Elastic element based three freedom degree precision movement support device

A technology of precision motion and support mechanism, applied in optical components, installation, optics, etc., can solve the problems of high precision requirements of space and parts processing, friction and return clearance hysteresis, complex bearing shafting mechanism, etc., to achieve simple implementation Flexible, bend-free, well-informed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

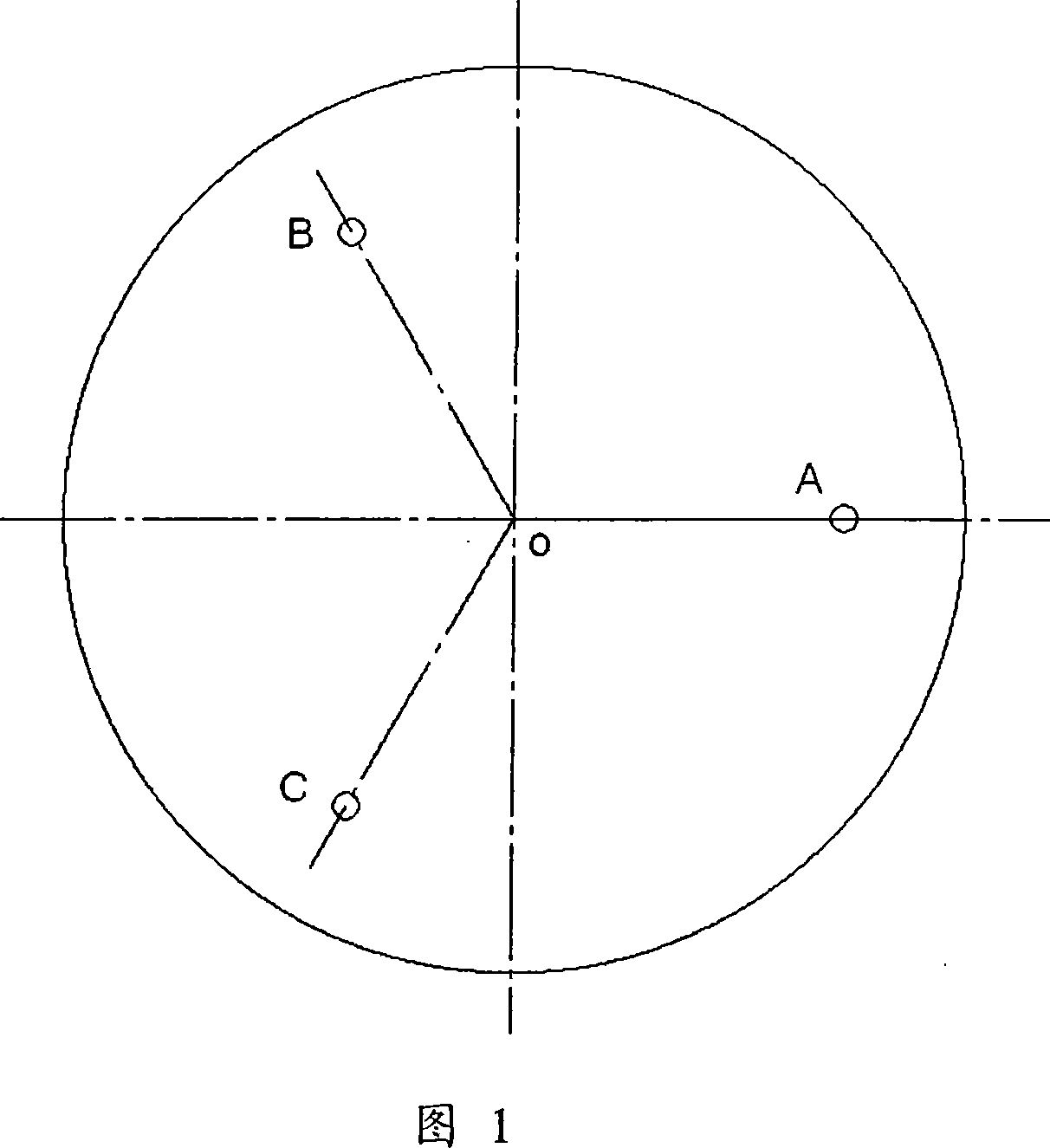

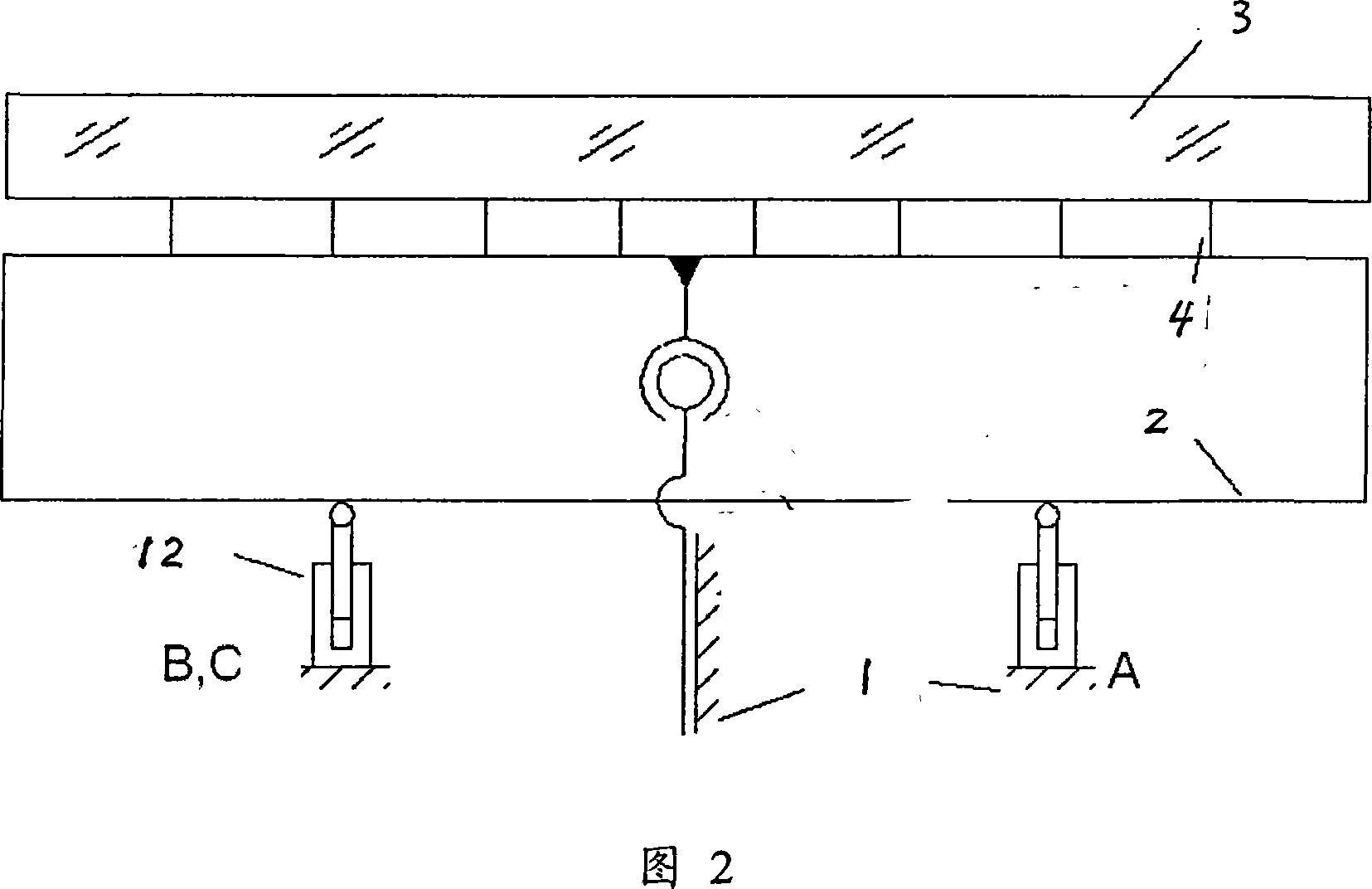

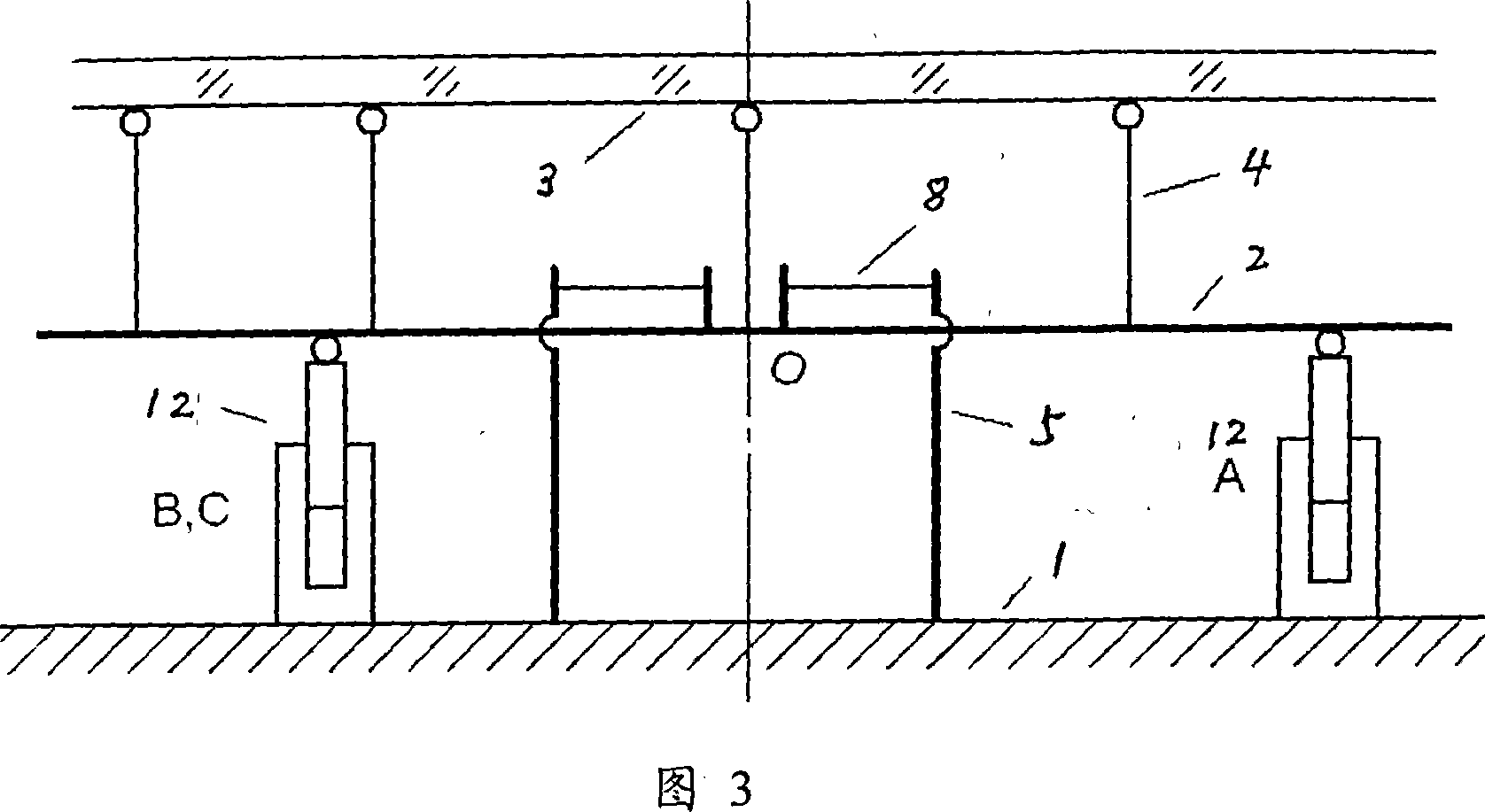

[0018] Embodiment 1, a three-degree-of-freedom precision motion support mechanism based on elastic elements, see Figures 3-7, the whole system can be regarded as a three-layer structure. On the frame 1, the size and orientation of the high-strength and high-elasticity diaphragm (support diaphragm) 8 are selected to select the installation position of the support column 5 formed by a regular hexagon at six points, and the six support columns 5 are fastened with the support column screws 13 Connected to the frame 1. The supporting column 5 passes through the through hole 15 on the supporting plate 2, and the supporting plate 2 is connected with the displacement movement mechanism 12. The adjusting washer 10, the supporting diaphragm 8 and the limit protection disk 11 are connected and fastened with the screw 9 and the supporting plate 2. The adjusting washer 10 is used to support the diaphragm 8 to adjust the installation height. The six corners of the supporting diaphragm 8 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com