Soybean straw sun-curing device for agricultural production

A technology for soybean straw and drying device, which is applied to circuit devices, battery circuit devices, transportation and packaging, etc., can solve the problems of straw turning and low drying efficiency of straw, and achieve the effects of improving efficiency, convenient operation and ensuring drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

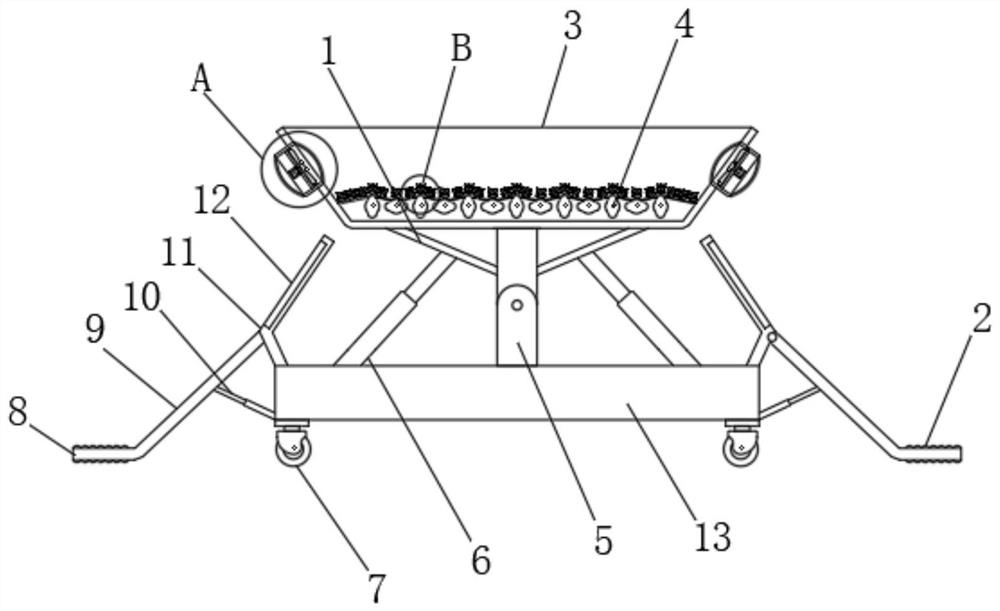

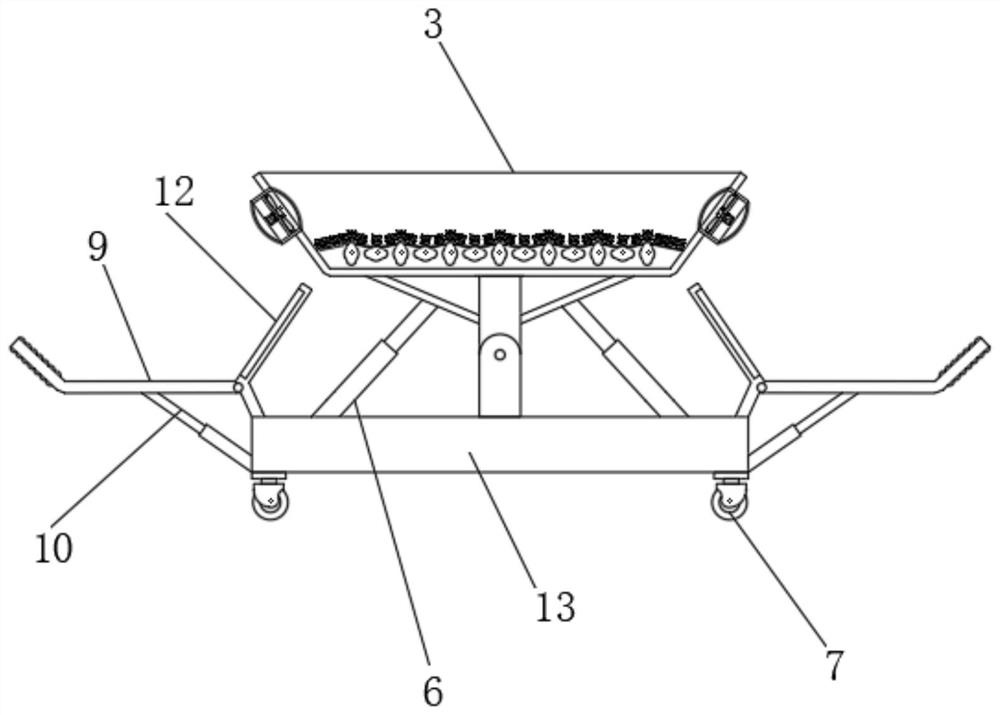

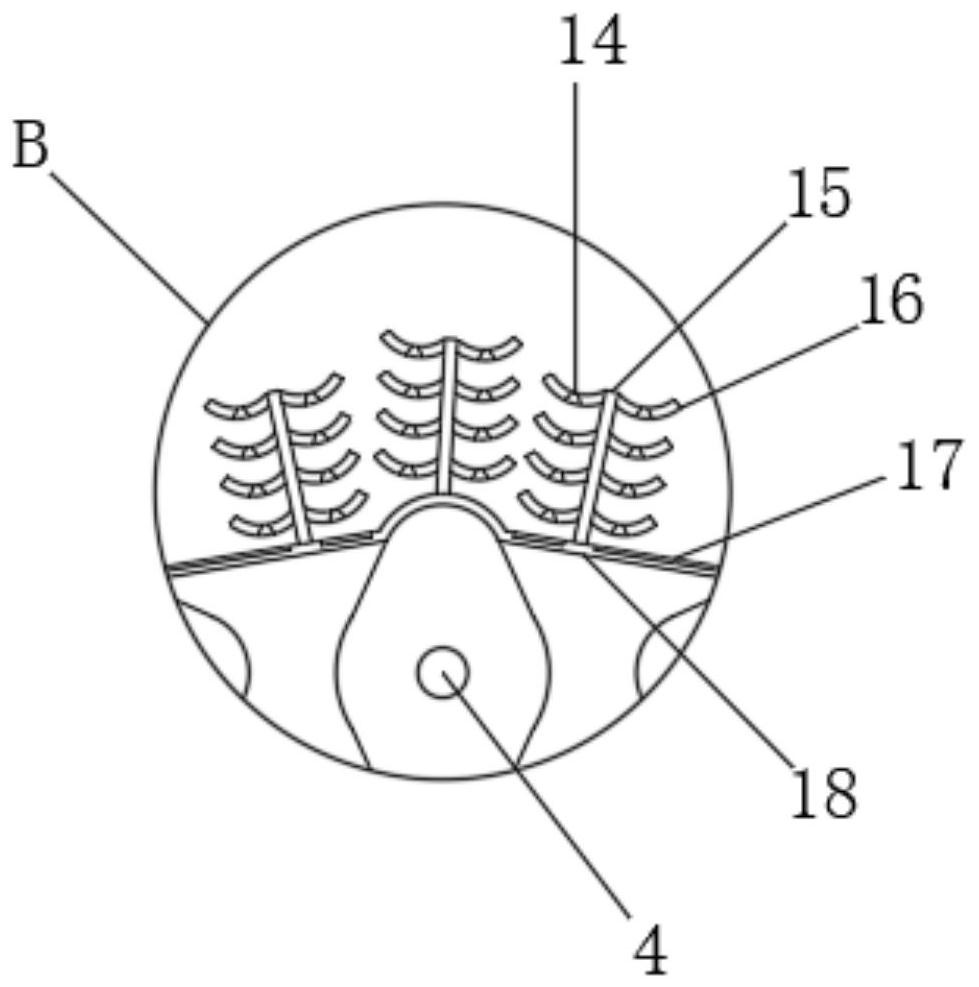

[0028] refer to Figure 1-5 , a soybean straw drying device for agricultural production, comprising a drying tank 3 and a base 13, the inner walls of both sides of the drying tank 3 are provided with the same elastic cloth 18, and the top outer wall of the elastic cloth 18 is provided with a supporting rod 15, supporting The outer walls on both sides of the rod 15 are provided with arc-shaped support plates 16, and the top outer wall of the arc-shaped support plate 16 is provided with a through hole 14. The cross section of the through hole 14 is an isosceles trapezoidal structure, and the elastic cloth 18 is close to the support rod The outer wall on one side of 15 is provided with an installation groove, and the inner wall of the installation groove is provided with a tinfoil reflective film 17, and the outer wall of one side of the drying tank 3 is fixed with a servo motor by screws, and the output shaft of the servo motor is connected with a double-sided cam through a coupl...

Embodiment 2

[0038] refer to Figure 1-2 , a soybean straw drying device for agricultural production. Compared with Embodiment 1, this embodiment also includes a fixing groove on the outer wall of the fixing plate 11, and a solar panel 12 on the inner wall of the fixing groove.

[0039] The solar panel 12 is capable of generating solar power and storing the generated power through the battery to develop new energy, save energy and protect the environment, and conform to the concept of sustainable development of life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com