Lamination processing equipment and packing box processing technique

A technology of processing equipment and processing technology, which is applied in the field of lamination processing equipment and packaging box processing technology, can solve the problems of waste of raw paper materials and lamination materials, insufficient economical use, environmental protection, and increased production costs, and achieve improved utilization and shape The effect of small requirements and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

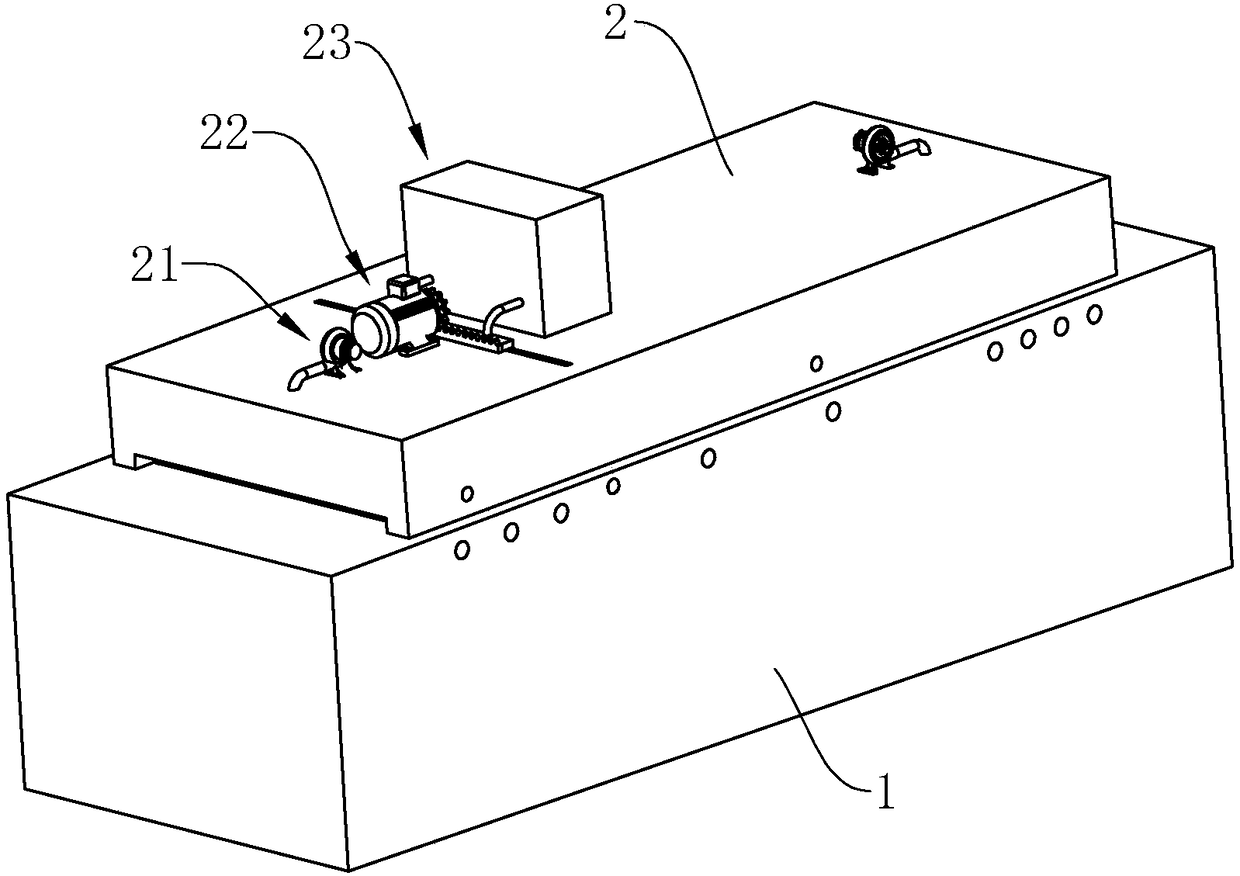

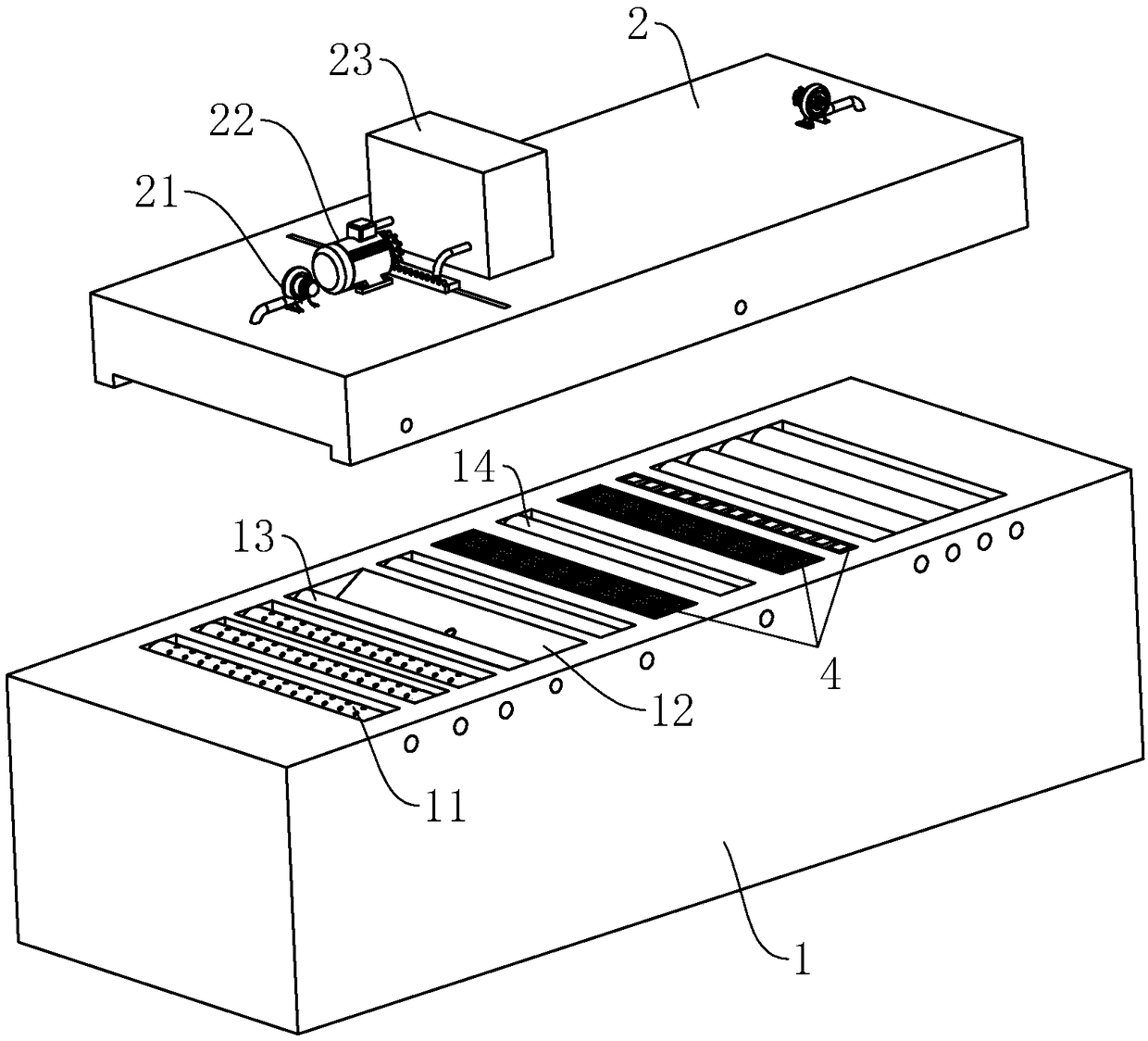

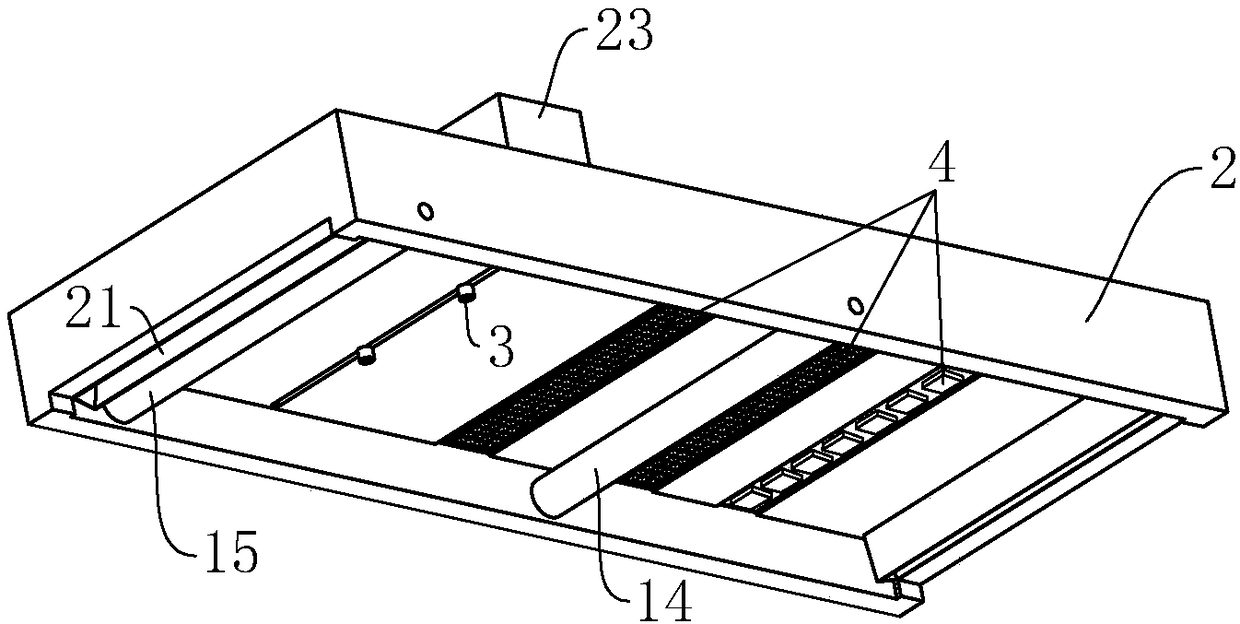

[0051] This embodiment discloses a packaging box coating processing equipment, such as figure 1 As shown, it includes a conveying platform 1 for conveying base paper and a dustproof cover 2 arranged above the conveying platform 1 to carry out a film coating operation on the conveying platform 1 .

[0052] Such as figure 2 and image 3 As shown, the dust cover 2 is installed along the length direction of the conveyor table 1, and is provided with a feed port and a discharge port on both sides. The base paper enters the film coating operation area inside the dust cover 2 from the feed port to complete the coating After the film is output from the discharge port. The conveying platform 1 is gradually inclined upward from the feed port to the discharge port. And, on the conveying table 1, conveying rollers 11 for conveying the base paper are arranged along the width direction. A number of conveying rollers 11 are arranged at intervals, and the outer peripheral surface is tang...

Embodiment 2

[0060] A packing box processing technology disclosed in this embodiment at least includes the following steps:

[0061] S1. Base paper cutting: According to the design drawings, the base paper is cut into the size and shape of the packaging box by a die-cutting machine at one time; during the process, the cut waste and burrs are collected and processed again for recycling and regeneration , The base paper is directly added with a flame retardant during processing, and the ignition point of the base paper is controlled to be higher than 230 degrees Celsius. Use the die-cutting machine to design the punch according to the design drawings, and reserve a test sample area on one side of the punch for one-time pattern cutting. The test sample area can be set at the edge contour of the base paper after cutting.

[0062] S2. Surface printing: The surface of the cut base paper is printed by a printing machine according to the printing needs of the design; after printing, it is dried, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com