Potato peeling processor

A processing machine and potato technology, applied in food processing, vegetable or fruit peeling, climate change adaptation, etc., can solve the problems of short service life, machine hair loss, complicated operation, etc. Long life and simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

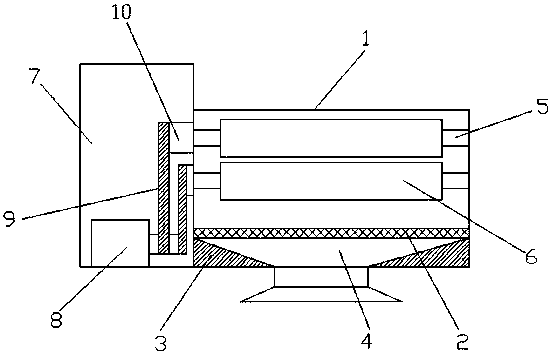

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

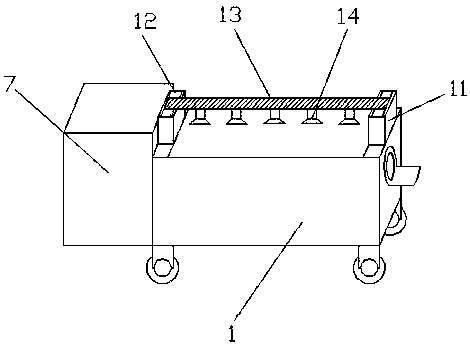

[0015] see Figure 1-2 , the present invention provides a technical solution: a potato peeling processor, comprising a peeling box 1, the inside of the peeling box 1 is provided with a sieve plate 2, a slope surface 3, a skinning groove 4, a rotating shaft 5 and Roller brush 6, the sieve plate 2 is fixedly connected to the lower part of the peeling box 1, the slope surface 3 is fixedly connected to the left and right sides of the skin loading tank 4, and the rotating shaft 5 is fixedly connected to the The inside of the peeling box 1 is described, the roller brush 6 is fixedly connected to the inside of the rotating shaft 5, the left side of the peeling box 1 is provided with a drive box 7, and the inside of the drive box 7 is provided with a drive motor 8. Chain 9 and gear 10,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com