be conveyed more stably, meanwhile, the distance between the two rotating rollers can be conveniently adjusted through the limiting grooves, and then the wood plates can be transmitted more accurately.

Owner:谢辉

Dust removing type circular screening machine for tea

The invention discloses a dust removing type circular screening machine for tea. The machine comprises a base, an outer screening bed, an inner screening bed, a screening net, a sealing cover, a ventilating pipe, an air blower, a tea outlet barrel, a dust collecting pipe and a vibrating assembly, wherein the vibrating assembly is fixedly arranged on the base and is fixedly connected to the outer screening bed; the outer screening bed is driven to up and down vibrate through the vibrating assembly; a plurality of through holes are formed in the sidewall of the inner screening bed, and the innerscreening bed is fixedly sleeved with the outer screening bed; a distance is reserved between the inner screening bed and the outer screening bed; sealing rings are fixedly mounted on the top parts of the outer screening bed and the inner screening bed; the sealing rings, the inner screening bed and the outer screening bed form an air storing empty chamber; one end of the ventilating pipe is arranged on the outer sidewall of the outer screening net while the other end of the ventilating pipe is connected to the air blower; the sealing cover is arranged on the top part of the outer screening bed; a connecting hole is formed in the sealing cover and is fixedly connected to the dust collecting pipe; the screening net is arranged on the inner wall of the inner screening bed; and the tea outlet barrel is fixedly arranged on the outer wall of the outer screening bed. The machine is simple in structure; adhered tea can be separated; and the tea can be subjected to dust removing.

Owner:安徽省双寨茶业有限公司

Expansive soil conveying mechanism for moisture-proof treatment

ActiveCN113418379AReduce gapGood sealing effectBio-packagingDrying solid materialsStructural engineeringFan blade

The invention discloses an expansive soil conveying mechanism for moisture-proof treatment. The expansive soil conveying mechanism comprises a conveying box, sealing equipment is installed at an upper end opening of the conveying box, drying boxes are installed on the two sides of the inner wall of the conveying box, transmission drying assemblies are rotationally connected into the drying boxes, and guide plates fixedly connected with the inner wall of the conveying box are arranged between the two drying boxes. Through mutual cooperative use of connecting shafts, first bevel gears, second bevel gears, transmission shafts, transmission blades and fan blades, when the device moves, the connecting shafts can rotate, then the transmission shafts drive the transmission blades to rotate, expansive soil at the bottom is rapidly conveyed upwards, the expansive soil is turned over, and the transmission shafts are matched to drive the fan blades to rotate, rapid dehydration treatment of the expansive soil which is accumulated inside and absorbs water to expand is achieved, extrusion of expansion of the expansive soil to the inner wall of a compartment is reduced, and the danger during transportation is effectively reduced.

Owner:CHINA FIRST HIGHWAY ENG +1

Camellia oleifera crushing device

ActiveCN113318809AAchieve cleaning effectRealize automatic flippingGrain treatmentsAgricultural engineeringStructural engineering

The invention relates to a camellia oleifera crushing device which comprises a supporting rack and a working table. The supporting rack is fixedly arranged on the worktable, a driving air cylinder is arranged on the supporting rack, a driving lower end of the driving air cylinder is fixedly connected with an air cylinder arm, the lower end of the air cylinder arm is fixedly connected with a crushing hammer, an inner crushing barrel is arranged under the crushing hammer, and the inner crushing barrel is arranged in an outer crushing barrel. A structure of an existing camellia oleifera crushing device is optimized. In a working process, the optimized camellia oleifera crushing device crushing device not only can achieve an effect of cleaning the camellia oleifera crushing device, but also can achieve an effect of automatic stirring, so that on the one hand, the work efficiency can be improved and on the other hand, the work efficiency can be improved effectively, and therefore, in an actual application, the device is higher in practical value.

Owner:安徽东旭大别山农业科技有限公司

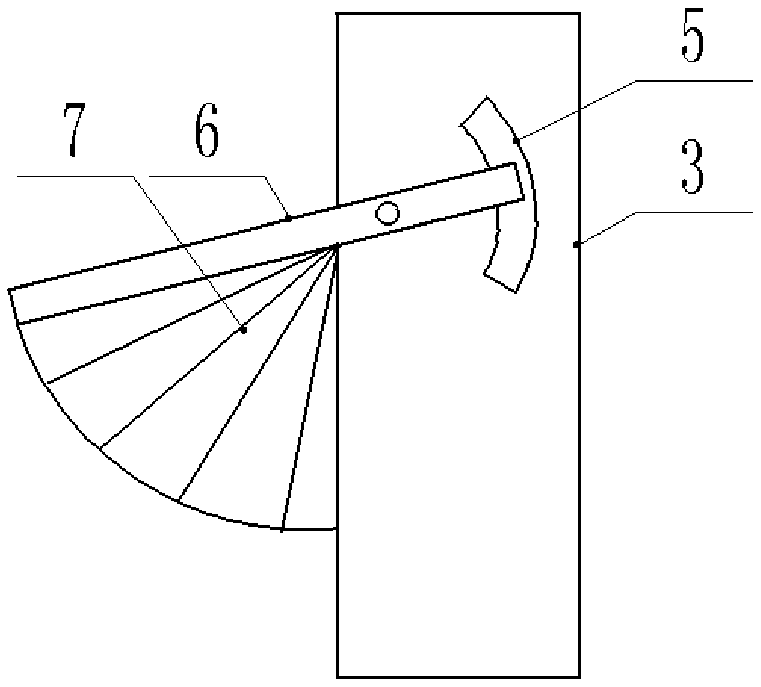

Waste incineration device with intermittent wind impact combustion supporting and vibration ash removal functions

InactiveCN112325290AAchieve flippingAchieve continuous vibrationBlast-producing apparatusIncinerator apparatusEnvironmental geologyWaste material

The invention provides a waste incineration device with intermittent wind impact combustion supporting and vibration ash removal functions and relates to the technical field of incineration devices. The problems that in the incineration process of an existing device, residues are likely to be accumulated on an incineration frame, incinerated objects cannot be turned over in the incineration process, so that the incineration efficiency is reduced is solved, and the phenomenon that organic linkage combination of wind power combustion supporting and residue removing cannot be achieved through thestructural improvement, so that vibration residue removing and turning of incinerated objects cannot be achieved in a linkage mode while wind power combustion supporting is achieved exists are solved. The waste incineration device with the intermittent wind impact combustion supporting and vibration ash removal functions comprises an incineration box body. An incineration frame structure is mounted in the incineration box body. Due to the fact that spraying holes are formed in each air inlet pipe in the rectangular array shape, the spraying holes are distributed in the fan shape, and the spraying holes distributed in the fan shape jointly form a gas combustion supporting structure. When the air inlet pipes reciprocate, wind power collected through air collecting bases can be sprayed out through the spraying holes, and combustion supporting of incinerated objects is achieved.

Owner:日照市睿尔泽新材料科技有限公司

Cooker with anti-scald function

ActiveCN108567316AAchieve flippingImprove the cooking effectCooking-vessel lids/coversCooking vessel supportCookerScalding

The invention discloses a cooker with an anti-scald function, and belongs to the technical field of cooking equipment. The cooker with the anti-scalding function comprises a box body, wherein the boxbody comprises a bottom plate, a back plate and a side plate; a heating stove is connected to the center of the bottom plate, symmetrical support plates are fixedly connected to the bottom plate, a connecting shaft is rotationally connected between the support plates, a bracket plate is fixedly connected to the connecting shaft, and a strut is fixedly connected to the bracket plate, a lantern ringis fixedly connected to the top end of the strut; the bracket plate is rotationally connected with a pan through a connection column, and the pan is located in the lantern ring; a feeding box is fixedly connected to the top of the side plate, the side, located in the box body, of the feeding box is located above the pan, and the pan is in sealed connection with a pan cover; symmetrical limiting holes are formed in the inner wall of the pan, and an extraction ring is fixedly connected with the center of the pan cover. The cooker is convenient to operate, the pan cover is closed and opened by aU-shaped rod, and harm to the human body caused by direct contact with the pan cover is avoided.

Owner:山东天智信息科技有限公司

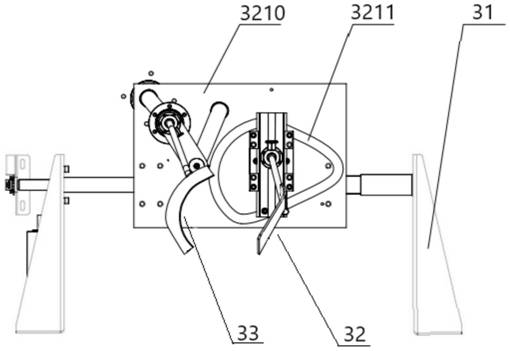

Automatic/semi-automatic cooking equipment with double turners

PendingCN112656208ALow shape requirementRealize stirringCooking insertsElectric machinerySemi automatic

The invention discloses automatic or semi-automatic cooking equipment with double shovels. The equipment comprises a rack, a pan and a turner system; the pan is arranged on the rack; the turner system is arranged above or beside the pan through a bracket; the turner system comprises a main turner assembly driven by a motor and an auxiliary turner assembly driven by a motor; the main turner assembly comprises a main turner head, a main turner handle and a main turner track conversion mechanism; and the auxiliary turner assembly comprises an auxiliary turner head, an auxiliary turner handle and an auxiliary turner track conversion mechanism. During cooking, the main turner head and the auxiliary turner head move from the opposite directions to the center of the pan along the inner wall of the pan under the driving of the motors and the action of the main turner track conversion mechanism and the action of the auxiliary turner track conversion mechanism respectively; when the main turner head and the auxiliary turner head meet, the main turner head can slide on the upper surface, away from the pan, of the auxiliary turner head.

Owner:深圳卡帕智能系统有限公司

Dried bean curd frying device

InactiveCN105230692AAvoid stickingReduce labor intensityBaking ovenOil/fat bakingEngineeringWork safety

The present invention discloses a dried bean curd frying device which comprises an oil groove, an electric heater and a metal belt conveyor. A material shovel plate is provided in the oil groove, the edge of the shovel plate leans on the metal belt conveyor under the action of gravity; the dried bean curd frying device also comprises a feeding material conveyor for feeding materials into the oil groove, a groove lid arranged on the oil groove and controllers which respectively control the electric heater, the metal belt conveyor and the feeding material conveyor. According to the dried bean curd frying device, dried bean curds are sent into the oil groove by the feeding material conveyor, the dried bean curd frying process is accomplished on the metal belt conveyor in the oil groove, and the fried dried bean curds are transported out of the oil groove by the metal belt conveyor. During the frying process, dried bean curds on the metal belt conveyor are shoveled by the material shovel plate so as to achieve turnover of the dried bean curd and avoid the adhesion between the metal belt conveyor and the dried bean curd. The dried bean curd frying device realizes automatic material feeding, material discharging and material turnover, the work intensity is low, and the work safety is good.

Owner:CHONGQING YUPAI AGRI PROD DEV

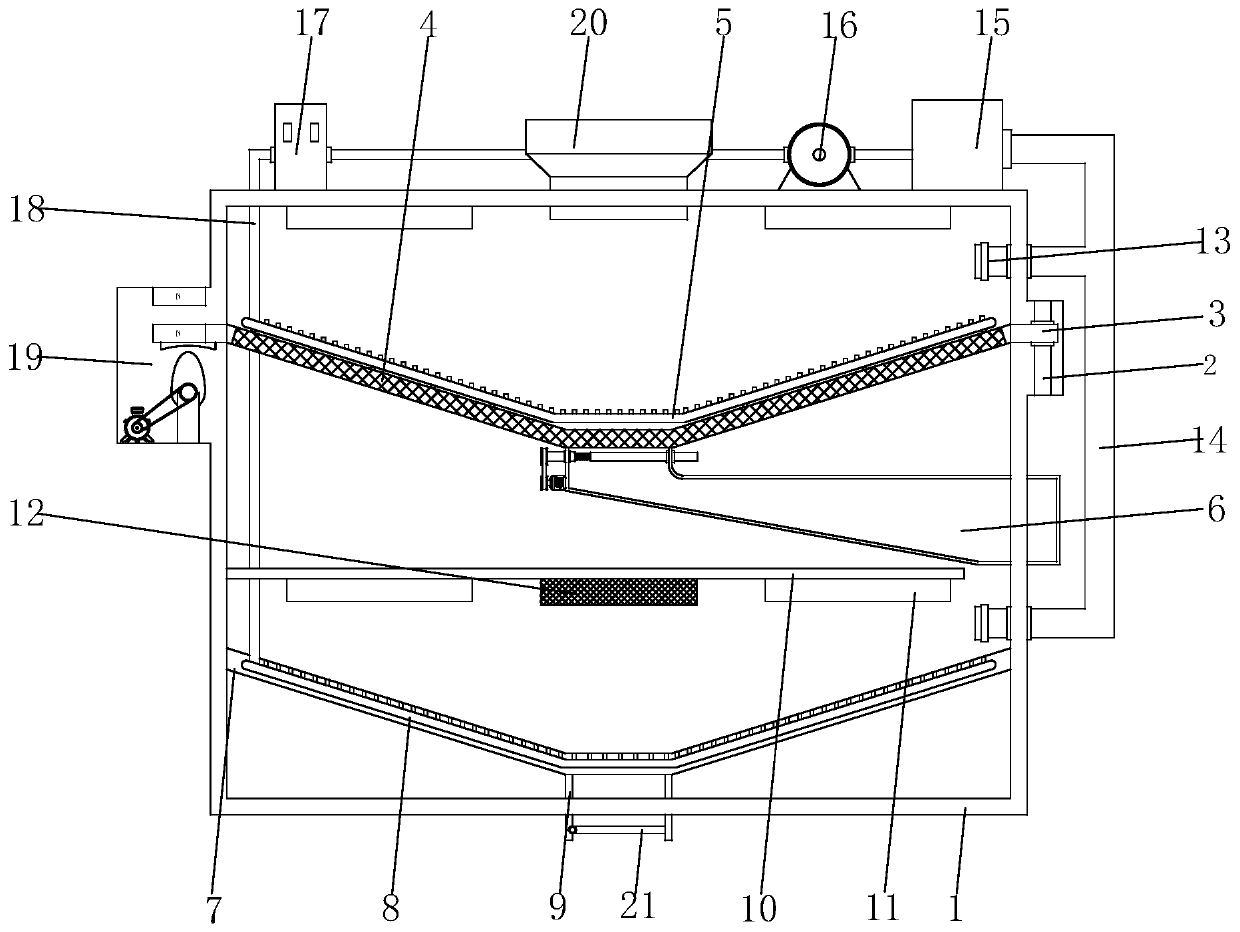

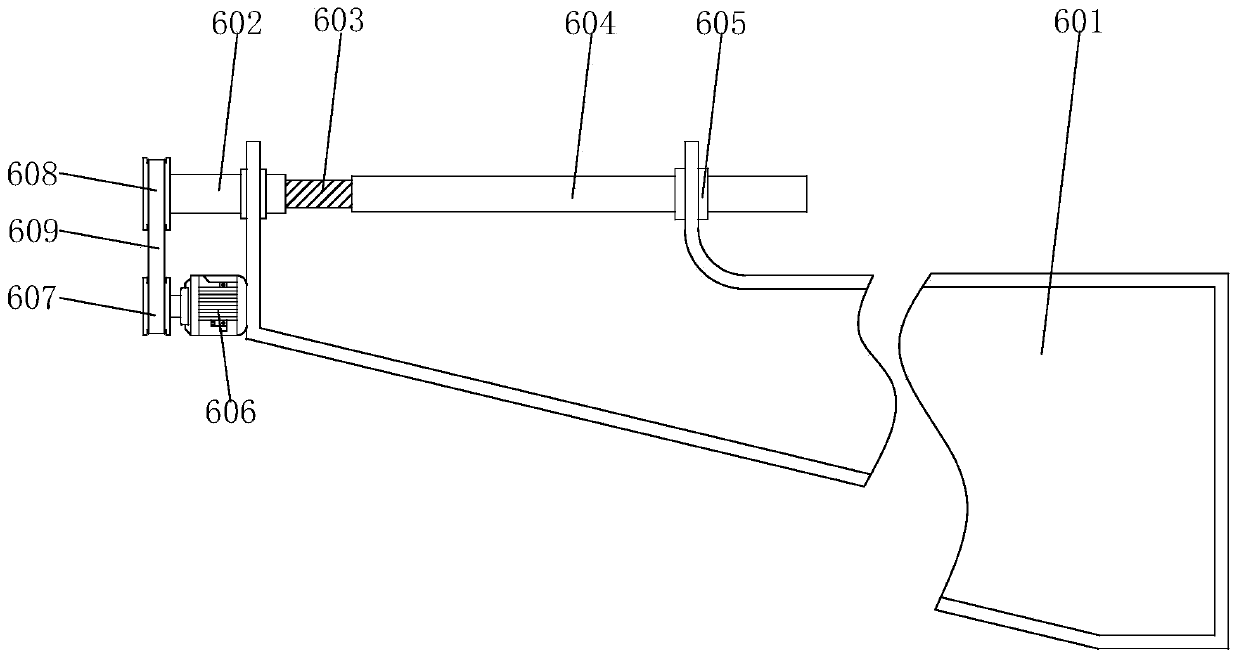

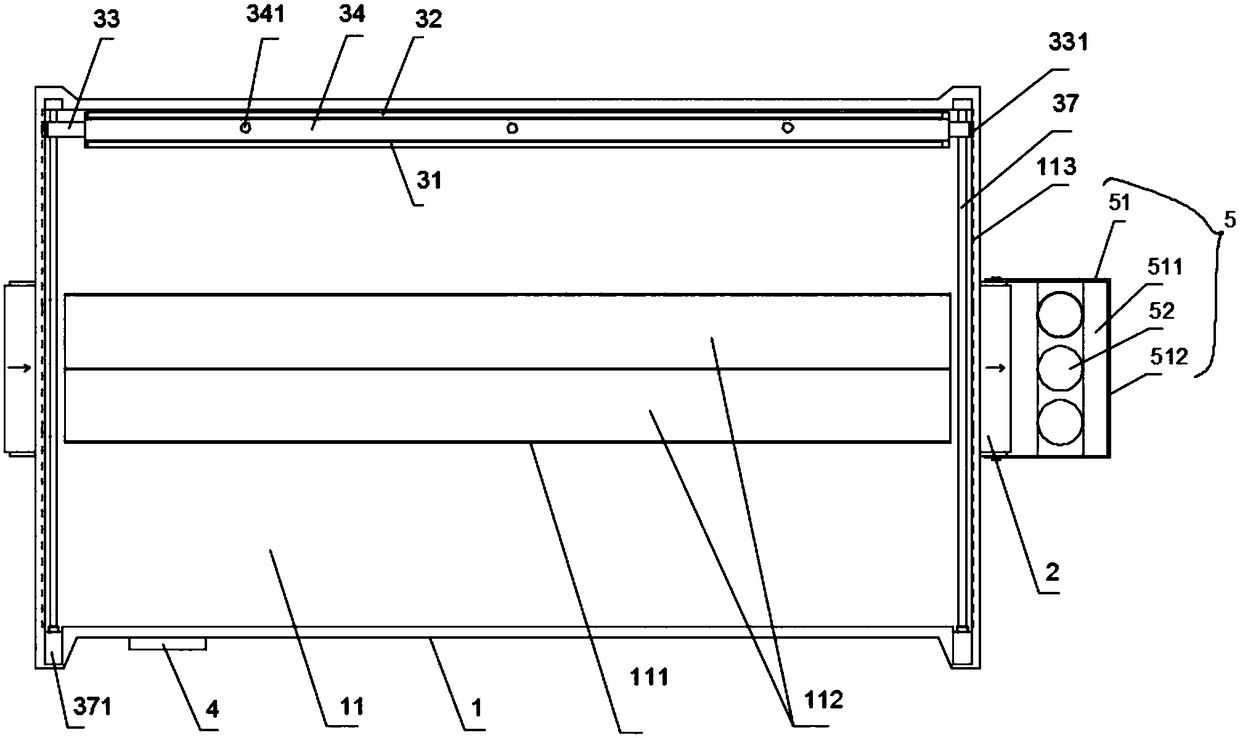

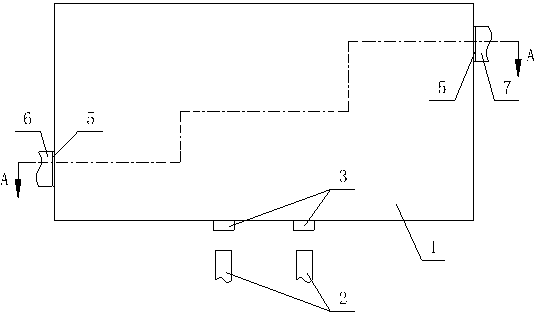

Tea leaf withering system

PendingCN104186724AAvoid direct accessBurn out preventionPre-extraction tea treatmentEngineeringMechanical engineering

The invention particularly relates to an improvement on a tea leaf withering system, and aims at providing a tea leaf withering system with uniform temperature in a withering space. The tea leaf withering system comprises a hot air furnace, a withering room and a withering conveying structure, wherein the withering room consists of an outer room and an inner room; the bottoms of the outer room and the inner room are connected integrally; a rectangular cavity is formed between the top of the inner room and the outer room; an annular cavity is formed between the four walls of the inner room and the four walls of the outer room; the periphery of the rectangular cavity is communicated with the top of the annular cavity; through holes communicated with the interior of the inner room and the annular cavity are formed in the four walls of the inner room; an air outlet chamber is formed in the center of the inner room, and the bottom and the top of the air outlet chamber are connected with the inner room integrally; through holes communicated with the interior of the inner room and the interior of the air outlet chamber are formed in the side wall of the air outlet chamber; an air outlet communicated with the exterior of the outer room is formed in the bottom of the air outlet chamber; an air inlet pipeline communicated with the rectangular cavity is arranged on one side of the outer room; an air outlet pipe of the hot air furnace is opposite to the air inlet pipeline; a distance is reserved between the air outlet pipe and the air inlet pipeline; a withering conveying structure is positioned between the inner room and the air outlet chamber. The tea leaf withering water loss uniformity is guaranteed.

Owner:BAOSHAN CHANGNING HONG TEA GRP

Potato peeling processor

InactiveCN108208866AAchieve flippingAvoid the problem of machine hair sheddingClimate change adaptationVegetable peelingDrive motorEngineering

The invention discloses a potato peeling processor. The structure of the potato peeling processor comprises a peeling box, wherein a sieve plate, slope surfaces, a peel containing tank, rotating shafts and roller brushes are arranged in the peeling box; the sieve plate is fixedly connected to the lower part of the interior of the peeling box; the slope surfaces are fixedly connected to the left side and the right side of the peel containing tank; the rotating shafts are fixedly connected to the interior of the peeling box; the roller brushes are fixedly connected to the inner sides of the rotating shafts; a driving box is arranged on the left side of the peeling box; and a driving motor, a chain and a gear are arranged in the driving box. According to the potato peeling processor, the roller brushes are arranged in a spacing manner to form a semi-closed cleaning tank; all the roller brushes rotate in the same direction, so that materials are turned over; spraying water is used for rapid and thorough cleaning, and brushing, peeling and the like are performed; and the materials of the roller brushes are processed by a special technology, and the hairs of the roller brushes are all manually-planted, so that the problem of the drop of hairs planted by a machine is solved. The potato peeling processor has the characteristics of being large in effective volume of cleaning and peeling, high in efficiency of cleaning and peeling, capable of saving water and performing continuous cleaning, simple in operation, long in service life and the like.

Owner:贵州长顺八妹农副产品开发有限公司

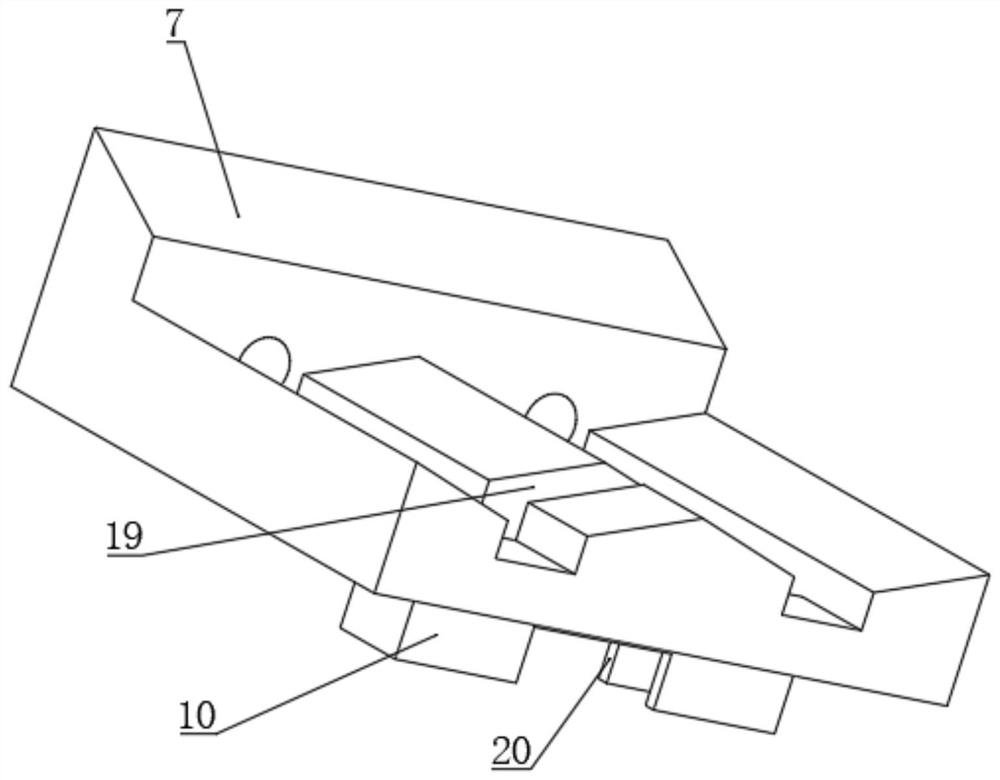

Paris polyphylla processing device

InactiveCN108626972ARealize automatic movementAchieve flippingDrying solid materials with heatDrying gas arrangementsEngineeringParis polyphylla

The invention relates to the technical field of paris polyphylla processing and discloses a paris polyphylla processing device. The paris polyphylla processing device comprises a support, wherein an airing plate is arranged on the support, the airing plate is connected to the support in a rotating manner, and a torsional spring is mounted between the airing plate and the support. The paris polyphylla processing device further comprises a rotating mechanism, wherein the rotating mechanism comprises a round wheel arranged on the support in a rotating manner, the eccentric part of the round wheelis provided with an eccentric column, a connecting rod is hinged to the eccentric column, a push rod is hinged to the end, far from the eccentric column, of the connecting rod, and a screw rod is hinged to the end, far from the eccentric column, of the push rod; the screw rod is transversely connected to the support in a sliding manner, and a matched sliding sleeve is arranged on the screw rod ina sleeving manner; the sliding sleeve is connected to the support in a rotating manner, and the sliding sleeve is located below the airing plate; and a cam is fixedly arranged on the sliding sleeve,and the large-diameter end of the cam is intermittently pressed against the bottom of the airing plate and pushes the airing plate to rotate on the support. Through the paris polyphylla processing device, the automatic turning of paris polyphylla on the airing plate can be realized, the uniform air-drying of the paris polyphylla is ensured, and the processing efficiency is increased.

Owner:DAOZHEN GELAO & MIAO AUTONOMOUS COUNTY RUIFA AGRI TECH DEV CO LTD

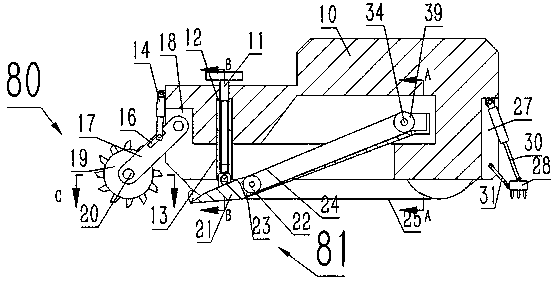

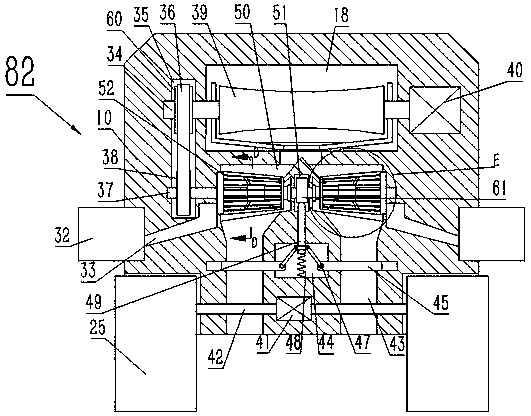

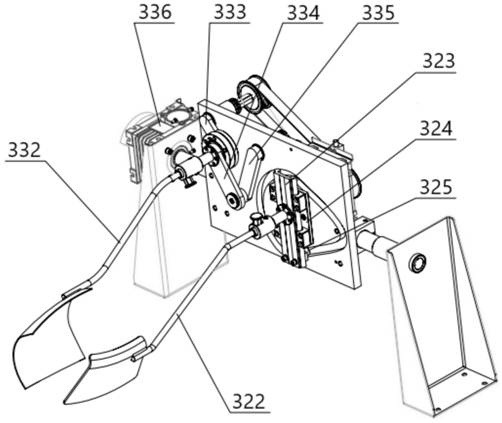

Thai yoghourt stir-frying machine and application method thereof

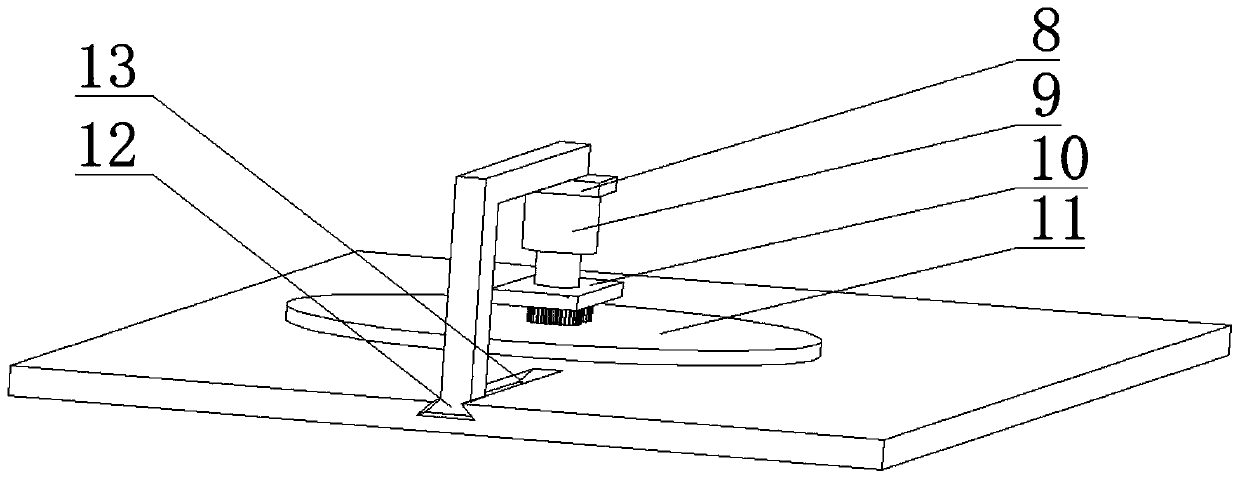

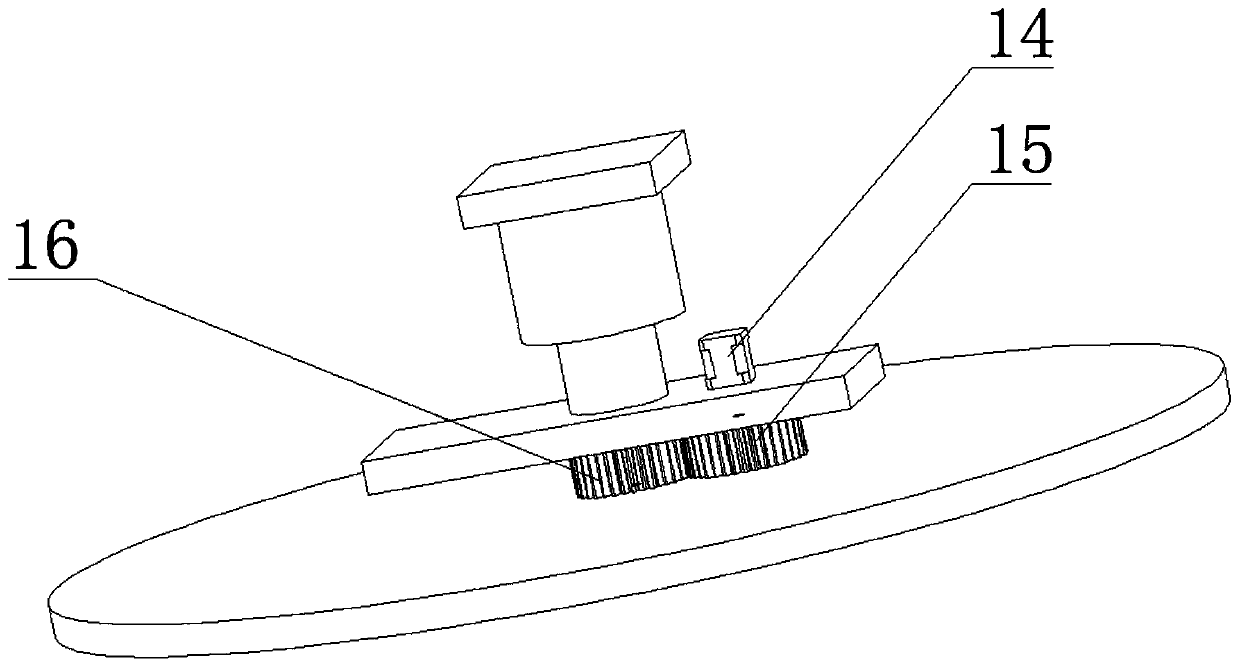

PendingCN107821590ASimple structureReasonable layout distributionMilk preparationToothed gearingsMechanical engineeringEngineering

The invention relates to a Thai yoghourt stir-frying machine and an application method thereof. The Thai yoghourt stir-frying machine comprises a cabinet. A horizontal turntable which is driven by a driving mechanism through a first output transmission mechanism to rotate is arranged on a table top of the cabinet. A support frame is arranged on the table top of the cabinet. A yoghourt stir-fryingmechanism which cooperates with the turntable and is driven by the driving mechanism through a second output transmission mechanism to realize intermittent lifting is arranged on the support frame. Ayoghourt stirring mechanism which cooperates with the turntable is arranged on the table top of the cabinet. The Thai yoghourt stir-frying machine is equipped with multiple vertical shovel plates foryoghourt stir-frying operation simultaneously. In comparison with manual operation with mostly two shovel plates, production efficiency of the invention is remarkably raised. Through an arc-shaped baffle plate which fits with the turntable, turning of yoghourt is realized. The machine of the invention is simple and practical.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com