Evaluation device and method of well cementation flushing efficiency

A technology for evaluating device and efficiency, applied in the field of oil and gas well cementing, can solve the problems of the evaluation method is not widely applicable, the device design is complex, and the repeatability is limited, so as to achieve reliable evaluation, simple design, improved repeatability and comparison. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

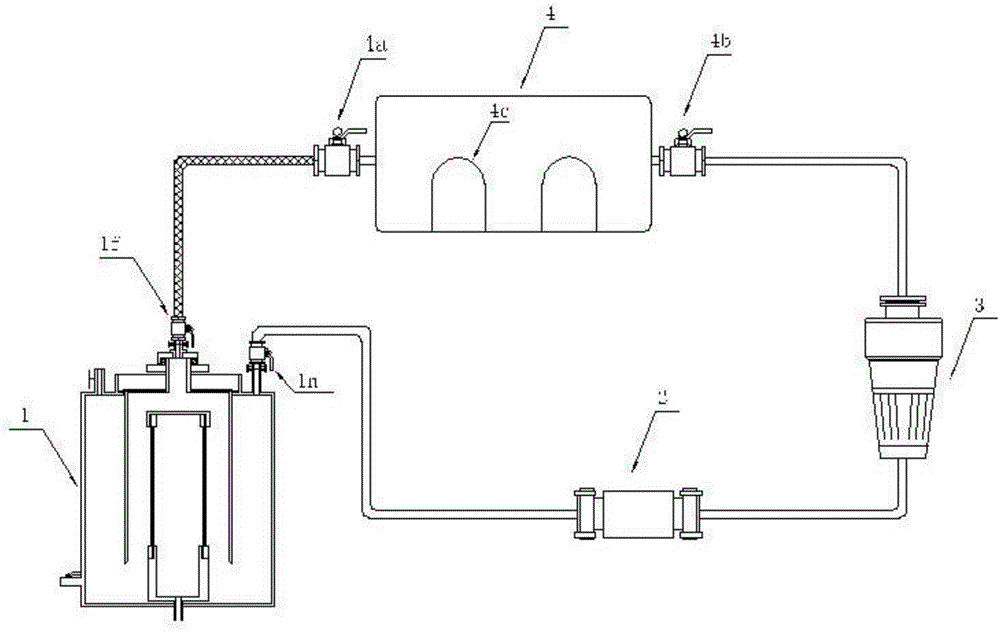

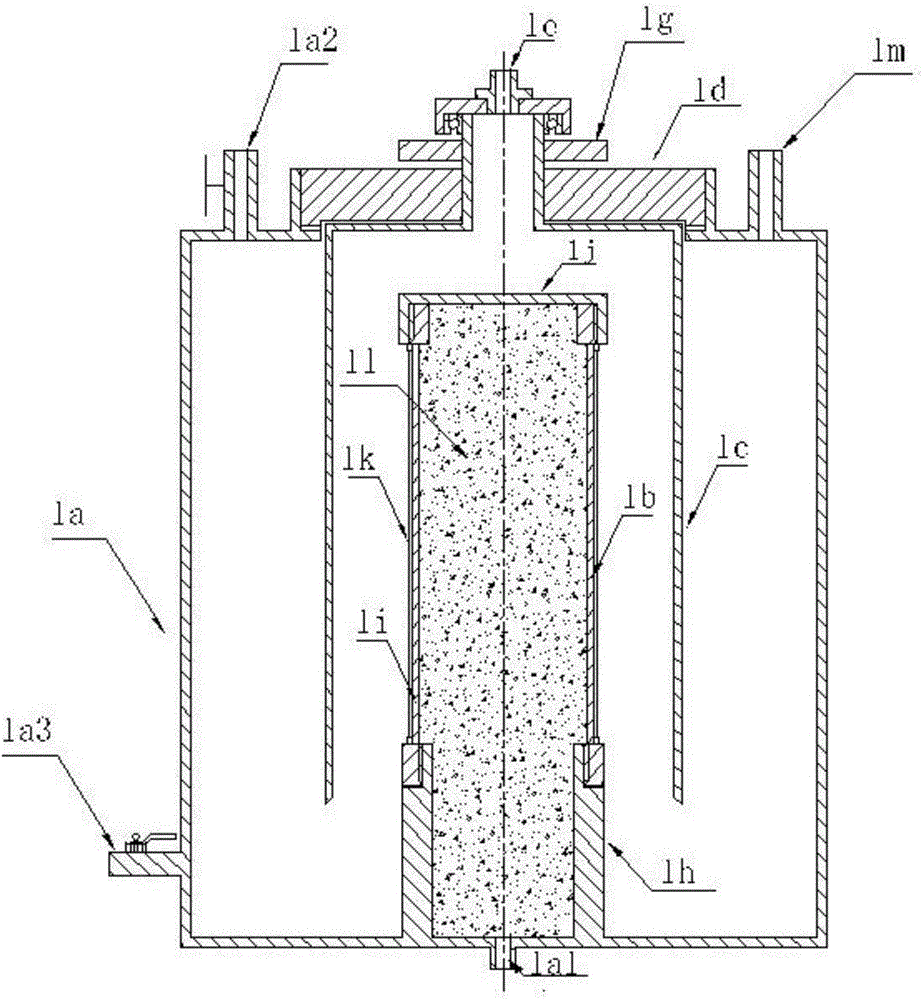

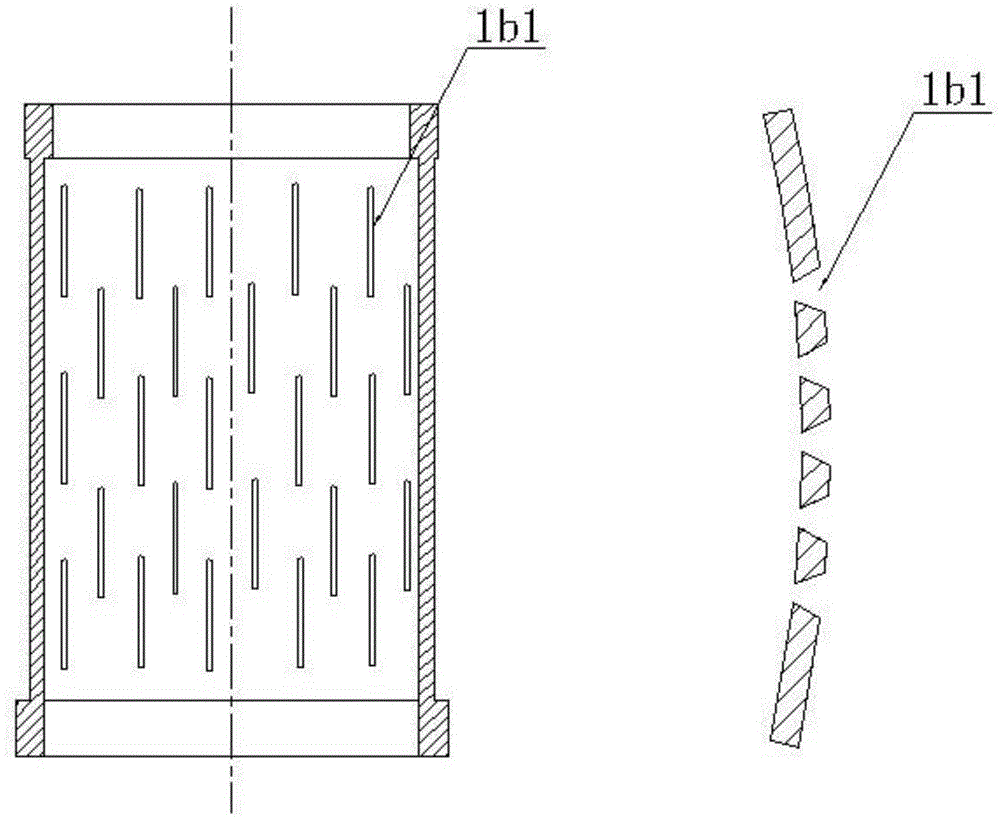

[0050] Such as figure 1 As shown, the cementing flushing efficiency evaluation device of the present invention includes a simulated wellbore 1, an electromagnetic flowmeter 2, a power pump 3 and a heating water tank 4, and the liquid inlet 1m of the simulated wellbore is connected with a simulated casing liquid inlet valve 1n through a union. The liquid outlet 1e of the simulated wellbore is connected with the simulated wellbore liquid outlet valve 1f through a union; the inlet of the heating water tank is equipped with a heating water tank inlet valve 4a, the outlet of the heating water tank is equipped with a heating water tank outlet valve 4b, and the bottom of the water tank is equipped with a water tank emptying valve The liquid outlet valve of the heating water tank is connected in series with the power pump 3, the electromagnetic flowmeter 2 and the simulated wellbore liquid inlet valve 1n through pipelines, and the simulated wellbore liquid outlet valve 1f is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com