Patents

Literature

204results about How to "Low shape requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

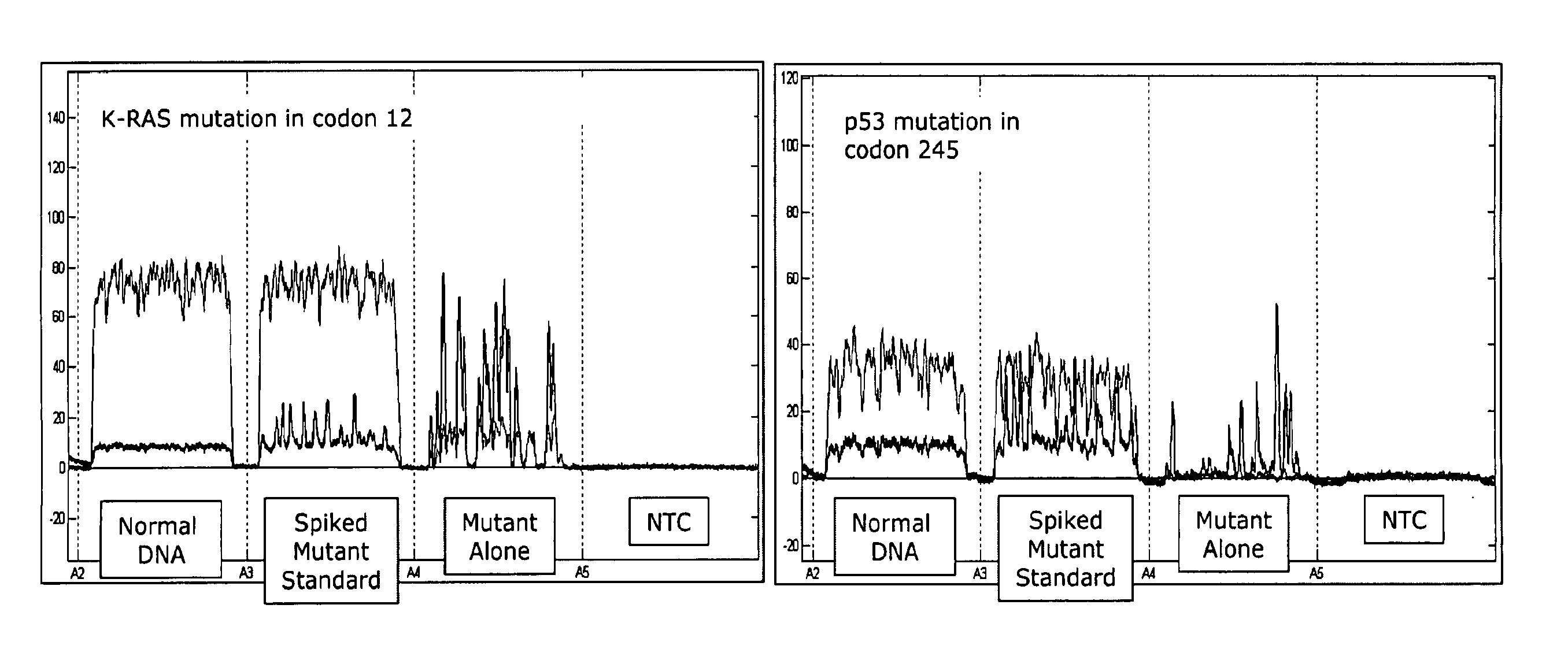

Methods of detecting low copy nucleic acids

ActiveUS20080090244A1Reduce cross contaminationReduce pollutionHeating or cooling apparatusMicrobiological testing/measurementEmulsionChemistry

Methods are provided for detecting low copy nucleic acids of interest in a sample. In one method, a sample comprising a nucleic acid of interest is aliquotted into a plurality of reaction mixtures, at least two of which are single-copy reaction mixtures. The reaction mixtures are subjected to one or more amplification reactions while flowing through a channel of a microfluidic device. At least one of the reaction mixtures is formulated in an aqueous phase of an emulsion comprising aqueous droplets suspended in an immiscible liquid. The nucleic acid of interest is present as a single copy in at least one aqueous droplet of the aqueous phase prior to performing the amplification reaction(s). Amplification is performed on the reaction mixture when it is formulated in the emulsion. The nucleic acid is continuously flowed during a plurality of steps of the method.

Owner:CAPLIPER LIFE SCI INC

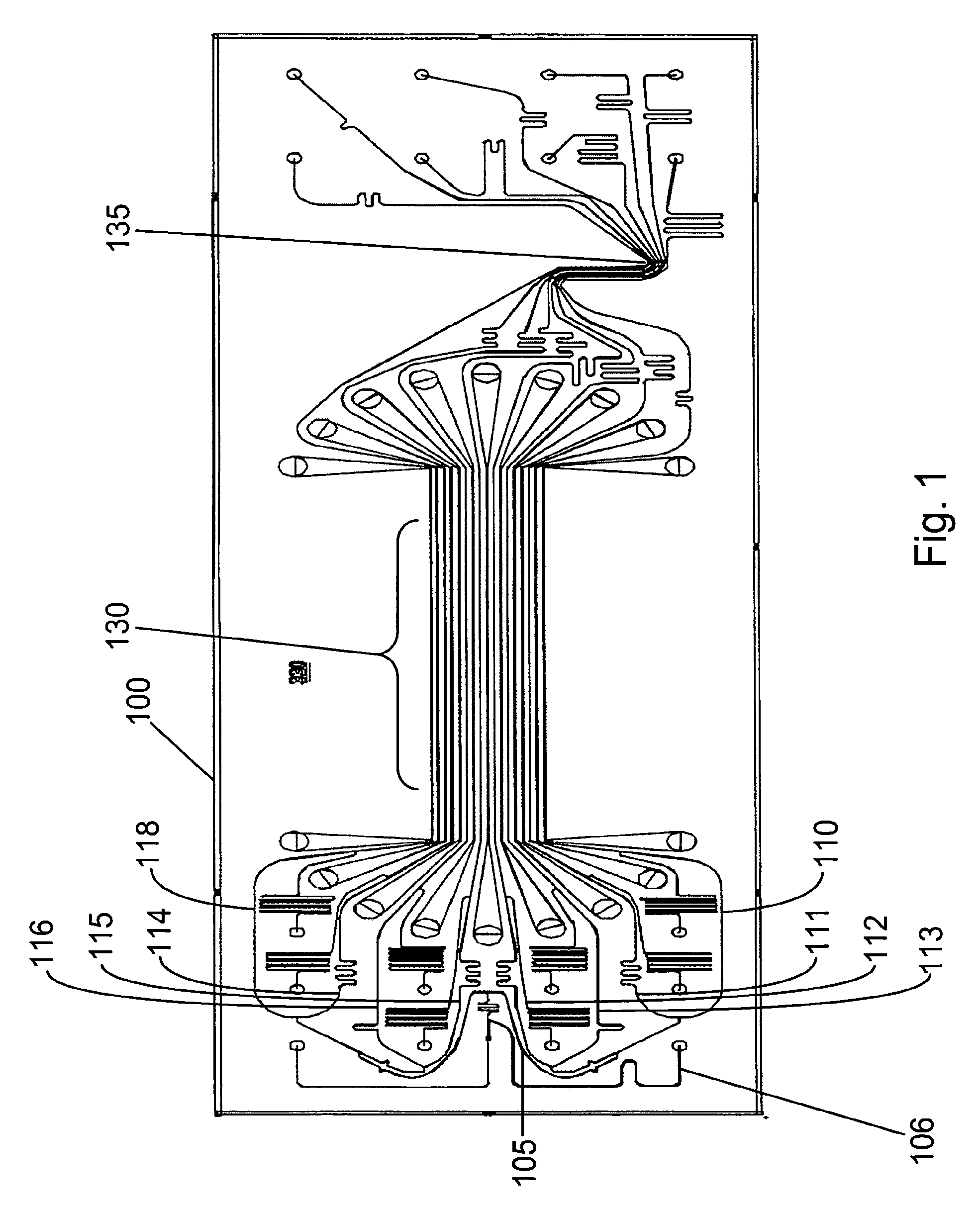

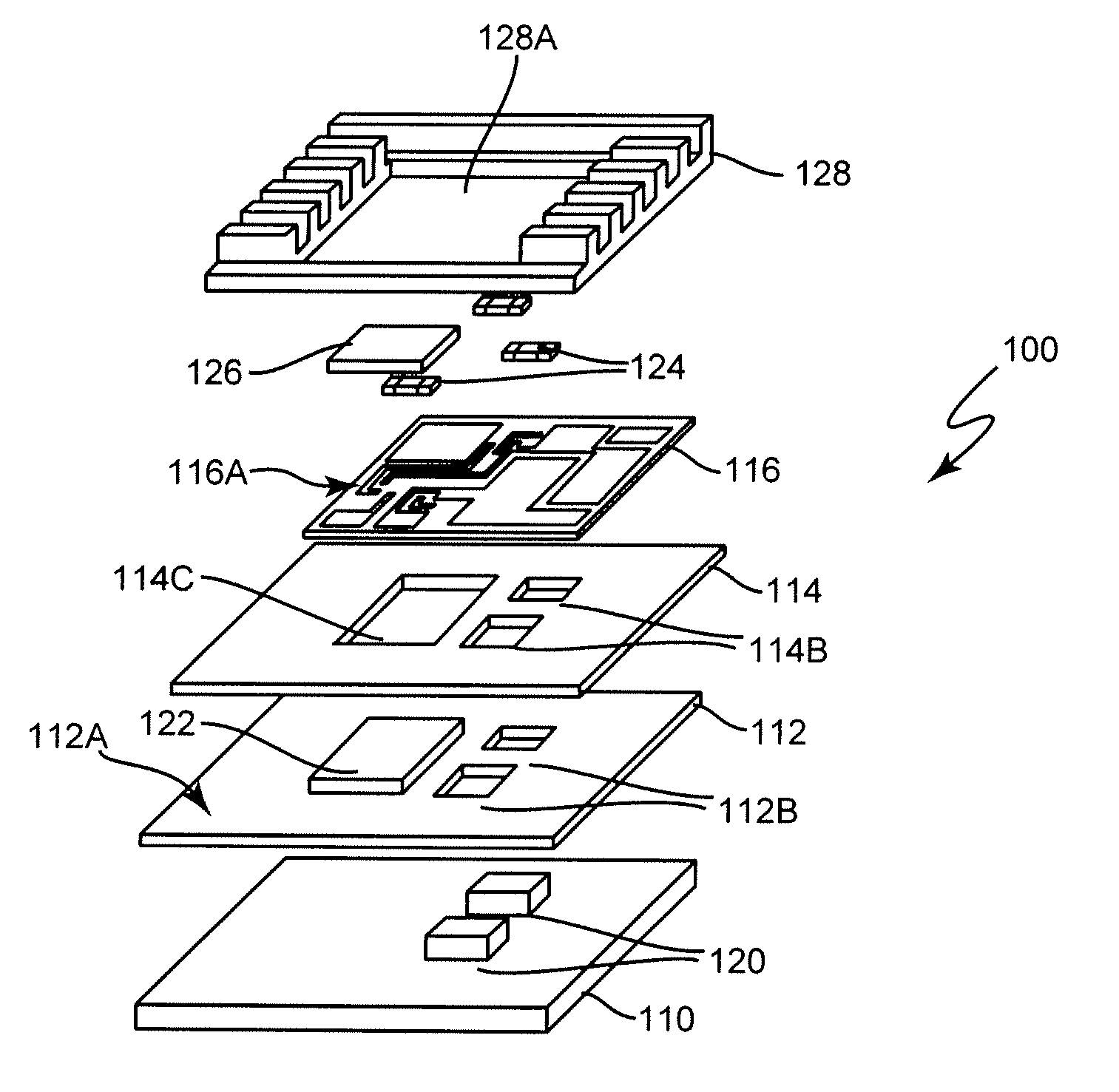

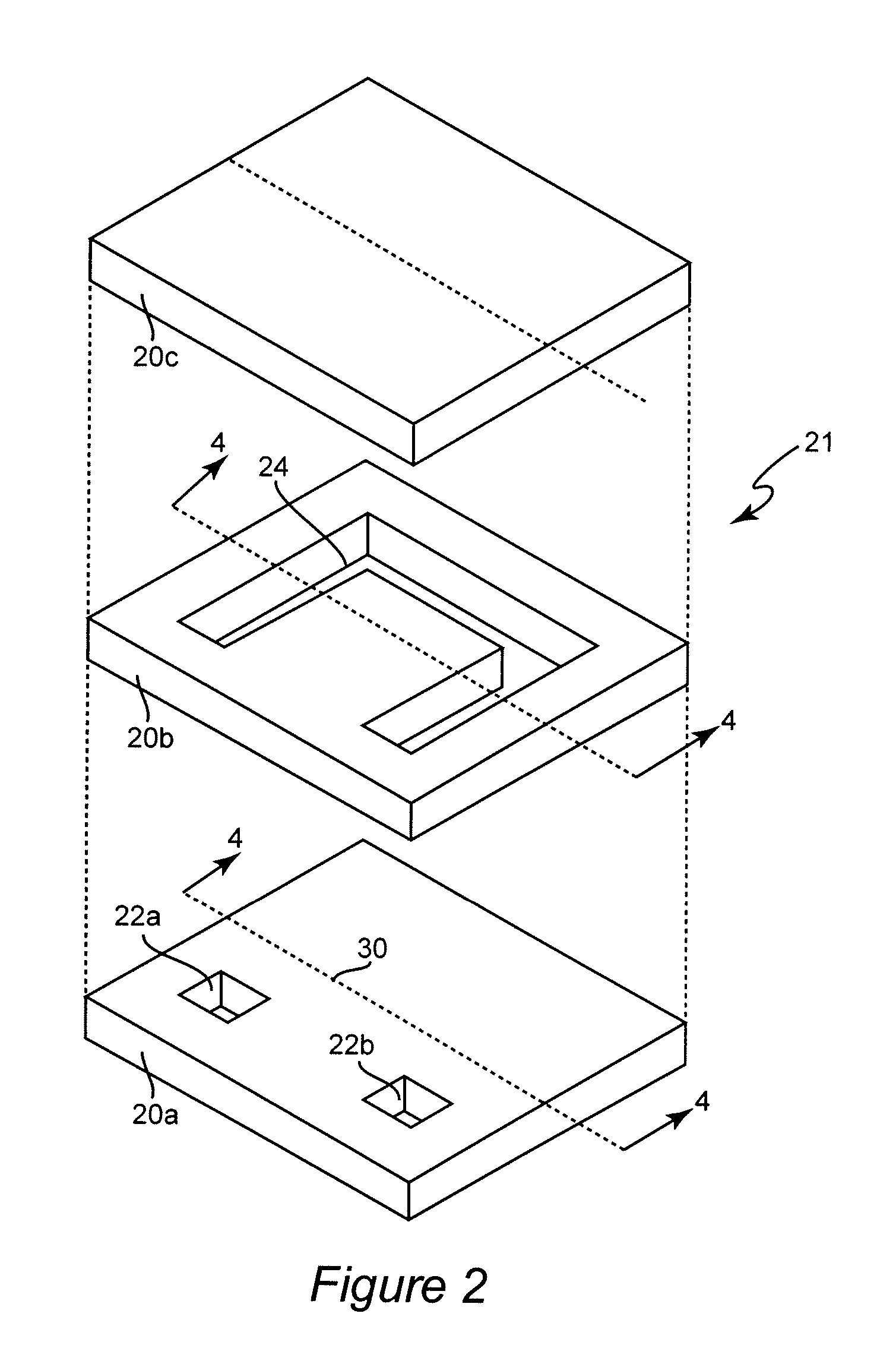

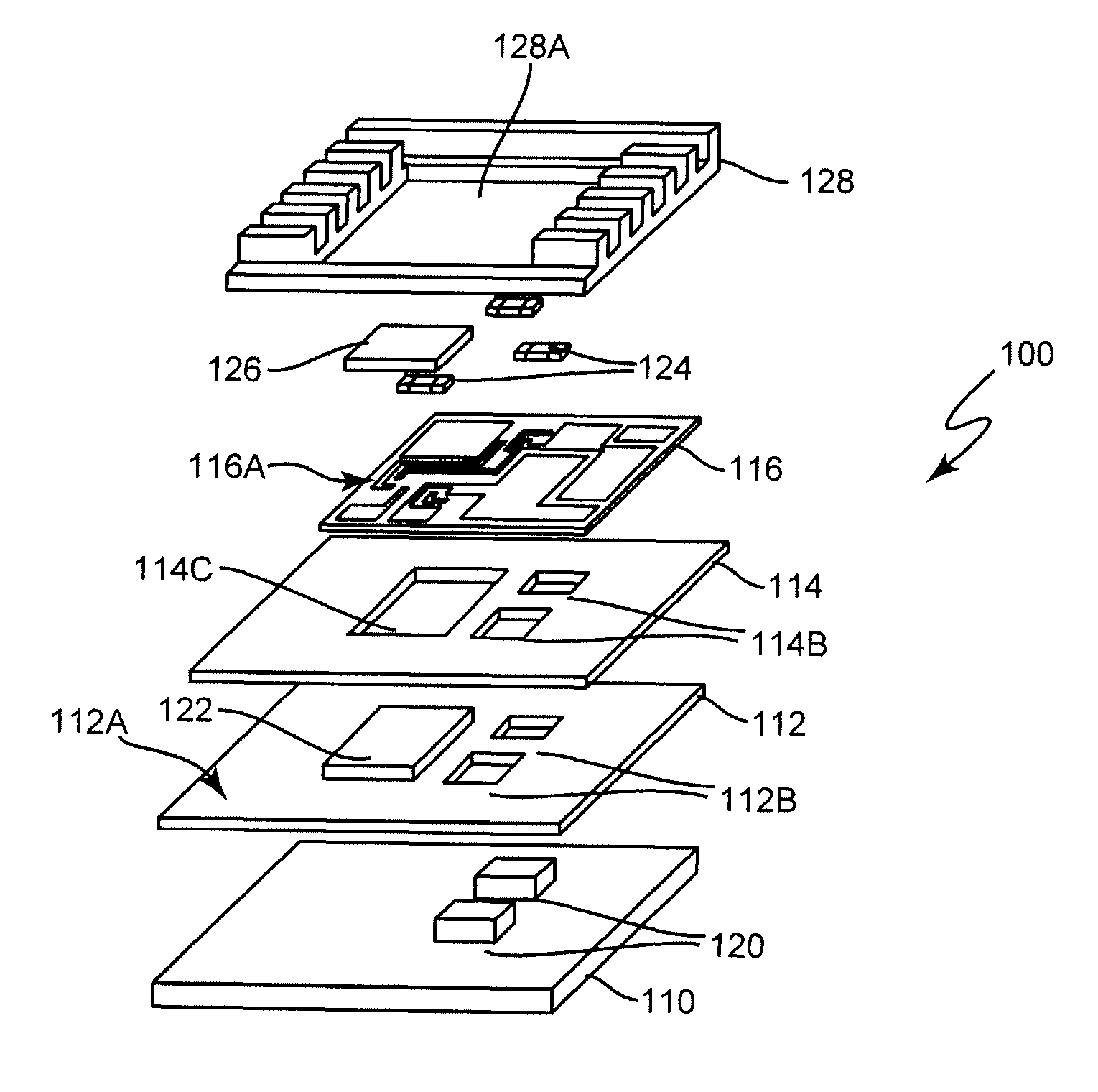

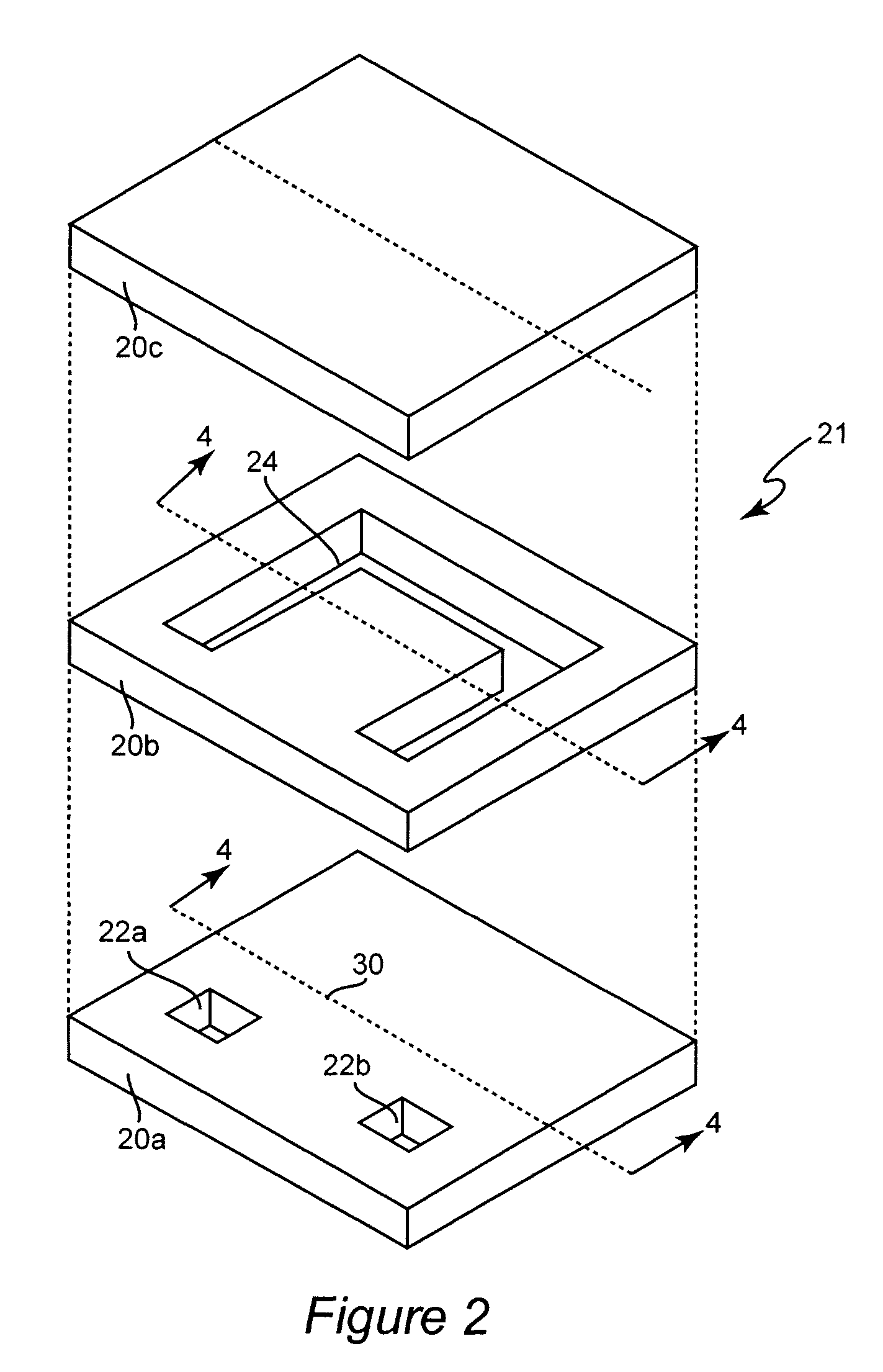

Method and Apparatus for Three-Dimensional Integration of Embedded Power Module

InactiveUS20070230221A1Reduces packaging overheadPackaging overhead is reducedTransformers/inductances coolingTransformers/inductances coils/windings/connectionsCo-fired ceramicInductor

A modified planar Low Temperature Co-Fired Ceramic (LTCC) high conductance inductor, embedding a large cross section conductor, supports a stacked arrangement of heat spreader, inductor and active device layers. Interlayer electrical connections connect the layers. Optionally, a DC-DC converter includes the modified planar LTCC high conductance inductor, embedding a large cross section conductor, supporting a stacked arrangement of heat spreader, capacitor and active device layers, the active devices layer including the switching transistors. The active devices layer may include semiconductor dies embedded in a substrate.

Owner:VIRGINIA TECH INTPROP INC

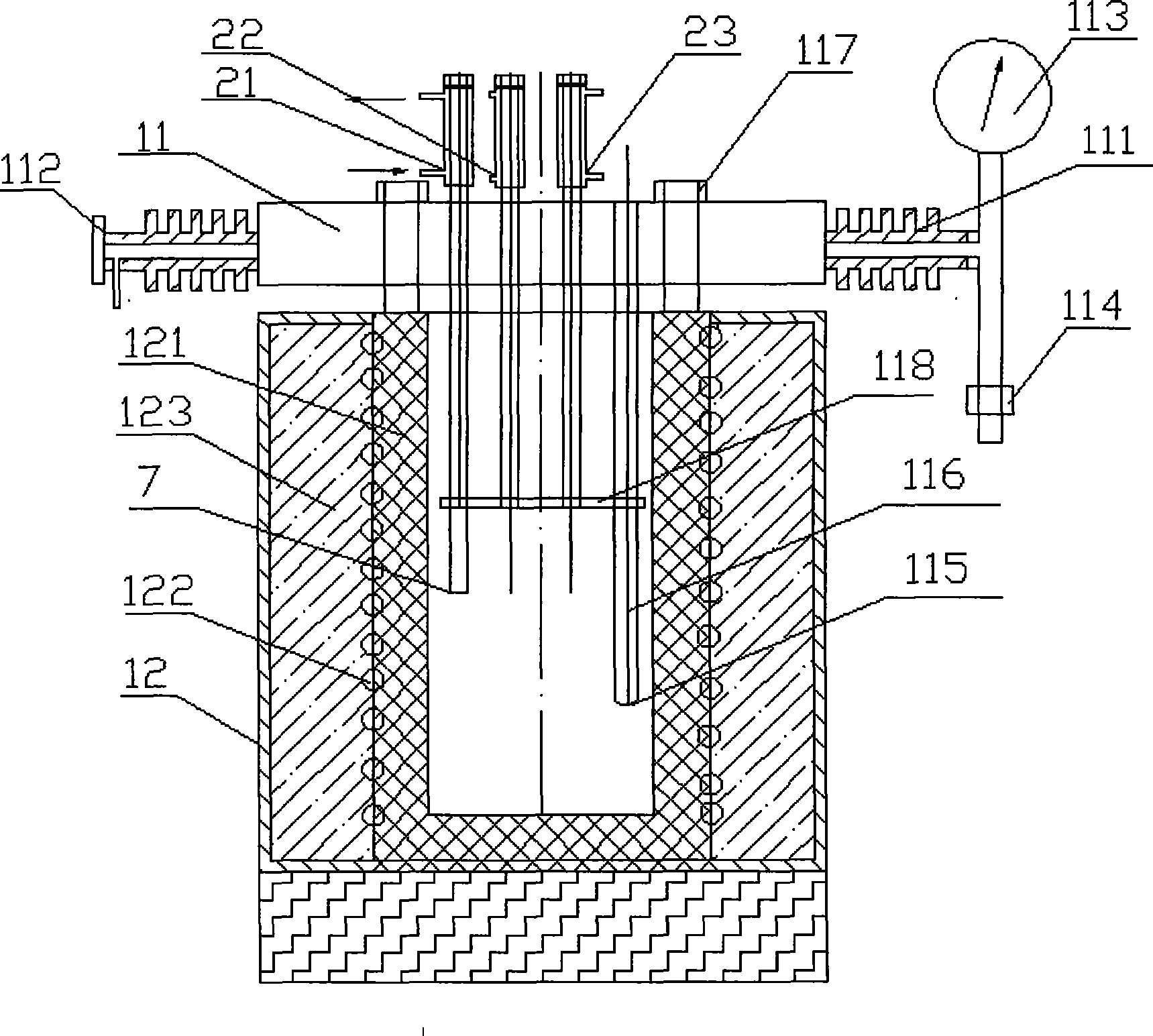

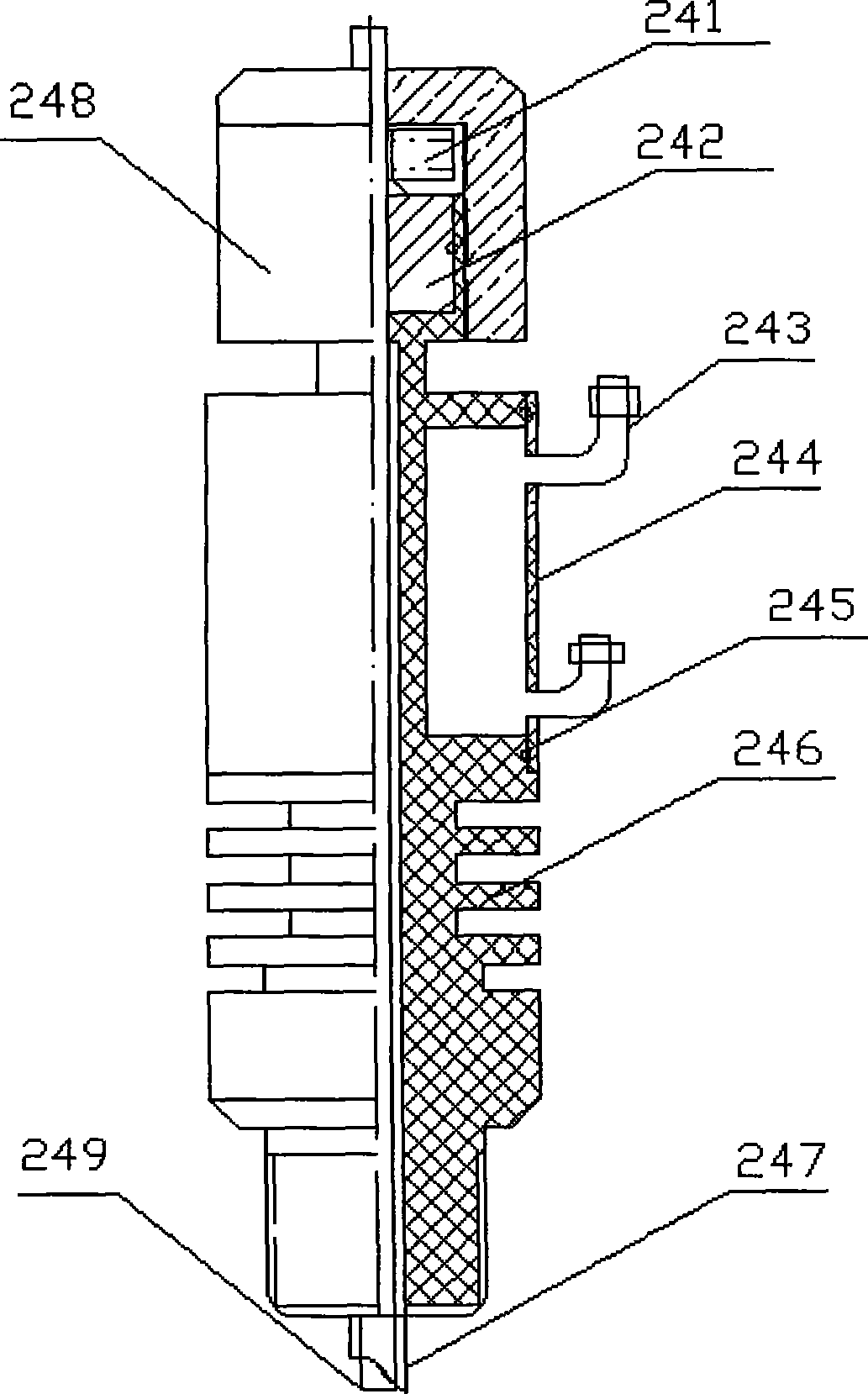

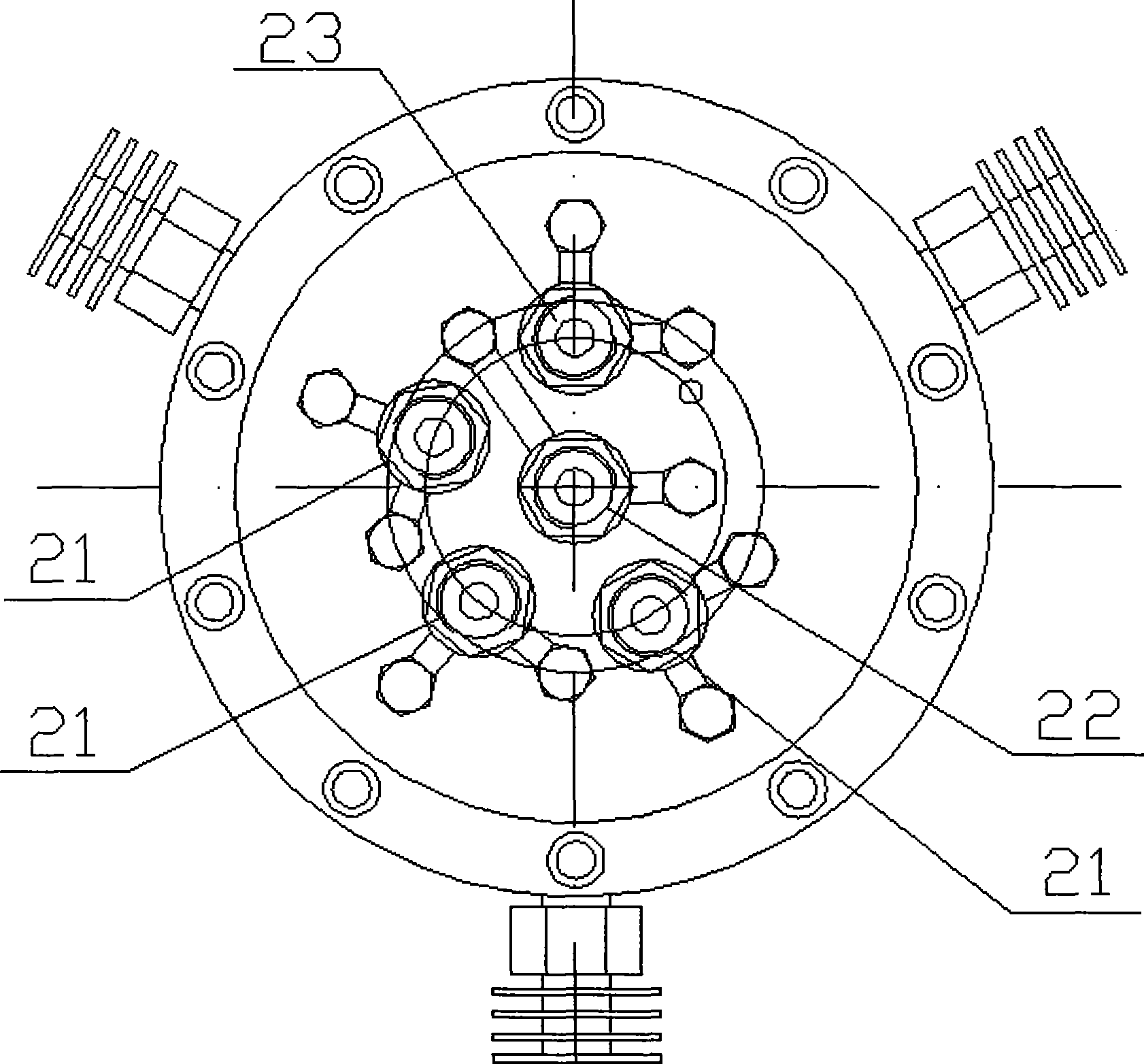

Experimental facility for testing electrochemical signals of various materials in high-temperature high-pressure environment

InactiveCN101520402ACompact structureEasy to operateWeather/light/corrosion resistanceMaterial analysis by electric/magnetic meansAuxiliary electrodeSignal on

The invention discloses an experimental facility for testing electrochemical signals of various materials in a high-temperature high-pressure environment, which comprises a high-pressure kettle, an electrode system, a temperature controller, an external electrochemical tester and a circulating water cooling system, wherein the outer side of the high-pressure kettle is provided with a heating electric stove wire, and the outer surface of the high-pressure kettle is provided with an asbestos thermal insulation layer; a kettle cover is provided with a heat dispersion rod, an air relief valve, a pressure meter, a safe rupture disk, and a thermocouple; the electrode system on the kettle cover consists of a working electrode, a reference electrode and an auxiliary electrode, and can perform corrosion electrochemical signal test on three samples simultaneously; and the output of electrochemical signals on the surfaces of the samples under a condition of a high-temperature high-pressure water environment is achieved. The experimental facility can conveniently simulate the practical working conditions of a first loop and a second loop of a nuclear power plant and test the electrochemical signals in the corrosion process of various samples simultaneously, and can research corrosion actions and mechanisms of various materials simultaneously in a high-temperature high-pressure environment; besides, the experimental facility has the advantages of compact structure, safety and reliability and convenient operation, and can improve the testing efficiency.

Owner:SHANGHAI UNIV

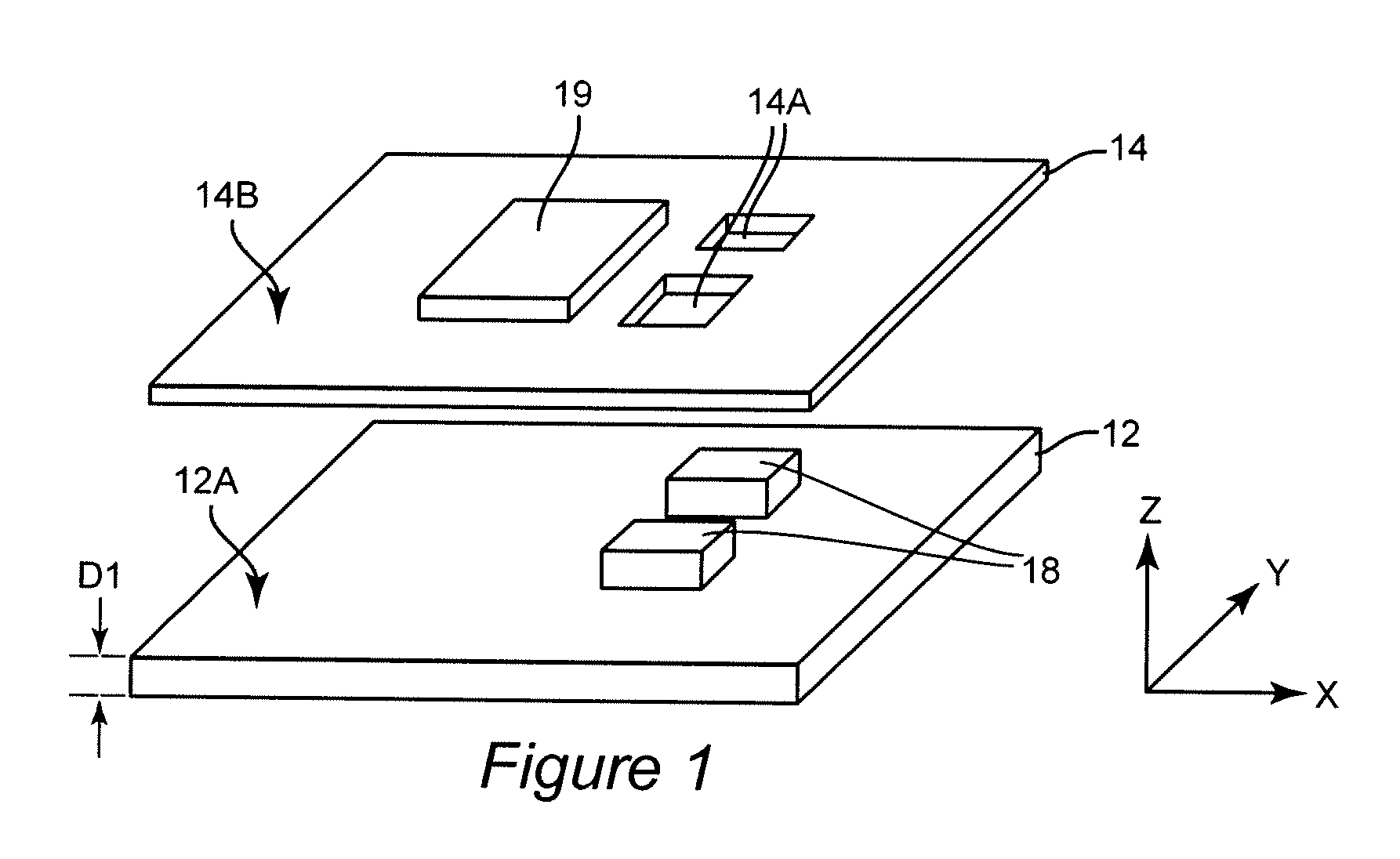

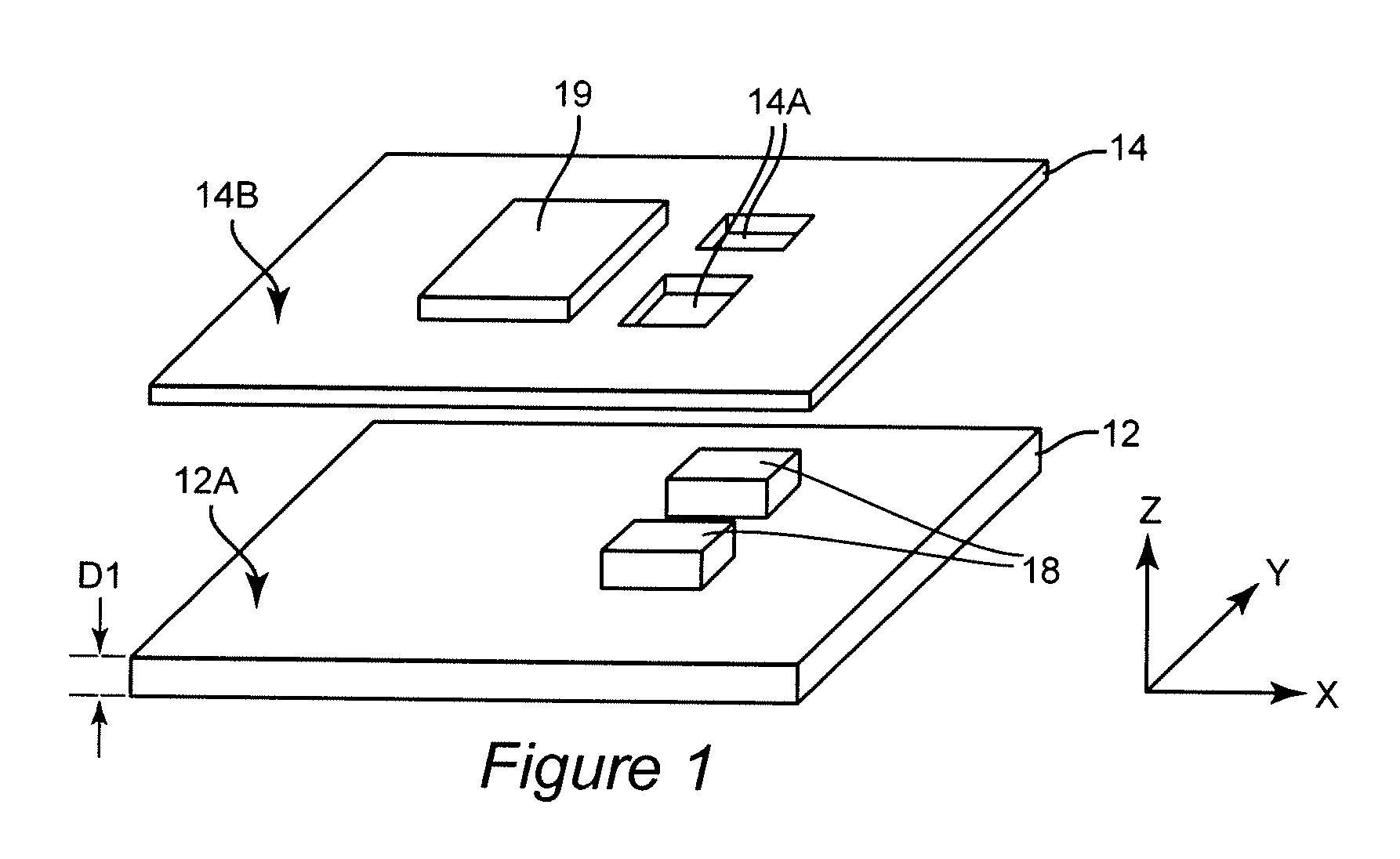

Passive alignment using elastic averaging in optoelectronics applications

InactiveUS7454105B2Same precisionAccurate locationSolid-state devicesCoupling light guidesEngineeringMaterials science

In an optoelectronic assembly in which one or more beam paths are to be aligned with a corresponding number of active optical elements, the cooperation between flexible alignment features and fixed alignment features achieves elastic averaging so as to provide the target accuracy. By averaging dimensional and positional errors over a large number of localized couplings of the flexible and fixed alignment features, elastic averaging provides the same accuracy as the more costly and complex kinematic alignment techniques.

Owner:BROADCOM INT PTE LTD

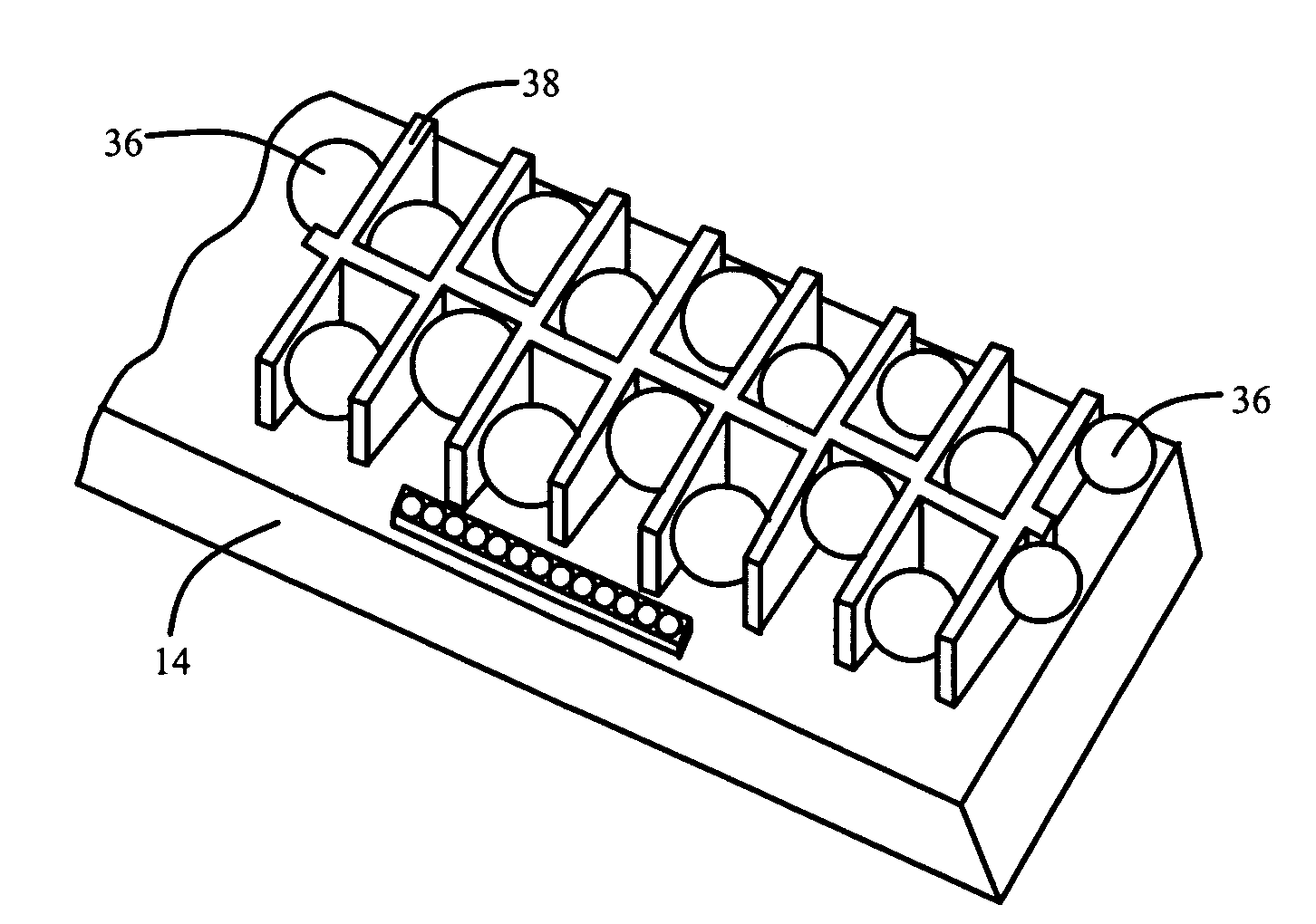

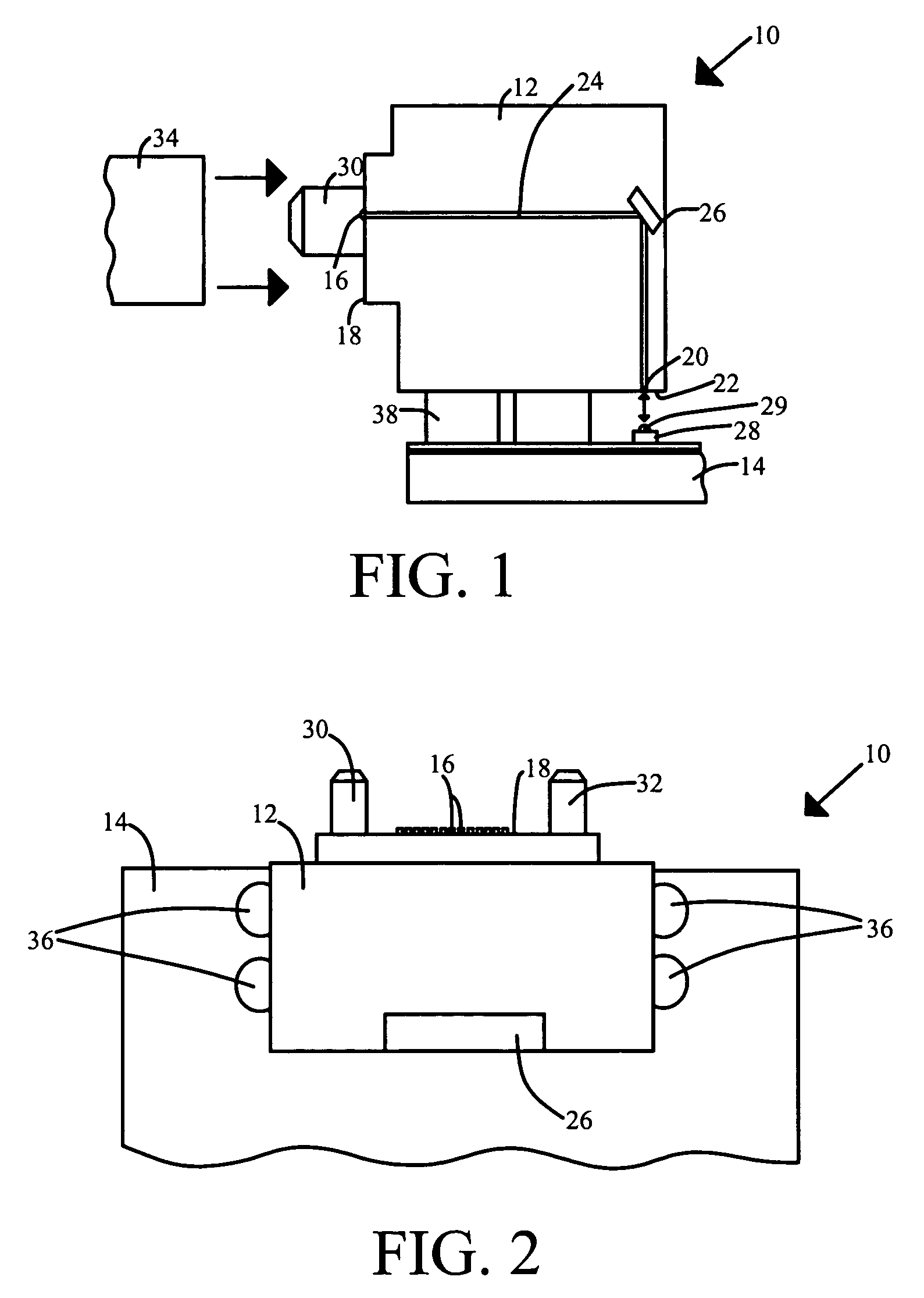

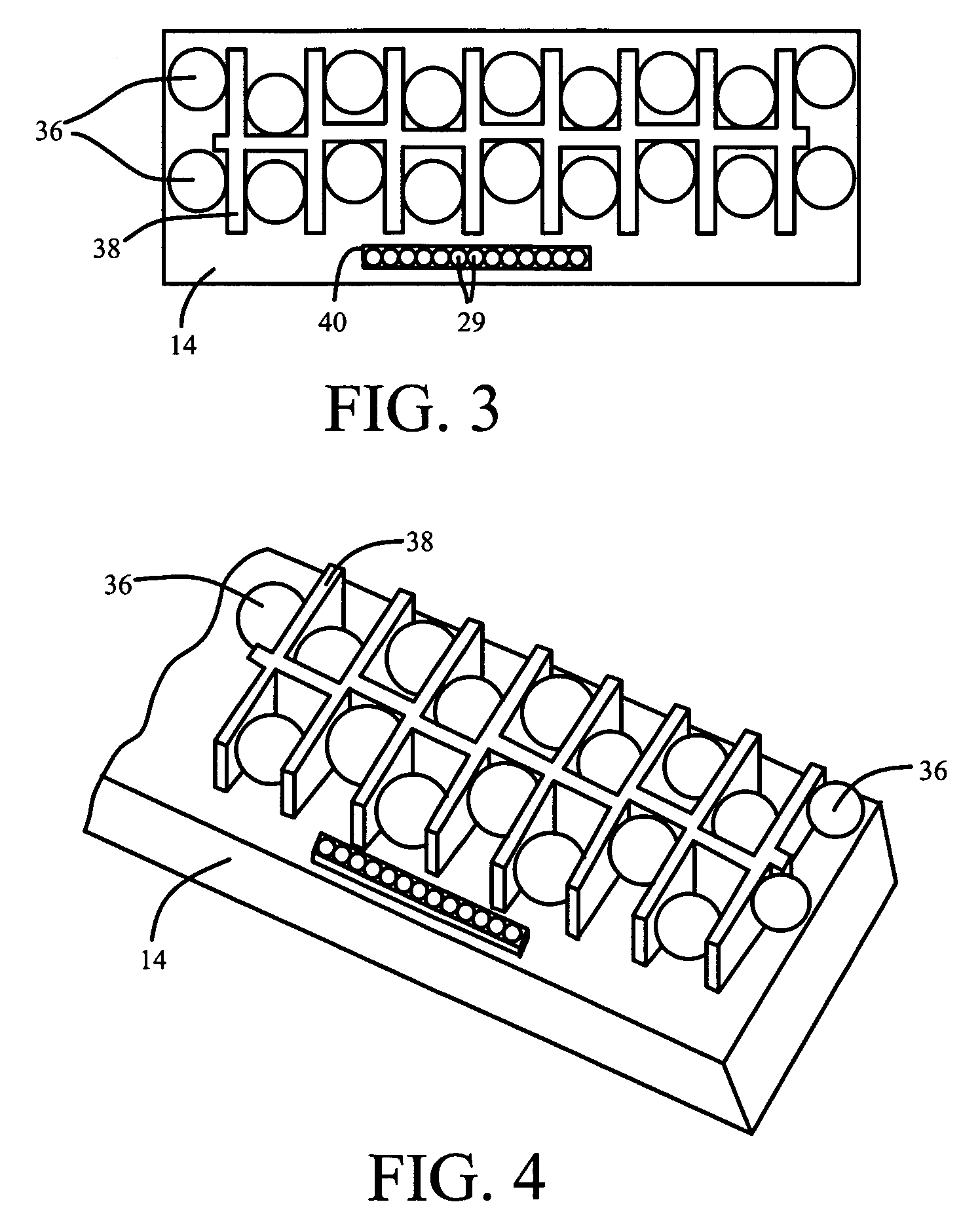

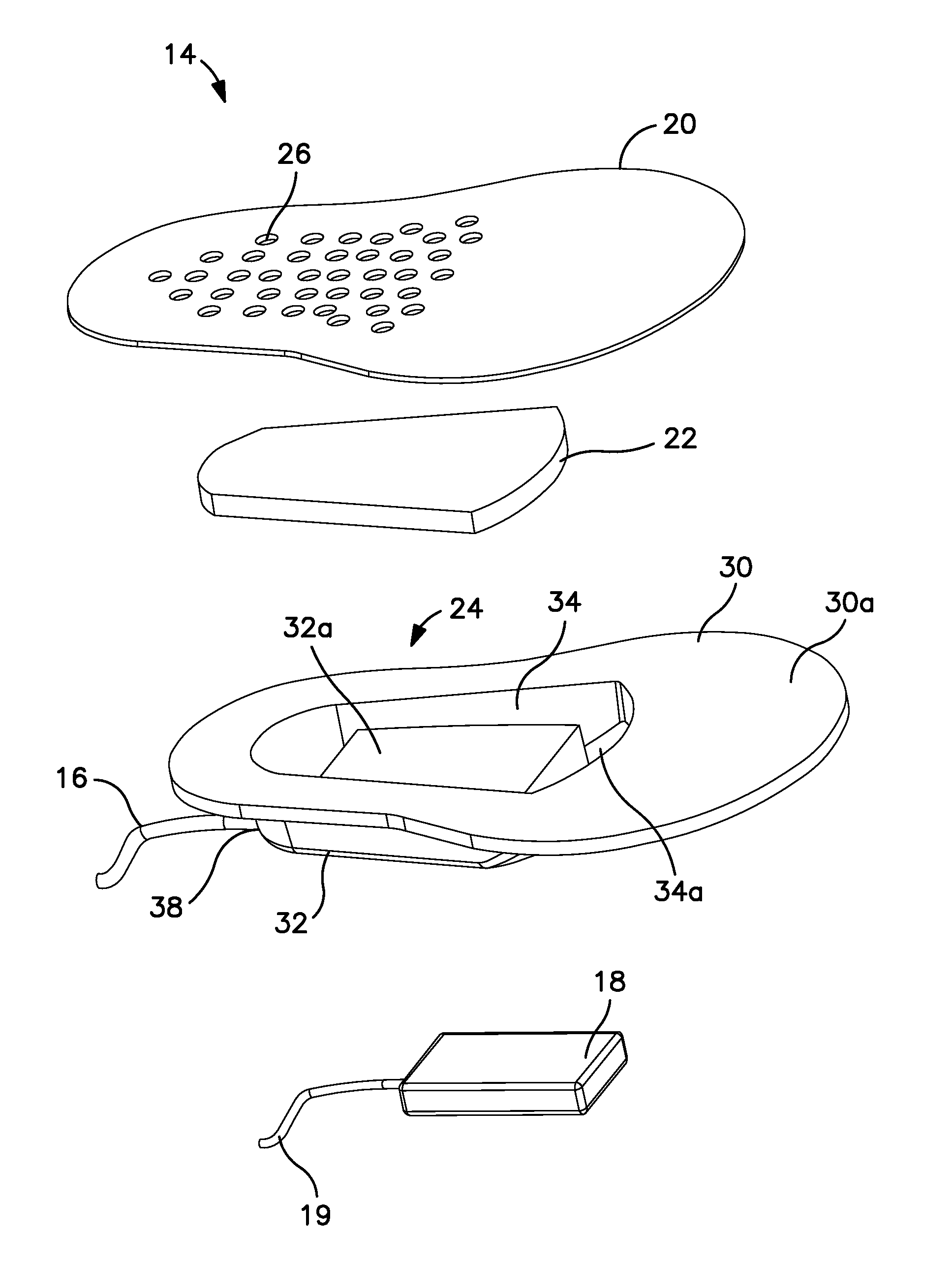

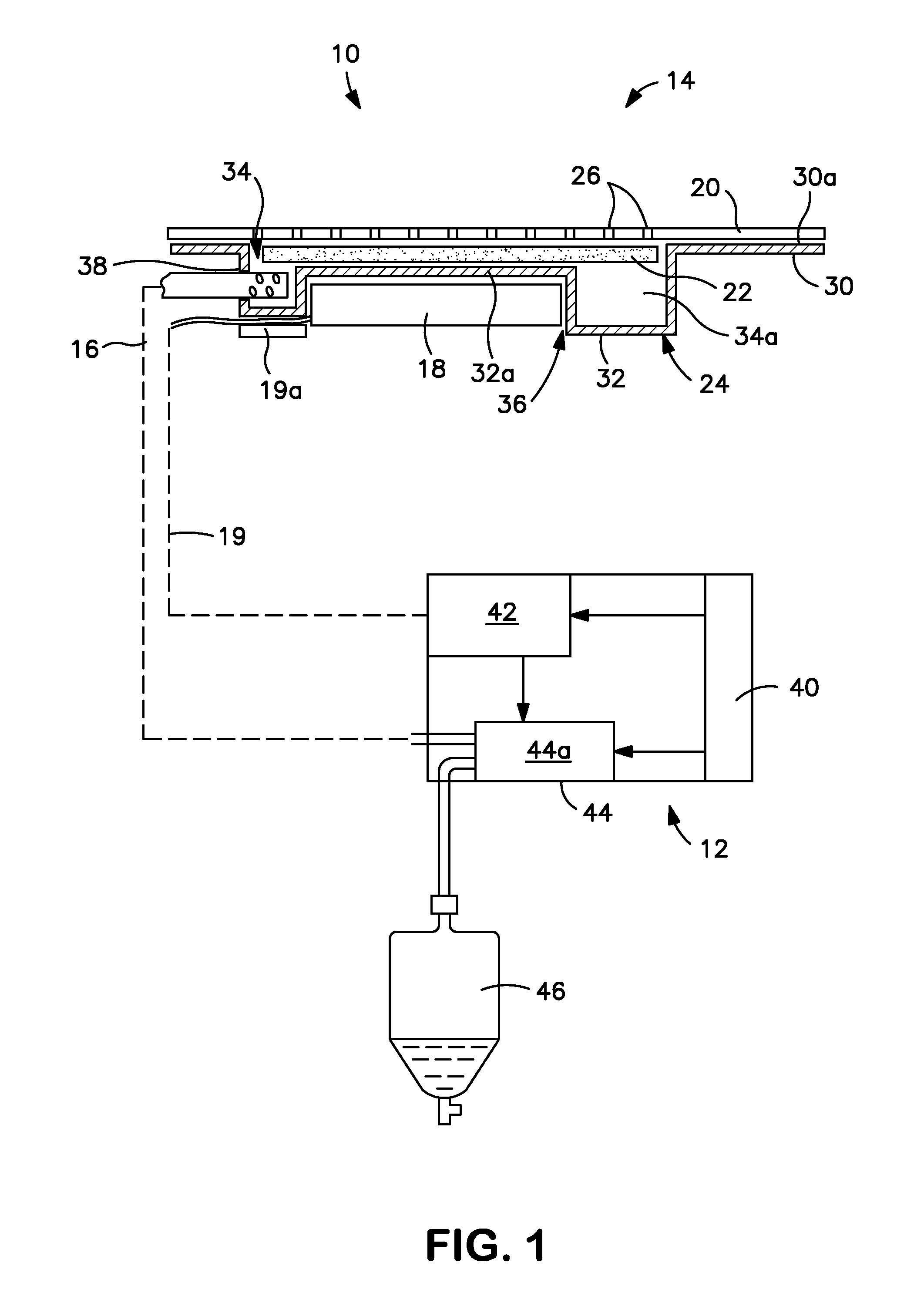

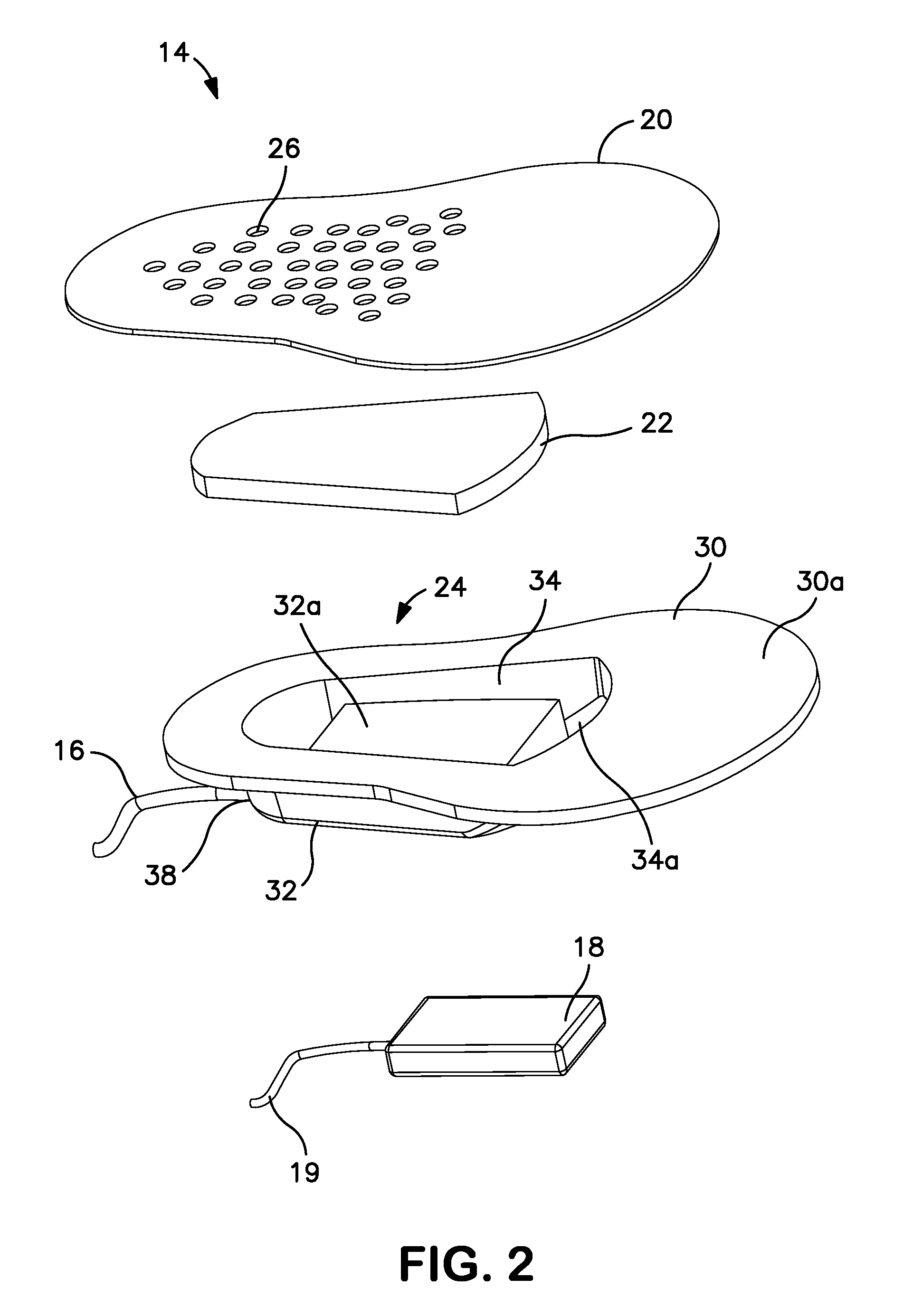

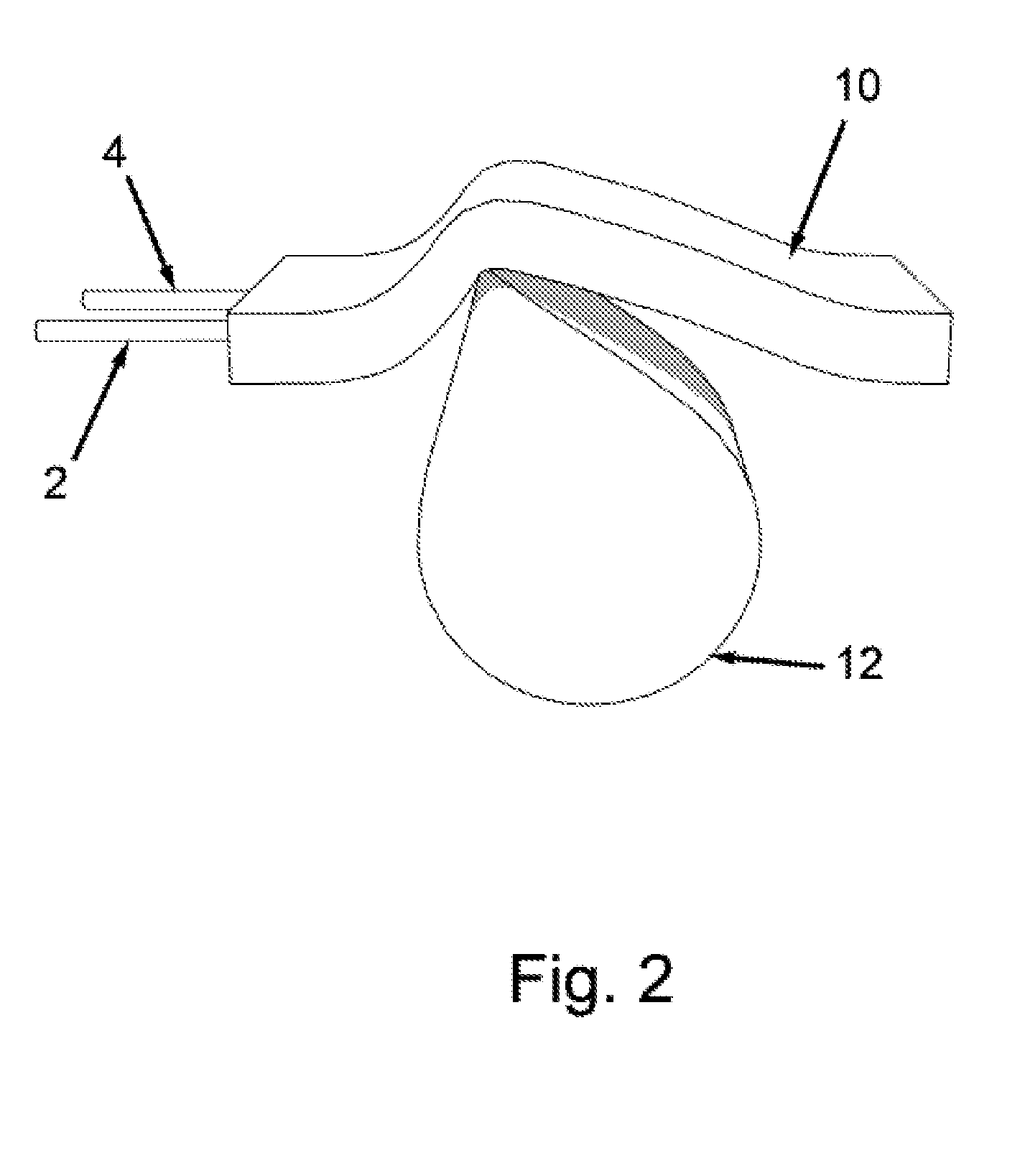

Aspiration system and body interface device for removing urine discharged by the human body

ActiveUS20100234820A1Reliable sensingPrevent leakage and spillagePlastersMedical devicesSkin contactEngineering

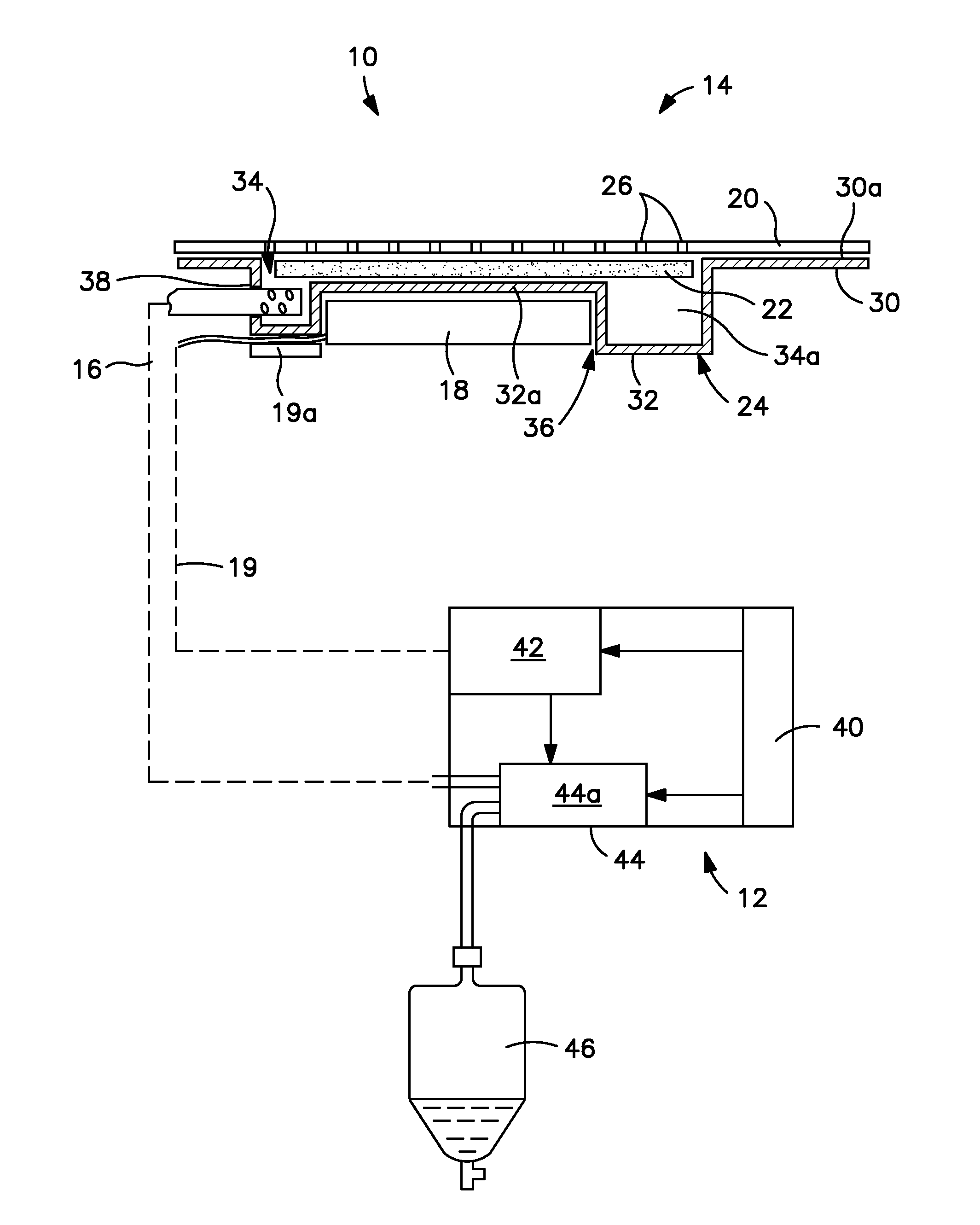

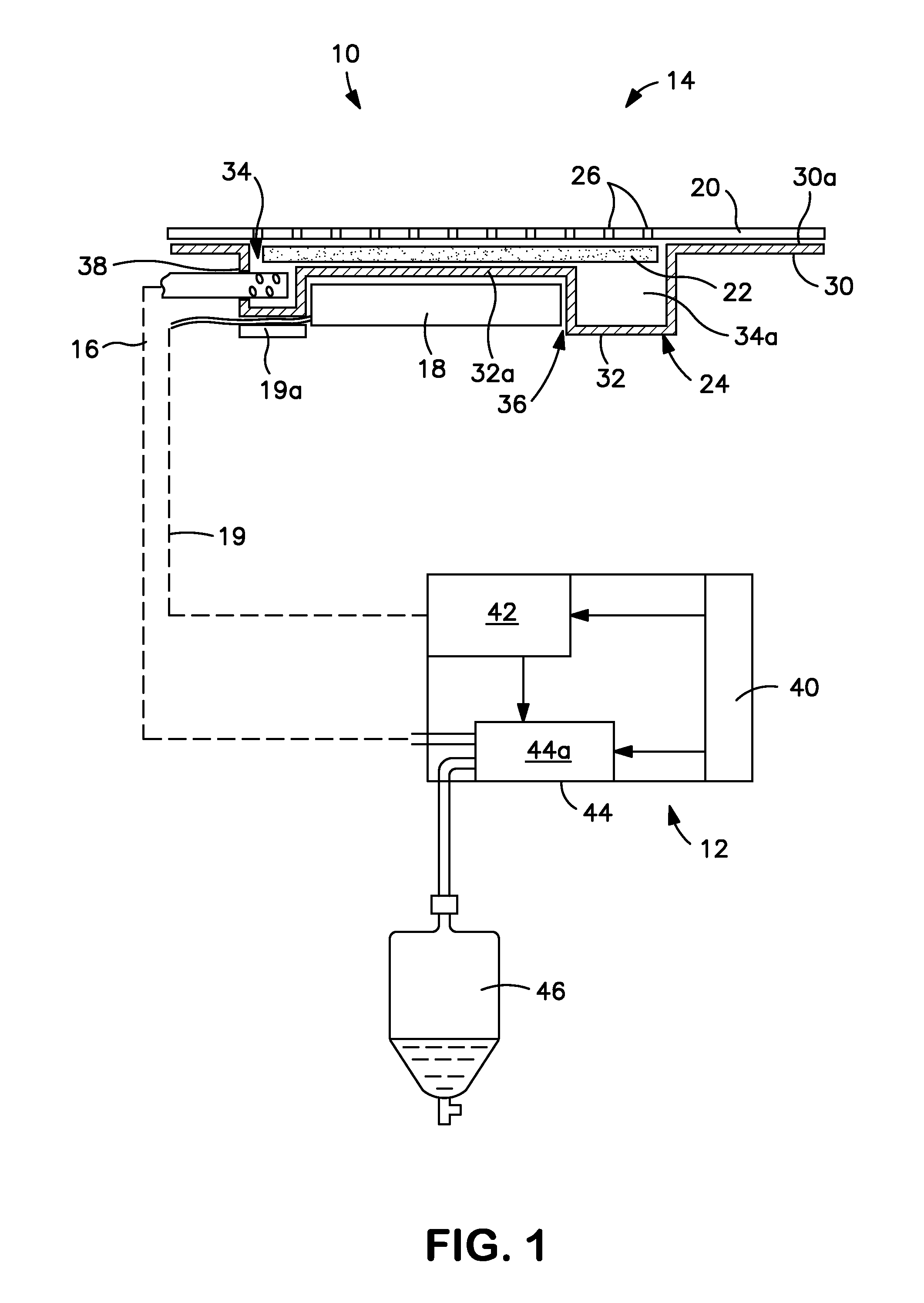

A body interface device for a urine aspiration system comprises a skin contact pad with gel adhesive for adhering to the skin, and a flexible cover attached to the pad. The pad includes at least one aperture for admitting urine through the pad into the body interface device. The flexible cover has a bulged form projecting away from the gasket. The flexible cover defines a urine receiving chamber facing towards the gasket, and recess facing away from the chamber for receiving at least a portion of a non-contact liquid sensor. The recess and chamber have a wall portion in common that separates the recess and the chamber. A liquid acquisition material in the chamber receives and transports urine for rapid sensing by the non-contact sensor. An aspiration unit is responsive to the non-contact liquid sensor to apply aspiration suction to the body interface device, upon detection of urine.

Owner:CONVATEC TECH INC

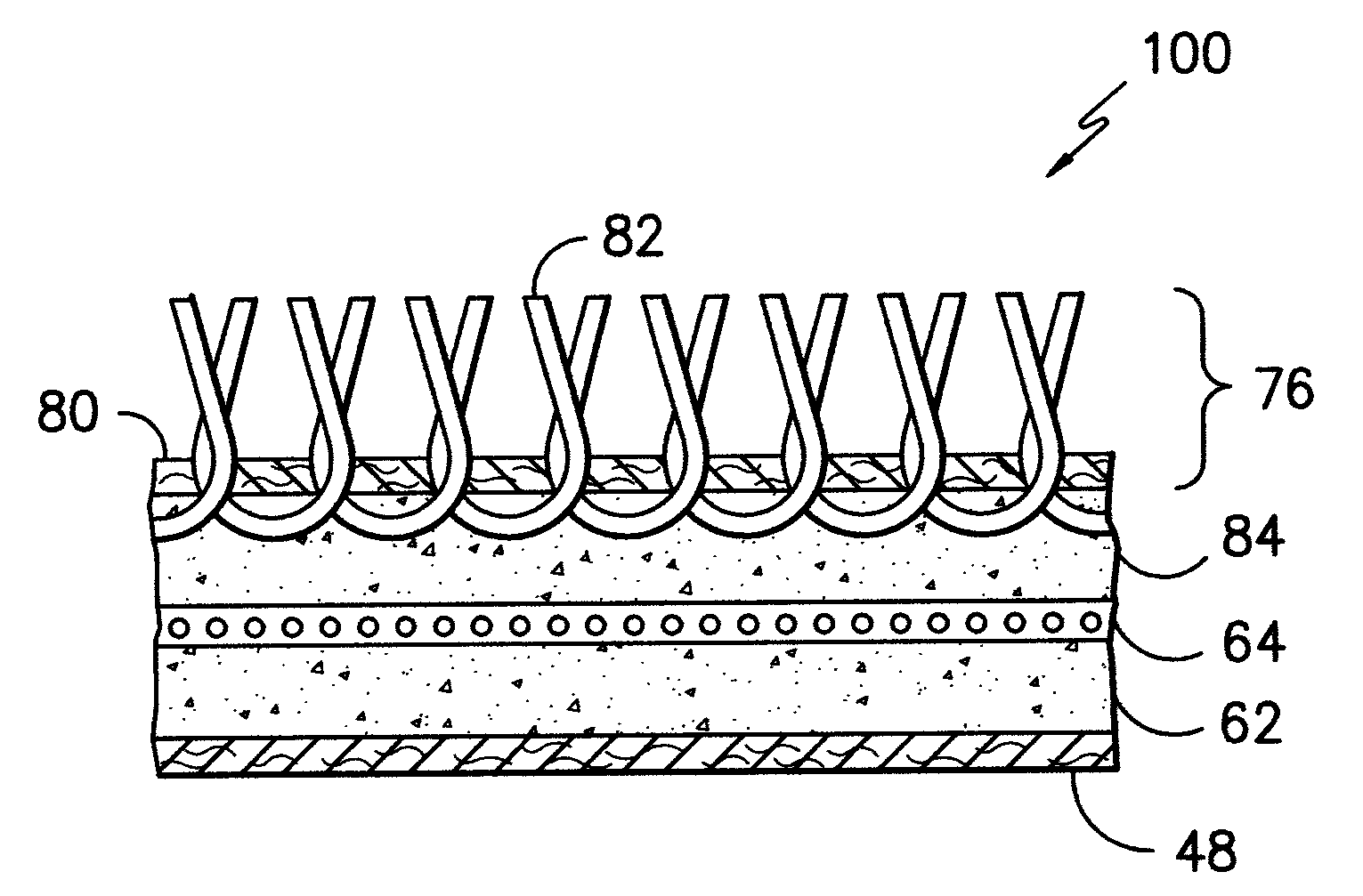

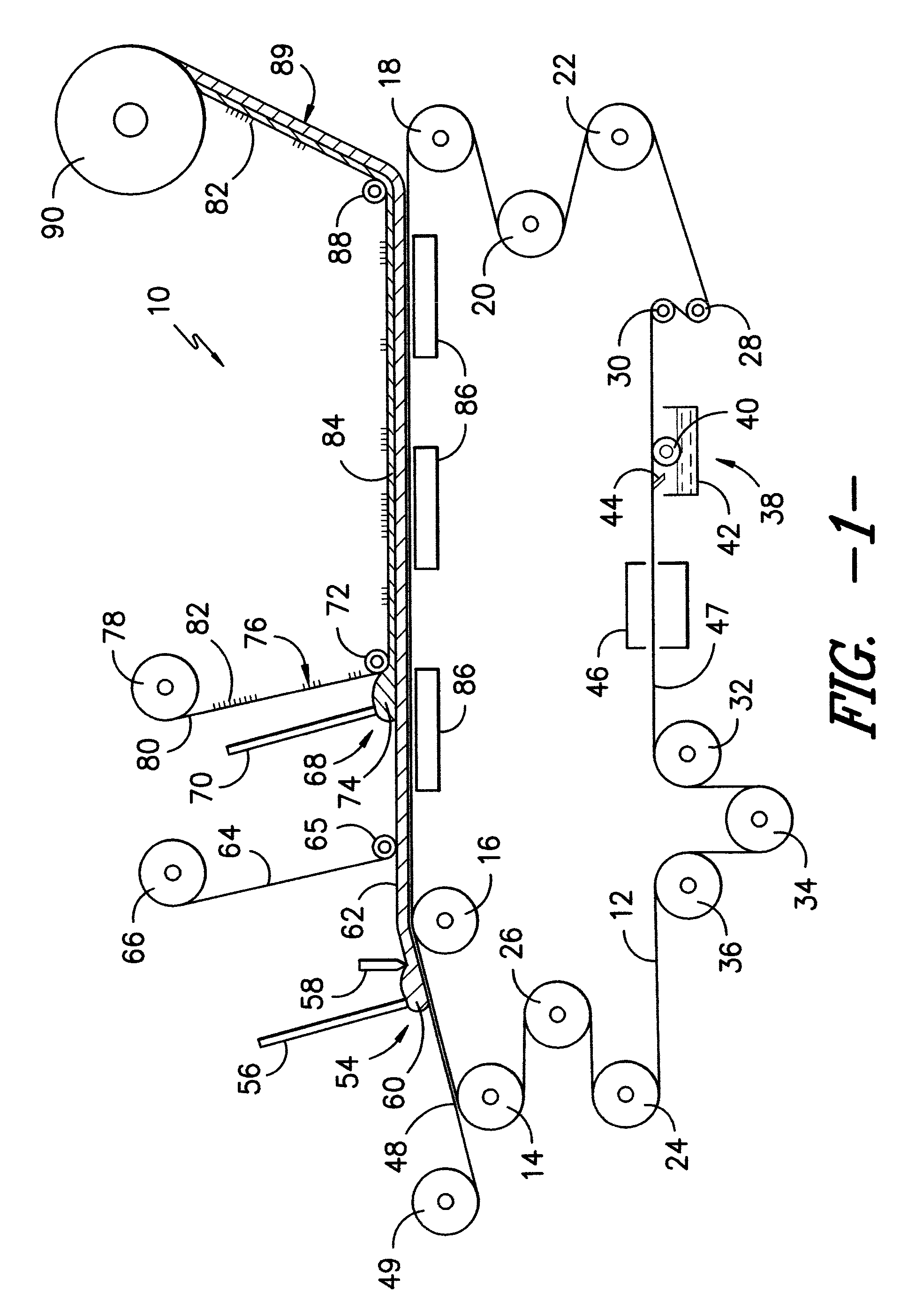

Flooring products and methods

InactiveUS20090029097A1Simple methodLow shape requirementPretreated surfacesWood working apparatusFloor coveringWater content

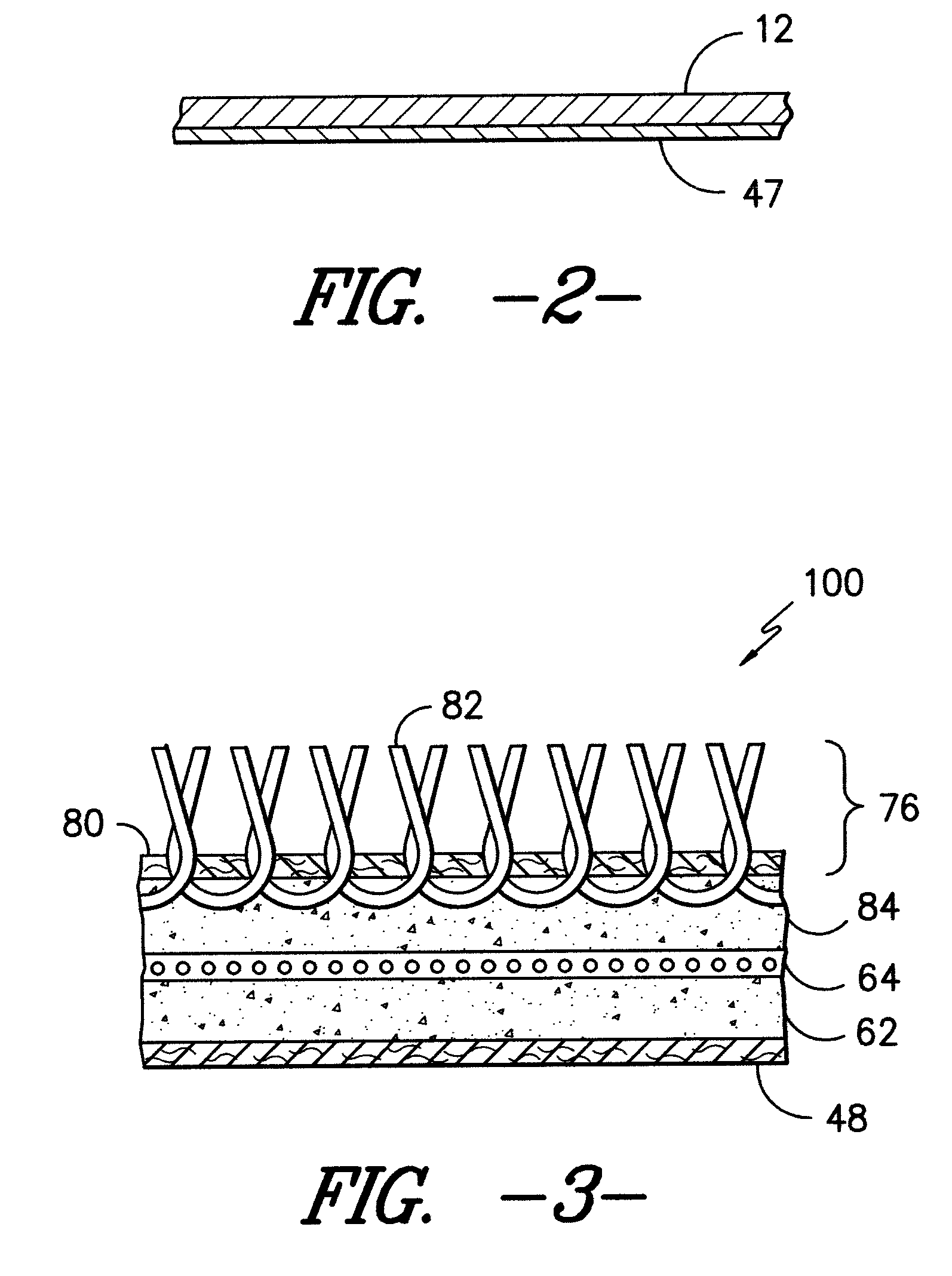

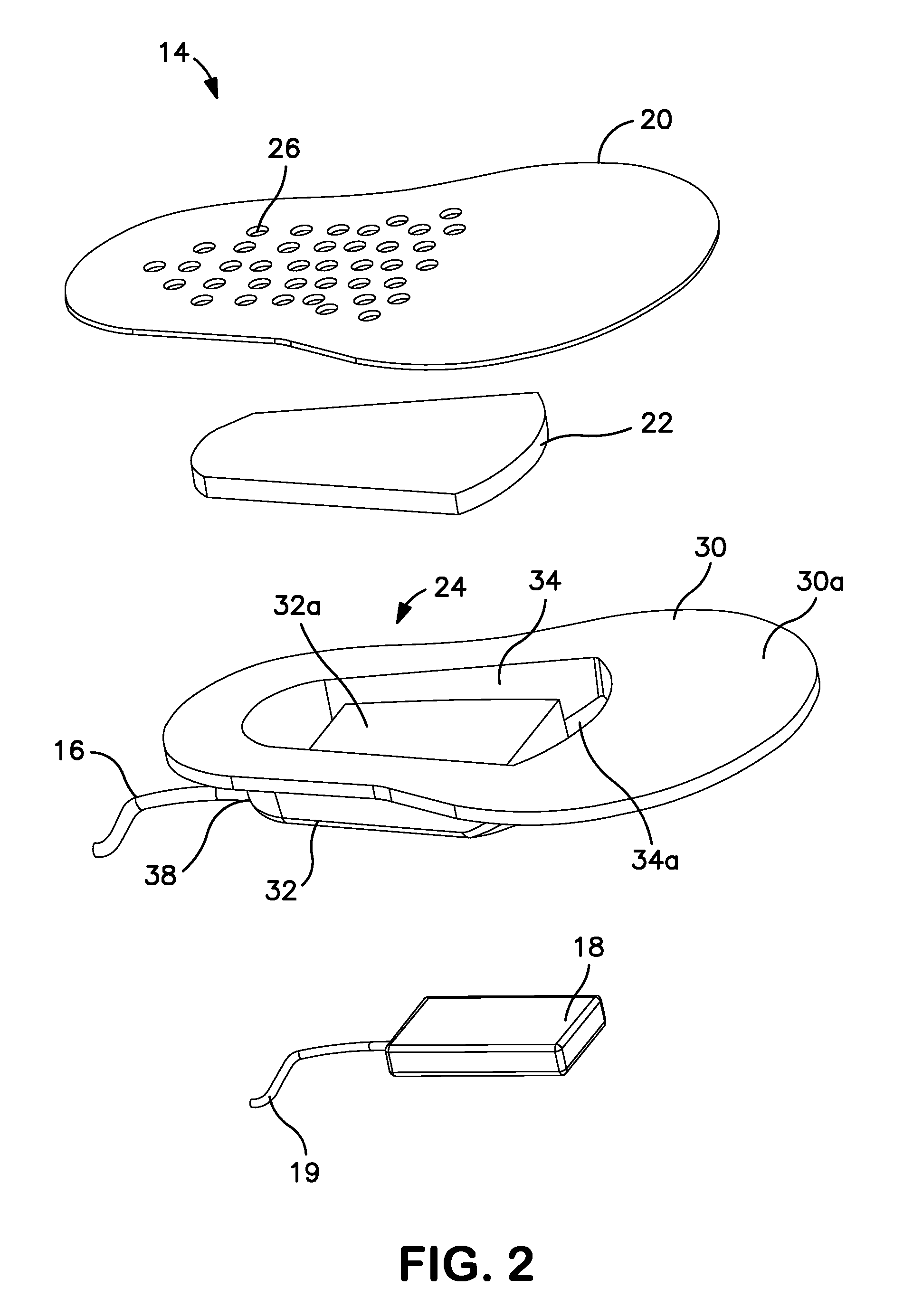

At least certain embodiments of the present invention relate to flooring products, methods of producing flooring products, and polyurethane compositions for use in flooring products, for example, for forming a layer of polyurethane on a textile, fabric or material, such as a flooring fabric. The compositions comprise the reaction product of castor oil having a water content of less than or equal to about 0.2% by weight; a monol, and an isocyanate, wherein the reactants have a soft segment functionality of about 2.0 to about 2.64. Methods of using the compositions and flooring products including the compositions are also disclosed. At least selected embodiments may provide compositions for use in floor coverings having a show surface such as a textile or fabric face material in contacting overlying relation to a polyurethane backing with or without additional structures, layers, backings, and / or the like, as well as apparatus, processes, and / or methods for making such floor coverings, uses for such floor coverings, and / or the like. In at least one particular embodiment, a floor covering such as a carpet, carpet tile, area rug, floor mat, roll goods, or the like incorporates a textile or fabric face disposed in contacting overlying relation to at least one polyurethane layer.

Owner:RIDDLE DENNIS L +5

Aspiration system and body interface device for removing urine discharged by the human body

ActiveUS8303554B2Reliable sensingPrevent leakage and spillagePlastersBathroom accessoriesHuman bodySkin contact

A body interface device for a urine aspiration system comprises a skin contact pad with gel adhesive for adhering to the skin, and a flexible cover attached to the pad. The pad includes at least one aperture for admitting urine through the pad into the body interface device. The flexible cover has a bulged form projecting away from the gasket. The flexible cover defines a urine receiving chamber facing towards the gasket, and recess facing away from the chamber for receiving at least a portion of a non-contact liquid sensor. The recess and chamber have a wall portion in common that separates the recess and the chamber. A liquid acquisition material in the chamber receives and transports urine for rapid sensing by the non-contact sensor. An aspiration unit is responsive to the non-contact liquid sensor to apply aspiration suction to the body interface device, upon detection of urine.

Owner:CONVATEC TECH INC

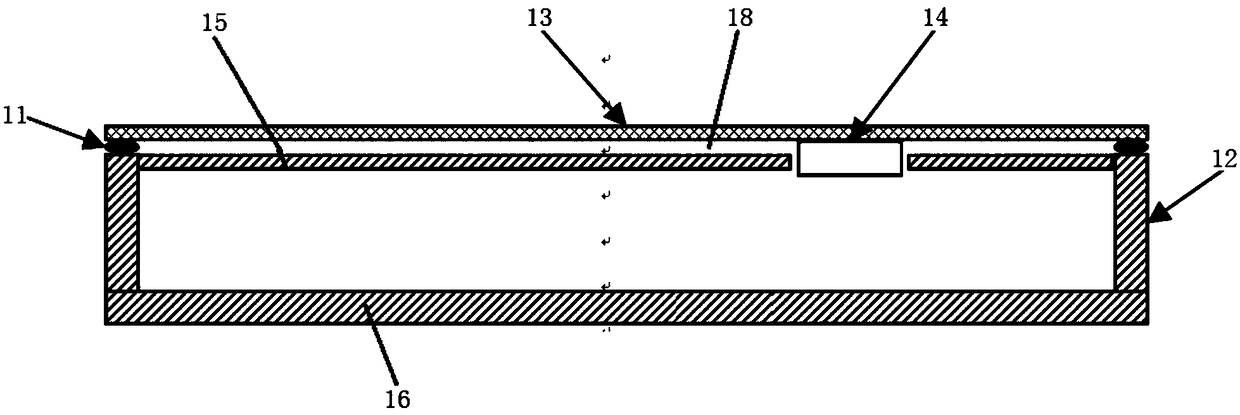

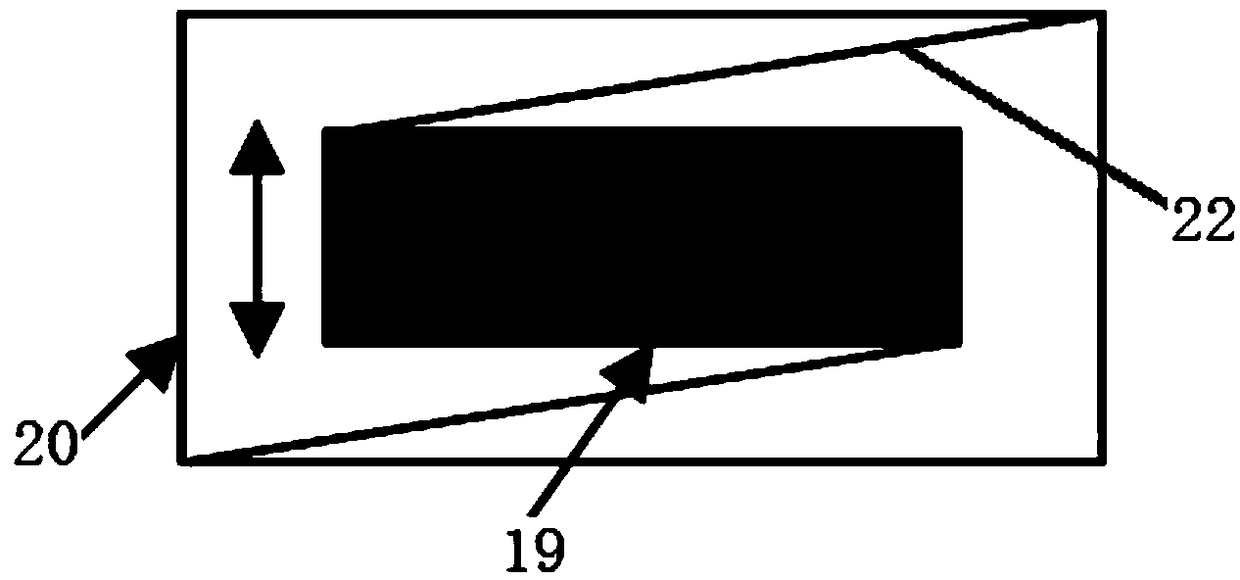

Electronic display equipment and electronic equipment

ActiveCN108881523AReduce leakageImprove electro-acoustic conversion efficiencyElectrical transducersTelephone set constructionsEngineeringElectric signal

The invention discloses electronic display equipment and electronic equipment. The electronic display equipment comprises a shell, a screen and a vibration device; at least a part of the screen is connected with at least a part of the shell through a flexible connection device; the flexible connection device has elastic, the vibration device is fixed on the screen, the vibration device is configured to produce vibration in response to an electric signal of the external circuit, and drive the screen to make sound by vibration. In the electronic display equipment disclosed by the embodiment of the invention, the screen and the shell are connected through the flexible connection device but not in fixed connection; the screen cannot drive the shell to vibrate together in the vibration, therebyeffectively reducing the sound leaking caused by the vibration of the shell.

Owner:GOERTEK INC

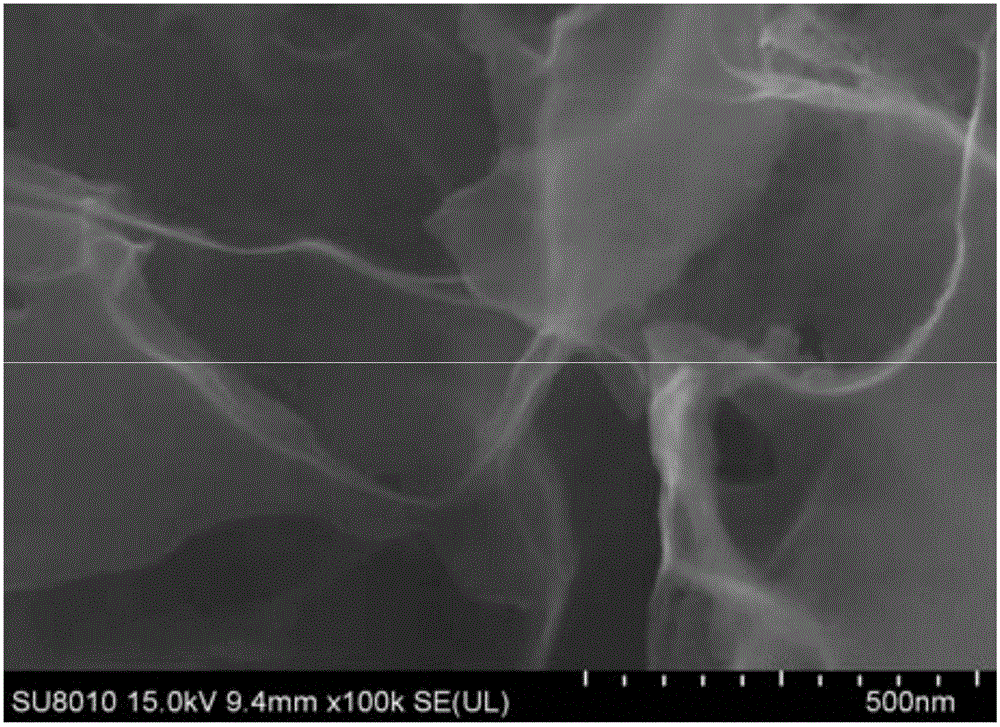

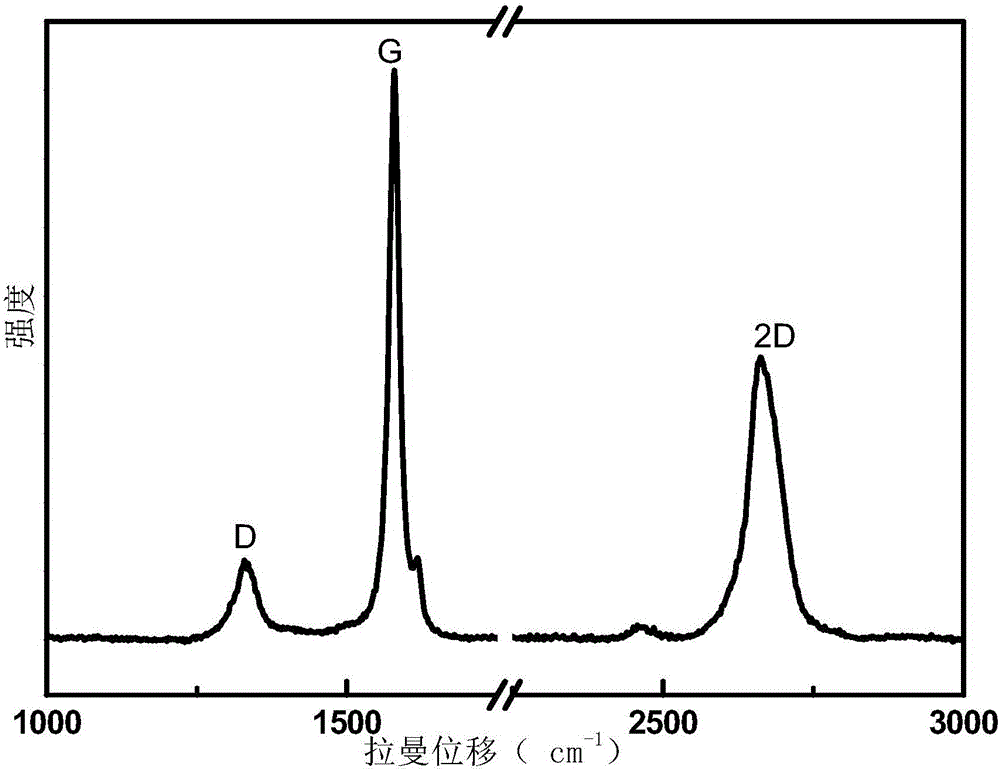

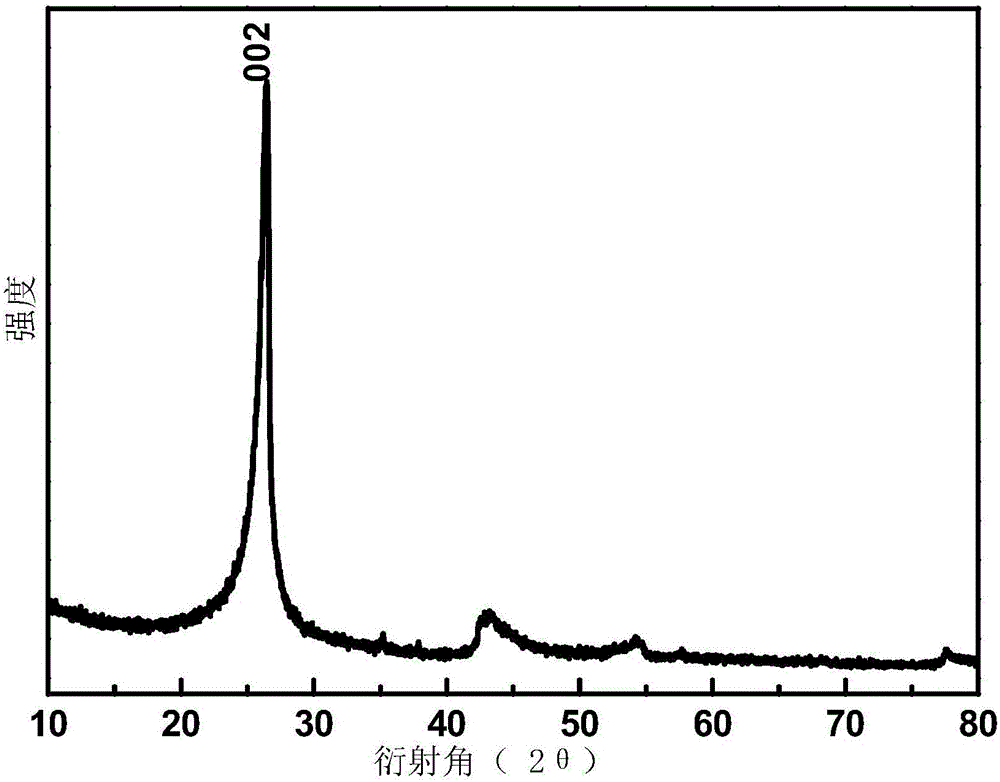

Method for preparing graphene by using lignin

The invention belongs to the technical field of carbon material manufacturing technology, and in particular relates to a method for preparing graphene by using lignin as a raw material. The method is as follows: a layered or powdered material is used as a substrate, the lignin and a catalyst precursor are alternately assembled on the surface of the substrate by a layer-by-layer electrostatic self-assembly method, then a lignin / catalyst precursor / substrate composite is put into a double-temperature-zone tubular furnace, a H2 / Ar mixed gas is introduced into the double-temperature-zone tubular furnace at a certain speed, at the same time the double-temperature-zone tubular furnace is heated by a certain procedure, after the double-temperature-zone tubular furnace is heated to target temperature, the temperature of the double-temperature-zone tubular furnace is held for a certain time, when the double-temperature-zone tubular furnace is cooled to room temperature, the sample is taken out, and is soaked in an acid for catalyst removal, and after a plurality of times of washing and vacuum drying, the graphene is obtained. The method has the advantages of simple process and convenient operation, and the prepared graphene is good in growth, controllable in layer number and considerable in yield.

Owner:SOUTH CHINA UNIV OF TECH

Production technology of zirconia grinding fluid

ActiveCN101649183ASmall particle sizeLow shape requirementOther chemical processesPolishing compositions with abrasivesFlat glassSoft materials

The invention discloses production technology of zirconia grinding fluid, relating to the new material processing field. The production technology is as follows: adding zirconia powder into high-speed dispersing water according to the weight share, then adding wetting dispersants, grinding aids, mixed lipids and alcohols, after full dispersion, sending the materials to a high-speed sand grinder for sand grinding, grinding the corners of the zirconia powder to round spheres and then adding coloring agents to adjust the colors. The production technology is characterized in that the production technology is free from the influences of the grain sizes and shapes of the zirconia raw materials and has lower production cost. The product can be used for grinding and polishing lenses, plate glass,glass bulbs, glasses, watch cases, display screens and the like, and is especially suitable for grinding and polishing the spherical glass made of soft materials.

Owner:HUNAN HAOZHI TECH

Locking Device Using Shape Memory Materials

InactiveUS20100229610A1Low costOvercome problemsShaftsNon-mechanical controlsBiomedical engineeringShape-memory polymer

The disclosed devices use shape memory materials, and specifically shape memory polymers and composites to allow or disallow mechanical or physical movement. By positioning the shape memory polymer so it is near the mechanical device which is to be moved, the shape memory polymer will allow or disallow the motion of the mechanical device depending on the state the shape memory polymer is in. When the shape memory polymer is in its hard rigid state the device cannot move. Once activated the shape memory polymer will become soft and pliable, whereupon with sufficient force the mechanical device can be moved to a new position. Once in this new position the SMP can either remain in its relaxed state, the SMP can return to a hard rigid state and maintain its deformed shape, or the SMP can return to its original shape to ensure the device does not move.

Owner:CORNERSTONE RES GROUP

Method and apparatus for three-dimensional integration of embedded power module

InactiveUS7932800B2High conductanceImprove abilitiesTransformers/inductances coolingTransformers/inductances coils/windings/connectionsElectrical conductorElectrical connection

A modified planar Low Temperature Co-Fired Ceramic (LTCC) high conductance inductor, embedding a large cross section conductor, supports a stacked arrangement of heat spreader, inductor and active device layers. Interlayer electrical connections connect the layers. Optionally, a DC-DC converter includes the modified planar LTCC high conductance inductor, embedding a large cross section conductor, supporting a stacked arrangement of heat spreader, capacitor and active device layers, the active devices layer including the switching transistors. The active devices layer may include semiconductor dies embedded in a substrate.

Owner:VIRGINIA TECH INTPROP INC

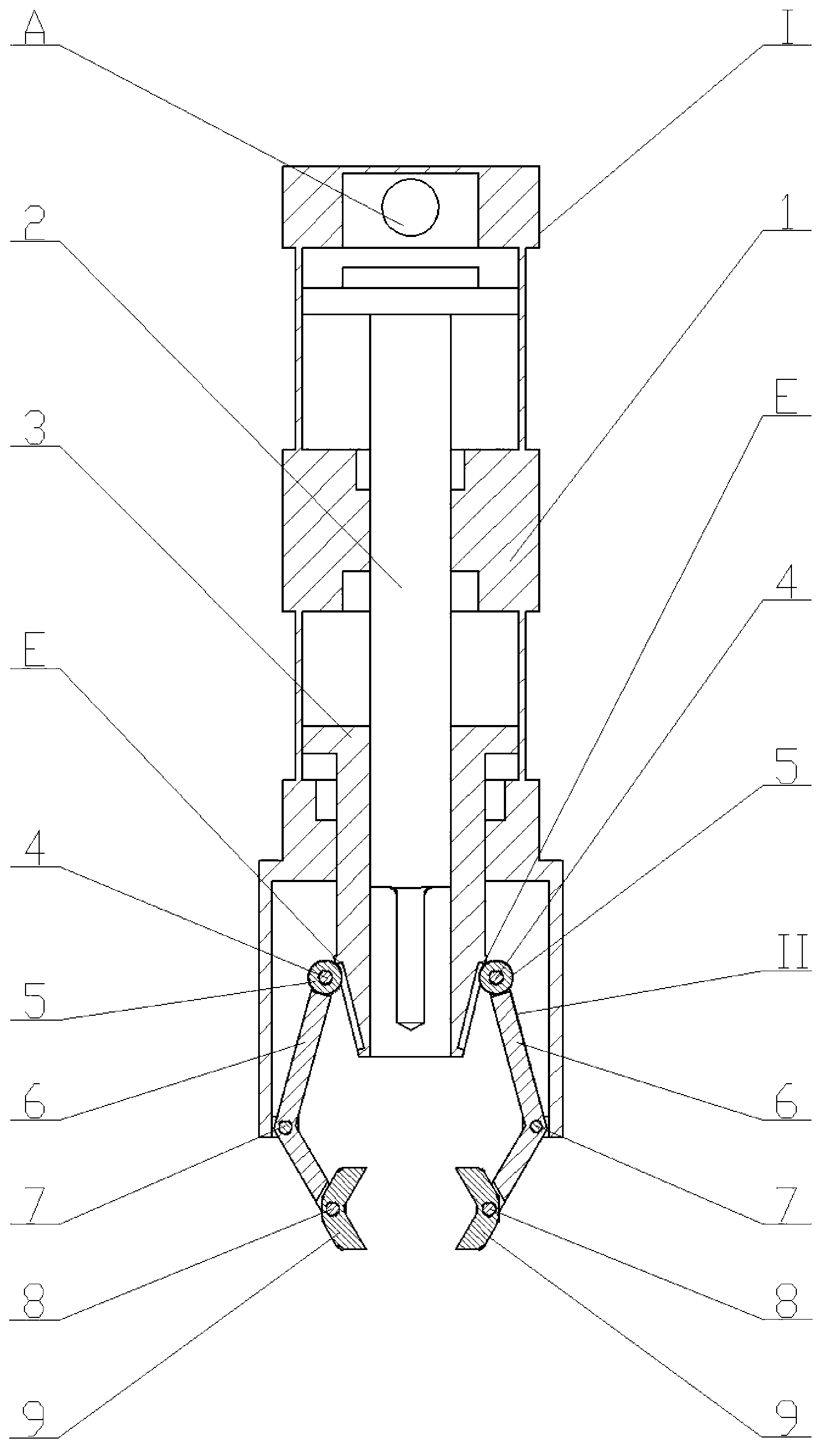

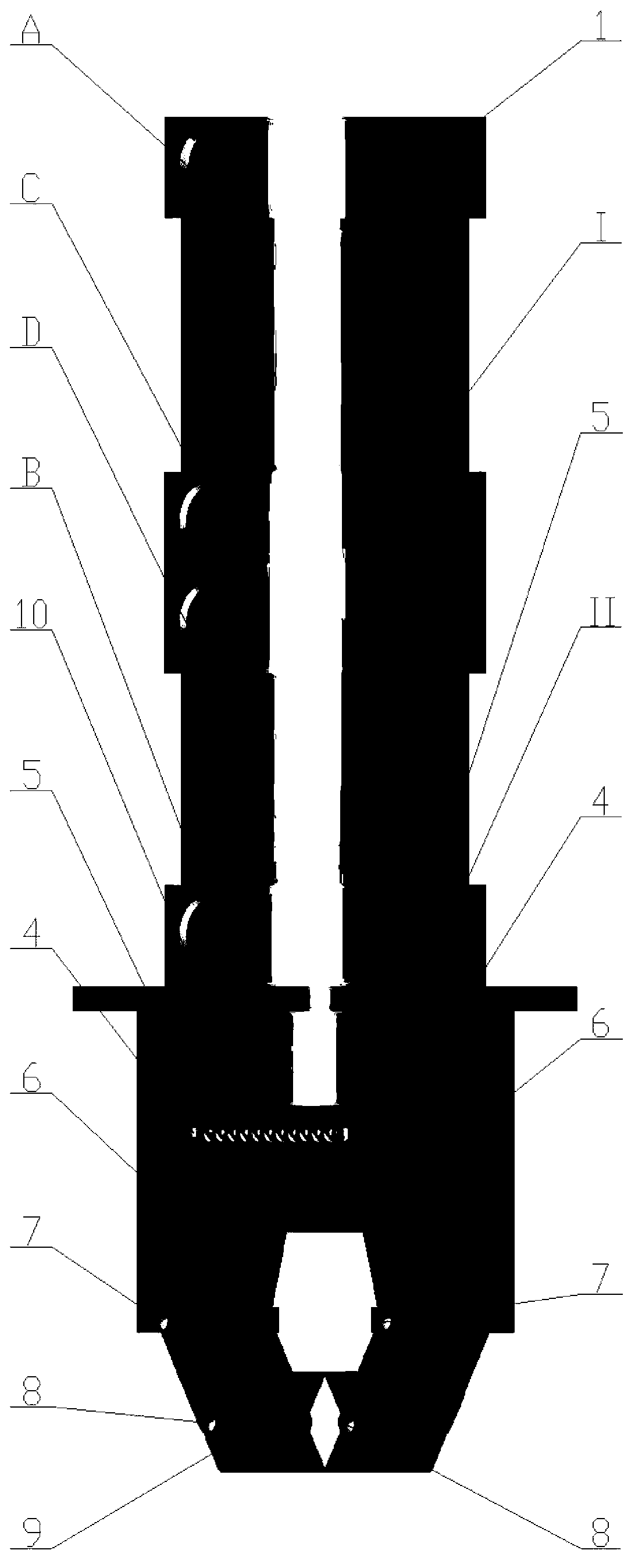

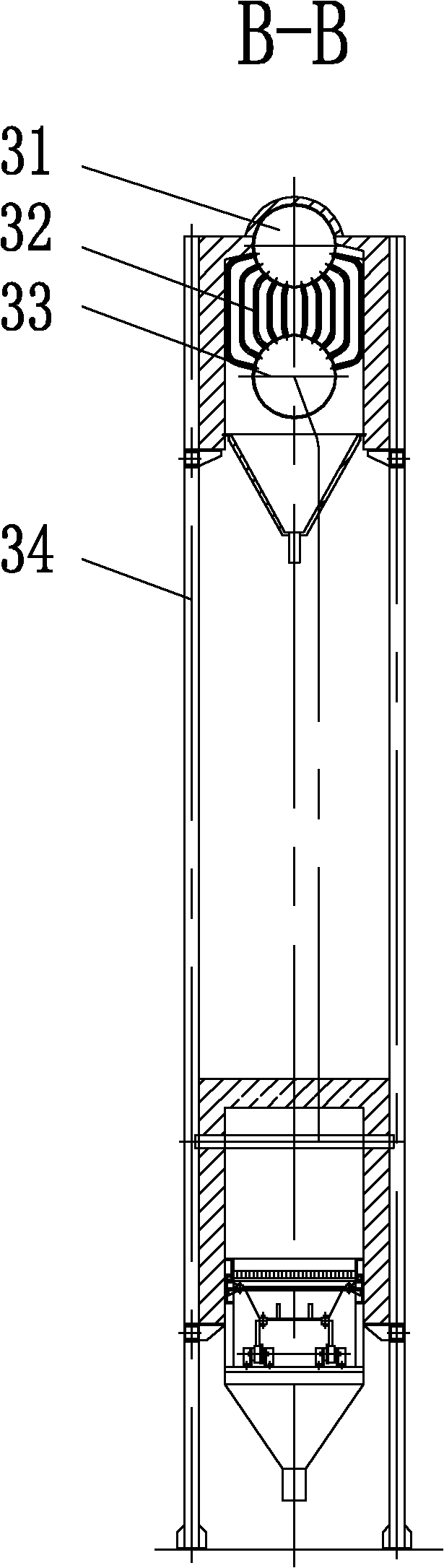

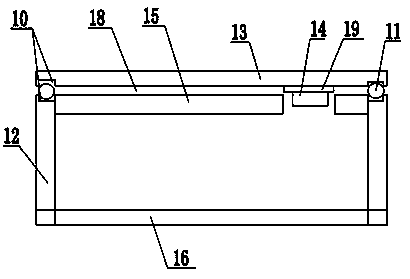

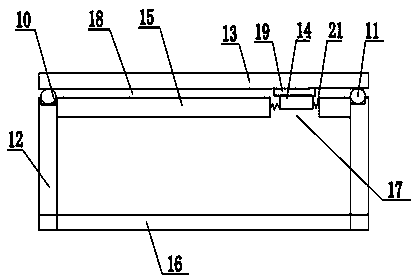

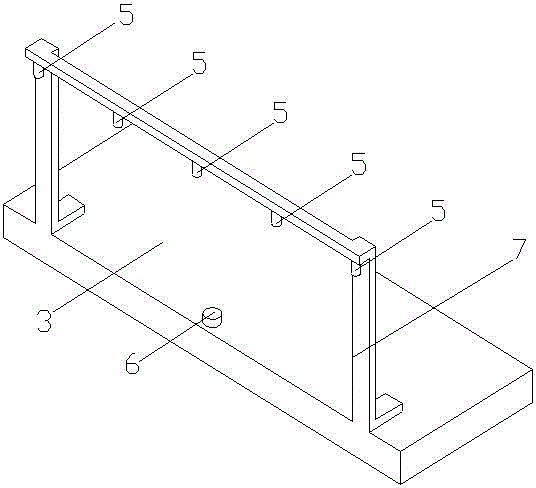

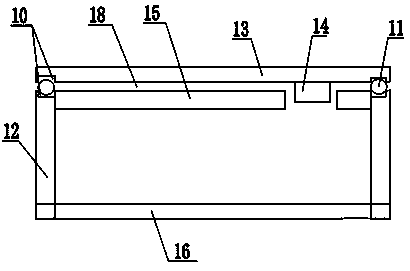

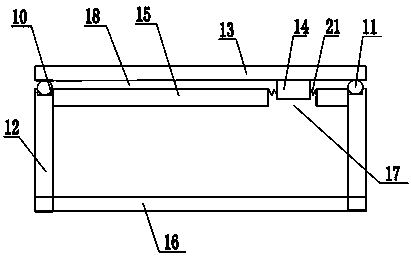

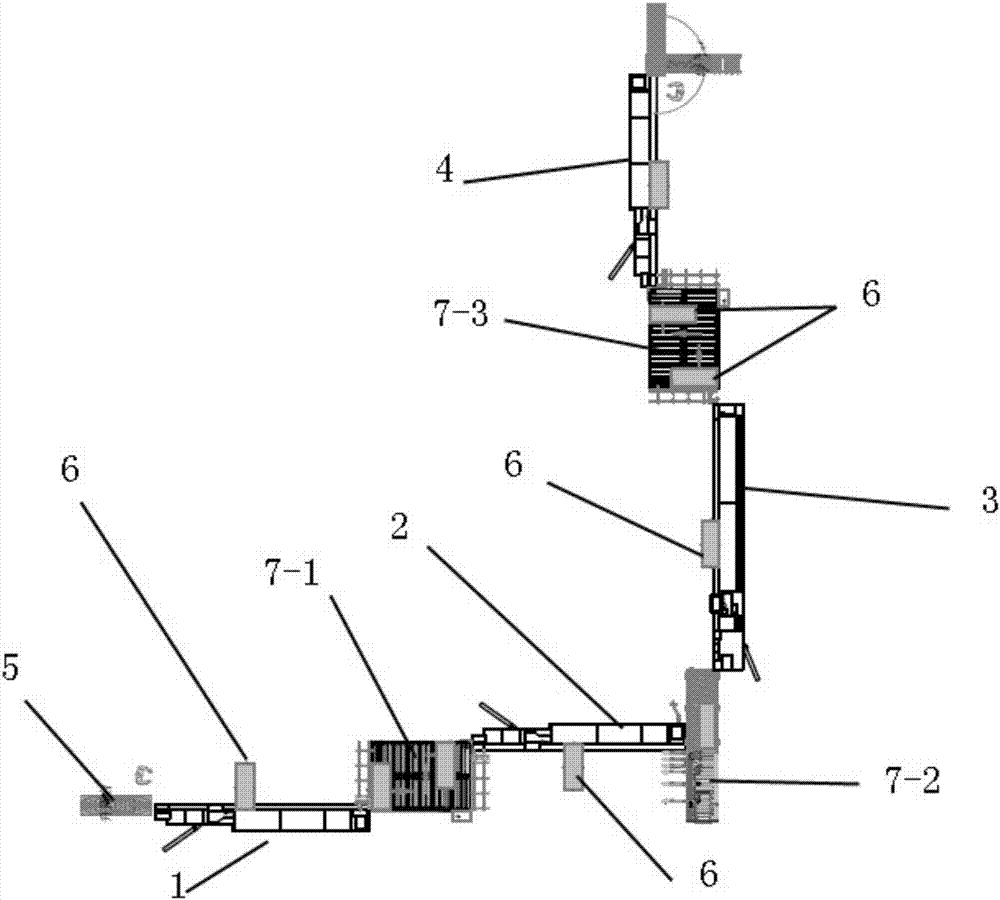

Pneumatic high-speed throwing device

InactiveCN103072692ALow shape requirementEasy clampingAircraft componentsLaunching weaponsEngineeringMechanical engineering

The invention relates to a pneumatic high-speed throwing device, belonging to the field of aircrafts, in particular to the pneumatic high-speed throwing device which is placed in a narrow space. The device has the functions of clamping and high-peed throwing, and comprises a throwing device and a clamping device, wherein the throwing device consists of an air cylinder with double piston rods and four air ports, an upper piston rod and a lower piston rod. The clamping device comprises two synchronous shafts, two rolling sleeves, two bending plates, two middle rotating shafts, two lower rotating shafts, two V-typed clamps and two tensioning springs. The device can be used in a narrow installation space and a short stroke space to realize large throwing force, a high speed and an angle, the separation and throwing are carried out simultaneously, and respective control on separation and throwing is not needed to be considered. According to the device, a throwing device is integrated, the device can be installed according to a required angle, the installation is convenient, the size is small, and the clamping of throwing materials are extremely convenient.

Owner:DALIAN UNIV OF TECH

Preparation of metal doped diamond-like surface ion liquid lubricant self-assembled lubricating film

InactiveCN101463466AImprove tribological propertiesExcellent friction reductionVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

The invention discloses a method for preparing a metallic contamination adamantine surface ionic liquid lubricant self-assembly lubricative film. The method takes ionic liquid lubricant as raw material, adopts magnetron sputtering equipment to prepare a metallic contamination adamantine carbon film and assembles the liquid lubricant film which is stable, uniform and ordered on the carbon film. The method is characterized in that the preparation process is operated at normal temperature, and the requirements for the material and the shape of a substrate are lower; the film is stable and uniform, and has lower surface roughness; the film also has good performances on antifriction, wear resistance and adhesion resistance. The test of friction and wear proves that the ionic liquid lubricant and adamantine has good combining performance and better performances on antifriction, wear resistance and adhesion resistance, so that the lubricative film is expected to become the effective means of solving the problems of protecting and lubricating materials I the technical fields such as space machinery, information technology, etc.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

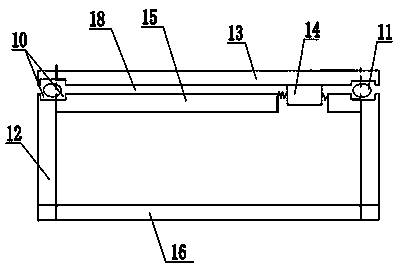

Lamination processing equipment and packing box processing technique

ActiveCN108189475ALow shape requirementNo precise requirementBox making operationsPaper-makingEnvironmental engineeringEnvironmentally friendly

The invention discloses lamination processing equipment and a packing box processing technique. The problems that during packing box lamination operation, cut-off waste is hard to recycle, base papermaterials and lamination materials are wasted, the production cost is increased, resource waste is caused, and the operation is not economical and environmentally friendly are solved. According to thetechnical scheme, the processing technique includes the steps that residual lamination waste is cut off after one-time forming cutting, printing and lamination of base paper, and folding is carried out after die pressing. Raw materials can be fully utilized and recycled during product, resource waste is reduced, and better environmental protection and economy efficiency during using are realized.

Owner:厦门宗泰工贸有限公司

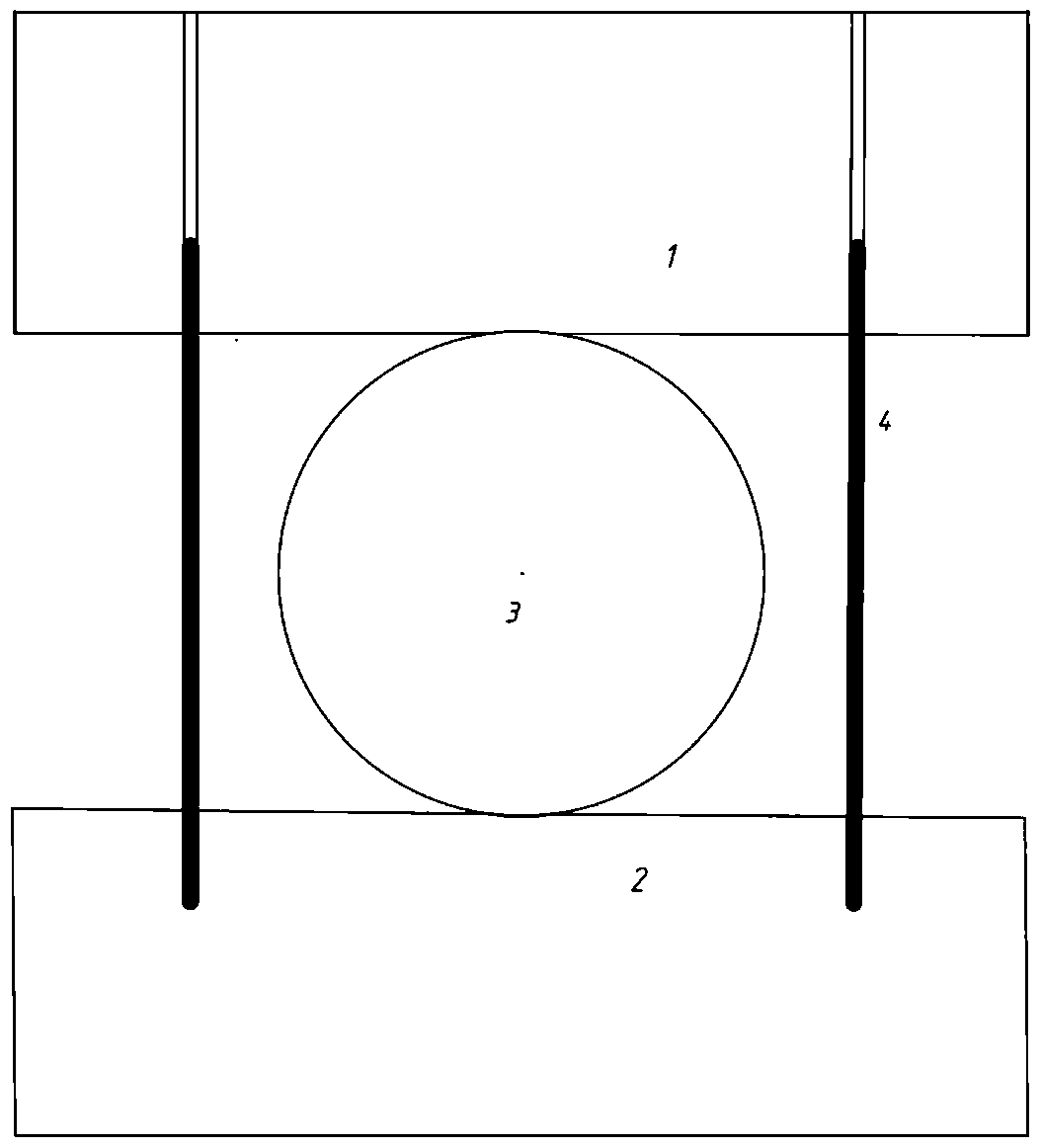

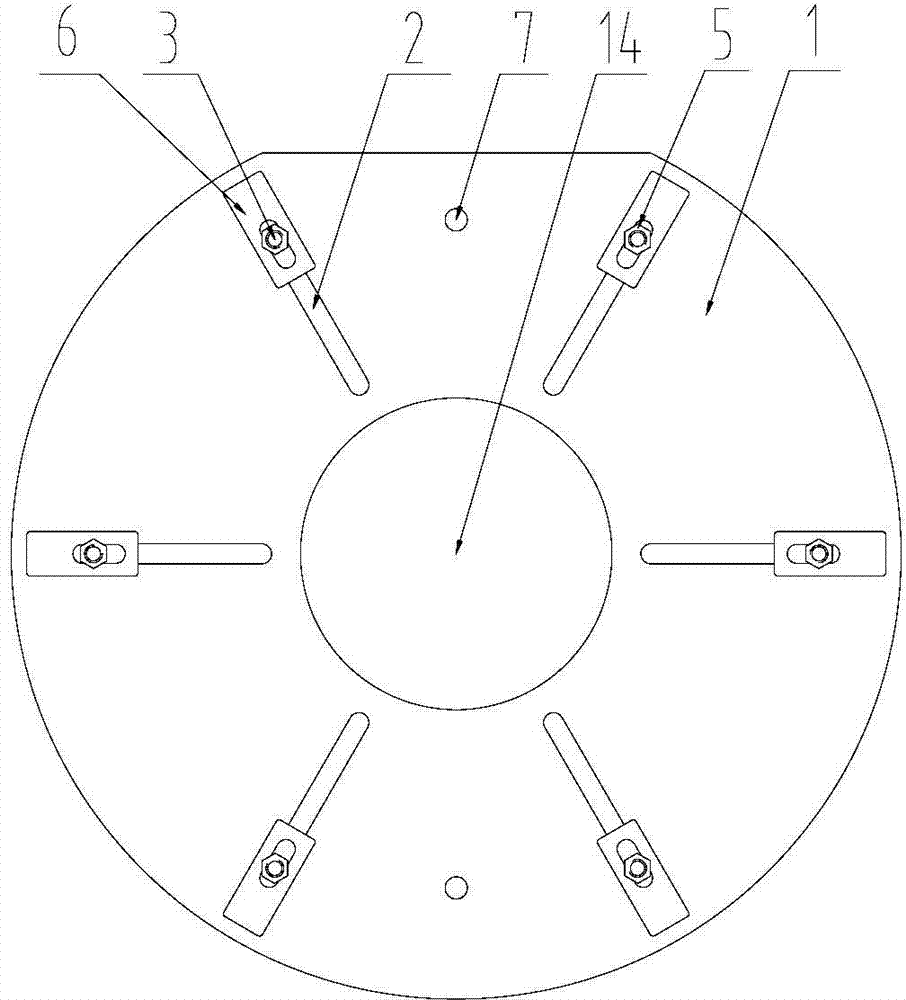

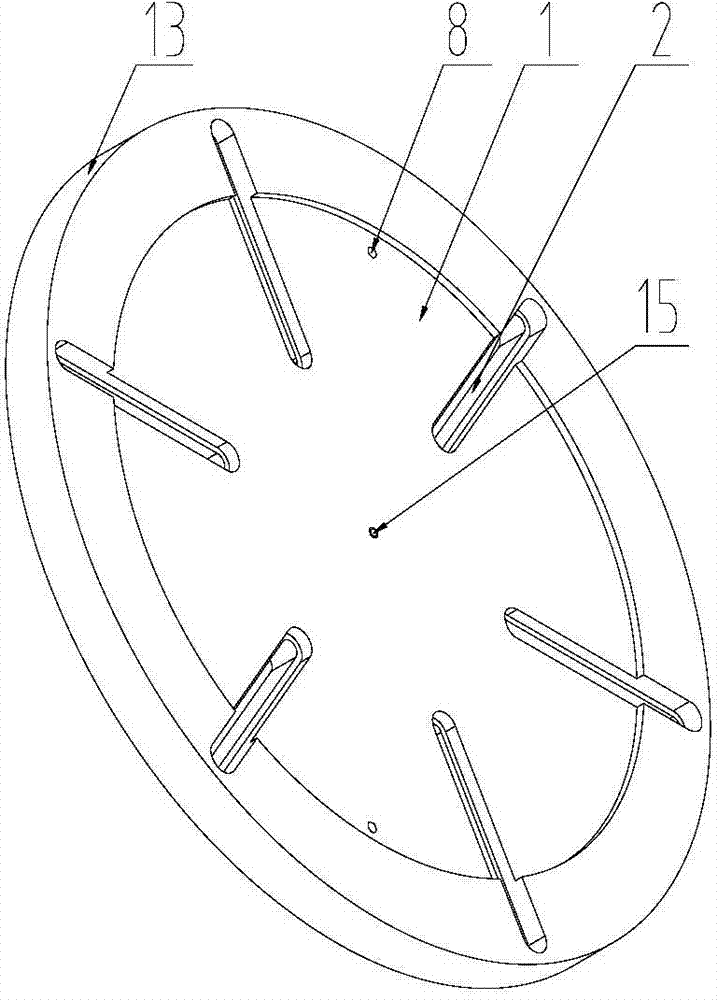

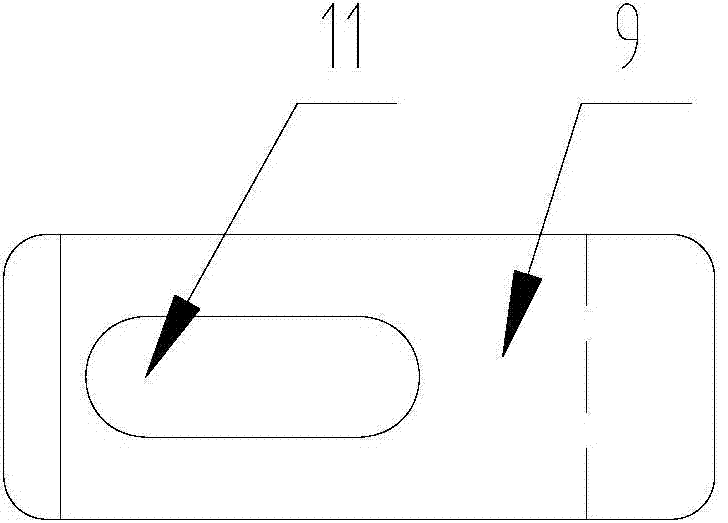

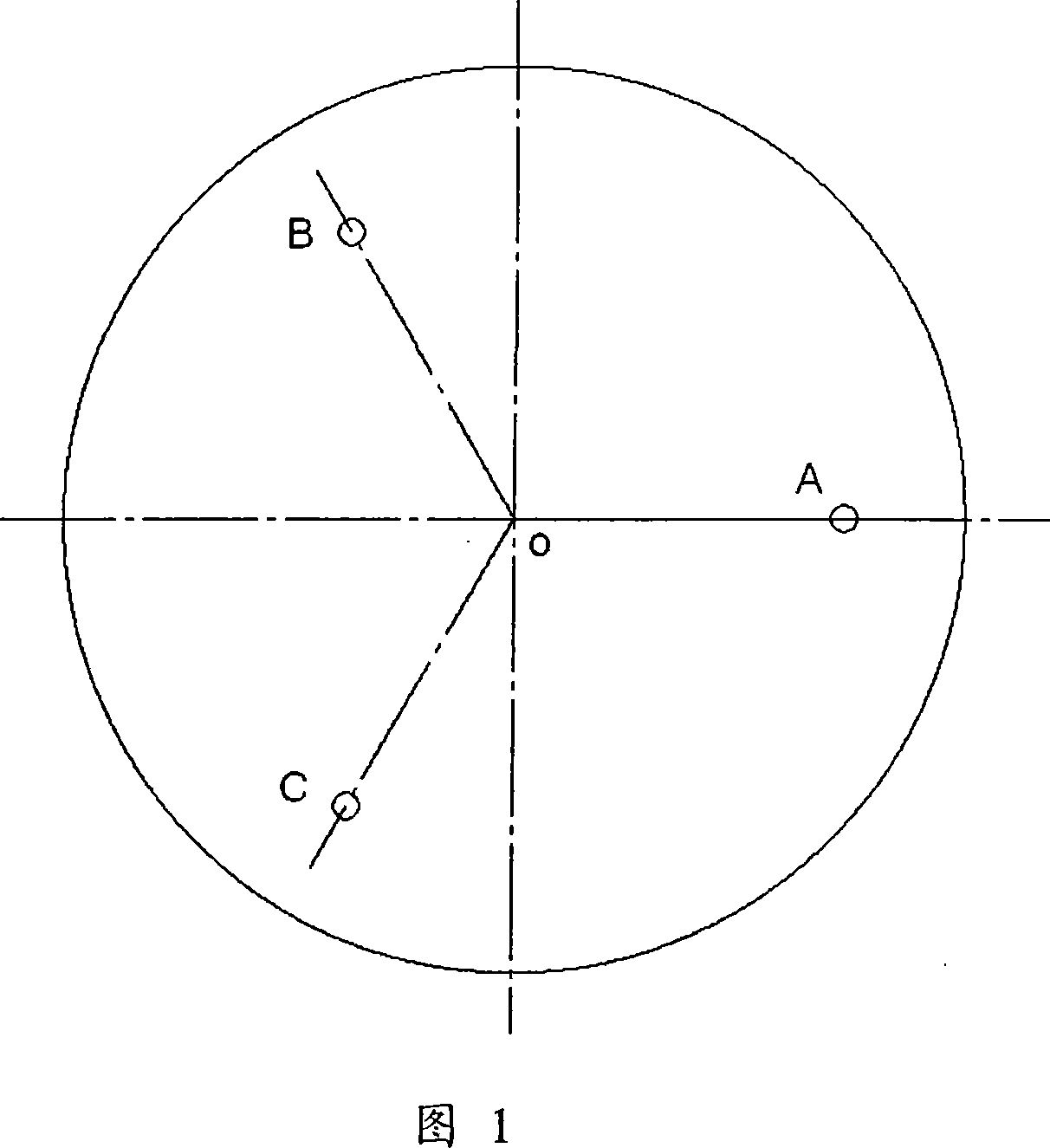

Method and device for testing tensile strength

InactiveCN105043866AReduce size requirementsLow shape requirementMaterial strength using tensile/compressive forcesCircular discStrength of materials

The invention discloses a method for testing tensile strength, which is used for testing the tensile strength of to-be-tested materials with ratio between compressive strength and tensile strength being less than 5, and belongs to the technical field of testing on the mechanical properties of materials. According to the invention, a Brazilian disc splitting method is adopted for testing the tensile strength of the to-be-tested material; during testing by using the Brazilian disc splitting method, a pair of testing clamps with V-shaped slots are used for applying pressure load to the diameter direction of the sample of a disc-shaped to-be-tested material; each V-shaped slot comprises an arc part positioned at the bottom of the slot and an extension part extending along the tangential directions at tow ends of the arc part; the arc part is a section of arc with diameter equal to that of the sample of the to-be-tested material and with angle of 20-40 degrees; and the lateral thickness of the V-shaped slot is equal to or greater than the thickness of the sample of the to-be-tested material. The invention further discloses a device for testing the tensile strength. The method and the device have the advantages of being low in requirements on sample size and shape, simple and convenient in testing, accurate in testing result and the like.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

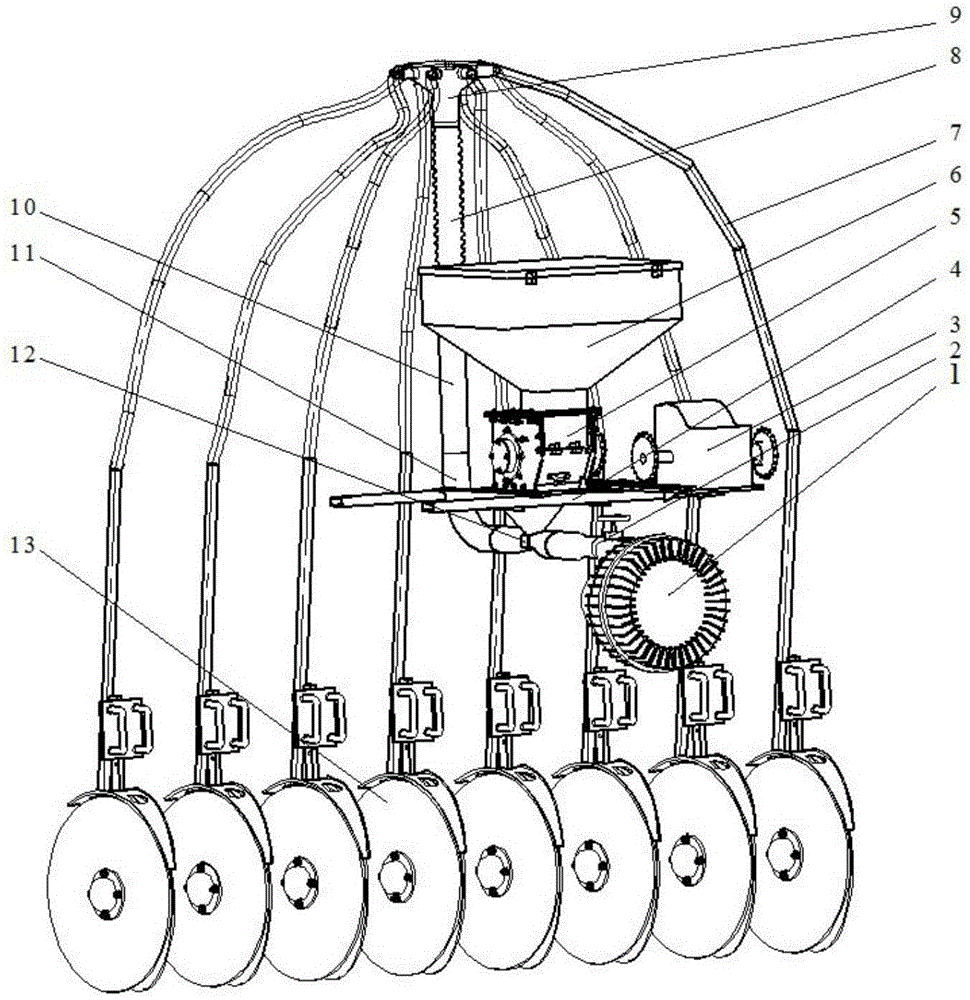

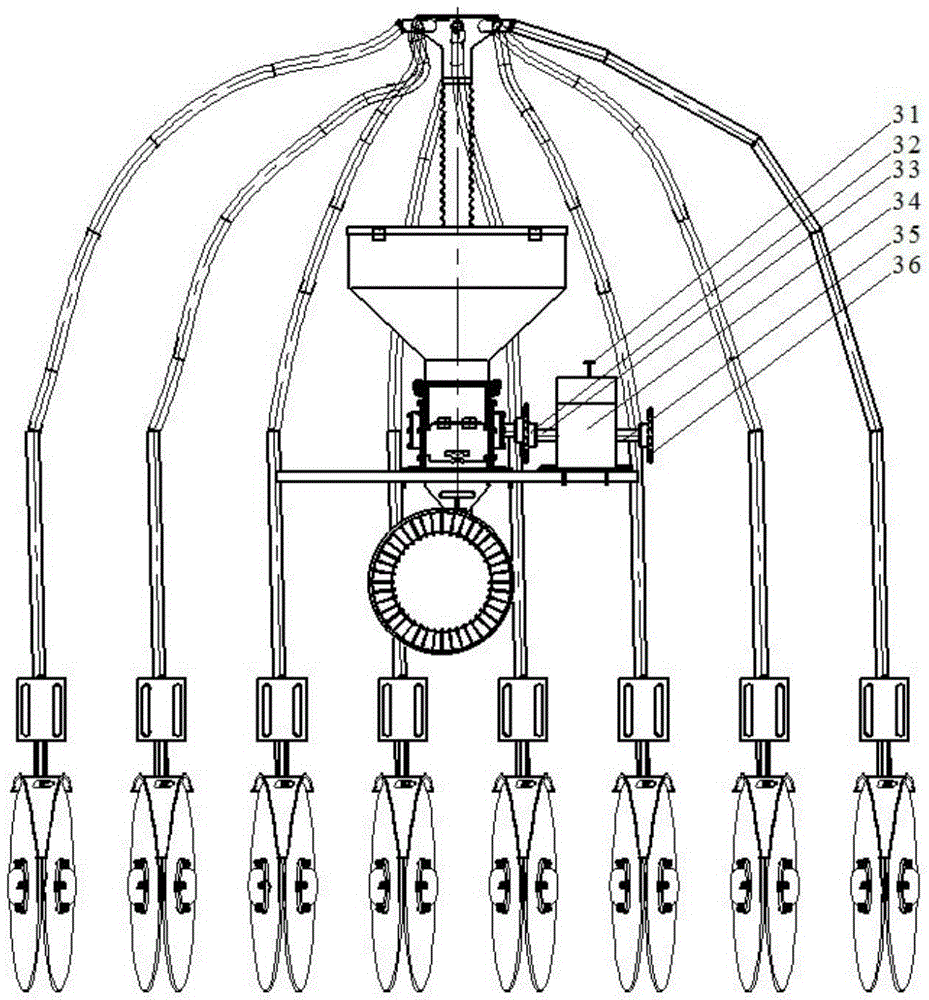

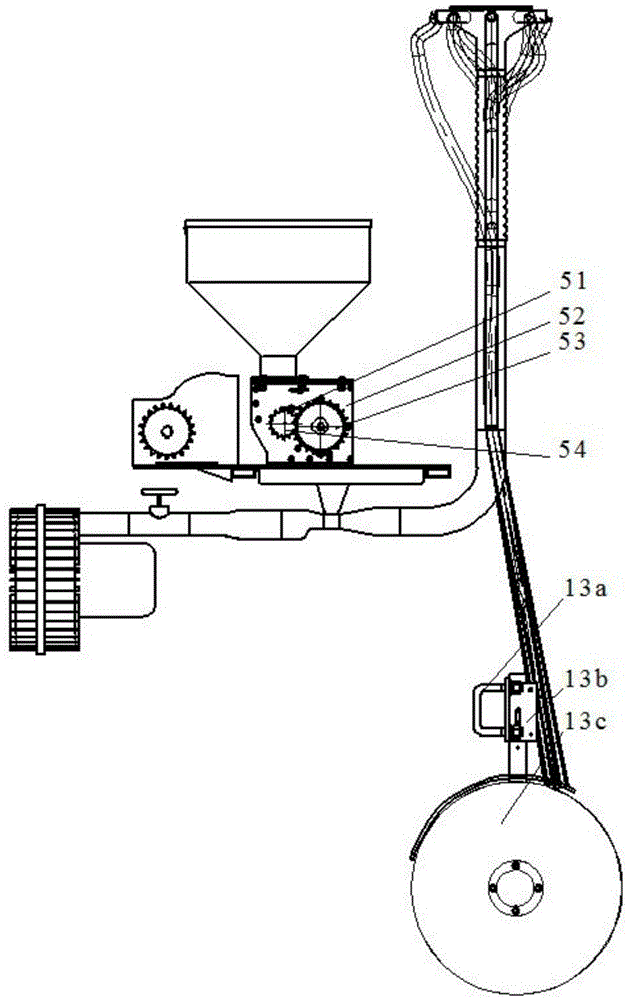

Rape and wheat dual-purpose pneumatic centralized discharging device

ActiveCN105453774ASimple structureEasy to installPlantingSeed depositing seeder partsDual purposeTransmission system

The invention discloses a rape and wheat dual-purpose pneumatic centralized discharging device. The device comprises a fan, a pressure regulation valve, a support frame, a seed supply unit, a seed box, a seed discharging tube, a pressure increasing tube, a distributing unit, a seed delivery tube, a seed delivery elbow, a supply unit, a double-disk opener and a speed changing unit for regulating the rotation speed of the seed supply unit and transmitting power. According to the centralized discharging device, sowing in eight lines can be completed simultaneously, seed feeding, exchanging and discharging are facilitated, a transmission system and the whole device structure are simplified, and the device is convenient to operate.

Owner:HUAZHONG AGRI UNIV

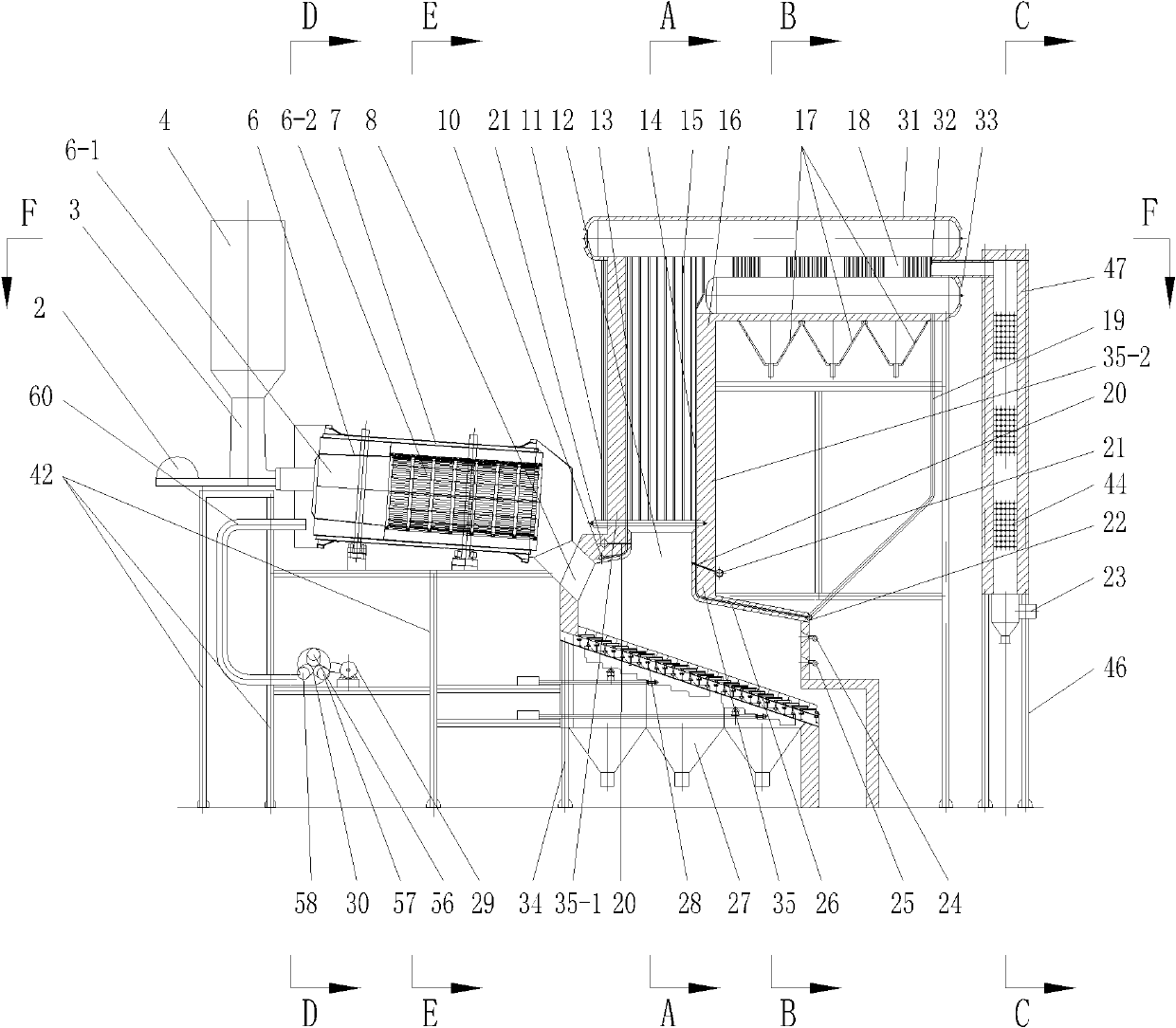

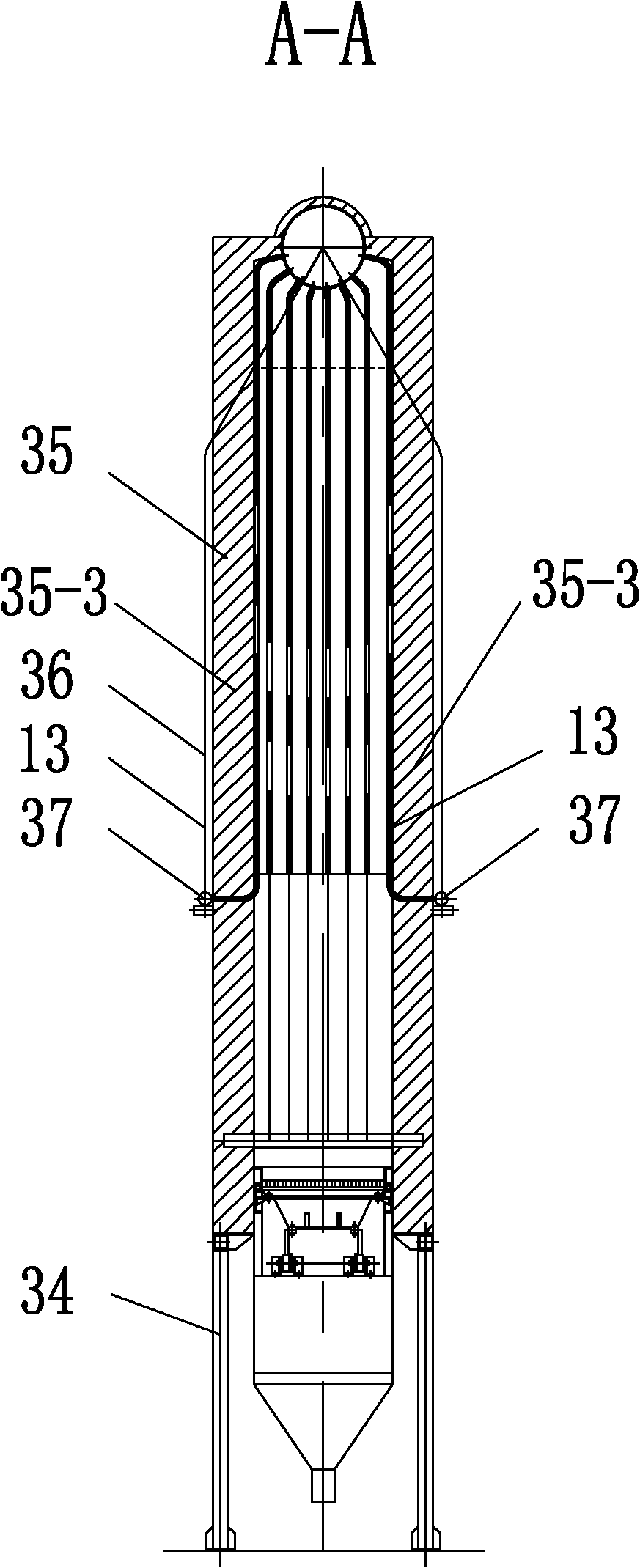

Three-dimensional hierarchical air supply combined waste incinerator

InactiveCN102168853ASmall granularityLow shape requirementIncinerator apparatusAir preheaterAir interface

The invention relates to a three-dimensional hierarchical air supply combined waste incinerator, in particular to a waste incinerator. The waste incinerator provided by the invention solves the problems of single function and narrow application range of the traditional waste incinerator. In the waste incinerator provided by the invention, the lower end of a feeding device is communicated with one end of a rotary drying pyrolysis device; the other end of the rotary drying pyrolysis device is communicated with a grate type incinerator; the feeding device and the rotary drying pyrolysis device are fixedly installed on a first bracket; two groups of secondary air spray pipes are both communicated with a secondary air main pipe; one group of the two groups of secondary air spray pipes is positioned above a rear arch and arranged on the outer side wall of a rear wall, and the other group of secondary air spray pipes are arranged at the lower end of a front wall; each group of secondary air spray pipes is communicated with a hearth; a high-temperature smoke interface is communicated with a horizontal flue through a pipeline; an intermediate-temperature smoke interface is communicated with a tail flue through a pipeline; and an air interface is communicated with the air outlet of an air preheater through a pipeline. The waste incinerator provided by the invention is used for incinerating waste.

Owner:HARBIN INST OF TECH

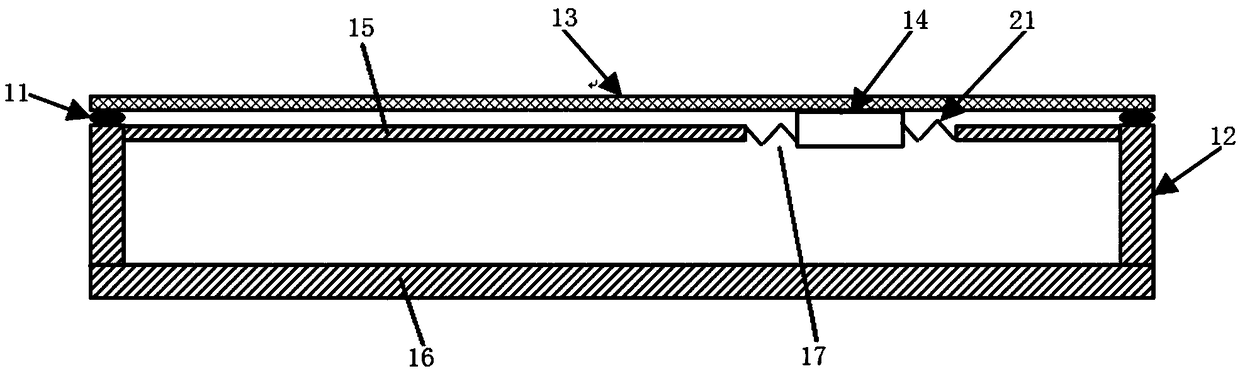

Electronic display device and electronic device

ActiveCN109032257AReduce leakageAffect performanceDigital data processing detailsDisplay deviceElectric signal

The invention discloses an electronic display device and an electronic device, the electronic display device includes a housing, a screen and a vibration device. At least a portion of the screen is connected to at least a portion of the housing by a flexible connection device, at least one of that screen and the house is provided with a receiving groove for fixing the flexible connection device, the flexible connecting device has elasticity, and the vibration device comprises a stator subsystem and a vibration subsystem, wherein the stator subsystem is fixedly connected with the screen througha heat insulating device, the vibration subsystem generates vibration in response to an electric signal of an external circuit and drives the stator to vibrate, and the stator drives the screen to vibrate and sound. The screen and the housing are connected by a flexible device, and the heat insulation device reduces the heat diffusion of the vibration device to the screen and effectively protectsthe screen by providing a flexible connection device accommodating groove to enhance the connection strength between the flexible connection device and the shell and the screen.

Owner:刘博文

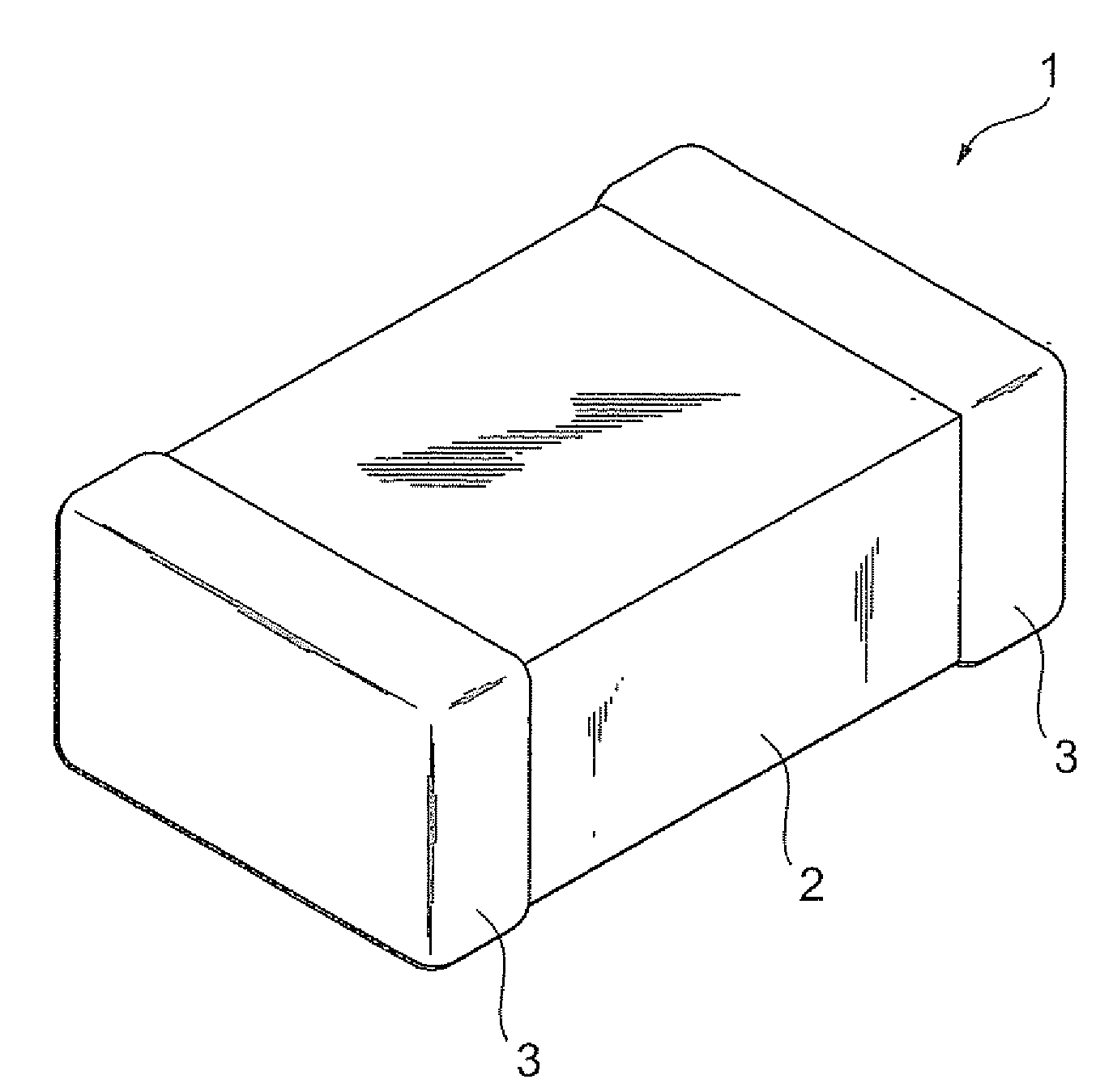

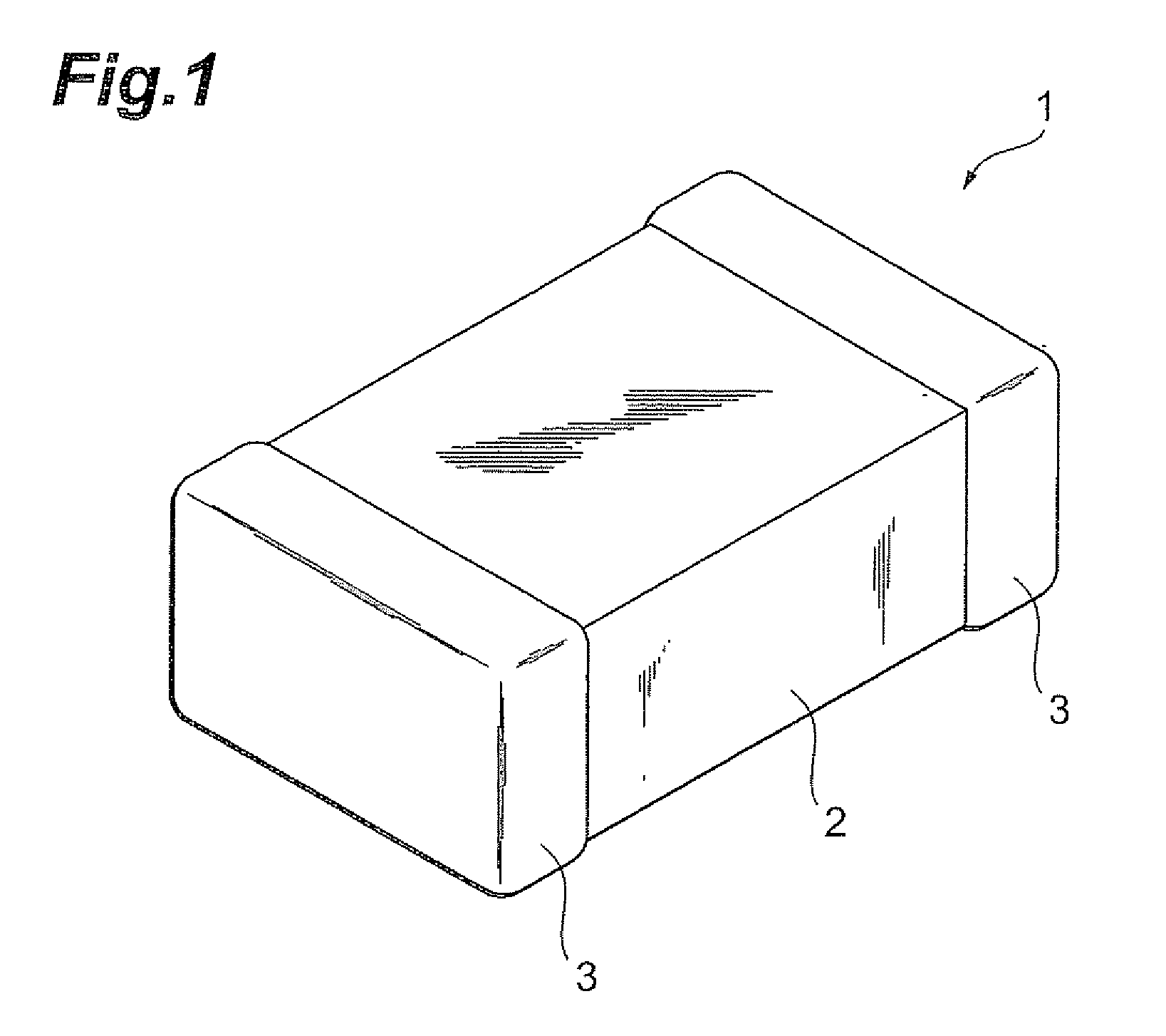

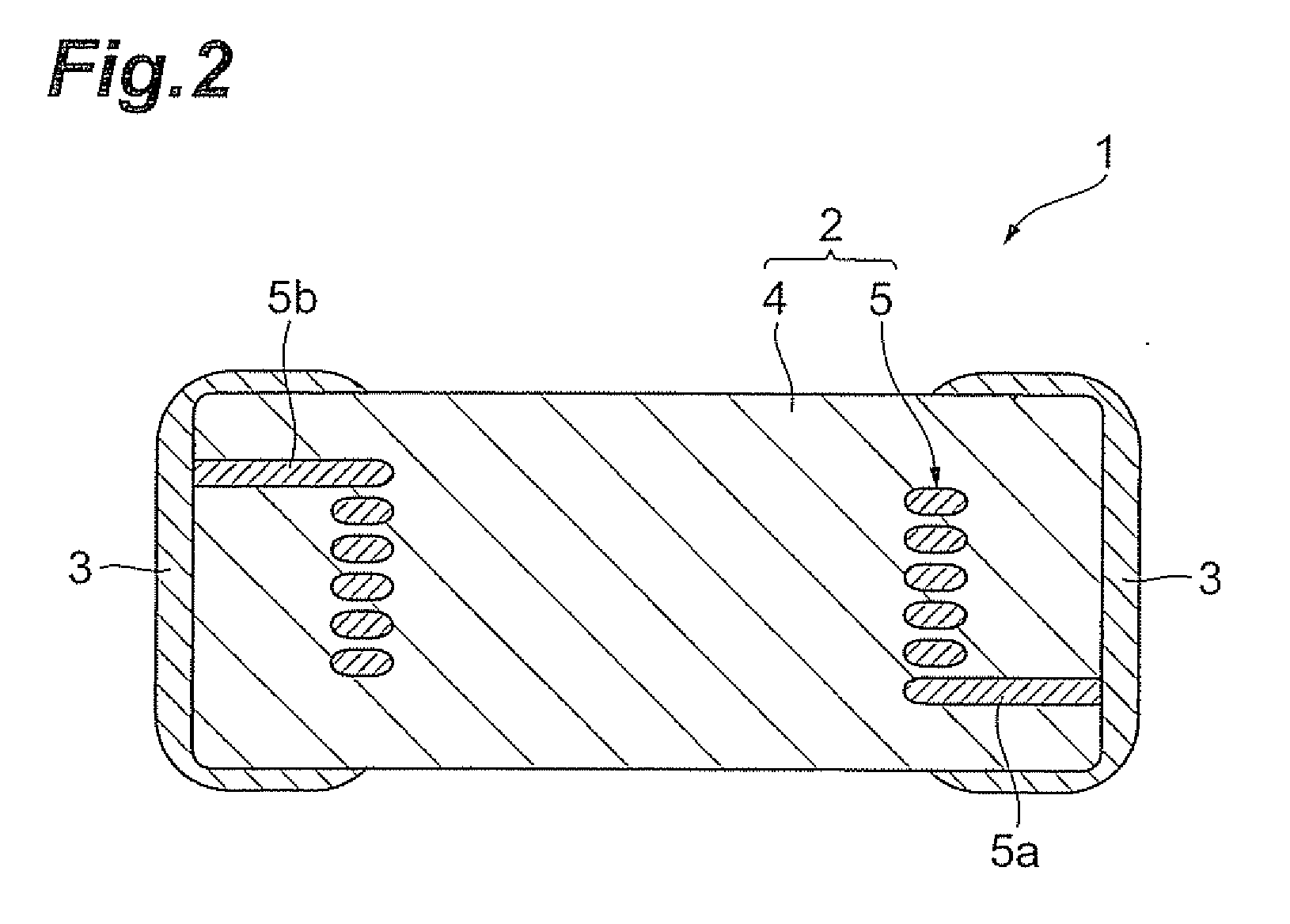

Ferrite paste, and method for manufacturing laminated ceramic component

InactiveUS20080283188A1Reduced strengthLow shape requirementLamination ancillary operationsLaminationOrganic solventPolyvinyl alcohol

The ferrite paste according to the present invention contains a ferrite powder and an organic vehicle, and the organic vehicle contains an organic solvent and a binder made of a polyvinyl acetal resin and ethyl cellulose. The binder content in the ferrite paste is at least 3.0 weight parts and no more than 5.0 weight parts per 100 weight parts of the ferrite powder, and the polyvinyl acetal resin content is at least 0.5 weight part and no more than 2.0 weight parts per 100 of the weight parts ferrite powder. The ethyl cellulose content is the remainder of subtracting the polyvinyl acetal resin content from the binder content.

Owner:TDK CORPARATION

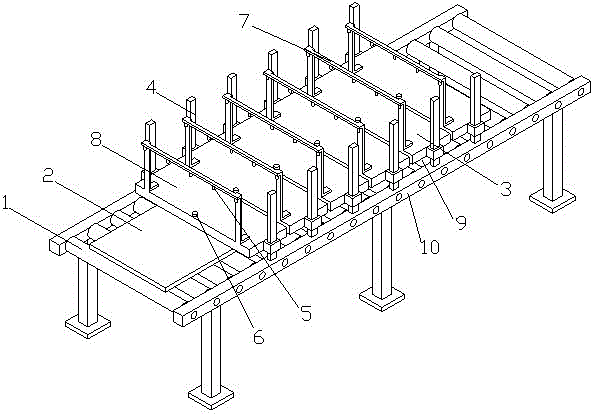

Universal milling fixture for diffuser blades

InactiveCN104741953ALow form factor requirementsLow costPositioning apparatusMetal-working holdersEngineeringUltimate tensile strength

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

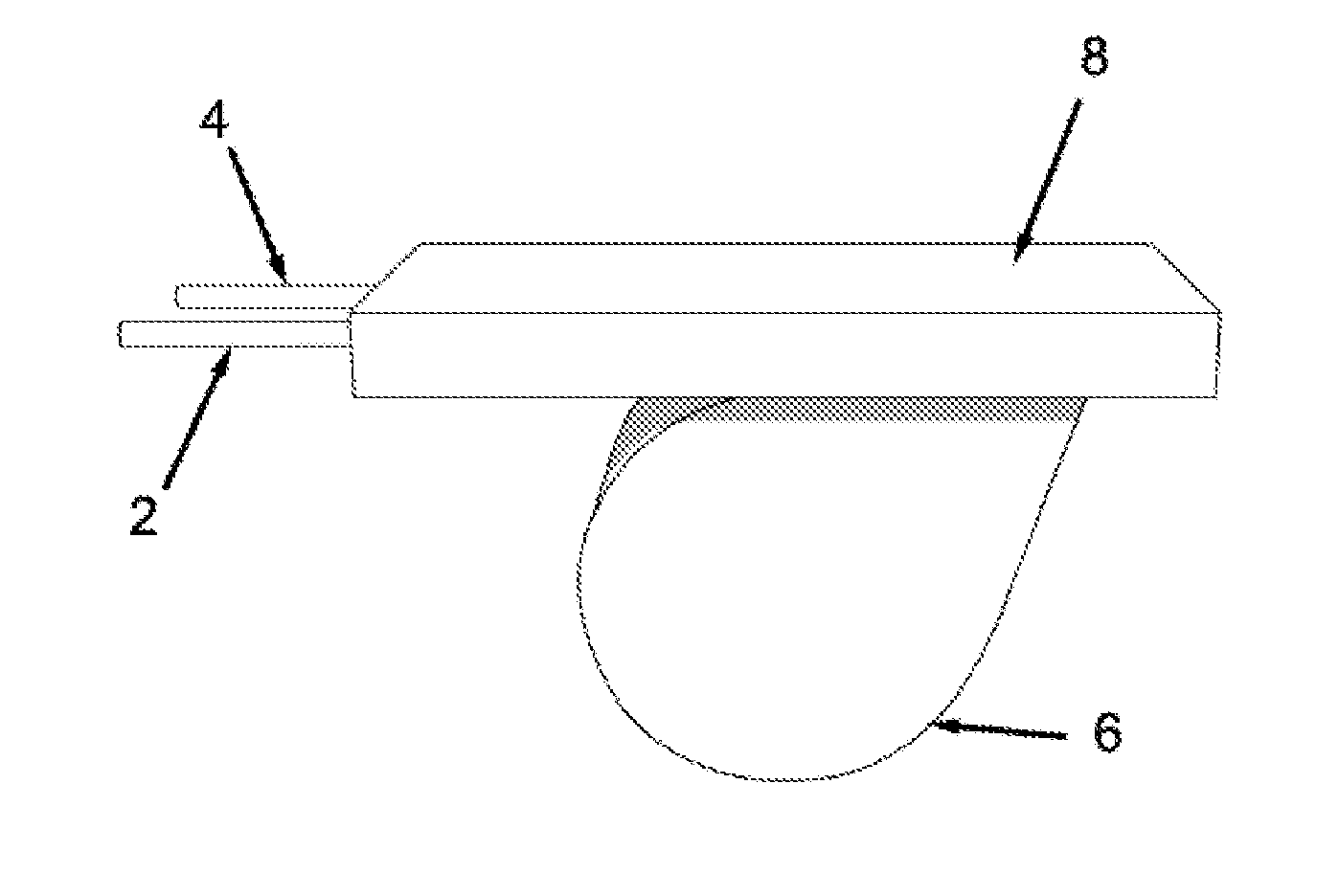

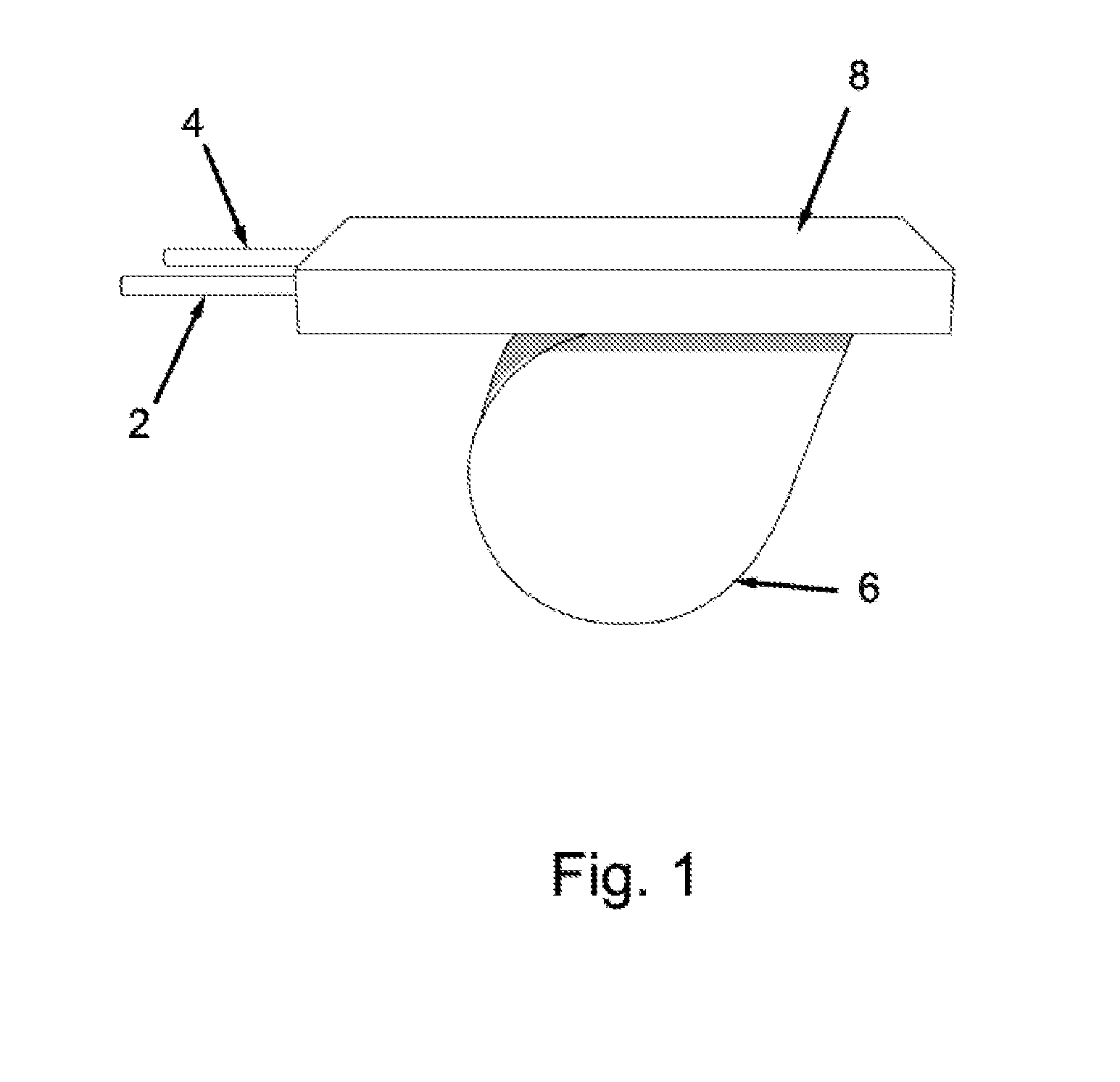

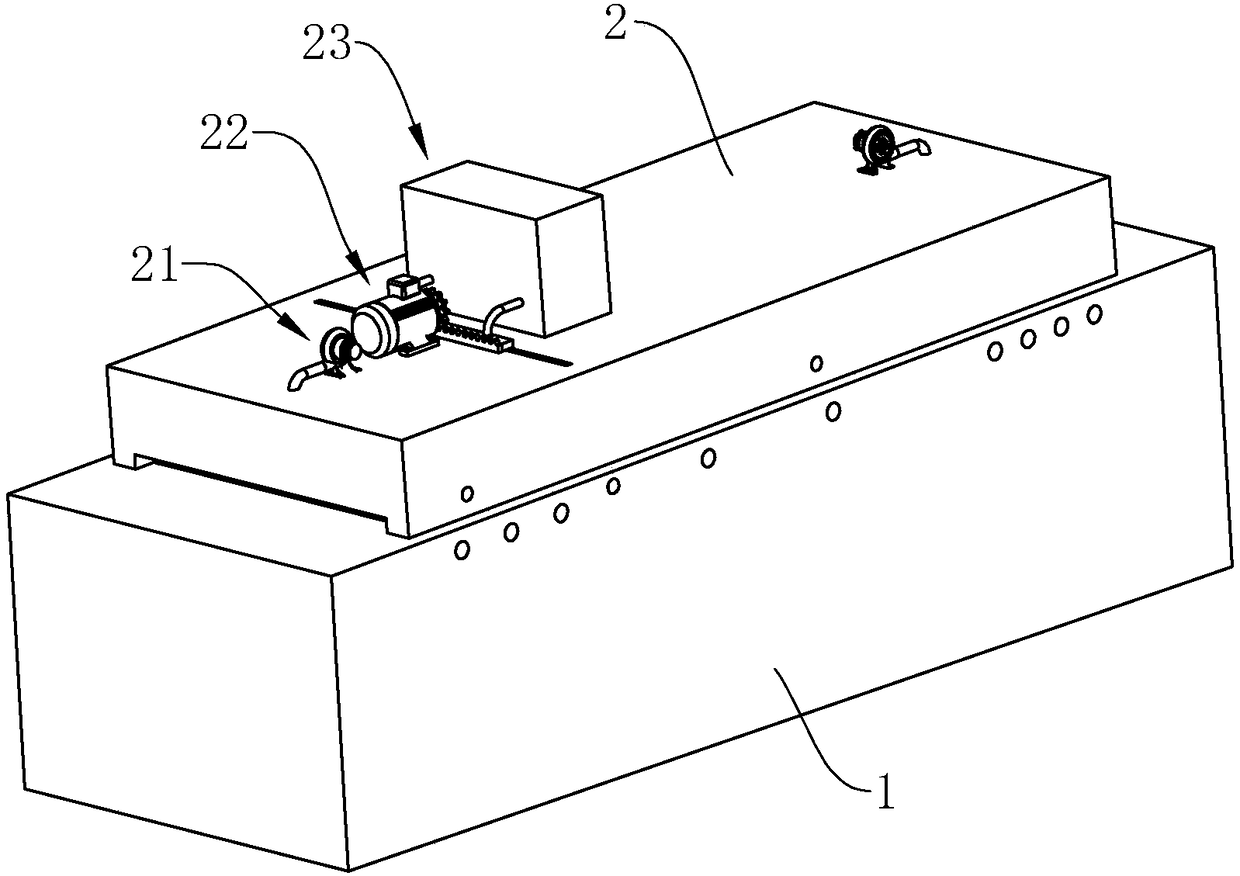

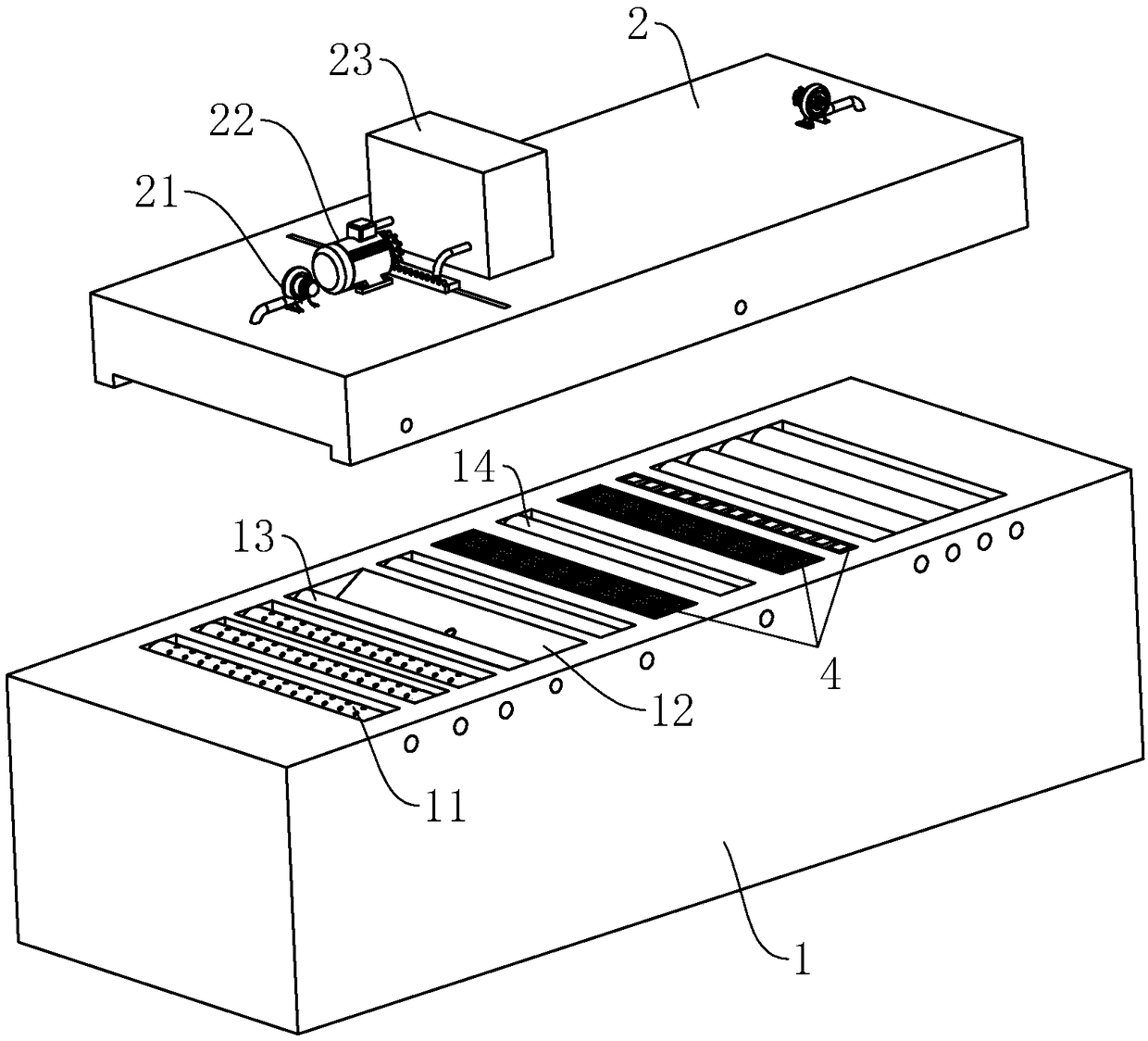

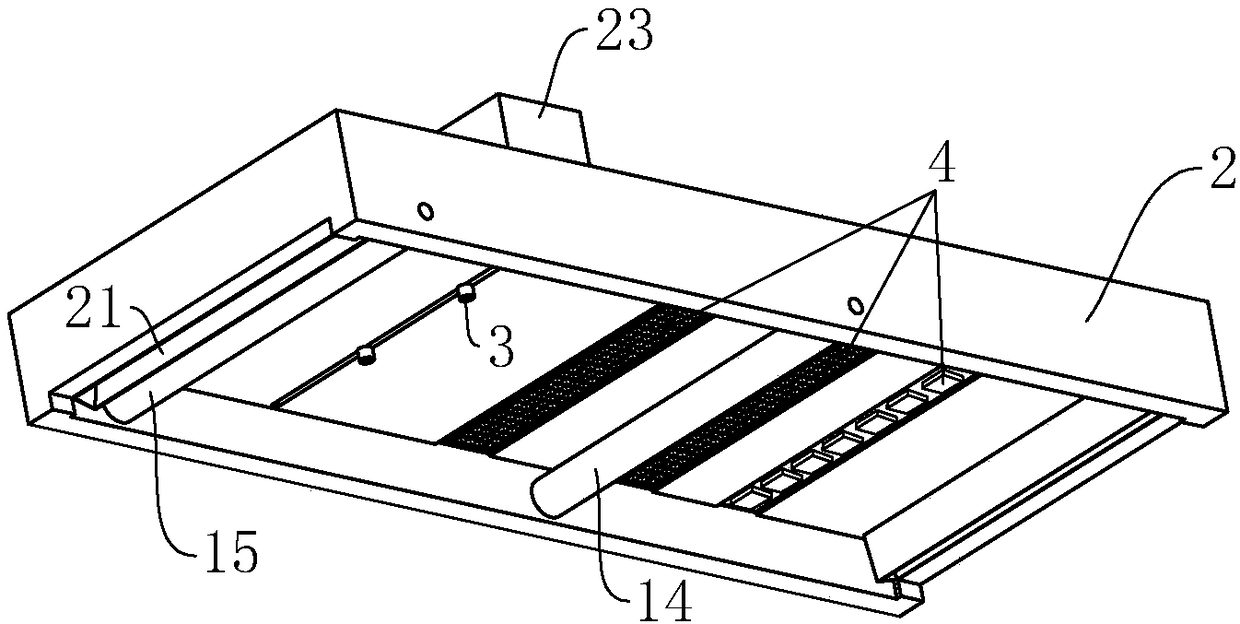

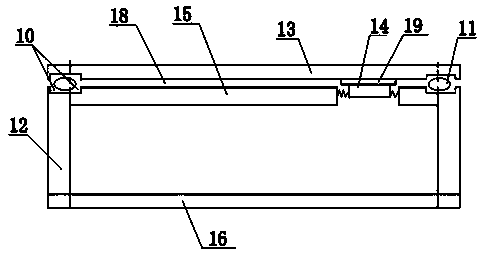

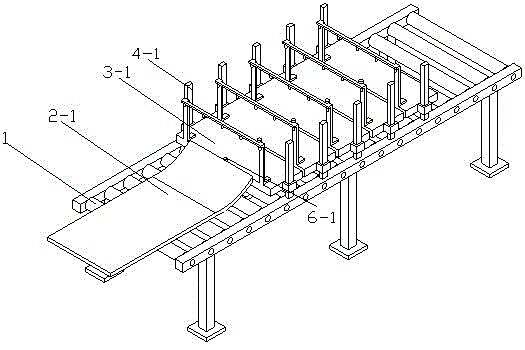

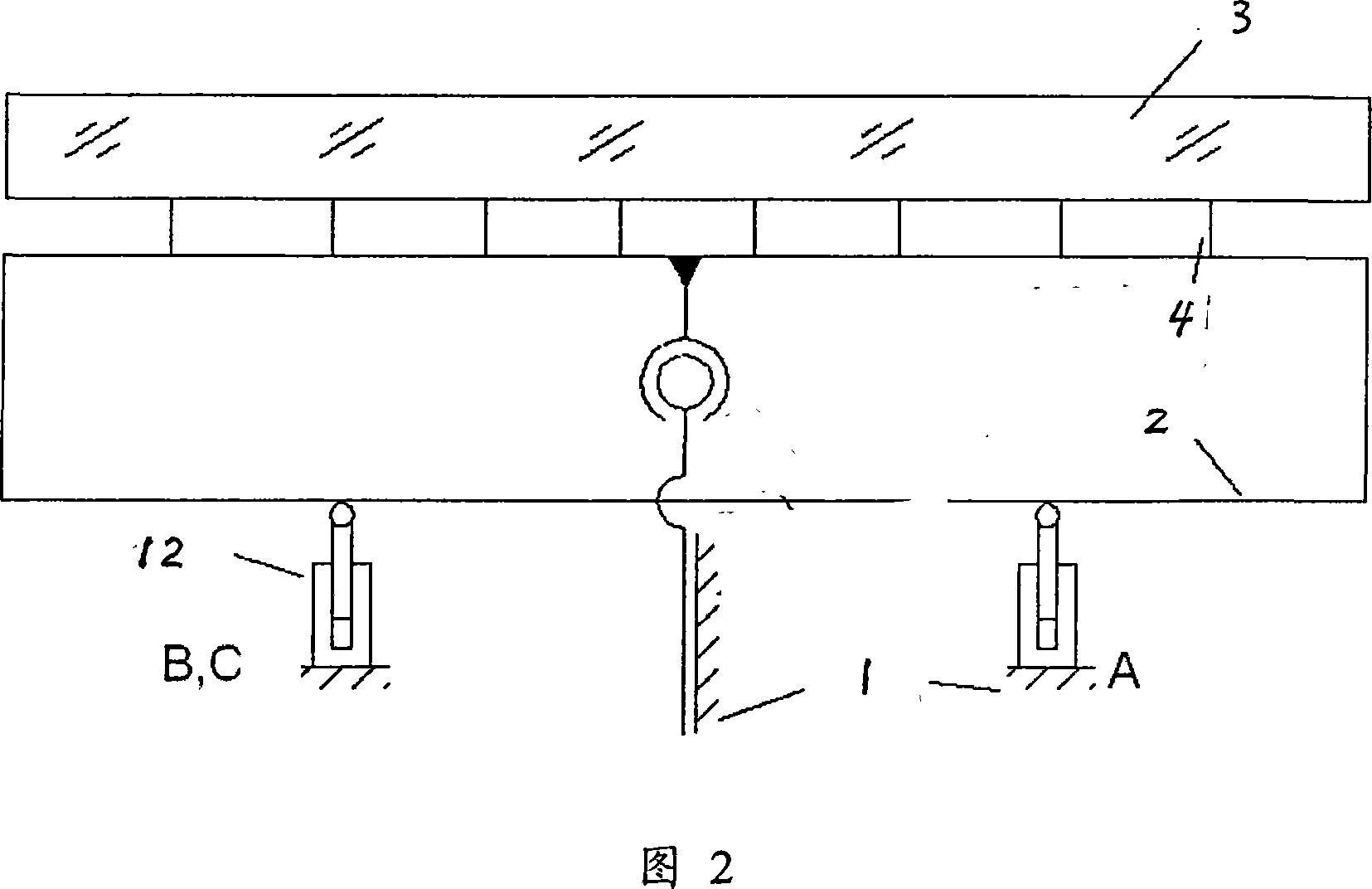

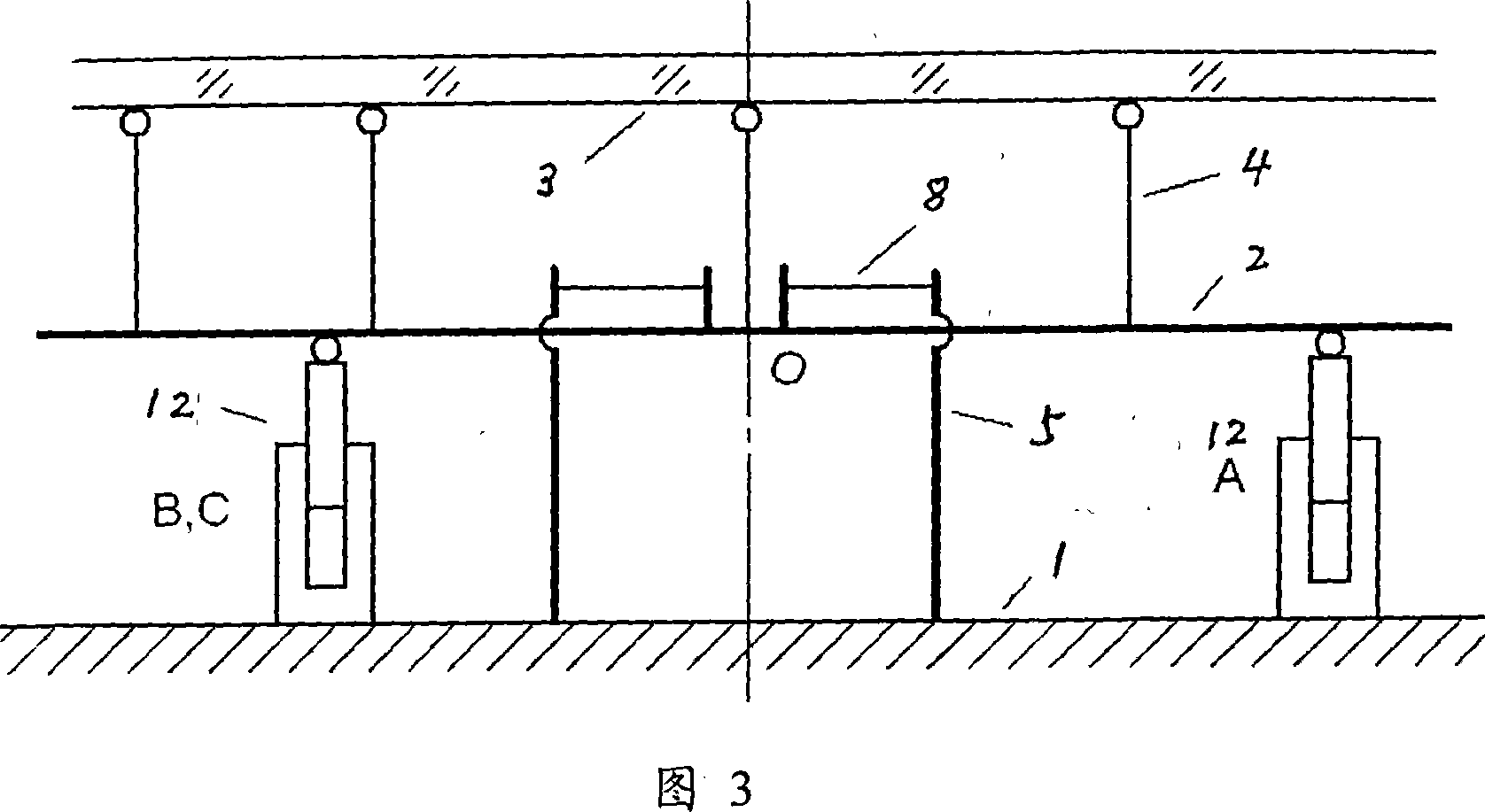

Induction heating method and device with self-adaptive distance adjusting function

ActiveCN105648164ABroaden and enhance processing capabilitiesIncrease productivityFurnace typesIncreasing energy efficiencyControl systemEngineering

The invention discloses an induction heating method suitable for steel plates with any warping degree. Firstly, a steel plate (2) is moved to an inlet of inductors (8) of an induction heating furnace through a roller bed system (1), displacement sensors (5) located on the upper portion of the front end of each upper inductor (3) are used for detecting the distance between the surface of the steel plate and the sensors and sending a measurement result to an intelligent processing unit; secondly, the intelligent processing unit works out the warping degree of the steel plate and an upper inductor position adjusting mode and sends the warping degree of the steel plate and the upper inductor position adjusting mode to a PLC control system; thirdly, the PLC control system sends adjustment commands to an upper inductor position adjusting system (4), so that the distance between the steel plate and the upper inductors is kept relatively constant; and fourthly, when the steel plate enters the inductors, infrared temperature measuring units (6) mounted at the inlet ends of the upper inductors are used for detecting the temperature of the steel plate, power needed for heating the steel plate to a target temperature is worked out, and an inductor heating system is started to heat the steel plate, so that when the steel plate leaves the induction heating furnace, the temperature of the steel plate reaches the target temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

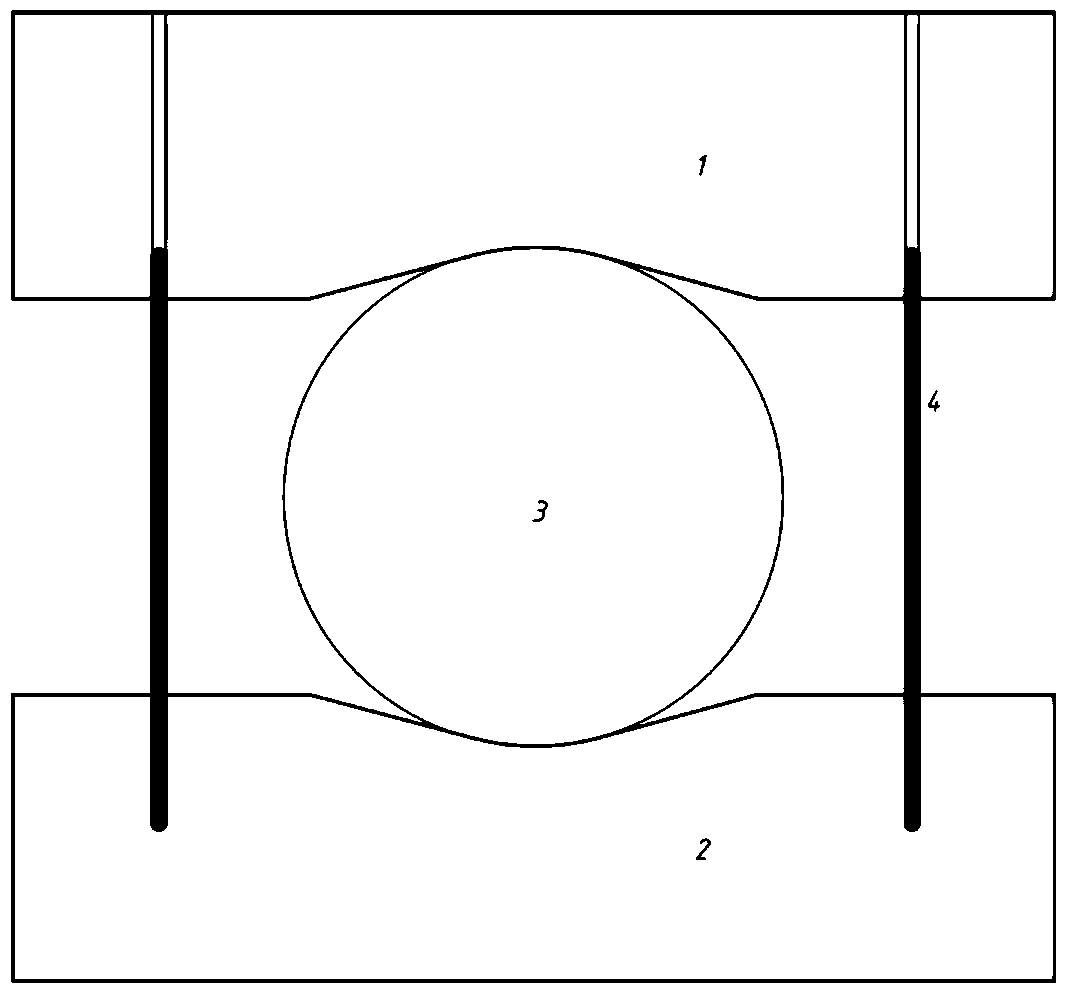

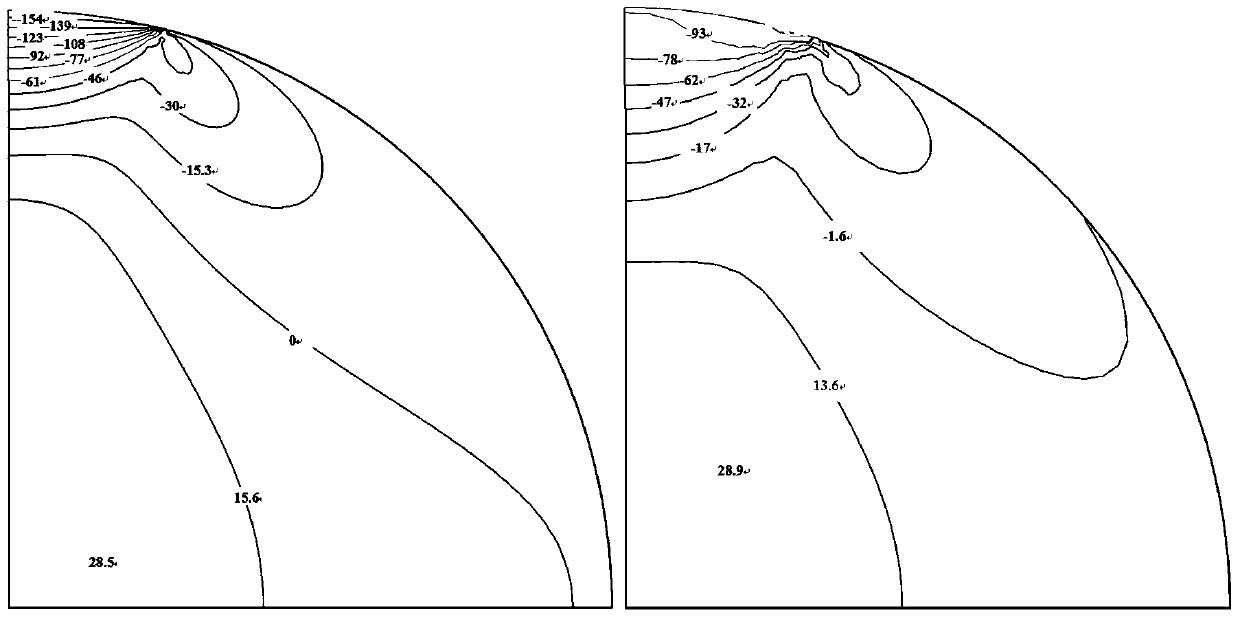

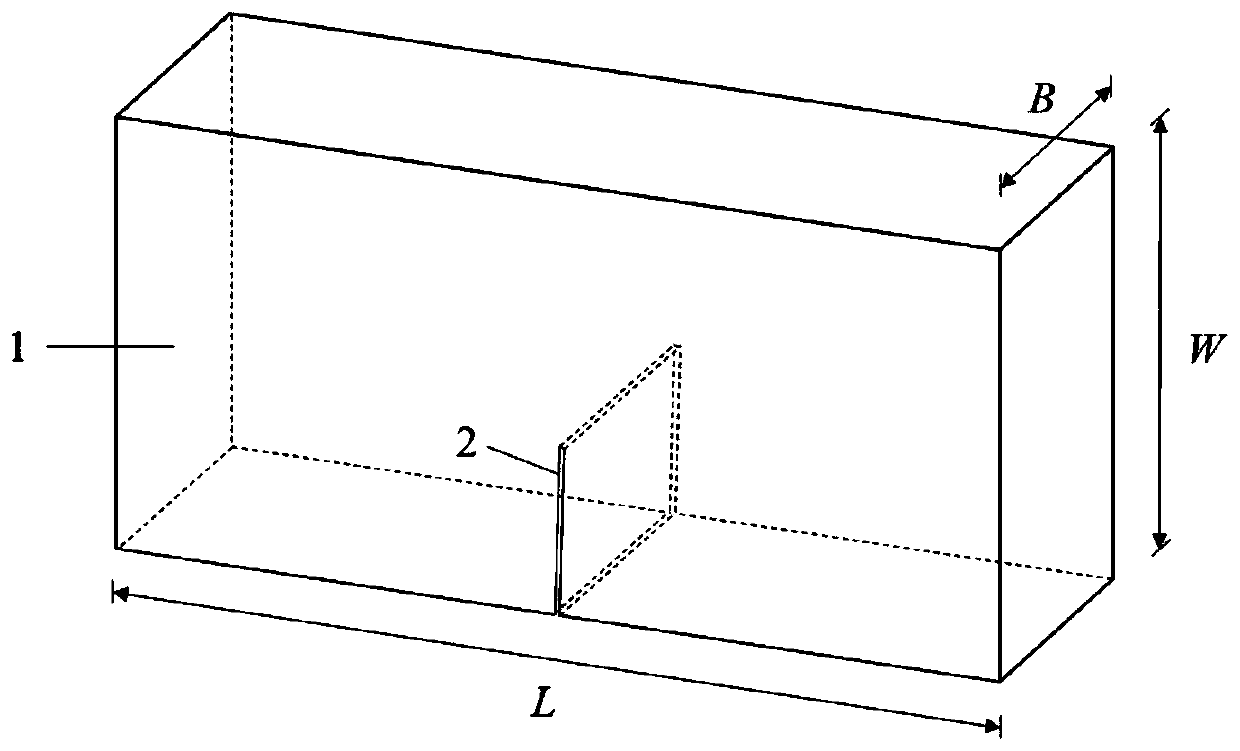

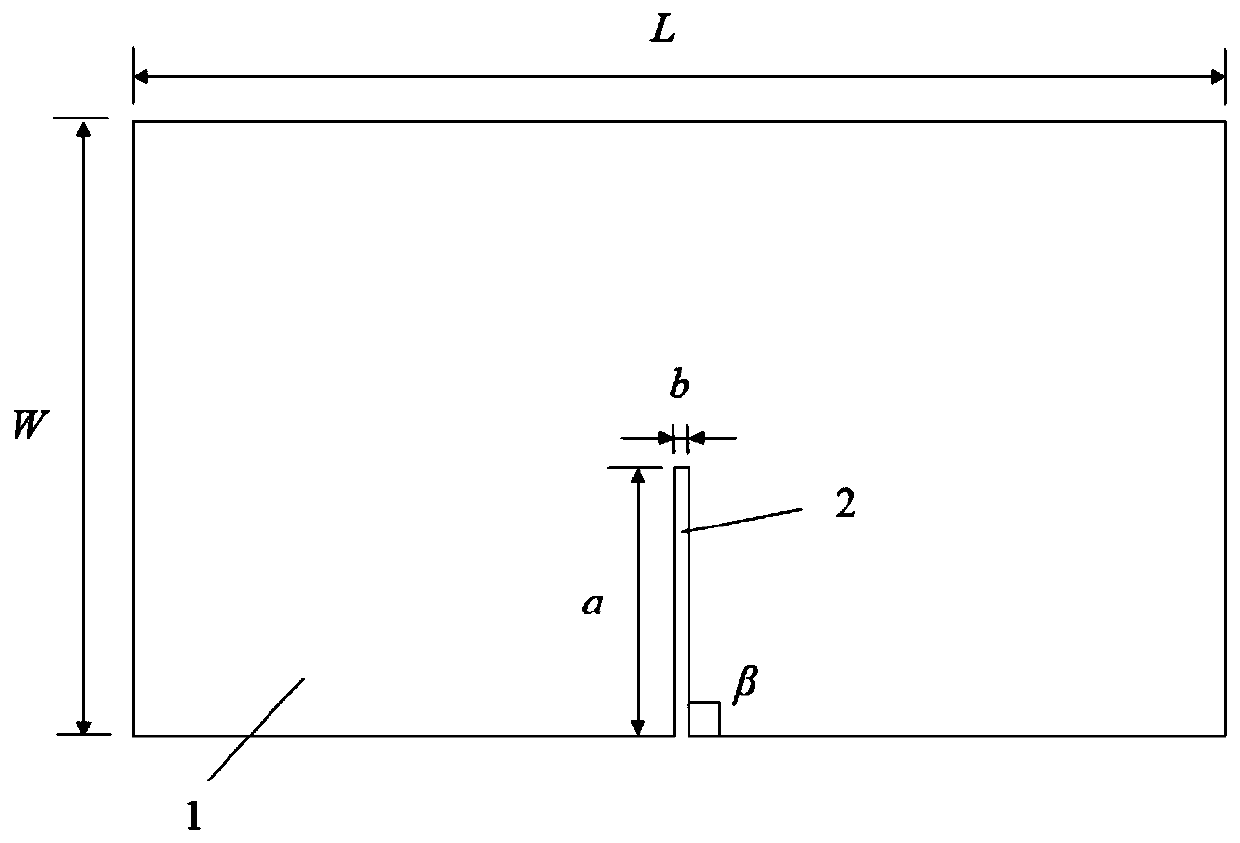

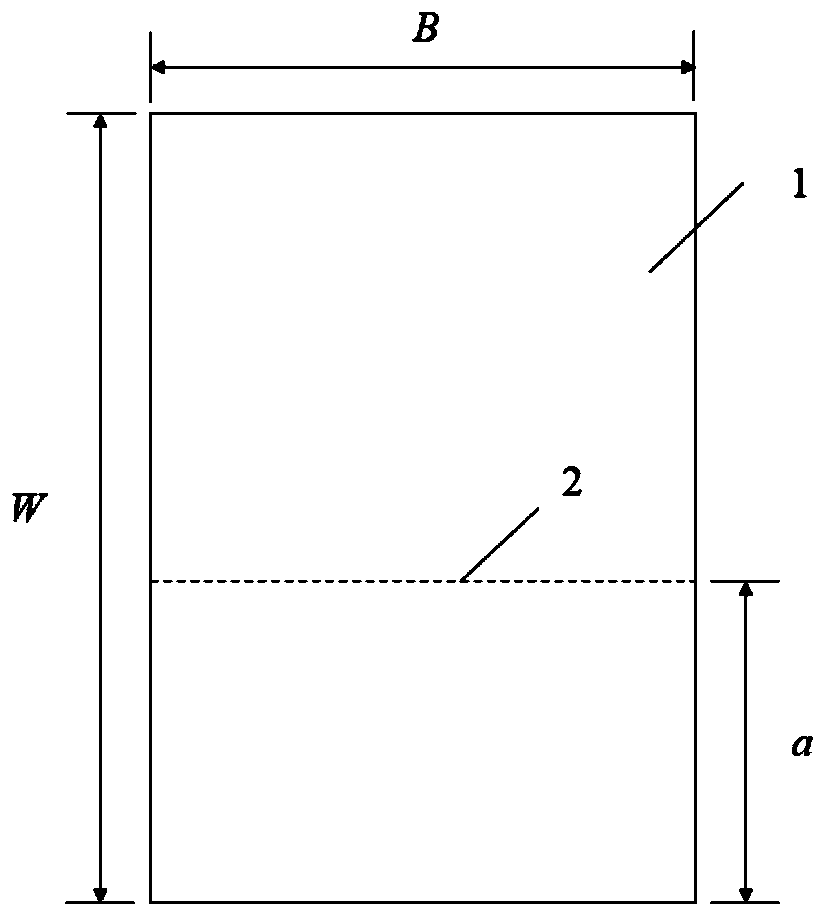

Method for testing rock composite fracture toughness based on asymmetric three-point bending loading of NDB sample

ActiveCN109781548ARich fracture toughness testing technology systemSimple structurePreparing sample for investigationMaterial strength using steady bending forcesNon symmetricEngineering

The invention provides a method for testing rock composite fracture toughness based on asymmetric three-point bending loading of an NDB sample, and the method comprises the steps: enabling a test piece body to be a rectangular deep beam (NDB) with a cutting groove, enabling the shape of the test piece body to be a cuboid, prefabricating a cutting groove with the height of a in the middle cross section of the body, extending towards the thickness direction of the body, and penetrating through the front and rear end faces in the body thickness direction; wherein the length L of the test piece body is twice the width W of the test piece body, and the thickness B is not less than 0.8 W. Based on the NDB sample, the invention provides a method for carrying out rock purity type I, rock purity type II and rock purity type I-II composite fracture toughness testing by using asymmetric three-point bending loading, and application of tension and shear load is realized through asymmetric loading.The NDB sample used in the invention has a simple structure and is easy to process by using rock blocks. A clamp used for loading is a common three-point bending clamp, only asymmetric arrangement ofthe supports is needed, experiment loading is quite convenient, and the pure I type, the pure II type and the I-II-type composite fracture toughness of the whole composite loading interval can be achieved.

Owner:SICHUAN UNIV

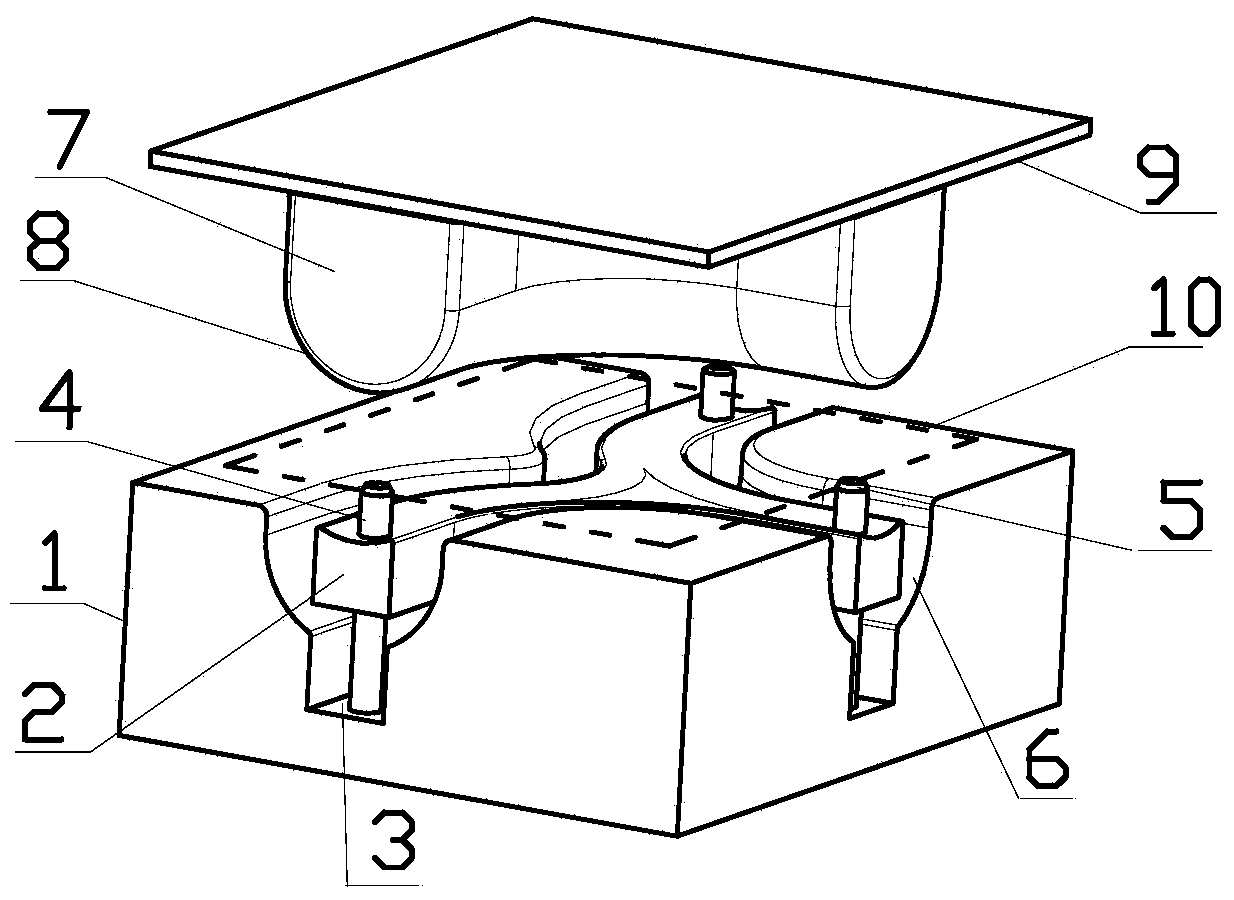

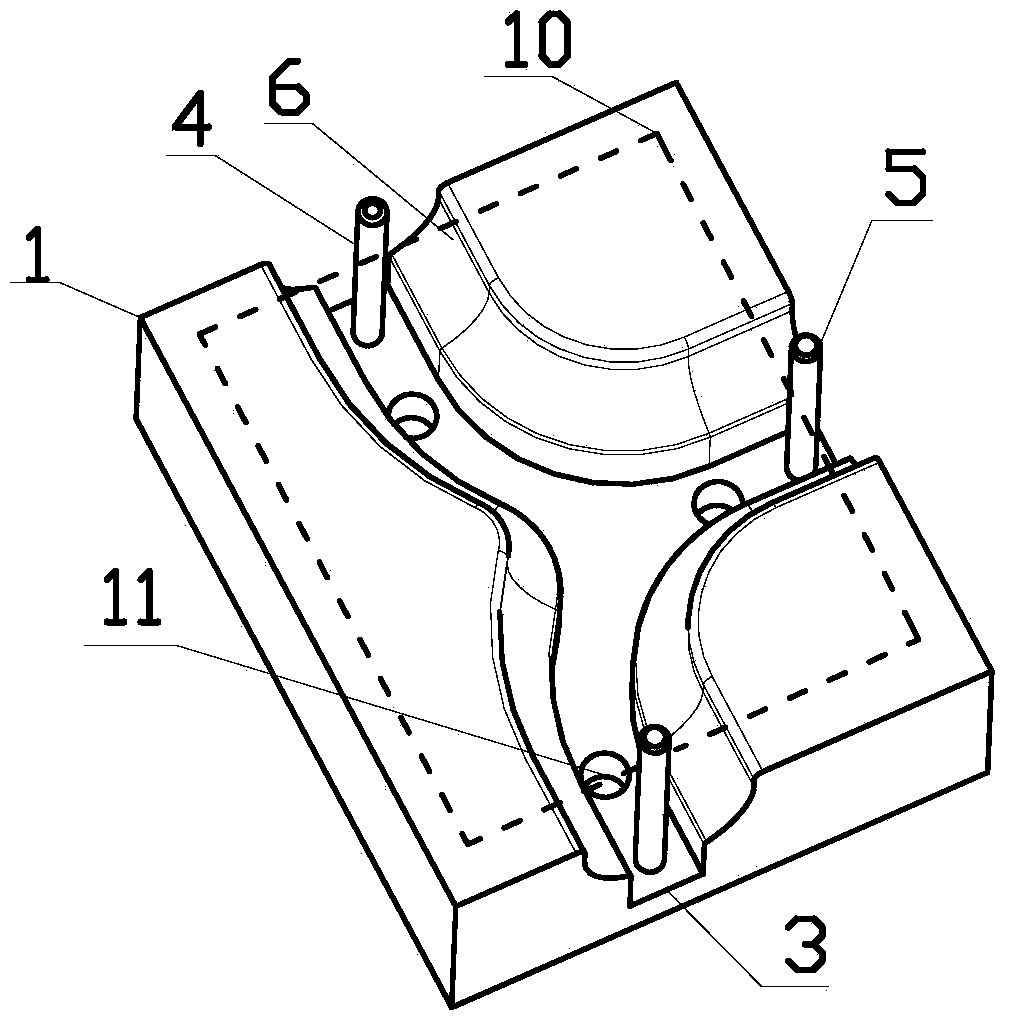

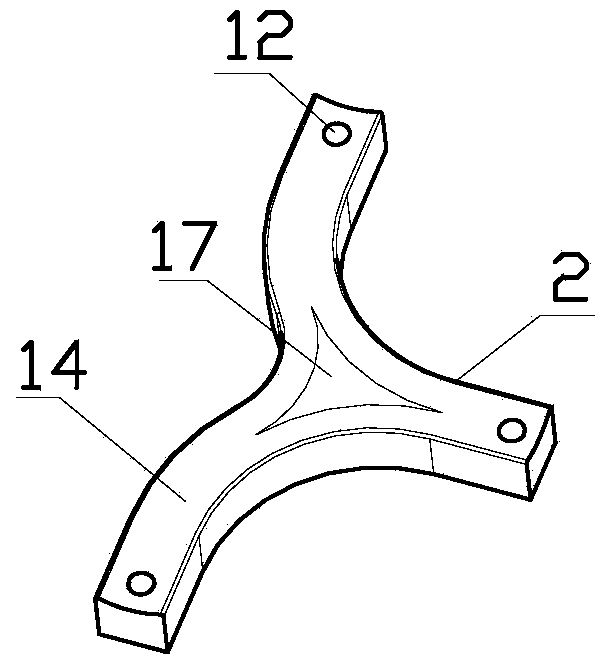

Forming method of tee joint half-tube part and compound punching die

The invention provides a punching forming method of a tee joint half-tube part and a die. The punching die comprises a lower die body, an upper die body and a pressing block, wherein the lower die body is provided with a concave face, a receding groove, a guide column and an ejection rod through hole, the pressing block corresponds to the receding groove in shape, the pressing block is provided with a first guide hole corresponding to the guide column, the upper die body is provided with a convex face corresponding to the concave face, the convex face is provided with a second guide hole corresponding to the guide column, an unfolded rough material is arranged between the convex face of the upper die body and the upper surface of the pressing block, and the part is formed after the upper die body and the pressing block press the rough material and die closing is carried out.

Owner:XI'AN AIRCRAFT INTERNATIONAL

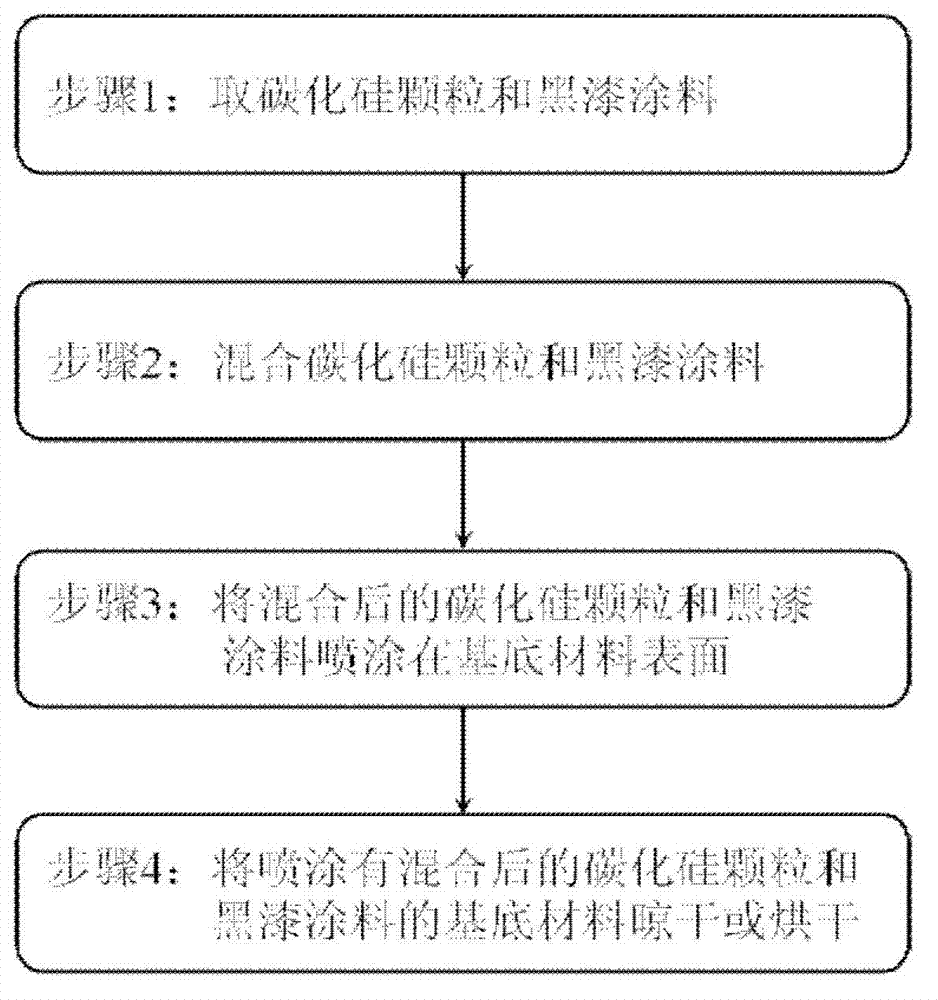

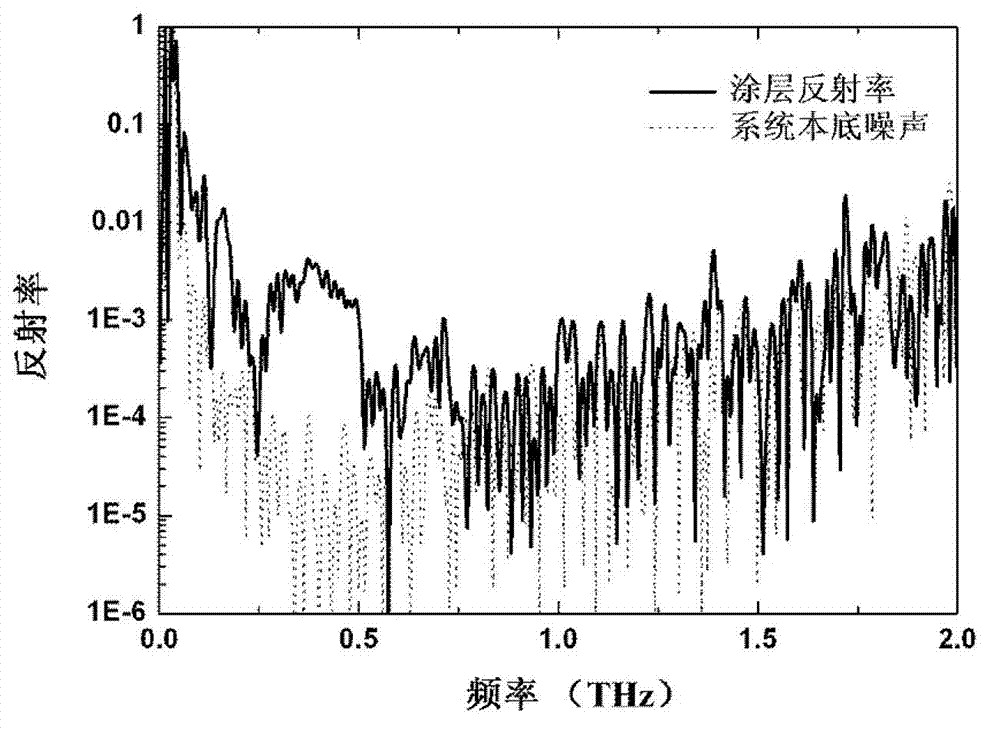

Method for preparing coatings with high broadband absorptivity at terahertz waveband

ActiveCN103191857AImprove absorption rateEasy to trace the source of the quantityCoatingsSpecial surfacesLacquerBlack paint

Disclosed is a method for preparing coatings with high broadband absorptivity at terahertz waveband. The method comprises the steps of step one, taking silicon carbide particles and black paint; step two, mixing the silicon carbide particles with the black paint; step three, spraying the mixed silicon carbide particles and the black paint on the surface of a substrate material; and step four, drying the substrate material with the mixed silicon carbide particles and the black paint sprayed to complete preparation. The coating material is simple to prepare, high in absorptivity and broad in absorption band, complete absorption of electromagnetic radiation broadband with the frequency higher than 0.05 THz (corresponding wavelength shorter than 6mm) is achieved through mixing of the silicon carbide particles with the black paint, and the coating can be used for absolute measurement of terahertz waveband radiation intensity and invisibility of targets in the terahertz waveband.

Owner:NAT INST OF METROLOGY CHINA

Electronic display device and electronic device

ActiveCN108810765AReduce leakageImprove electro-acoustic conversion efficiencyElectrical transducersIdentification meansEmbedded systemDisplay device

The invention discloses an electronic display device and an electronic device. The electronic display device comprises a casing, a screen and a vibration device, wherein at least a part of the screenis connected to at least a part of the casing through a flexible connecting device, at least one of the screen and the casing is provided with a receiving groove for fixing the flexible connecting device, the flexible connecting device is elastic, the vibration device is fixed on the screen, and the vibration device is configured to vibrate in response to electrical signals of an external circuitand drive the screen to vibrate and sound. The screen is connected with the casing by the flexible device instead of a fixed connection, and the casing does not vibrate when the screen vibrates, thereby effectively reducing the sound leakage caused by the vibration of the casing. The connection strength of the flexible connecting device to the casing and the screen is improved by the flexible connecting device receiving groove.

Owner:刘博文

Elastic element based three freedom degree precision movement support device

The invention relates to a three-freedom-degree accurate motion support device based on flexible element, wherein a frame and a support plate are arranged with three independent linear displacement devices A, B and C parallel with the mirror normal line and distributed along the circumference of a support mirror in equal 120 degrees, while the center is arranged with a rotary motion couple and an axial motion guide coupler. The invention is characterized in that the two couples comprise that the frame is fixed with a plurality of support posts uniformly distributed on a concentric circle, which are respectively fixed with the outer edge of a membrane (as flexible membrane or support membrane) with high strength and flexibility, to function eccentric pre-stress on the flexible membrane to expand the membrane, and the center of the flexible membrane is fixed with a support plate. The invention can avoid rolling or sliding connection and realize the displacement without return space, with low cost, but without lubricant, special maintenance or the like.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

Chromizing coating modified by rare earth oxide and preparation method and application thereof

The invention discloses a rare-earth oxide modified chromizing coating and its preparation method and uses. Modified chromizing coating constituent is made up of infiltrated chrome, composite deposit metal M and minim rare-earth oxide rare-earth oxide Re#-[x]O#-[y]is Re=Ce, Y, La etc. According to mass percent, chrome content of chromizing coating surface layer is 35-55 portion, and others are M and minim rare-earth oxide, in which M coming from M-Re#-[x]O#-[y] composite deposit. The process is as follows: using metal Ni, Fe , Co, carbon steel or low-alloy steel as base material, making M-Re#-[x]O#-[y] composite deposit on base material using composite electric plating method, diffusing for chromizing, getting rare-earth oxide modified chromizing coating. The invention has a simple and mature process. and coating can physically grow protective compact Cr#-[2]O#-[3]oxidation film under high temperature, which is intensively adhesive to coating base body. Coating have good oxidation and corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Edge sealing method of L-shaped four-machine connecting edge sealing machine

PendingCN106863541ALow shape requirementImprove edge banding efficiencyWood working apparatusDomestic articlesEngineeringEdge banding

The invention discloses an edge sealing method of an L-shaped four-machine connecting edge sealing machine. The four-machine connecting edge sealing machine comprises a first edge sealing machine body, a second edge sealing machine body, a third edge sealing machine body and a fourth edge sealing machine body which are in an L-shaped connecting shape. The edge sealing method comprises the following steps that (1) a lifting table ascends to the height of the feeding face of the first edge sealing machine body, and a plate is placed on an automatic feed mechanism; (2) the automatic feed mechanism conveys the plate to the first edge sealing machine body, and the edge a is sealed; (3) the plate with the edge a sealed is conveyed to the second edge sealing machine body through a first conveying device set, and the edge b is sealed; (4) the plate with the edge b sealed is conveyed to the third edge sealing machine body through a second conveying device set, and the edge c is sealed; and (5) the plate with the edge c sealed is conveyed to the fourth edge sealing machine body through a third conveying device set, and the edge d is sealed. According to the edge sealing method of the L-shaped four-machine connecting edge sealing machine, the edge sealing efficiency is high, the requirement for the shape of the plate is not high, a special-shaped plate (such as an L-shaped plate) with two sets of edges parallel can be sealed, and meanwhile the situation that edge sealing is adjusted through rotation for the plate in the edge sealing process is not needed.

Owner:FOSHAN BEITE OFFICE SYST EQUIP CO LTD

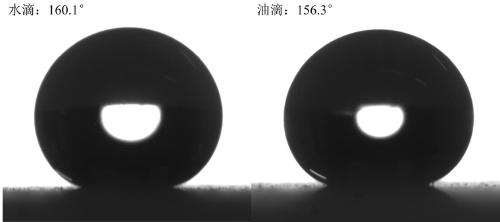

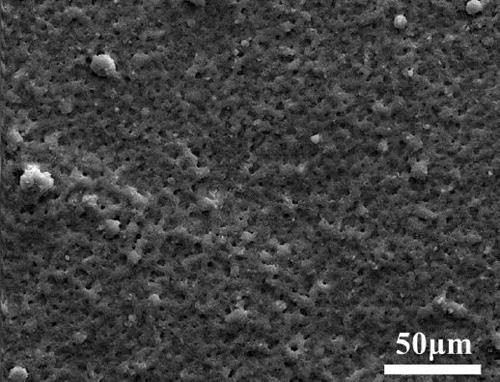

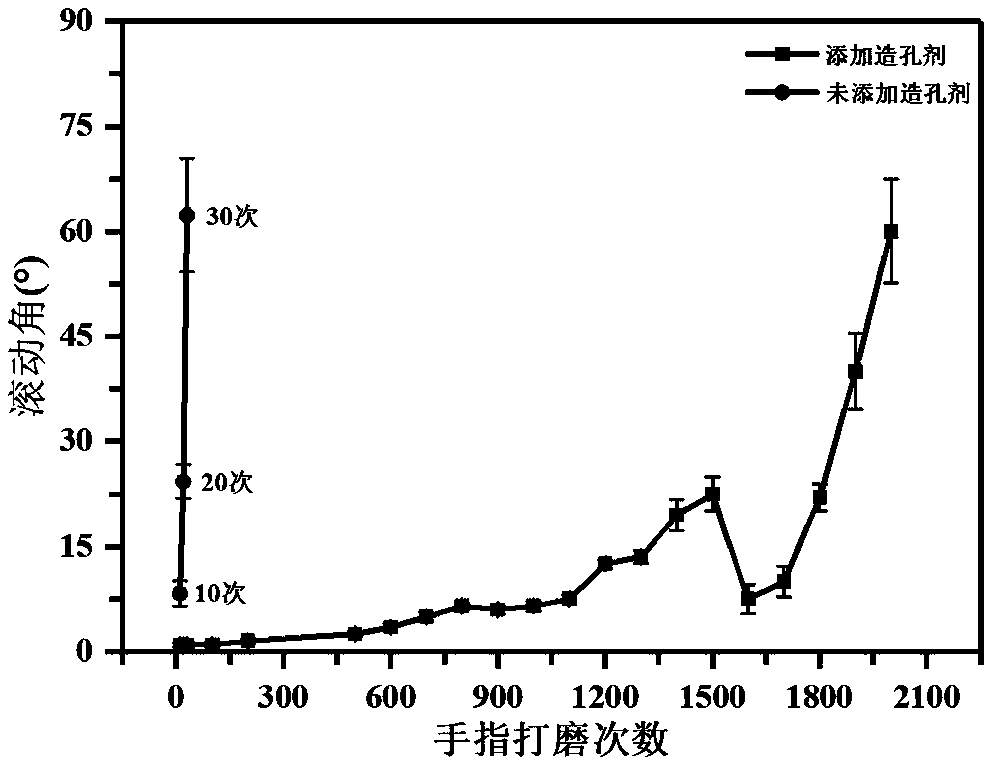

High-wear-resistance super-amphiphobic nanometer coating layer, and preparation method thereof

InactiveCN110105824AAvoid residueAvoid processing powerPretreated surfacesPolyurea/polyurethane coatingsMaterials preparationMildew

The invention discloses a high-wear-resistance super-amphiphobic nanometer coating layer, and a preparation method thereof, and belongs to the technical field of ultra infiltration functional coatinglayer material preparation. The preparation method comprises following steps: first, a resin is dissolved in a volatile organic solution, a pore forming agent is added into the volatile organic solution, continuous mechanical stirring is carried out for uniform dispersion of the pore forming agent, then the surface of a substrate is coated with an obtained mixture, then is coated with a super-amphiphobic nanometer coating material, and is introduced into a baking oven for curing of the pore forming agent so as to obtain the high-wear-resistance super-amphiphobic nanometer coating layer. The preparation method can be used on substrates such as wood, cement, and glass, the wear resistance of the high-wear-resistance super-amphiphobic nanometer coating layer is improved obviously, a problem in the prior art that hydrophobic surface is easily destroyed is solved, and under severe environment, coating layer stain resistance, self cleaning performance, fogging resistance, ice resistance, corrosion resistance, and mildew resistance are maintained. The preparation technology and equipment are simple; operation is convenient; cost is low; and the preparation method is suitable for large scale preparation and industrialized production.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com